Patents

Literature

144results about How to "Violent reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel liquid injection and activation process for lithium ion batteries

InactiveCN102315417ASpeed up entrySmooth entrySecondary cells charging/dischargingCell component detailsElectrical batteryPre-charge

The invention relates to a novel liquid injection, infiltration and pre-charging process for lithium ion batteries. The process comprises the following steps: (S1) carrying out vacuum operation on a lithium ion battery before liquid injection, injecting a predetermined amount of electrolyte, and filling a proper amount of film forming additive gas into the battery after injection of electrolyte is finished; (S2) employing the manner of cyclical fluctuation negative pressure infiltration, wherein, fluctuation of negative pressure is expressed with a waveform function instead of a simple first grade linear function; (S3) carrying out formation under the conditions of changing negative pressure and changing temperature, wherein, the negative pressure and temperature both increase gradiently with time, a charging current is not constant and varies in a manner of small gradient increase. The invention enables a predetermined amount of electrolyte to be rapidly absorbed by anode and cathode materials and diaphragms of the battery, and absorption time is short while full absorption is realized, thereby improving the utilization rate of the electrolyte and shortening time for liquid injection; addition of a proper amount of film forming additive gas is beneficial for the formation of SEI membranes and enables inreversible capacity loss of the battery in initial charge to be reduced; the method of pre-charging brought forward in the invention enables uniform and stable SEI membranes to form on the surface of electrodes, thereby improving safety performance and electrochemical performance of lithium ion batteries; the process is simple and is easy to control, investment cost for equipment used in the process is low, and the process is easy to realize.

Owner:HUNAN UNIV

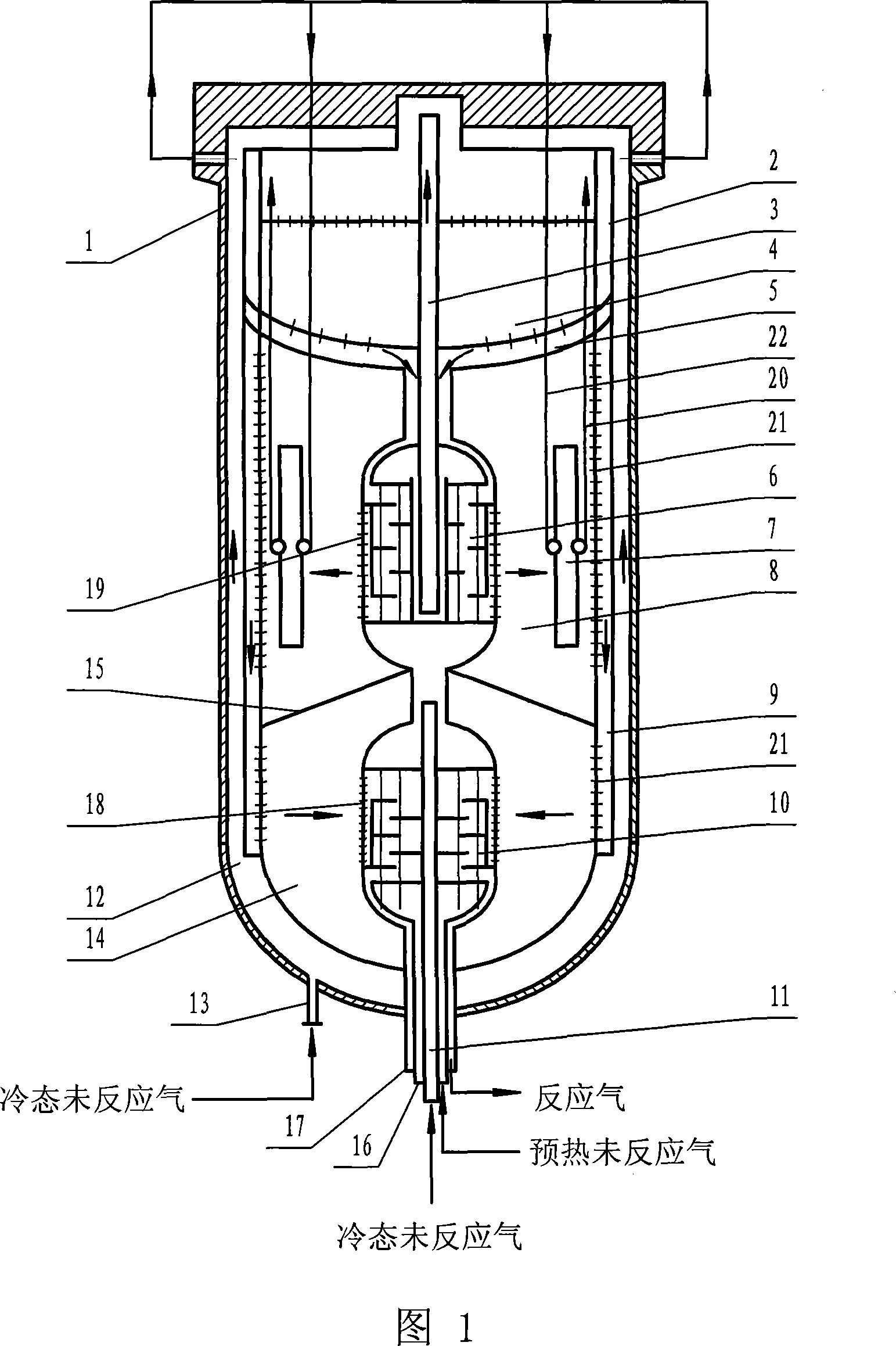

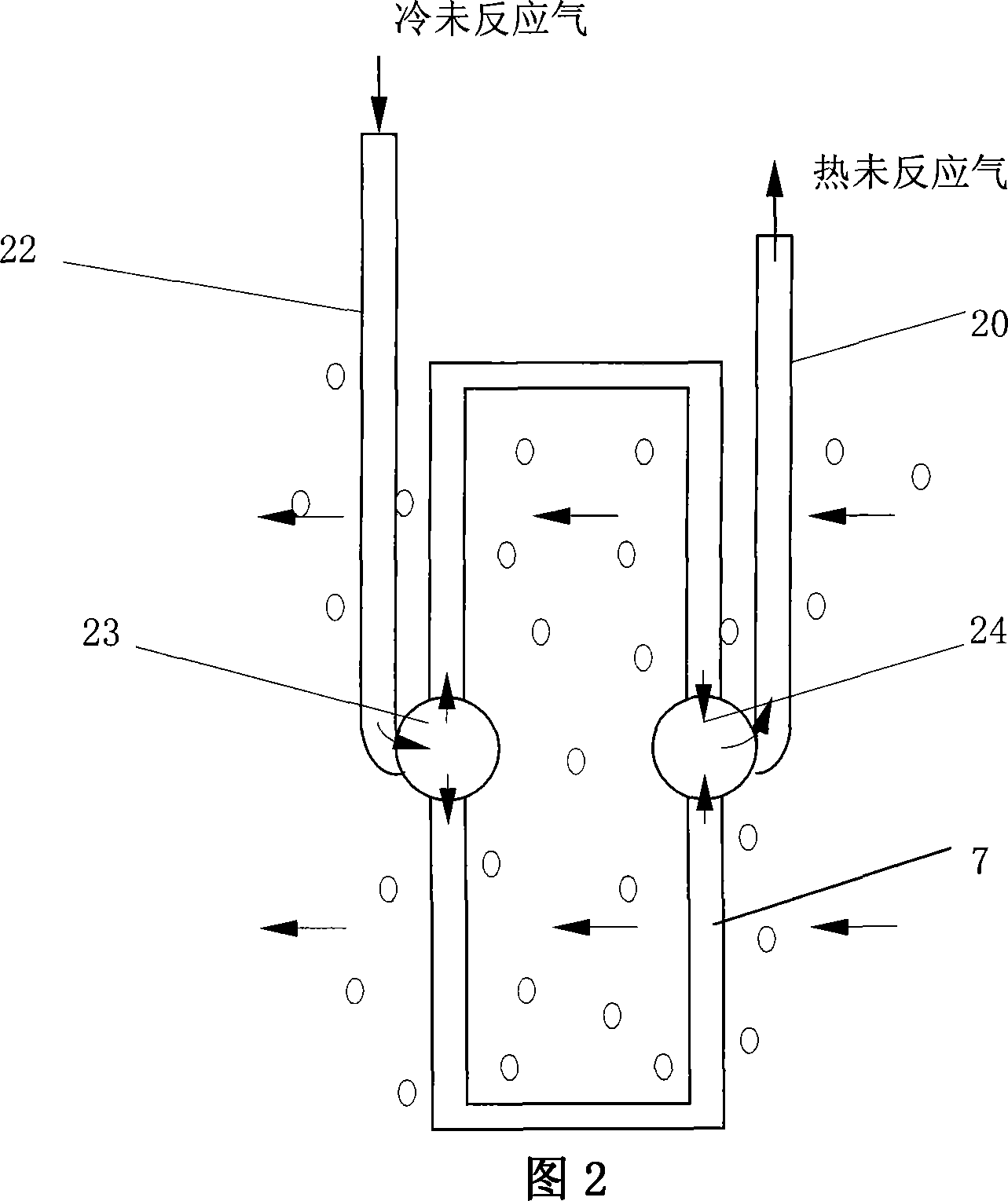

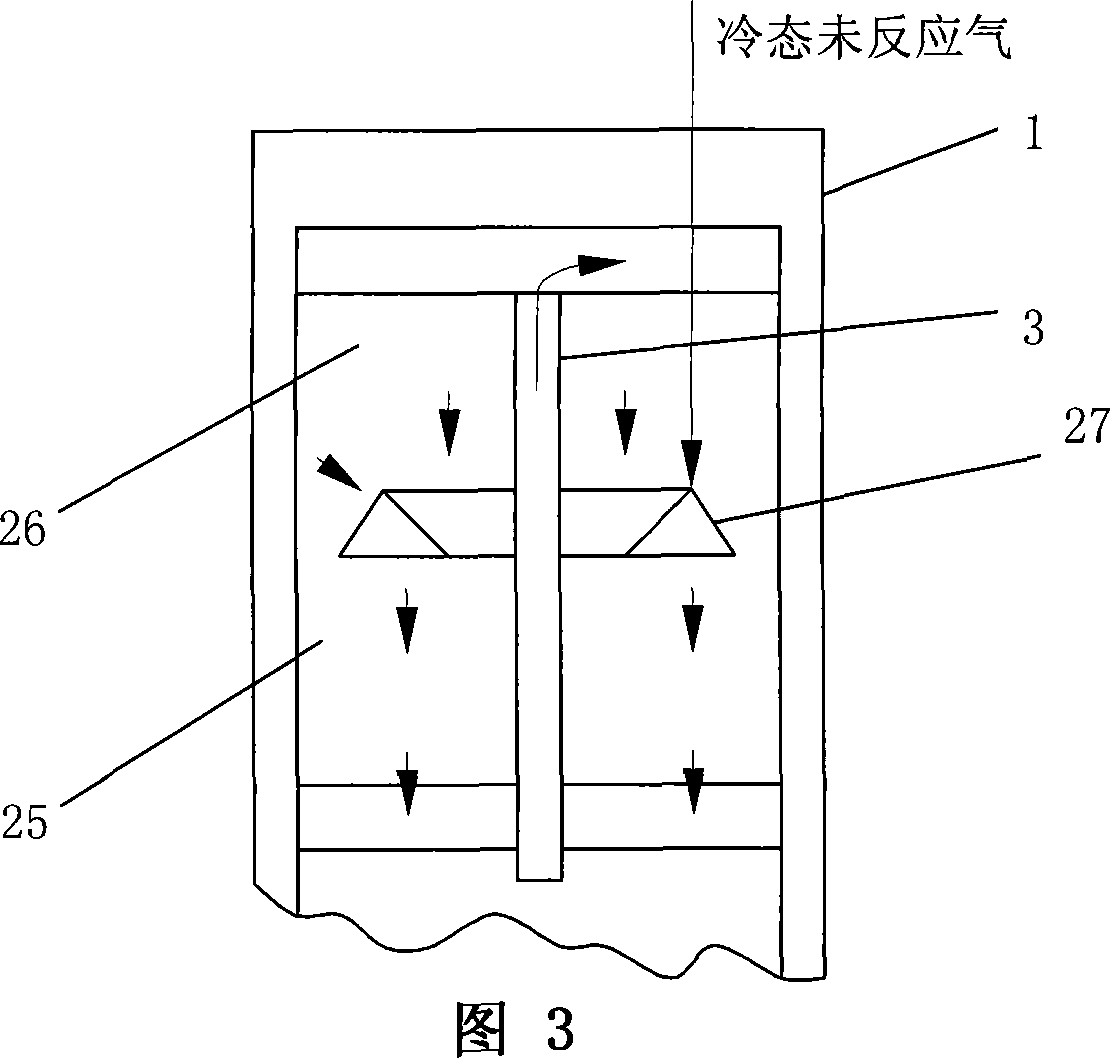

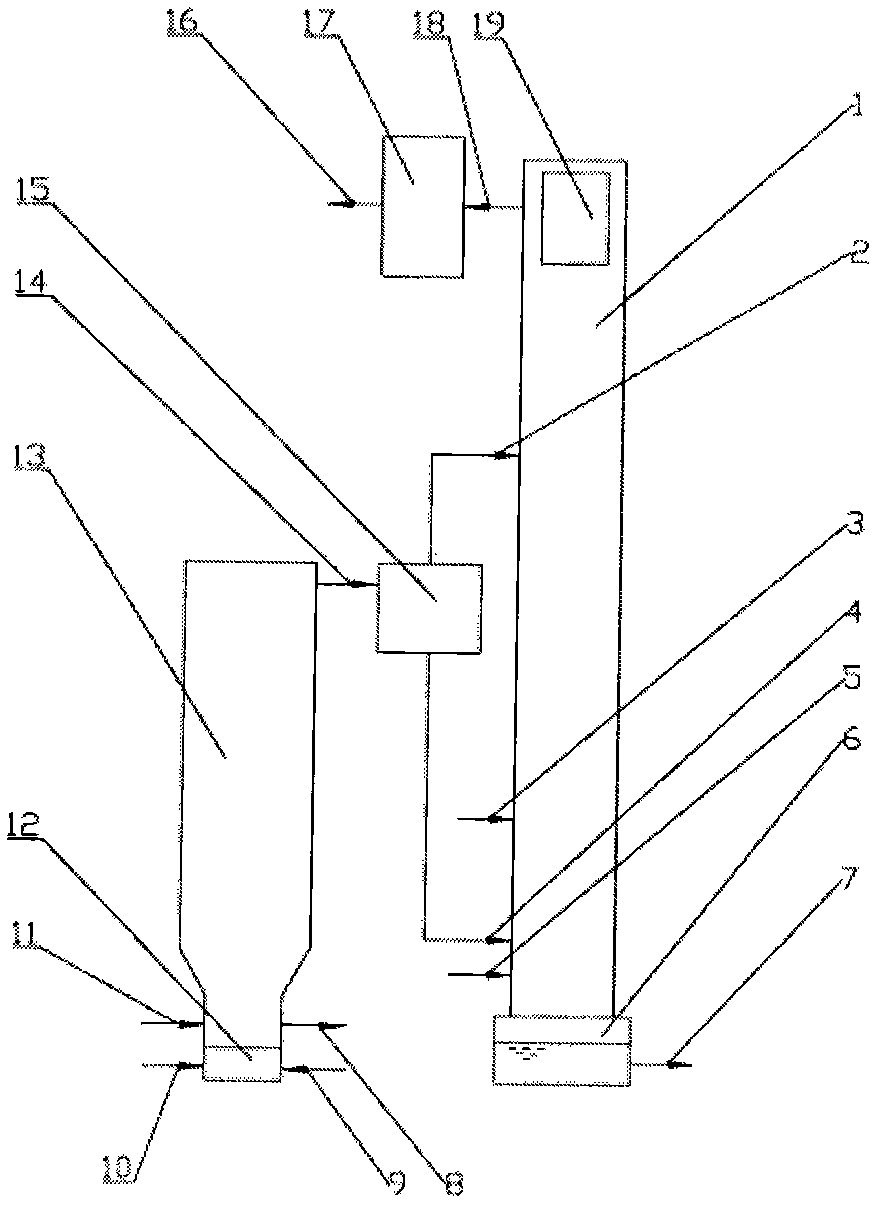

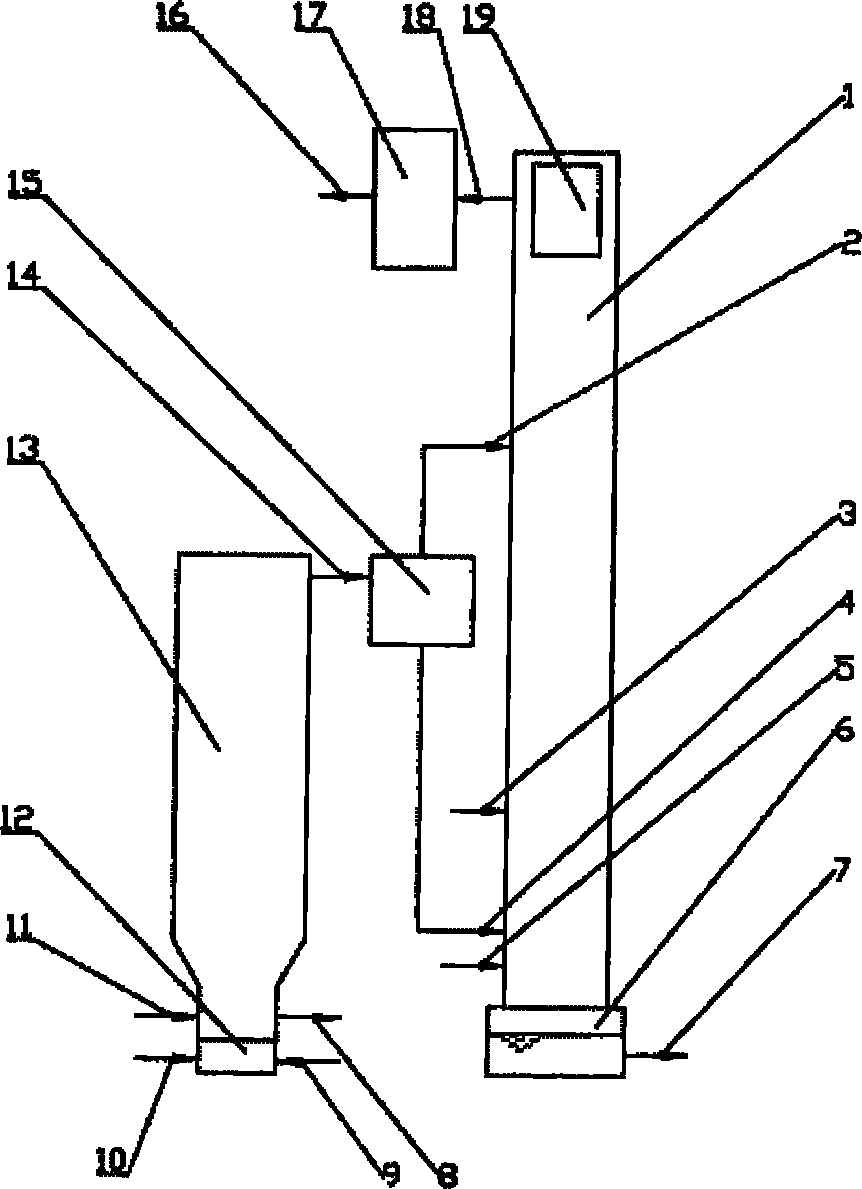

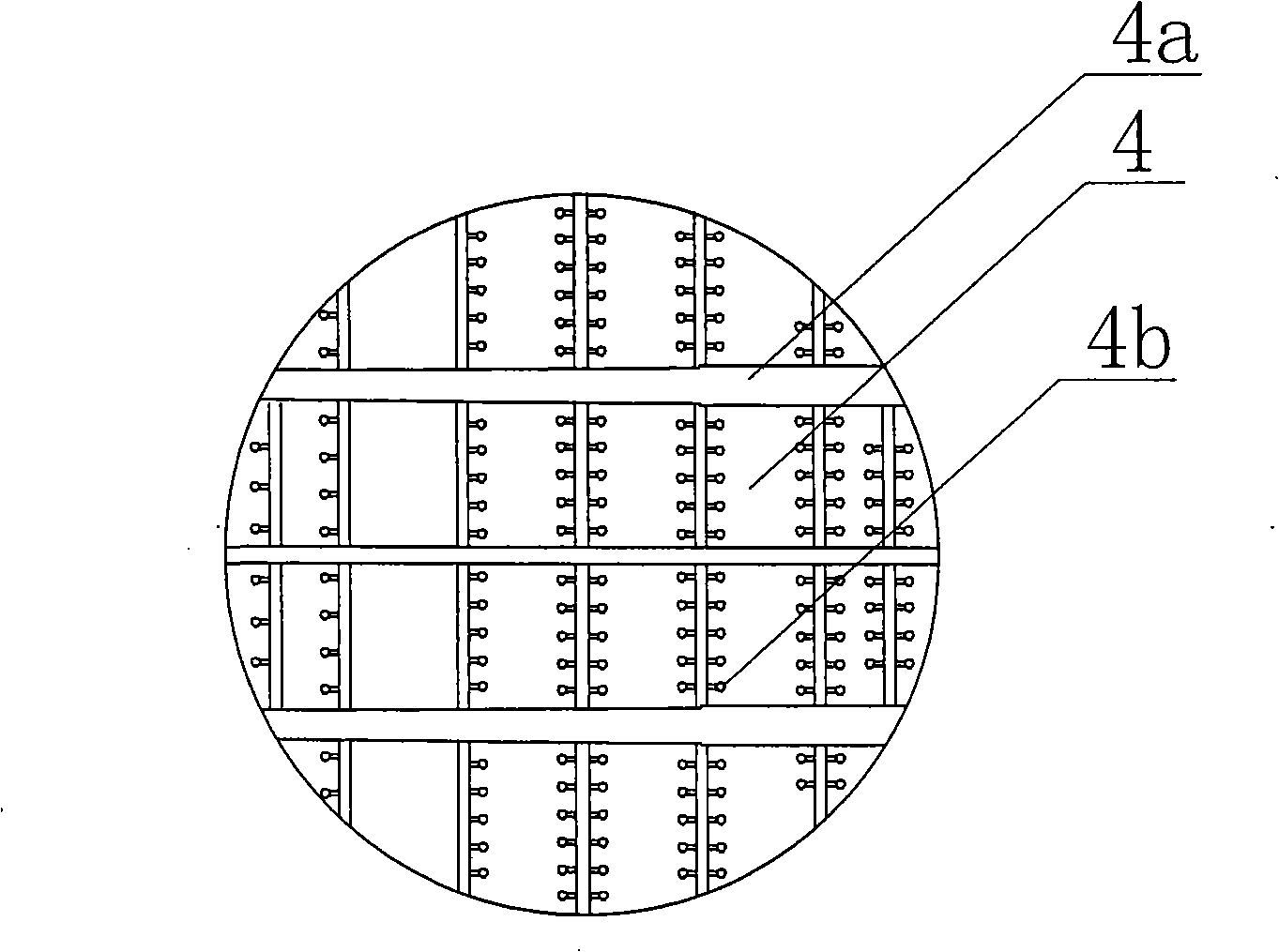

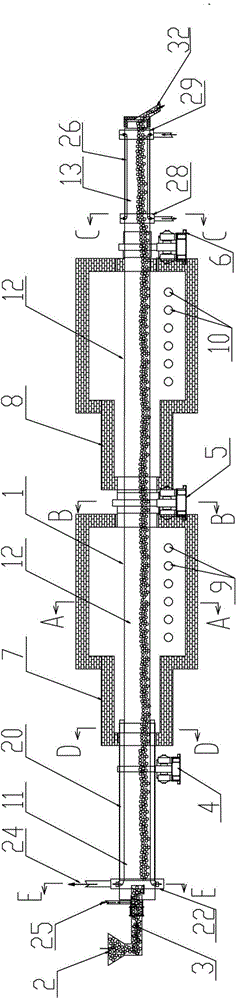

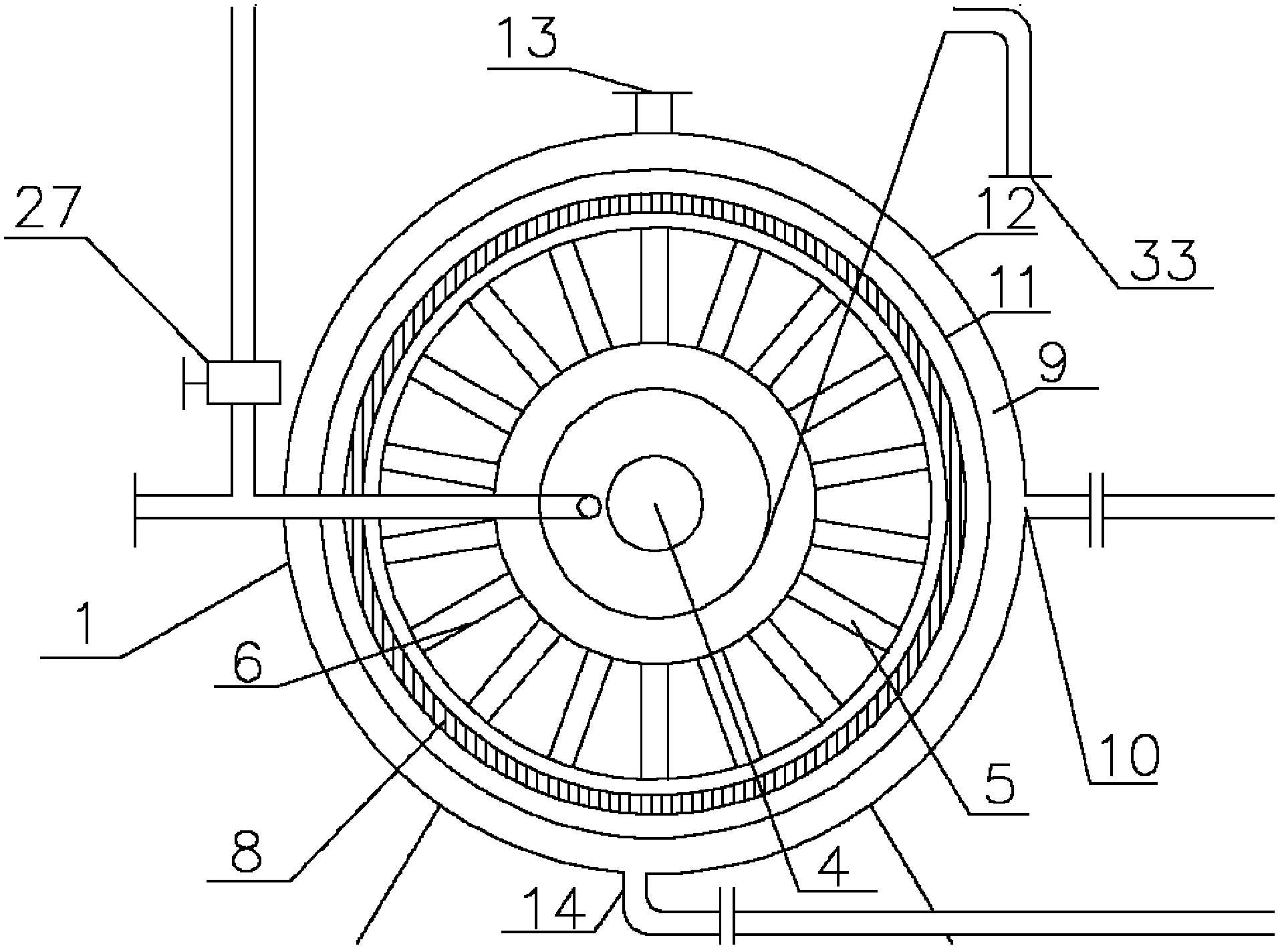

Multi-bed layer shaft radial synthesizing tower

ActiveCN101143729AAdjustable temperatureHigh activityOrganic compound preparationChemical industryPlate heat exchangerEngineering

A multi-bed axial radial synthesis tower for the preparation of ammonia or methanol is disclosed. The tower consists of an external cylinder and an internal cylinder; the internal cylinder is divided into three layers from the top to the bottom; the third layer is provided with a lower heat exchanger; the second layer is provided with an upper heat exchanger and the periphery is provided with a cooling tube bundle heat exchanger; the upper heat exchanger is connected in series with the lower heat exchanger; a cylinder wall of the upper heat exchanger is provided with a communication hole; an upper end of the upper heat exchanger is communicated with a first layer through an air collector; a lower port of a central tube is positioned in the upper heat exchanger and an upper port of the central tube is located on an upper part of the first layer; a cylinder wall of the internal cylinder is provided with a radial basket ring gap, which is communicated with the second layer and the third layer; one side of the cooling tube bundle heat exchanger is communicated with an upper part of the ring gap of the external cylinder, an upper port of an upward tube on the other side is positioned on an upper part of the first layer; a catalytic bed in the internal cylinder is divided into three layers and four segments; the first layer is an axial adiabatic reaction segment, the second layer consists of a radial adiabatic reaction segment and a radial internal cooling segment, and the third layer is a radial adiabatic reaction segment. The tower has a simple structure, a high net value of the production of ammonia or methanol, a high utilization rate of energy, a low circulating power consumption and remarkable energy saving effects.

Owner:HUNAN ANCHUN ADVANCED TECH

Calcium-magnesium hydrogen producing agent

InactiveCN102783691AOut-of-the-boxStrong reducing agentCosmetic preparationsToilet preparationsWrinkle skinSkin elasticity

The invention discloses a calcium-magnesium hydrogen producing agent, of which the main component is a hydrogen producing agent. The hydrogen producing agent is selected from one or various combination of calcium hydride, magnesium hydride, calcium hydroxide magnesium, magnesium-magnesium hydride, calcium-calcium hydride, magnesium-calcium hydride, calcium-magnesium hydride, calcium-magnesium-magnesium hydride, calcium-magnesium-calcium hydride, calcium-magnesium-magnesium hydride-calcium hydride, coral calcium hydroxide magnesium, Na MgH3, and Mg2FeH6. the calcium-magnesium hydrogen producing agent can be added into water, beverage or wine as an additive, or can be coated on the surface of skin or taken as soaking liquid to remove internal or surface active oxygen. The calcium-magnesium hydrogen producing agent has a remarkable prompting effect for recovering various oxidized damages, relieving discomfort caused by drinking, diluting stain and wrinkle of the skin, recovering skin elasticity, and delaying senescence.

Owner:李志林

Method for smelting medium ferrovanadium

The invention belongs to the metallurgy field and in particular relates to a method for smelting medium ferrovanadium. The invention aims to solve the technical problem of an electro-aluminothermic process with high vanadium recovery from smelting and is specifically characterized by adopting the mixed materials of V2O5 and V2O3 as the raw materials and using the electro-aluminothermic process to smelt the medium ferrovanadium. The method comprises the following steps: A. preparing bottom materials and main materials; B firstly adding the bottom materials for smelting at the initial stage of smelting; C. then adding the main materials after the bottom materials react steadily; and D. refining. The bottom materials include aluminium, V2O5, iron and lime. The main materials include V2O3, aluminium, V2O5, iron, lime and fluorite. The method not only fully utilizes the reaction heat, but also simplifies the technological process, reduces the viscosity of the slag and ensures the ferrovanadium recovery from smelting to be steadily increased by over 96%.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

Failure point positioning method for semiconductor power device failure analysis

InactiveCN102854429AConvenient to judge timeViolent reactionElectrical testingElectrical resistance and conductanceLight beam

The invention provides a failure point positioning method for semiconductor power device failure analysis. The failure point positioning method comprises the following steps of: performing chemical corrosion on a metal aluminum layer covering the surface of a power device by utilizing a chemical corrosion stripping technology, completely removing the aluminum layer, and completely keeping a barrier layer below the metal aluminum layer; positioning the front side of the power device by utilizing a micro light microscope and a light beam induced resistance variation technology, simulating electric conditions under the failure conditions, electrifying by using a point needle method, simulating the electric conditions, and finding possible failure points; and performing physical verification of electronic package assembly failure analysis by utilizing the positioning result of an electronic package assembly failure analysis tool on the previous steps, and finding the final physical failure point. The failure point positioning method has the advantages that the metal aluminum layer is effectively stripped, and the integrity of the barrier layer is kept; and moreover, the positioning speed and efficiency of the semiconductor power device failure point are greatly improved, and an extremely high precision is kept.

Owner:SHANGHAI FALAB TEST

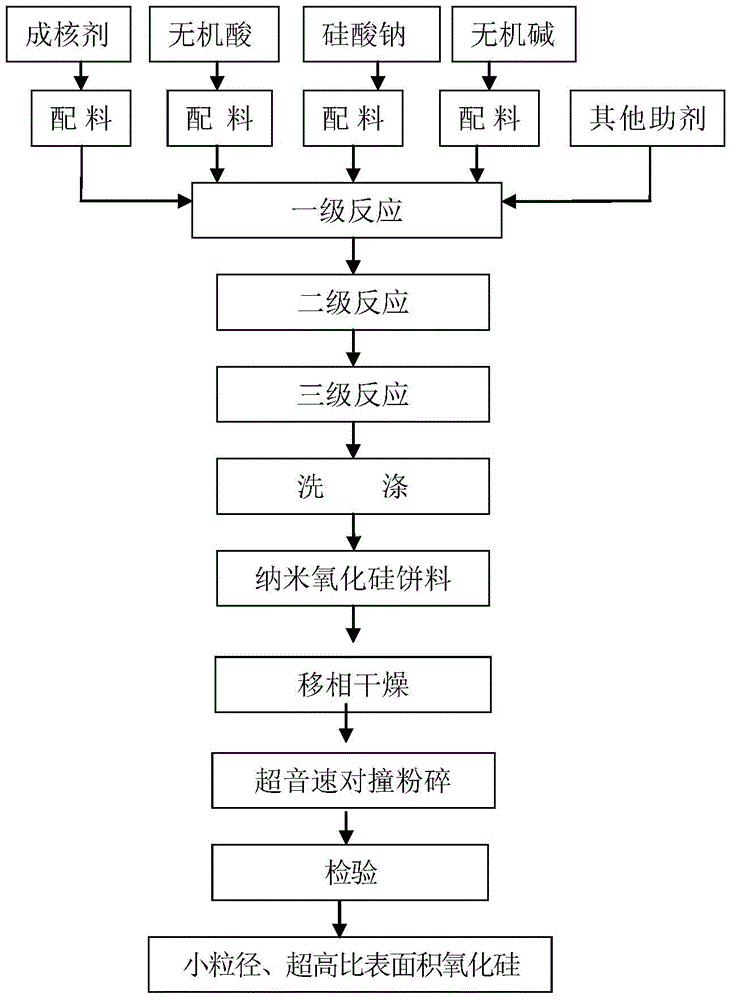

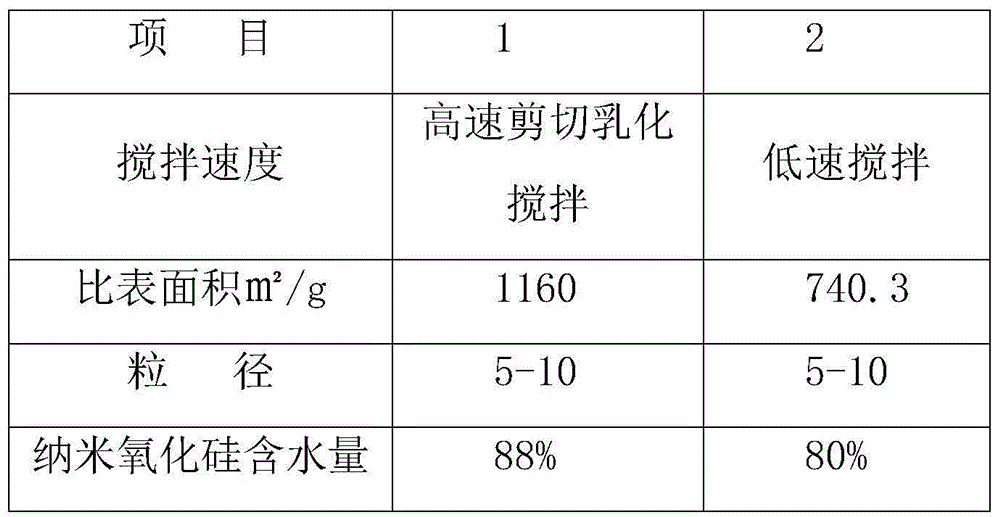

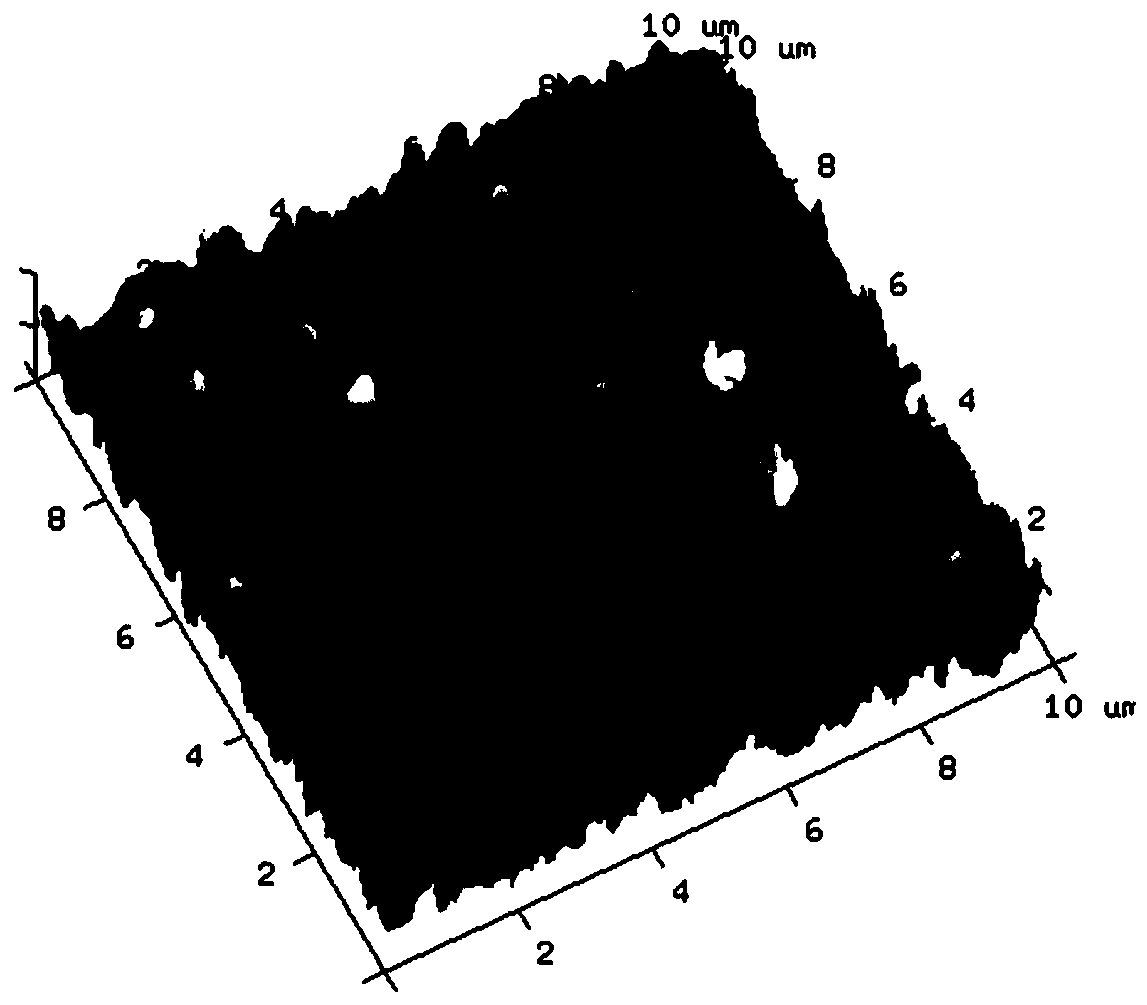

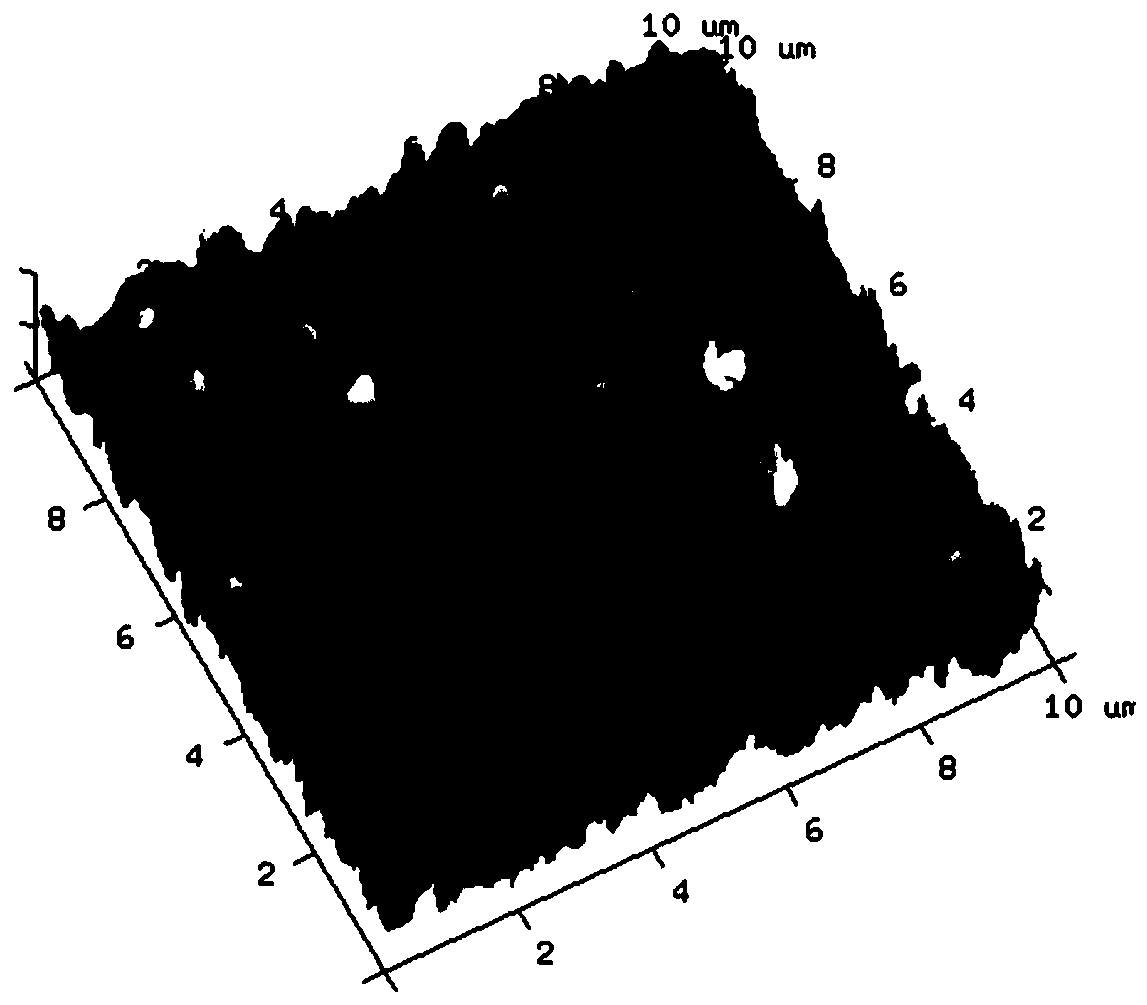

Small-particle-size ultrahigh-specific-area nano silicon oxide

ActiveCN104828828AConcentration Stable EquilibriumLow reaction temperatureSilicaNanotechnologyStrong acidsOxide

The invention discloses a small-particle-size ultrahigh-specific-area nano silicon oxide which is prepared by the following steps: adding metered inorganic acid, water glass, a nucleator, a dispersing agent and pure water into a reaction vessel, and emulsifying and stirring by high-speed shearing to perform primary reaction; added metered primary reaction product, inorganic acid and a nucleator into a reaction vessel, stirring at low speed to perform secondary reaction; regulating the pH value of the reaction product after secondary reaction to less than 3, and carrying out aging reaction under such conditions to stably form the particles; and carrying out deacidifying-desalting washing on the product under strong acid conditions to obtain the small-particle-size ultrahigh-specific-area nano silicon oxide. The particle size of the nano silicon oxide can reach 5-10nm, and the specific area is up to 600-1160 m<2> / g. The nano silicon oxide has small particle size and ultrahigh specific area, and thus, has excellent effects when being applied to multiple fields.

Owner:上饶市安纳拓新材料有限公司

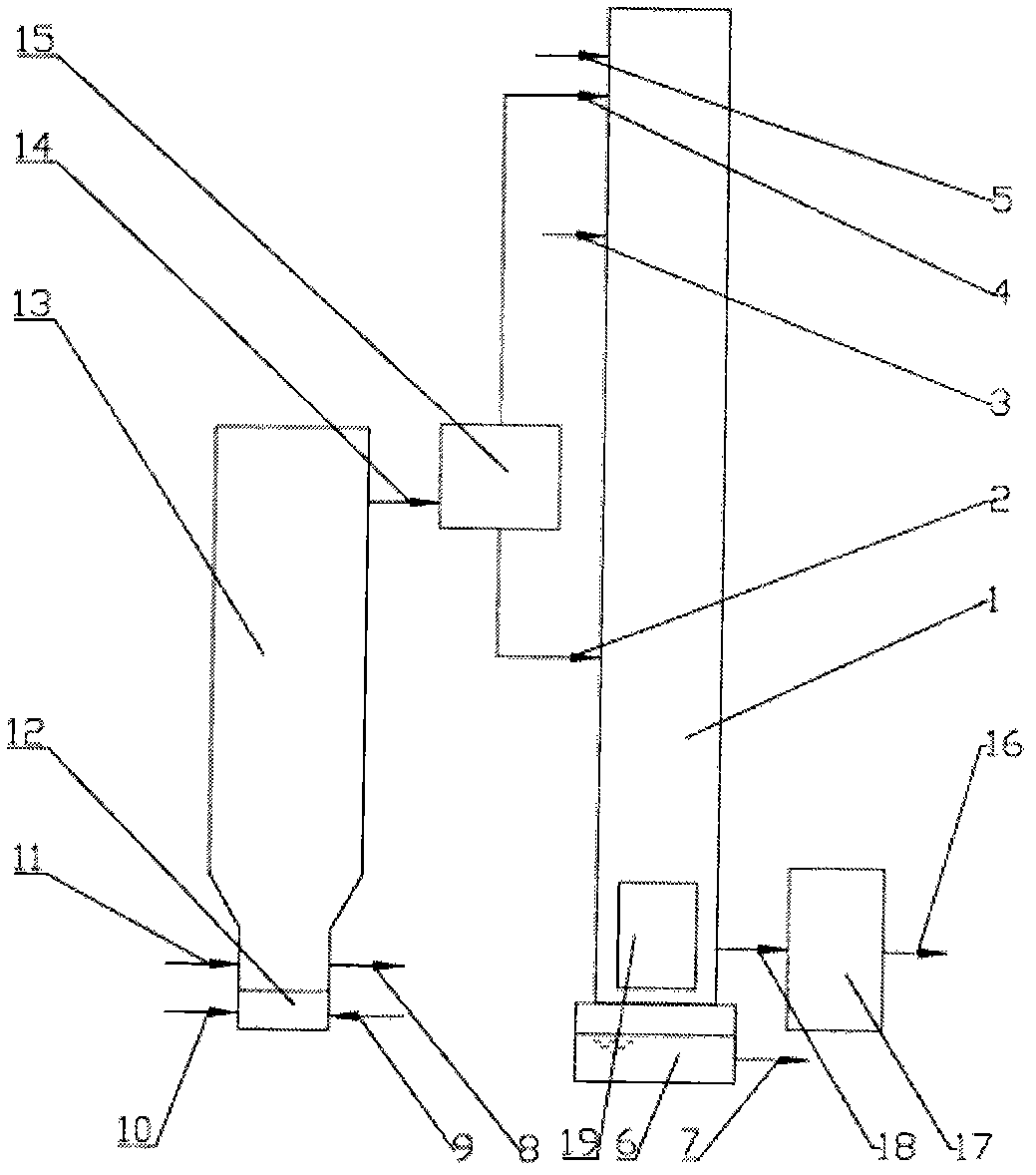

Coal gasification method

InactiveCN102373089ALow investment costLow running costGranular/pulverulent flues gasificationFluidized bedOxygen

The invention provides a fluidized bed-entrained flow bed gas gasification method. The method comprises the following steps: 1) carrying out reaction on raw material coal and a mixture of air and steam or a mixture of oxygen and steam to obtain gas containing incompletely reacted coal and ash; 2) separating the gas obtained from the step 1) to obtain condensed fine coal air-flow and light fine coal air-flow, and carrying out reaction on the condensed fine coal air-flow with air or oxygen to obtain gas containing coal and ash; 3) carrying out reaction on the gas obtained from the step 2) and steam to obtain gas containing coal and ash; 4) carrying out reaction on the gas obtained from the step 3), the light fine coal air-flow separated from the step 2) and a mixture of steam and carbon dioxide to obtain final gas containing coal and ash. The method lowers investment and operating cost of a traditional pulverizing system by an entrained flow bed gasification method and has a substantially increased gasification temperature than a traditional fluidized bed gasification method, so as to reduce equipment cost and increase gasification efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

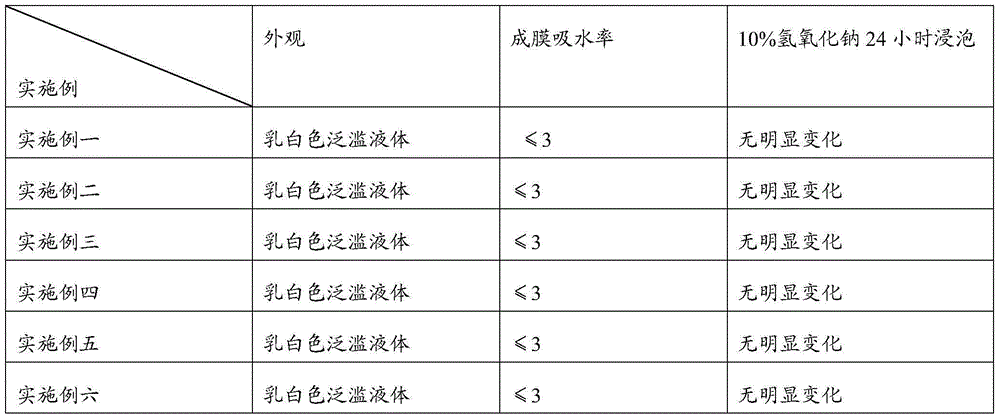

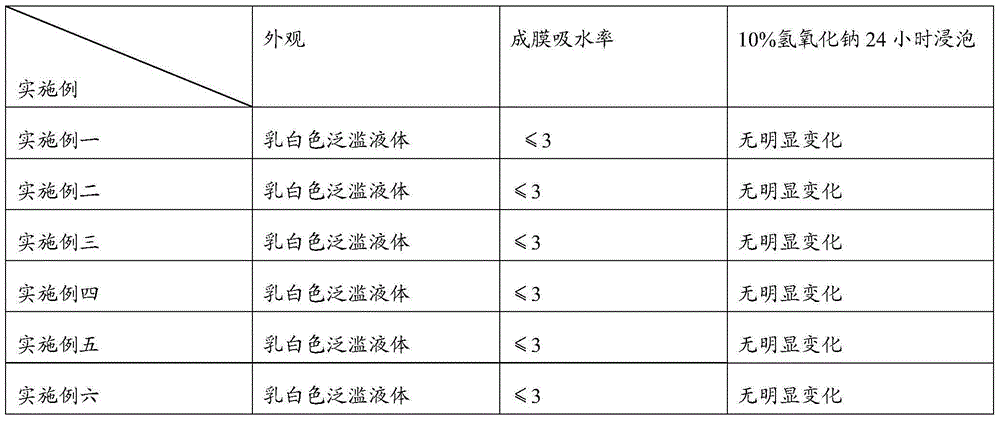

Waterborne polyurethane emulsion, preparation method for waterborne polyurethane emulsion, application of waterborne polyurethane emulsion to wallpaper basement membrane and wallpaper basement membrane

The invention relates to waterborne polyurethane emulsion which is prepared from the following raw materials in parts by weight: 100-120 parts of polyester polyol, 45-55 parts of diisocyanate, 10-12 parts of hydrophilic chain extender, 7-9 parts of a salt-forming agent, 270-300 parts of water and 0.5-1 part of an end-capping agent containing fluorocarbon groups. The invention further relates to a preparation method for the waterborne polyurethane emulsion, an application of the waterborne polyurethane emulsion to a wallpaper basement membrane and the wallpaper basement membrane. The waterborne polyurethane emulsion has the advantages of no pungent smell, environmental protection, good membrane-forming property and adhesion, and very good water-proof and alkali-proof properties; the preparation method for the waterborne polyurethane emulsion has the advantages of simplicity, easiness for operation and favorability for large-scale production and application; the wallpaper basement membrane has the benefit of capability of guaranteeing good water-proof and alkali-proof properties and product stability and enriching the types of wallpaper basement membrane products at the same time.

Owner:FUJIAN POLYTECH TECH CO LTD

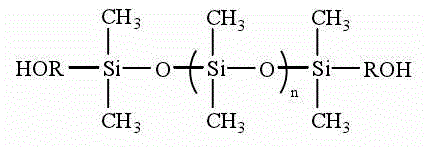

Highly moisture permeable modified polyurethane and preparation method thereof

The invention discloses highly moisture permeable modified polyurethane and a preparation method thereof. The invention solves the problem that dihydroxyalkyl polysiloxane and polyether polyol are separated from each other due to poor intersolubility by adopting a prepolymerization method. The highly moisture permeable polyurethane with an excellent mechanical property is prepared by the following steps: 1, prepolymer synthesis: namely carrying out reaction on polyisocyanates and dihydroxyalkyl polysiloxane different in proportion at 40-120 DEG C for a while by selecting different solvents according to different molecular weights of dihydroxyalkyl polysiloxane; and 2, synthesis of polyurethane: namely adding polyether polyol and a solvent in a stoichiometric ratio at 60-100 DEG C, gradually adding the prepolymer, controlling the adding speed, and obtaining a polyurethane product with proper viscosity by controlling the proportion of OH / NCO. The modified polyurethane can be applied to coating fabric surfaces in occasions with high waterproof, moisture permeable and mechanical performances and relatively high thermal stability.

Owner:QUANZHOU DECHENG TECH RESIGN

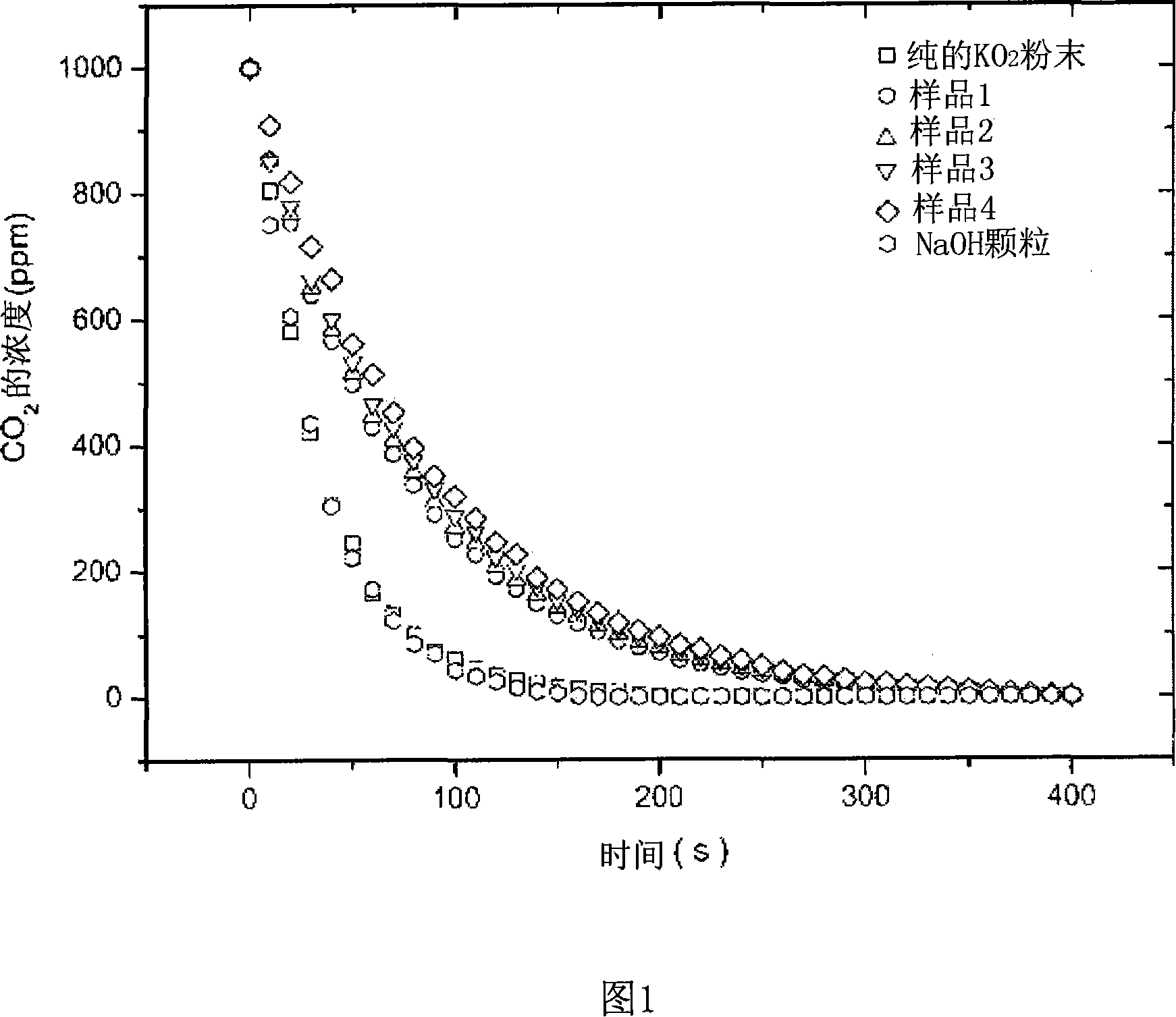

Polymer composition for air purification

Disclosed herein are a polymer composition for air purification and a filter manufactured using the polymer composition. The polymer composition comprises a peroxide or superoxide and silicone (i.e. an organopolysiloxane). Since the silicone has a high gas permeability, the polymer composition comprising the peroxide or superoxide as an air purifier rapidly absorbs harmful gases and is highly stable even when in contact with water, allowing the polymer composition to show superior characteristics. Particularly, since the polymer composition comprises a stabilizer, it is highly stable and thus is not spontaneously ignited even at very high temperatures. Accordingly, the polymer composition can be manufactured into filters having various shapes by common rubber processing.

Owner:卢万均

Emulsion type ceramic antifoulant

InactiveCN103073995AEasy to produceImprove performanceAntifouling/underwater paintsPaints with biocidesHydrogenSolvent based

The invention discloses an emulsion type ceramic antifoulant. The emulsion type ceramic antifoulant comprises a high polymer organosilicon material, an emulsifier, a curing agent, an acid restrainer and water. The basic composition and mass fraction of the raw materials are listed as follows: 5-20 percent of hydrogen silicone oil, 2-10 percent of methyl silicone oil, 0.5-5 percent of hydroxyl silicone oil, 2-10 percent of 107 silicone rubber, 0.5-3 percent of emulsifier, 0.2-1 percent of curing agent, 0.2-1 percent of acid restrainer, and the balance of water. According to the invention, the high polymer organosilicon material, the emulsifier, additives and the like are fixed, water is added for emulsification to obtain a stable oil-in-water system; the amine curing agent and the acid restrainer are adopted to greatly improve the antifouling property under the premise of ensuring the stability of the emulsion; and the antifoulant can be used to replace the petroleum solvent type antifoulant and has an extensive application prospect.

Owner:FOSHAN DINGSHUN TECH CO LTD

Preparation method of eggshell hydrolysate, as well as product and application of eggshell hydrolysate

InactiveCN102524521AQuality improvementIncrease egg productionAnimal feeding stuffBiotechnologyElectrolytic agent

The invention discloses a preparation method of eggshell hydrolysate. The preparation method comprises the following specific steps of: collecting eggshells, and washing the collected eggshells to obtain the clean eggshells; placing the washed eggshells into an electrolyte solution prepared by a mixed solution of sodium chloride and hydrochloric acid for sterilization; collecting the sterilized eggshells, then drying and smashing the sterilized eggshells; and adding hydrochloric acid or acetic acid for carrying out acidolysis till the eggshells react with the hydrochloric acid or the acetic acid completely, filtering, collecting a filtrate, and obtaining the eggshell hydrolysate. The preparation method is simple, is low in cost, does not need any special equipment or reagent; and the prepared eggshell hydrolysate contains elements such as calcium, phosphorus, magnesium, and zinc, and can be used for improving the laying rate of poultry in later egg-laying period.

Owner:CHONGQING ACAD OF ANIMAL SCI

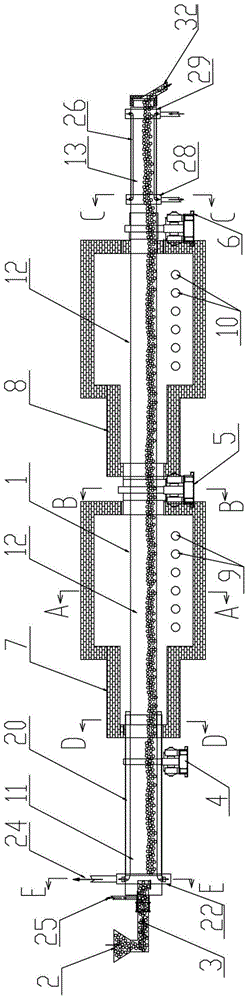

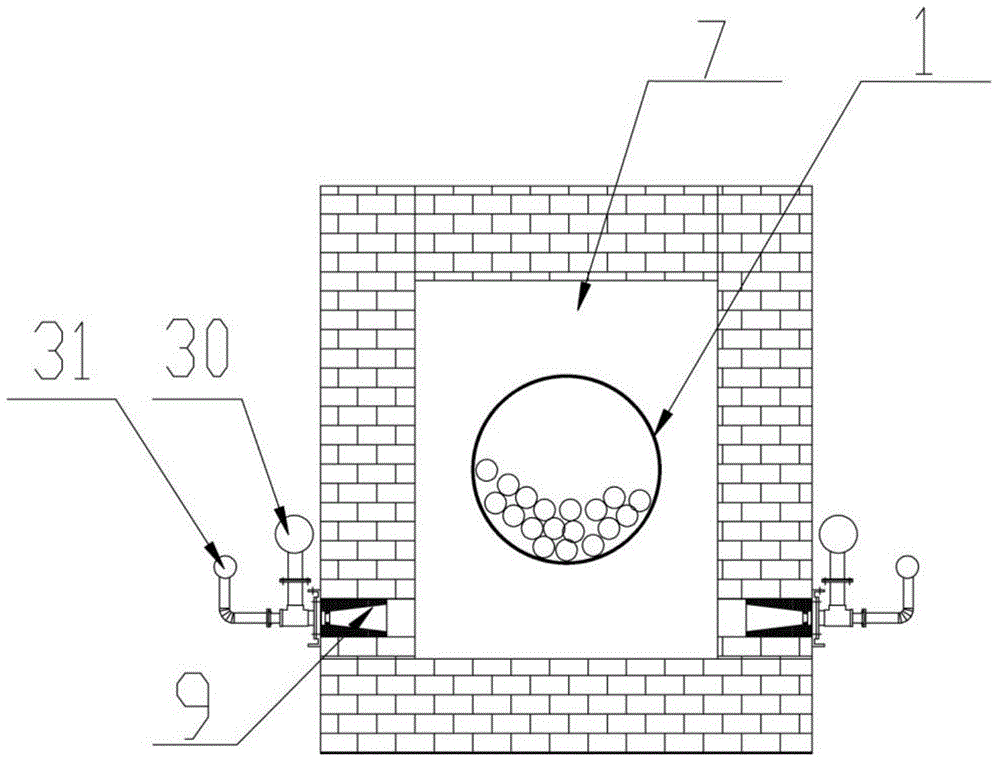

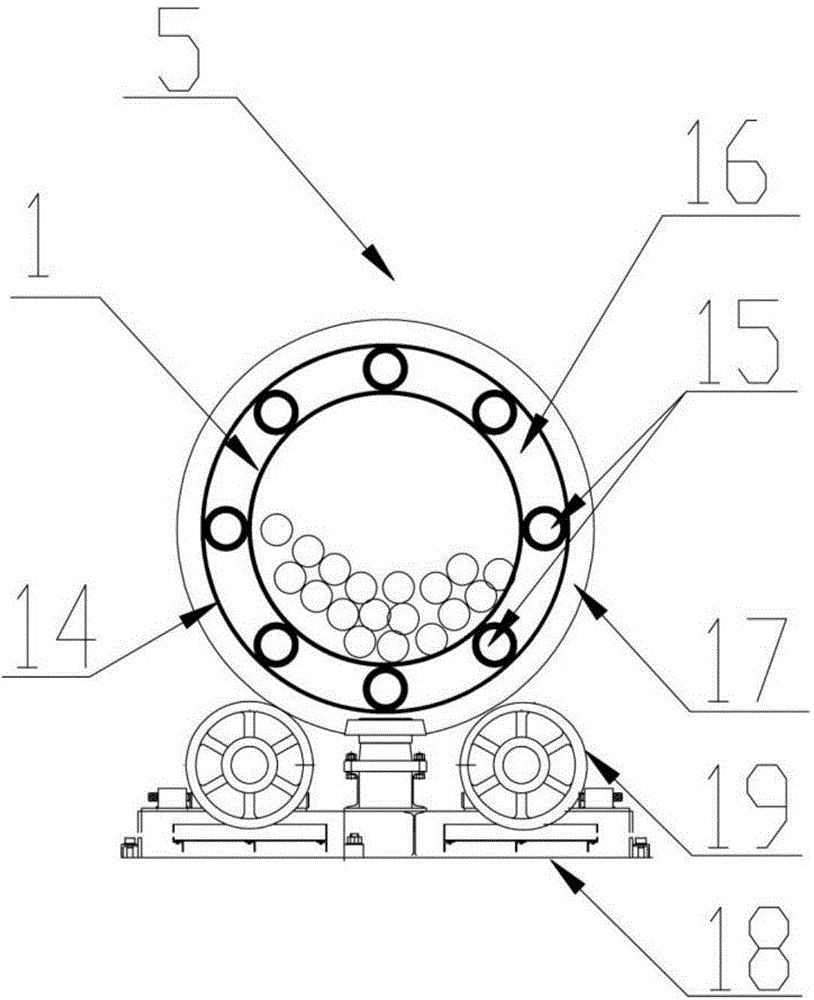

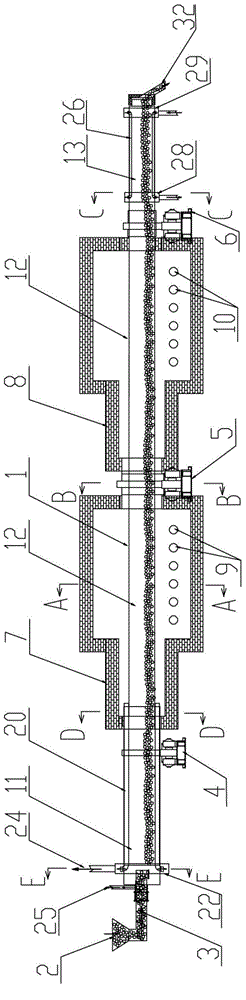

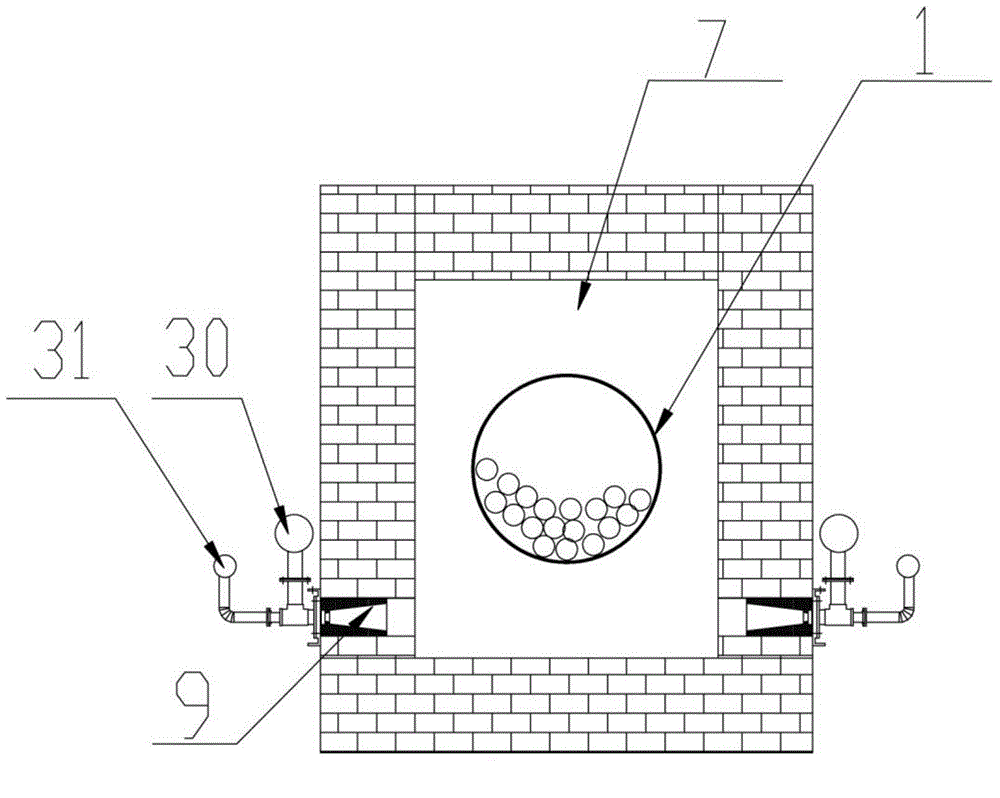

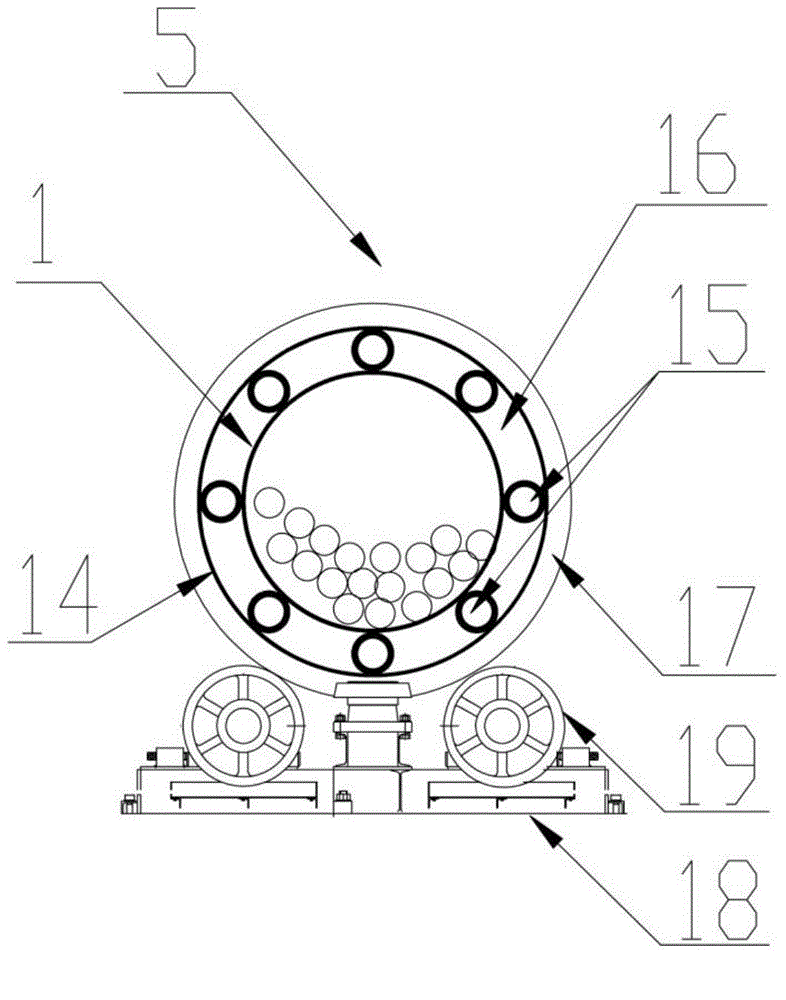

Whole-body type external-heating muffle type rotary kiln

InactiveCN104630407AContinuously stable temperatureReduced temperature required for reductionRotary drum furnacesRotary kilnLow graded

The invention belongs to the field of metallurgical equipment, and in particular relates to a whole-body type external-heating muffle type rotary kiln. A whole-body type continuous external heating muffle type coal-based rotary kiln device with a preheating section and a high-temperature section is adopted, the continuous stabilization of the temperature in a high-temperature area is realized, and a strict requirement on a reduction condition of reduced iron is met. By adopting a muffle-type heating mode, a reduction atmosphere in the rotary kiln is very full, the volatile gas is totally recycled, and the afterheat is fully utilized, so that the required reduction temperature of reduced materials can be greatly reduced, the reduction speed is greatly increased, the energy consumption is greatly reduced, and the carbon emission is reduced; by using non-caking coals with high granularity and high quality as reducing coals, the device is suitable for various iron raw materials with high grade, low grade and varieties, the reduction process is flexible, and the device has many advantages. According to a single production line of the device, the annual reduction treatment ore quantity can reach the maximum scale of 1,800,000-2,100,000 tons.

Owner:泉州寰锋冶金技术有限责任公司

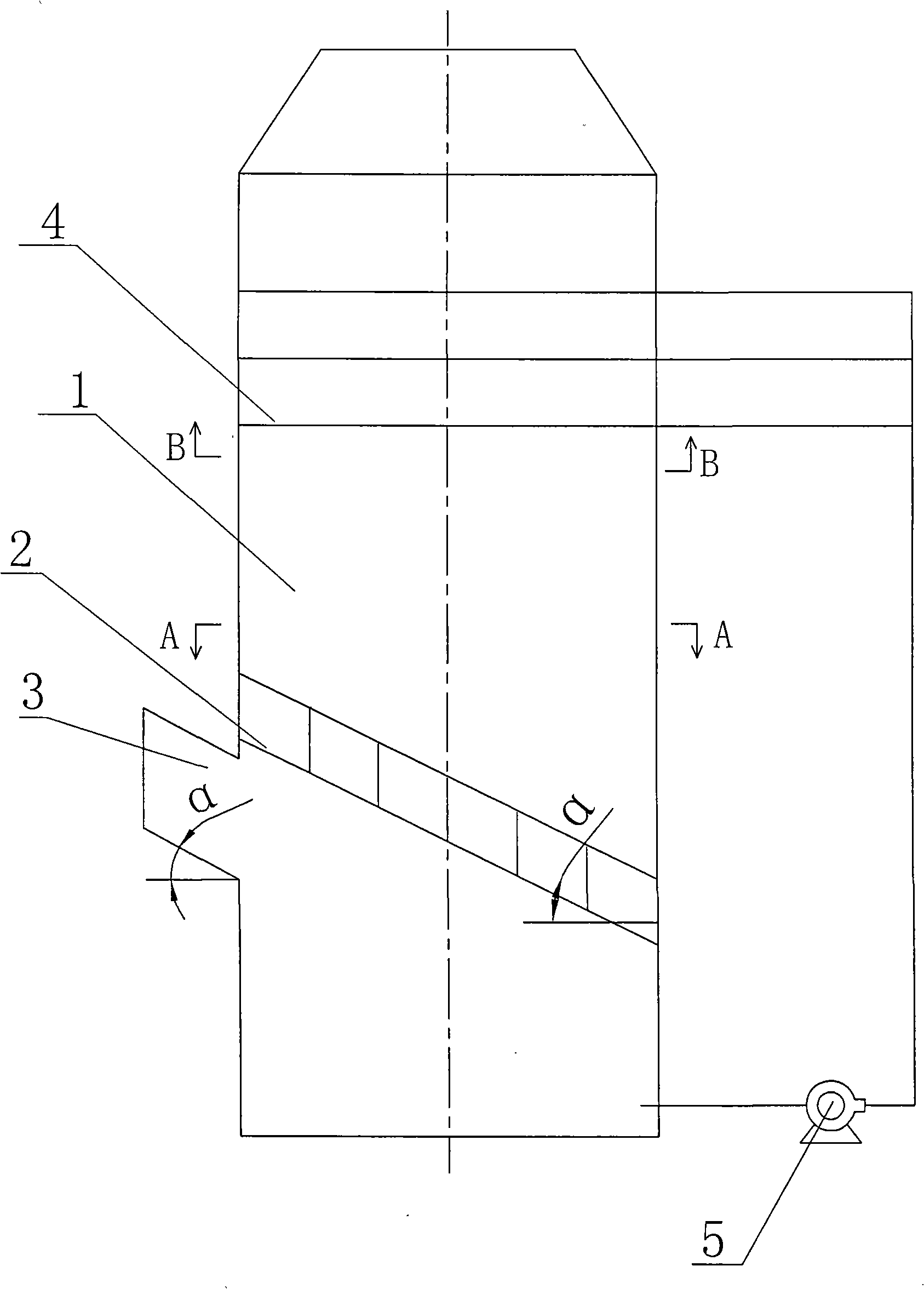

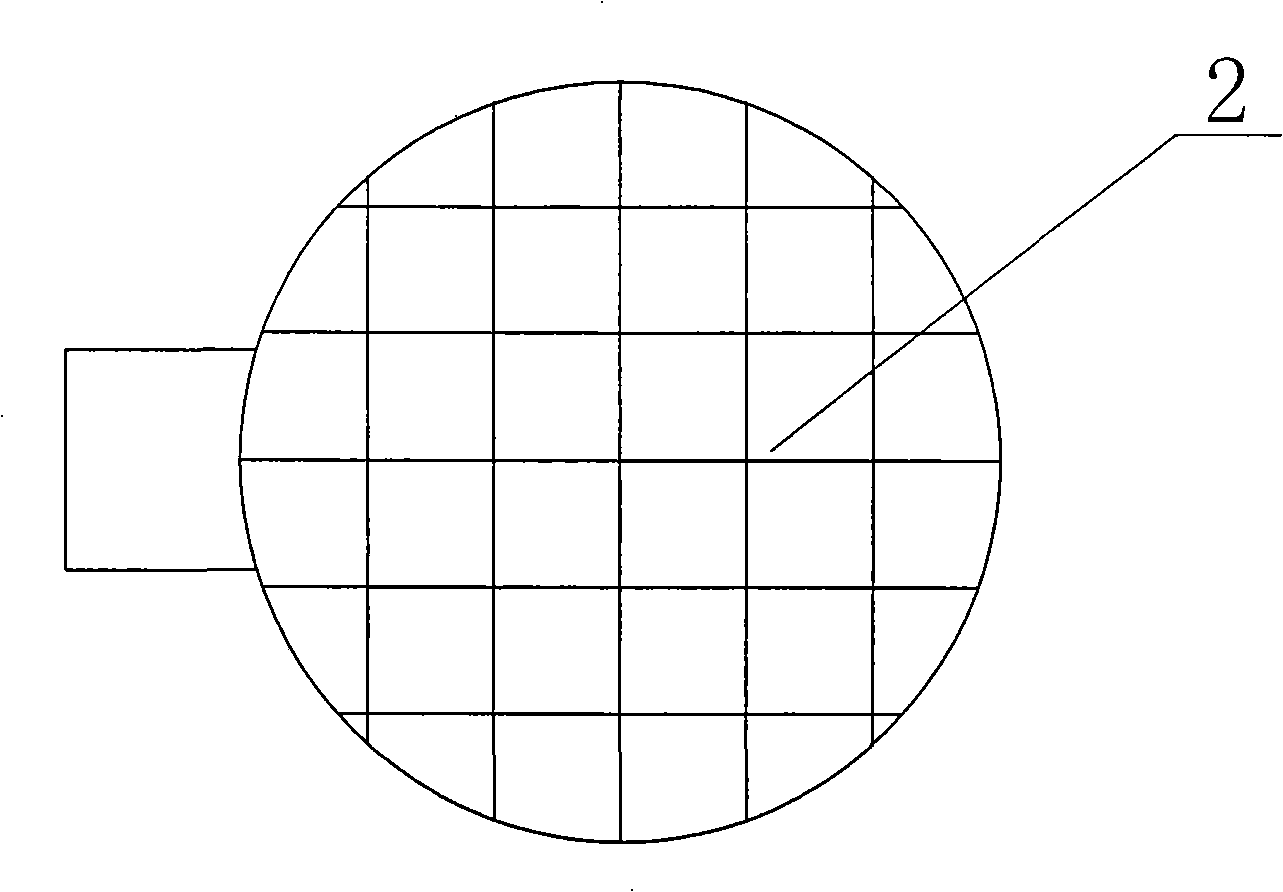

Biphase rectification flue gas desulfurization technique

ActiveCN101244363AReduce resistanceDoes not cause reduced reflux reactionsDispersed particle separationReaction rateGas phase

The invention discloses a dual-phase rectification flue gas desulfurization technology, which comprises a plurality of steps that (1) an absorption tower is arranged, (2) the flue gas is injected, (3) the limestone slurry is pumped in, and (4) the reaction product is collected. The dual-phase rectification flue gas desulfurization technology is characterized in that (1) the nonuniformity of flow field inside the spray tower is utilized, (2) the even rectification of liquidoid and gas phase is not processed on account of the design of rectifying plate and spray layer intentionally, (3) the resistance of flue gas is decreased and the velocity of flow of flue gas is uninfluenced, and (4) the liquidoid and the gas phase are kept turbulent state consistently because of the nonuniformity of liquidoid and gas phase. The dual-phase rectification flue gas desulfurization technology has the advantages of fierce collision, intense reaction, enough absorption, good performance of desulfurization, high efficiency, fast reaction rate, good performance of counter-current reaction, optimization of flow field, low system pressure drop, energy-saving, low device cost and maintenance cost, and direct maintenance and shift of inner parts without building temporary maintenance platform in the process of maintenance of absorption tower inner parts.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

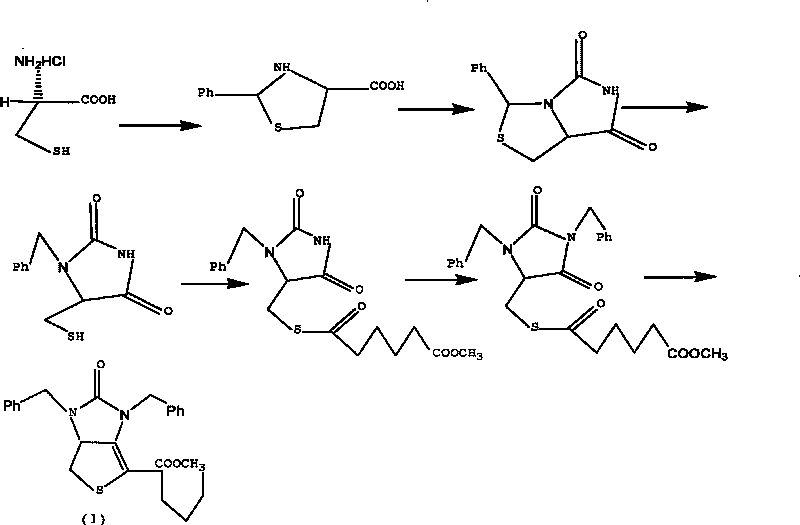

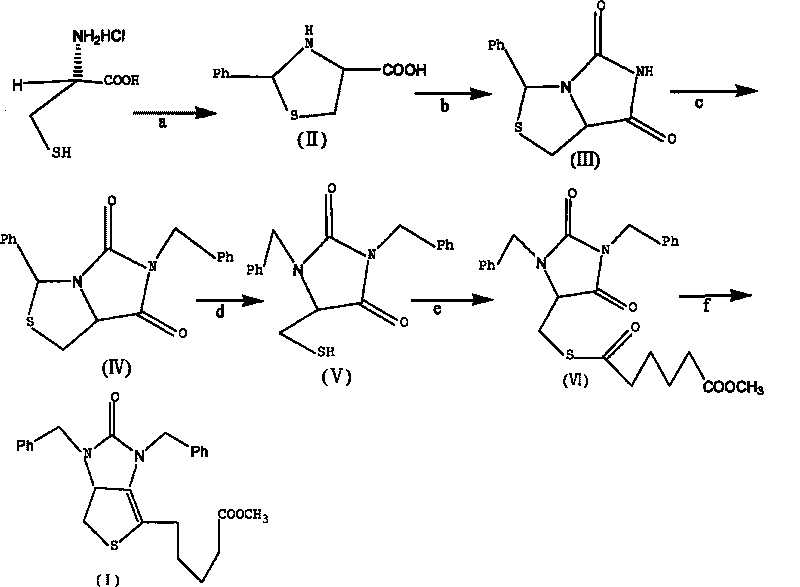

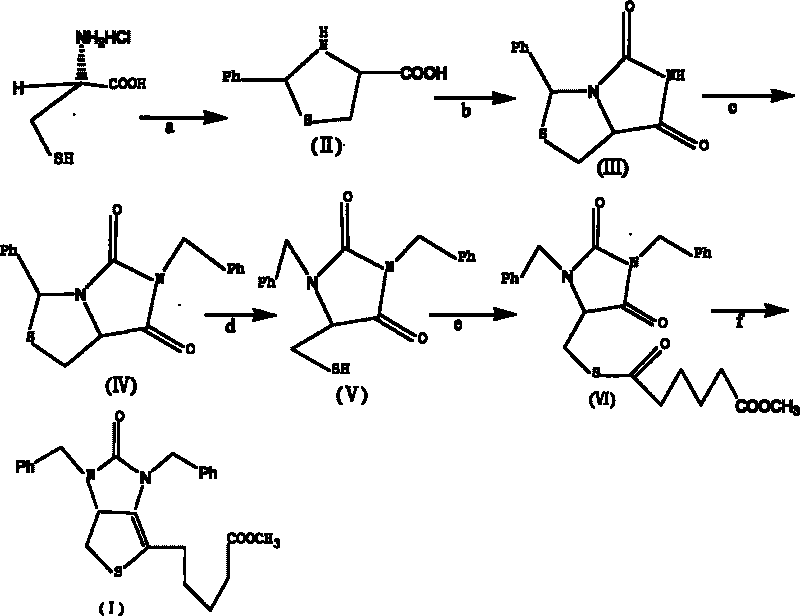

Method for preparing D-(+)-biotin intermediate

ActiveCN101735242AEasy to buyIncreased riskOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsBenzoyl bromideBenzaldehyde

The invention provides a method for preparing a D-(+)-biotin intermediate. The method comprises the steps of: taking L-cysteine monohydrochloride as a starting material; using benzaldehyde and sodium cyanate as a ring closure reagent to synthesize (7aR)-3-phenyl-6-benzyl-1H, 3H-imidazo[1, 5-C]thiazole-(6H, 7aH)-5, 7-dione through the cyclization; then utilizing benzyl bromide to perform benzyl protection on N atoms; then taking zinc as a reducing agent to perform ring-opening synthesis on N, N-dibenzyl-L-sulfhydryl hydantoin; introducing a side chain through an esterification reaction with monomethyl adipate acyl chloride; and taking titanium as the reducing agent to perform reductive ring closure to generate the intermediate. According to the method, the cheap and readily available sodium cyanate is used as the ring closure reagent to replace sodium isocyanate which is toxic and difficult to purchase in an original method, reaction conditions are optimized and reaction order is adjusted, so the disadvantages of harsh reaction conditions and low yield in the original method of ring opening first and then benzyl protection are overcome by the method of performing benzyl protection on the N atoms of an imidazole part first and then performing ring opening; and the total yield reaches 34.0-38.0 percent.

Owner:安徽泰格生物技术股份有限公司

Combined method for extracting iron and dephosphorizing by reducing, smelting and dressing low-grade high-phosphorus hard-dressing iron (manganese) ore

The invention belongs to the technical field of metallurgy and in particular relates to a combined method for extracting iron and dephosphorizing by reducing, smelting and dressing low-grade high-phosphorus hard-dressing iron (manganese) ore. Raw ore is firstly subjected to fine grinding, dressing, iron extracting and dephosphorizing to obtain relatively low-phosphorous rich ore powder, then separation of iron from slag and reduction are carried out on the low-phosphorous rich ore powder, and after reduced metallized pellets are cooled, fine grinding and wet magnetic separation are carried out, so that metal iron powder / manganese-containing metal iron powder with TFe content more than or equal to 90%, etaFe content more than or equal to 92% and P content less than or equal to 0.07% is obtained. The combined method for extracting iron and dephosphorizing by reducing, smelting and dressing the low-grade high-phosphorus hard-dressing iron (manganese) ore has the advantages that low reduction temperature and short reduction time are controlled, increase of P content in the final product is avoided as high temperature above 1250 DEG C and long reaction time are adopted in the traditional method and P element and Fe in phosphorite react to generate phosphide, especially stable Fe3P; and if the raw ore is ferrous manganese ore, a manganese-rich powder byproduct with Mn content more than or equal to 45% can be obtained, additional value of the product is high, and energy conservation, environmental protection and low carbon content are realized.

Owner:泉州寰锋冶金技术有限责任公司

Soft gel self-driving micro motor and preparation method thereof

The invention discloses a soft gel self-driving micro motor and a preparation method thereof. The preparation method mainly comprises the following steps: dispersing monomers, a cross-linking agent, an initiator and a catalyst which form a soft gel material in an aqueous solution by utilizing an in-situ polymerization method; forming the aqueous solution which is mixed uniformly into a shape required by a motor in a mould; loading catalyst solution on the gel by adopting a simple injecting method after high vacuum silicone grease protection treatment is performed; adsorbing the catalyst solution by utilizing the hydrophilic property of the gel to complete the manufacturing process of the soft gel-based micro self-driving motor. The self-driving process of the micro motor is realized in hydrogen peroxide solution. The method disclosed by the invention is easy to operate, low in equipment requirement, and suitable for scale production. The obtained soft gel-based micro self-driving motor can be used in the field of environment, such as water treatment, and meanwhile, provides a feasible driving ideal for the development of an intelligent soft robot.

Owner:SOUTH CHINA UNIV OF TECH

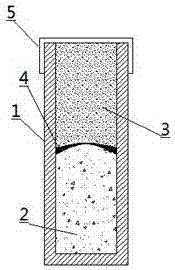

Dry powder fire extinguisher achieving automatic spraying

The invention discloses an automatic injection dry powder fire extinguisher, which comprises a columnar, hollow metal shell, and an injection port is opened on the top of the metal shell; It is filled with an ABC fire extinguishing dry powder layer; a latex film is separated between the expansion agent layer and the ABC fire extinguishing dry powder layer; the edge of the latex film is adhered to the inner wall of the metal shell; the injection port is covered with metal foil. The expansion agent layer may be composed of raw materials that generate expansion gas when heated in the prior art. After a fire occurs, the expansion agent layer produces a large amount of expansion gas, which makes the latex film expand until it explodes, and finally the powder of the ABC fire extinguishing dry powder layer is sprayed out to cover the flame to realize fire extinguishing.

Owner:吕海党

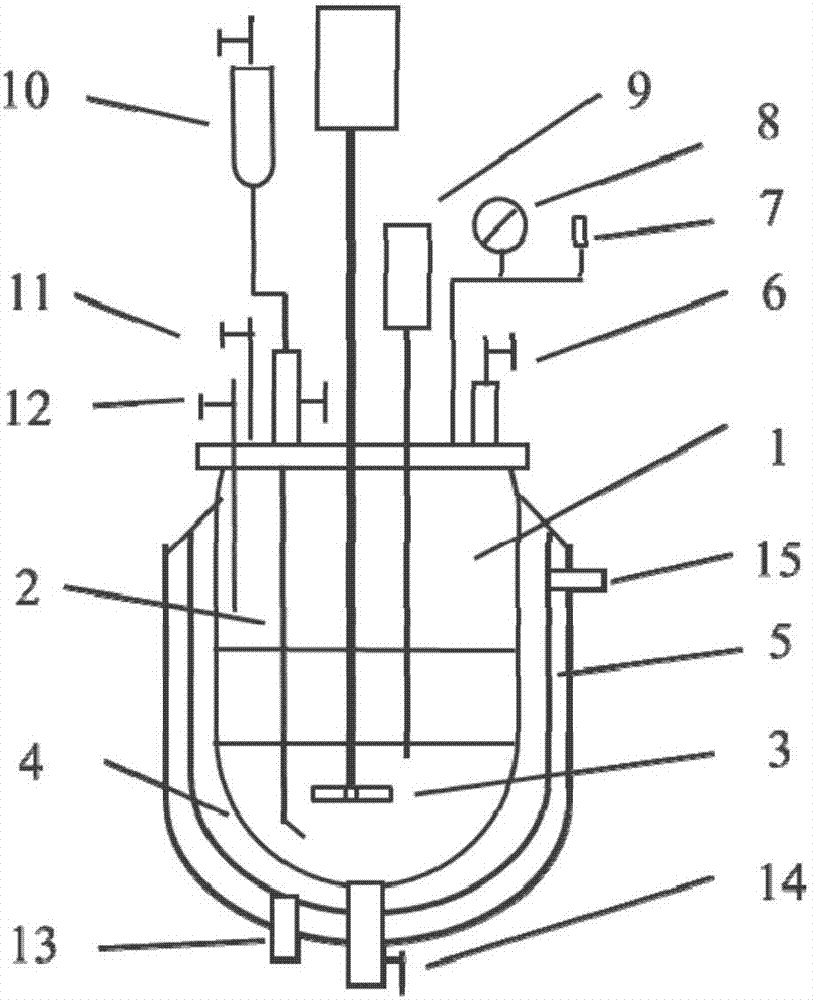

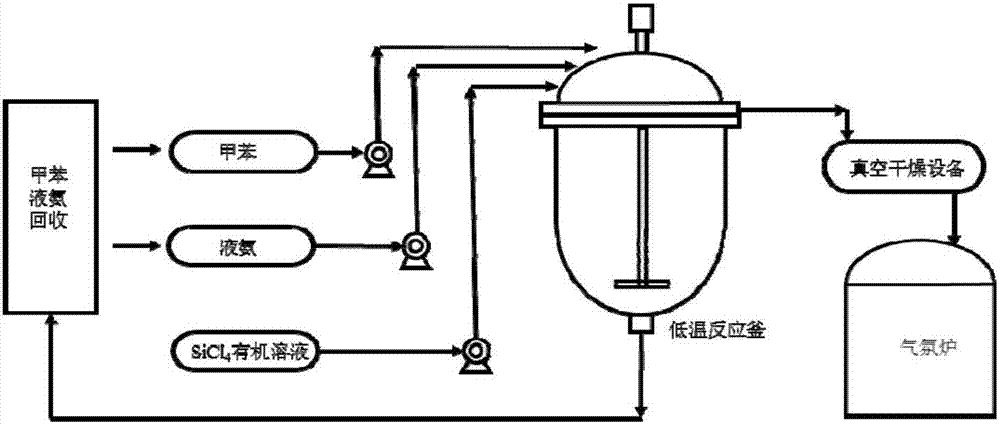

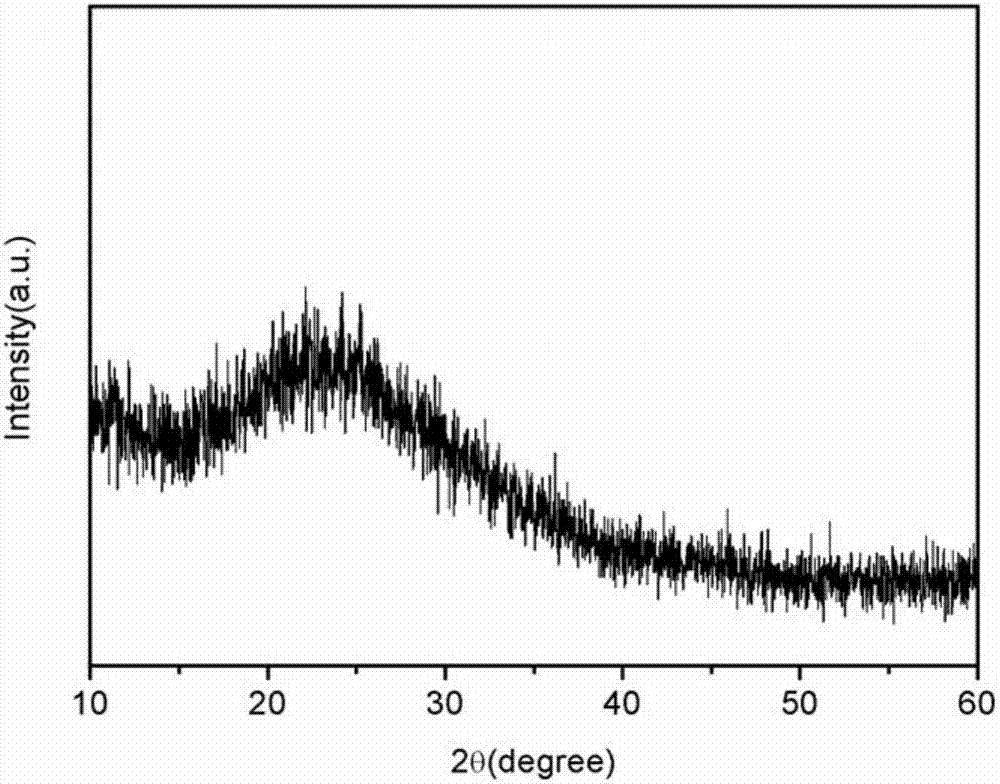

Preparation method of alpha-phase silicon nitride powder

ActiveCN107954723AEasy to cleanSimple internal structureNitrogen compoundsChemical/physical/physico-chemical stationary reactorsInterfacial reactionReaction rate

The invention discloses a preparation method of alpha-phase silicon nitride powder. The preparation method comprises the following steps: (1) reacting silicon tetrachloride with liquid ammonia in a two-liquid-phase interface of an organic solvent and the liquid ammonia to obtain a precursor which is silylimine, wherein the organic solvent is methylbenzene or a mixture of the methylbenzene and dimethylbenzene; (2) carrying out thermal decomposition on the silylimine to obtain non-shaped silicon nitride powder; and (3) carrying out crystallization treatment on the non-shaped silicon nitride powder in step (2) to obtain the alpha-phase silicon nitride powder. In the method, silicon tetrachloride reacts with the liquid ammonia on the two-liquid-phase interface of the organic solvent and the liquid ammonia, the silicon tetrachloride is diluted at low temperature, the reaction rate can be reduced by control over feeding speed, synthesis of the precursor can be controlled effectively, the circumstance that aggregates are formed by the precursor is avoided, the reaction area is expanded by interfacial reaction, and the speed of NH4Cl dissolved in the liquid ammonia is increased. The prepared alpha-Si3N4 powder is controllable in crystal form and morphology, grain sizes are distributed uniformly, a technological process is simple, and production requirements can be met.

Owner:浙江英德赛半导体材料股份有限公司

Method for closed-ring synthesizing anthraquinone from o-benzoylbenzoic acid

InactiveCN1683305AIncrease the feeding speedSave unloading timeOrganic compound preparationQuinone preparationChemistrySpent acid

The process of close-ring synthesizing anthraquinone from o-benzoylbenzoic acid includes the following steps: A. heating o-benzoylbenzoic acid in close-ring reactor to eliminating surface water; B. adding fuming sulfuric acid with SO3 content of 16-24 % in 1.3-1.8 times weight of o-benzoylbenzoic acid and close-ring reaction at 138-200 deg.c for 1 hr; C. separating the reaction product in separating reactor, filtering, water washing, drying, etc. to obtain dry anthraquinone product. The present invention has less sulfuric acid consumption, low production cost, less exhausted waste acid, low power consumption and short reaction time.

Owner:赵振国

Method for smelting medium ferrovanadium

The invention belongs to the metallurgy field and in particular relates to a method for smelting medium ferrovanadium. The invention aims to solve the technical problem of an electro-aluminothermic process with high vanadium recovery from smelting and is specifically characterized by adopting the mixed materials of V2O5 and V2O3 as the raw materials and using the electro-aluminothermic process tosmelt the medium ferrovanadium. The method comprises the following steps: A. preparing bottom materials and main materials; B firstly adding the bottom materials for smelting at the initial stage of smelting; C. then adding the main materials after the bottom materials react steadily; and D. refining. The bottom materials include aluminium, V2O5, iron and lime. The main materials include V2O3, aluminium, V2O5, iron, lime and fluorite. The method not only fully utilizes the reaction heat, but also simplifies the technological process, reduces the viscosity of the slag and ensures the ferrovanadium recovery from smelting to be steadily increased by over 96%.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

Waterborne polyurethane emulsion as well as preparation method thereof, application of waterborne polyurethane emulsion to wallpaper basement membrane, and wallpaper basement membrane

InactiveCN104804168ANo pollutionNo irritating smellPolyurea/polyurethane coatingsEnvironmental resistancePolyester

The invention relates to waterborne polyurethane emulsion which is prepared from the following raw materials in parts by weight: 100-120 parts of polyester polyol, 45-55 parts of diisocyanate, 10-12 parts of hydrophilic chain extender, 7-9 parts of a salt-forming agent and 270-300 parts of water. The invention further relates to a preparation method for the waterborne polyurethane emulsion, an application of the waterborne polyurethane emulsion to a wallpaper basement membrane and the wallpaper basement membrane. The waterborne polyurethane emulsion has the advantages of no pungent smell, environmental protection, good membrane-forming property and adhesion, and very good water-proof and alkali-proof properties; the preparation method for the waterborne polyurethane emulsion has the advantages of simplicity, easiness for operation and favorability for large-scale production and application; the wallpaper basement membrane has the benefit of capability of guaranteeing good water-proof and alkali-proof properties and product stability and enriching the types of wallpaper basement membrane products at the same time.

Owner:FUJIAN POLYTECH TECH CO LTD

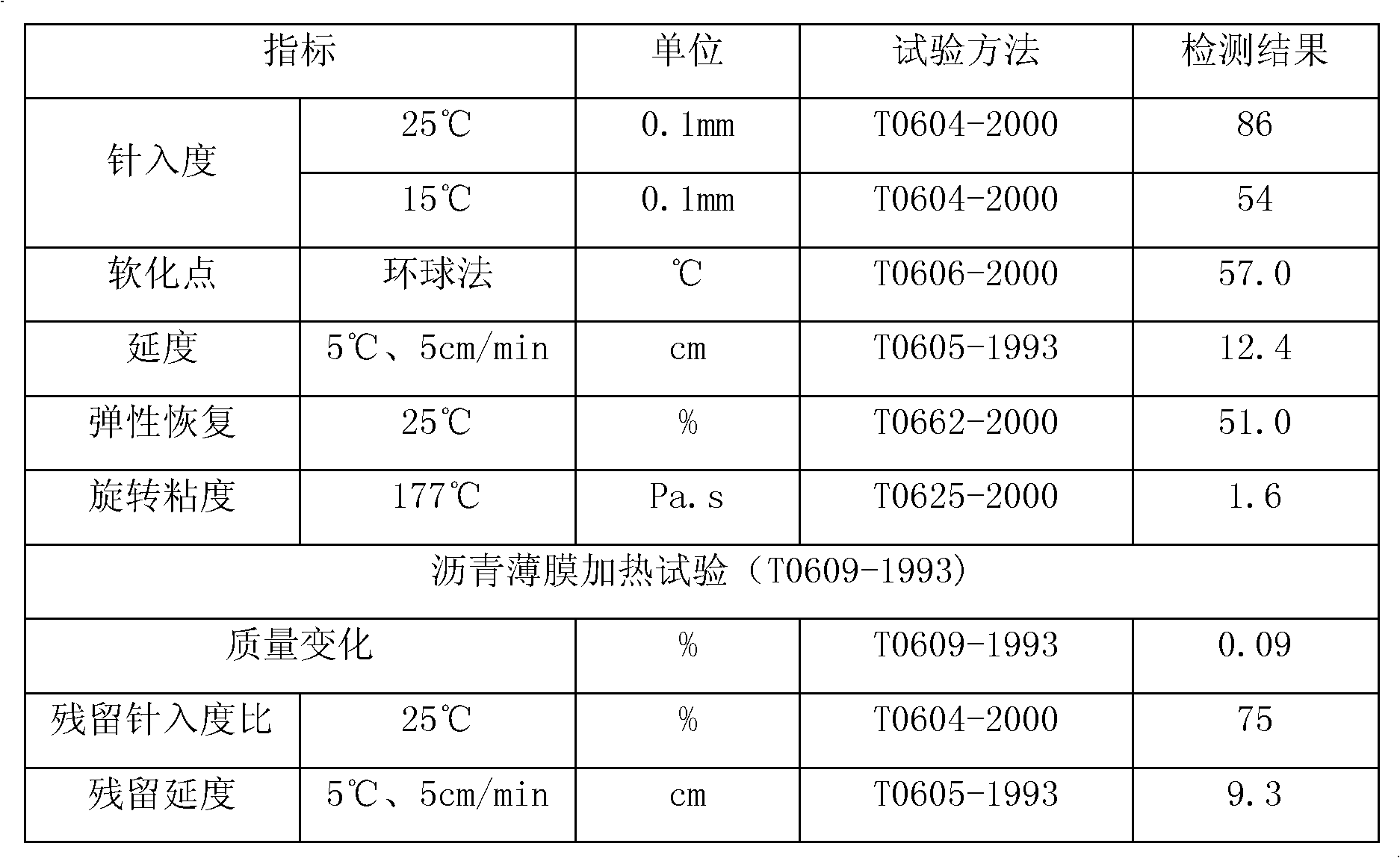

Modified asphalt stabilizer and preparation method thereof

InactiveCN105647201AImprove mixing uniformityImprove stabilityBuilding insulationsPolymer scienceSulfur

The invention discloses a modified asphalt stabilizer and a preparation method thereof. The stabilizer is prepared from, by weight, 20-40% of elemental sulfur, 10-20% of organic sulfur, 20-40% of rubber oil, 20-35% of 200# asphalt and 1-5% of dispersing agent. The prepared stabilizer is in a liquid state. Compared with a traditional solid modified asphalt stabilizer, the modified asphalt stabilizer can be combined with all kinds of different modified asphalt products more easily, the stability of modified asphalt can be improved, and storage and long-distance transportation of the modified asphalt can be benefited better.

Owner:ZHONGHAI ASPHALT SICHUAN CO LTD

Metronidazole effervescence patch and technique of preparing the same

ActiveCN101152176AImprove the bactericidal effectGood synergyOrganic active ingredientsAntimycoticsChlorhexidine AcetateTalc

The invention discloses a Metronidazole, Clotrimazole and Chlorhexidine Acetate Effervescent Tablet and the preparation method. Each tablet has the following proportion of contents: metronidazole 0.2 gram, clotrimazole 0.16 gram, acetic acid chlorhexidine acetate 0.008 gram, fumaric acid 0.108 to 0.162 gram, tartaric acid 0.012 to 0.018 gram, solium bicarbonate 0.12 to 0.18 gram, starch 0.02 to 0.04 gram, dextrin 0.003 to 0.007 gram, hydroxypropyl cellulose 0.007 to 0.013 gram, talc 0.01 to 0.017 gram, sodium dodecyl sulfate 0.01to 0.02 gram, and proper proportion of povidone K30 water solution. According to the preparation method, the components are mixed to produce granule (1) and granule (2); the talc, sodium dodecyl sulfate and the granule (1) and granule (2) are mixed uniformly; granule content is tested and according to the granule content, the tablet weight is identified for tabletting. The invention overcomes the shortages with prior art, enables the acetic acid chlorhexidine acetate to perform functions normally, performs synergistic effects of the three drugs, and greatly enhances the cure rate. Besides, the frothing volume is high, and within storage period, the quality is stable and the drug effects are not affected.

Owner:SHANDONG SBOND PHARMA

Method for reducing and separating granular iron rapidly at low temperature

The invention belongs to the technical field of metallurgy and particularly relates to a method for reducing and separating granular iron rapidly at a low temperature. The method comprises the following steps: crushing iron ore, drying, grinding the dried iron ore into fine iron ore powder, adding iron powder, lime powder, ordinary glass powder and fluorite powder into the fine ore powder, spraying with water, mixing, pelletizing or pressing to form pellets; drying the wet pellets, adding reducing coal and a desulfurizing agent, feeding the mixture into a rotary muffle kiln, and carrying out reduction reaction; separating the tail power of a reducing agent from metalized pellets in the high-temperature material from reduction reaction by using a dry magnetic separator; crushing the metalized pellets, and sieving to obtain the granular iron with the size of 3-20mm and the density of 5.8-7.2t / m<3>; polishing the power further, and separating magnetically by adopting a wet process to obtain the high-grade iron powder. The iron ore can be reduced rapidly at a relatively low reducing temperature, the granular iron can be separated, and the yield of the granular iron can be more than 90%. Compared with the Japanese ITmk3 reduction technology, the method provided by the invention can achieve the purposes of saving energy, reducing emission and decreasing carbon to a great extent.

Owner:泉州寰锋冶金技术有限责任公司

Method for preparing reverse osmosis membrane by utilizing ethyl silicate as oil-phase cosolvent

The invention relates to a method for preparing a reverse osmosis membrane by utilizing ethyl silicate as an oil-phase cosolvent. The method comprises the following steps: infiltrating a supporting film into a water-phase solution to sufficiently infiltrate the supporting film by the water-phase solution; infiltrating the film into an Isopar G solution containing the ethyl silicate and trimesoyl chloride to initiate interfacial polymerization to form an aromatic polyamide separation layer; and performing thermal treatment on the film at 70-90 DEG C to obtain the aromatic polyamide composite reverse osmosis membrane. The method provided by the invention has a simple preparation process and low costs, and is easy to implement, and the prepared aromatic polyamide composite reverse osmosis membrane has high flux of >=3L*m<-2>*h<-1>*bar<-1> and a high rejection rate of >=99.00%; and in addition, the method can also provide reference for preparation of other high-performance aromatic polyamide composite separation membranes.

Owner:TIANJIN UNIV

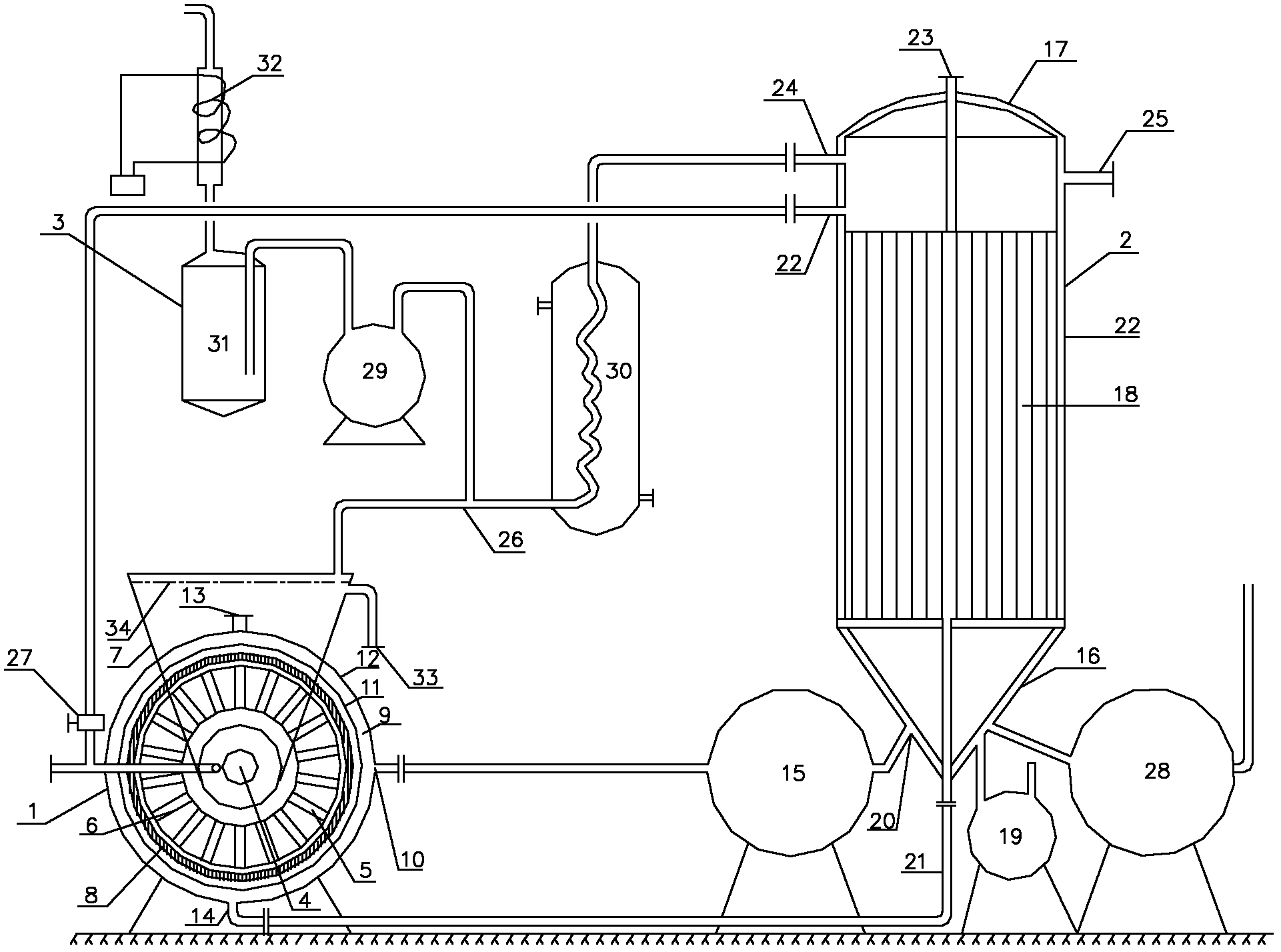

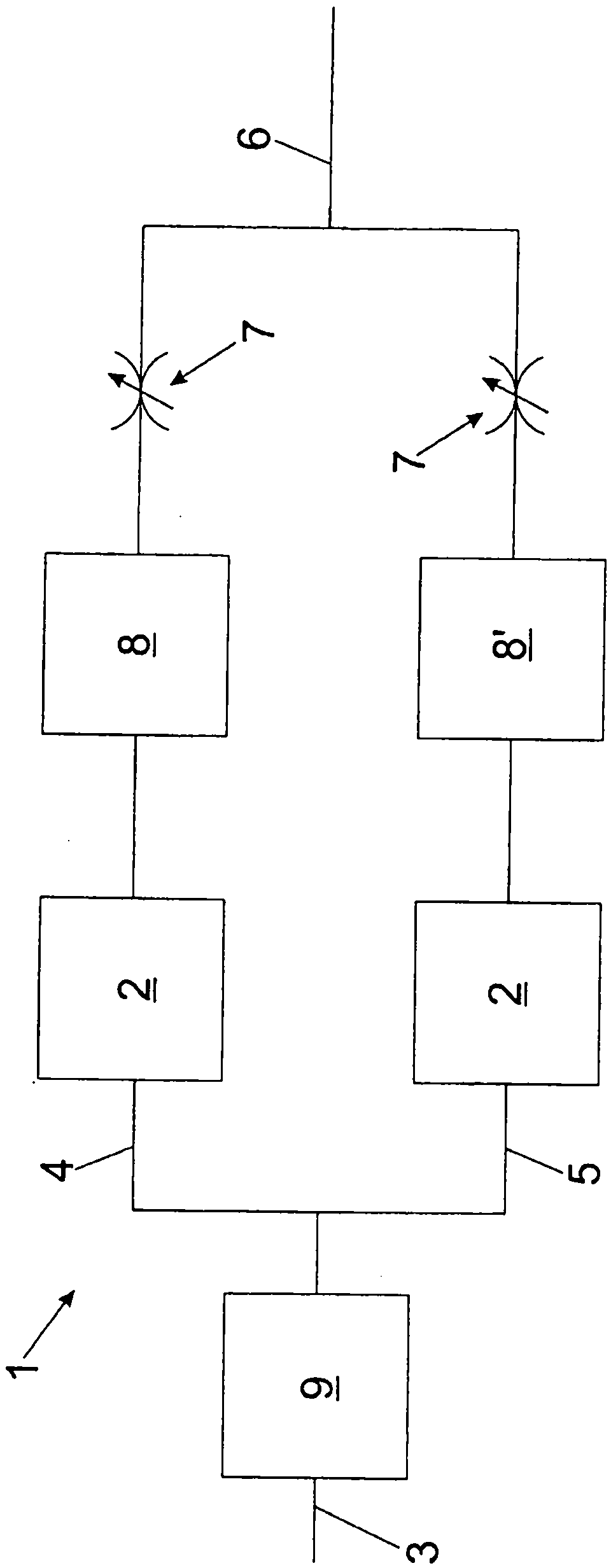

Device for producing modified asphalt and method for producing modified asphalt by using device

InactiveCN102444074AWell mixedViolent reactionRoads maintainenceBuilding insulationsShell and tube heat exchangerEngineering

The invention discloses a device and a synthetic method for producing modified asphalt. The device comprises a mixing device provided with a raw material inlet, wherein the mixing device is communicated with a heat insulation tower; the heat insulation tower is provided with a mixture inlet and a discharge hole, the mixture inlet is formed on the lower part of the heat insulation tower, and the discharge hole is formed on the upper part of the heat insulation tower; and matrix asphalt and modifier are fully mixed and delivered to the heat insulation tower for synthesizing, fluid flows through gaps of shell and tube heat exchangers from bottom to top to exchange heat in a large area, and the mixture follows rise of the fluid level and relative motion of the shell and tube heat exchangers, so that the flowability of the mixture is ensured, and the mixture is heated more uniformly and fully.

Owner:剑阁正能科技有限公司

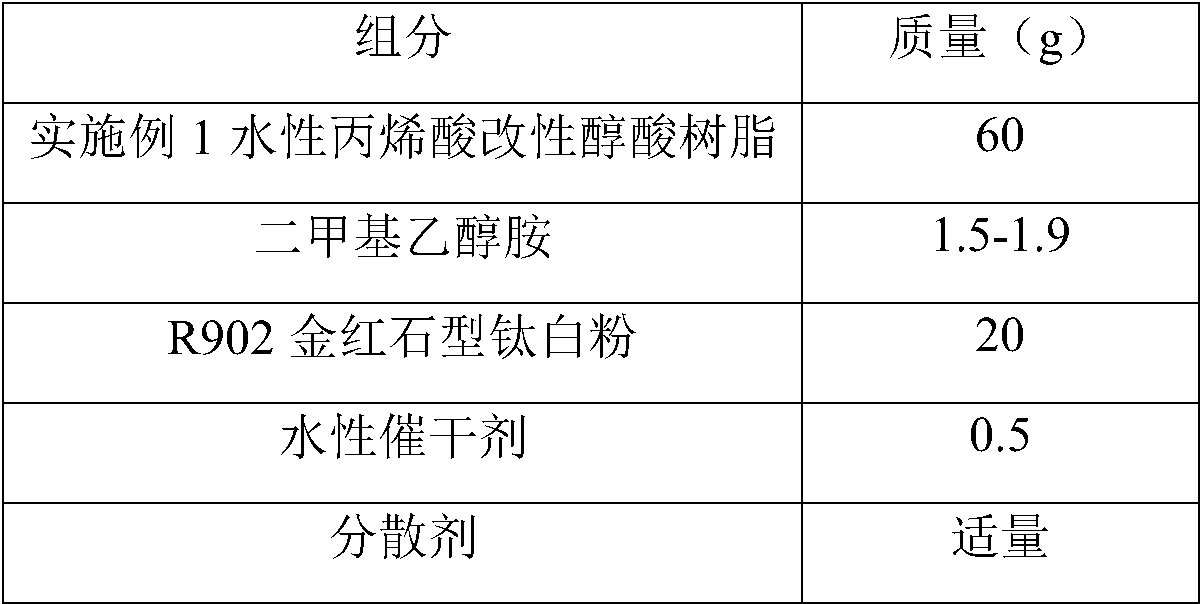

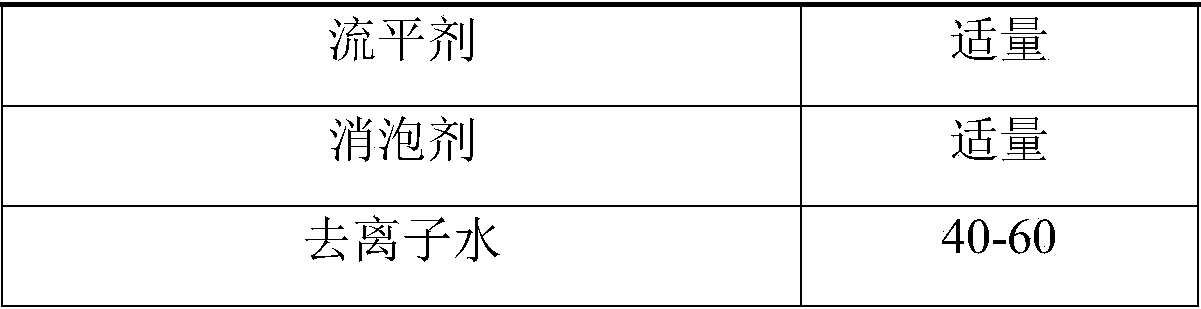

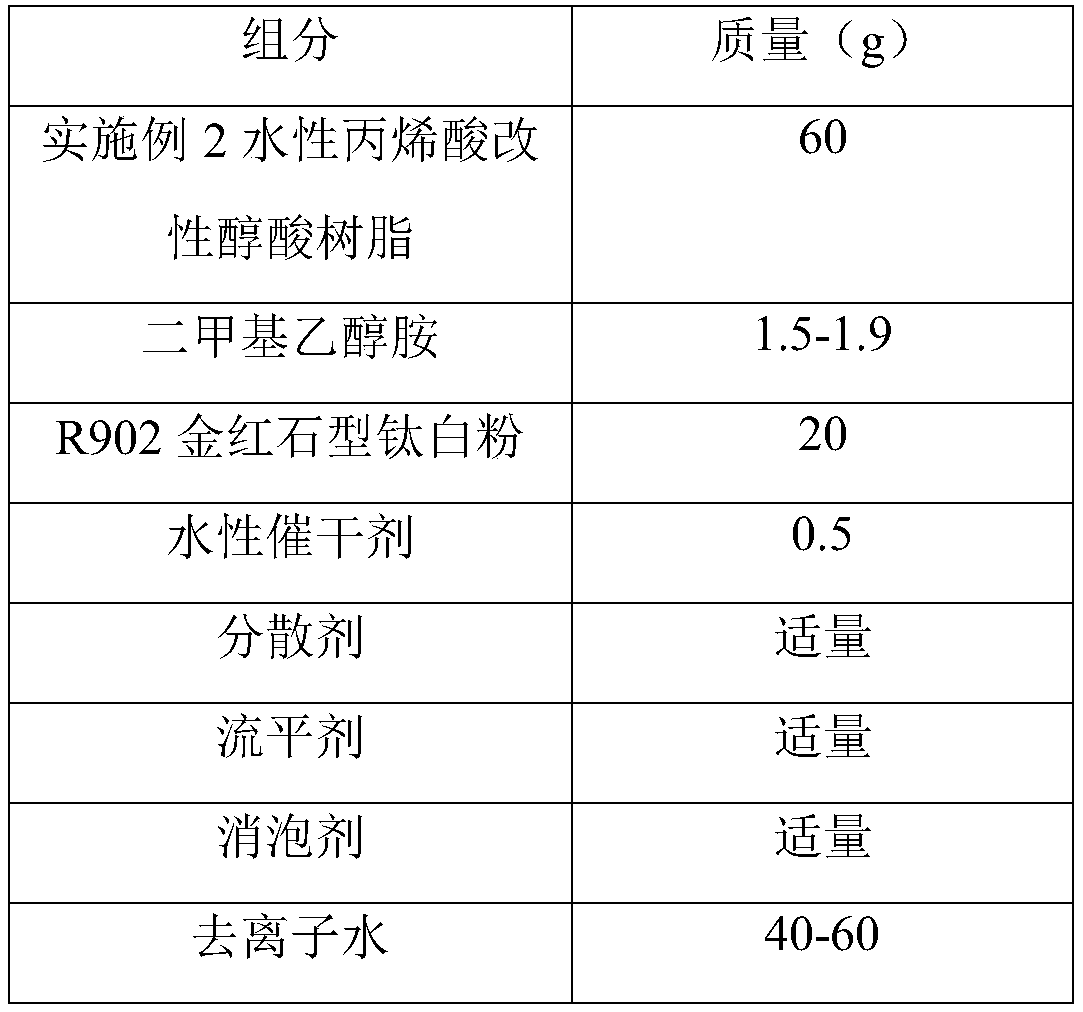

Waterborne acrylic acid modified alkyd resin and preparation method

ActiveCN109306037AUniform molecular weightDry no differencePolyester coatingsSide chainOleic Acid Triglyceride

The invention discloses waterborne acrylic acid modified alkyd resin and a preparation method. The waterborne acrylic acid modified alkyd resin is prepared from the following raw materials: 22 to 24 percent of dry or semi-dry plant oleic acid, 14 to 15 percent of tribasic alcohol with a side chain, 13 to 14 percent of phthalic anhydride, 0.05 to 0.15 percent of a color reduction agent, 1 to 3 percent of refluxing xylol, 0.7 to 1 percent of cis-butenedioic anhydride, 2.5 to 2.7 percent of trimellitic anhydride, 4 to 5 percent of methyl methacrylate, 6 to 8 percent of styrene, 1 to 2 percent ofbutyl acrylate, 0.5 to 1 percent of an initiator and 28 to 29 percent of propylene glycol methyl ether. The waterborne acrylic acid modified alkyd resin is obtained by combining the above preferable raw materials; the waterborne acrylic acid modified alkyd resin has good environment protection performance and low toxicity, also keeps excellent comprehensive performance including glossiness, adhesion and, rigidity and the like and has very good technical effects.

Owner:江苏三木化工股份有限公司 +1

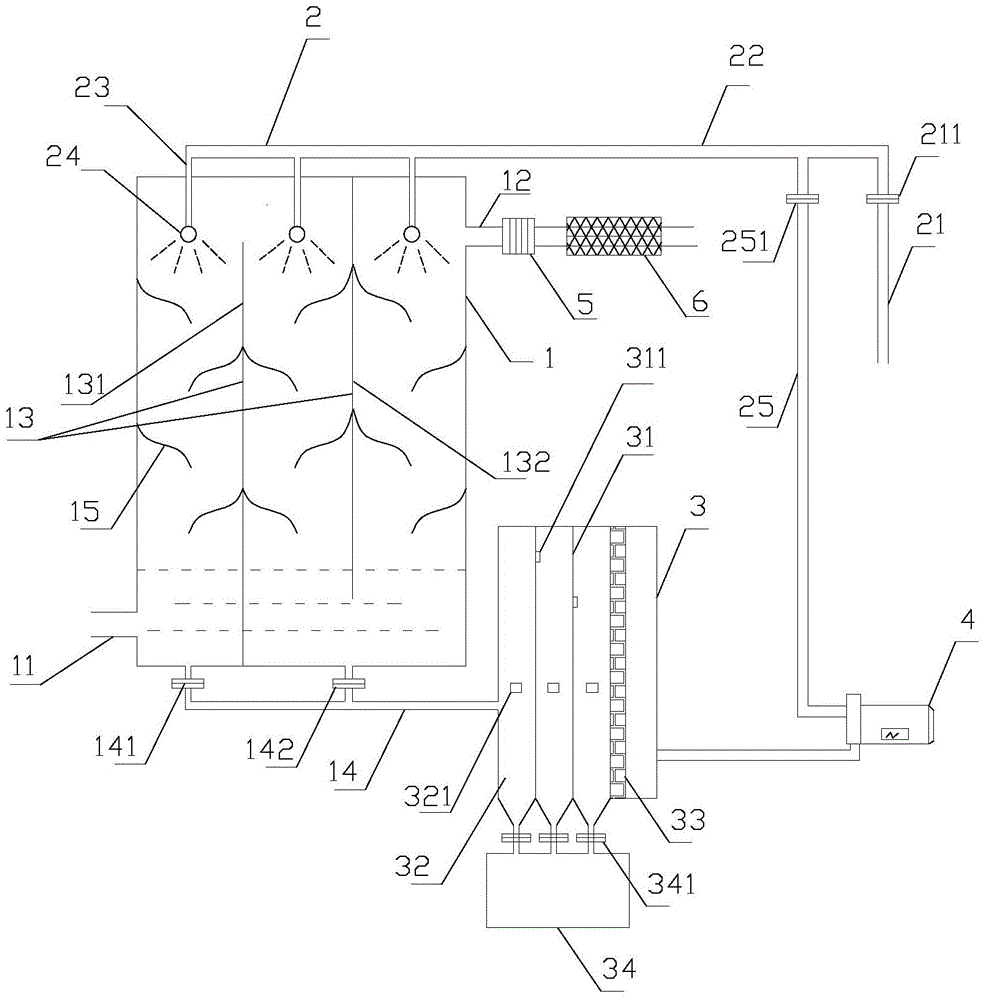

Flue gas desulfurization device

InactiveCN104437056AExtended flow pathIncrease contact timeDispersed particle separationEngineeringCirculating pump

The invention discloses a flue gas desulfurization device. The flue gas desulfurization device comprises a box body, a spraying mechanism, a regenerating tank and a circulating pump, wherein the box body is provided with a gas inlet pipe and a gas outlet pipe; partition plates which are arranged in an up-down staggered manner are arranged in the box body to divide the bottom of the box body into a first filter tank and a second filter tank; the bottoms of the first filter tank and the second filter tank are respectively connected with a liquid discharging branch pipe of a liquid discharging pipe; the spraying mechanism comprises a first liquid inlet pipe, a second liquid inlet pipe, and a first liquid inlet branch pipe, wherein a first desulfurizing agent is introduced into the first liquid inlet pipe; the first liquid inlet branch pipe is connected with the second liquid inlet pipe; the first liquid inlet pipe is connected with the second liquid inlet pipe; the first liquid inlet pipe and a spraying head are arranged at the top of the box body; a first liquid inlet which is connected with the liquid discharging pipe is formed in one side surface of the regenerating tank; a liquid outlet is formed in the side surface opposite to the first liquid inlet; a second desulfurizing agent is arranged at the bottom of the regenerating tank; the circulating pump is connected with the liquid outlet of the regenerating tank and the second liquid inlet pipe. The flue gas desulfurization device disclosed by the invention has a good desulfurization effect; the feculence cleaning operation of the regenerating tank is simple, and the desulfurizing agent in the regenerating tank is not required to be discharged, so that raw materials are saved.

Owner:GUANGXI NANNING HUAGUO ENVIRONMENT SCI & TECH

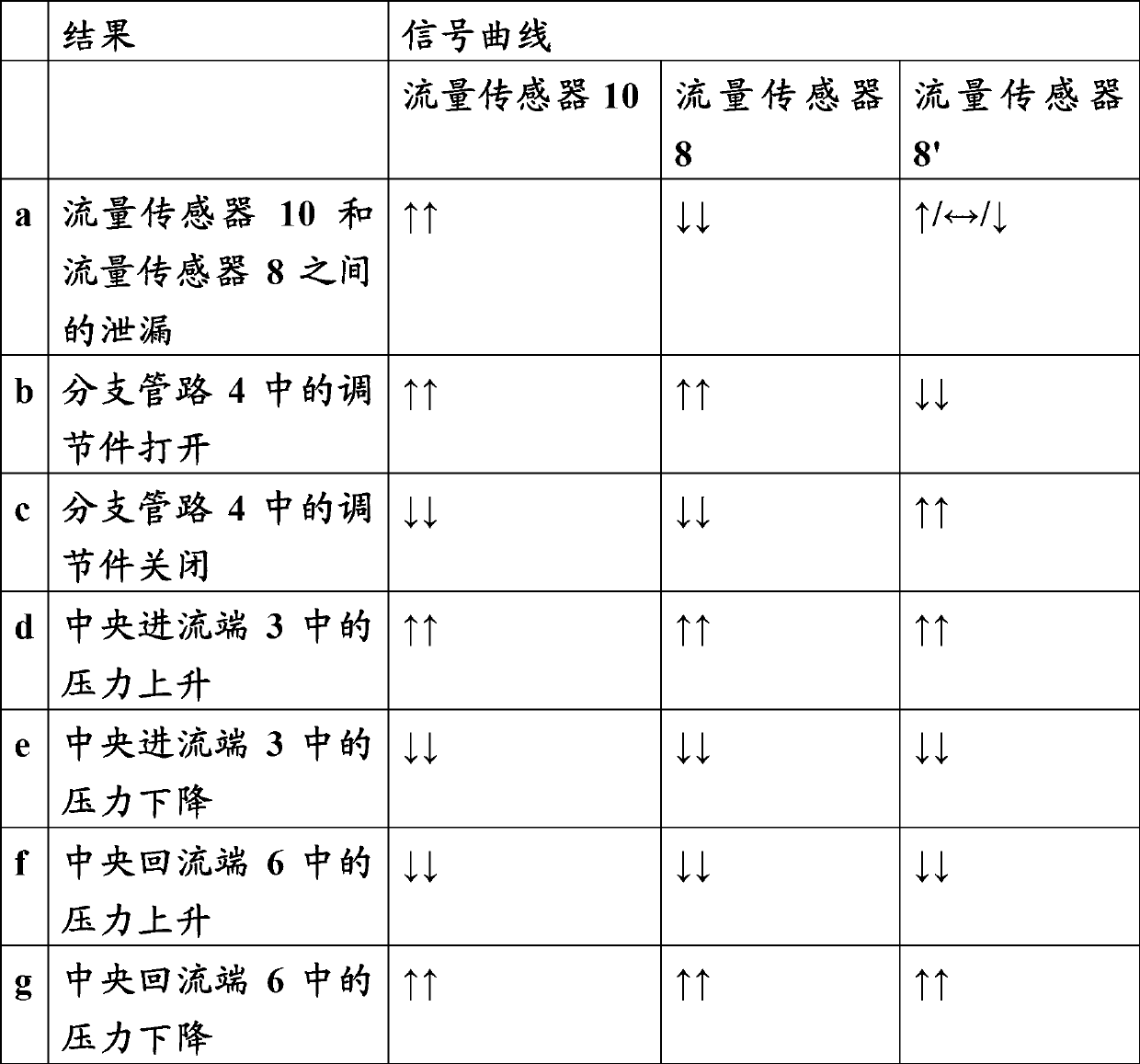

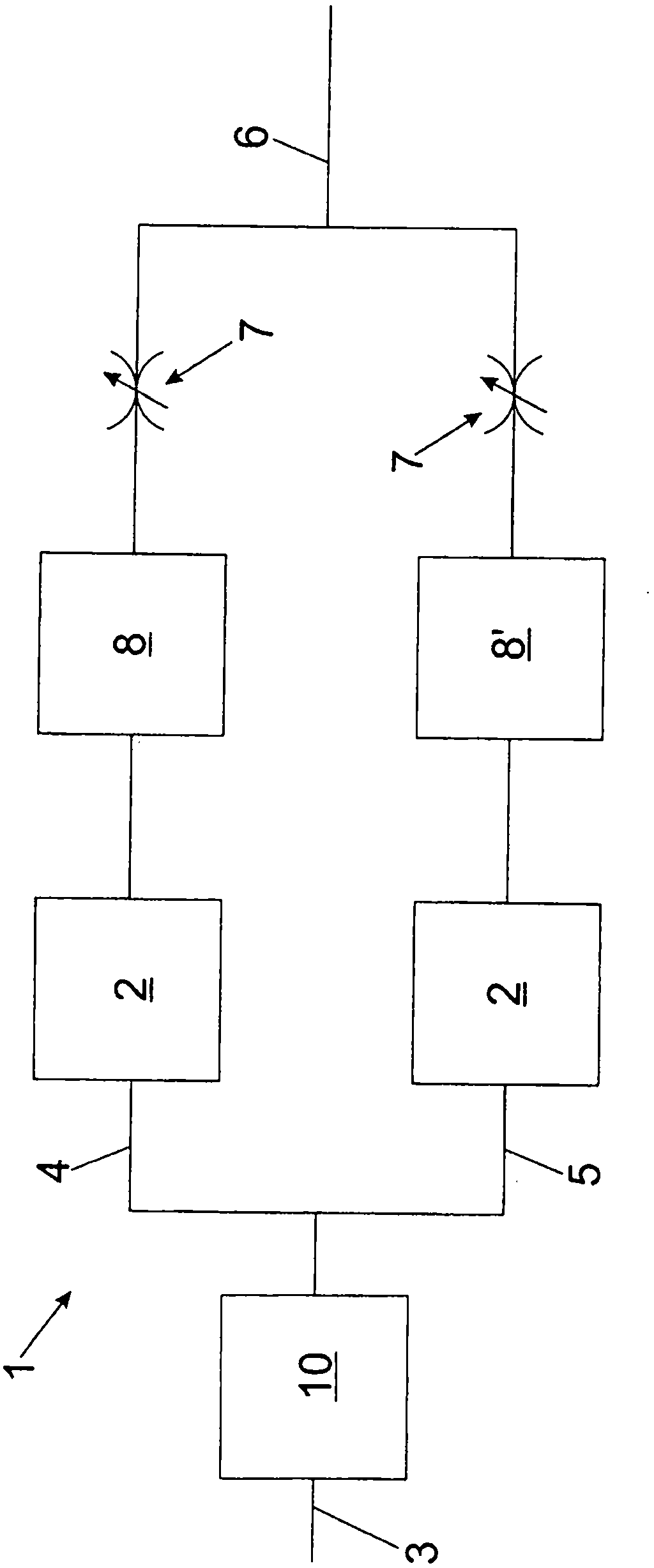

Method used for monitoring temperature control device of dies of injection molding machine or die-casting machine

ActiveCN103185656AOmit costSmall space requirementMeasurement of fluid loss/gain rateMonitoring temperatureEngineering

The invention relates to a method used for monitoring a temperature control device of dies of an injection molding machine or a die-casting machine. The temperature control device (1) comprises an inflow end (3) and a backflow end (6), and at least two branch pipelines (4,5) which are connected in parallel with the inflow end and the backflow end on a flowing technology. Each of the at least two branch pipelines (4,5) is provided with a flow sensor (8,8'). Through comparing measuring data provided by the flow sensor (8,8'), pressure surge in the inflow end (3) and the backflow end (6) are separated from existence of leakage.

Owner:ENGEL AUSTRIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com