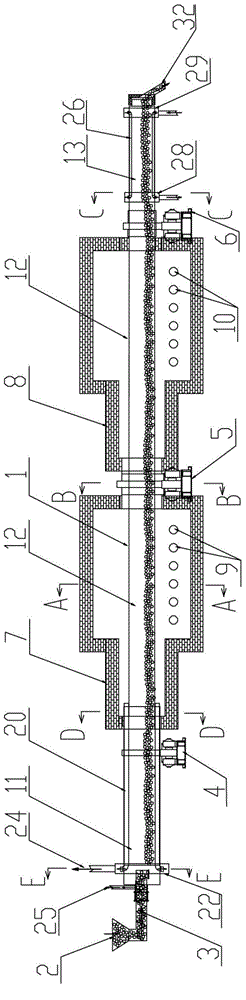

Method for reducing and separating granular iron rapidly at low temperature

A fast, granular iron technology, applied in the field of metallurgy, can solve the problems of high energy consumption and high reduction temperature, and achieve the effects of continuous and stable temperature in the high temperature zone, energy saving, and reduction of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

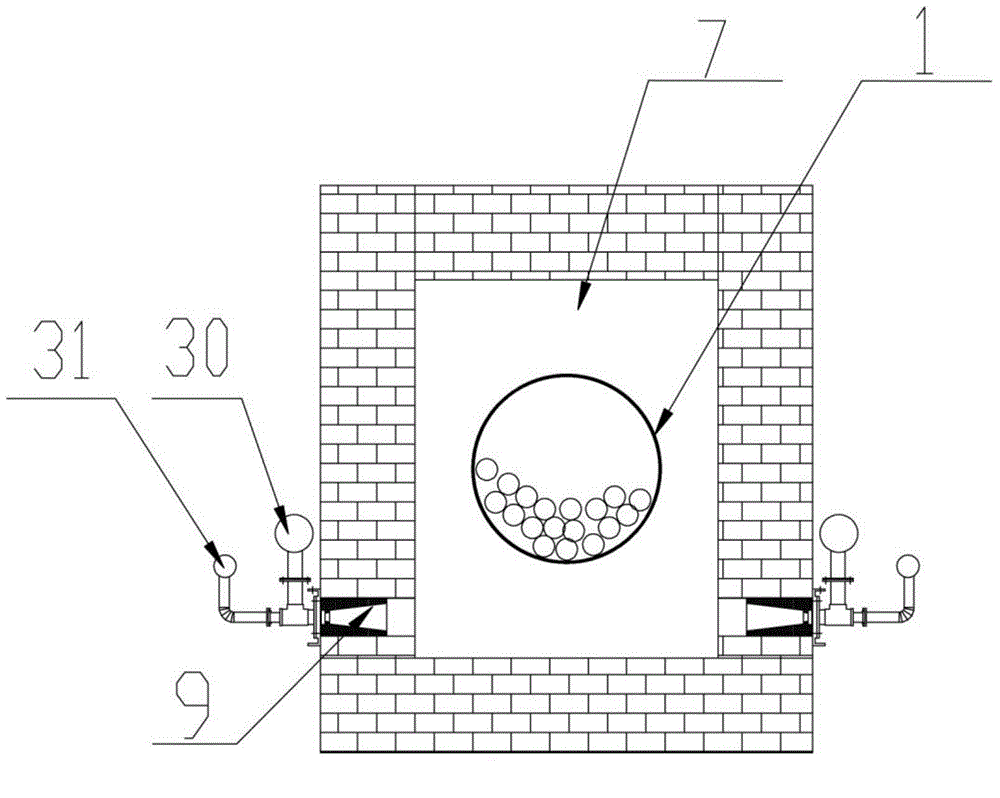

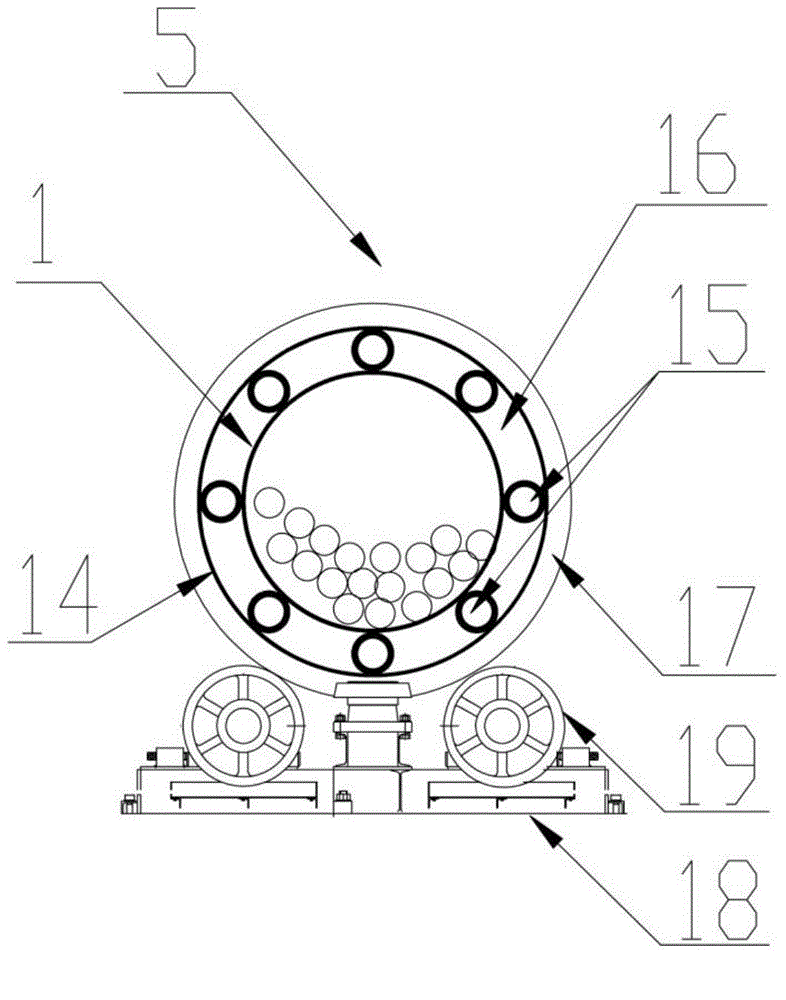

Method used

Image

Examples

Embodiment 1

[0060] A method for rapid reduction and separation of granular iron at low temperature, the steps are as follows:

[0061] (1) Use Sichuan TFe: 43.38% oolitic hematite, crush the ore, dry it, and grind it into -160 mesh 80% ore powder, add metal iron powder, lime powder, ordinary glass to the ore powder Powder and fluorite powder, the amount of each component is calculated by weight fraction: 84% mineral powder, 3% metal iron powder, 4% lime powder, 5% ordinary glass powder and 4% fluorite powder; the above components are uniformly mixed, sprayed Water forms pellets of ¢8~¢16mm;

[0062] (2) Dry the wet pellets in step (1) at 105°C for 2 hours, so that the moisture content is ≤0.5%, and the pellet strength is 118N / ball;

[0063] (3) Add anthracite coal powder (particle size 0~20mm, fixed carbon 65.45%) and lime powder (CaO≥93%, MgO≤5%, S≤0.05%) to the pellet obtained in step (2), the described anthracite coal powder The consumption of lime powder is 40% of pellet weight, and...

Embodiment 2

[0071] A method for rapid reduction and separation of granular iron at low temperature, the steps are as follows:

[0072] (1) Adopt Hunan TFe: 45.56% oolitic hematite, crush and dry the ore, and grind it into -160 mesh 80% ore powder, add metal iron powder, lime powder, ordinary glass to the ore powder Powder and fluorite powder, the amount of each component is calculated by weight fraction: mineral powder 84%, metal iron powder 3%, lime powder 4%, ordinary glass powder 3% and fluorite powder 6%; the above components are uniformly mixed, sprayed Press water to make pellets of 20×22×18mm;

[0073] (2) Dry the wet pellets in step (1) at 105°C for 2 hours, so that the moisture content is ≤0.5%, and the pellet strength is 229N / ball;

[0074] (3) Add anthracite coal powder (particle size 0~20mm, fixed carbon 65.45%) and lime powder (CaO≥93%, MgO≤5%, S≤0.5%) to the pellet obtained in step (2), described anthracite coal powder The consumption of lime powder is 35% of pellet weight...

Embodiment 3

[0082] A method for rapid reduction and separation of granular iron at low temperature, the steps are as follows:

[0083] (1) Use Liaoning Chaoyang TFe: 19.18%, Mn: 21.88% low-poor manganese iron ore. After the ore is crushed and dried, it is ground into -160 mesh accounting for 80% ore powder, and metal iron powder is added to the ore powder , lime powder, ordinary glass powder and fluorite powder, the amount of each component is calculated by weight fraction: 85% of mineral powder, 4% of metal iron powder, 3% of lime powder, 3% of ordinary glass powder and 5% of fluorite powder; After mixing evenly, spray water to form pellets of ¢8~¢16mm;

[0084] (2) Dry the wet pellets in step (1) at 105°C for 2 hours, so that the moisture content is ≤0.5%, and the pellet strength is 126N / ball;

[0085] (3) Add anthracite coal powder (particle size 0~20mm, fixed carbon 55.68%) and limestone powder (CaO≥53%, MgO≤5%, S≤0.05%) to the pellet obtained in step (2), the described anthracite co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com