Multi-bed layer shaft radial synthesizing tower

A shaft-radial, synthesis tower technology is applied in the field of radial gas-solid phase reactors and multi-bed shafts, which can solve the problems of unreasonable structure of gas-solidification chemical reactors, large reaction gas flow resistance, and low utilization rate of heat energy. , to achieve the effect of significant energy saving effect, low cycle power consumption and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

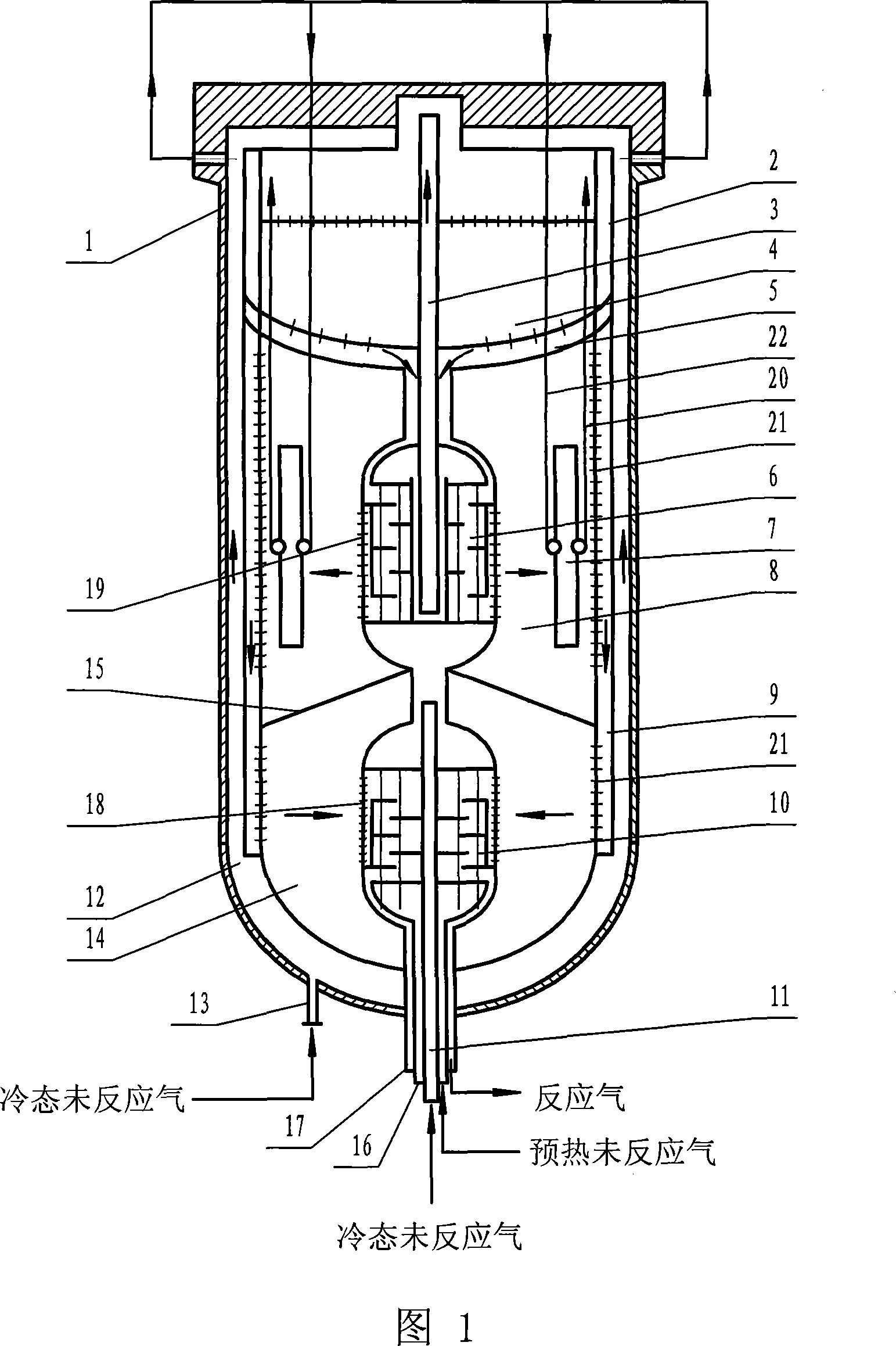

[0032]As shown in Figure 1, the multi-bed shaft radial synthesis tower of the present invention has an outer cylinder 1 and an inner cylinder 2, an annular gap 12 is arranged between the outer cylinder 1 and the inner cylinder 2, and the bottom of the outer cylinder 1 is provided with a The annulus 12 is connected to the cold unreacted gas inlet, and the inner cavity of the inner cylinder is divided into three layers from top to bottom. The first layer 4 and the second layer 8 are separated by the gas collector 5, and the second layer 8 and the second layer The three layers 14 are separated by partitions 15, the third layer 14 is provided with a lower heat exchanger 10 and the bottom of the outer cylinder 1 has a preheated unreacted gas inlet 16 communicated with the cold side of the lower heat exchanger 10, The bottom of the outer cylinder 1 has a reaction gas outlet 17 communicating with the hot side of the lower heat exchanger 10, and the cylinder wall of the lower heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com