Combined method for extracting iron and dephosphorizing by reducing, smelting and dressing low-grade high-phosphorus hard-dressing iron (manganese) ore

A technology of iron manganese ore and high phosphorus, applied in the field of metallurgy, can solve the problems of difficult dephosphorization, high operation cost, high production and operation cost, and achieve the effects of continuous and stable temperature, shortened reaction time, and large added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

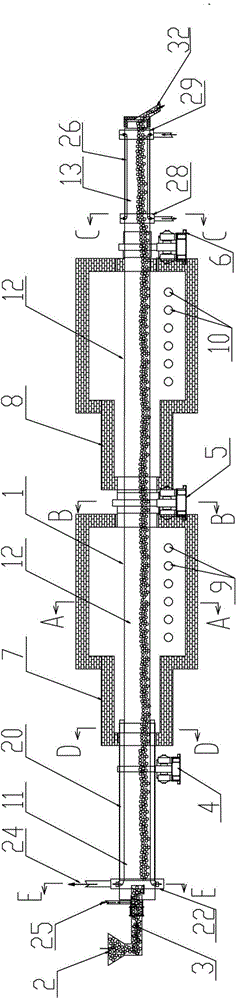

[0075] A method for combining reduction smelting and separation of low-lean and high-phosphorus refractory iron ore with iron extraction and dephosphorization, the steps are as follows:

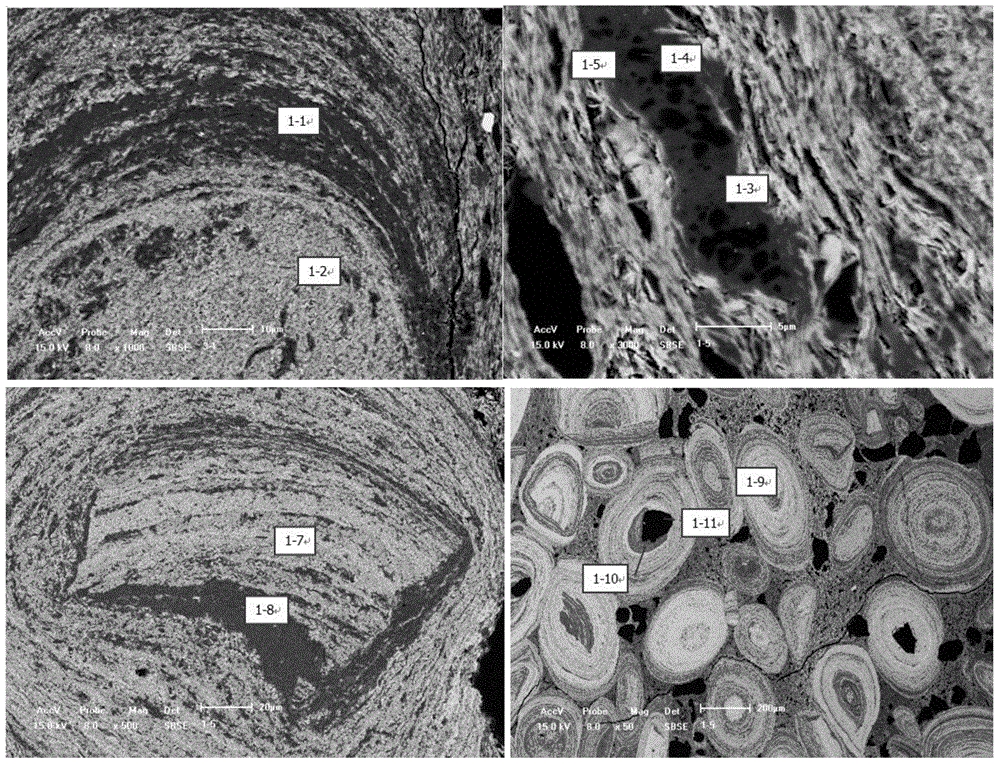

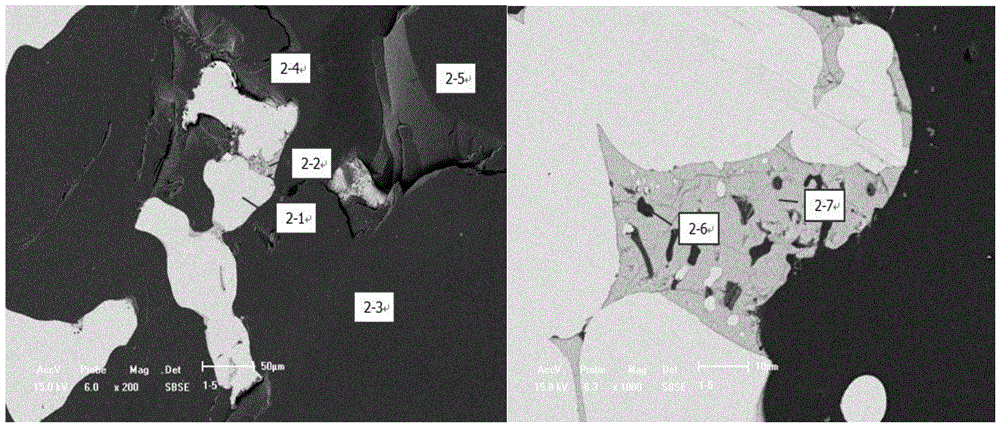

[0076] (1) Extracting iron and reducing phosphorus from raw ore

[0077] Select the oolitic hematite from Jiangyou, Sichuan (its main index is shown in Table 3), and the processing and grinding into 200 meshes account for 80% ore powder, and adopt 1200mT magnetic field strength wet magnetic separation to carry out mineral processing to obtain rich ore powder (the index is shown in Table 4);

[0078] table 3

[0079] name TFe% S% P% Oolitic hematite raw ore 36.77 0.11 0.36

[0080] Table 4

[0081] name TFe% S% P% Rich mineral powder 45.25 0.085 0.116

[0082] (2) Add internal carbon anthracite and additives to the rich ore powder obtained in step (1), after mixing evenly, spray water to form pellets of ¢8~¢16mm, and dry the wet pellets a...

Embodiment 2

[0091] A method for combining reduction smelting and separation of low-lean and high-phosphorus refractory iron ore with iron extraction and dephosphorization, the steps are as follows:

[0092] (1) Extracting iron and reducing phosphorus from raw ore

[0093] Select TFe: 25.64%, P: 2.38% low-iron and high-phosphorus refractory Hunan oolitic hematite, crush it into fine particles with a particle size ≤ 20mm, and carry out magnetization roasting at 800°C for 1.5h. After cooling, process and grind Fineness is 200 ~ 400 mesh ore powder, using 250mT magnetic field strength wet magnetic separation, to obtain TFe: 55.12%, P: 0.19%, iron recovery rate of 72.18% rich ore powder;

[0094] (2) Add internal carbon anthracite and additives to the rich ore powder obtained in step (1), after mixing evenly, spray water to form pellets of ¢8~¢16mm, and dry the wet pellets at 180°C for 2 hours; Wherein the mixed material is by weight percentage: rich ore powder 82.5%, internal carbon anthraci...

Embodiment 3

[0101] A method for reducing, smelting, and combining iron extraction and dephosphorization of low-poor, high-phosphorus refractory manganese ore, the steps are as follows:

[0102] (1) Extracting iron and reducing phosphorus from raw ore

[0103] Beipiao manganese ore in Liaoning Province (see Table 8 for its indicators) was selected, crushed into fine particles with a particle size of ≤20mm, and magnetized and roasted at 750°C for 1.0h. After cooling, it was processed and ground into ore powder with a fineness of 200 mesh. Magnetic field intensity dry type magnetic separation, obtain rich ore powder (magnetic material of dry selection) and manganese-rich powder, its index is shown in Table 9;

[0104] Table 8

[0105]

[0106] Table 9

[0107]

[0108] (2) Add internal carbon anthracite and additives to the rich ore powder obtained in step (1), after mixing evenly, spray water to form pellets of ¢8~¢16mm, and dry the wet pellets at 180°C for 2 hours; Among them, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com