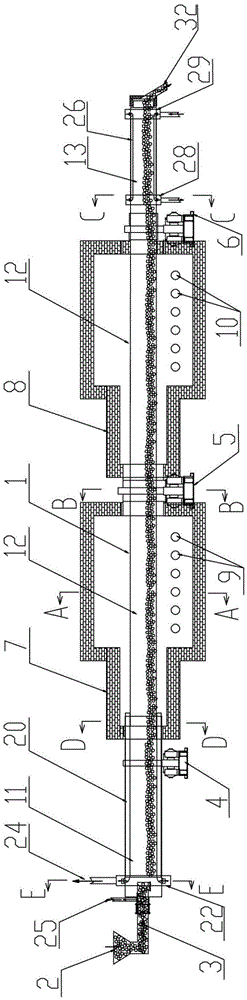

A coal-based method for rapid and deep reduction of high-density metallized pellets at low temperature

A metallized pellet and high-density technology, applied in the field of metallurgy, can solve problems such as long reduction time, energy consumption, and small reduced iron output, and achieve the effects of shortening reaction time, continuous and stable temperature, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

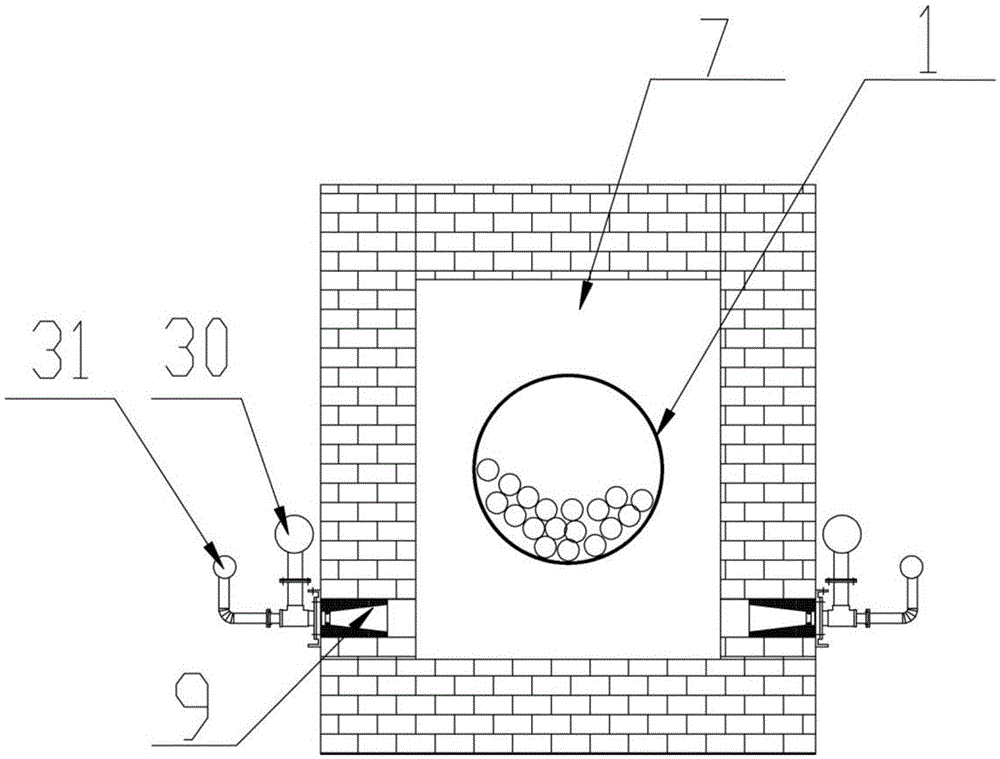

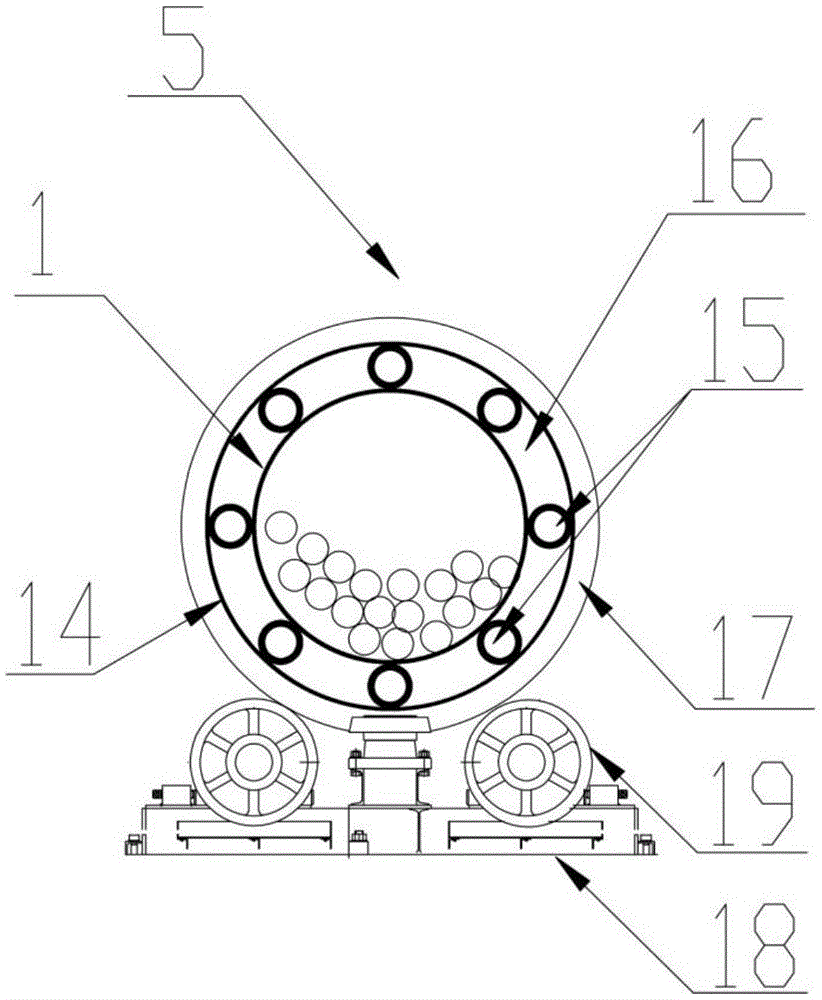

[0054] A coal-based low-temperature rapid deep reduction method for high-density metallized pellets, the steps are as follows:

[0055] (1) Dry the TFe: 69.28% iron scale (iron oxide scale) to be reduced, process it to 160-180 mesh, and mix it evenly with internal carbon powder and binder. The mixed material is by weight percentage: iron scale 91 %, bituminous coal powder (56.12% for fixed carbon, 9.8% for ash, 32.89% for volatile matter, 0.5% for S) 6.0%, 3.0% for dextrin powder; then spray water to form pellets of ¢8~¢16mm;

[0056] (2) Dry the wet pellets in step (1) at 105°C for 2 hours, and the measured pellet strength is 26N / ball;

[0057] (3) the pellet of step (2) and 0~15mm blue carbon powder (its index is shown in Table 1) are made into the material to be reduced, and the consumption of described blue carbon powder is the weight of iron scale described in the step (1). 30%; the reduced coal accounts for 100% in the reducing agent;

[0058] (4) Add the material to b...

Embodiment 2

[0066] A coal-based low-temperature rapid deep reduction method for high-density metallized pellets, the steps are as follows:

[0067] (1) Dry the TFe:68.45% iron ore powder to be reduced, process it to 160-180 mesh, and mix it evenly with internal carbon powder and binder. The mixed materials are: iron scale 91.2%, anthracite powder 7.0%, sodium humate 1.8%; then spray water to form pellets of ¢8~¢16mm;

[0068] (2) Dry the wet pellets in step (1) at 105°C for 2 hours, and the measured pellet strength is 28N / ball;

[0069] (3) the pellet of step (2) is made into the material to be reduced with 0~8mm anthracite coal powder (65% of fixed carbon), lime powder, and the consumption of described anthracite coal powder is the iron scale weight described in step (1) 40%; in the reducing agent, reduced coal accounts for 90%, and desulfurizer accounts for 10%;

[0070] (4) Add the materials to be reduced in step (3) into the preheating section of the muffled rotary kiln, and directl...

Embodiment 3

[0076] A coal-based low-temperature rapid deep reduction method for high-density metallized pellets, the steps are as follows:

[0077] (1) Dry the TFe:71.32% ultra-fine iron ore powder to be reduced, process it to 160-180 mesh, and mix it evenly with internal carbon powder and binder. The mixed material is: ultra-fine iron ore by weight percentage Powder 93%, charcoal powder 5.0%, dextrin powder 2.0%; then spray water to form pellets of ¢8~¢16mm;

[0078] (2) Dry the wet pellets in step (1) at 105°C for 2 hours, and the measured pellet strength is 28N / ball;

[0079] (3) the pellets of step (2) and 0~15mm blue carbon powder (its index is shown in Table 4) are made into the material to be reduced, and the consumption of described blue carbon powder is super fine iron ore described in step (1) 40% of powder weight; Reduced coal accounts for 100% in the reducing agent;

[0080] (4) Add the materials to be reduced in step (3) into the preheating section of the flame-trap type ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com