liquid heating device

A heating device and liquid technology, applied in the direction of fluid heaters, water heaters, heating element shapes, etc., can solve the problems of continuous change and adjustment of water temperature, complex casting aluminum production process, and intermittent water outlet, etc., to reduce power-on preheating The effect of waiting time, avoiding long-term use of leakage, and stabilizing the outlet water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

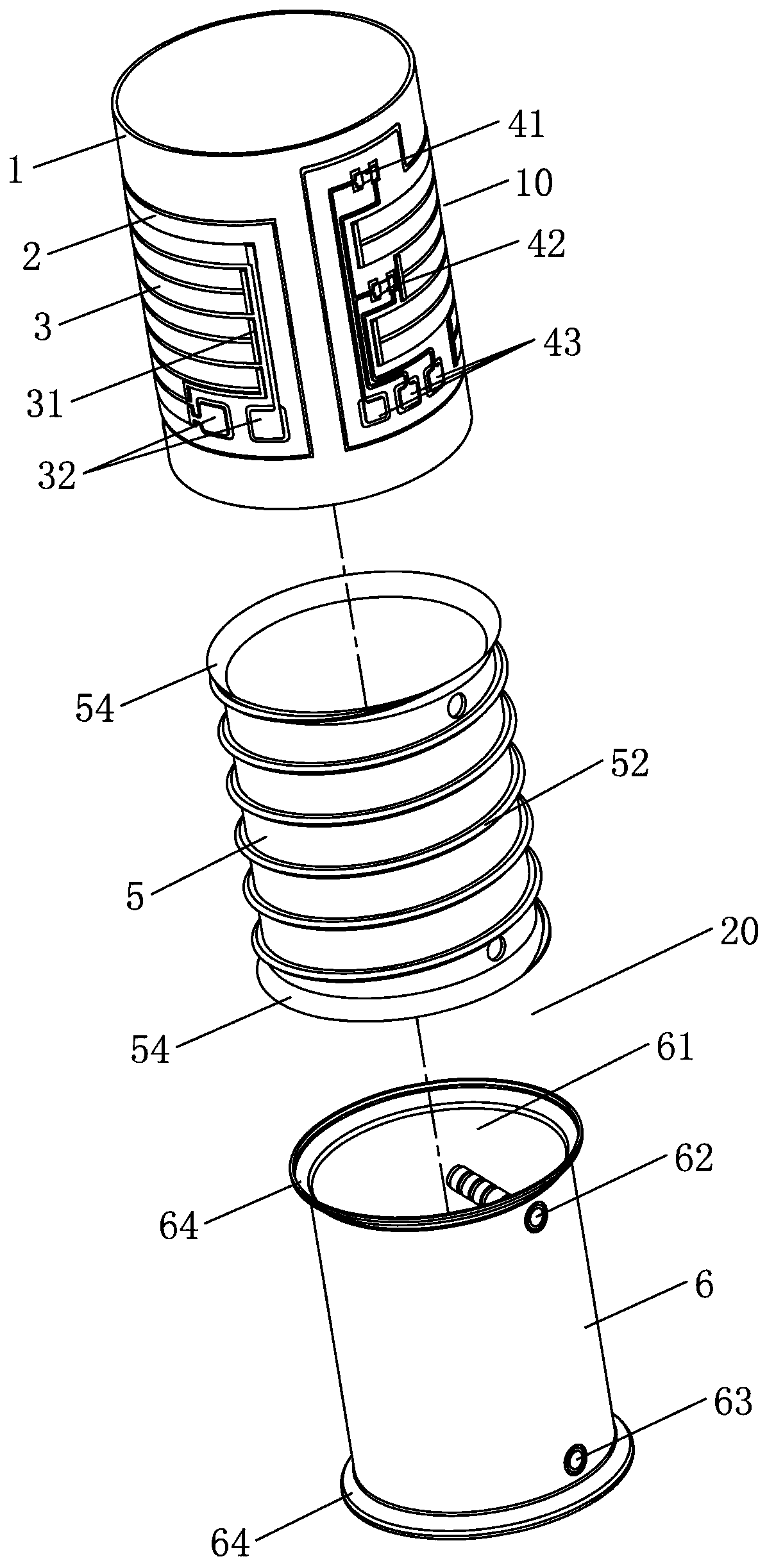

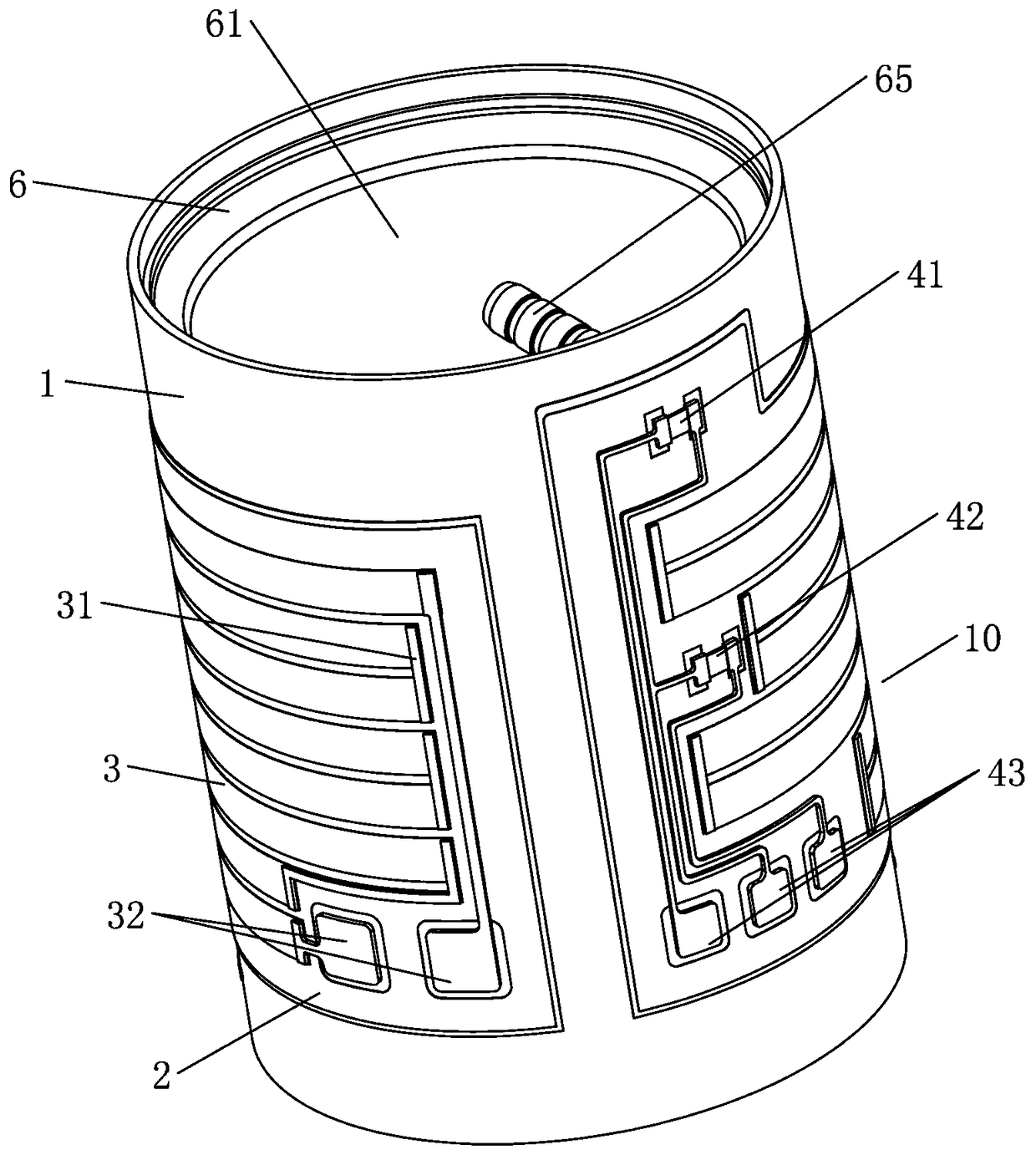

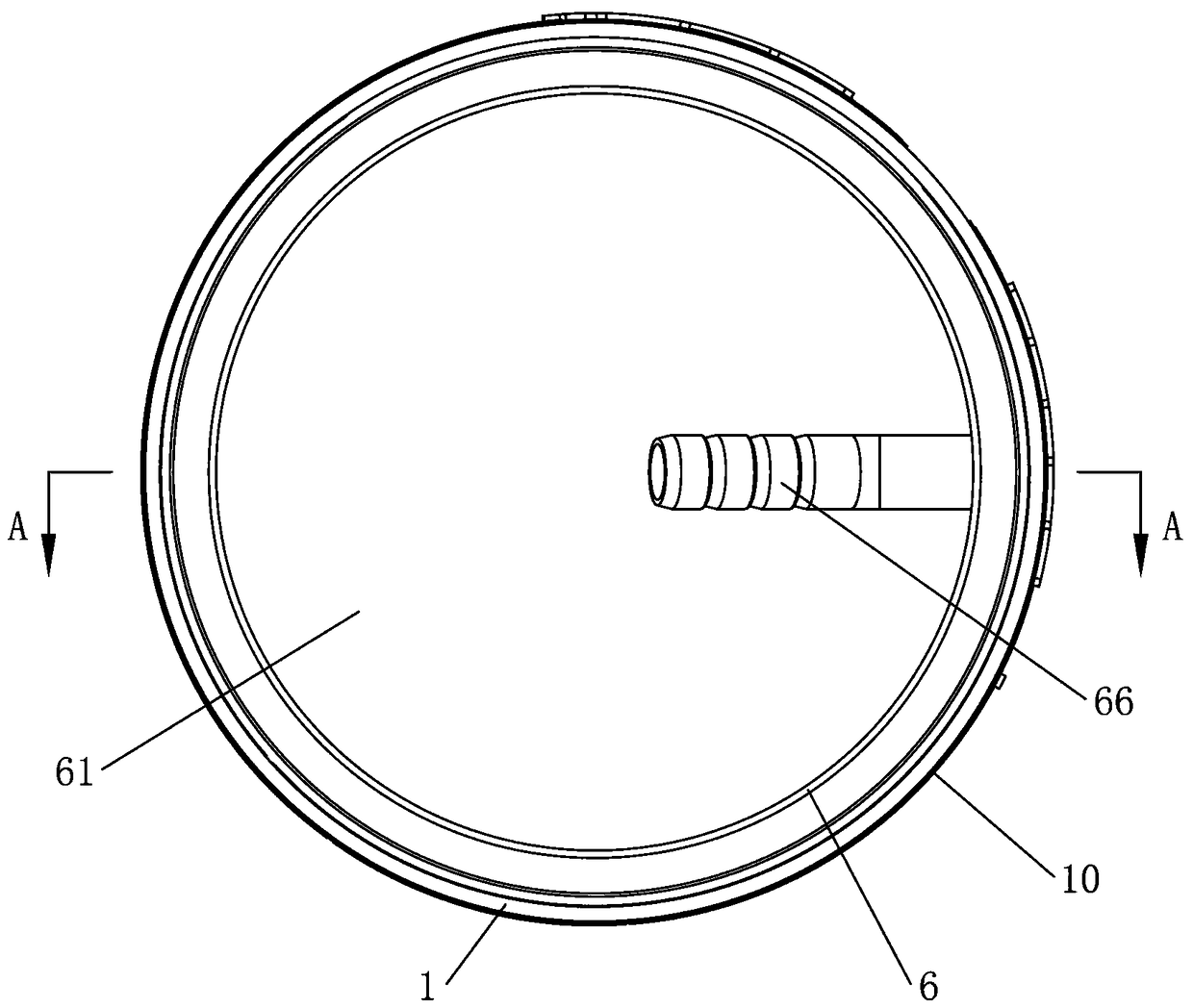

[0034] see Figure 1 to Figure 4As shown, a liquid heating device includes a main body 20 and a heating element 10 respectively in a cylindrical structure. The heating element 10 is set outside the surface of the main body 20. The heating element 10 is composed of an outer tube 1 and a heating element printed on the outer surface of the outer tube 1. Circuit structure, the main body 20 is composed of an inner tube 6 and a silicone sleeve 5, the two ends of the inner tube 6 are respectively sealed and matched with the two ends of the outer tube 1, an inner cavity is formed between the outer tube 1 and the inner tube 6, and the silicone sleeve 5 is set Outside the inner tube 6 and in the closed inner cavity, the outer surface of the silicone sleeve 5 is provided with convex ribs 52, and the ribs 52 are sealed and matched with the inner wall of the outer tube 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com