Patents

Literature

264results about "Sensing heat from liquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for additive manufacturing and repair of metal components

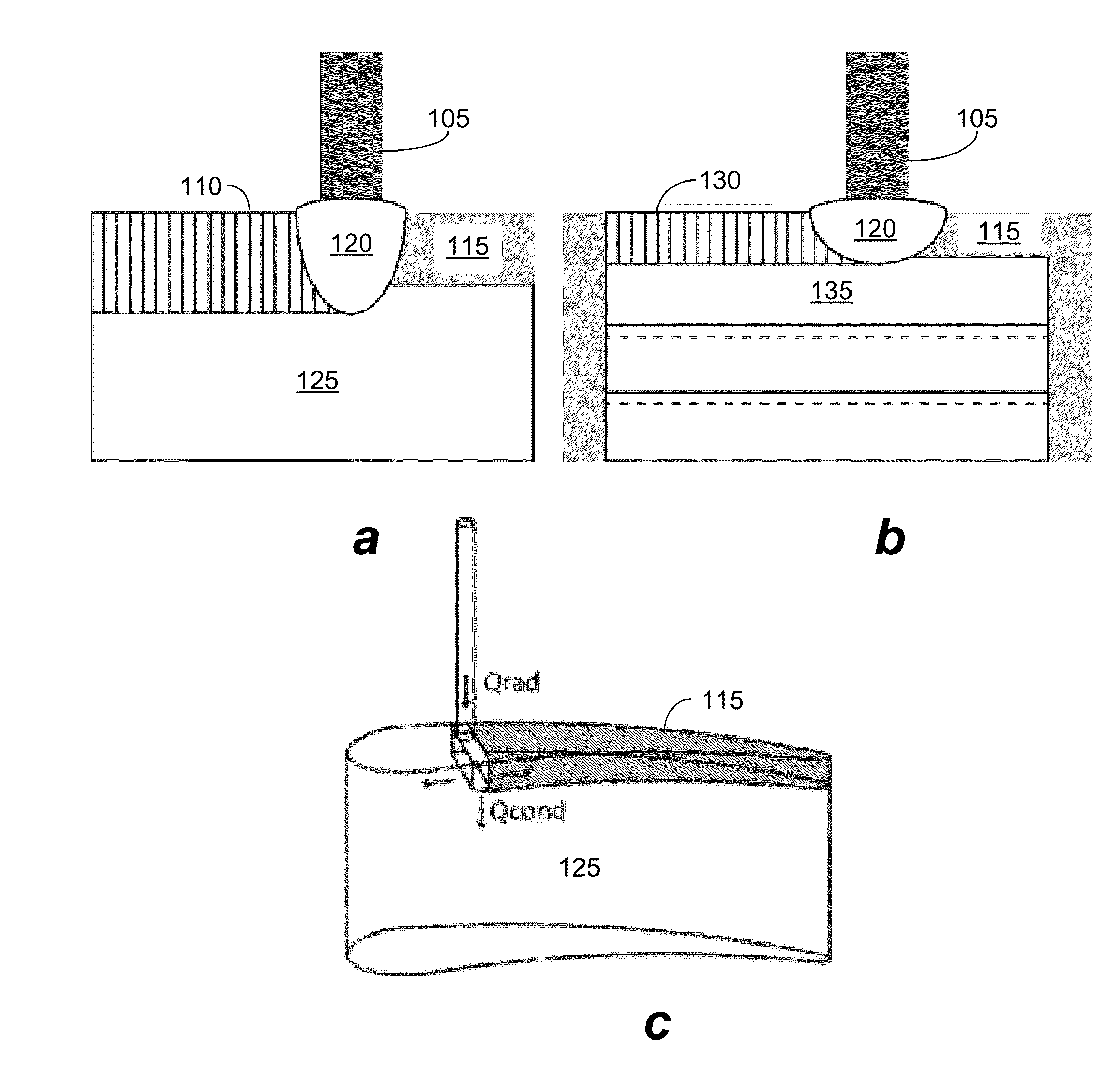

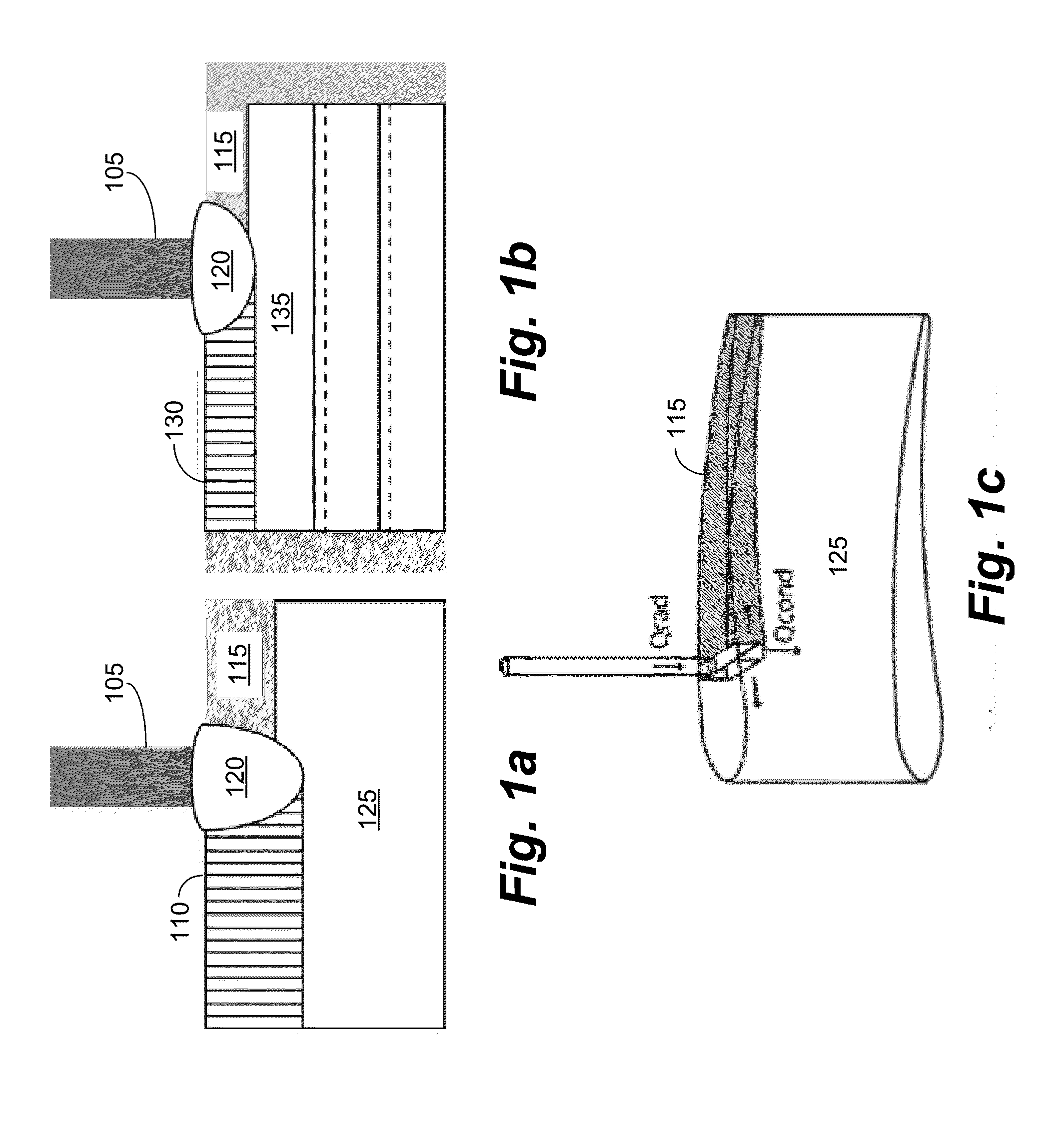

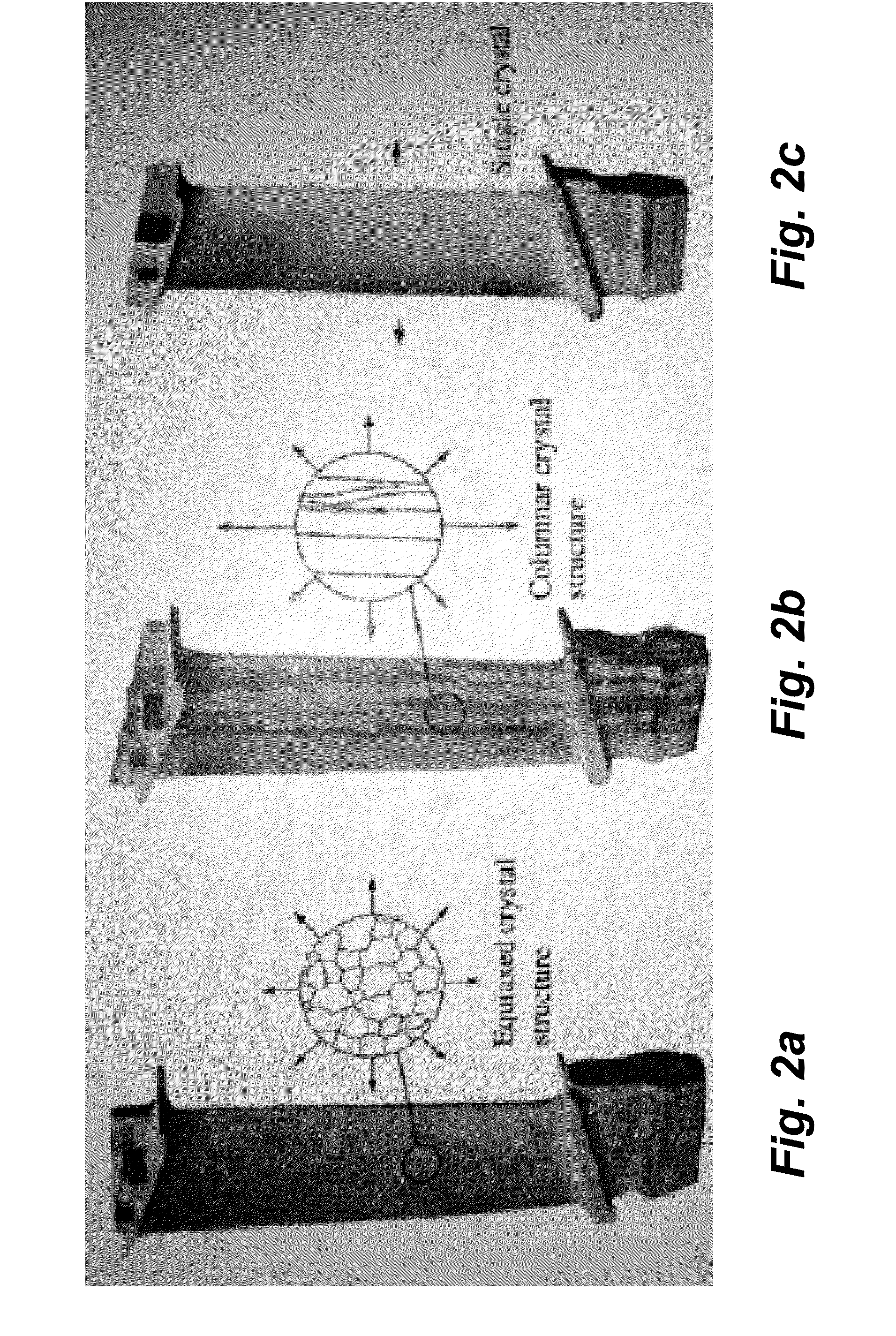

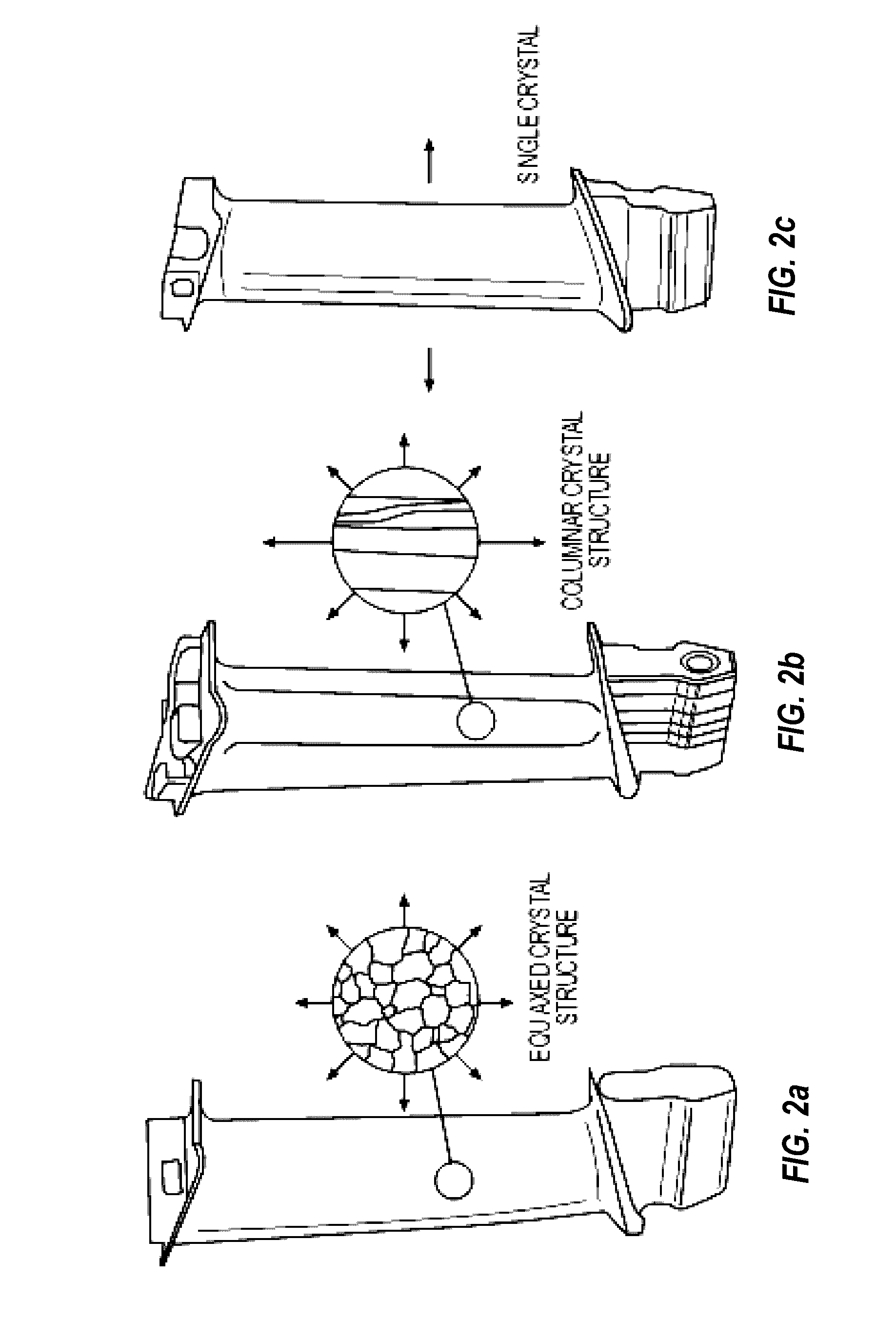

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

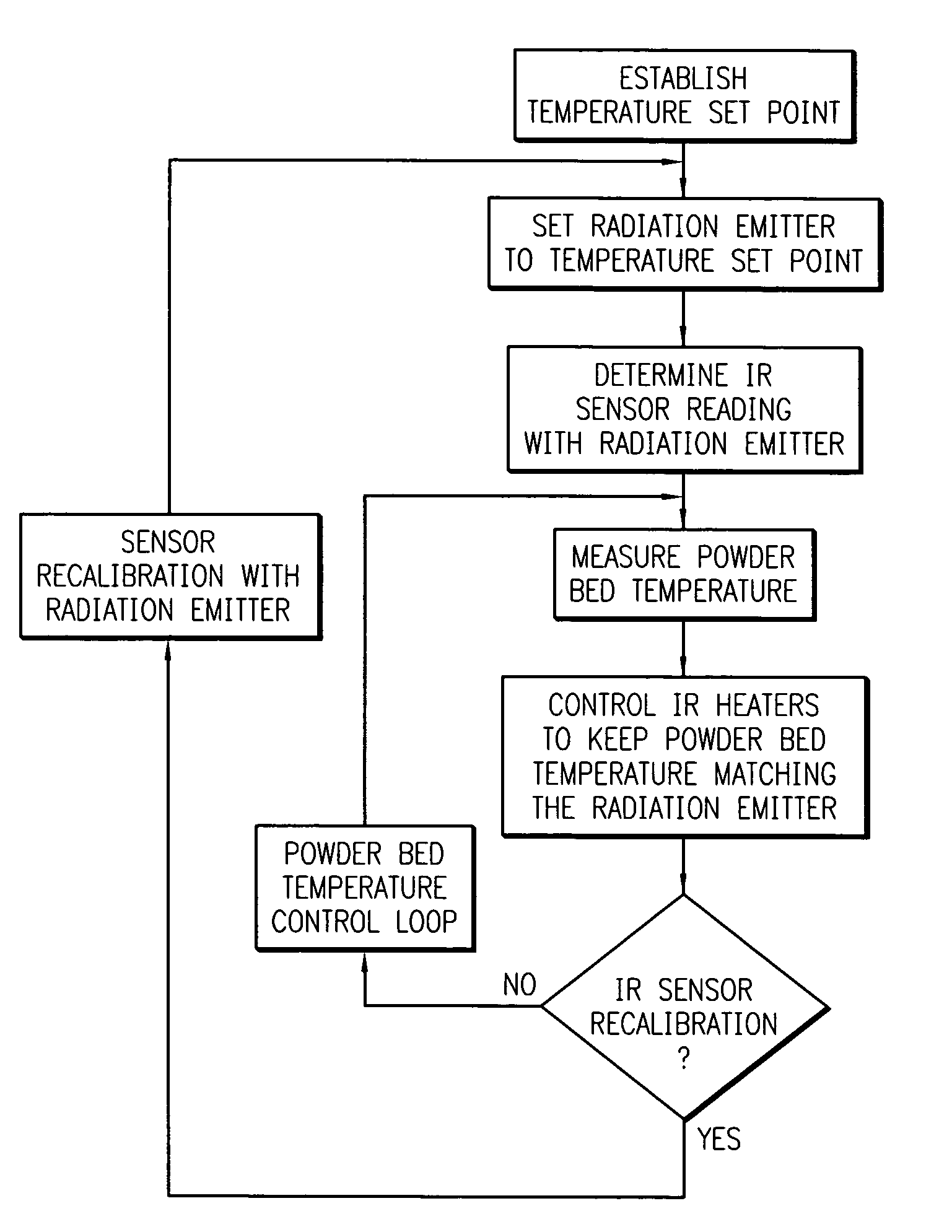

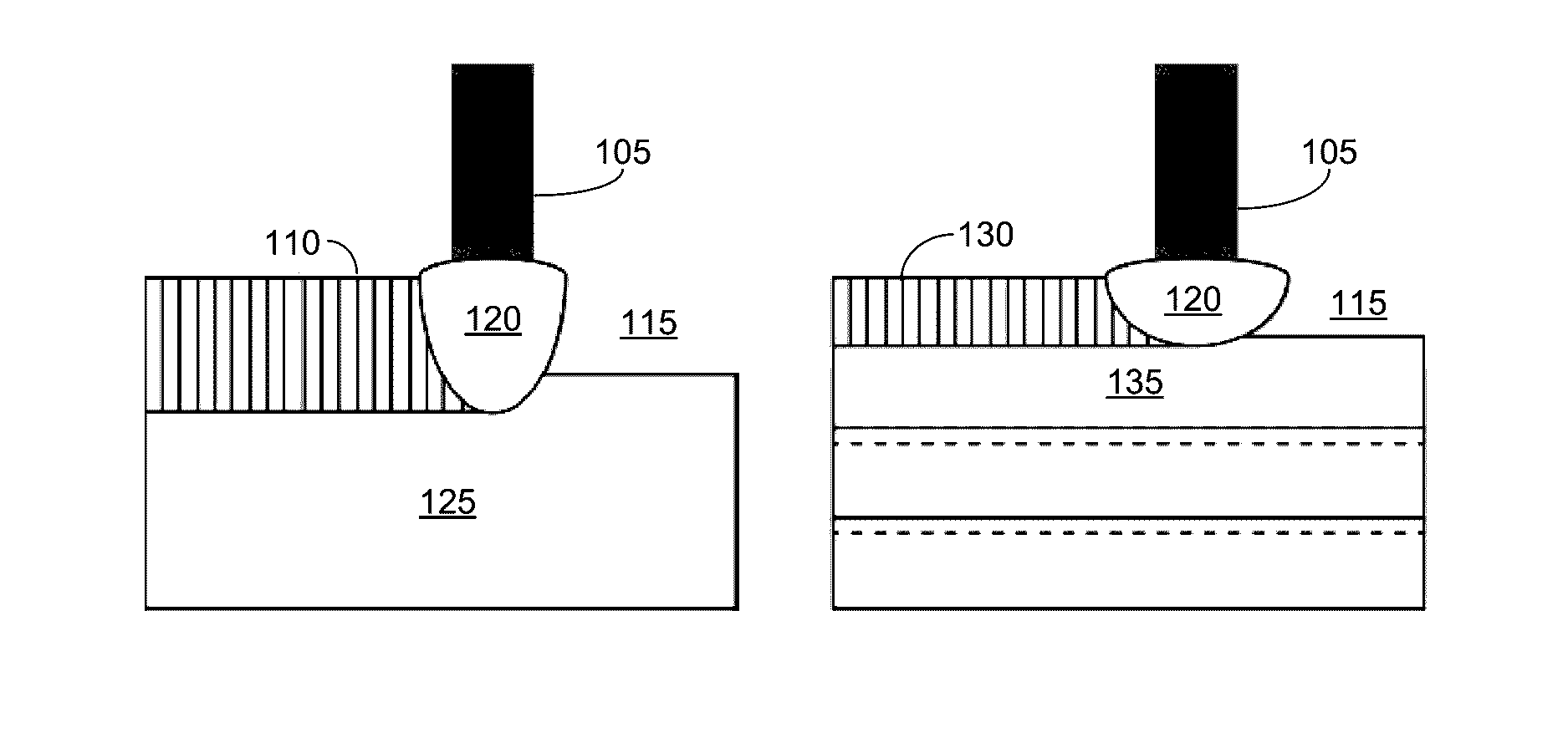

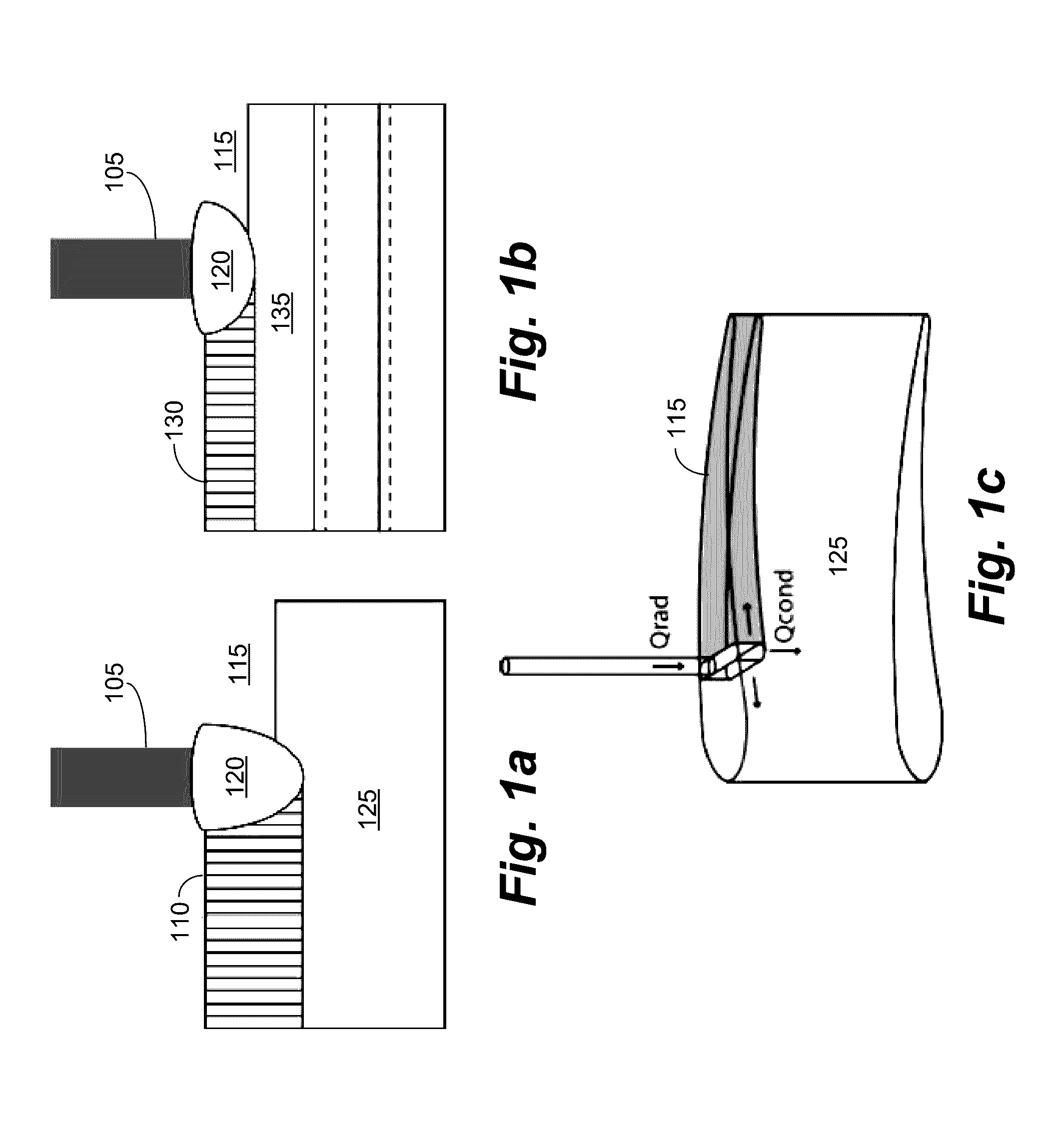

Continuous calibration of a non-contact thermal sensor for laser sintering

ActiveUS6930278B1Accurate monitoringHighly consistent mechanical propertyAdditive manufacturing apparatusIncreasing energy efficiencyAcousticsLaser

An apparatus and a method of using the apparatus wherein a radiation emitter is positioned adjacent a sensor apparatus within a process chamber in a laser sinter system that emits radiation to the sensor apparatus and a calibration apparatus receives readings from the sensor apparatus to compare temperature sensings received from the sensor apparatus with set emission signals from the radiation emitter to adjust the temperature sensings to calibrate the sensor apparatus during the forming of a three-dimensional article. The calibration is done repeatedly during the build process of the three-dimensional article.

Owner:3D SYST INC

Systems and methods for additive manufacturing and repair of metal components

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

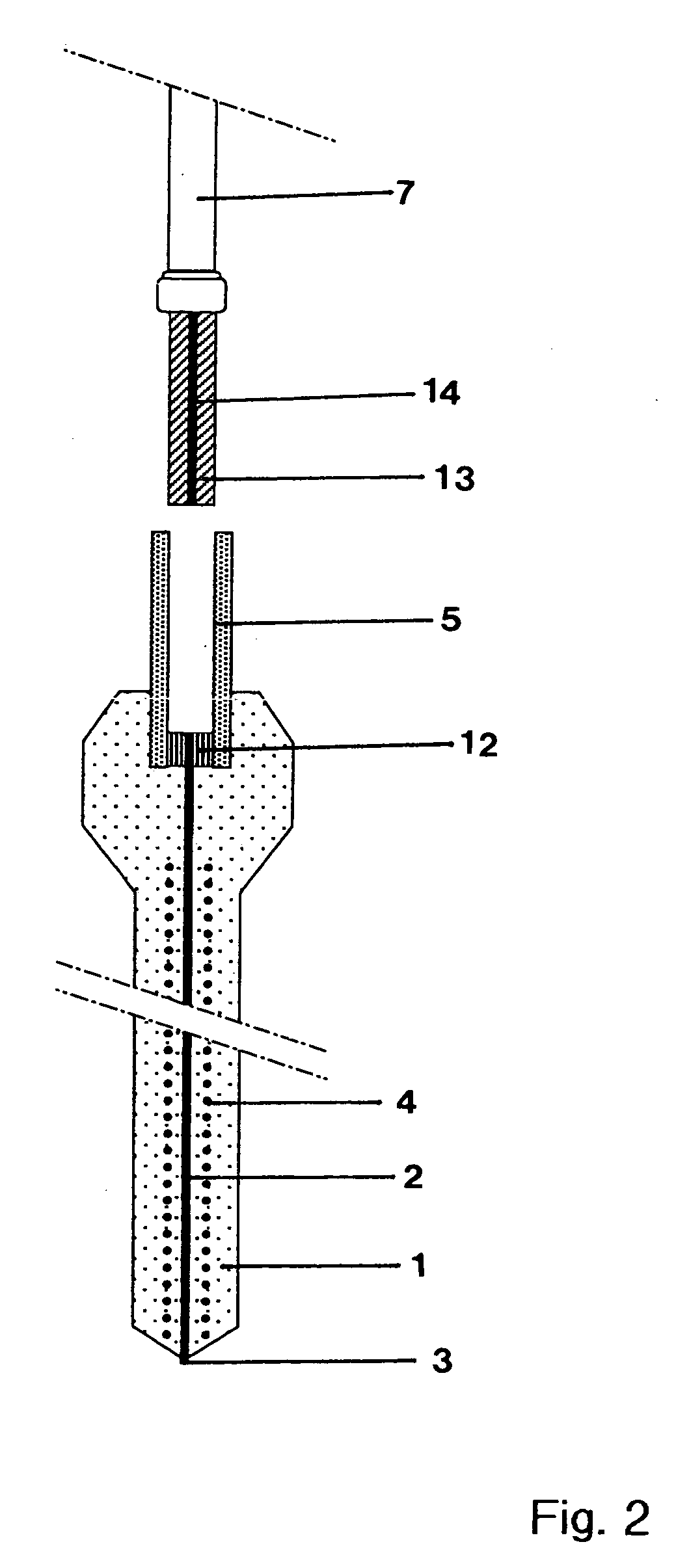

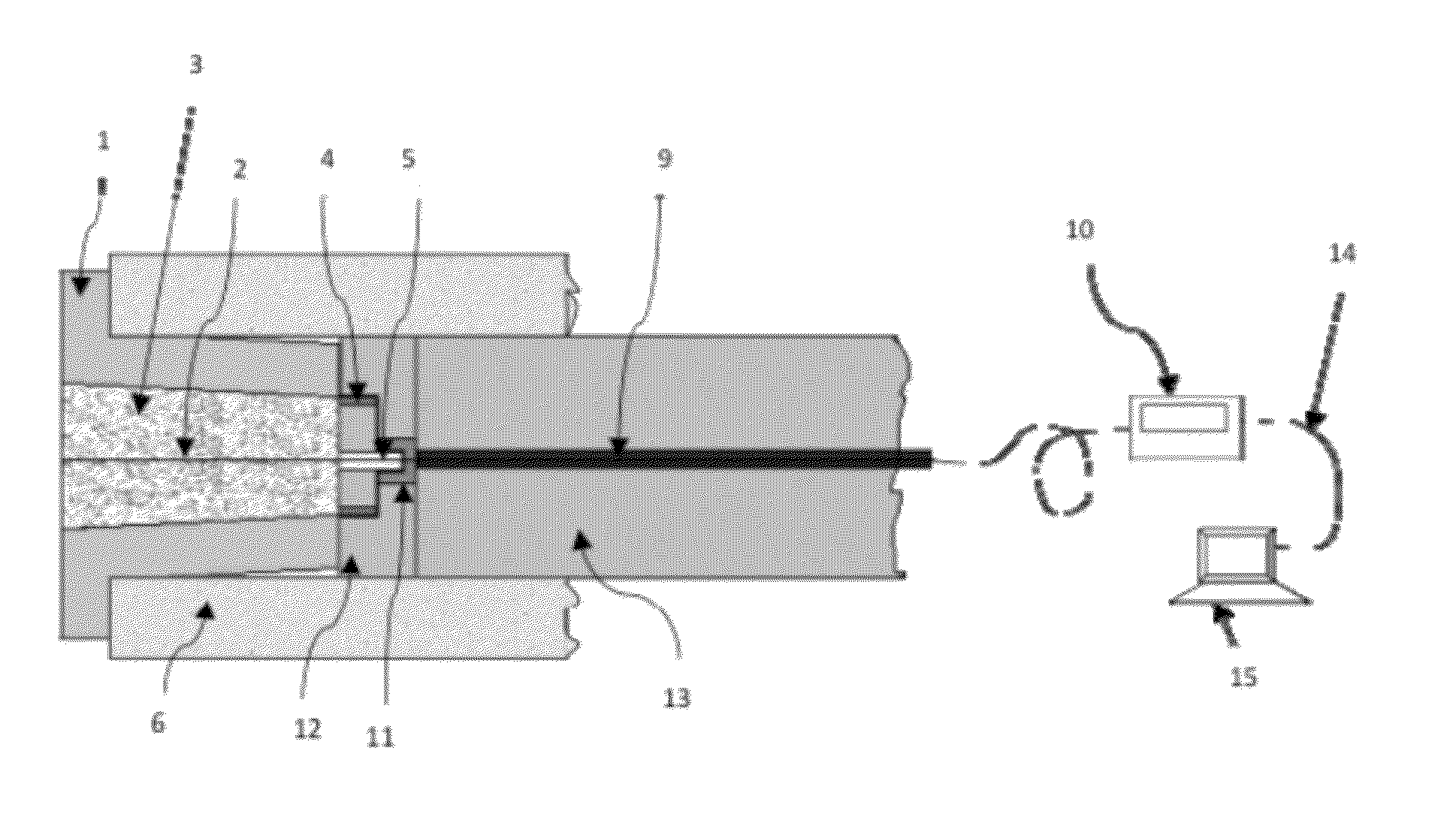

System and methods for real-time enhancement of build parameters of a component

ActiveUS20160114431A1Limited amountAccelerate buildingProgramme controlAdditive manufacturing apparatusControl signalElectric signal

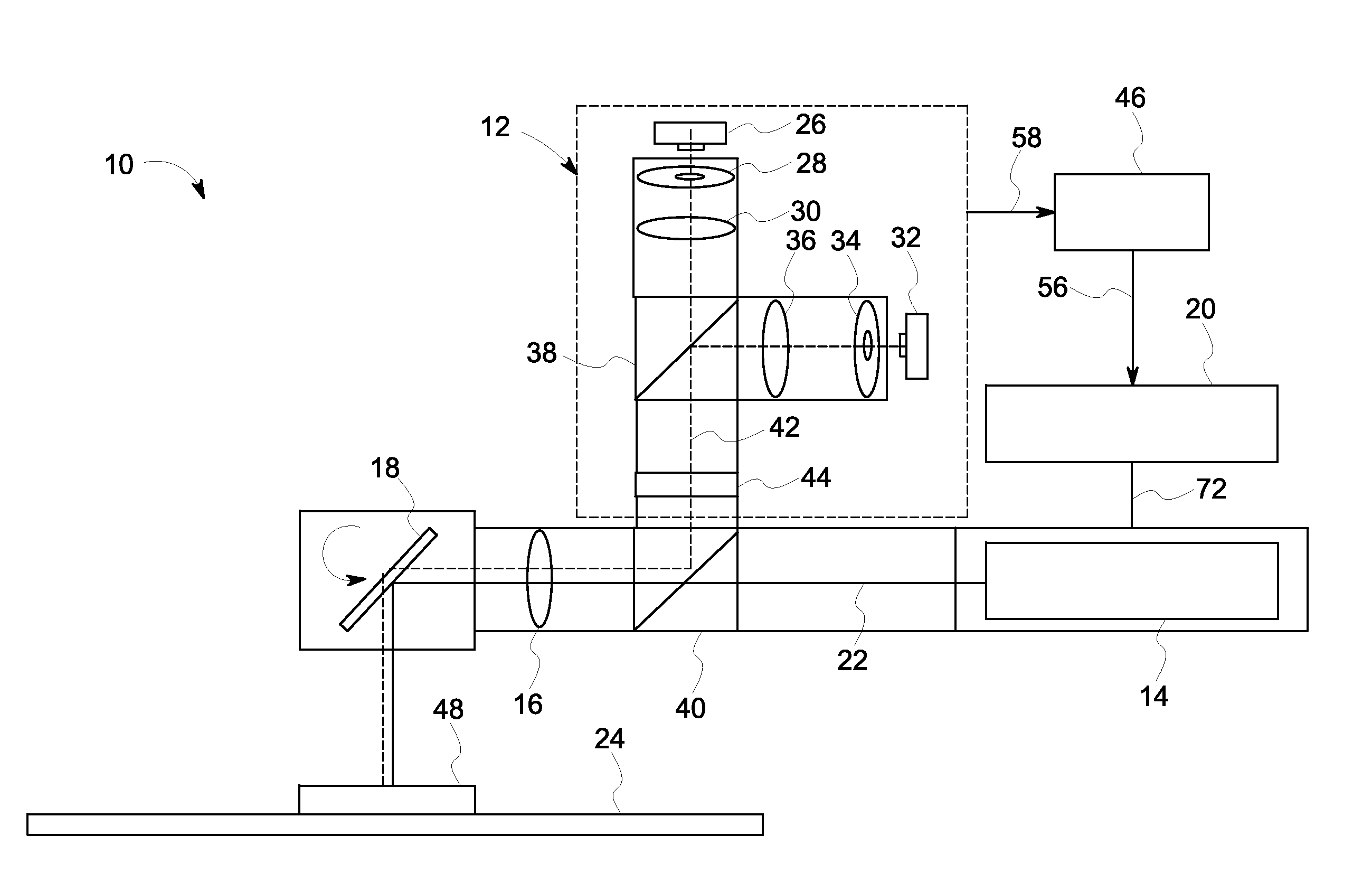

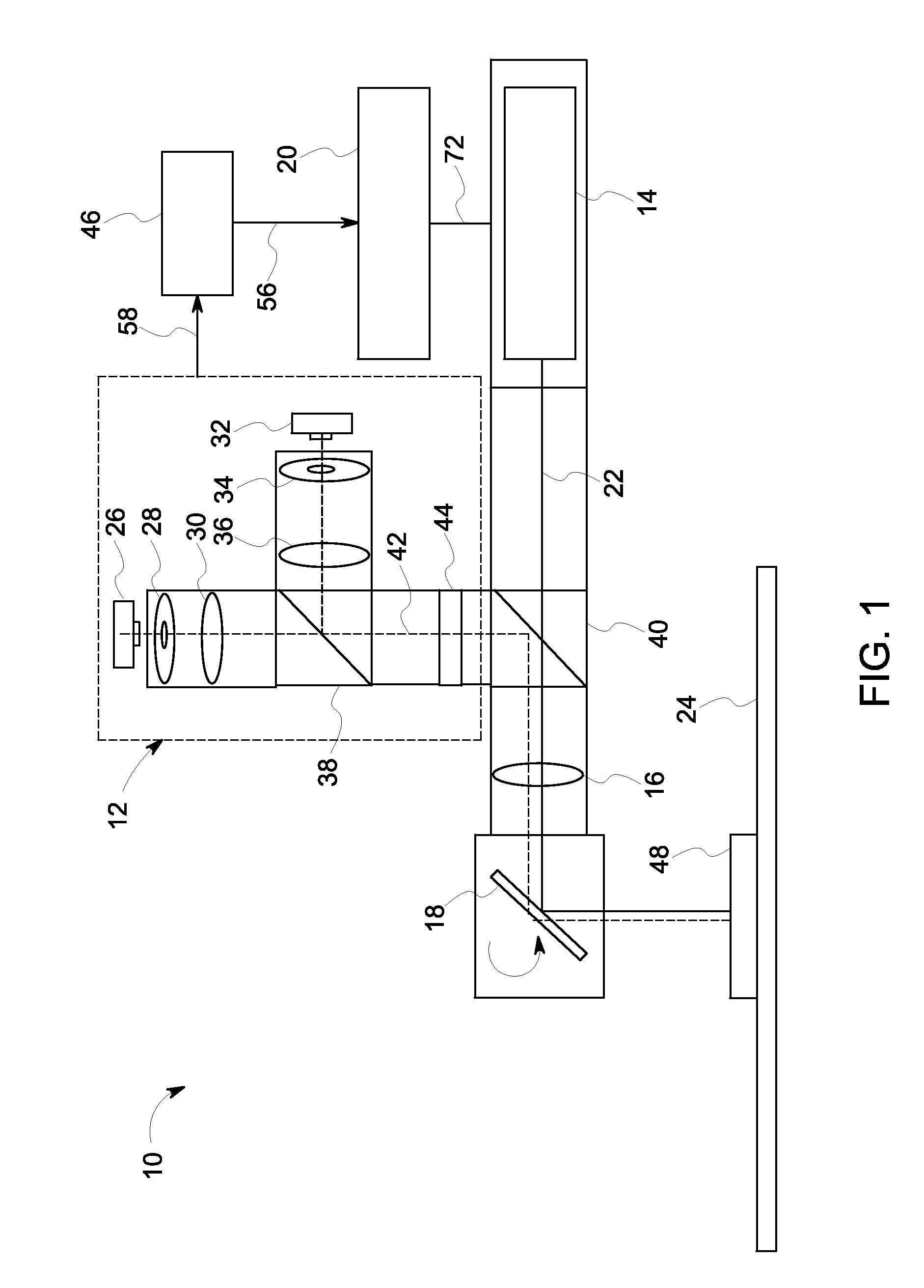

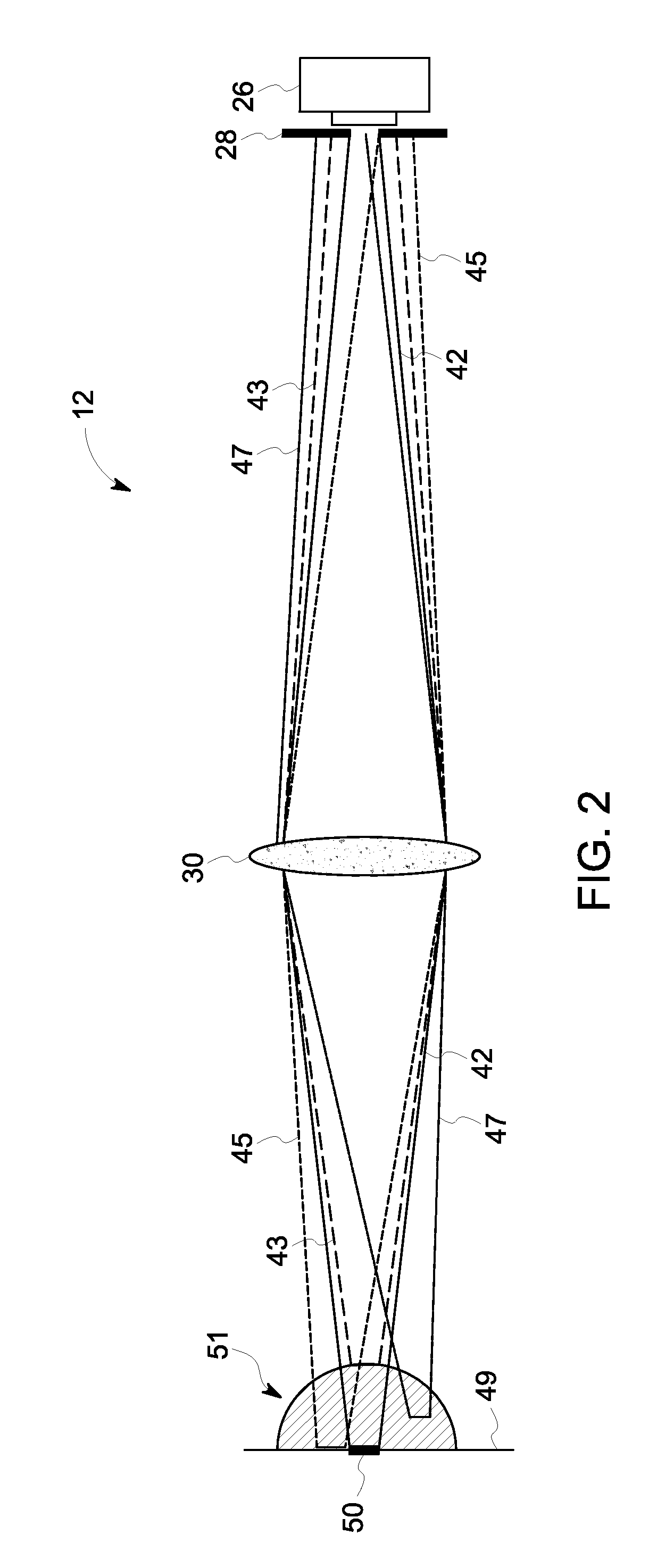

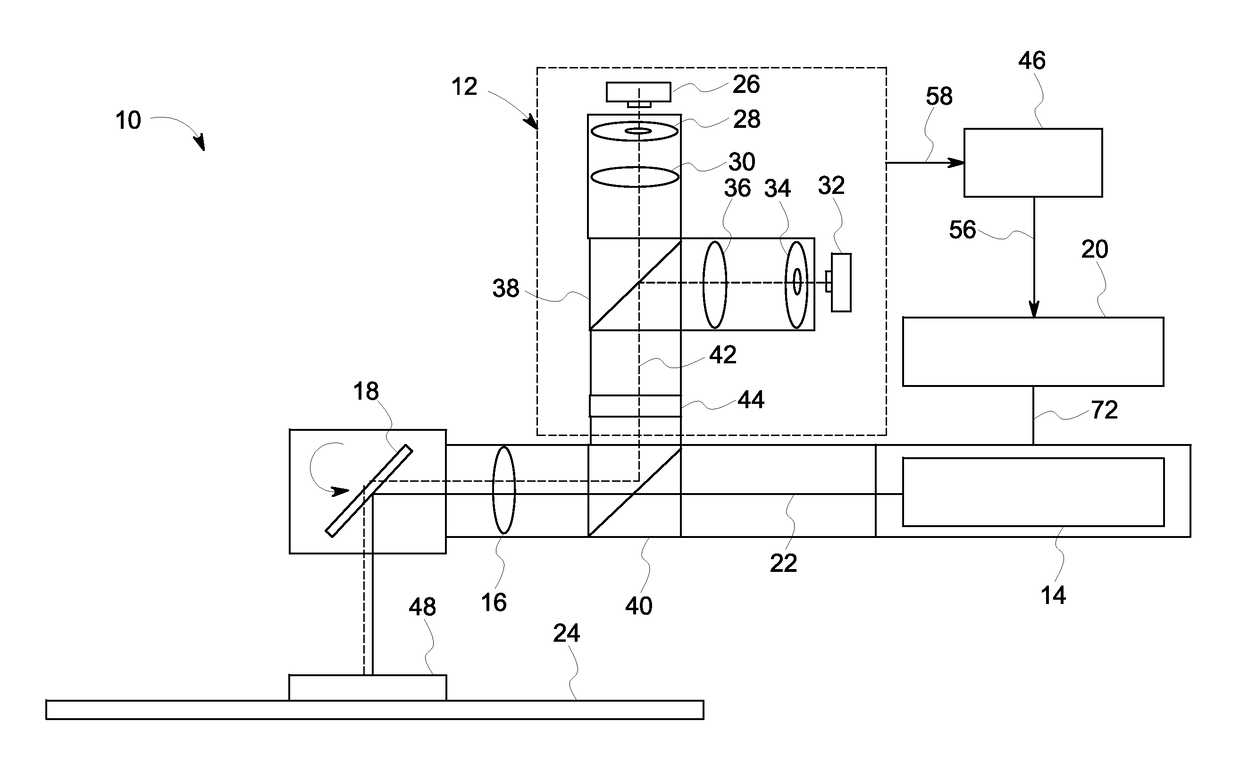

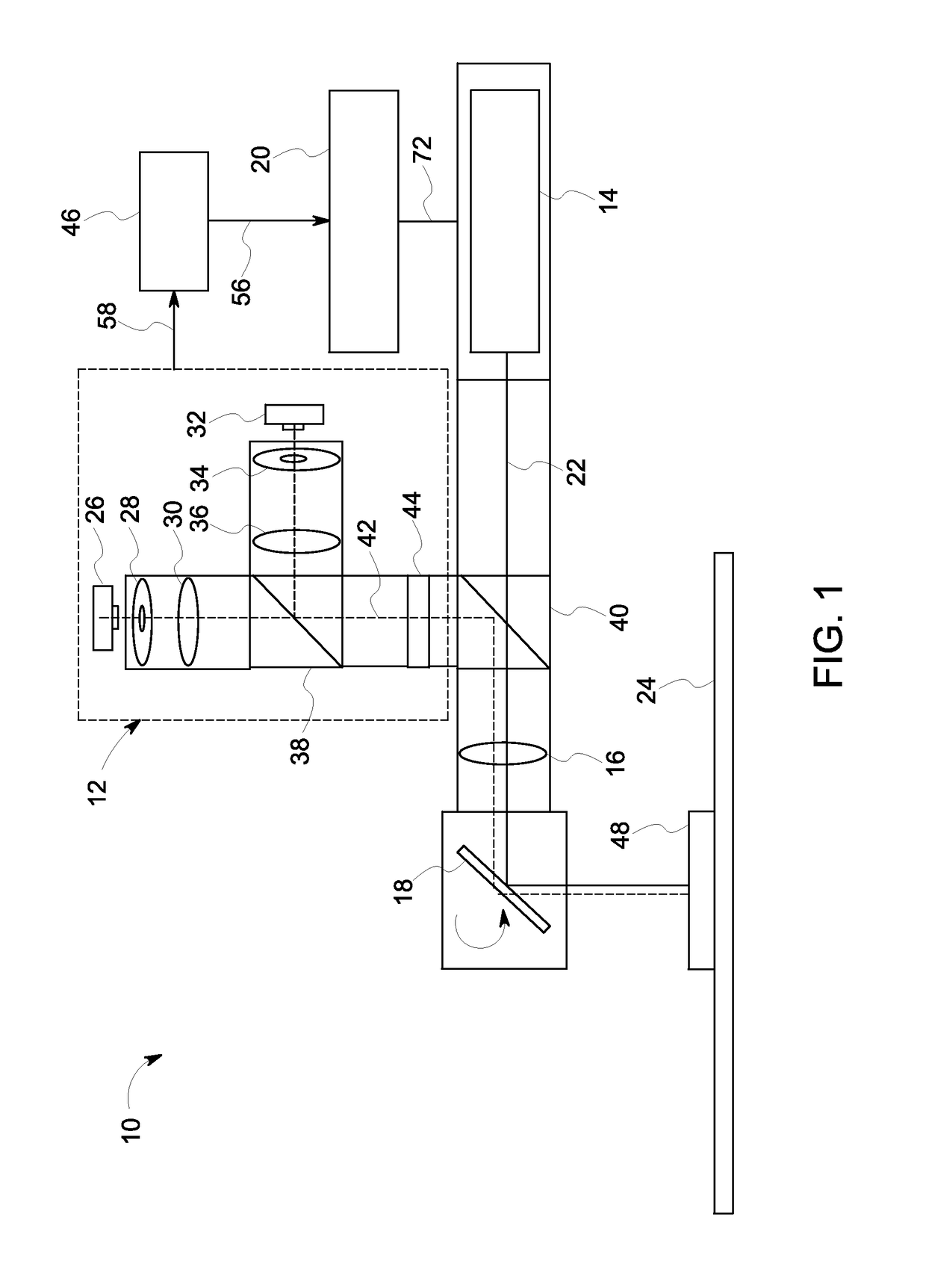

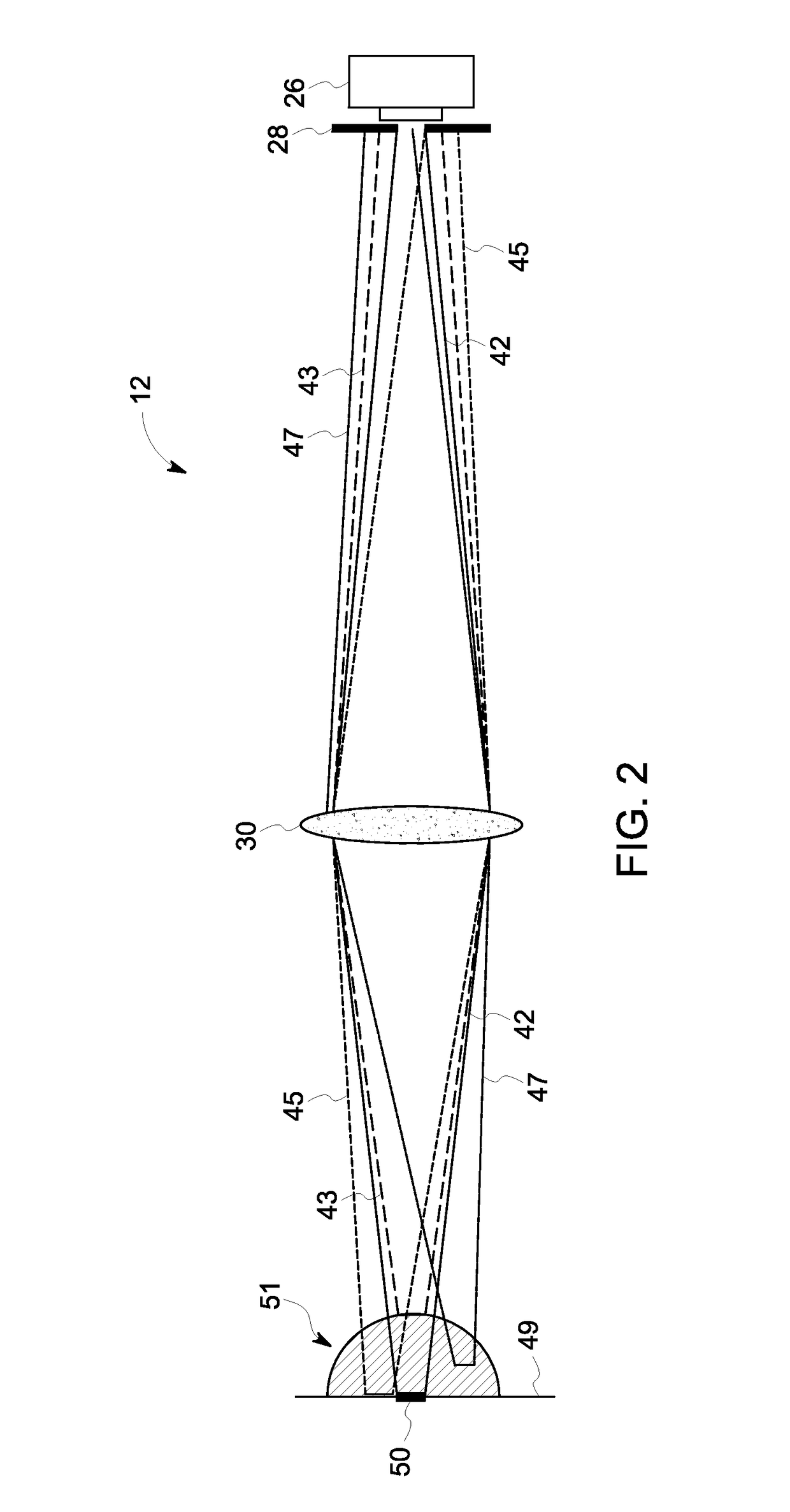

A direct metal laser melting (DMLM) system includes a laser device configured to generate a melt pool in a powder bed based on a build parameter. In addition, the DMLM system includes a confocal optical system directed at the melt pool and configured to receive an optical signal emitted by the melt pool. The DMLM system further includes an optical sensor operatively coupled to the confocal optical system that is configured to receive the optical signal and to generate an electrical signal in response to the optical signal. A computing device is configured to receive the electrical signal from the optical sensor and to generate a control signal in response. The control signal is configured to modify the build parameter of the direct metal laser melting system in real-time to adjust at least one of a melt pool size and a melt pool temperature to achieve a desired physical property of the component.

Owner:GENERAL ELECTRIC CO

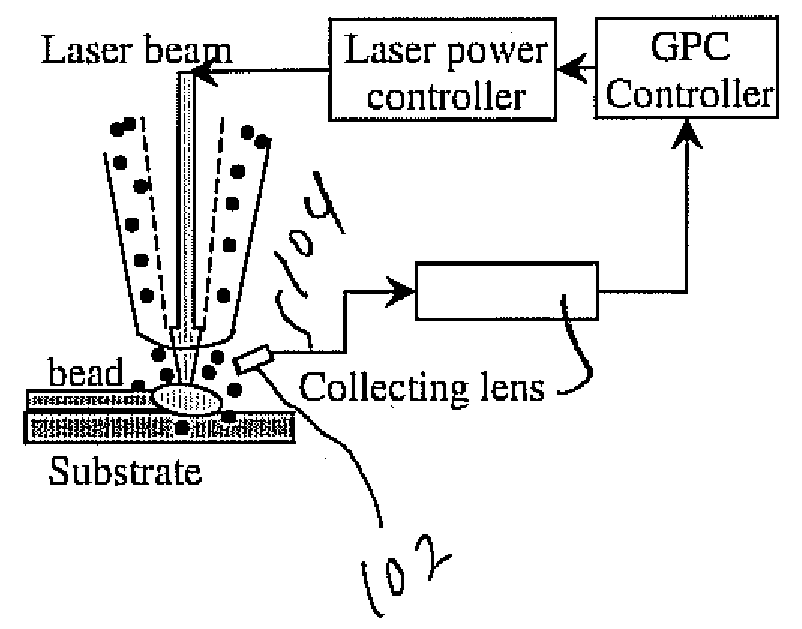

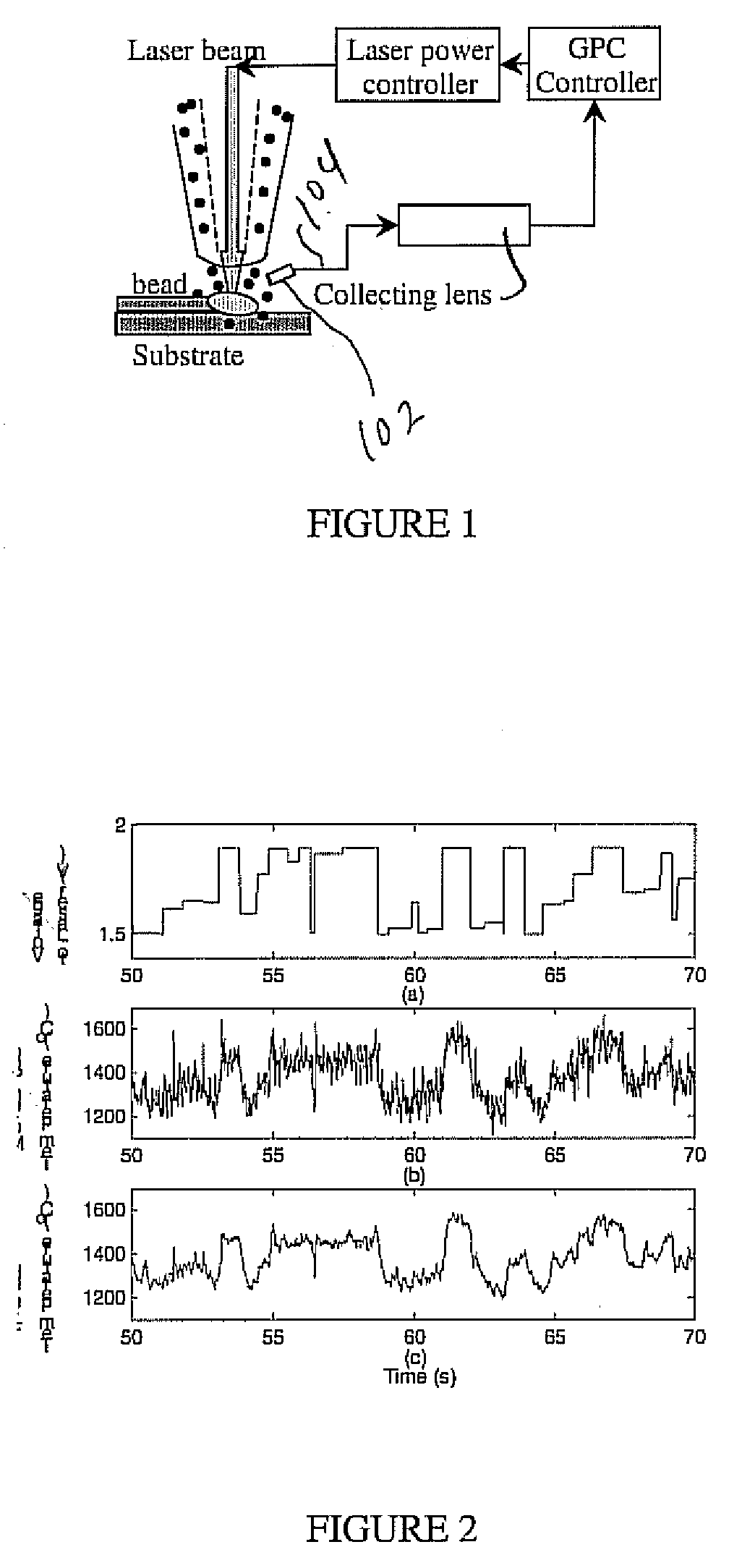

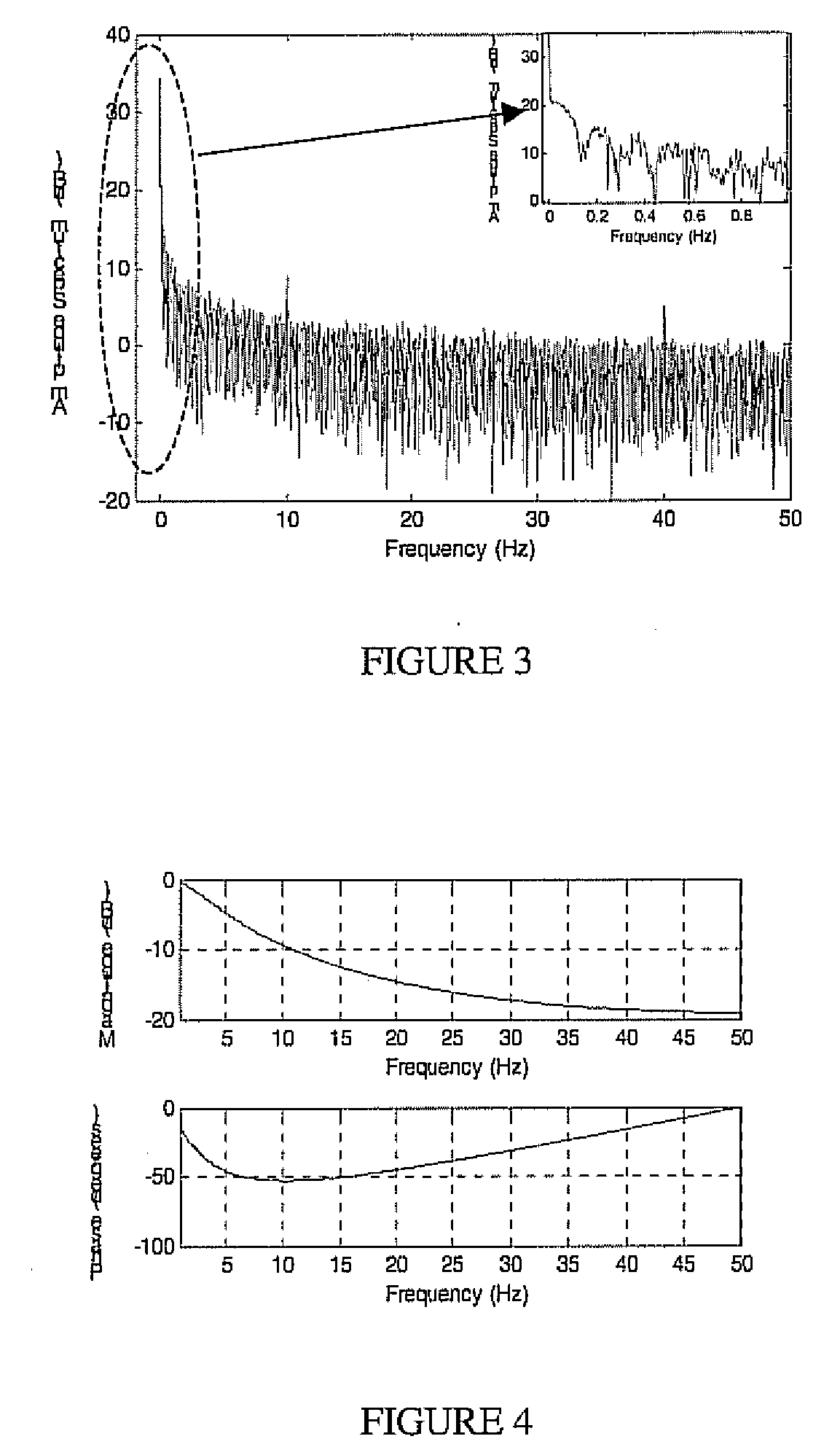

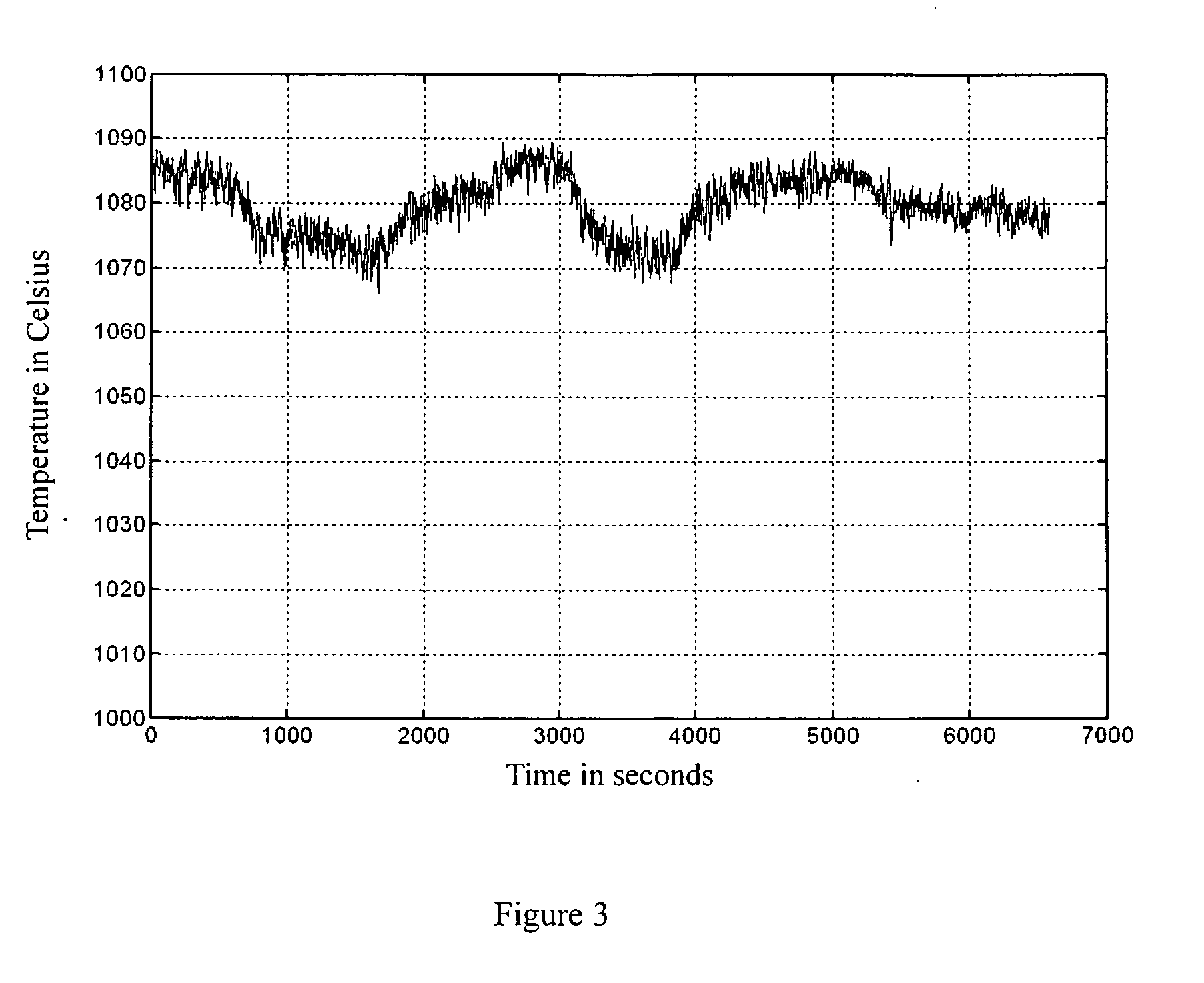

Real time implementation of generalized predictive control algorithm for the control of direct metal deposition (DMD) process

InactiveUS20080223832A1Increasing temperature profileHigh dimensional accuracyDigital computer detailsThermometers using physical/chemical changesControl systemLinear model

A linear model based generalized predictive control system controls the molten pool temperature during a Direct Metal Deposition (DMD) process. The molten pool temperature is monitored by a two-color pyrometer. A single-input single-output linear system that describes the dynamics between the molten pool temperature and the laser power is identified and validated. The incremental generalized predictive control algorithm with Kalman filter estimation is used to control the molten pool temperature.

Owner:P O M GRP THE

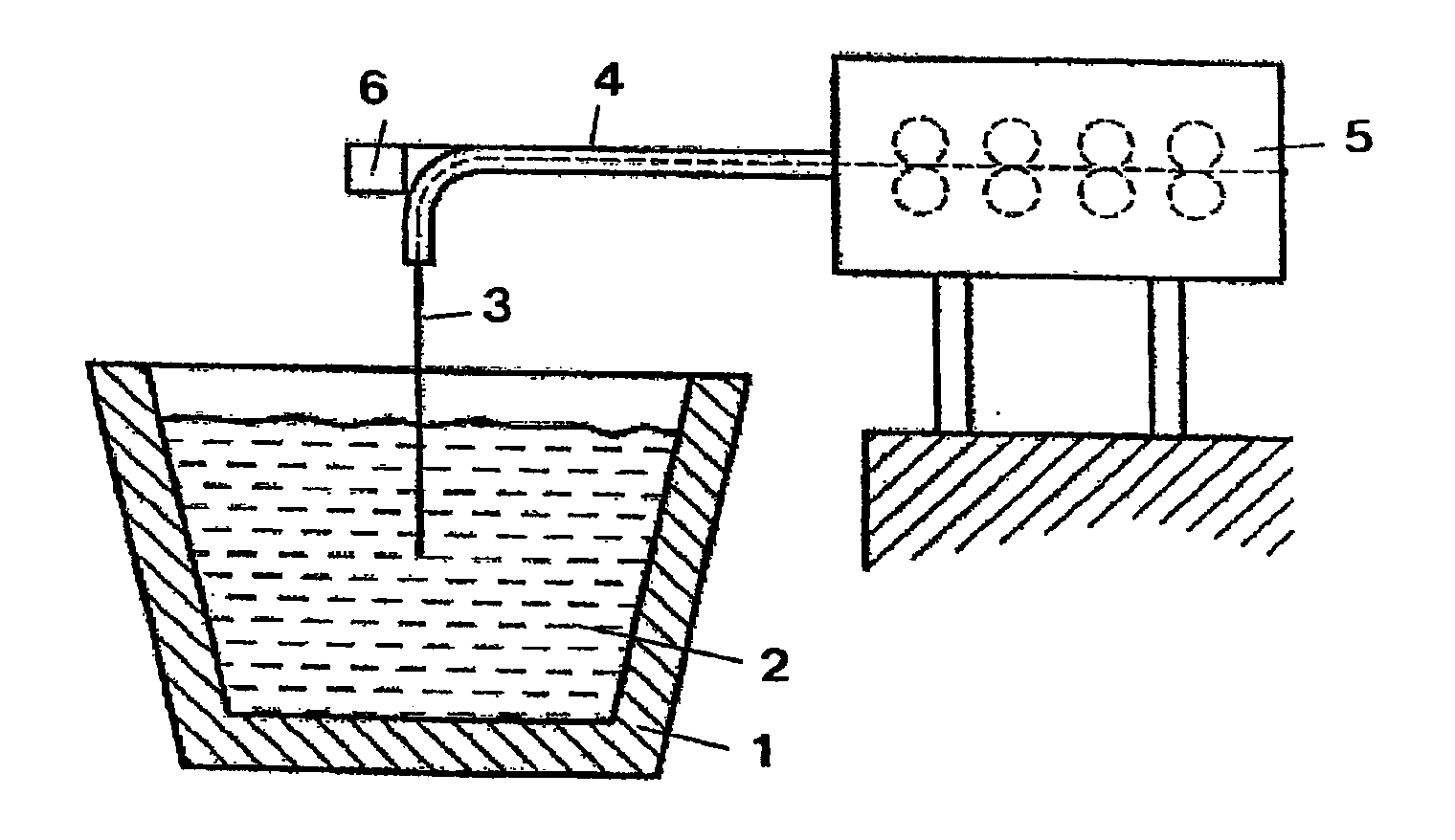

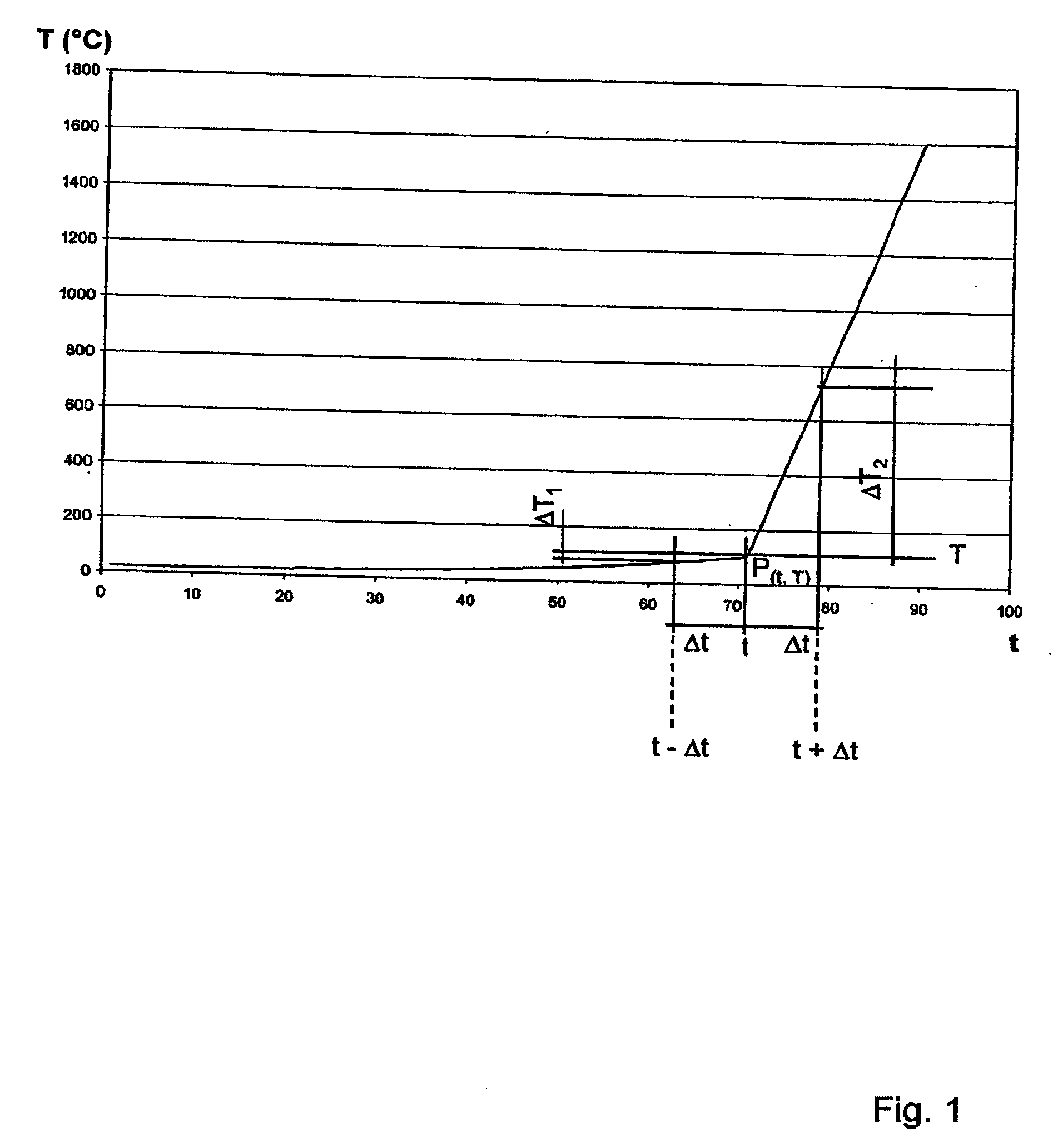

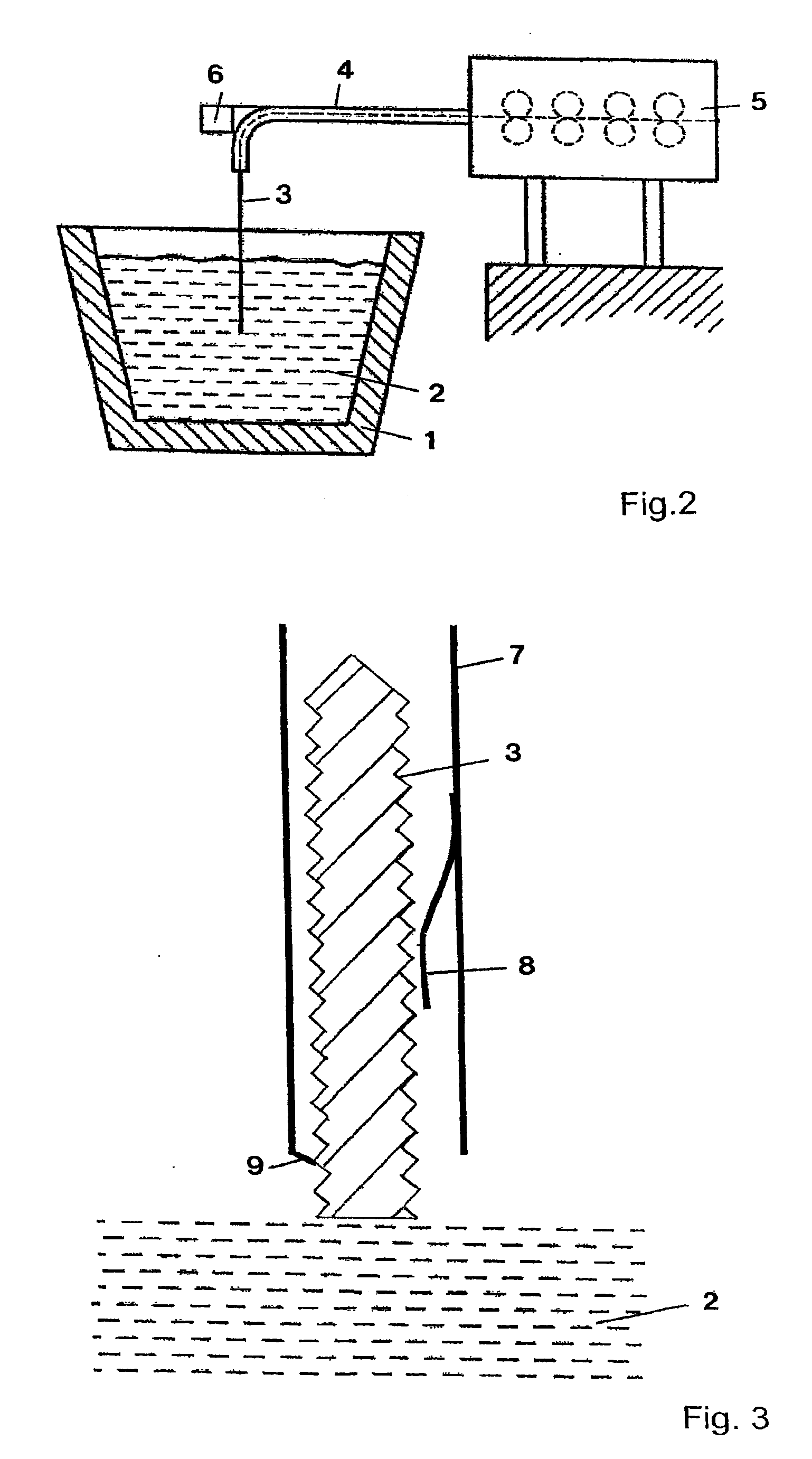

Method and device for measuring the temperature of a molten metal bath

ActiveUS20070268477A1Strong and effective changeIncrease heating speedThermometer detailsThermometers using physical/chemical changesMolten bathMolten metal

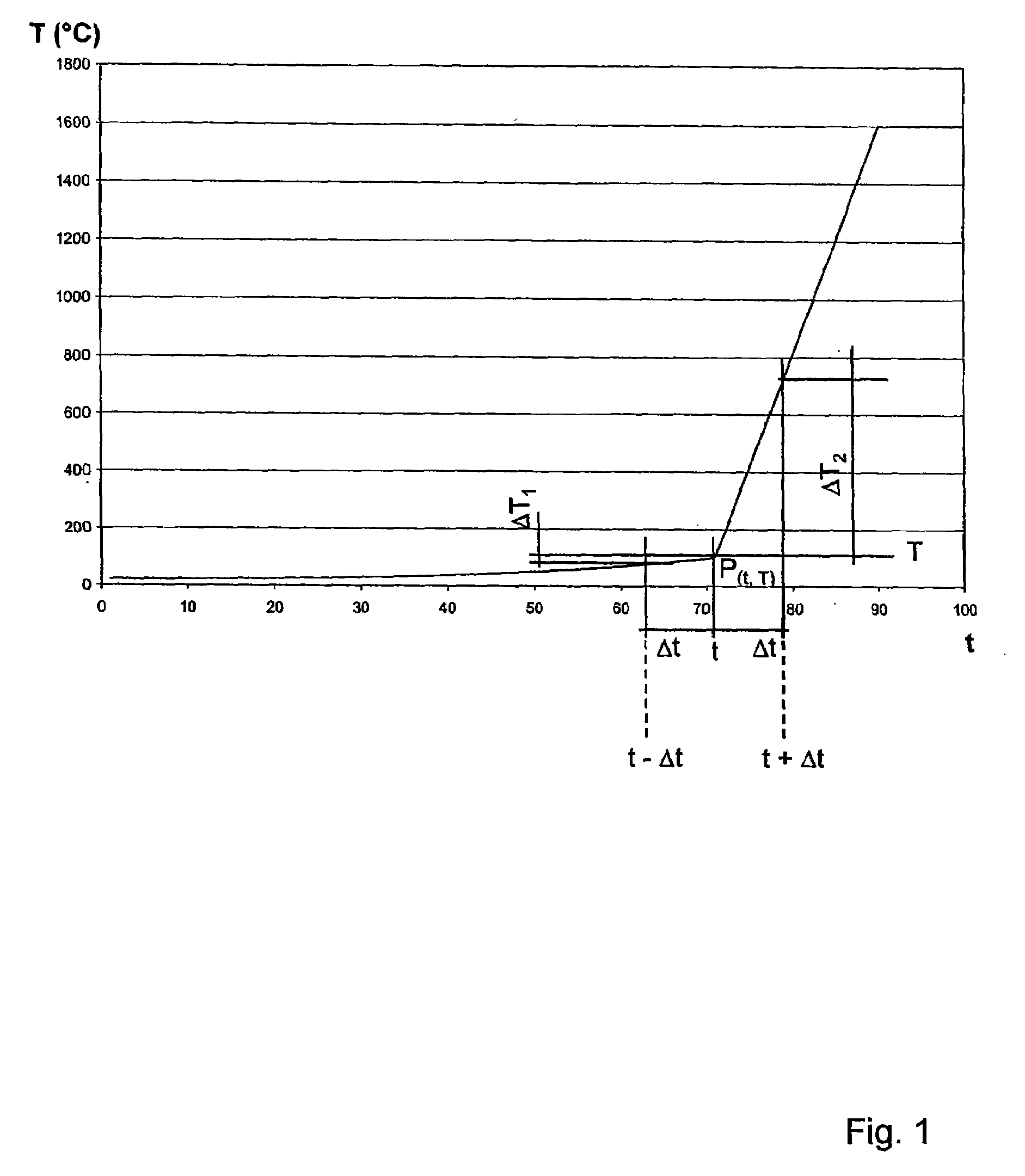

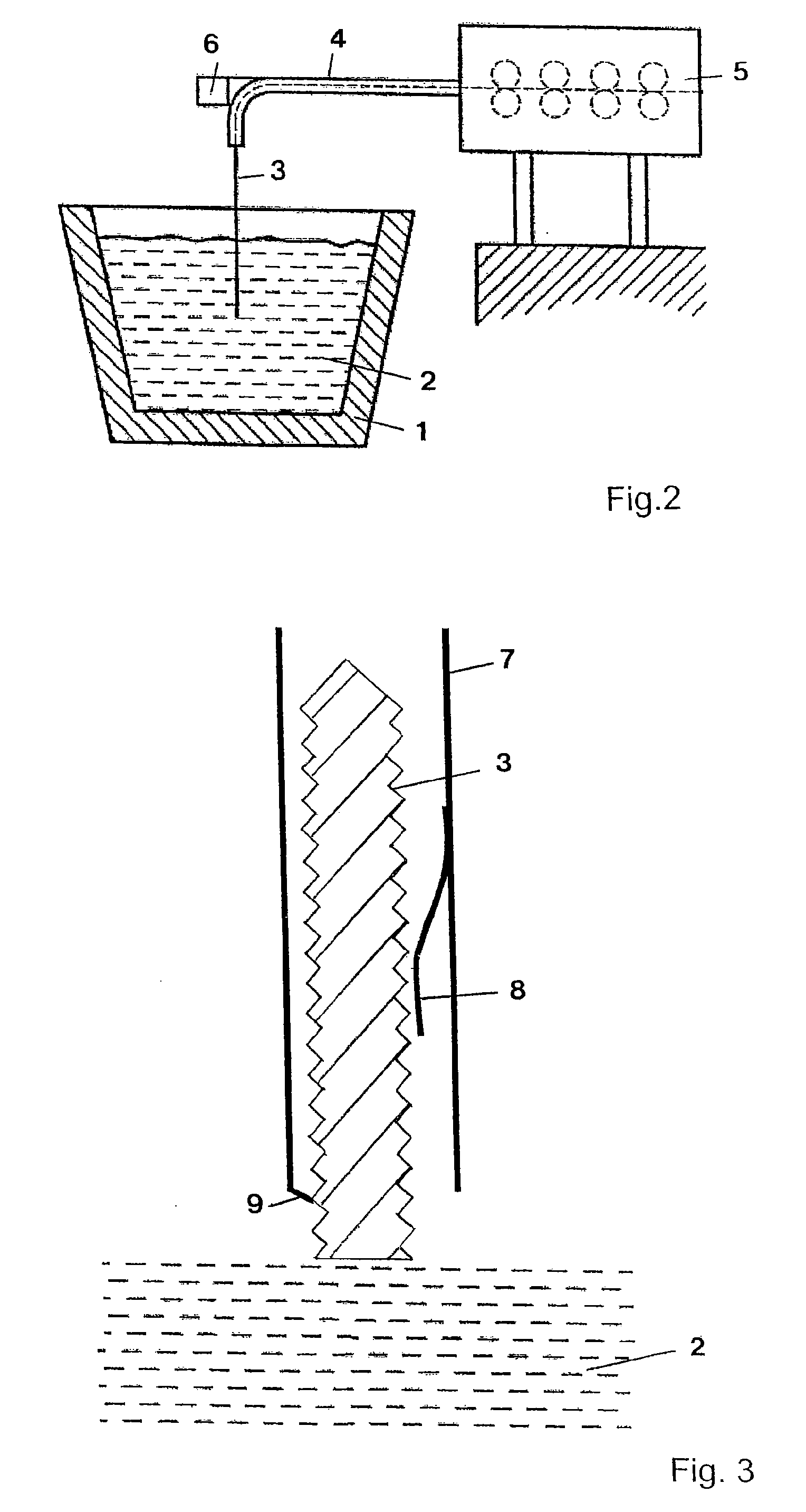

A method is provided for measuring a temperature of a molten metal bath by an optical fiber surrounded by a cover. The optical fiber is immersed in the molten bath, and the radiation absorbed by the optical fiber in the molten bath is fed to a detector, wherein the optical fiber is heated when immersed in the molten bath. The heating curve of the optical fiber has at least one point P(t0, T0), wherein the increase ΔT1 in the temperature T of the optical fiber over the time Δt in a first time interval t0−Δt up to the temperature T0 is smaller than the increase ΔT2 in the temperature of the optical fiber over the time Δt in an immediately following second time interval t0+Δt.

Owner:HERALUS ELECTRO NITE INT NV

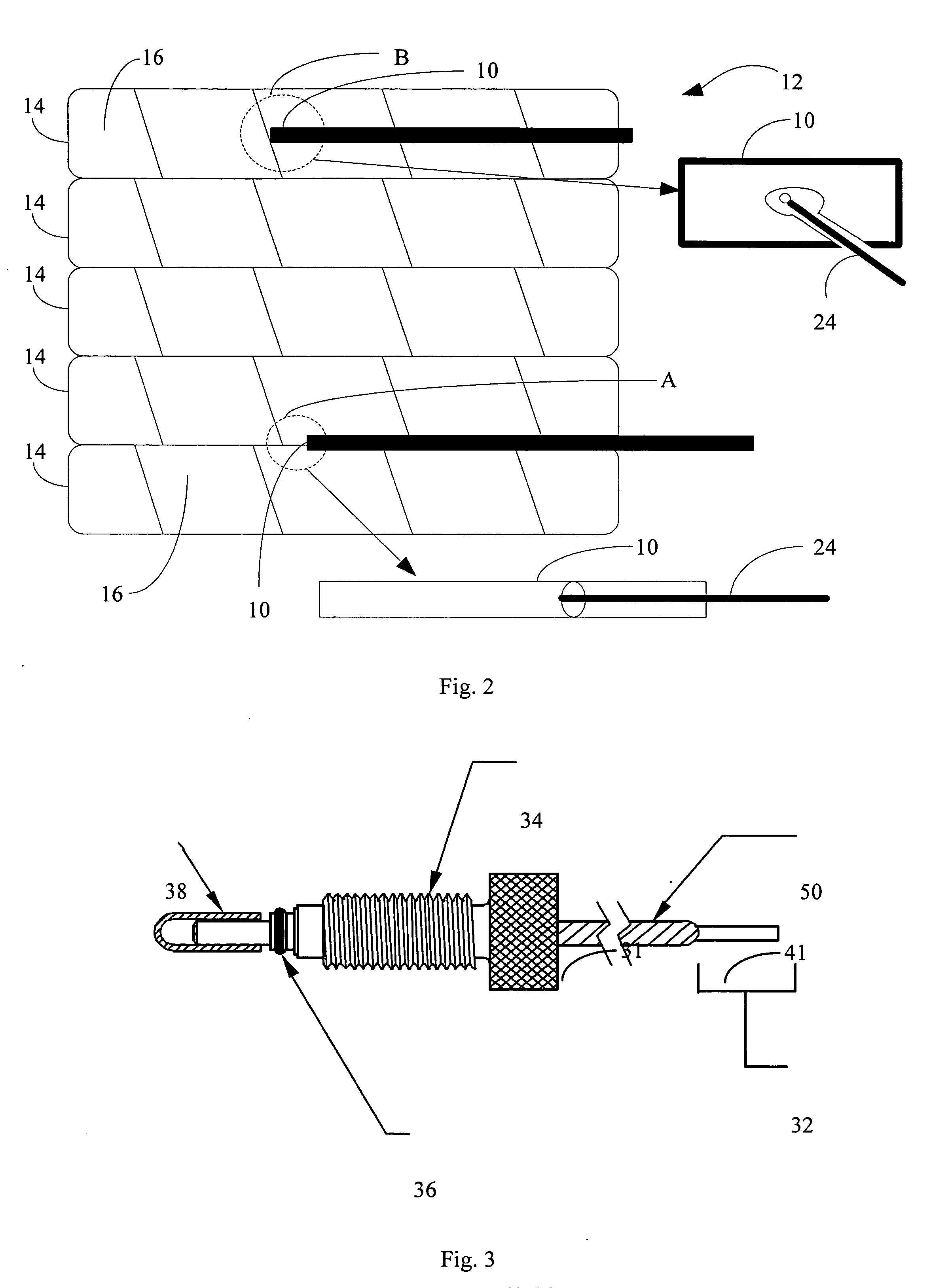

Electrical device measurement probes

A probe for use within a high voltage and high current electrical device is disclosed. The probe comprises an optical fiber, a substrate having a slot, and a photoluminescent material. The fiber has a first and second end and is configured to convey an activation light from the first to second end. A portion of the fiber is within the slot such that the slot receives the second end of the fiber. Emission of the photoluminescent material, as a function of temperature, is known. The photoluminescent material is disposed within at least a portion of the slot that faces the second end of the fiber so that they are in optical communication with each other. A change in intensity of a luminescent light emitted back into the fiber by the photoluminescent material when the activation light is conveyed by the fiber onto the photoluminescent material provides an indication of the integrity of the electrical device.

Owner:LUXTRON CORP

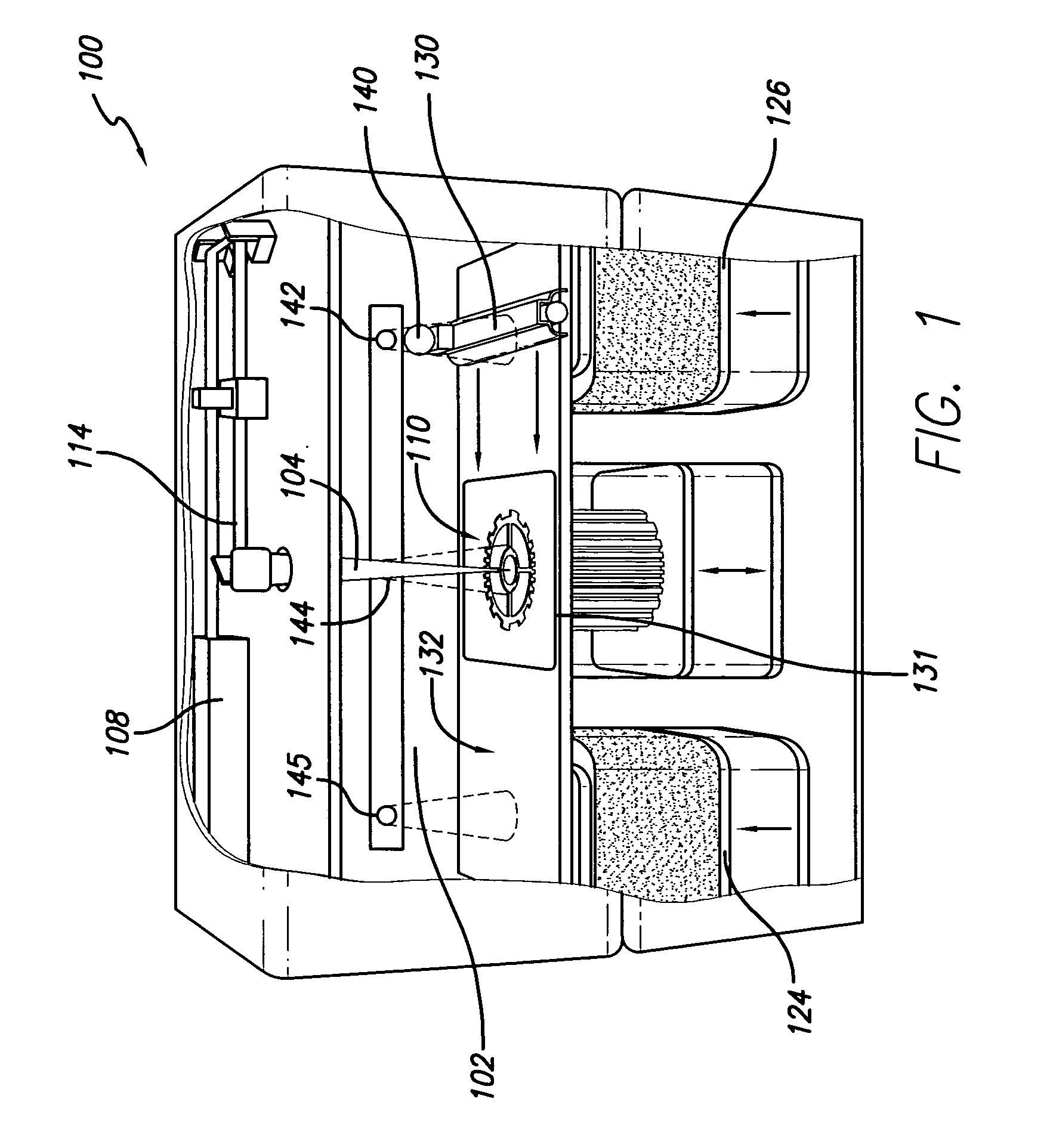

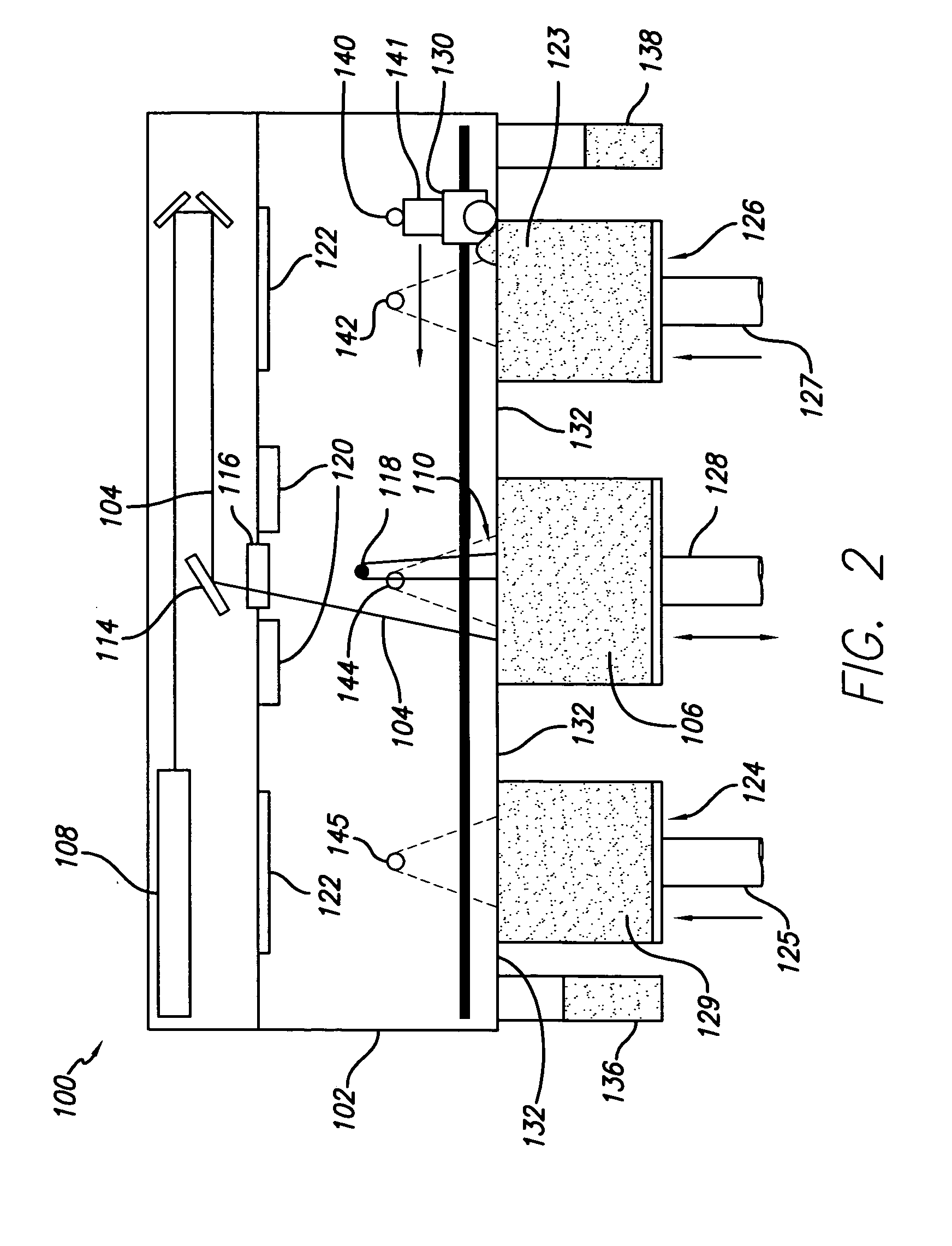

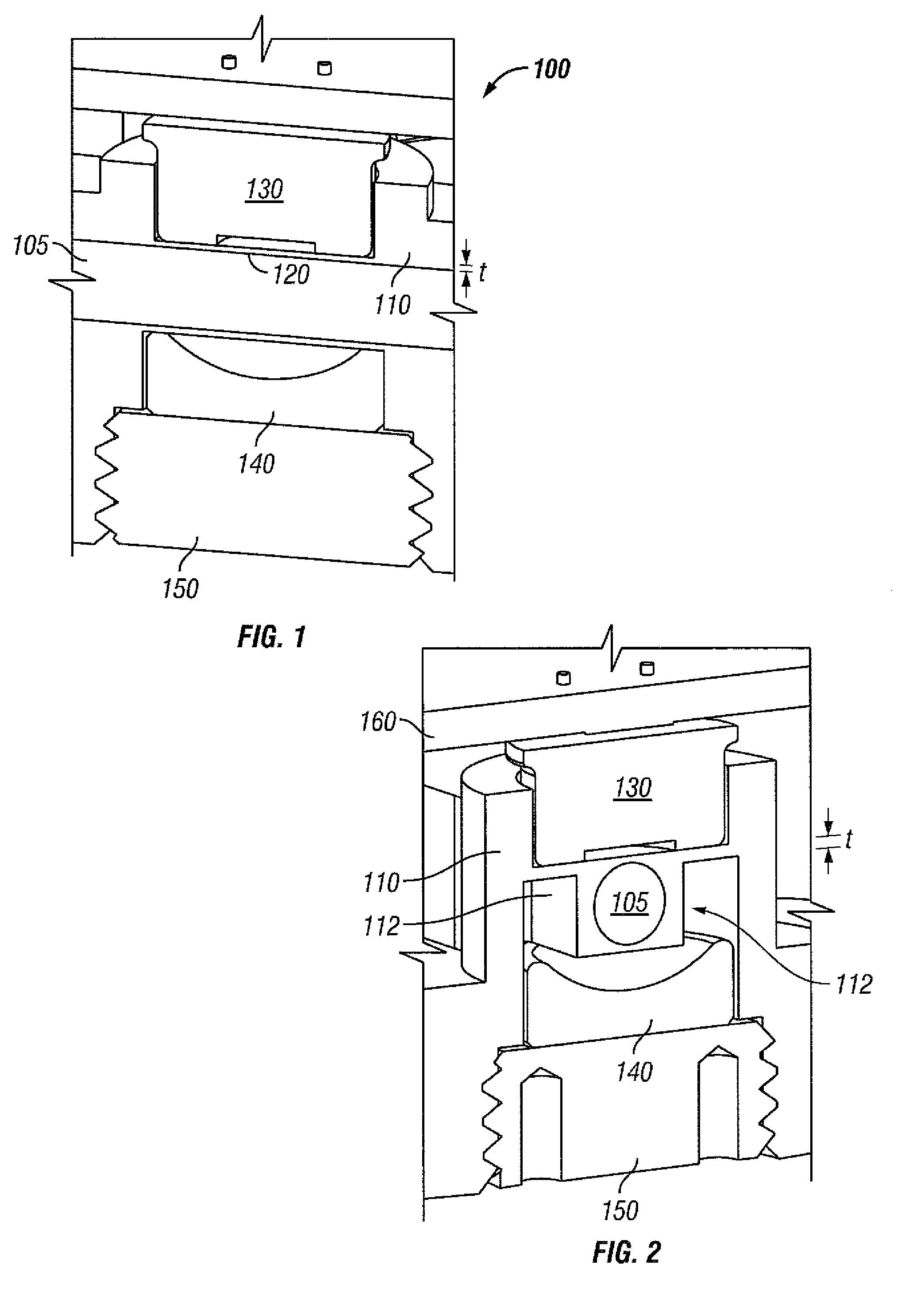

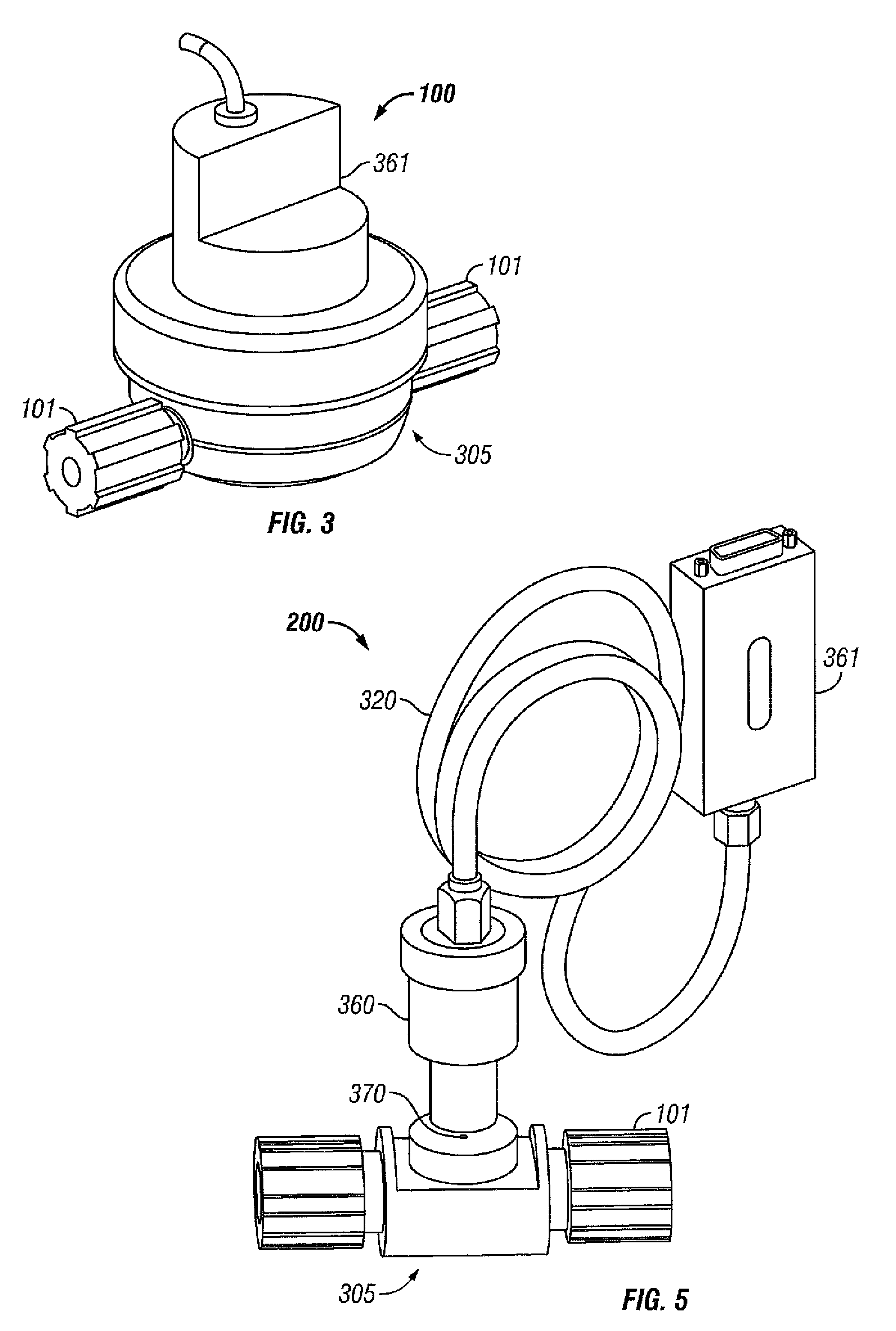

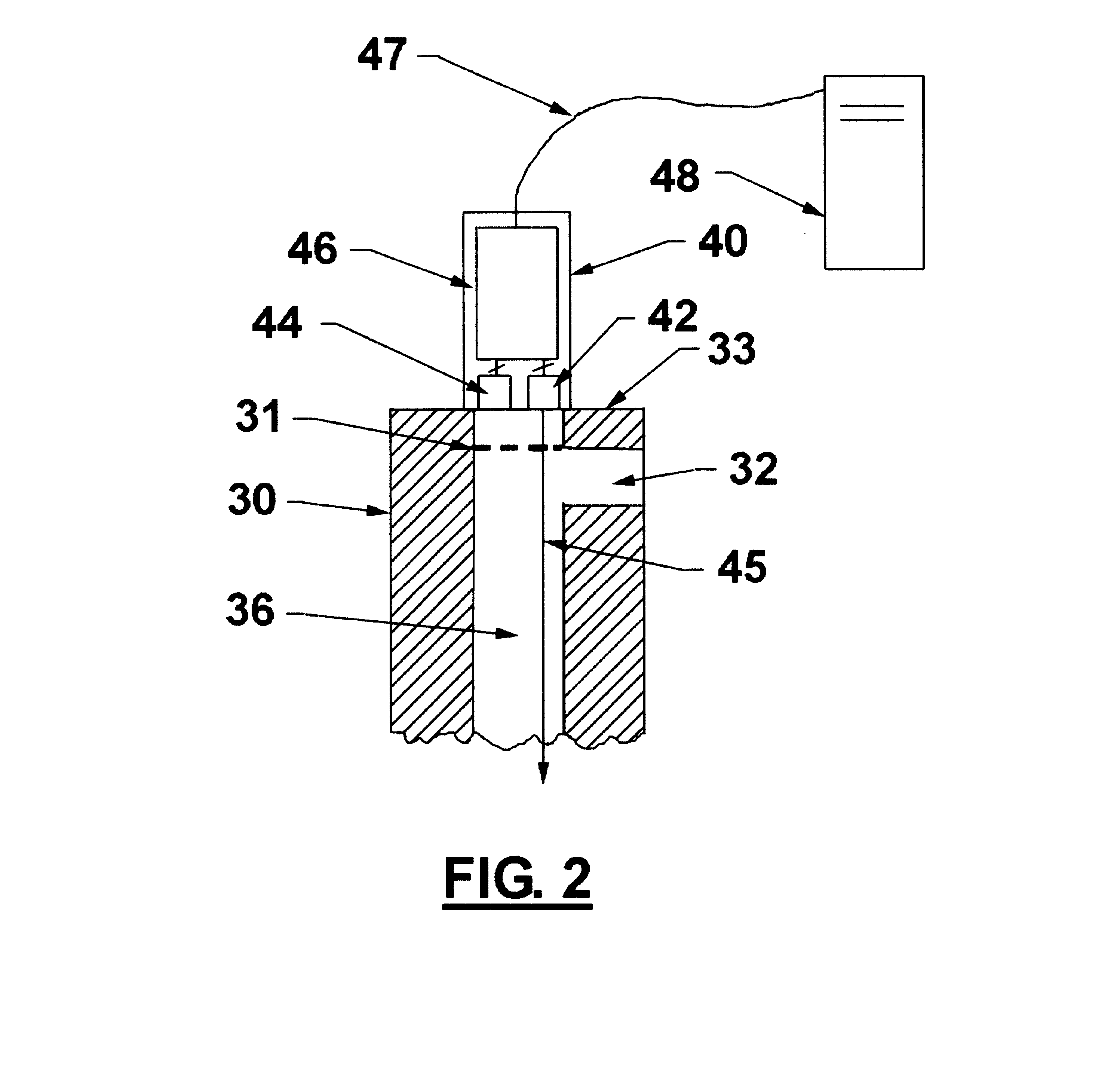

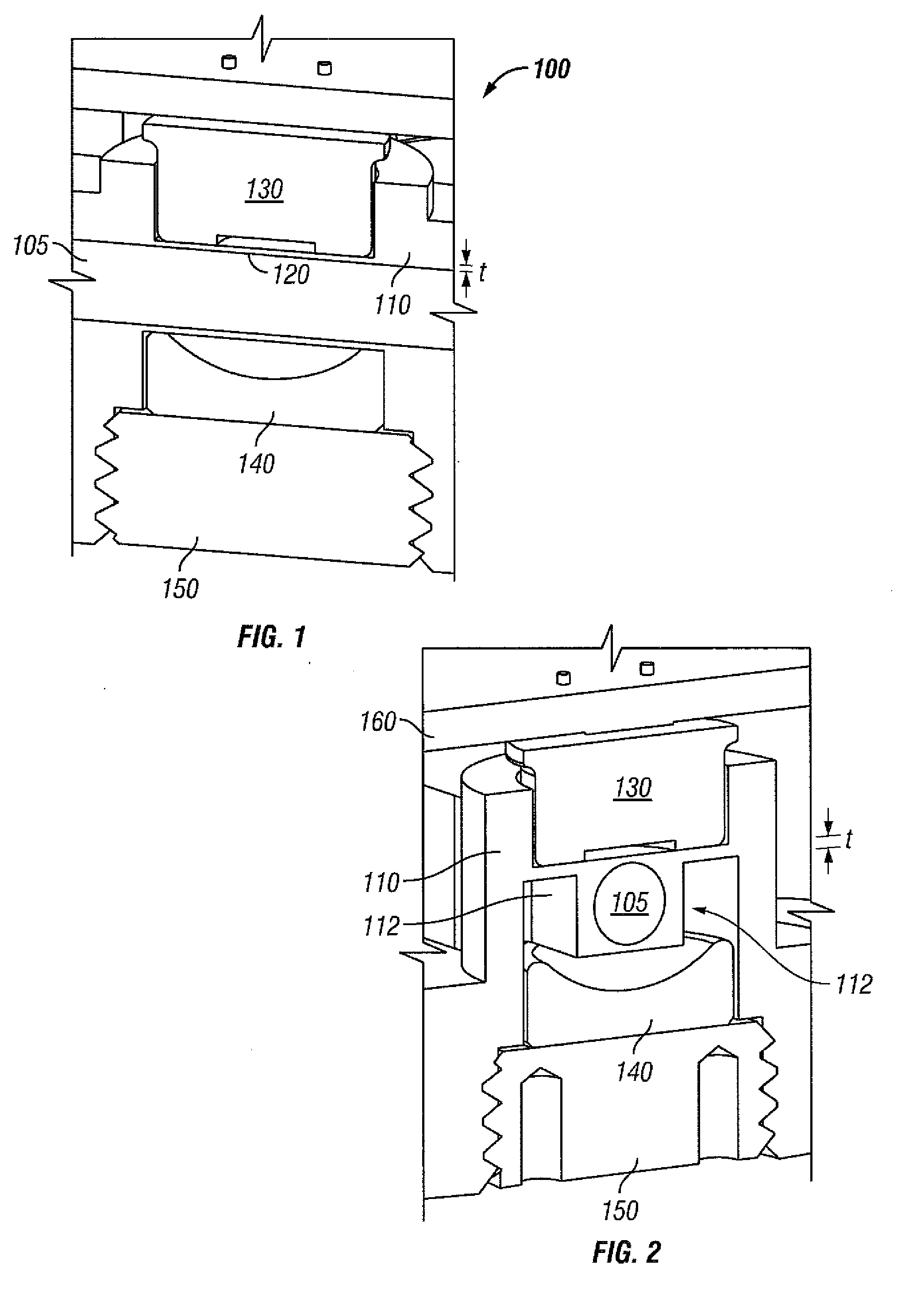

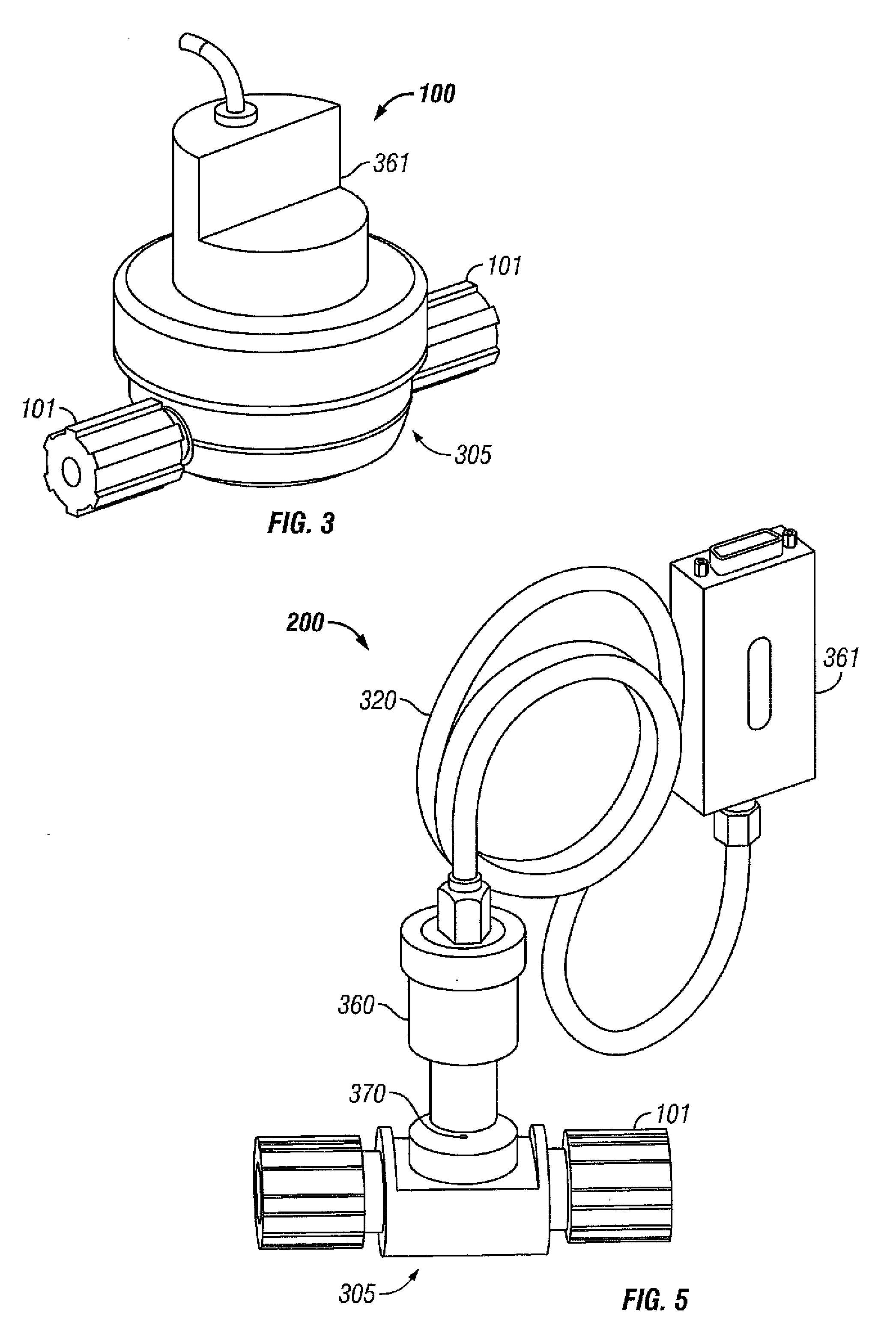

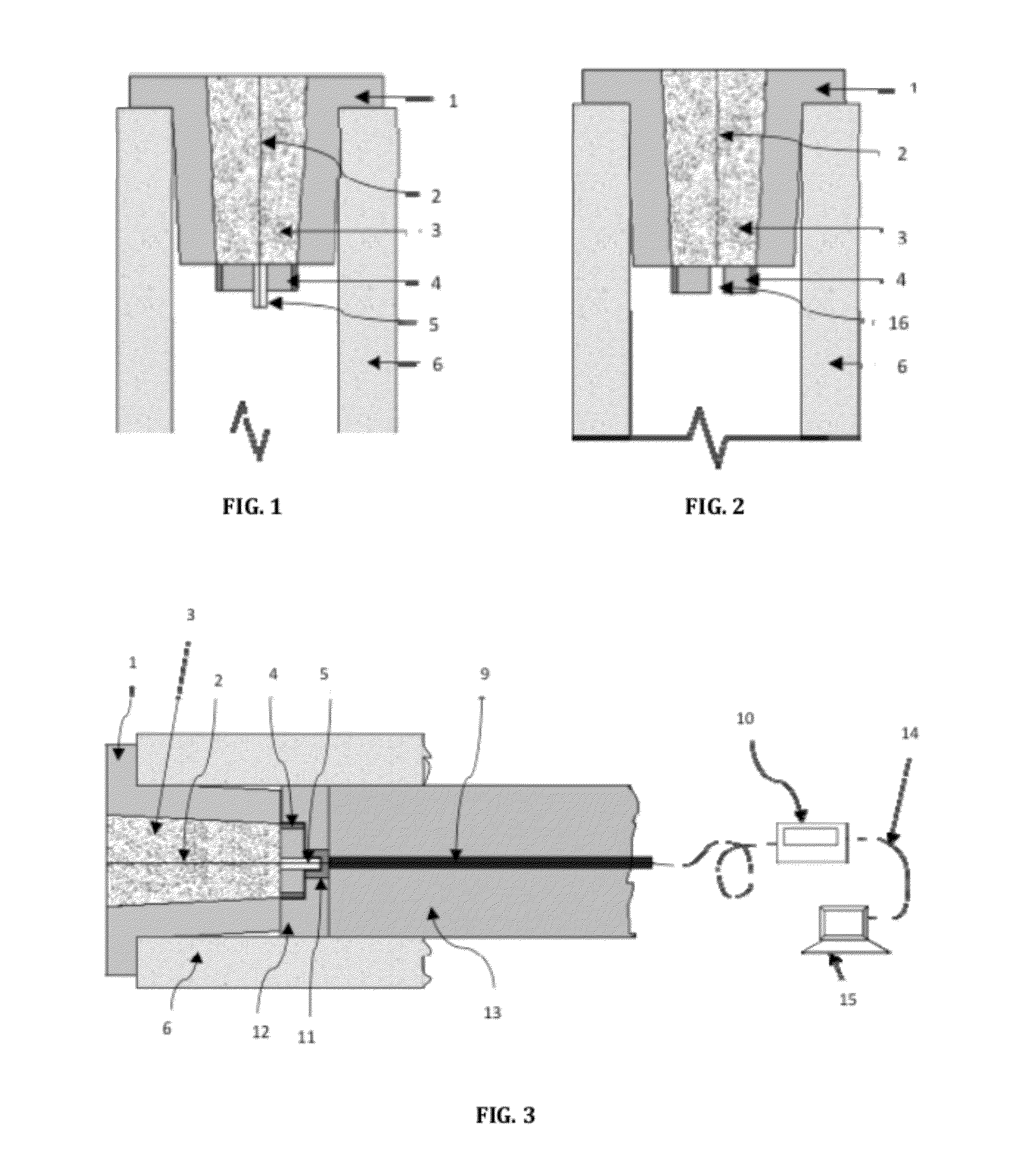

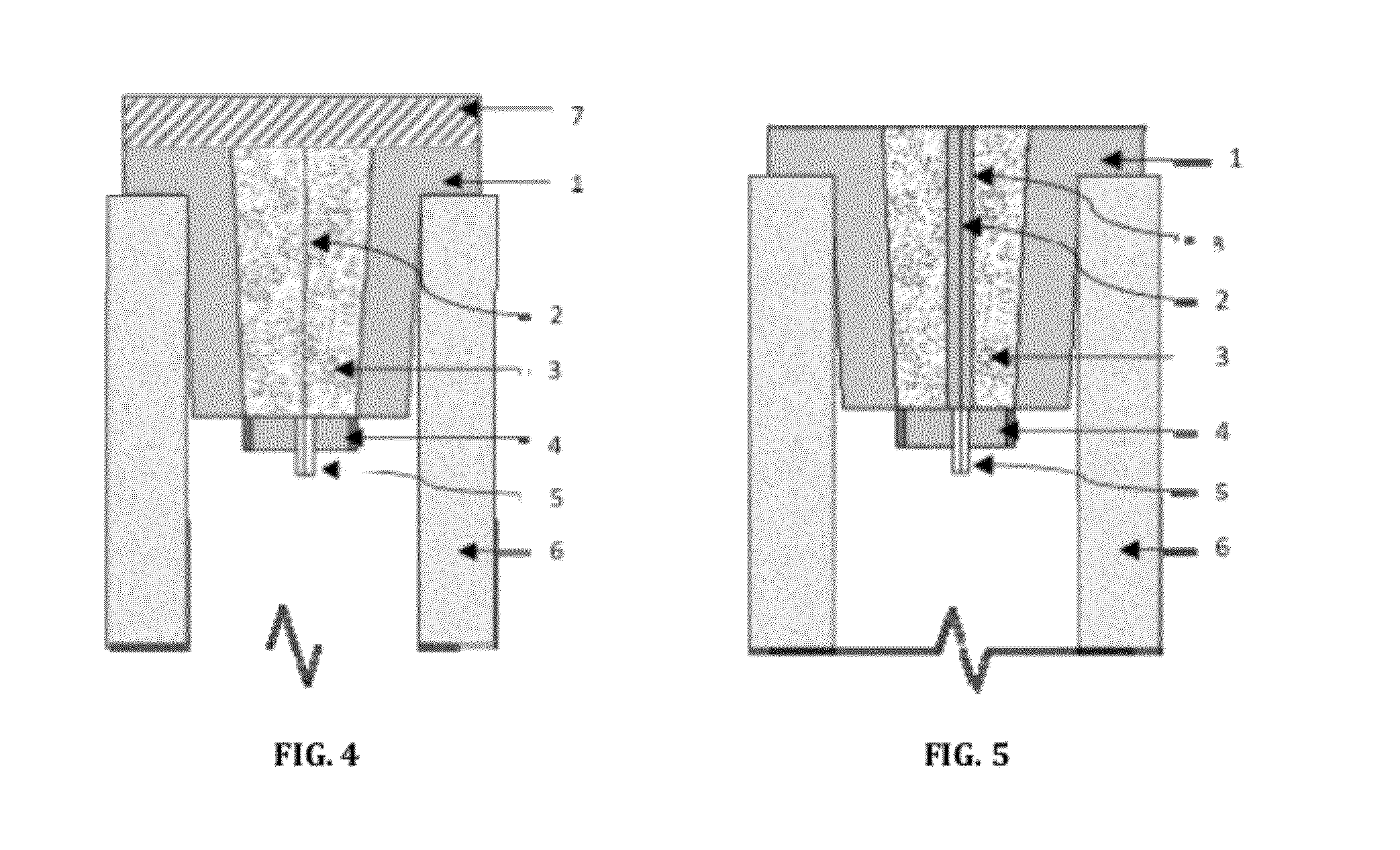

System and method for non-intrusive thermal monitor

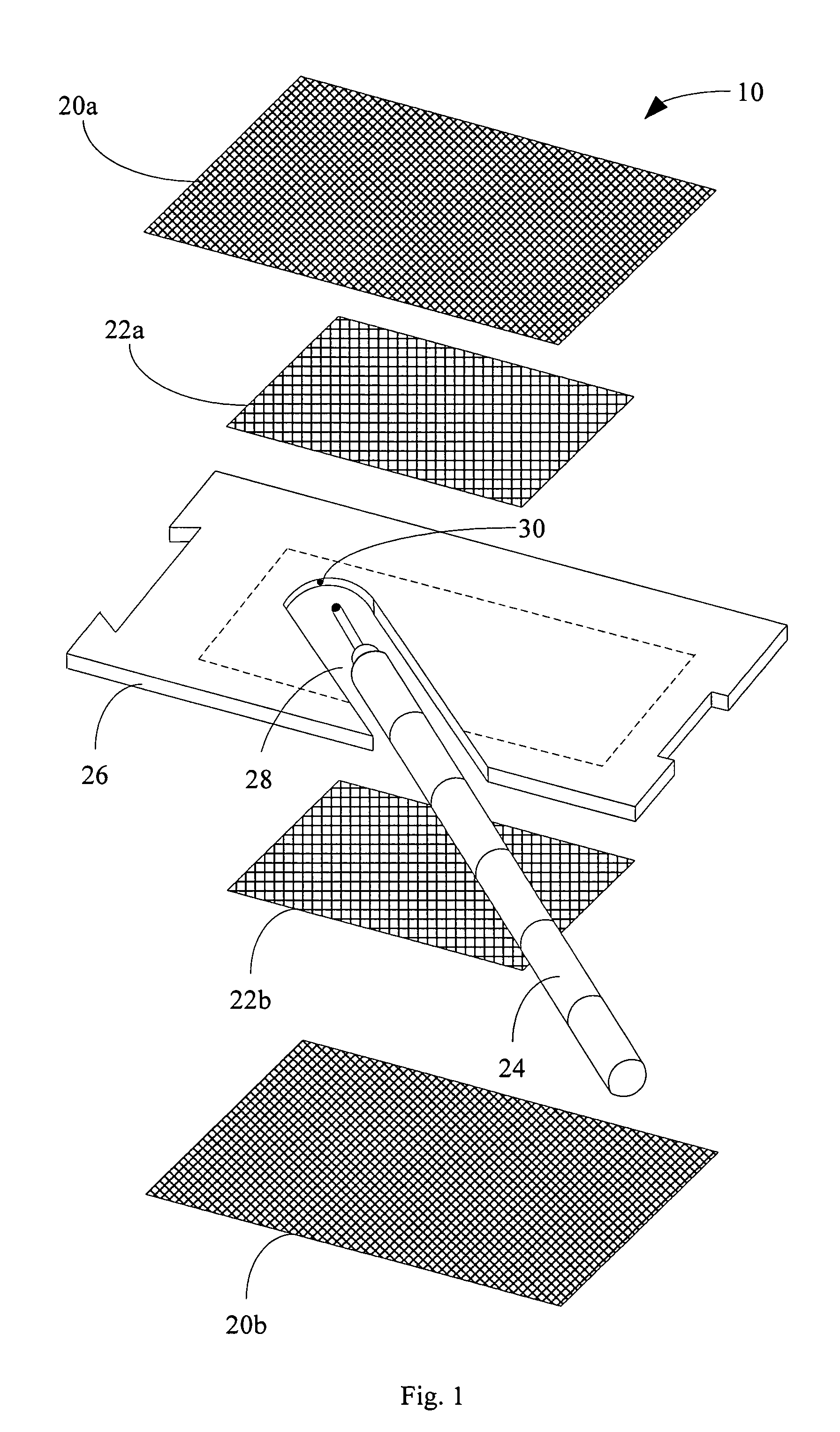

InactiveUS7726876B2Improve performanceExtend the lifespanThermometer detailsSensing heat from liquidsThermopileEngineering

Embodiments disclosed herein provide a non-intrusive thermal (NIT) monitor for sensing temperatures useful for semiconductor manufacturing applications. In some embodiments, a NIT monitor comprises a thermopile, a fluid housing with a fluid window, and an elongated member positioned between the thermopile and the fluid window for transmitting or reflecting infrared signals corresponding to a temperature of a fluid in the fluid housing. The fluid housing may have a cross-sectional profile to enable the manipulation of the fluid flow under the fluid window, enhancing the speed and accuracy of the temperature sampling. The elongated member, which may be hollow and coated with gold, may an extended piece of the fluid housing or a part of an optics housing. In some embodiments, the NIT monitor is connected to a main conditioning circuit board via a cable for processing the temperature measurements at a remote location.

Owner:ENTEGRIS INC

Device and method for measuring temperature in molten metals

ActiveUS20050175065A1Increase heightWithout reducing functionalityThermometer detailsThermometers using physical/chemical changesFiberMaterials science

A device is provided for measuring temperature in molten metals with an optical fiber. The optical fiber is connected directly or indirectly to a measurement instrument and is held by a carrier. The immersion end of the fiber is fed through a body that can be consumed in the metal melt. The consumable body exhibits a consumption rate of at most 10 cm / min, and the consumption rate is approximately equal to or greater than the rate at which the structure of the optical fiber is destroyed.

Owner:HERALUS ELECTRO NITE INT NV

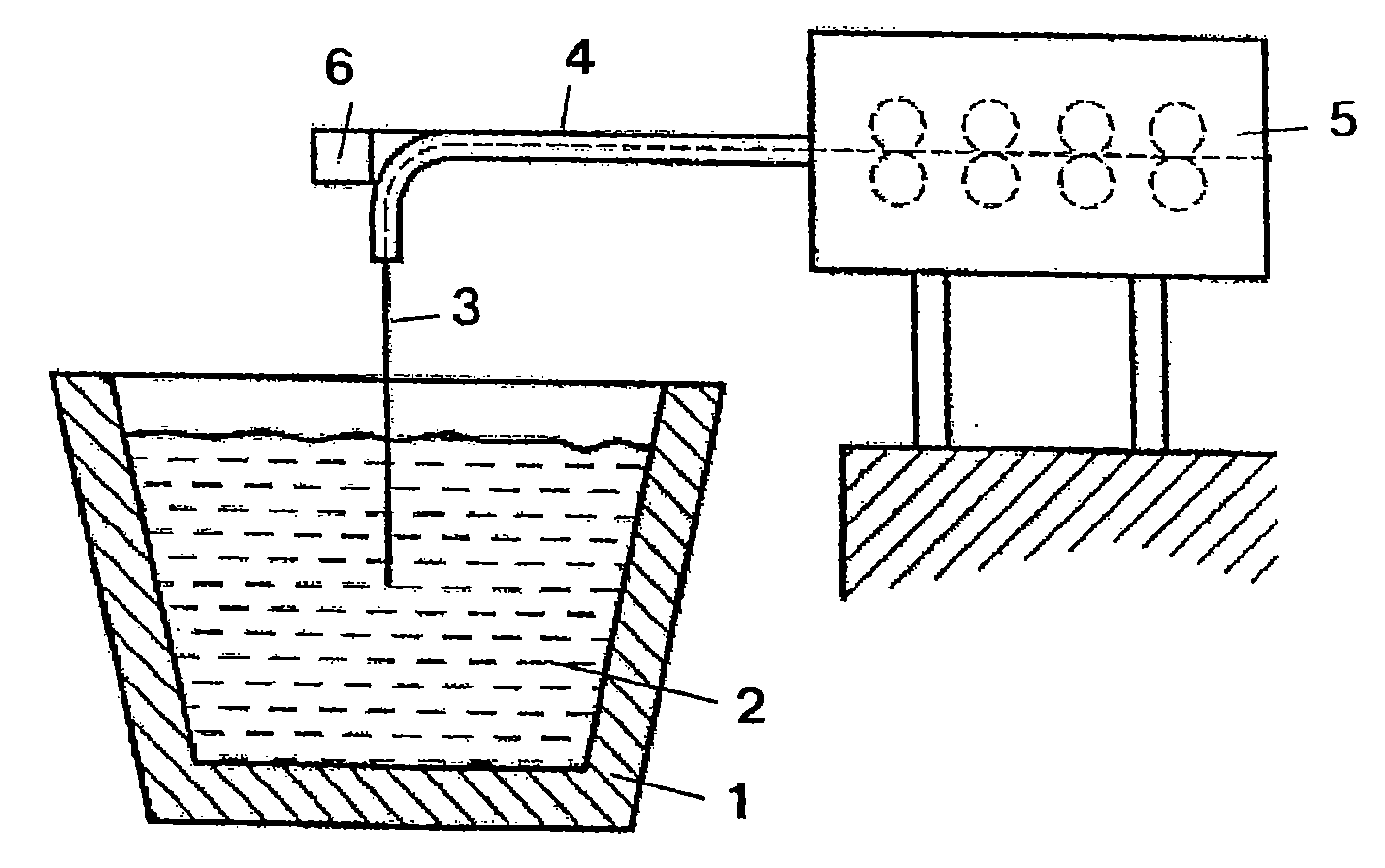

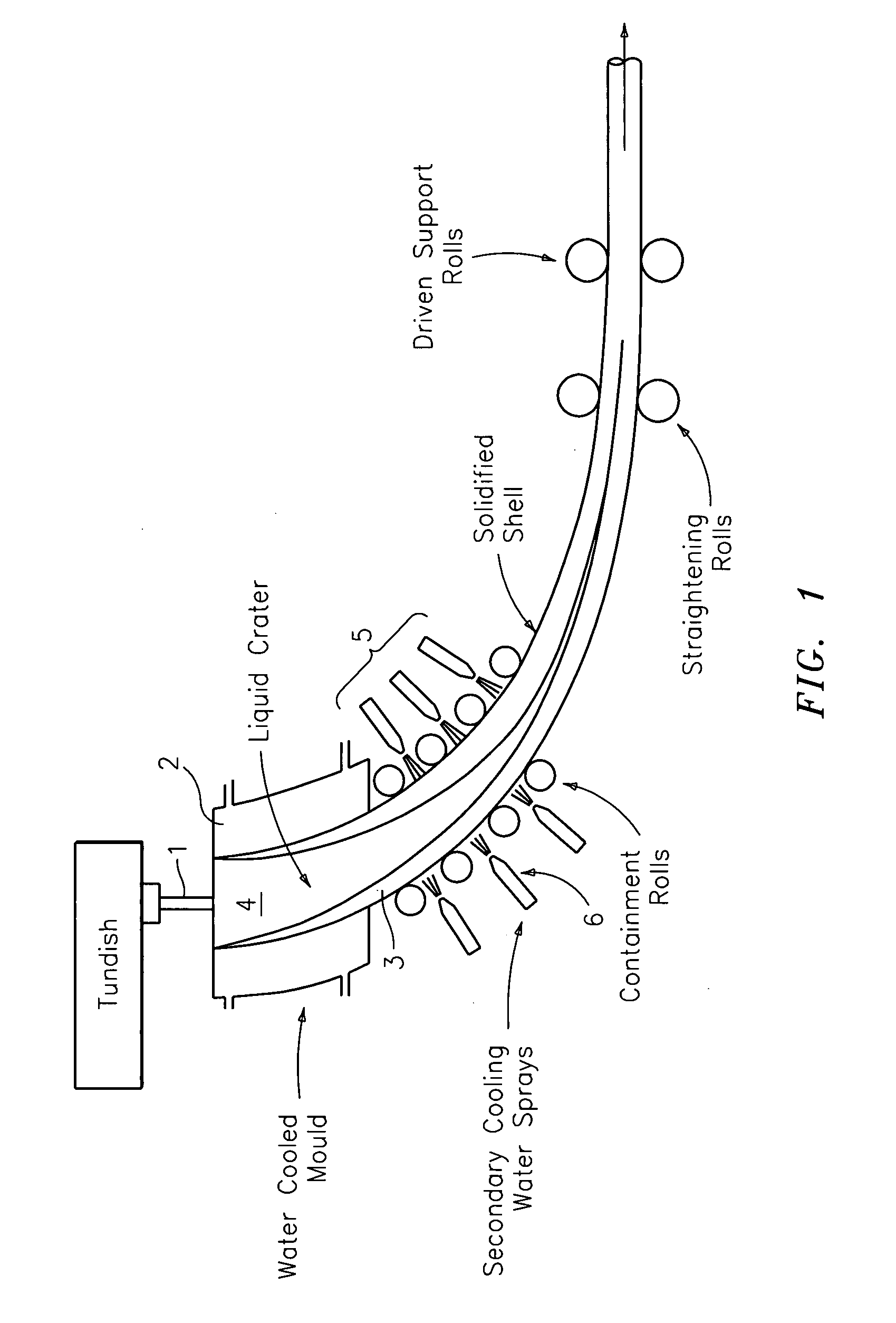

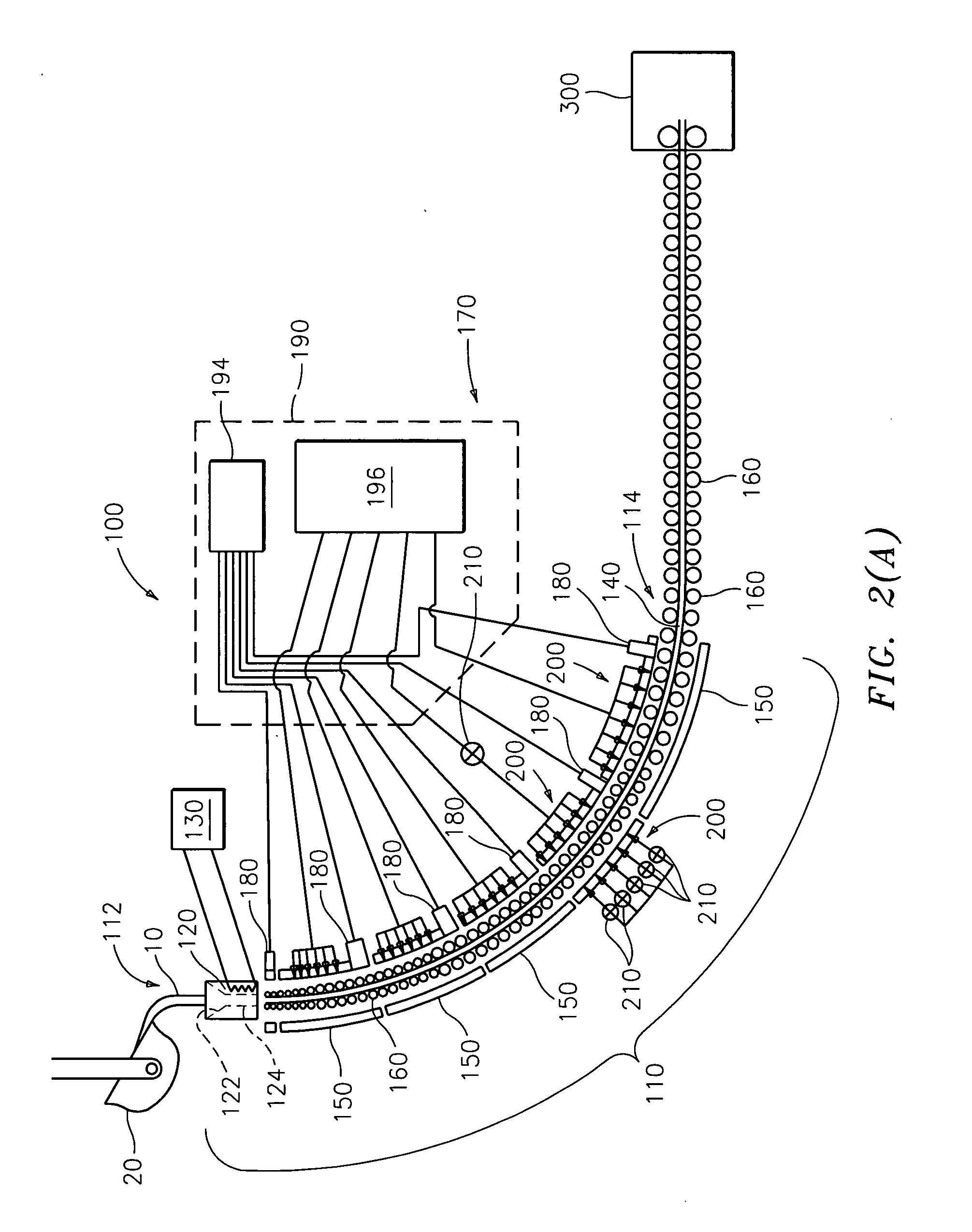

Active temperature feedback control of continuous casting

InactiveUS20070251663A1Uniform surface temperatureImprove efficiencyTemperature control using plurality of sensorsCasting safety devicesEngineeringFeedback control

The invention includes a system, method and machine readable program for dynamically controlling the casting of a material. Generally, the systems and methods described herein include an active control feedback system or aspects thereof including a temperature sensing device that is well-suited for the harsh environment of the interior of a caster such as a caster for casting metal. Temperature measurement can be accomplished either directly or indirectly. The system is configured to compare the measured temperature with an ideal casting temperature. The temperature sensing device is operably coupled to a cooling device that modulates a flow of coolant to dynamically cool the material being cast. In accordance with one embodiment of the invention, the cooling device includes a plurality of nozzles for delivering one or more cooling fluids to the material being cast.

Owner:ROSEMOUNT AEROSPACE +1

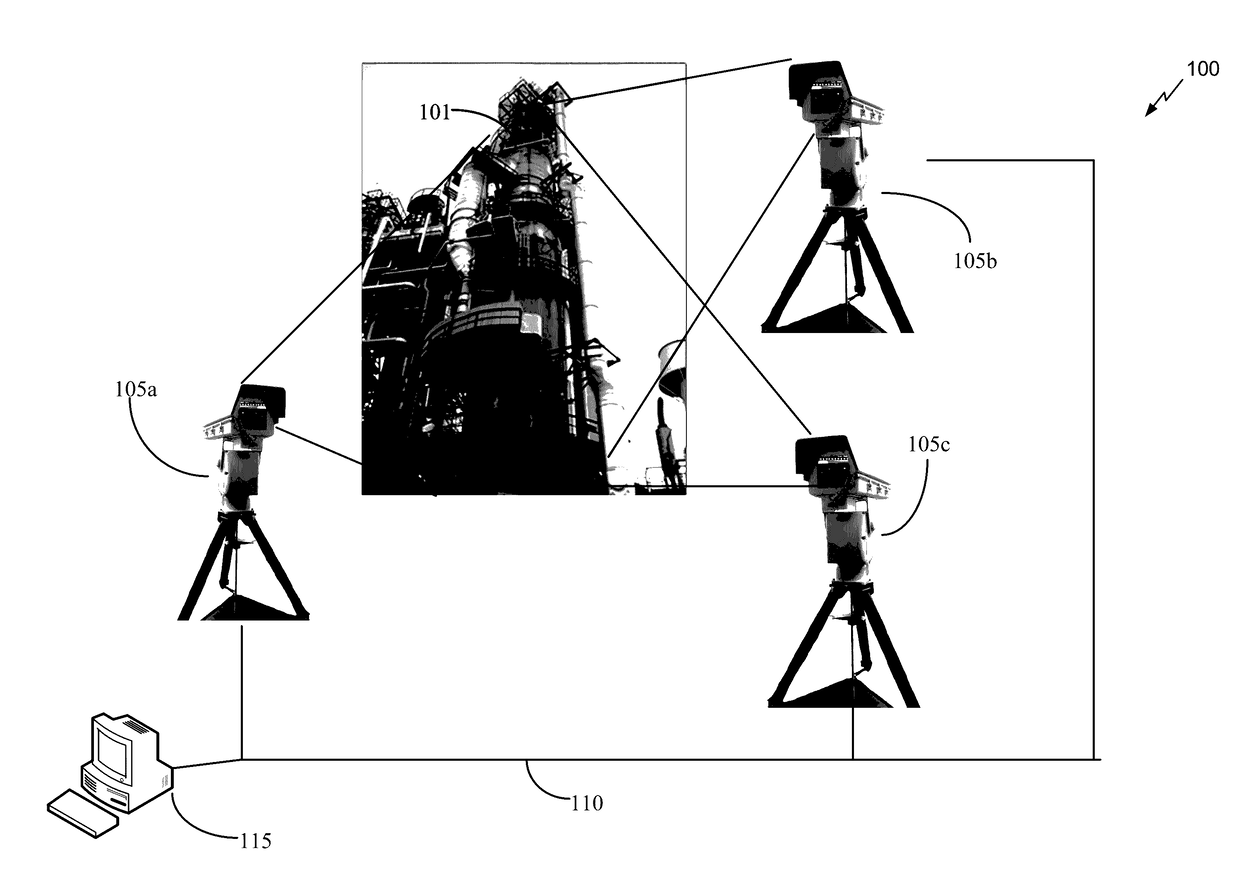

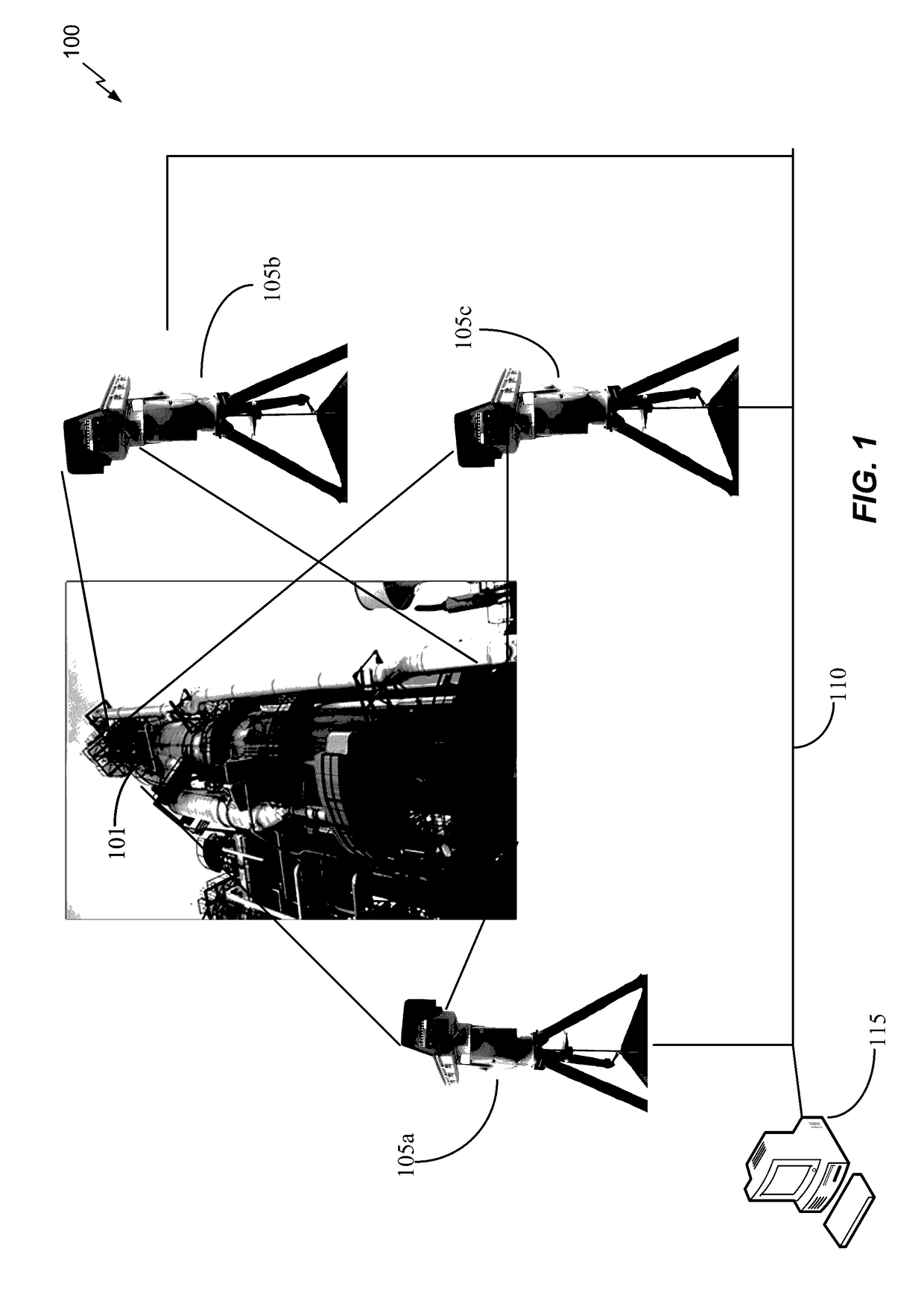

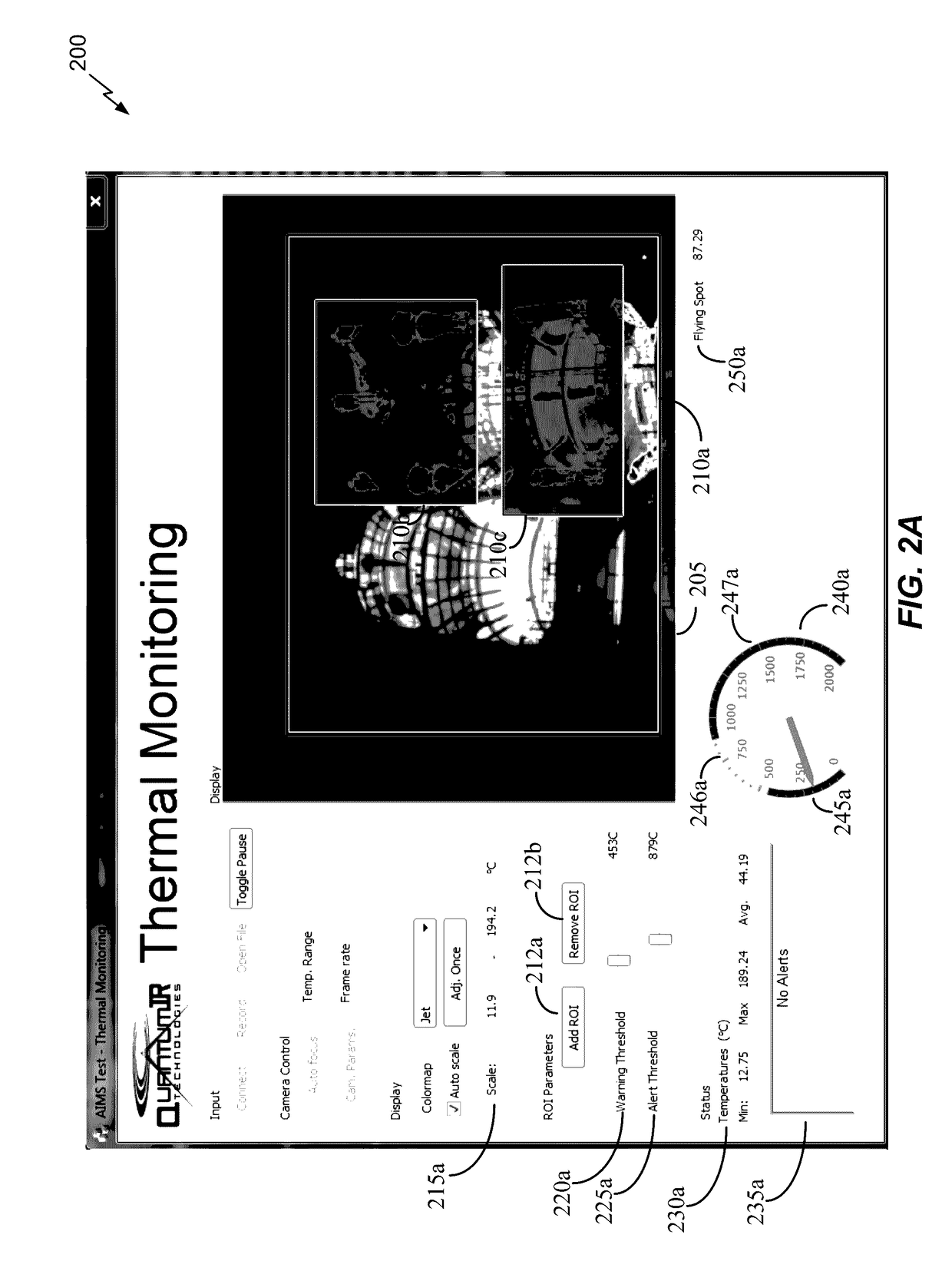

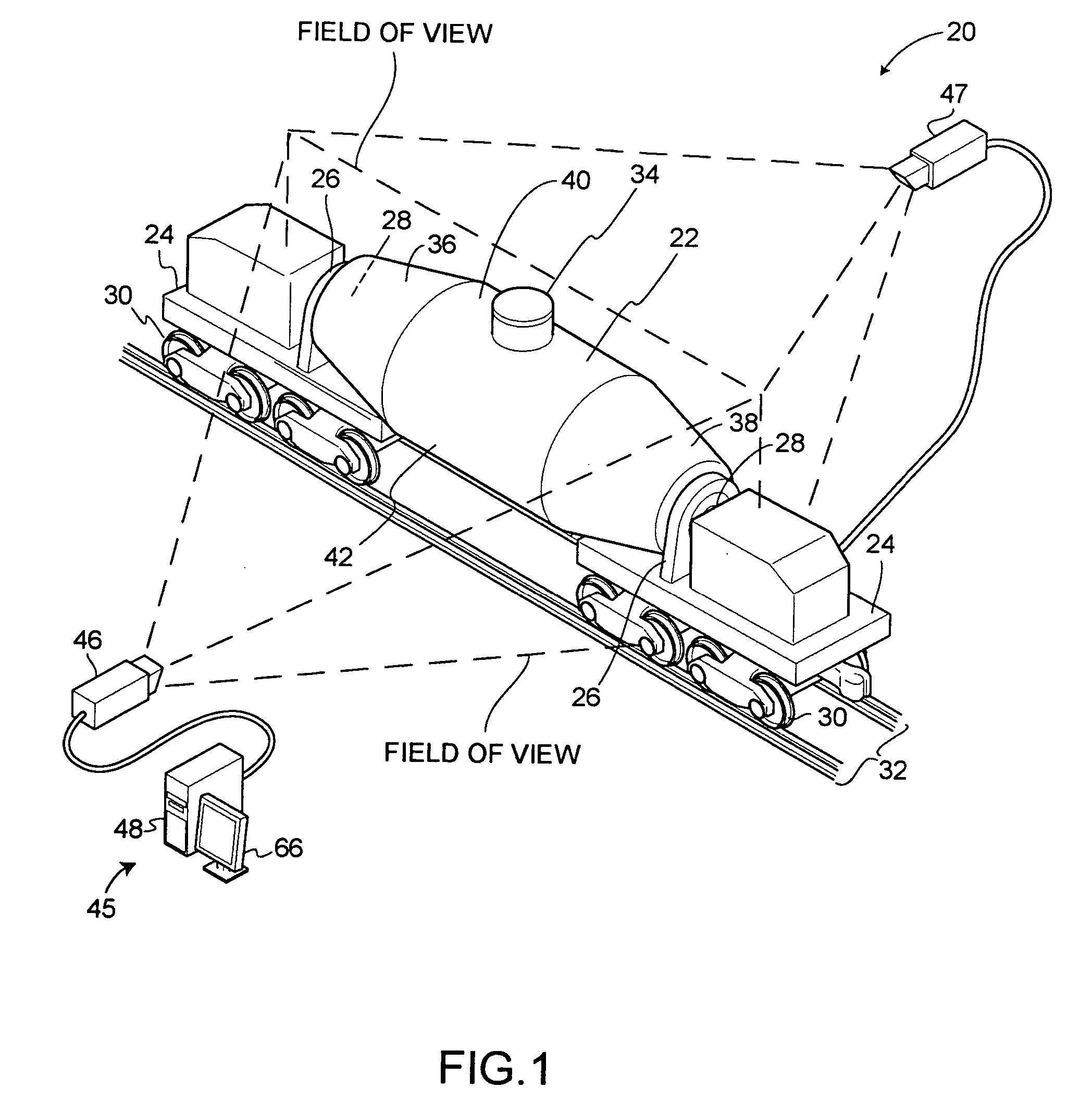

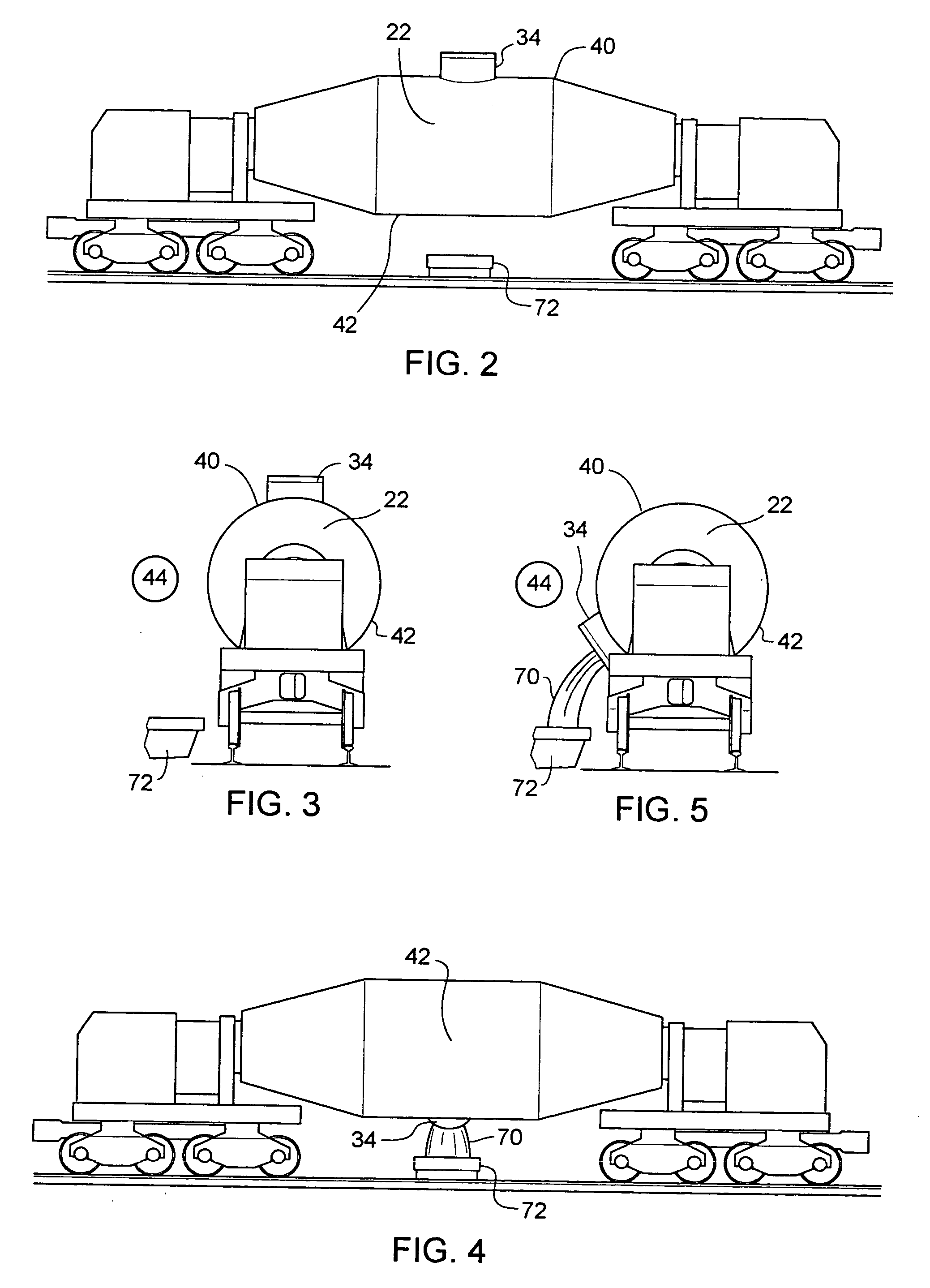

Methods and systems for hotspot detection

Methods and systems for monitoring an industrial process are disclosed. Some aspects of the system arrange multiple imaging sensors to image machinery associated with an industrial process. Regions of interest within images acquired by the multiple imaging sensors may be monitored for abnormal thermal conditions, and alerts generated as needed. Alerts may also be generated if temperatures within a region of interest exceed thresholds associated with that region of interest. Each region of interest may be independently monitored and have individualized alerting thresholds. In some aspects, images from the multiple imaging sensors may be stitched together, with the regions of interest based on the stitched image. In other aspects, regions of interest within images from separate imaging sensors may be linked together so as to share at least common alerting thresholds.

Owner:QUANTUM IR TECH LLC

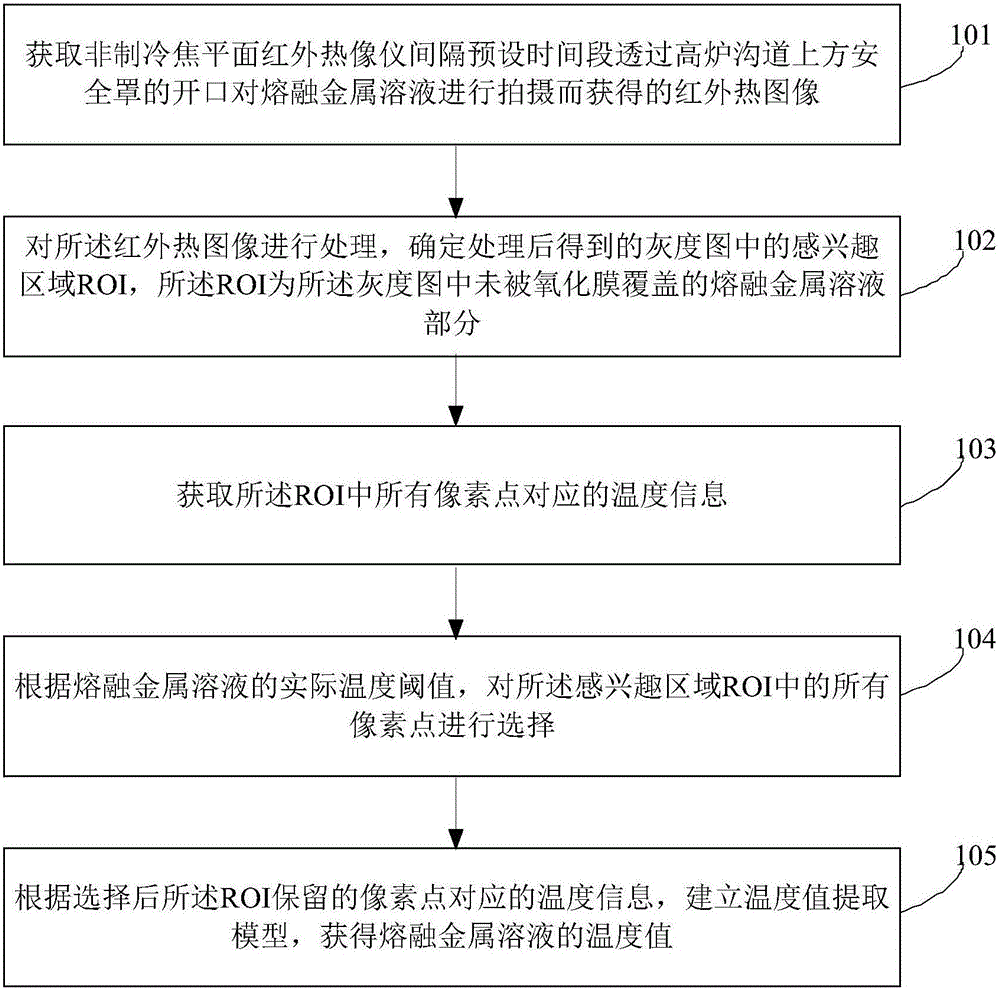

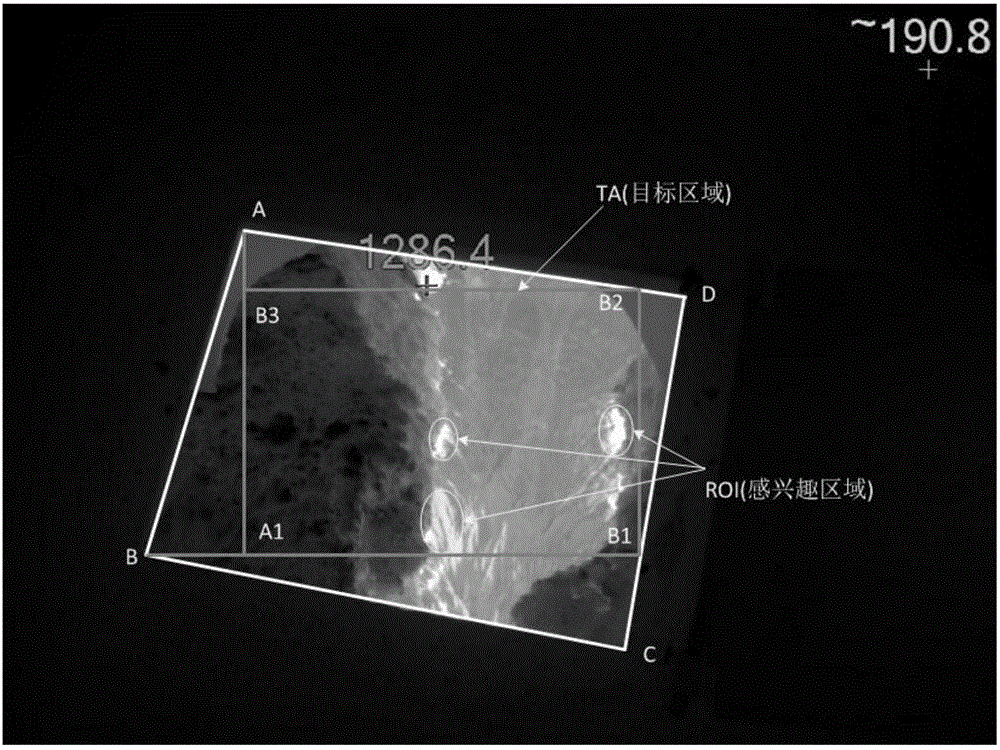

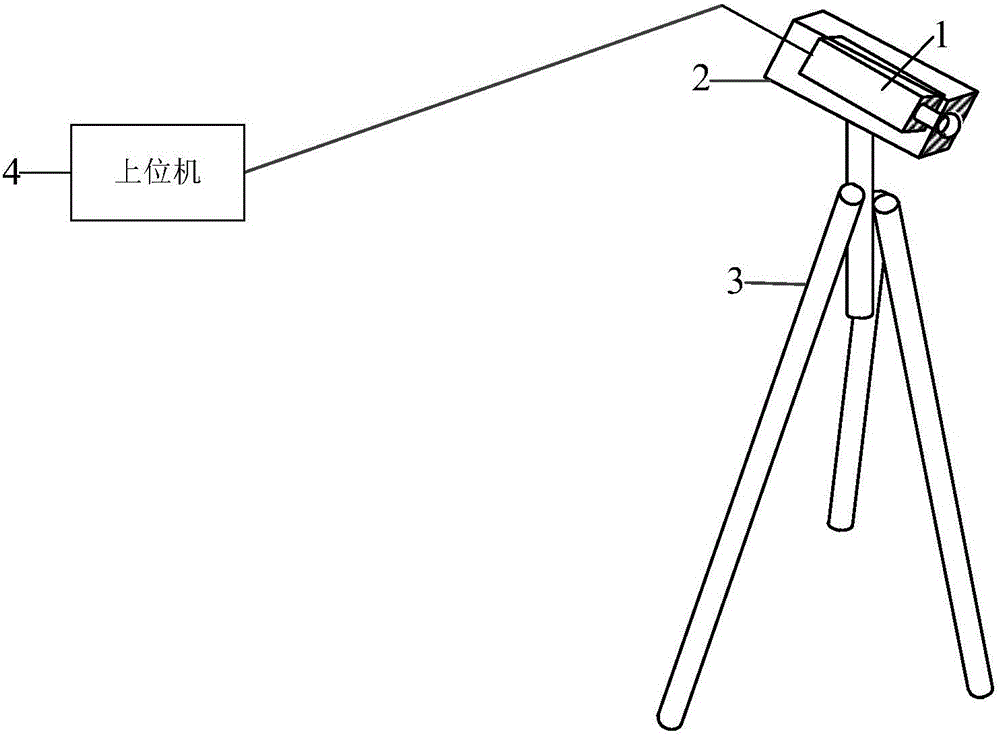

Non-contact molten metal solution temperature continuous monitoring method and system

ActiveCN106017691AHigh degree of automationAccurate detectionSensing heat from liquidsThermal thresholdContinuous monitoring

The invention provides a non-contact molten metal solution temperature continuous monitoring method and system. The method comprises the steps that an infrared thermal image which is acquired by an uncooled focal plane infrared thermography which shoots a molten metal solution through the opening of a safety mask above a blast furnace channel with the spacing of a preset time period; the infrared thermal image is processed, and an interested area ROI in a processed gray-scale image is determined, wherein ROI is a molten metal solution part which is not covered by an oxide film; temperature information corresponding to all pixels in the ROI is acquired; according to the actual temperature threshold of the molten metal solution, all pixels in the ROI are selected; according to the temperature information corresponding to the pixels retained by the ROI after selection, a temperature value extraction model is established to acquire the temperature value of the molten metal solution. According to the invention, fast, on-line, real-time, continuous and accurate temperature measurement can be carried out on the molten metal solution.

Owner:CENT SOUTH UNIV

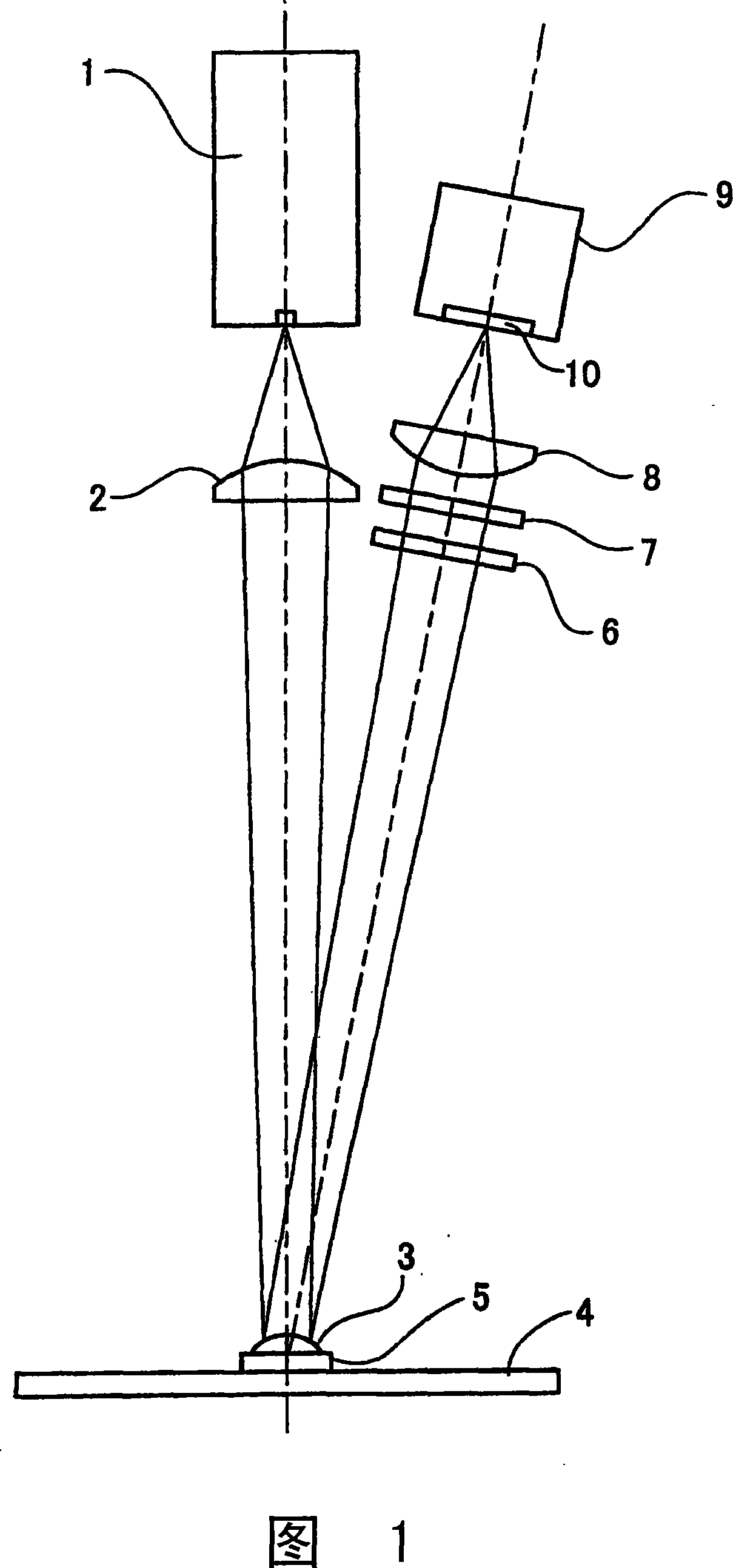

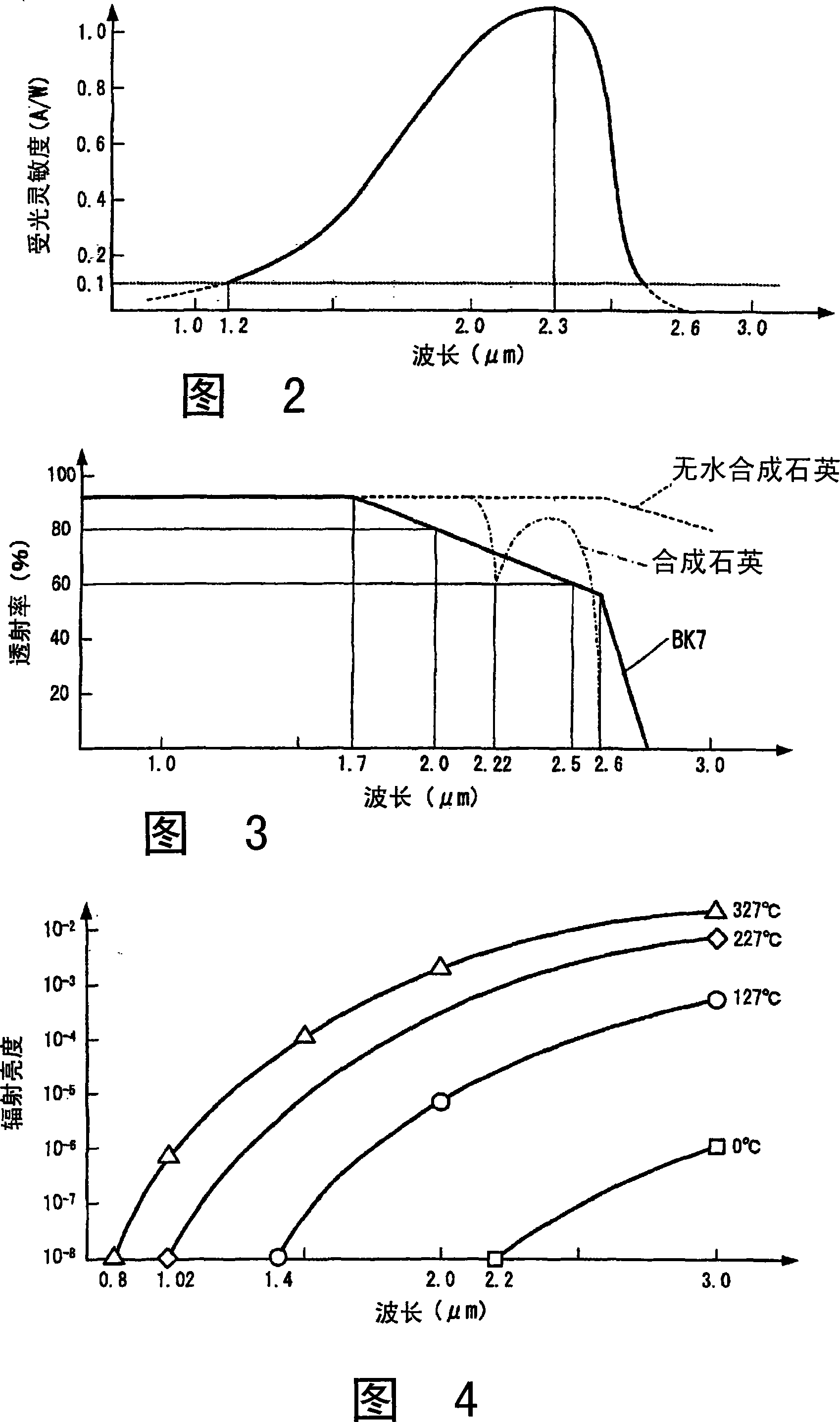

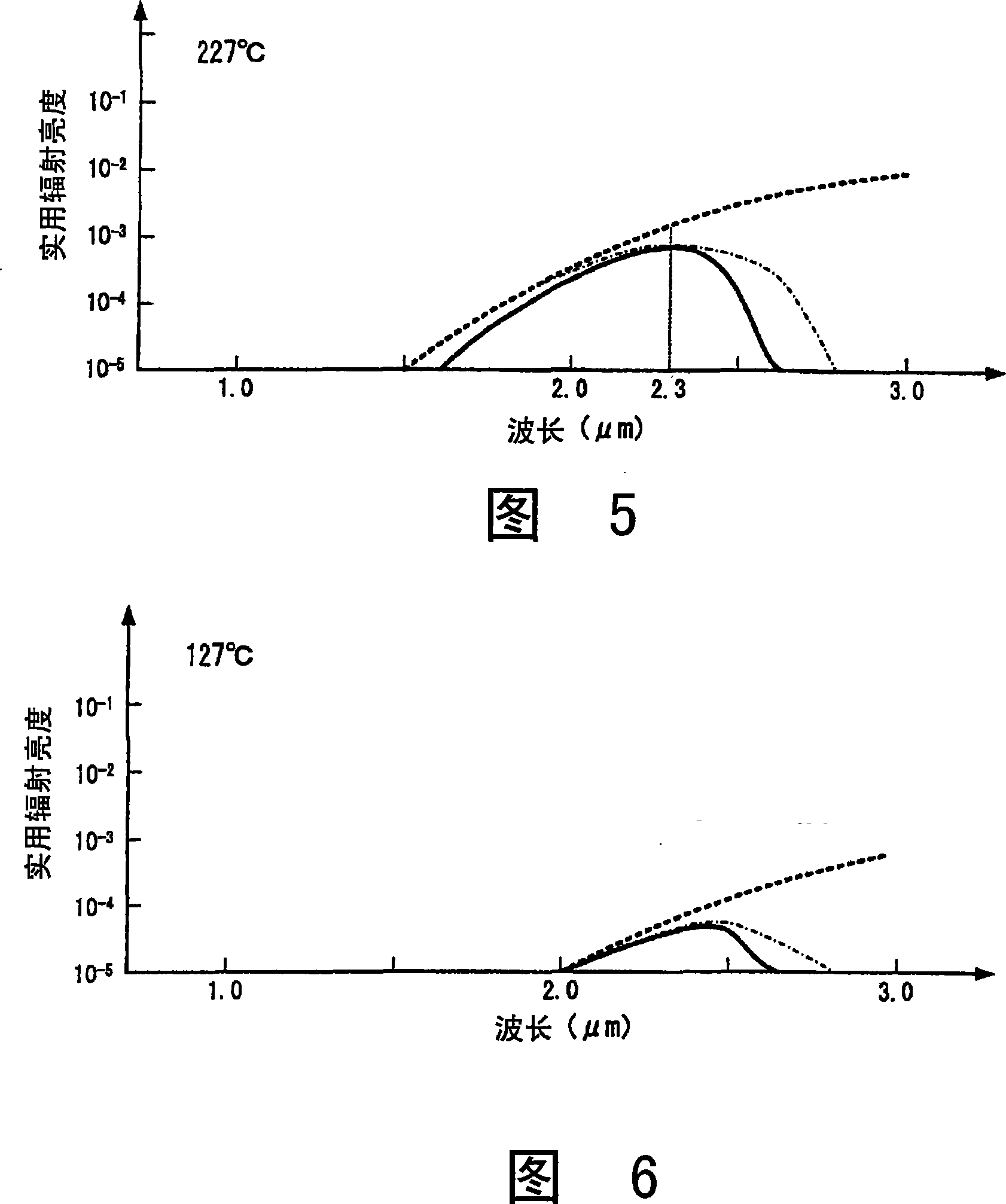

Laser heating device and laser heating method

InactiveCN101107501AAvoid burnsStable temperature controlLaser detailsPhotometryInfraredLaser heating

A laser heating device and a laser heating method enabling soldering that does not burn the periphery and resin bonding that does not burn resin by detecting a temperature change when solder or resin at a processing point is melted and an abnormal heating that may indicate a possible burn occurrence. An IR sensor (9) generates a signal based on the integrated value of the spectral radiation luminance of an IR ray radiated from solder to be heated. Prior to an actual soldering, a relational expression between the calibration values of an output signal from the IR sensor (9) and an actual master solder measuring temperature is determined in advance. At an actual soldering, an IR ray radiated from solder (3) is received by the IR sensor (9) and the temperature of the solder (3) is calculated based on an output signal from the IR sensor (9) and the above relational expression.

Owner:PANASONIC CORP

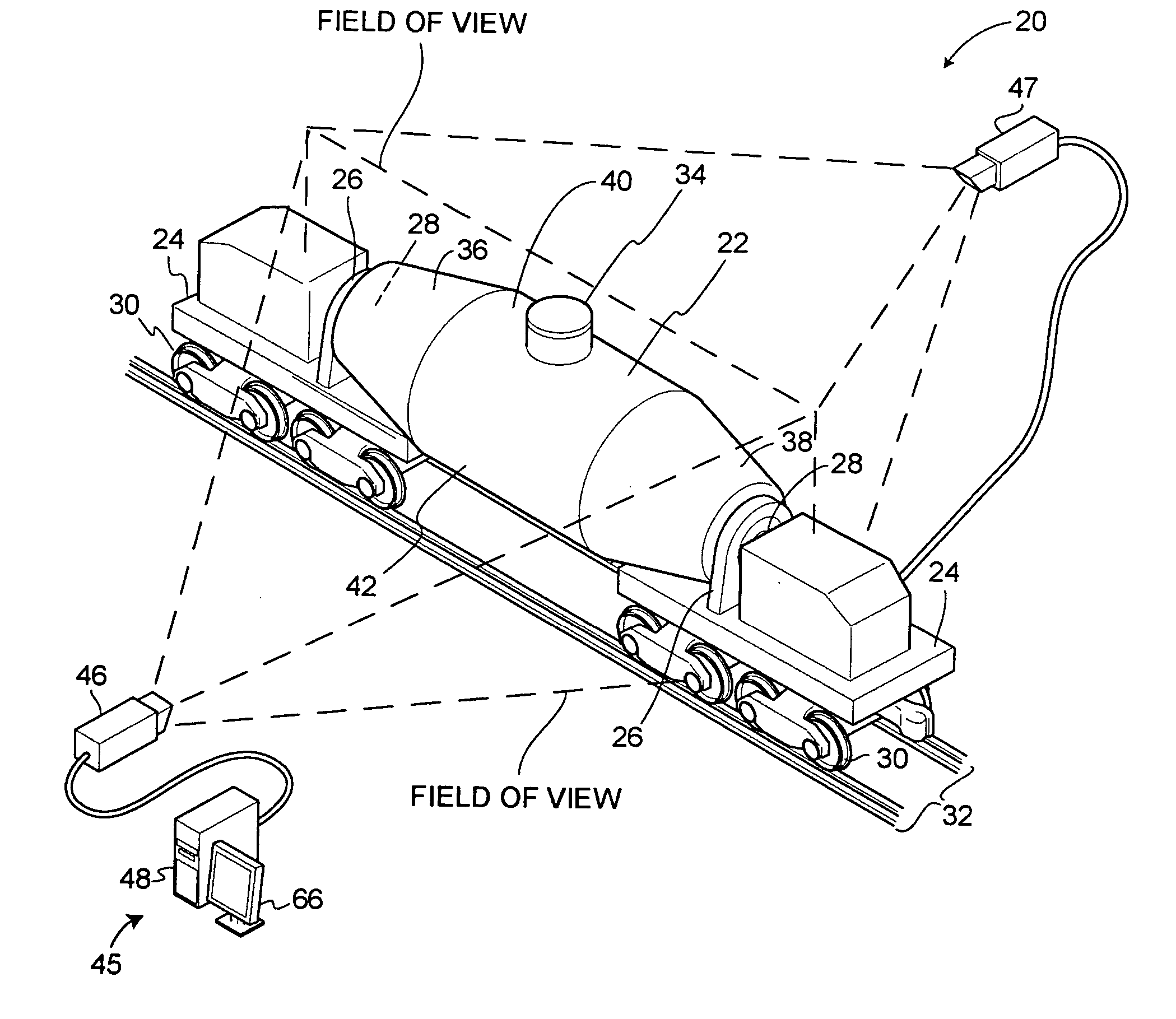

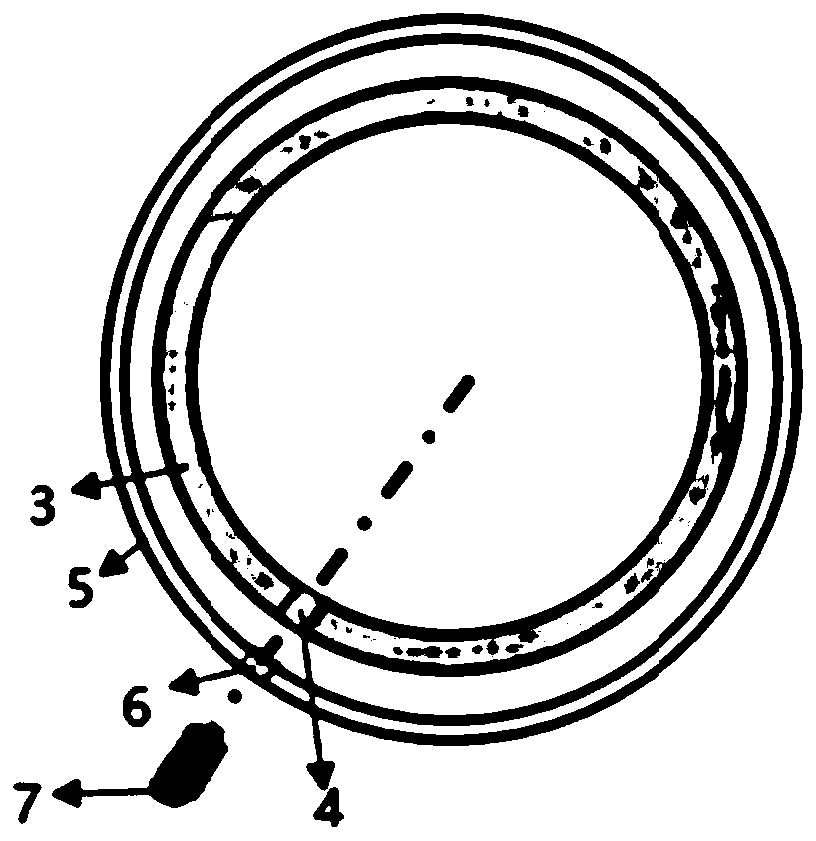

Apparatus and method of sensing the temperature of a molten metal vehicle

In accordance with one aspect of the disclosure, a method of sensing the temperature of a molten metal vehicle is provided. In one exemplary embodiment, the method includes utilizing at least one thermal imager located to the side of the molten metal during the dispensing of the molten metal and capturing at least one thermal image for determining the rotational position of the molten metal vehicle by calculating an area of the molten metal.

Owner:JOHN FLUKE MFG CO INC

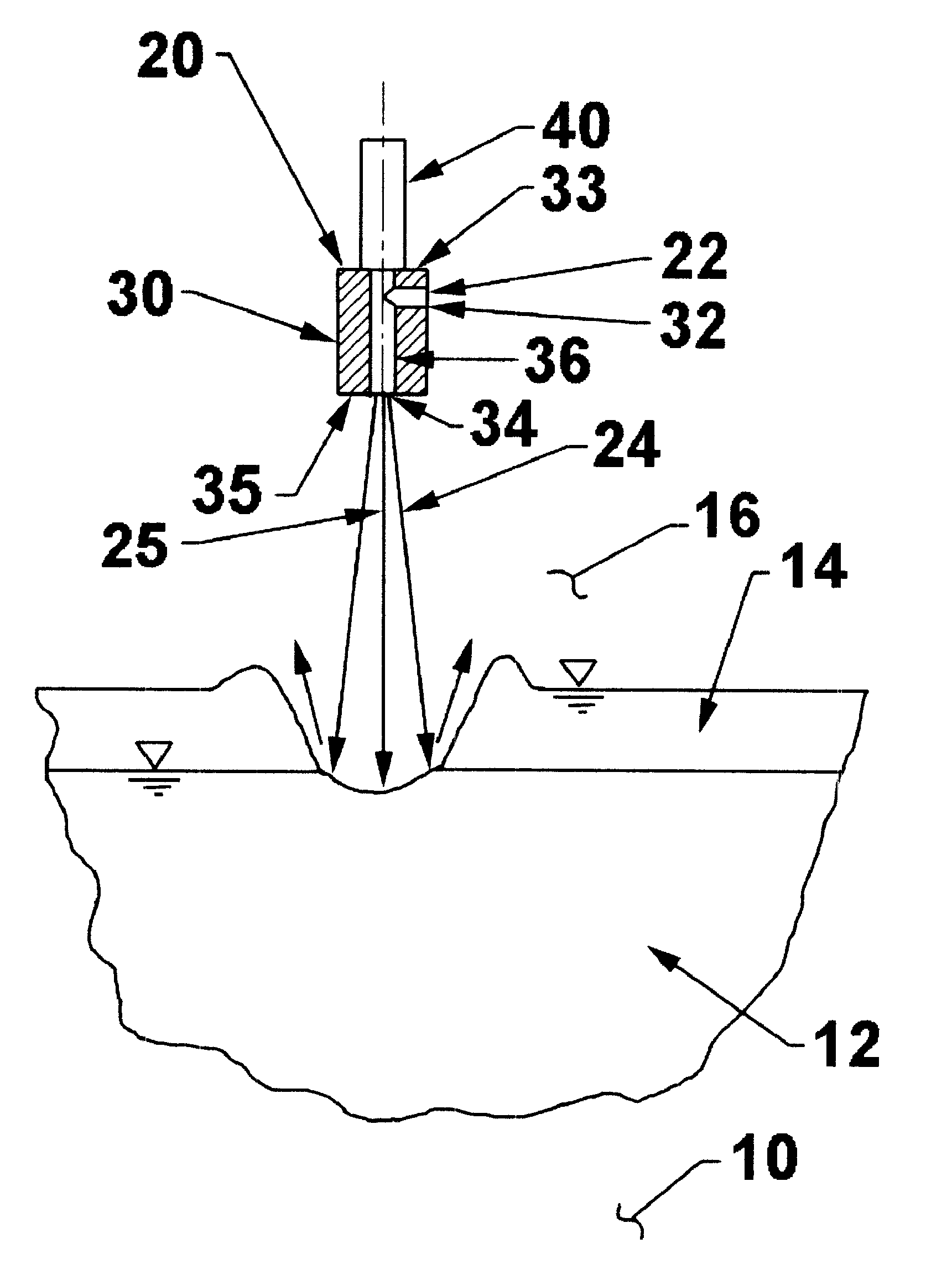

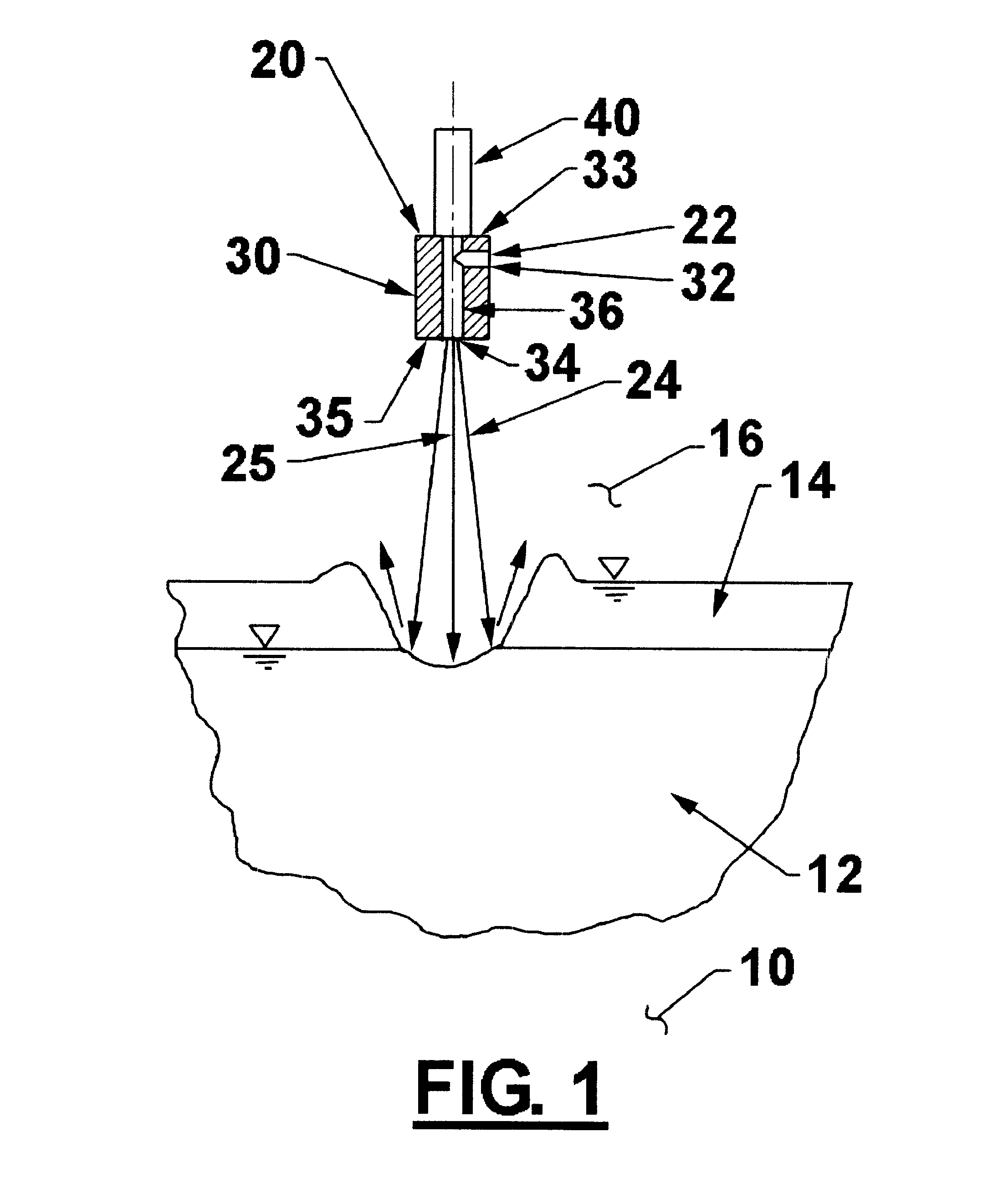

Remote sensing of molten metal properties

InactiveUS6596995B1Thermometer detailsMaterial analysis by optical meansMaterials scienceMolten metal

Provided are methods and apparatuses for the sensing of a property of a molten metal that lies beneath layers of interfering matter. A stream of gas is propelled into the layers of interfering matter at a velocity that is sufficient for the gas to penetrate through the layers of interfering matter and into the molten metal, thereby providing an opening through the layers of interfering matter. At the same time, energy emanating from the molten metal is detected and measured through the opening, so as to obtain an energy measurement. Then, the energy measurement is processed to determine a value for the desired property of the molten metal.

Owner:BENDER MANFRED

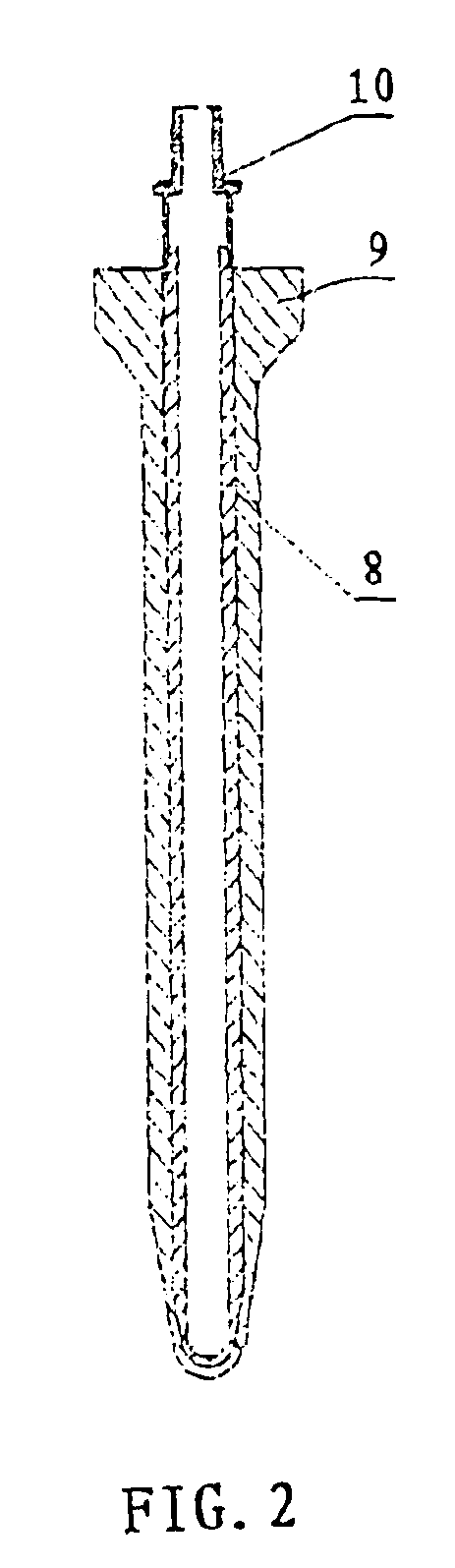

Method for continuously measuring melting steel temperature and measuring temperature pipe

InactiveUS6846105B2Radiation stableLow costThermometer detailsThermometers using electric/magnetic elementsMetallurgyMolten steel

The invention discloses a method for measuring the temperature of a molten steel continuously, comprises the following steps: providing a tube that is made of double bushings, both of the inner and outer bushings being close at one end and open at another end; putting the close end of the tube into the molten steel in such a way that the ratio of the length of the tube under the surface of the molten steel to the inner diameter of the inner bushing is equal or greater than 15 and the ratio of said length to the outer diameter of the outer bushing is greater than 3; connecting the open end of the tube with an infrared detector; and calculating the temperature of the molten steel through evaluating the radiation emitted by the inner bushing at the end that was put under the molten steel by means of the detector. A tube to implement the method is also disclosed.

Owner:NORTHEASTERN UNIV +1

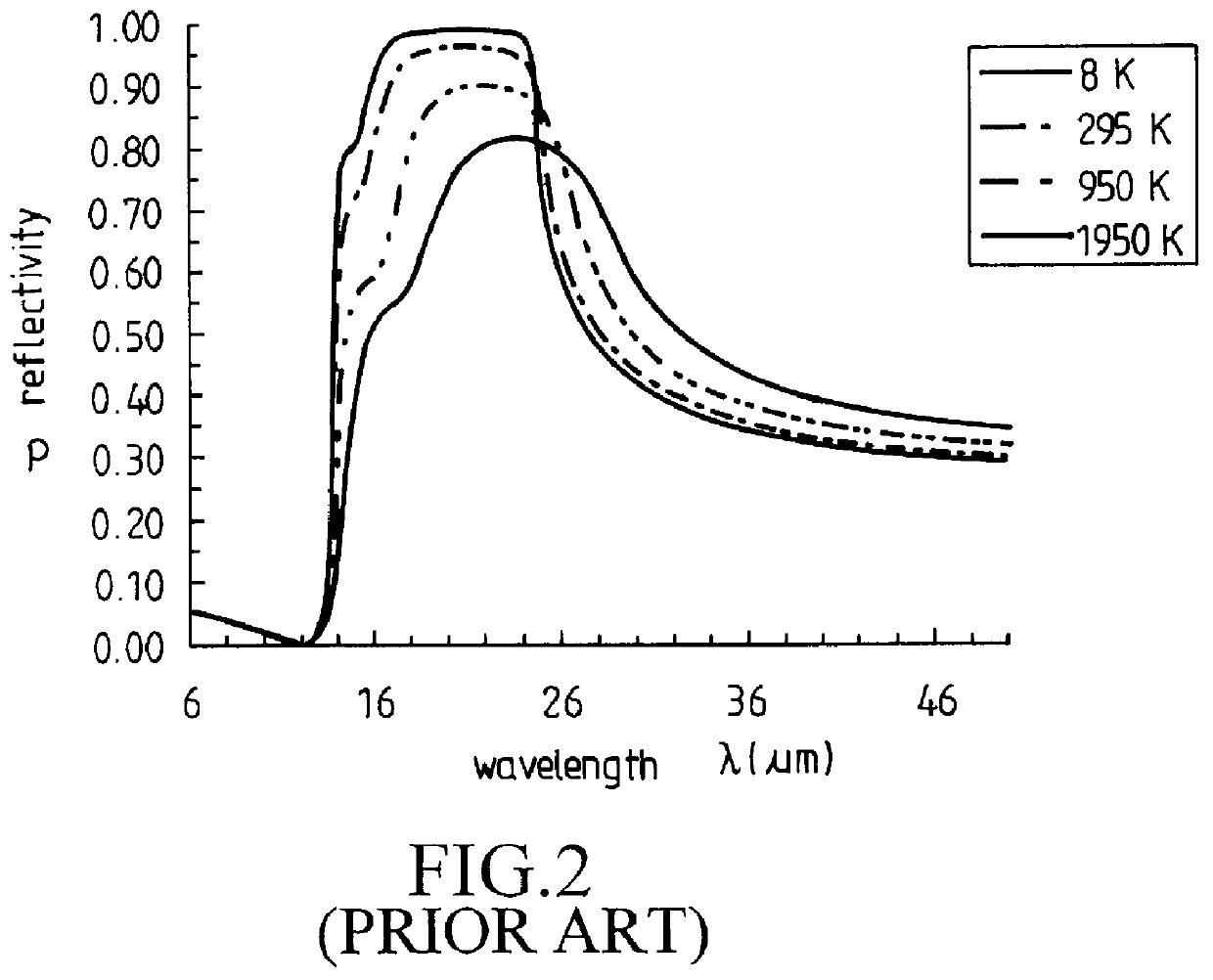

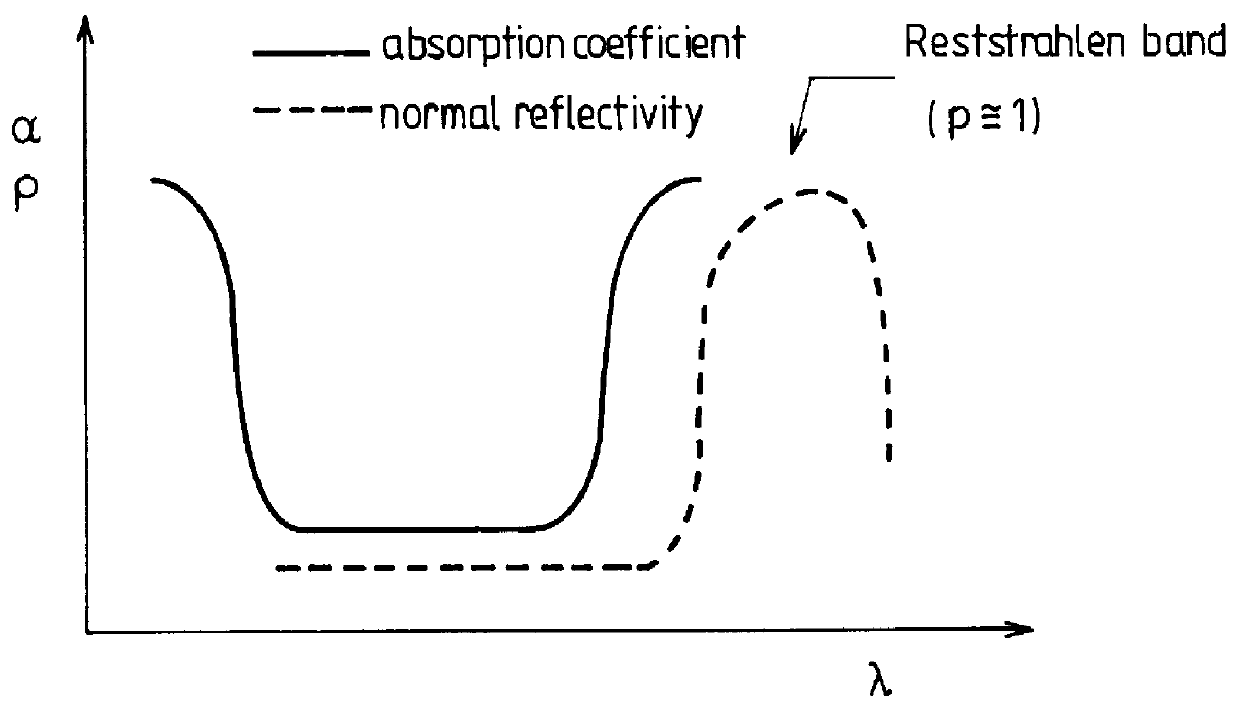

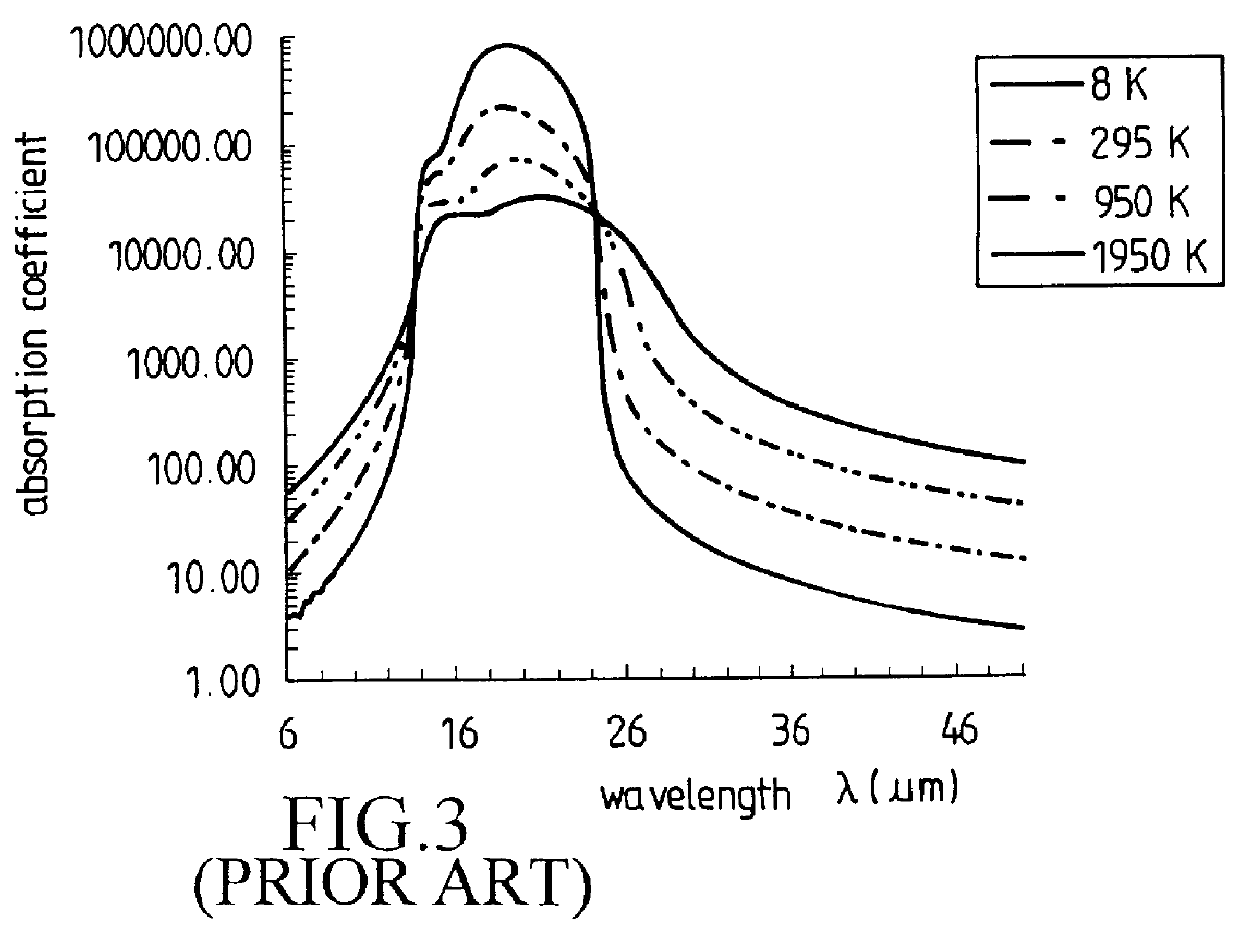

Non-contact method for measuring the surface temperature distribution of a melt during growth of ionic crystals

InactiveUS6074087ASpecific opticalReduce errorsThermometers using mean/integrated valuesSensing heat from liquidsPlanck's lawHigh absorption

The subject invention relates to a technique employing a calibrated thermal radiometer, and the radiation characteristics of ionic crystals to measure the temperature distribution of crystals during crystal growth. When in high temperature, the ionic crystals often exhibit a transparent region having low reflectance, and low absorption in the spectrum between the short-wavelength absorption edge and the long-wavelength absorption edge. In addition, these crystals have an opaque spectral region having low reflectance and high absorption, i.e. have surface radiation of high emissivity when the spectrum is in the range between the long-wavelength absorption edge and the onset of the Reststrahlen band. The spectral emissivity of the ionic crystal may not change significantly with a variation of temperature in this opaque region. According to Planck's law, the surface temperature distribution during crystal growth can be obtained after the surface radiation of the opaque region is detected, and the emissivity at the melting point is calculated.

Owner:NAT SCI COUNCIL

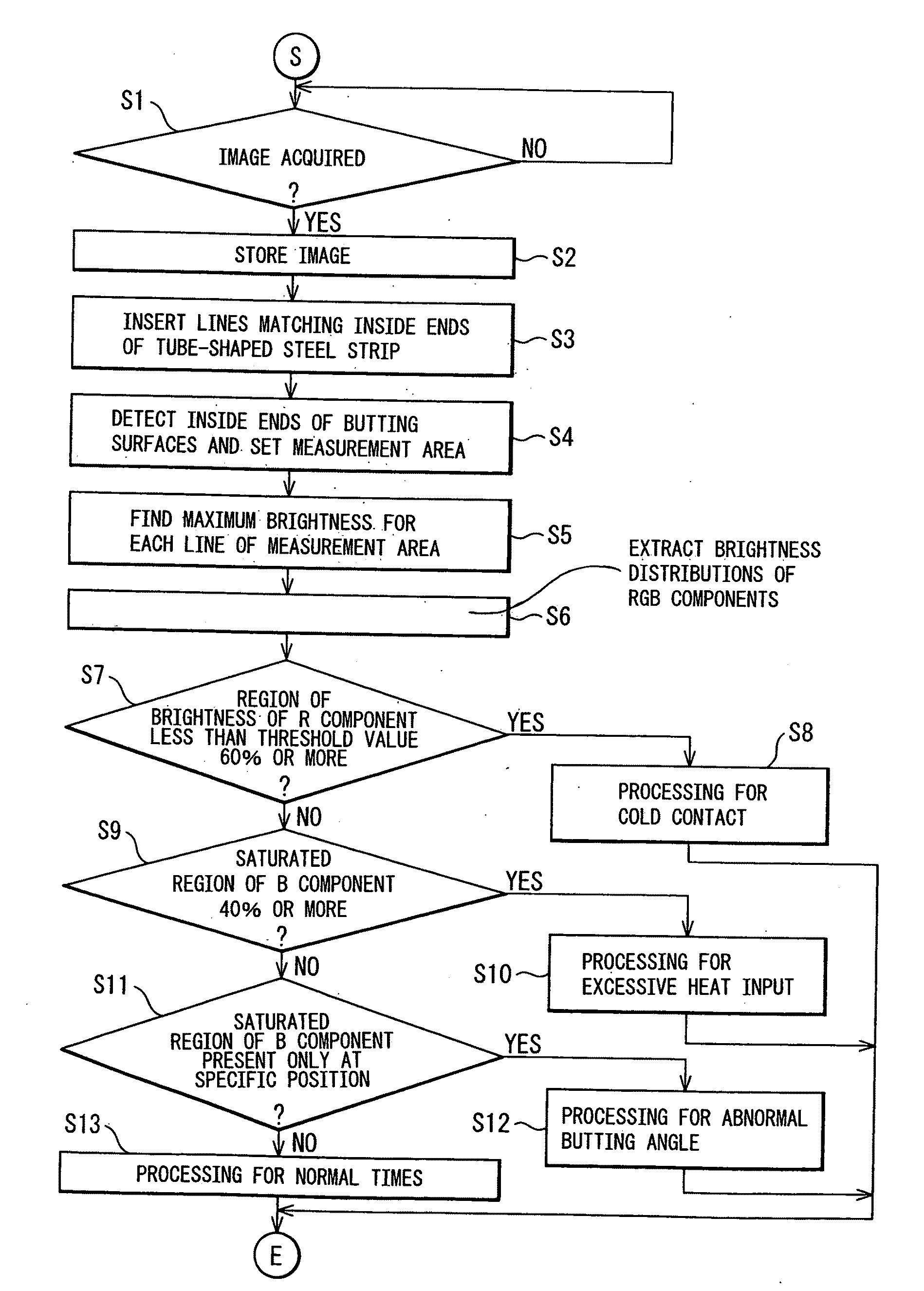

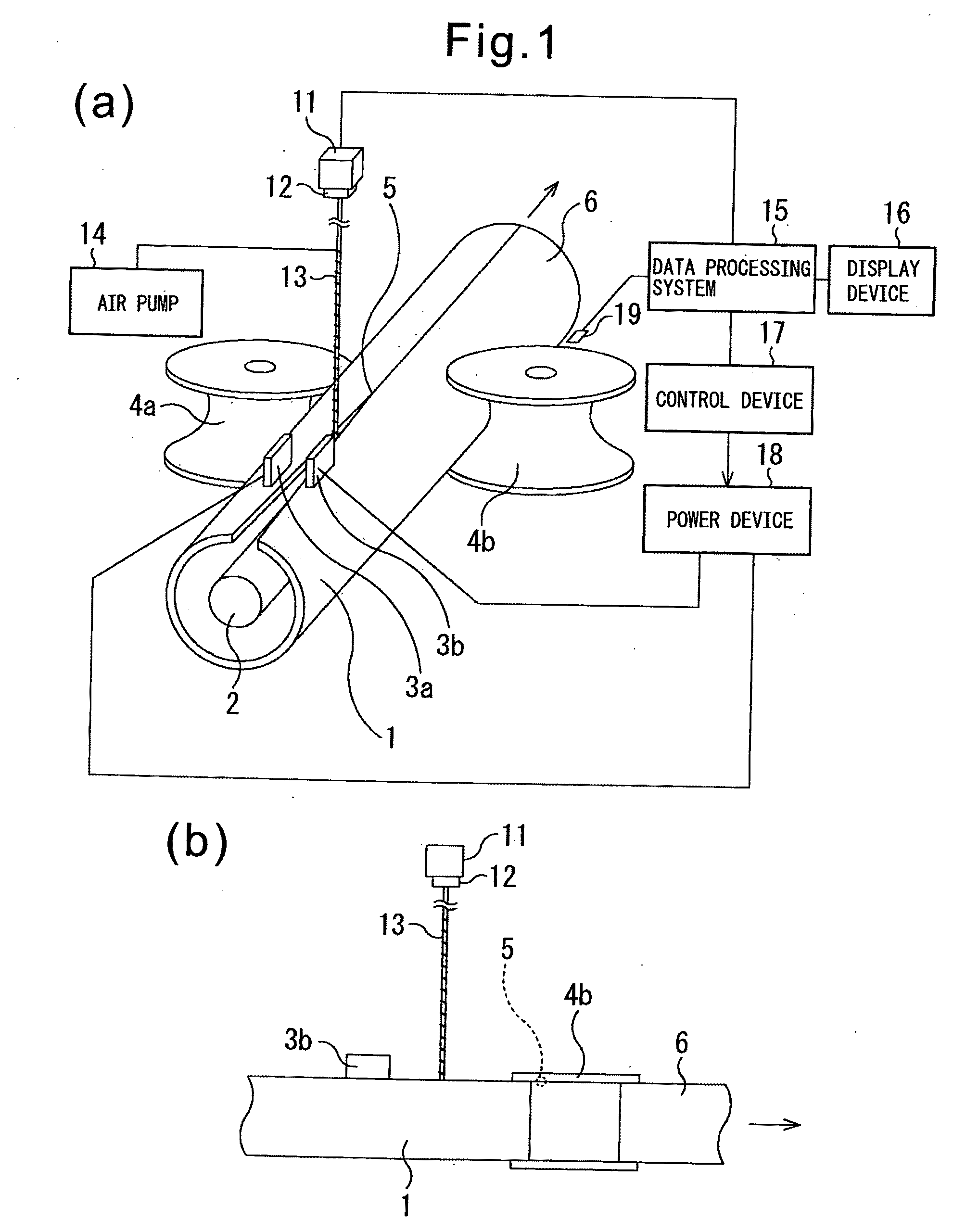

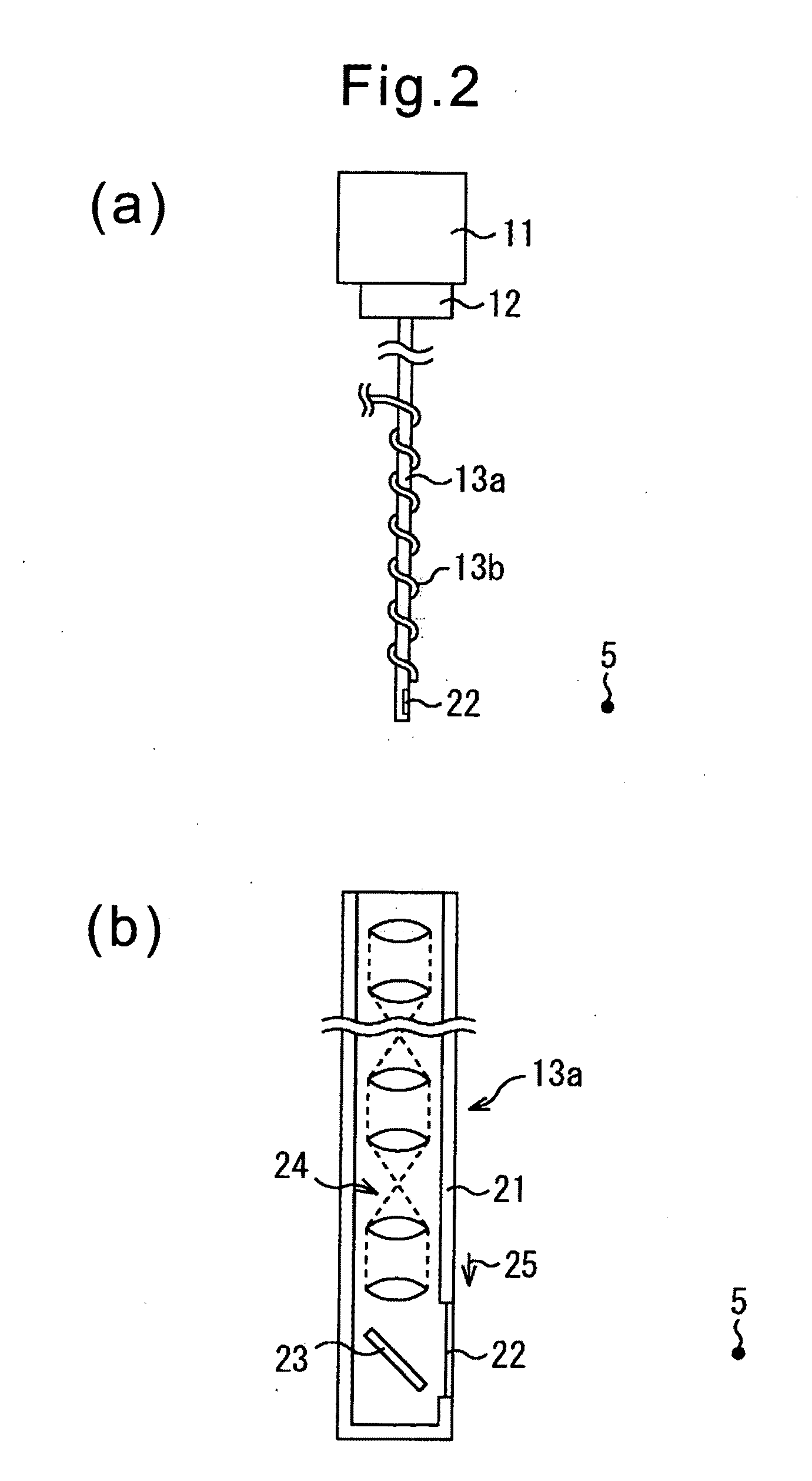

System and method for monitoring of welding state

ActiveUS20100232678A1Easily understandable formatImprove accuracySensing radiation from gases/flamesCharacter and pattern recognitionMolten stateImage resolution

A system and method for monitoring the molten state for enabling a molten state, butting state, or other state of electric-resistance-welded pipe on-line more accurately than in the past are provided. That is, a mirror 23 provided at a front end side inside a container 21 receives light emitted by the welded parts 5 of the tube-shaped steel strip 1 themselves through heat resistant glass 22 from the side direction and reflects the image of the welded parts 5 of the tube-shaped steel strip 1 in the direction of a relay lens 24 provided at a base end side of a relay lens unit 13. The relay lenses 24 relay the image of the welded parts 5 of the tube-shaped steel strip 1 to a conversion lens 12, then the conversion lens 12 forms that image on the imaging area of a CCD camera 11. Therefore, it is possible to capture the welded parts 5 of the tube-shaped steel strip 1 from the side direction by a resolution in accordance with the resolution of the CCD camera 11 and possible to obtain information of the welded parts 5 of the tube-shaped steel strip 1 more accurately than in the past and on-line.

Owner:NIPPON STEEL CORP

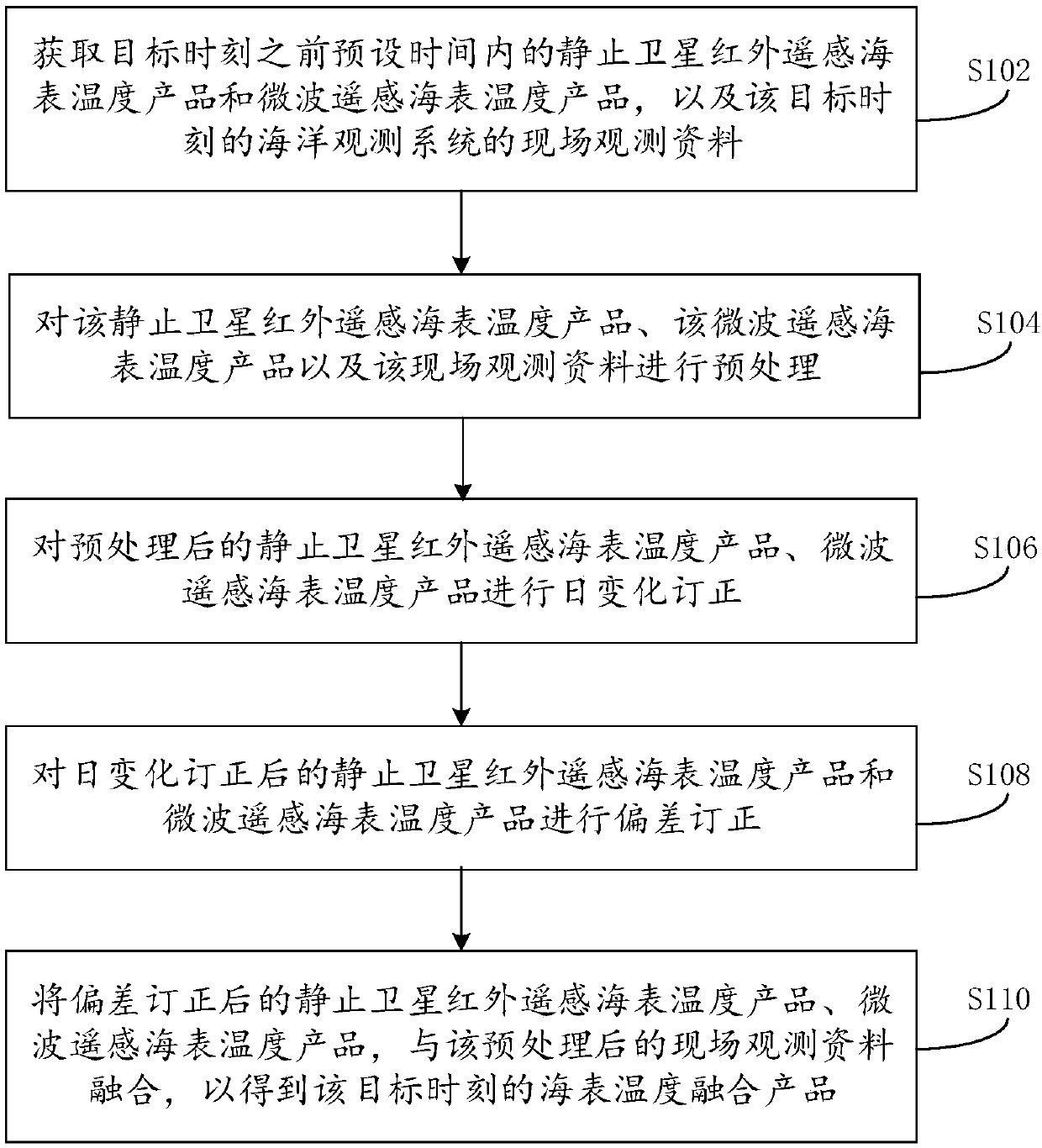

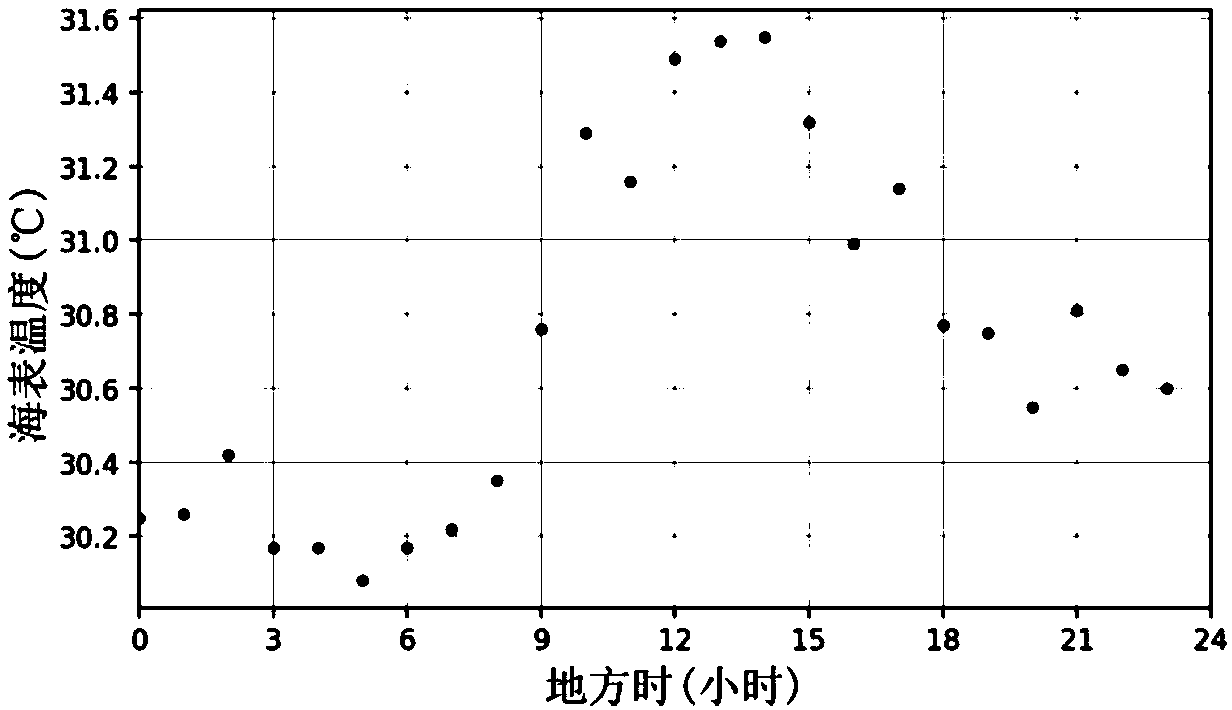

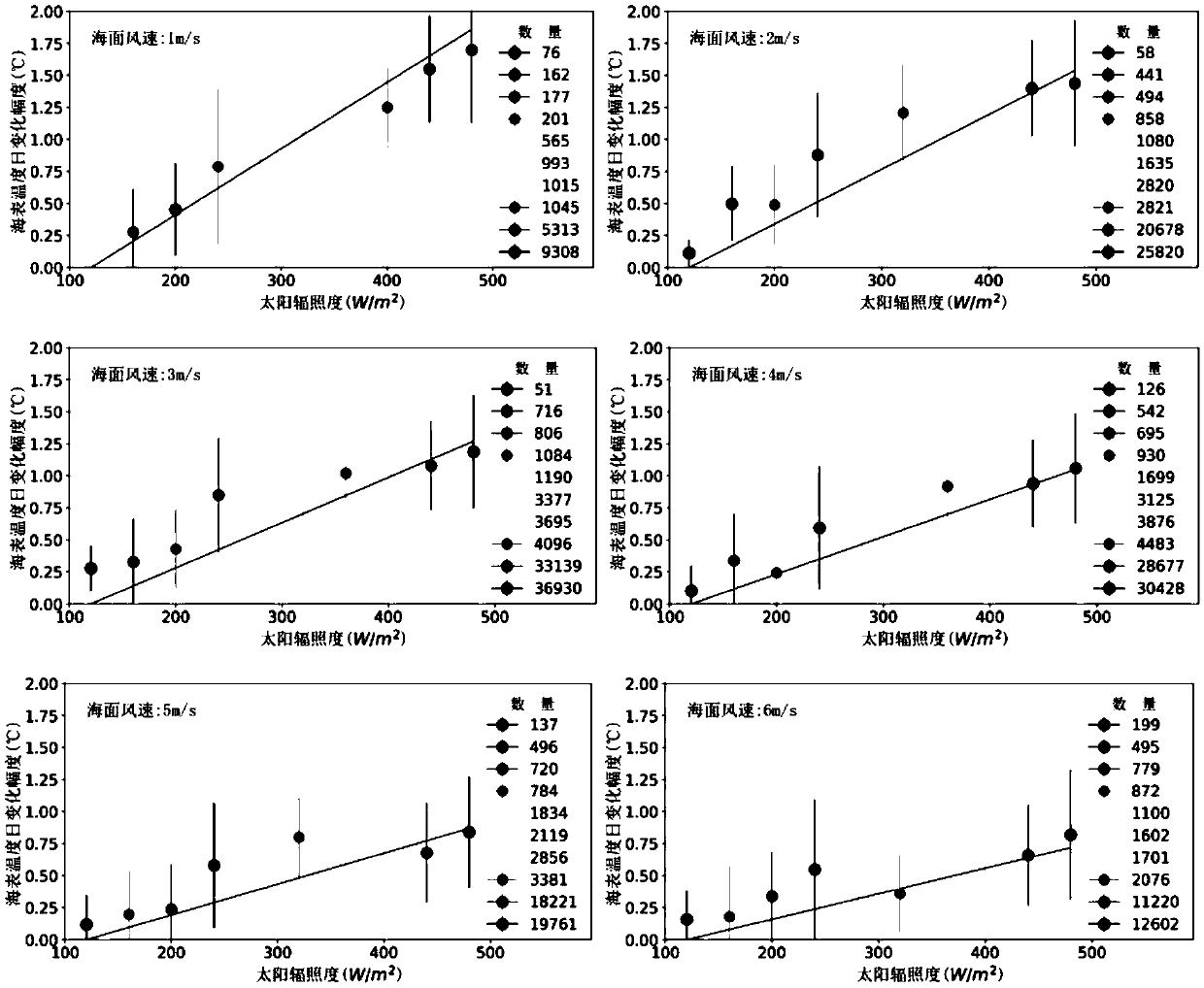

Sea surface temperature fusing method and system

ActiveCN109668635AImprove space coverageImprove spatial resolutionSensing heat from liquidsObservation dataInfrared remote sensing

The invention provides a sea surface temperature fusing method and system, and relates to the technical field of sea information. The method comprises the following steps: acquiring stationary satellite infrared remote sensing and microwave remote sensing sea surface temperature products in preset time before a target moment and on-site observation data of a sea observation system at the target moment; preprocessing the sea surface temperature products and the on-site observation data; carrying out daily change correction on the preprocessed sea surface temperature products; carrying out deviation correction on the stationary satellite infrared remote sensing temperature products and the microwave remote sensing sea surface temperature products subjected to daily change correction; fusingthe stationary satellite infrared remote sensing temperature products and the microwave remote sensing sea surface temperature products subjected to daily change correction with the preprocessed on-site observation data, so as to obtain sea surface temperature fusing products at the target moment. The sea surface temperature fusing method and system of the embodiment of the invention are capable of obtaining the sea surface temperature fusing products with high time-space resolution, high space coverage degree, gradual time level and high accuracy.

Owner:中国人民解放军61741部队

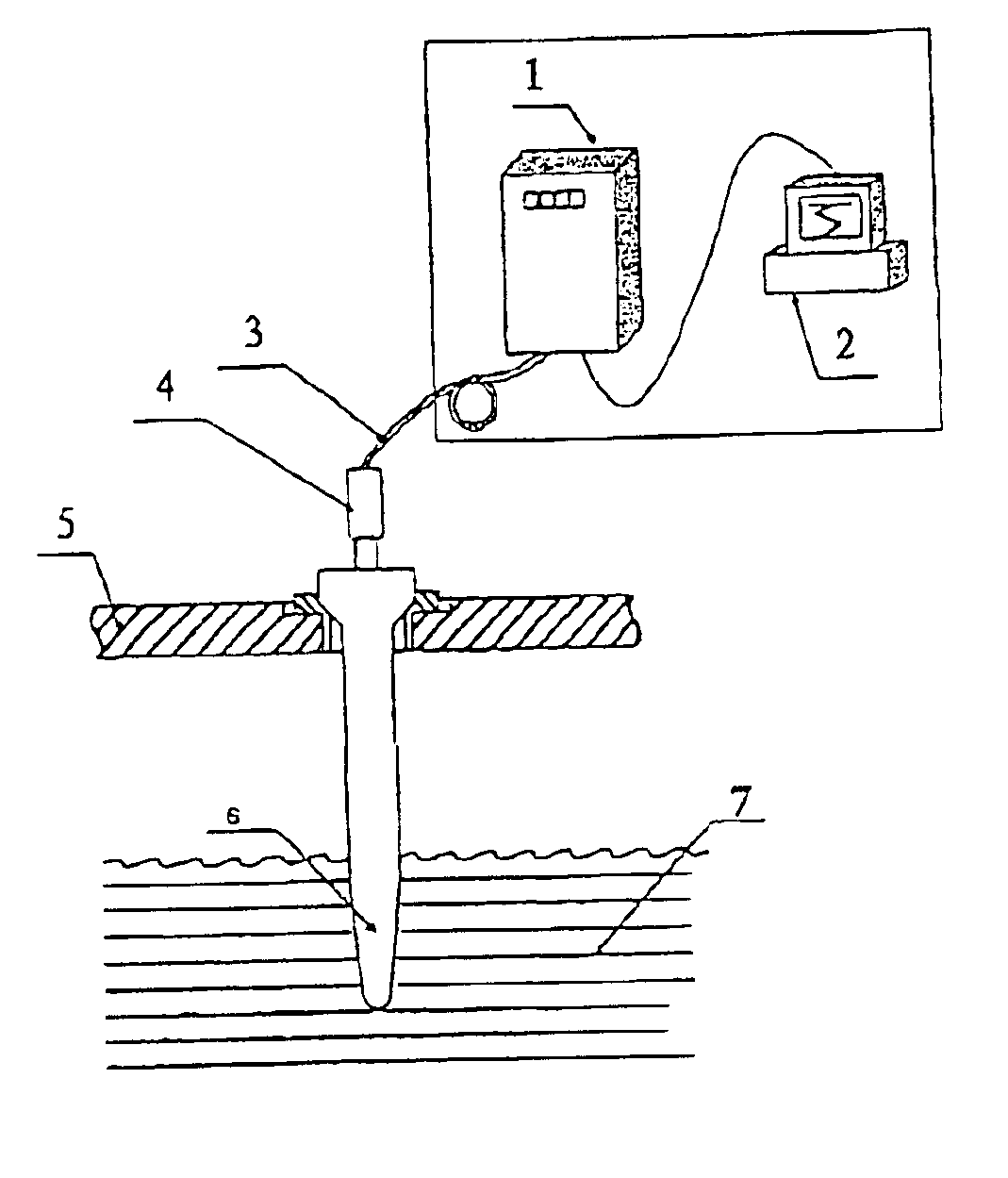

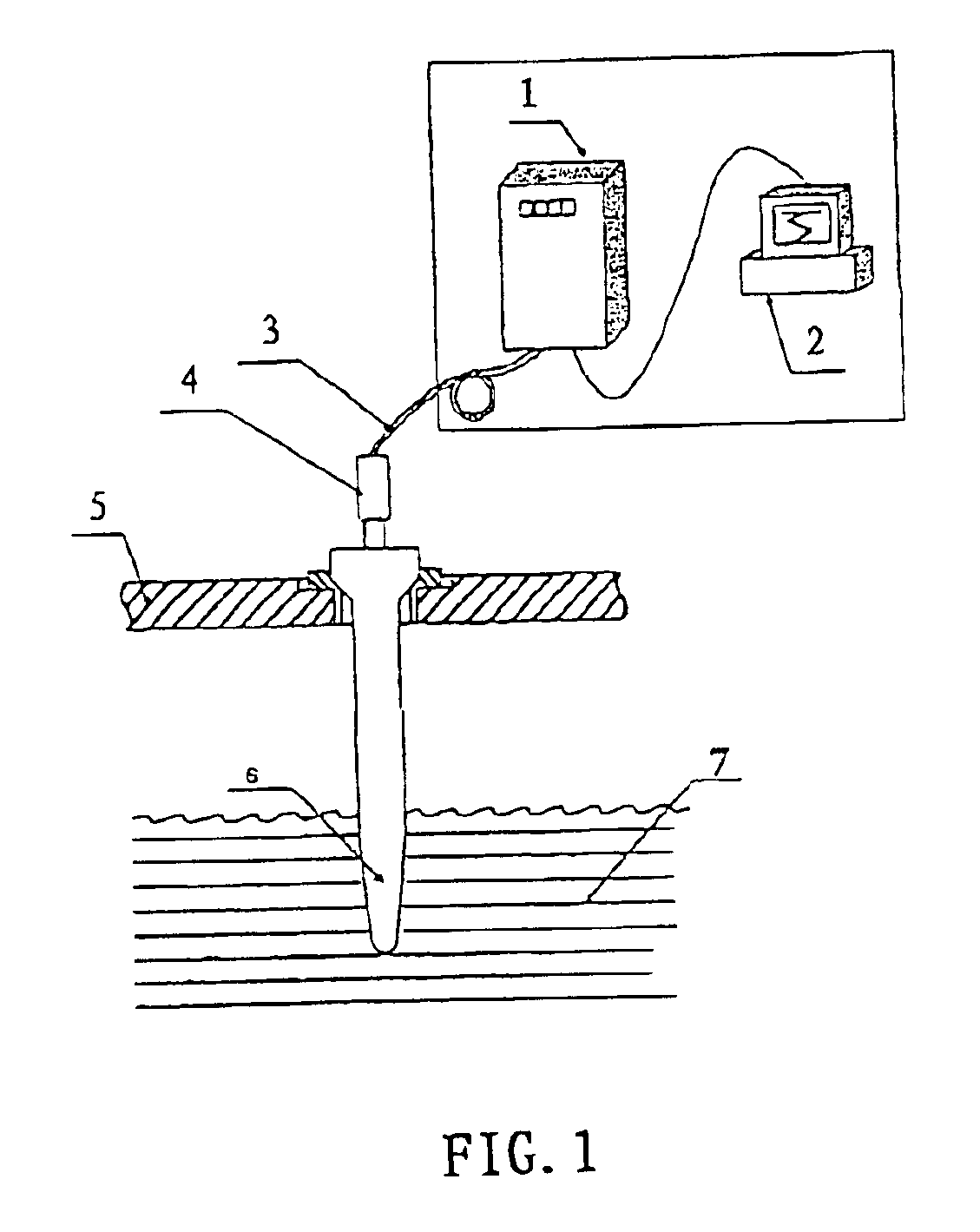

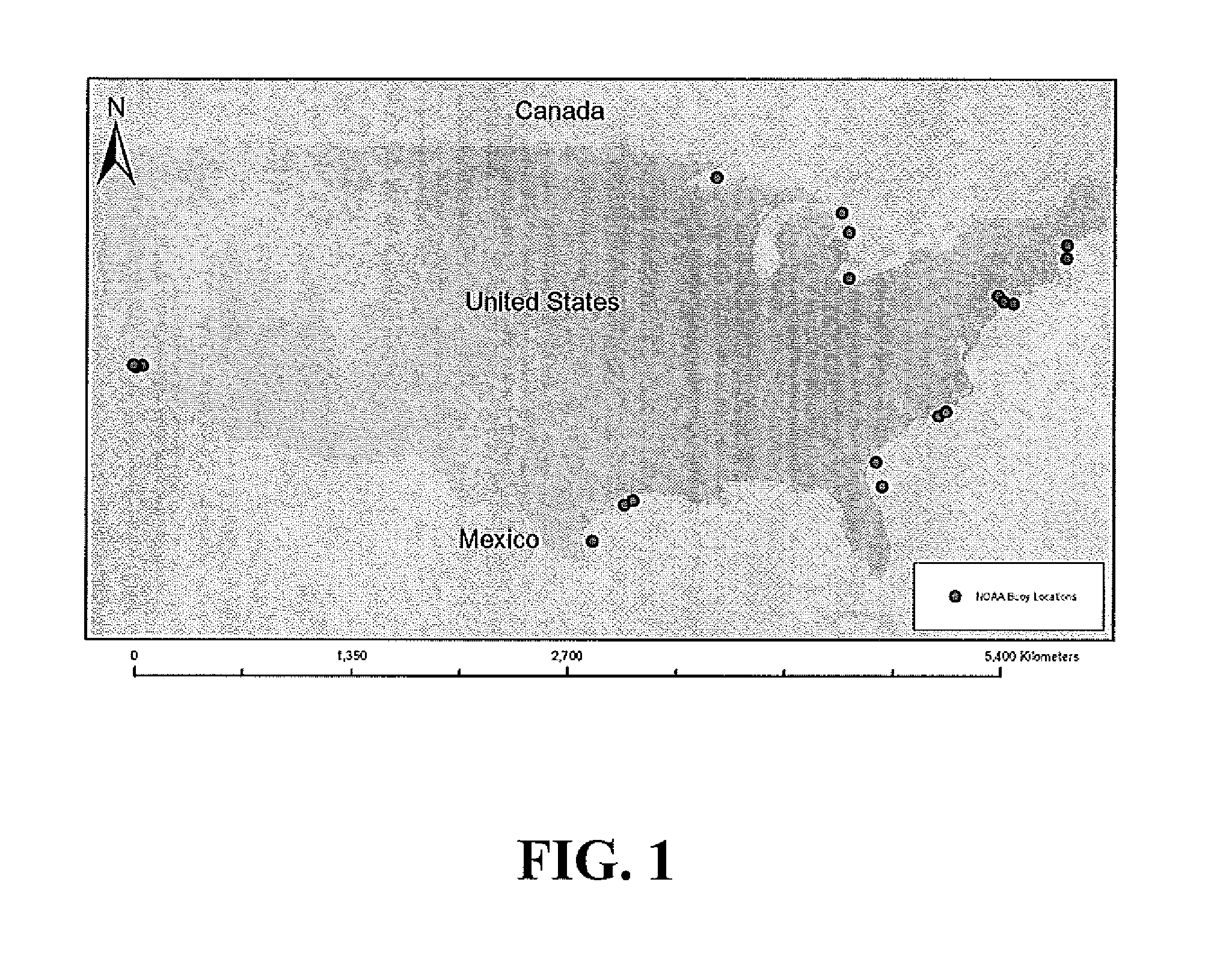

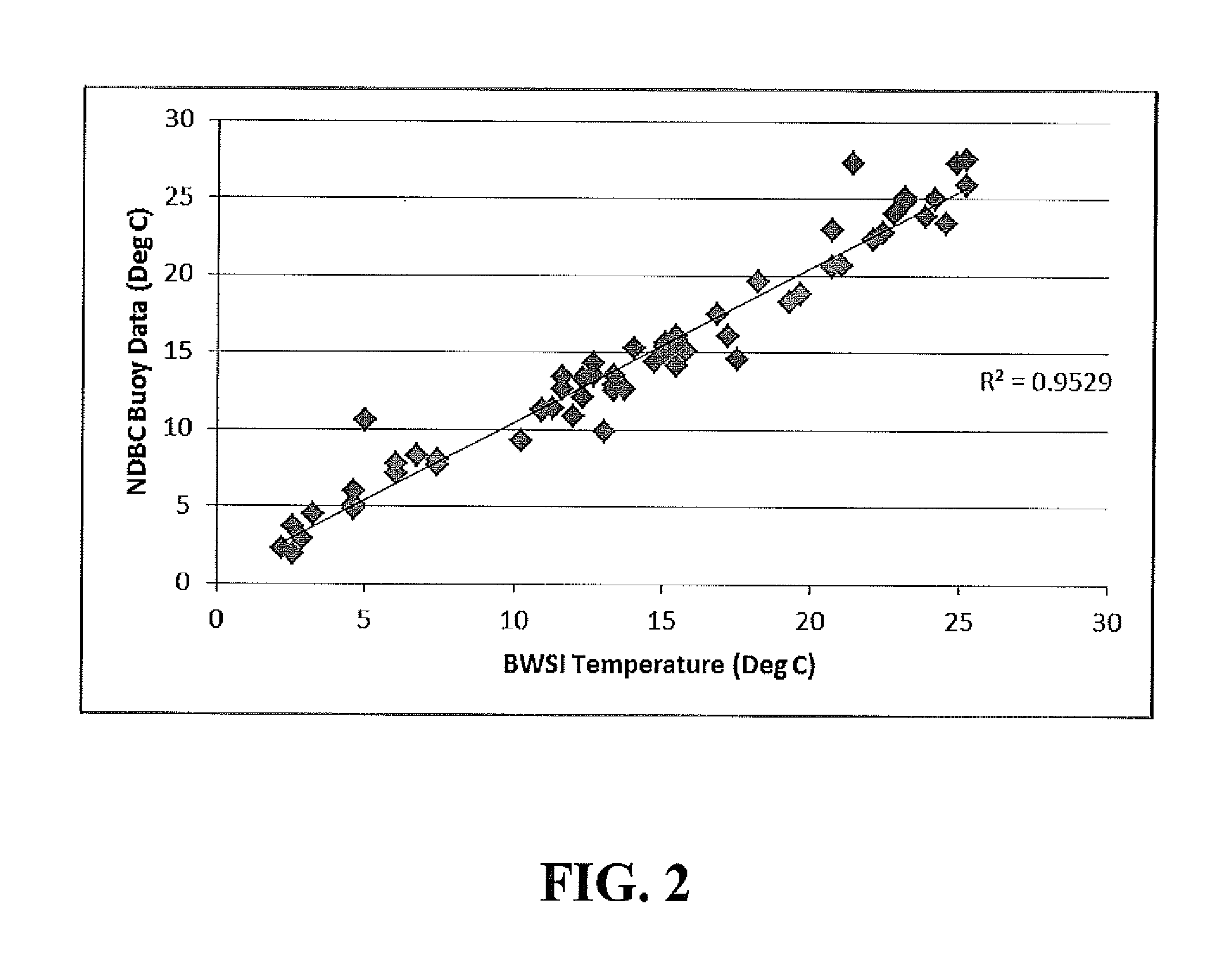

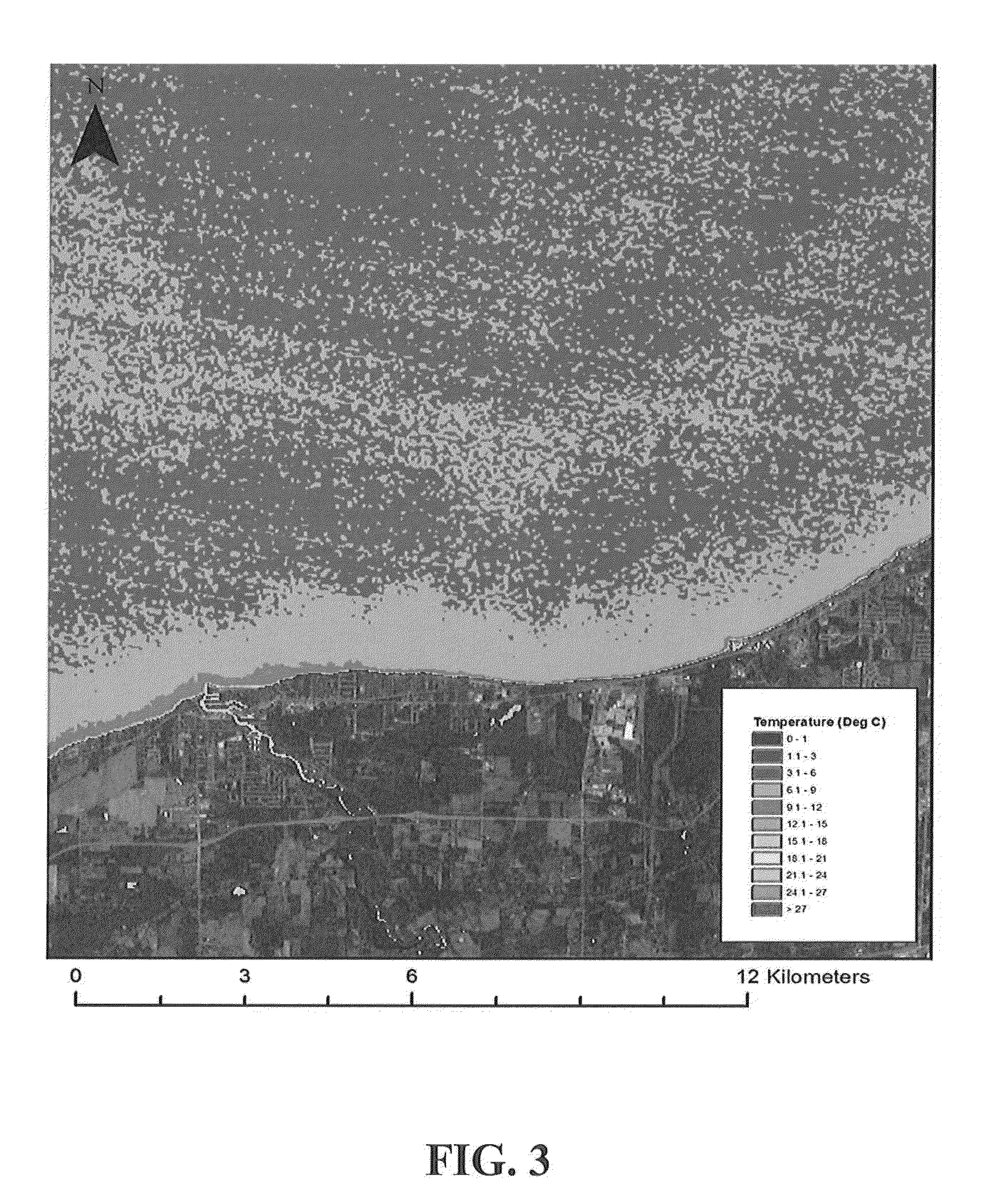

Method for monitoring water temperature

InactiveUS20140016667A1Drawing from basic elementsTesting waterSatellite imageryAtmospheric sciences

Methods are provided for monitoring water temperature using light reflected therefrom, where measurement of reflected light can be obtained from satellite imagery. Such methods include determining a temperature of a body of water by obtaining a measurement of thermal radiation from at least a portion of the body of water. The temperature of at least the portion of the body of water is then determined from the thermal radiation measurement by applying an algorithm relating the measurement to the temperature. The determined temperature can be output in various ways, including as numerical data and as graphical data, such as a temperature map of the body of water.

Owner:SANDERSON LOUIS M

System and methods for real-time enhancement of build parameters of a component

ActiveUS10112262B2Limited amountAccelerate buildingProgramme controlAdditive manufacturing apparatusControl signalElectric signal

A direct metal laser melting (DMLM) system includes a laser device configured to generate a melt pool in a powder bed based on a build parameter. In addition, the DMLM system includes a confocal optical system directed at the melt pool and configured to receive an optical signal emitted by the melt pool. The DMLM system further includes an optical sensor operatively coupled to the confocal optical system that is configured to receive the optical signal and to generate an electrical signal in response to the optical signal. A computing device is configured to receive the electrical signal from the optical sensor and to generate a control signal in response. The control signal is configured to modify the build parameter of the direct metal laser melting system in real-time to adjust at least one of a melt pool size and a melt pool temperature to achieve a desired physical property of the component.

Owner:GENERAL ELECTRIC CO

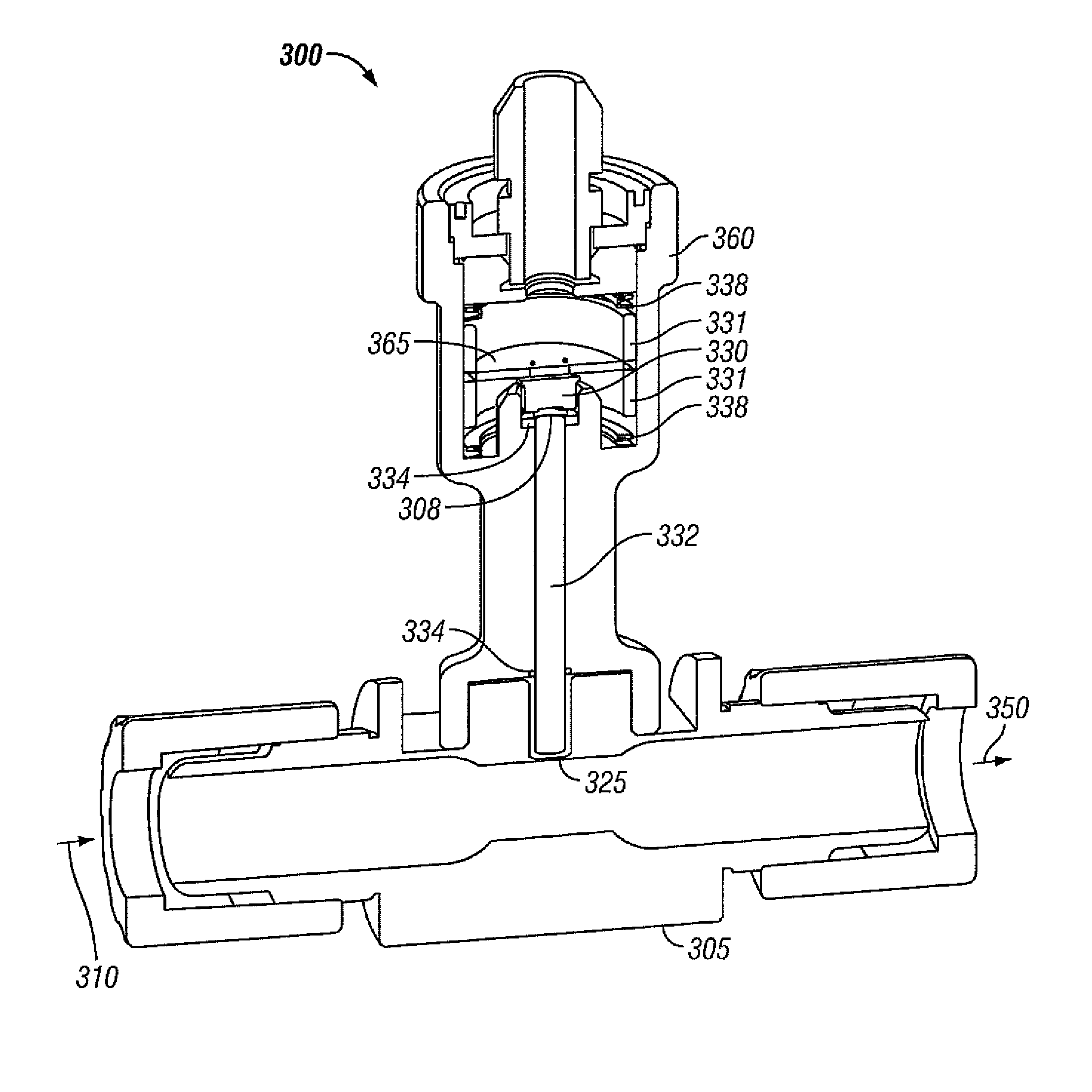

System and Method for Non-Intrusive Thermal Monitor

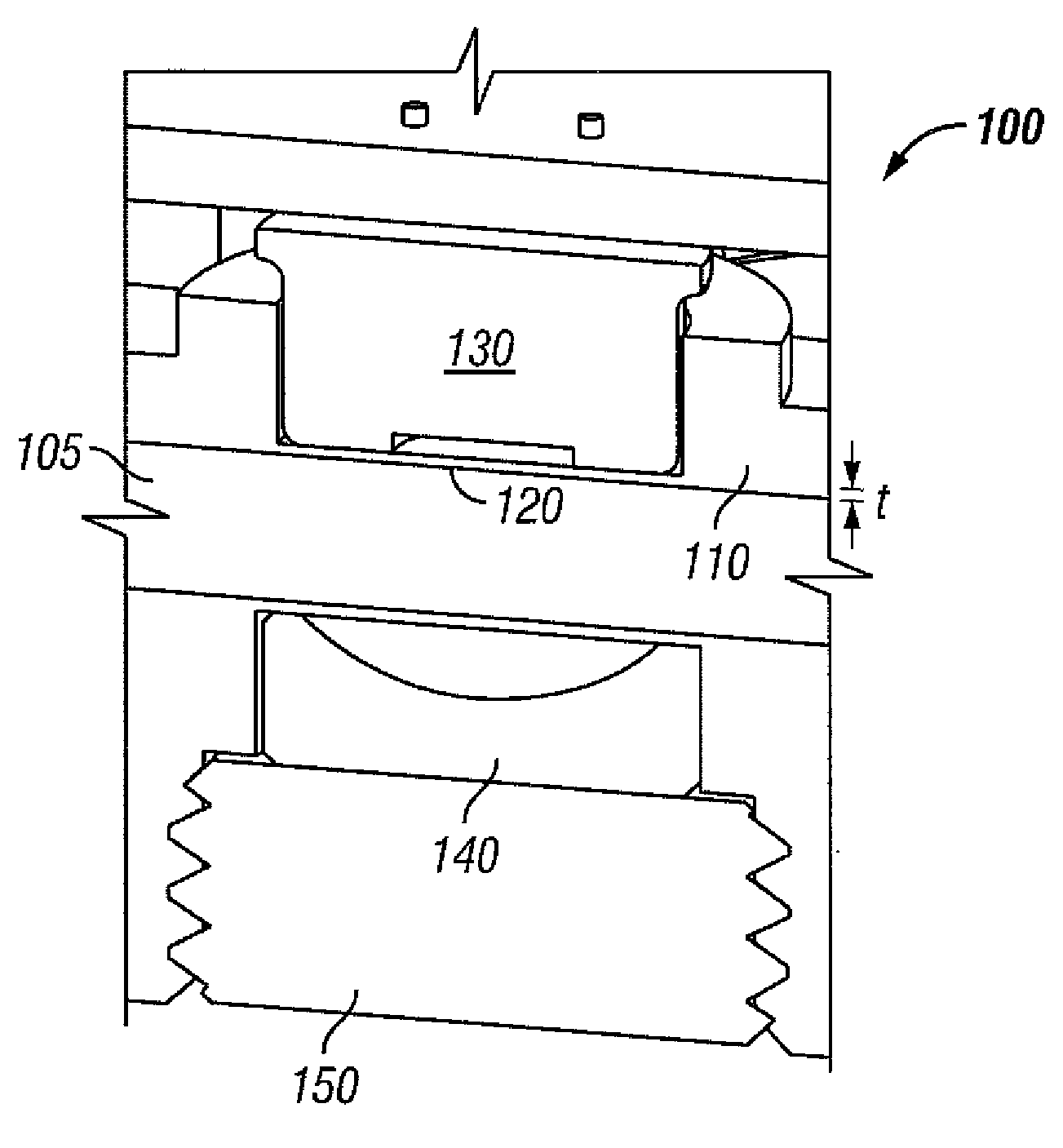

InactiveUS20080225925A1Improve performanceExtend the lifespanThermometer detailsSensing heat from liquidsThermopileEngineering

Embodiments disclosed herein provide a non-intrusive thermal (NIT) monitor for sensing temperatures useful for semiconductor manufacturing applications. In some embodiments, a NIT monitor comprises a thermopile, a fluid housing with a fluid window, and an elongated member positioned between the thermopile and the fluid window for transmitting or reflecting infrared signals corresponding to a temperature of a fluid in the fluid housing. The fluid housing may have a cross-sectional profile to enable the manipulation of the fluid flow under the fluid window, enhancing the speed and accuracy of the temperature sampling. The elongated member, which may be hollow and coated with gold, may an extended piece of the fluid housing or a part of an optics housing. In some embodiments, the NIT monitor is connected to a main conditioning circuit board via a cable for processing the temperature measurements at a remote location.

Owner:ENTEGRIS INC

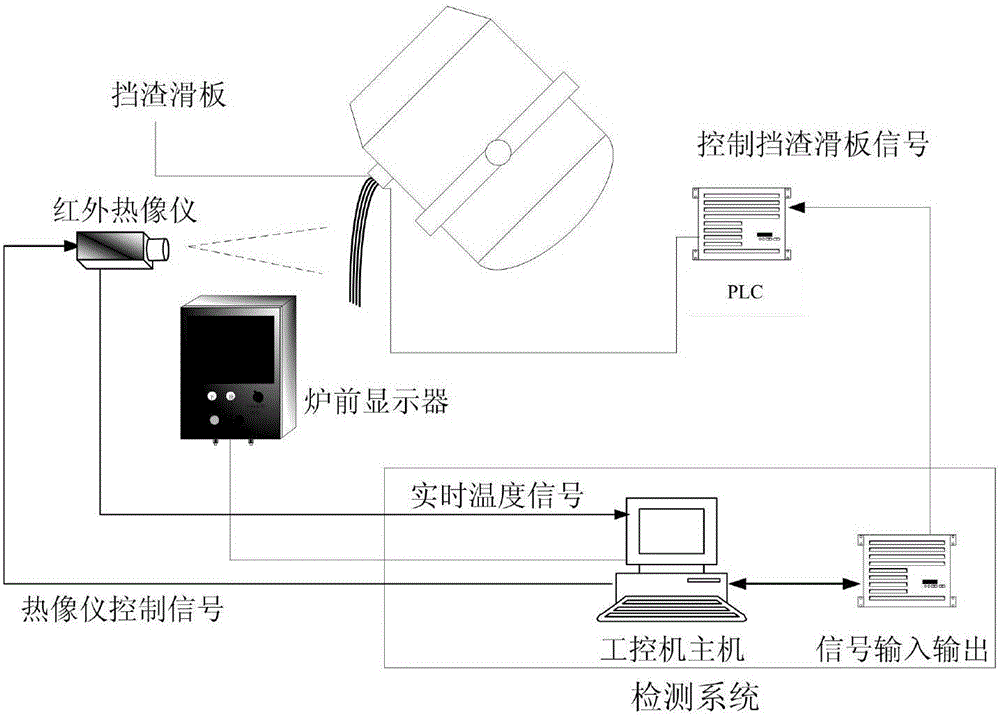

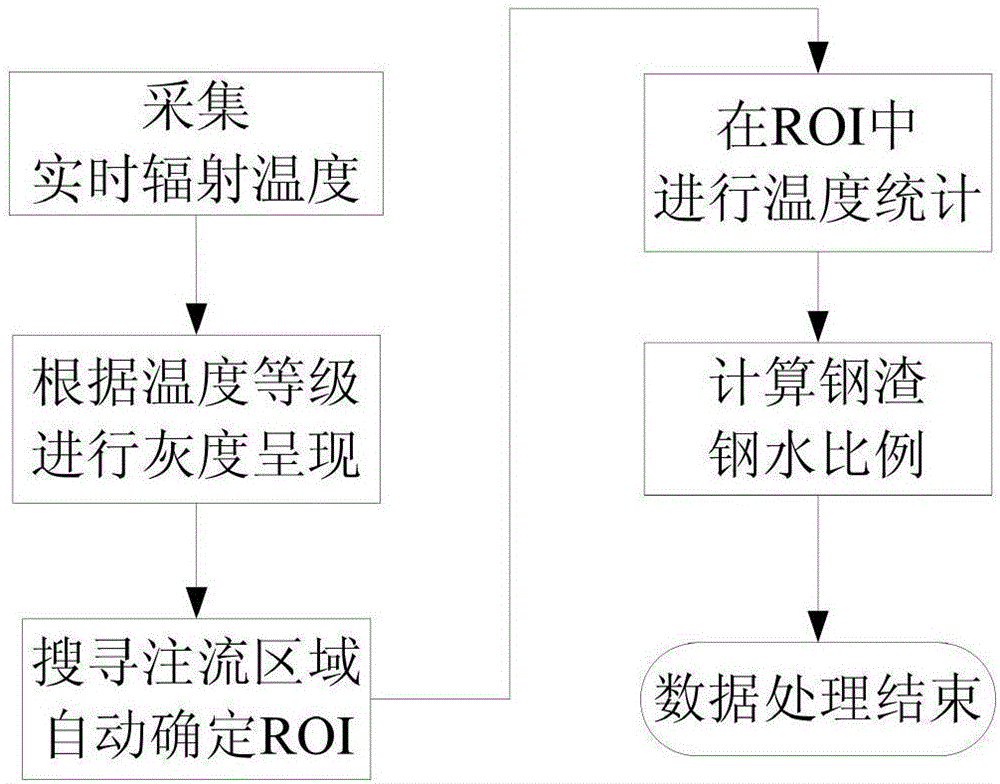

Converter roughing slag detection method based on infrared temperature measurement

InactiveCN106441584AEasy to analyzeReal-time calculation of slag contentManufacturing convertersSensing heat from liquidsSlagData acquisition

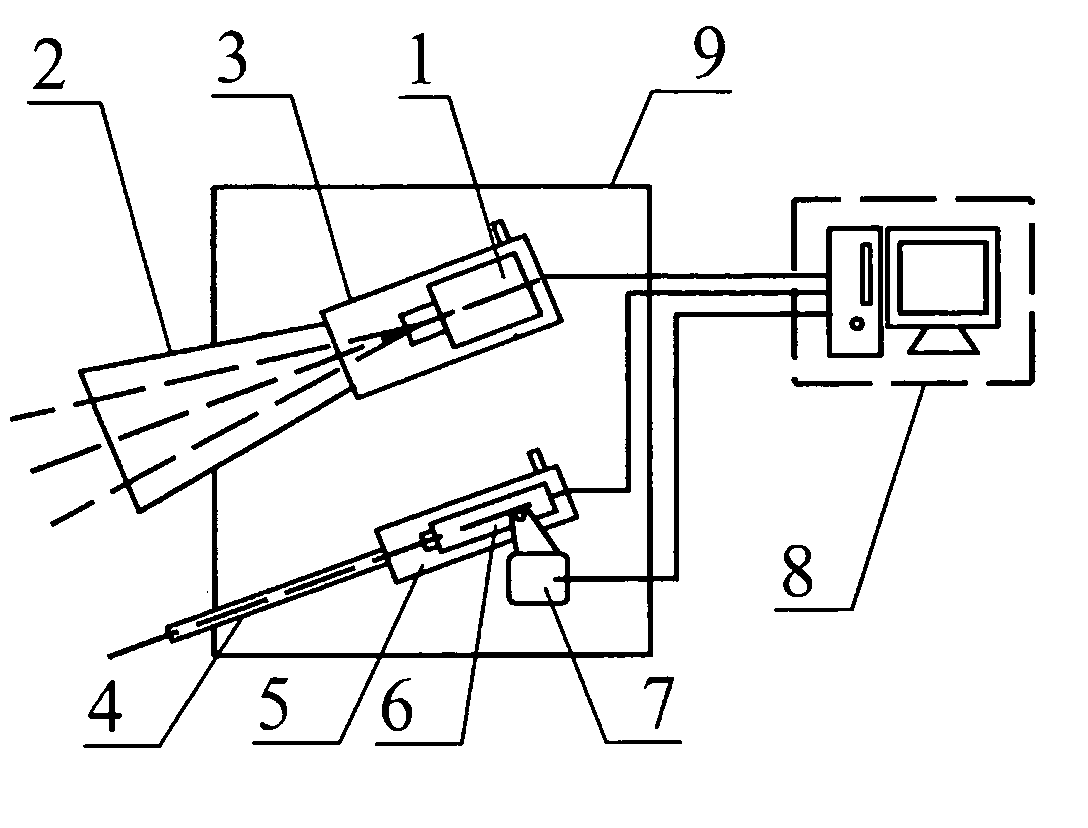

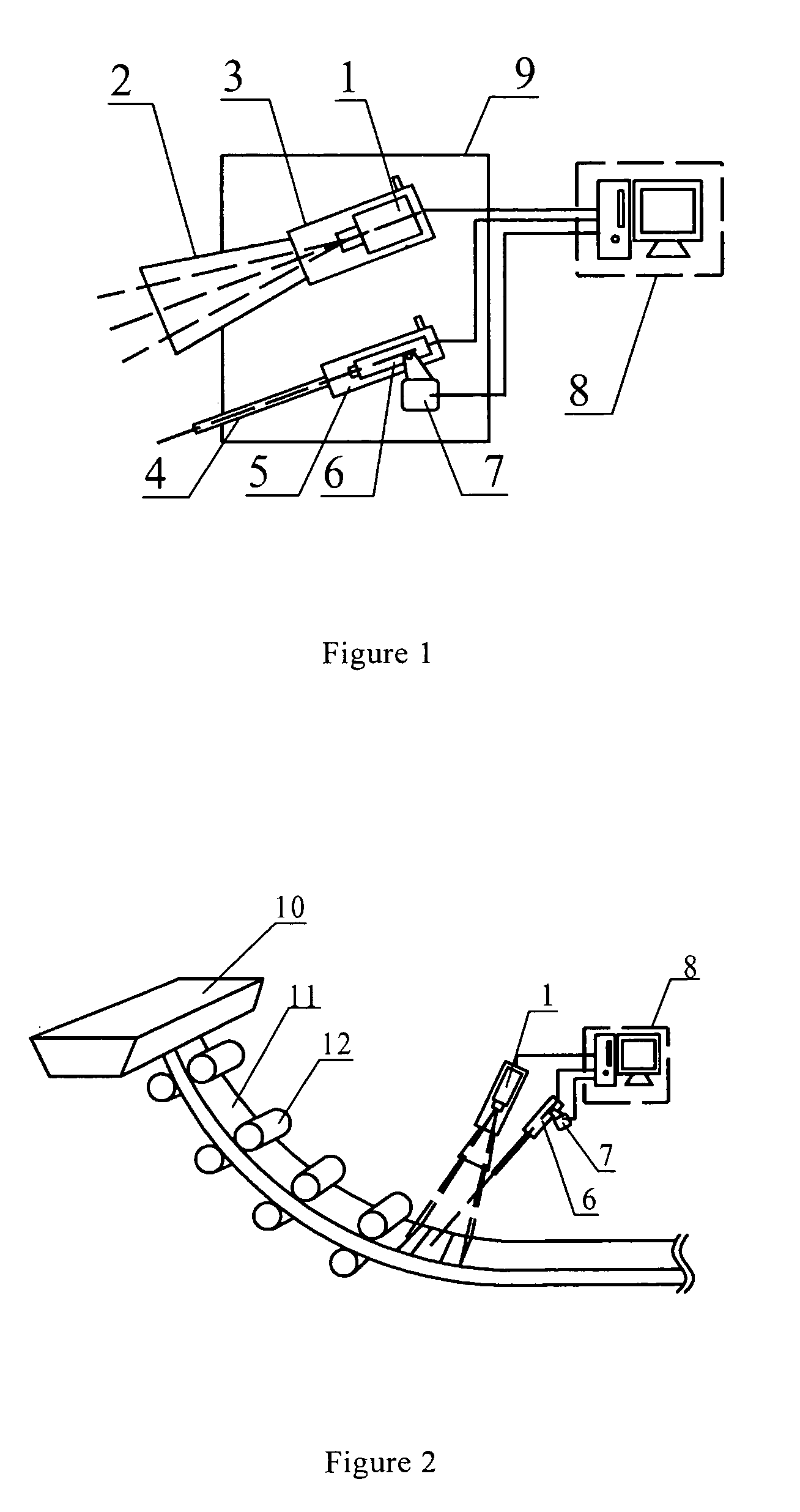

The present invention relates to a converter roughing slag detection method based on infrared temperature measurement. The method comprises: (1) employing an infrared thermal imager as an image and temperature data collection device, wherein the information output end of the infrared thermal imager is connected with an industrial control computer, the instruction output end of the industrial control computer is connected with the information input port of a converter PLC electric control cabinet; (2) disposing the infrared thermal imager at the position far away from the convertor and connecting the infrared thermal imager with the industrial control computer, performing real-time shooting of the steel tapping and steel stream images in the steel tapping process, obtaining the image data, and obtaining the real-time temperature data of the molten steel; (3) transmitting the obtained image data and real-time temperature data collected by the infrared thermal imager to the industrial control computer, and emitting an instruction through the industrial control computer to the converter PLC electric control cabinet through calculation and analysis; and (4) closing a sliding plate through a converter PLC electric control cabinet hydraulic pressure station, and finishing the slag stopping. The converter roughing slag detection method based on infrared temperature measurement can directly provide the infrared radiation temperature of each point of the surface of the detection molten steel through adoption of the infrared temperature measurement detection method, namely one single quantity is detected, the temperature measurement range is 300-2000 degrees, and the infrared radiation temperature of the molten steel in the steel tapping process can be directly obtained.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Apparatus and method for measuring the surface temperature of continuous casting billet/slab

ActiveUS20100236743A1Small geometryUneven thicknessThermometer detailsCasting safety devicesData processing systemRadiation thermometer

The present invention discloses a method and apparatus for measuring the temperature field on the surface of casting billet / slab, including: a thermal imager, an infrared radiation thermometer, a mechanical scanning unit, an image and data processing system; the thermal imager, the infrared radiation thermometer and the mechanical scanning unit are respectively connected to the image and data processing system; the infrared radiation thermometer is installed on the mechanical scanning unit and can measure the temperature of casting billet / slab surface by scanning; the thermal imager can measure the temperature of a certain area on the surface of casting billet / slab by thermal imaging. The present invention makes use of the combination of high-resolution thermal imager and scan-type infrared radiation thermometer, through the model-based filtering method, overcomes the influence of iron scales on the surface of casting billet / slab, and implements real-time stable measurement of surface temperature of casting billet / slab.

Owner:NORTHEASTERN UNIV +1

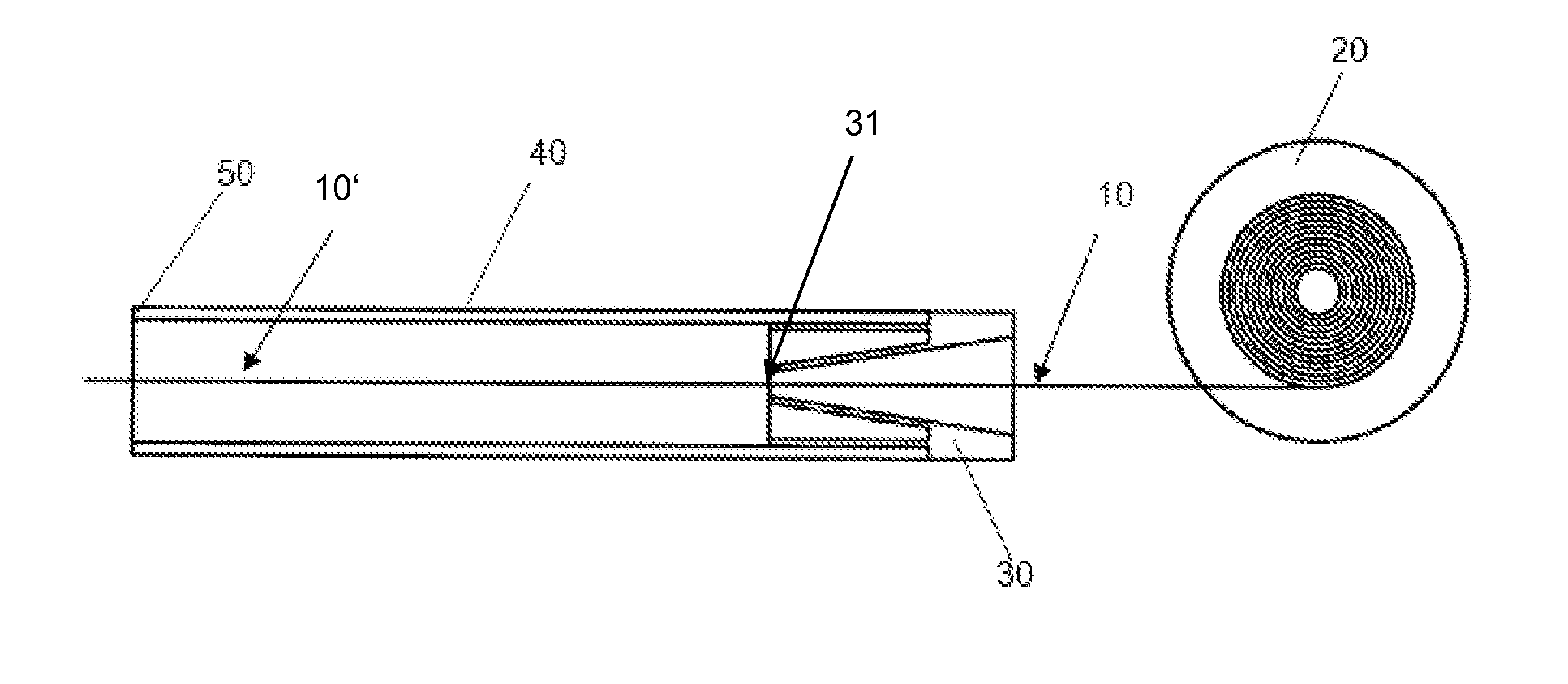

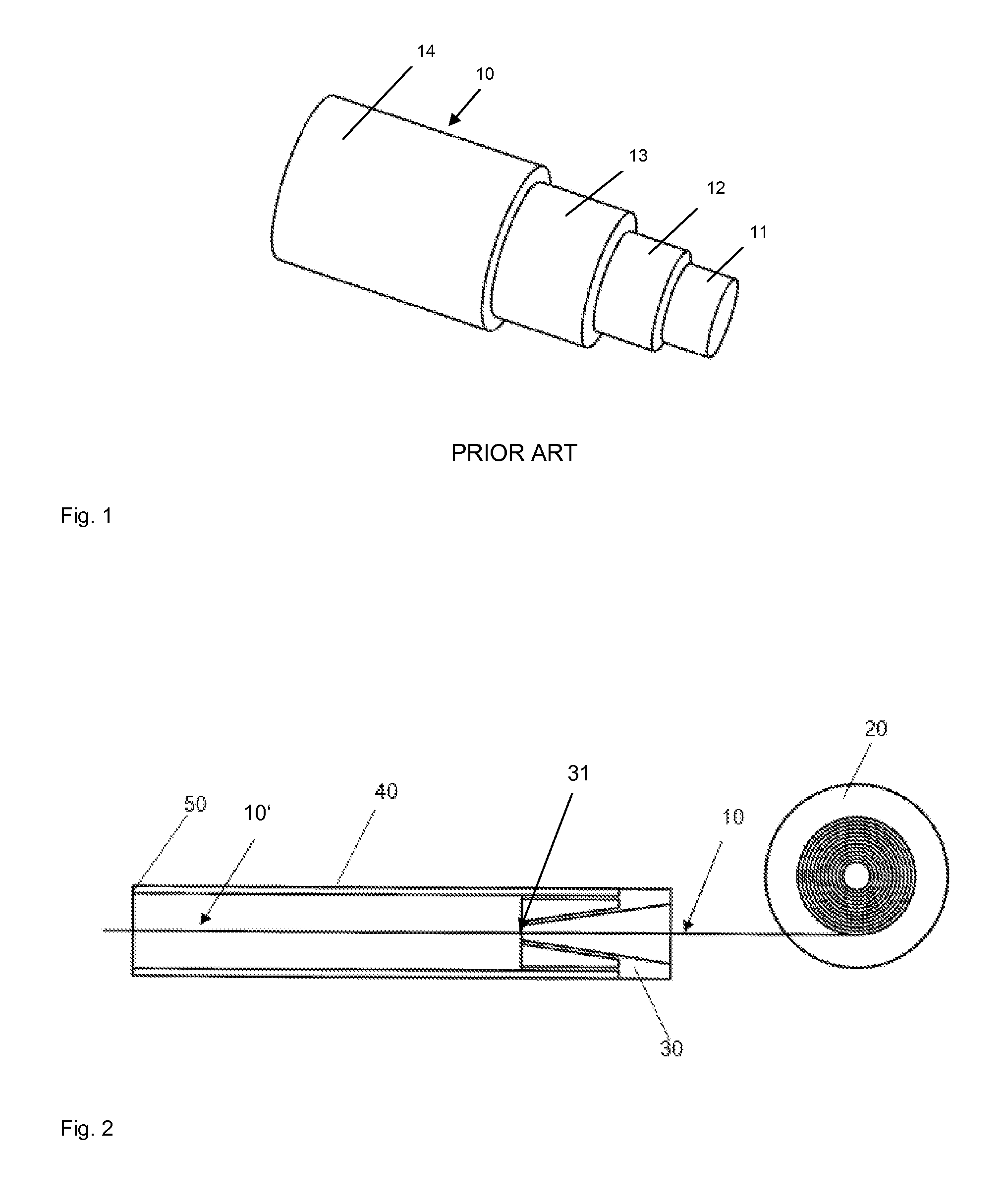

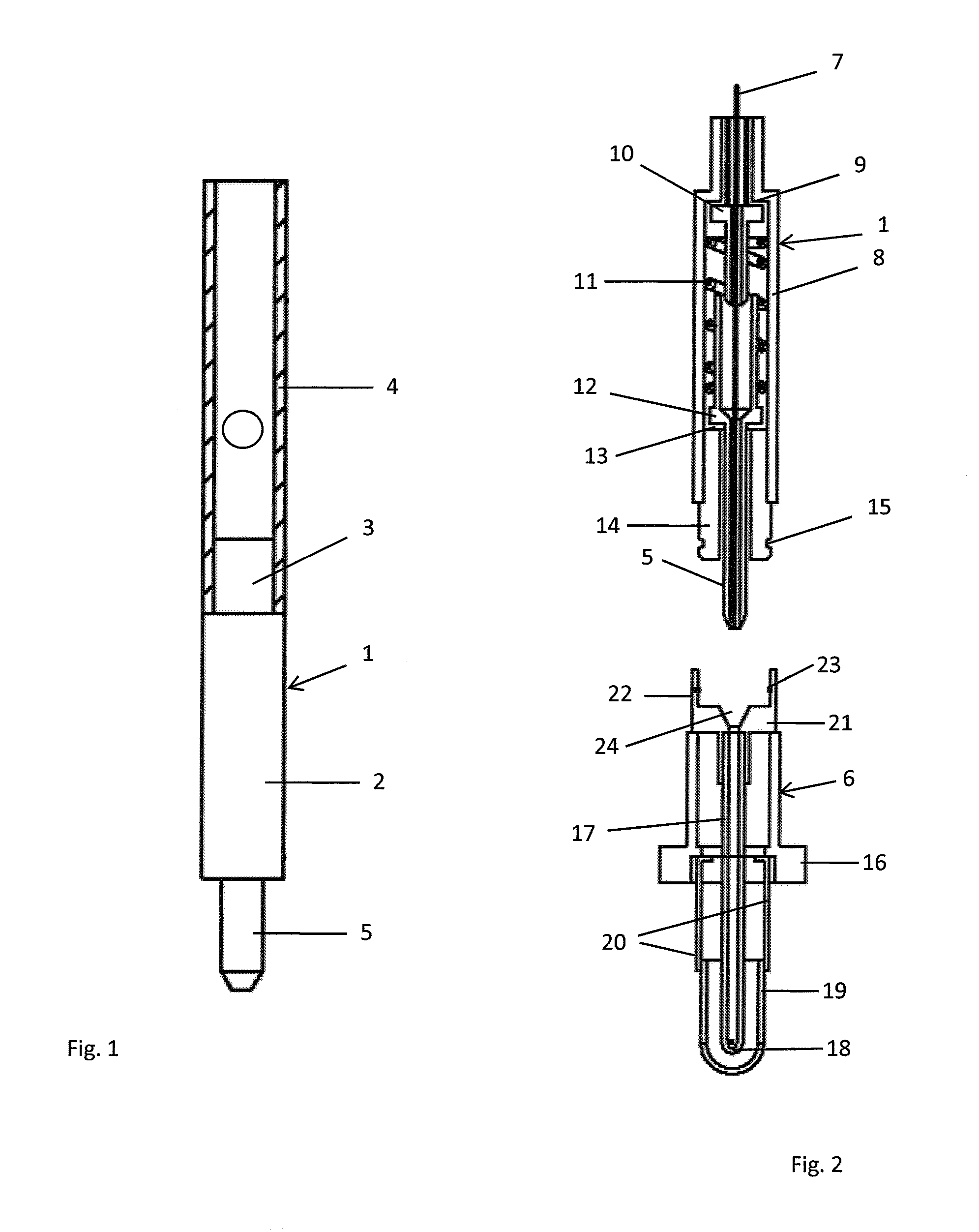

Method and apparatus for measuring the temperature of a molten metal

ActiveUS20140321504A1Low costHigh sampling frequencyThermometer detailsThermometers using physical/chemical changesGuide tubeMaterials science

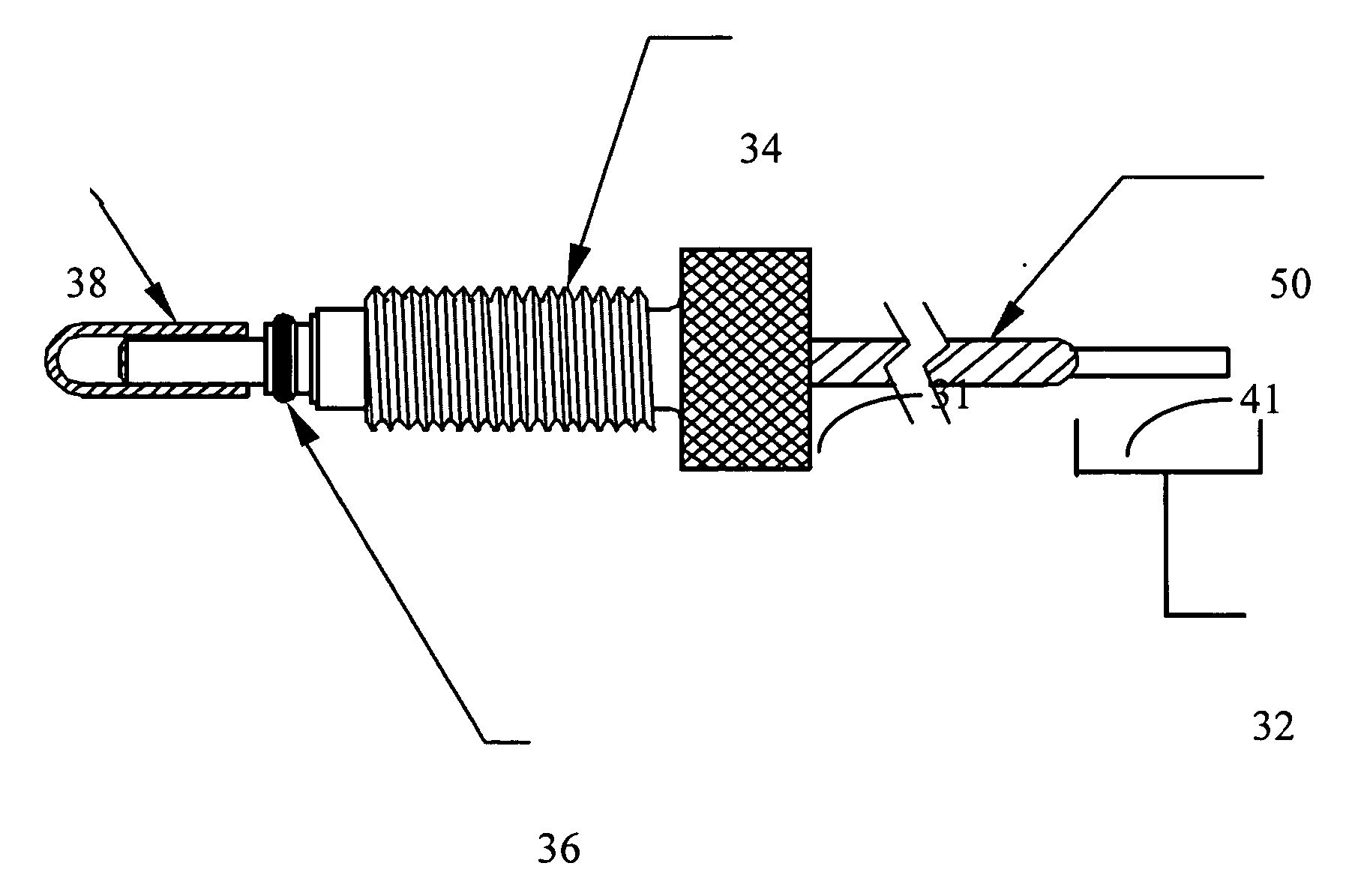

A method, device and apparatus are provided for measuring the temperature of a melt, particularly of a molten metal, with an optical fiber, fed into the melt through a disposable guiding tube. The optical fiber and an immersion end of the tube are immersed into the melt and have feeding speeds which are independent from each other. An elastic plug is arranged within the tube or at an end of the tube opposite the immersion end. The optical fiber is fed through the elastic plug, and the elastic plug reduces a gap between the optical fiber and the tube, which has a larger inner diameter than the outer diameter of the optical fiber. The apparatus includes a fiber coil and a feeding mechanism for feeding the optical fiber and the tube, including at least two independent feeding motors, one for feeding the optical fiber and one for feeding the tube.

Owner:HERALUS ELECTRO NITE INT NV

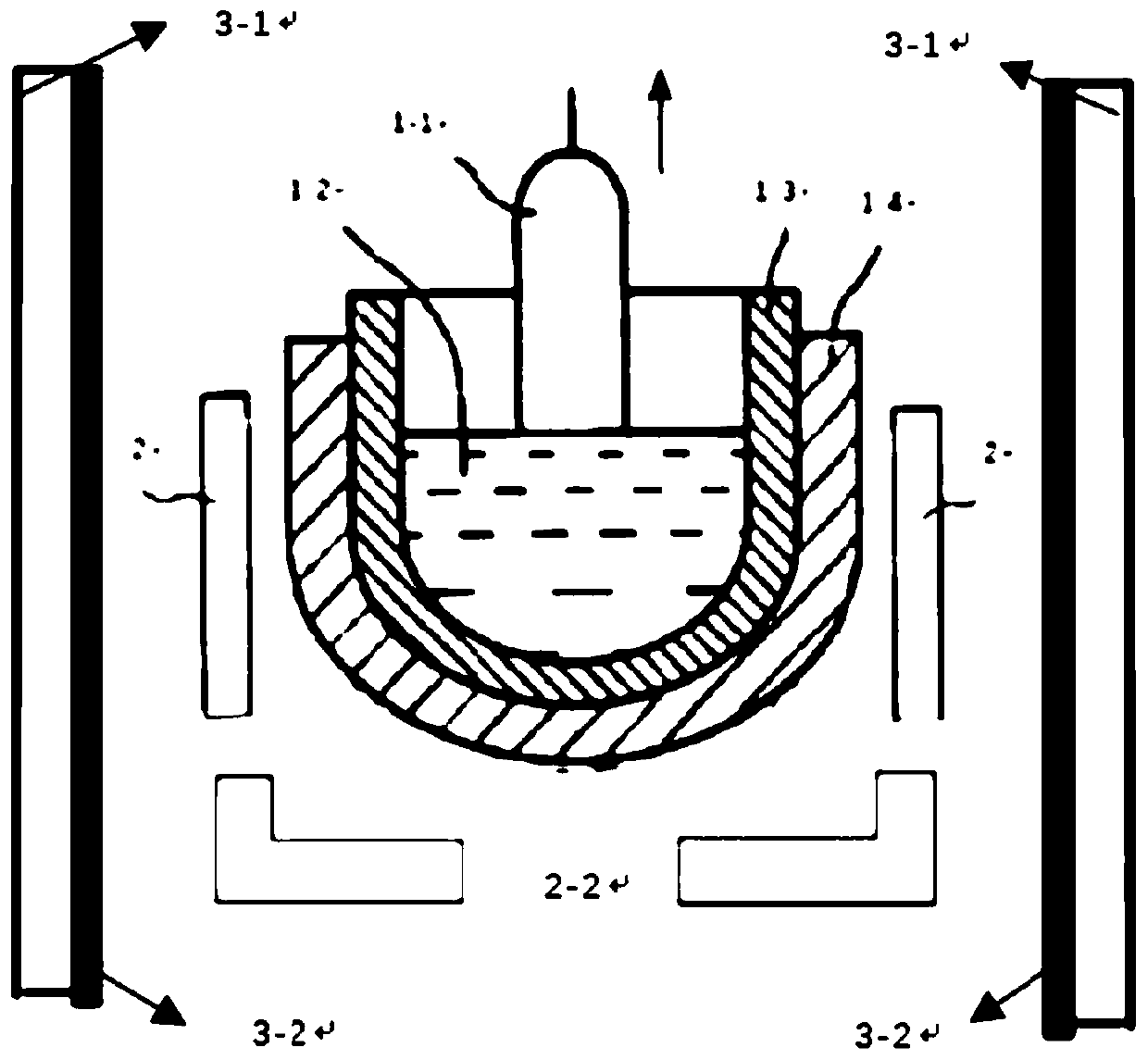

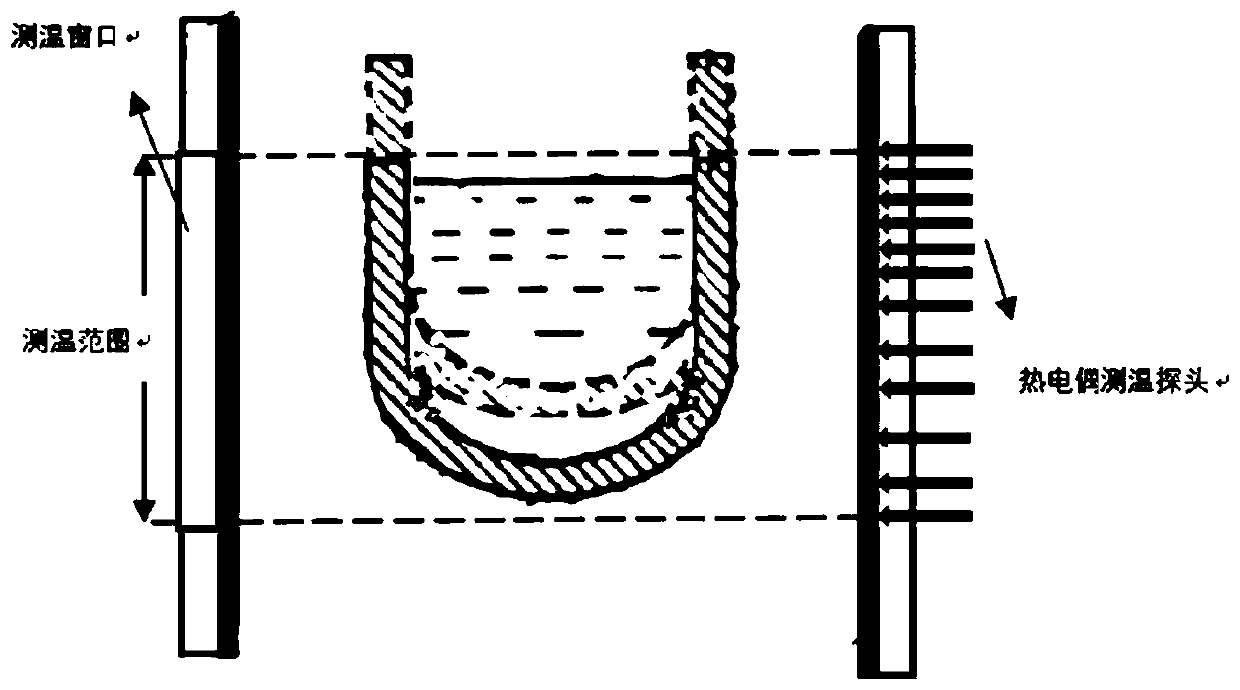

Czochralski crystal growing furnace and measurement control method for longitudinal temperature gradient of Czochralski crystal growing furnace

PendingCN110284186ALow costImprove qualityPolycrystalline material growthThermometers using electric/magnetic elementsThermal insulationOxygen content

The invention discloses a Czochralski crystal growing furnace and a measurement control method for the longitudinal temperature gradient of the Czochralski crystal growing furnace, and belongs to the field of monocrystalline silicon production. The Czochralski crystal growing furnace comprises a crucible and a heater; a thermal insulation layer is arranged on the periphery of the heater; the crucible comprises a quartz crucible body and a periphery supporting crucible body, wherein the quartz crucible body is used for containing a melt, and the periphery supporting crucible body sleeves the outer side of the quartz crucible body; the heater comprises a main heater body and an auxiliary heater body, wherein the main heater body surrounds the periphery of the crucible, and the auxiliary heater body is arranged at the bottom of the crucible; and a plurality of thermocouple temperature measurement probes are arranged in the vertical direction outside the thermal insulation layer at intervals, or the thermal insulation layer is provided with a first window for allowing an infrared thermometer to measure the temperature. According to the Czochralski crystal growing furnace and the measurement control method for the longitudinal temperature gradient of the Czochralski crystal growing furnace, the temperature distribution of the melt in the quartz crucible body is detected and controlled so as to realize scientific and accurate control over the crystal pulling process, the temperature of the melt at the bottom of the crucible is controlled to be as low as possible in the crystal pulling process so as to obtain monocrystal with lower oxygen content, the highest temperature of the melt in the crucible is controlled to be as low as possible so as to obtain the monocrystal with lower defect density, and therefore the pulling speed is higher, the crystal pulling cost is lower, and in addition, the monocrystal quality is greatly improved.

Owner:刘冬雯

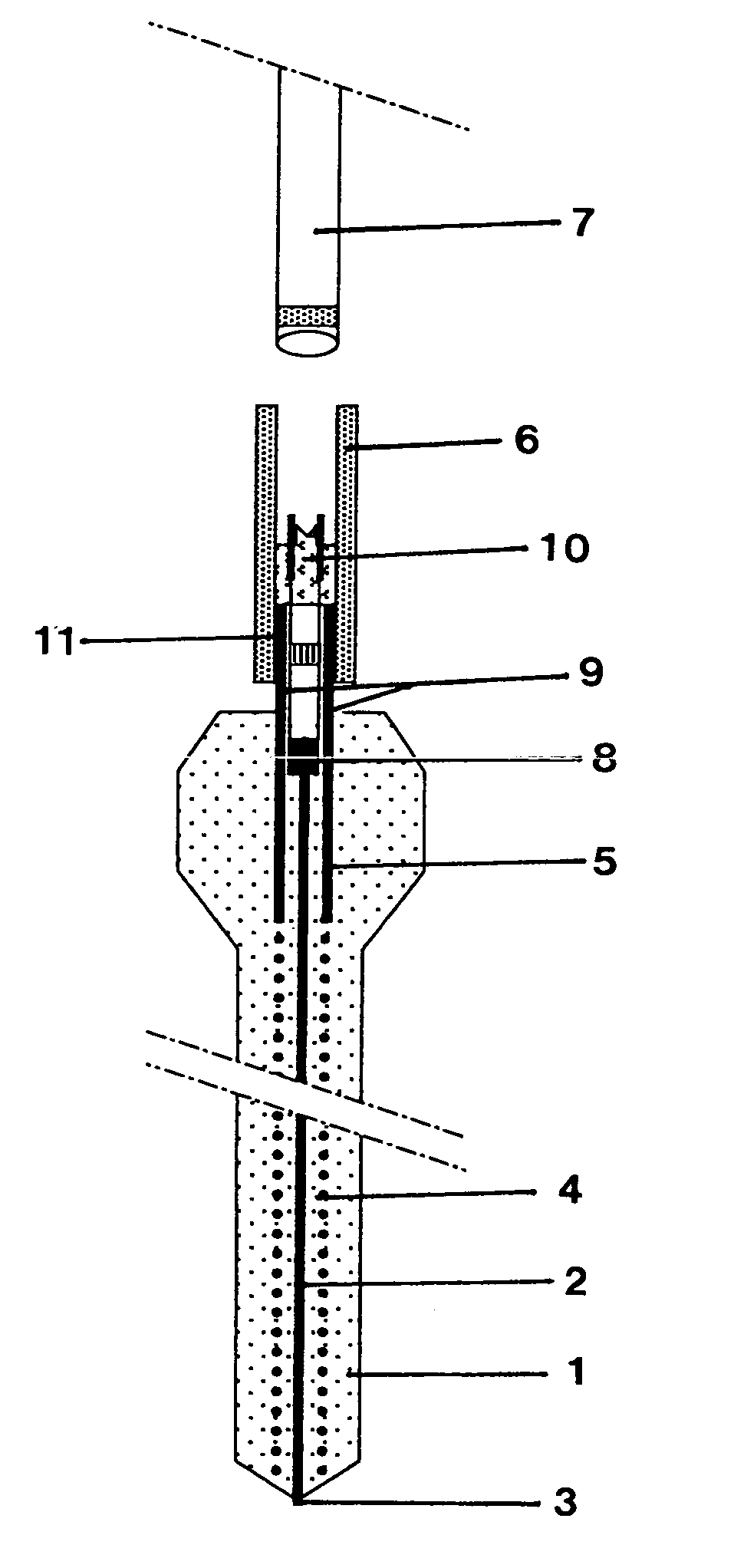

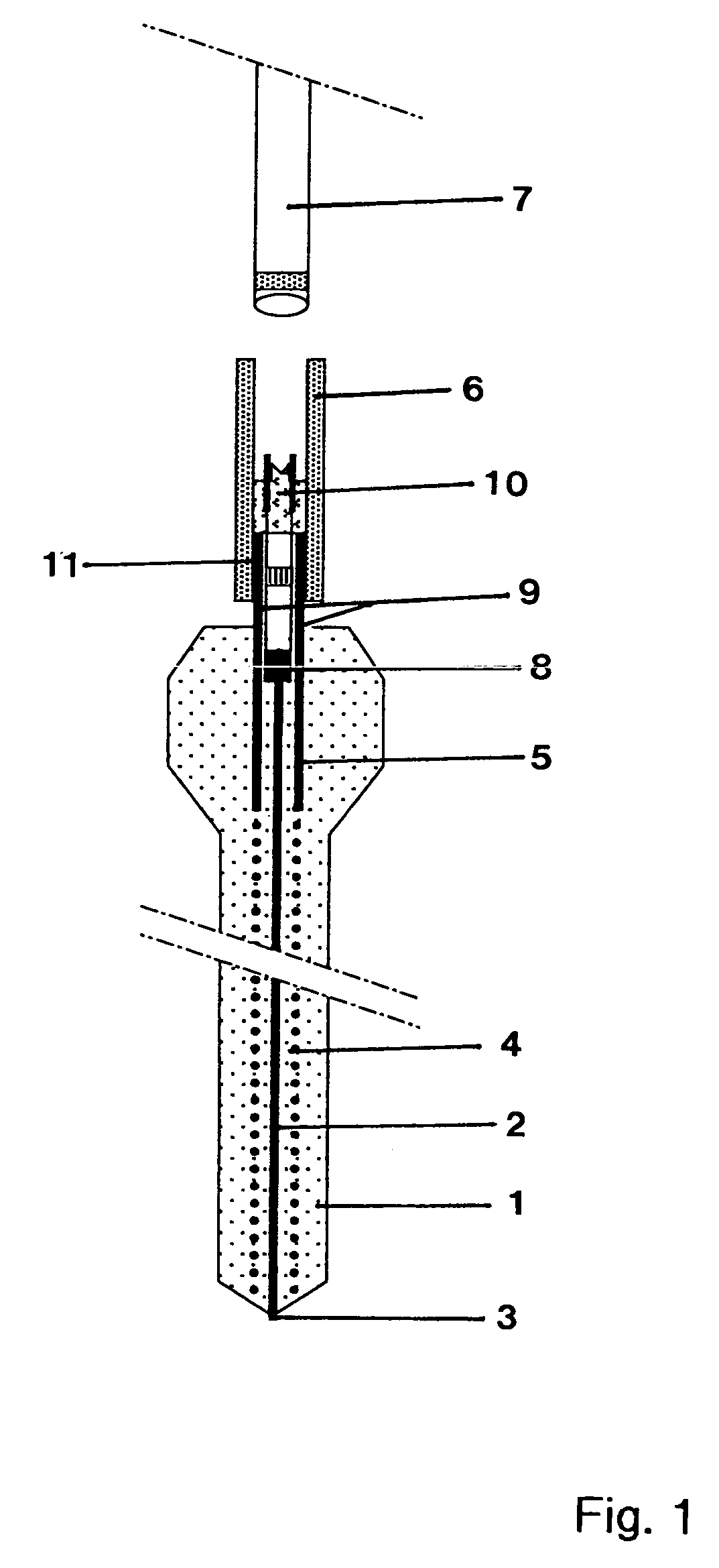

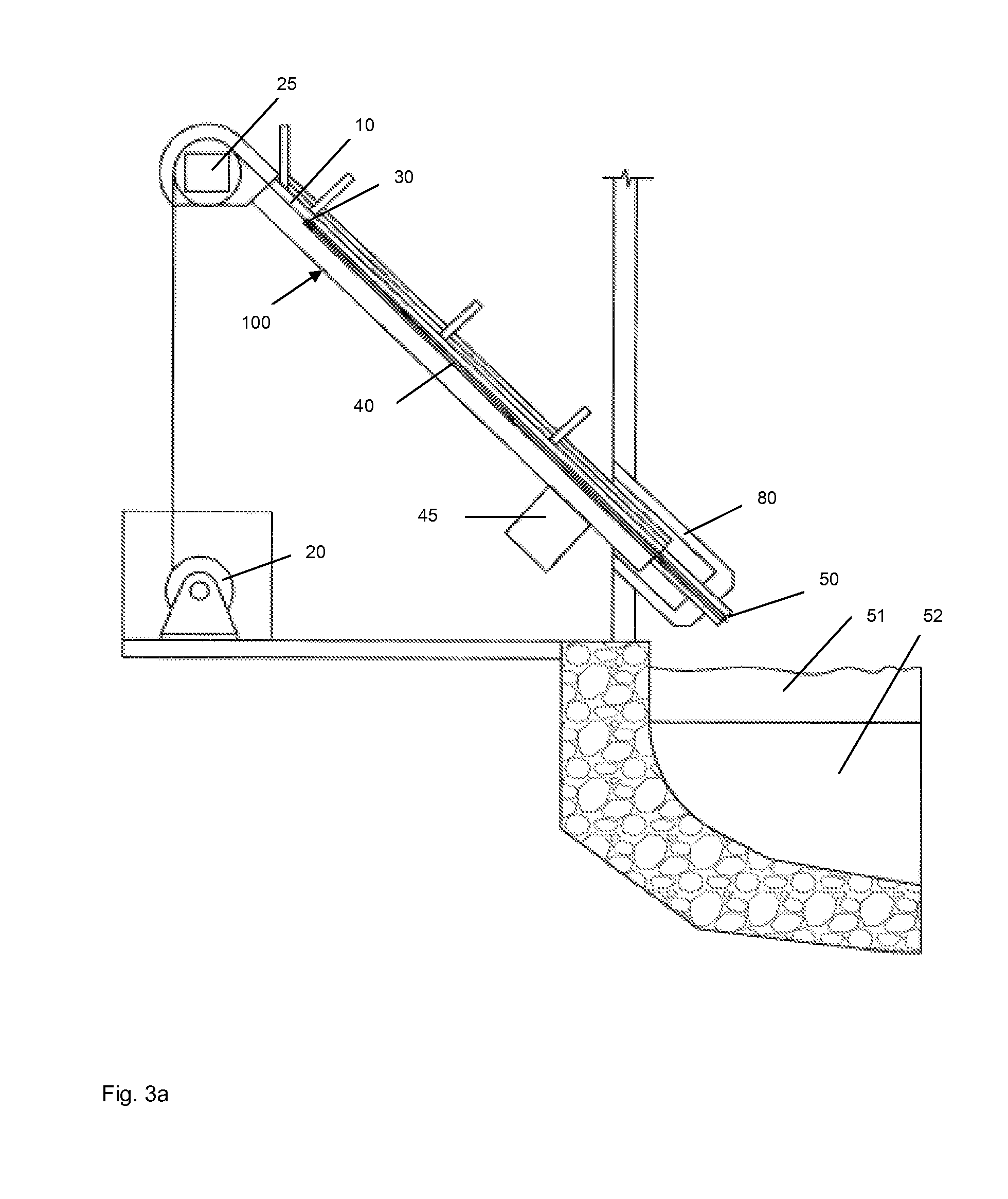

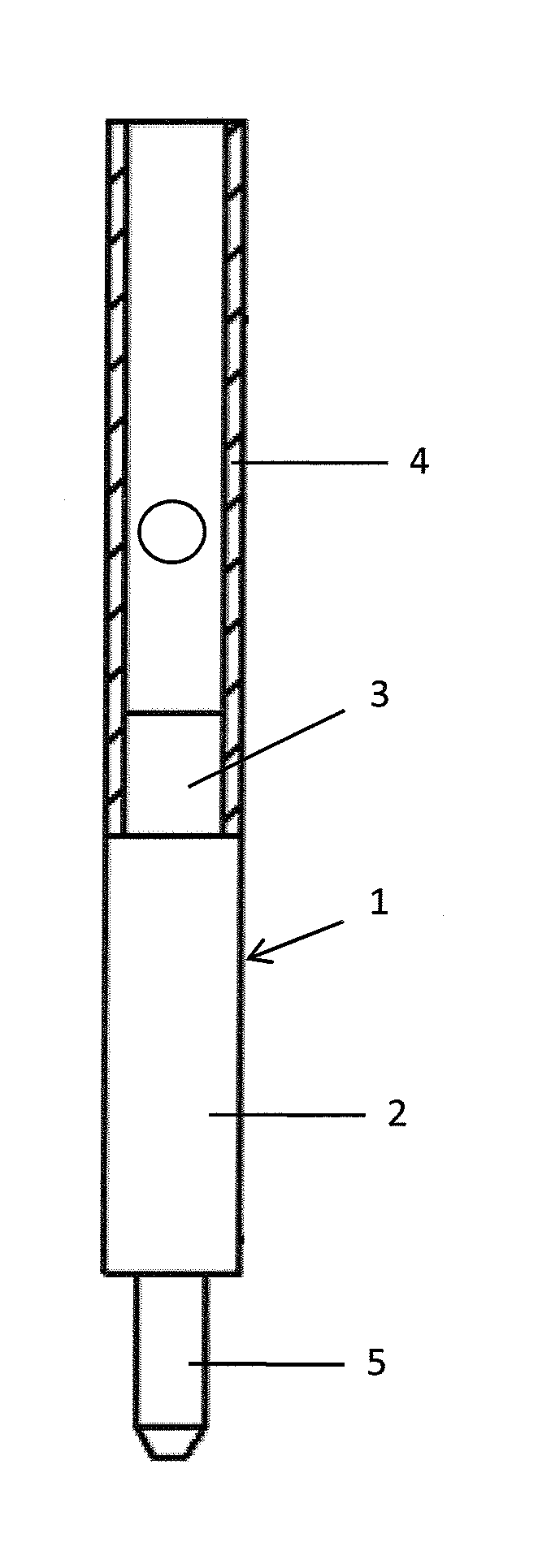

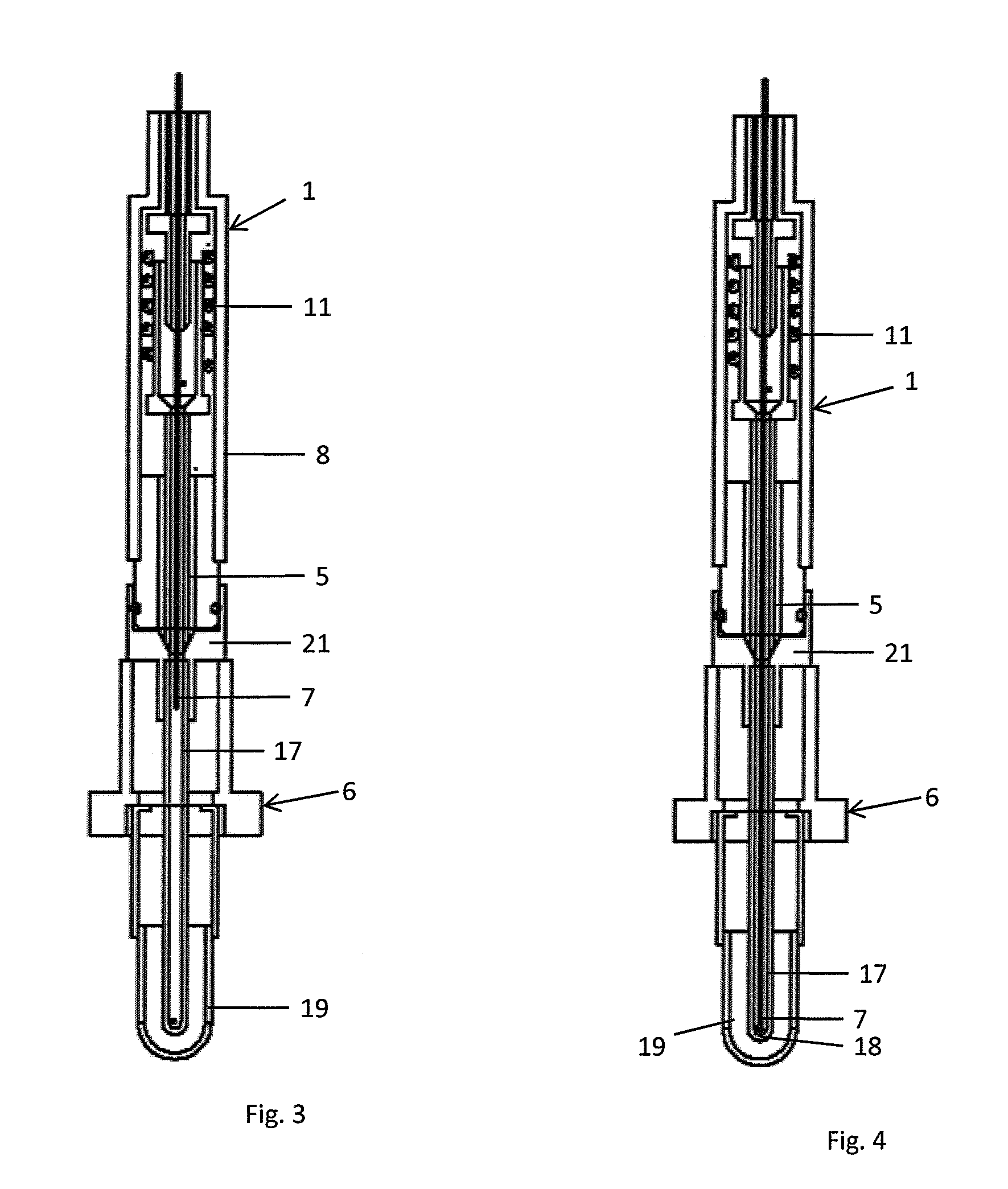

Sensor arrangement for the measuring of parameters in melted material

ActiveUS20130322489A1Operational securityEasy to useThermometers using physical/chemical changesSensing heat from liquidsGuide tubeEngineering

A sensor arrangement for melted materials includes an upper part and a detachable lower part. A tube extends coaxial to a longitudinal axis of the lower part, is closed on its end facing away from the upper part, and is open on the other end. The tube is arranged on an immersion end of the lower part facing away from the upper part. A guide tube, extending coaxial to a longitudinal axis of the upper part and being open on both ends, is arranged in a guide sleeve. A pressure acting in the direction of the lower part is applied to the guide tube by an elastic body and the guide tube touches against the lower part. One opening of the guide tube and the open end of the tube of the lower part are arranged adjacent to each other and coaxial to the longitudinal axis of the lower part.

Owner:HERALUS ELECTRO NITE INT NV

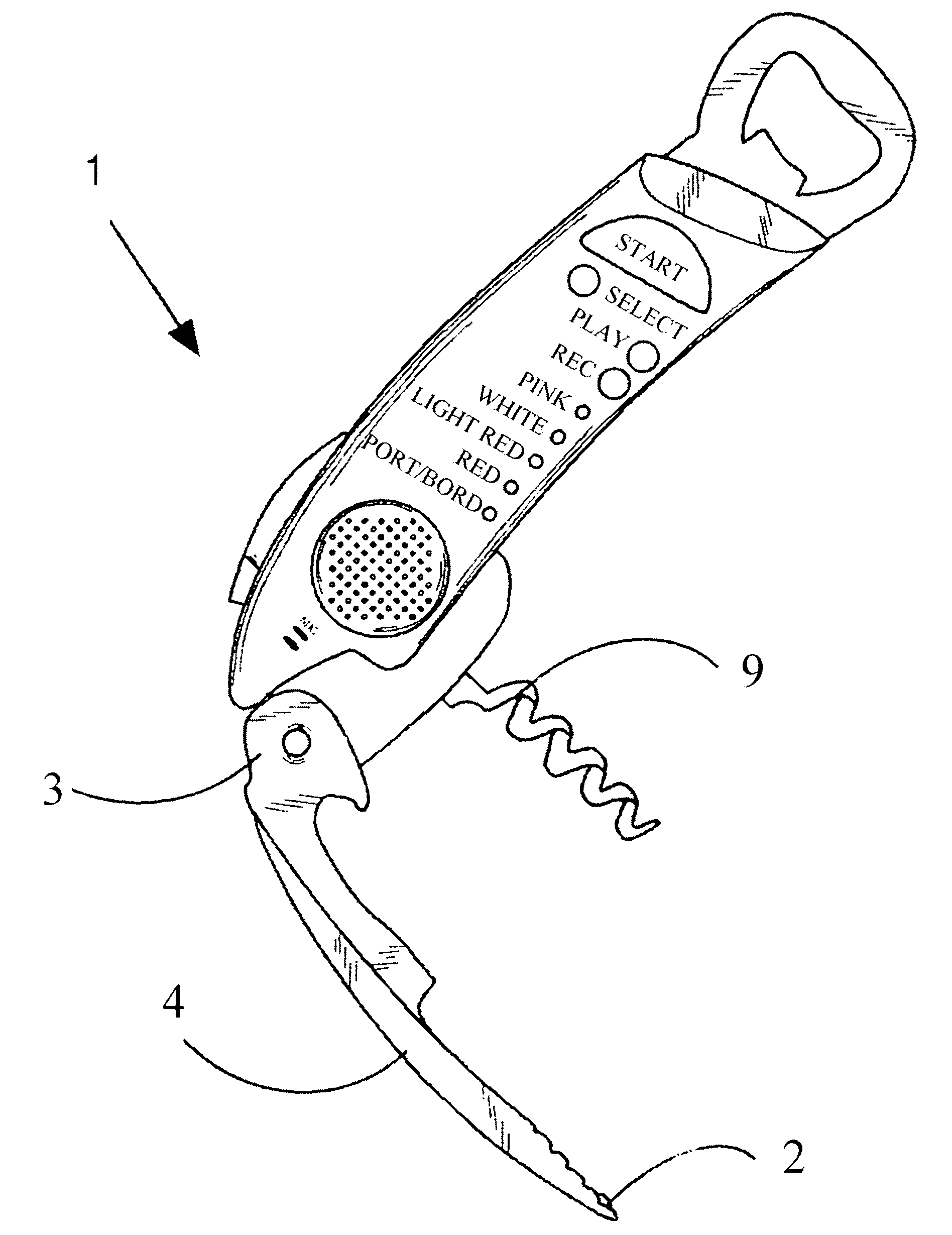

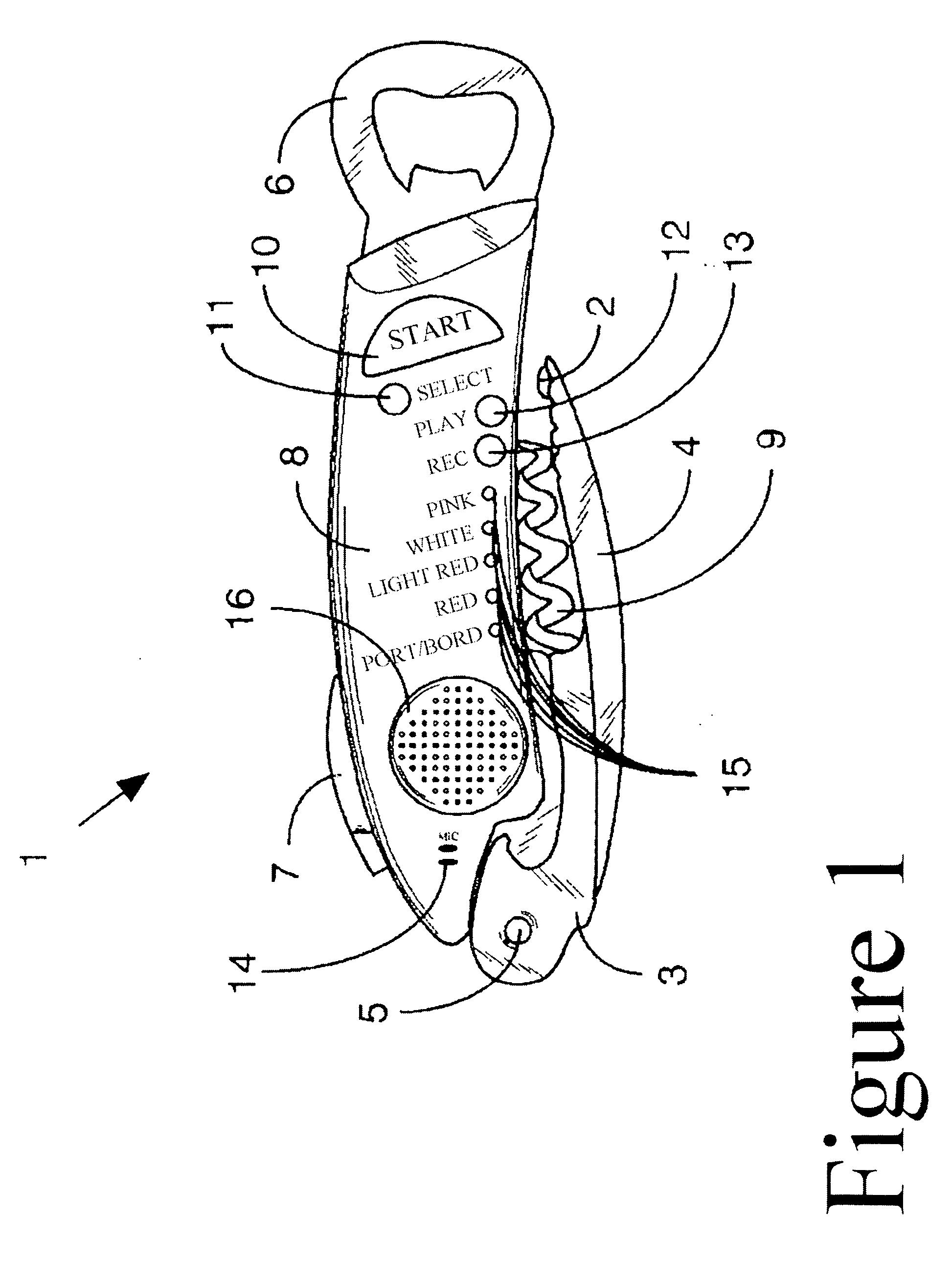

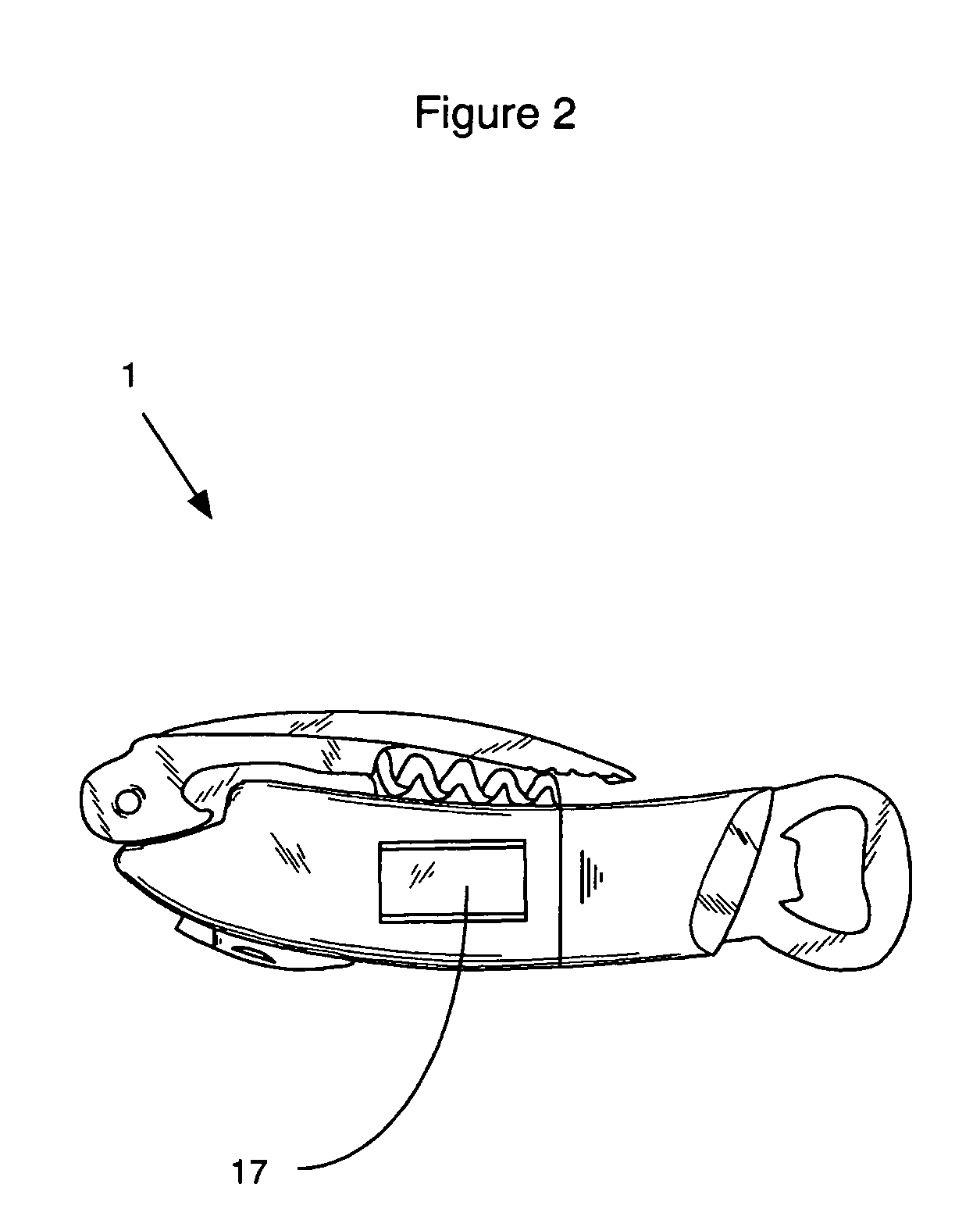

Liquid temperature detectors

Disclosed are devices and methods for measuring the temperature of a liquid in a container, the device either having a temperature sensor for measuring the temperature of the outer surface of the container, a probe for directly measuring the contents of the container, or an IR detector for measuring IR radiation passing, through, re-emitted by, and emitted by the container. The device may be in the form of a corkscrew, bottle opener, pen, or simple casing, The temperature reading may be outputted to the user audibly and / or visually, such as with an LCD display. In one embodiment, there are mounted a plurality of indicator lamps, each lamp representing a particular type of liquid, a control for selecting the type of liquid whose temperature is to be measured, an infrared detector, an output indicating to the user whether the temperature of the liquid is above or below a predetermined temperature range.

Owner:HARRIS DEBRA FOGEL

Temperature measuring method in molten metal bath

ActiveUS20100020845A1Increase heating speedStrong and effective changeThermometer detailsThermometers using physical/chemical changesMolten bathMolten metal

Owner:HERAEUS ELECTRO NITE INT NV

Immersion type sensor for measuring temperature

InactiveUS20120327971A1High emissivityLong residence timeThermometer detailsSensing heat from liquidsContact typeHot Temperature

A device for measuring the temperature of molten metal irrespective of the nature of the metal, particularly, an immersion / contact type temperature sensing device involving optical fiber which can be universally used for different materials and would be adapted for safe and repetitive immersion in molten metal for measurement of molten metal temperatures and the like. The proposed immersion / contact type temperature sensing device involves combination two-color and multi-color pyrometric detection technique is capable of cost effective and discrete-time temperature measurement of molten metal. The advancement is thus directed to serve as a ready and fast accurate measurement of molten metal temperature and the like.

Owner:GODA JYOTI

Popular searches

Liquid-phase epitaxial-layer growth By zone-melting liquids Domestic articles Additive manufacturing with solids Special data processing applications Single crystal growth details Welding/cutting media/materials Welding/soldering/cutting articles Manufacturing data aquisition/processing Metal working apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com