Device and method for measuring temperature in molten metals

a technology of molten metals and optical fibers, applied in the direction of heat measurement, optical radiation measurement, instruments, etc., can solve the problem that the cladding cannot provide the optimum protection of the optical fiber, and achieve the effect of improving the general functionality of the device, improving the control of consumption, and reducing the functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

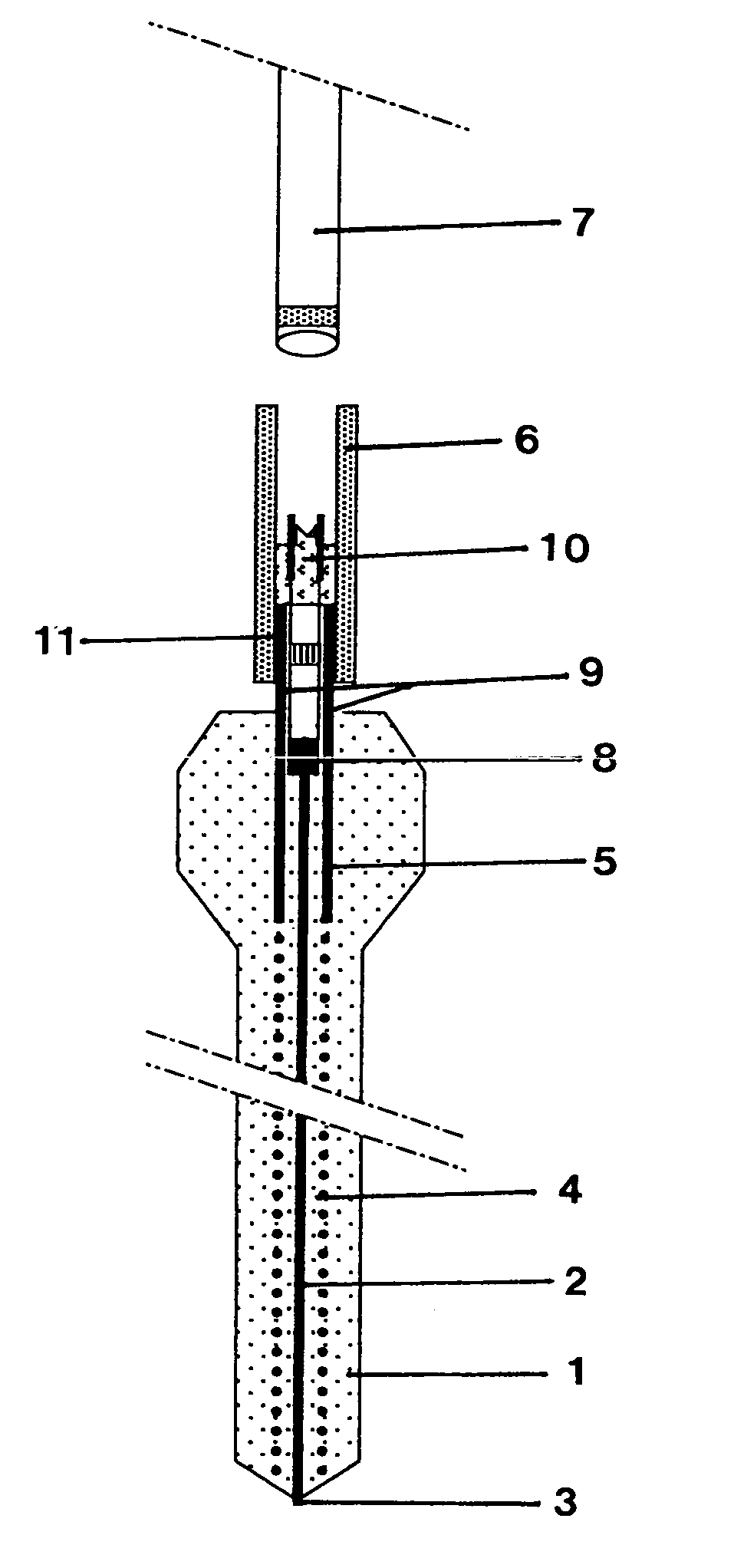

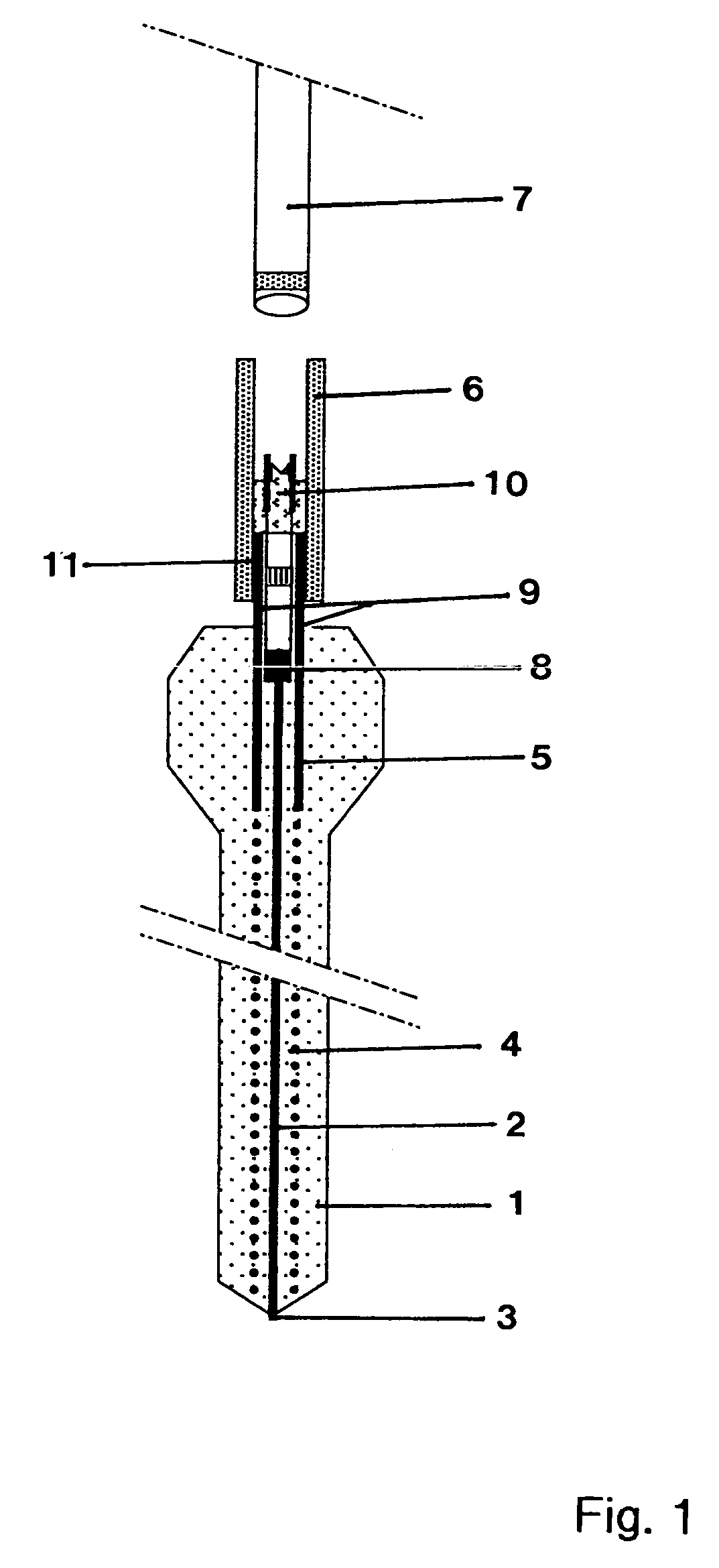

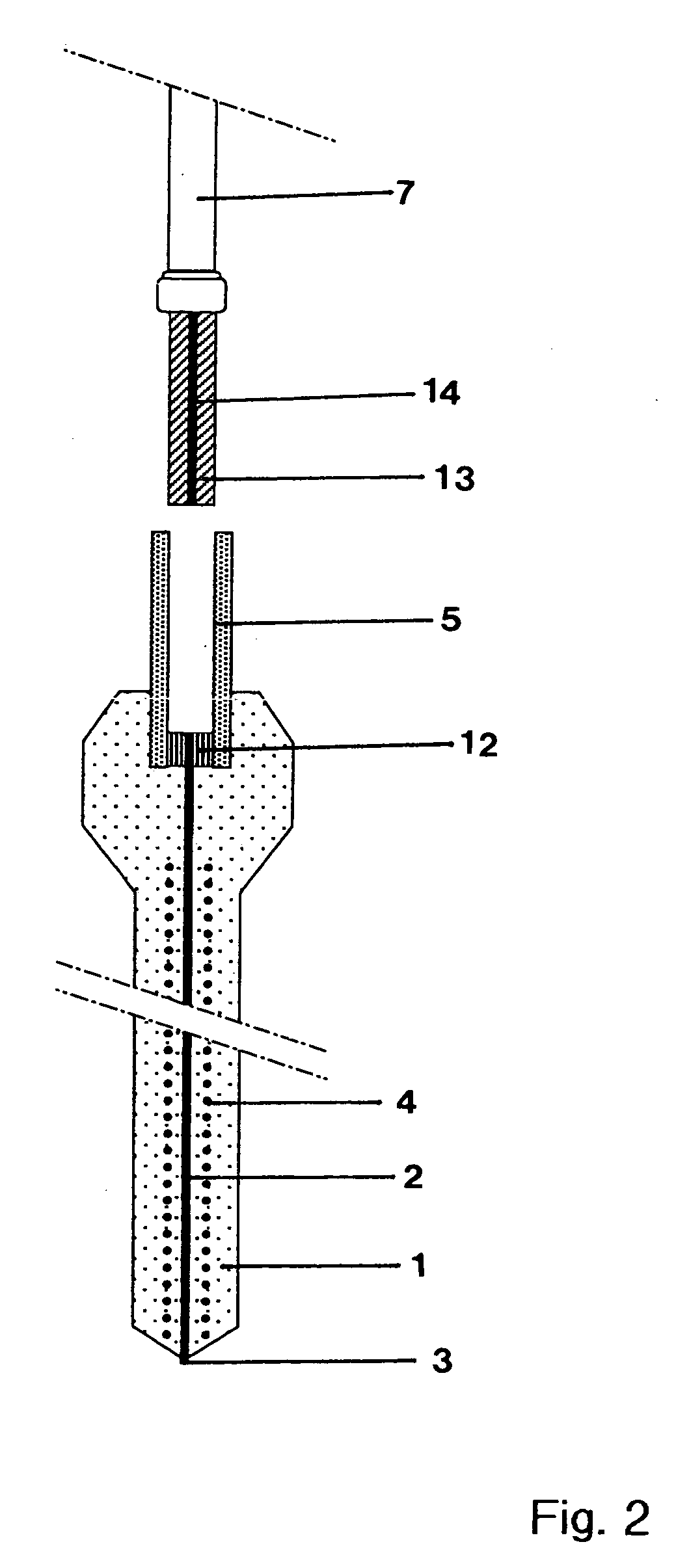

[0016] The consumable body 1 shown in FIG. 1 is essentially formed, for example, from particles of molding sand, inorganic cement, or fly ash, wherein the bonding of the particles is accomplished by pressing or by the use of binding agents. The body 1, along whose longitudinal axis the optical fiber 2 is located, is immersed in a molten metal for measurement. Here, the end 3 of the optical fiber 2 receives measurement signals in the form of optical radiation, from which the temperature of the metal melt is calculated in a known way.

[0017] An abrasion-resistant coating can be applied on the surface of the body 1 to protect the body 1 during handling, especially outside of the molten metal. Within the molten metal the consumable body 1 slowly dissolves, starting from the immersion tip (adjacent the fiber end 3), such that the bonding between the particles of the body 1 slowly breaks up. The process begins at the immersion tip, because this is the first part exposed to the molten meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com