Laser heating device and laser heating method

A laser heating and laser technology, which is applied in the direction of semiconductor laser optical devices, lasers, measuring devices, etc., can solve the problem that the temperature of the heated object cannot be measured, and achieve the effect of stable temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

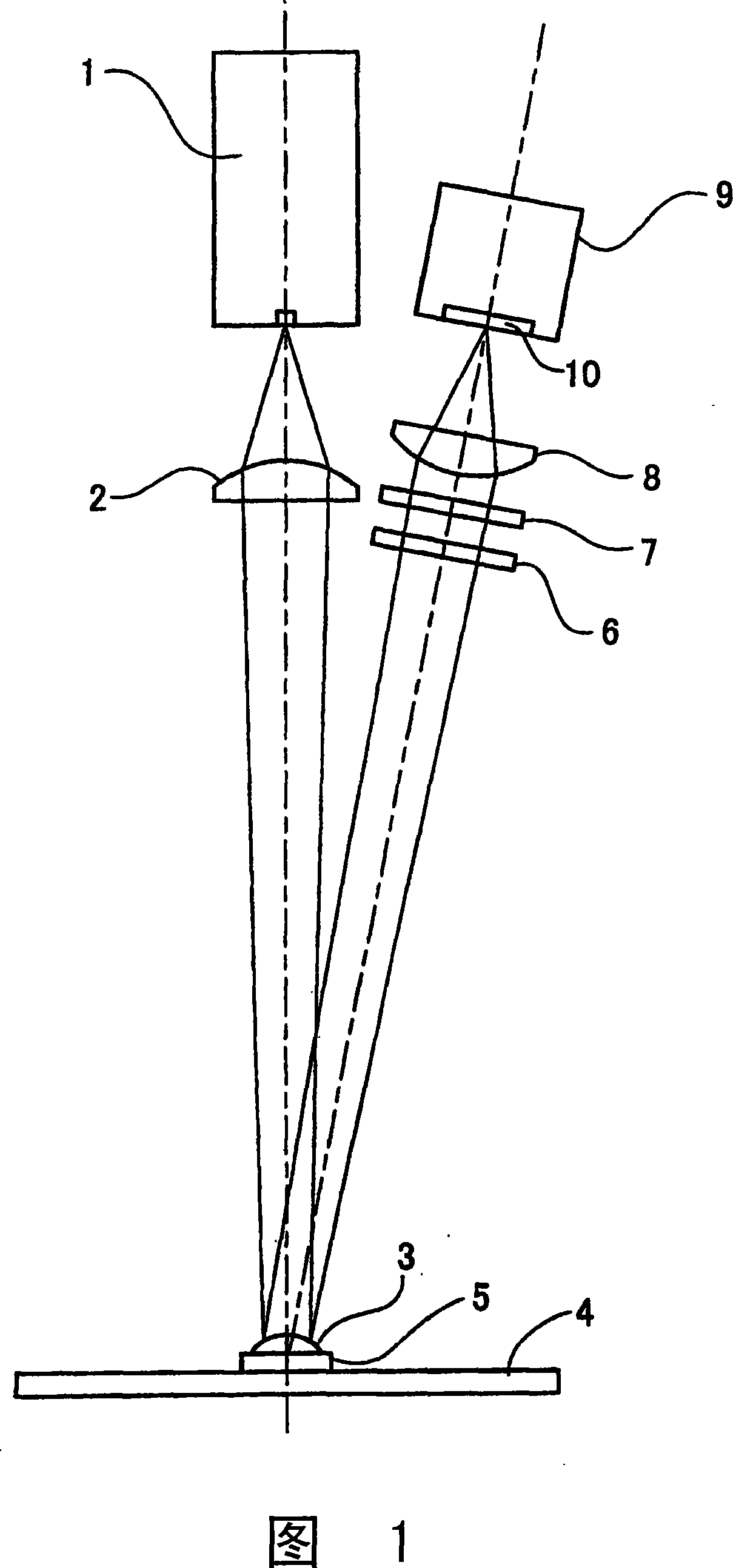

[0046] Hereinafter, a laser heating device and a laser heating method according to embodiments of the present invention will be described with reference to the drawings.

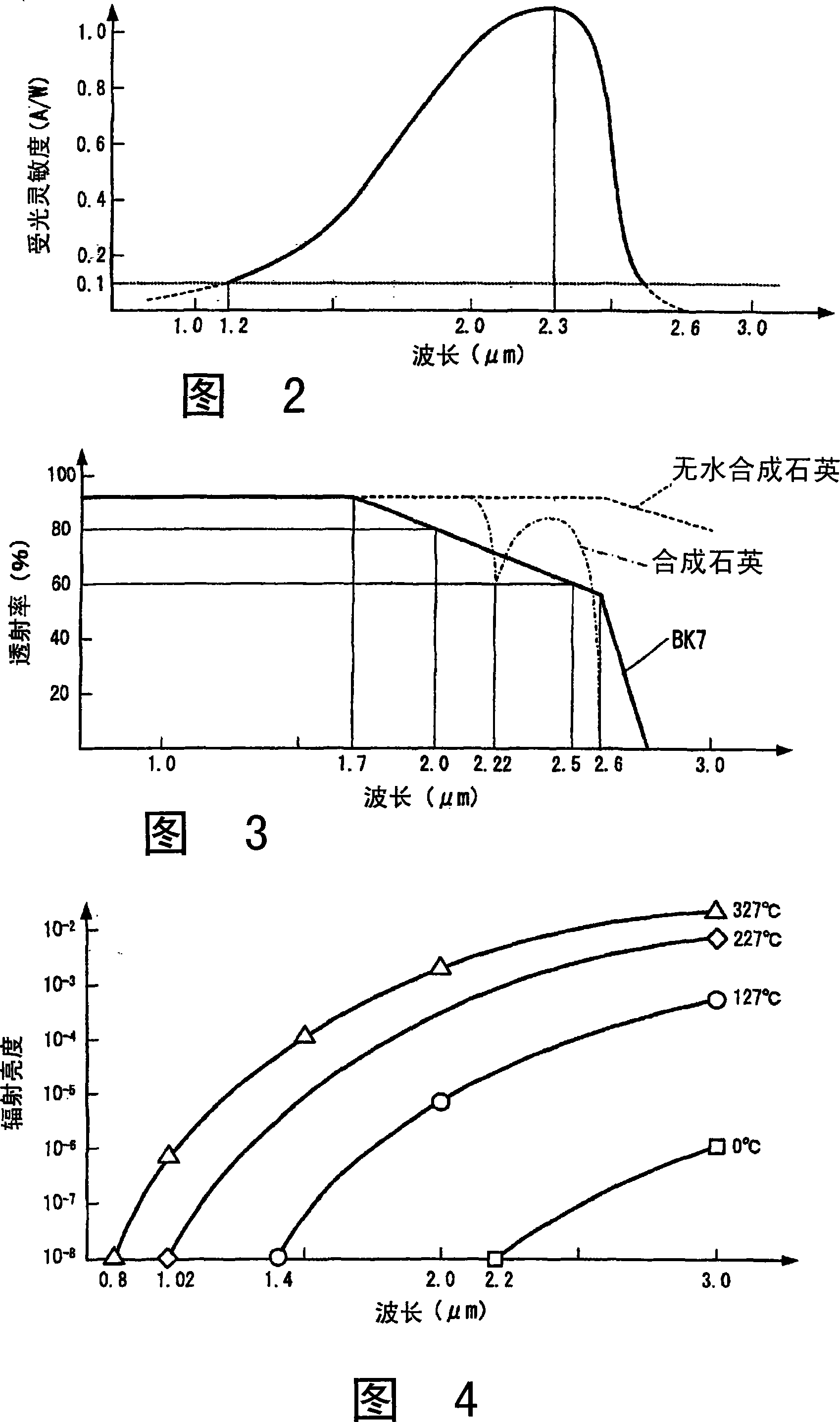

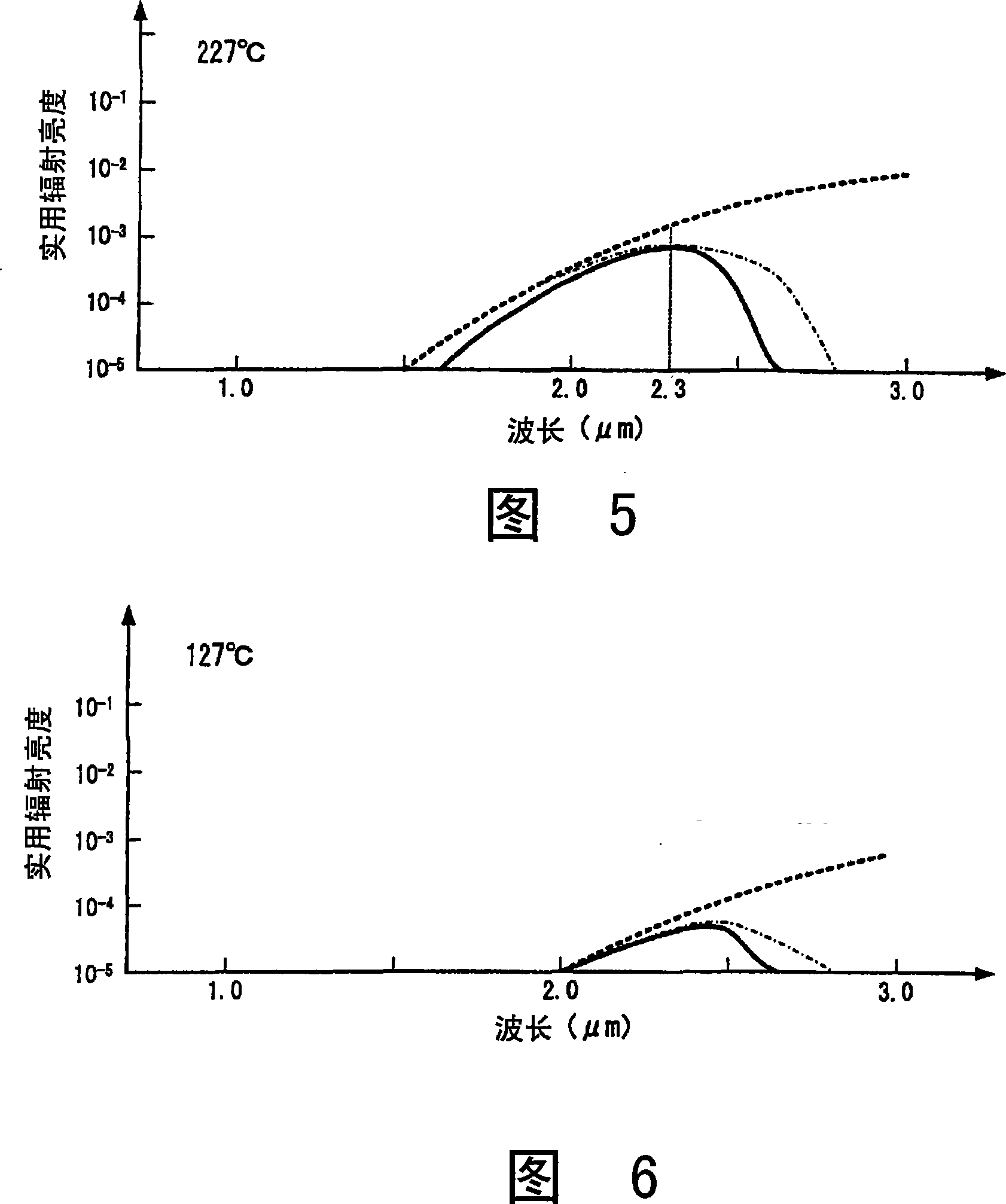

[0047] In the following embodiments, an infrared sensor is provided that generates a signal based on an integrated value of the spectral radiance of infrared rays received by the light receiving surface. Furthermore, before performing the laser heating processing, the relational expression of the calibration value of the output signal of the said infrared sensor and the actual measurement temperature of the object to be heated for calibration is calculated|required in advance. Then, when the laser heating processing is actually performed, among the light radiated or reflected from the object to be heated and its peripheral portion, infrared rays other than the light of the wavelength of the laser light are guided to the light receiving surface of the infrared sensor, The temperature of the object to be heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com