Czochralski crystal growing furnace and measurement control method for longitudinal temperature gradient of Czochralski crystal growing furnace

A technology of temperature gradient and control method, which is applied in the direction of radiation pyrometry, thermometer, single crystal growth, etc., can solve the problem of not being able to control the temperature gradient of the melt, and achieve the effect of improving the quality of crystal pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

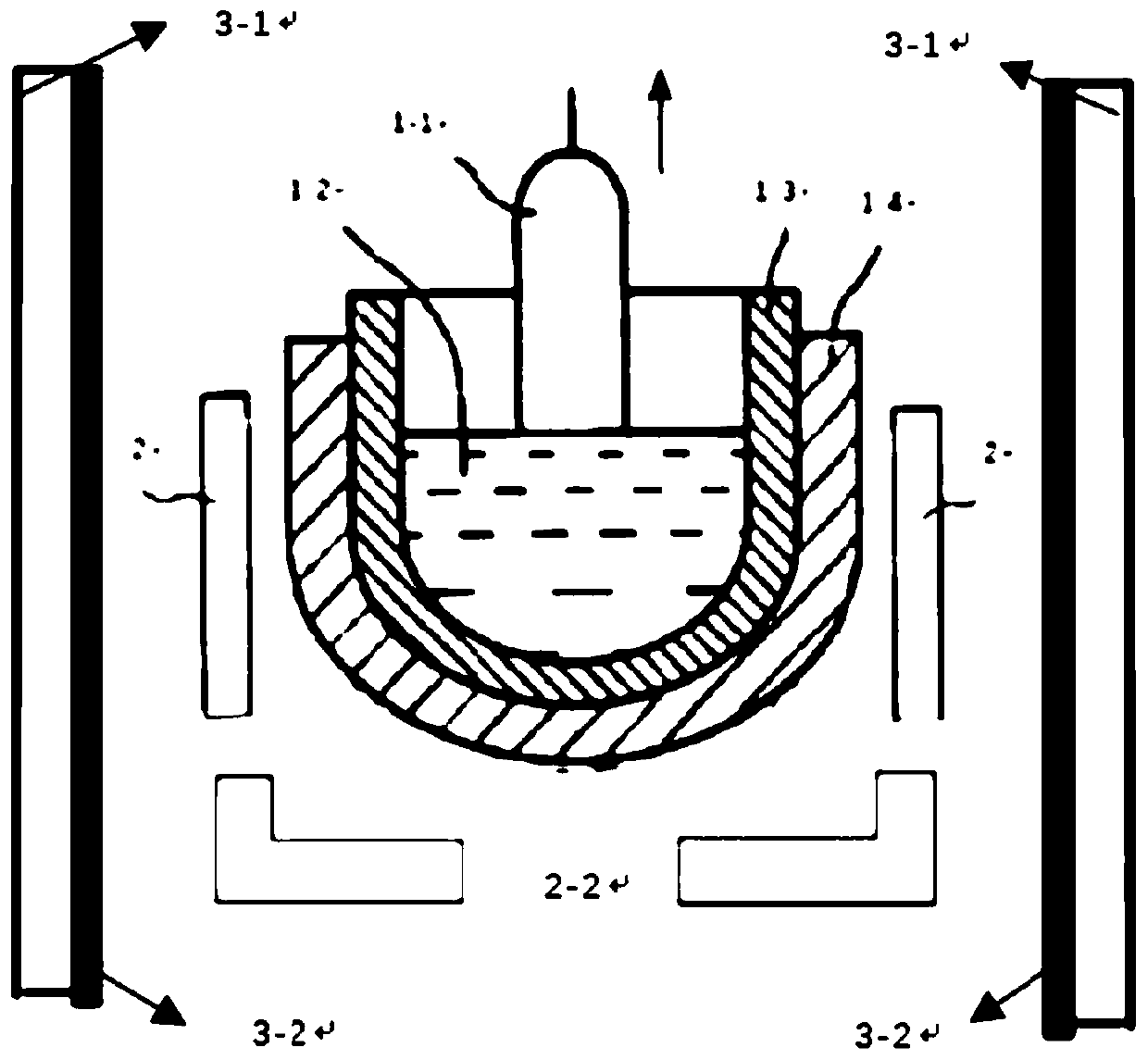

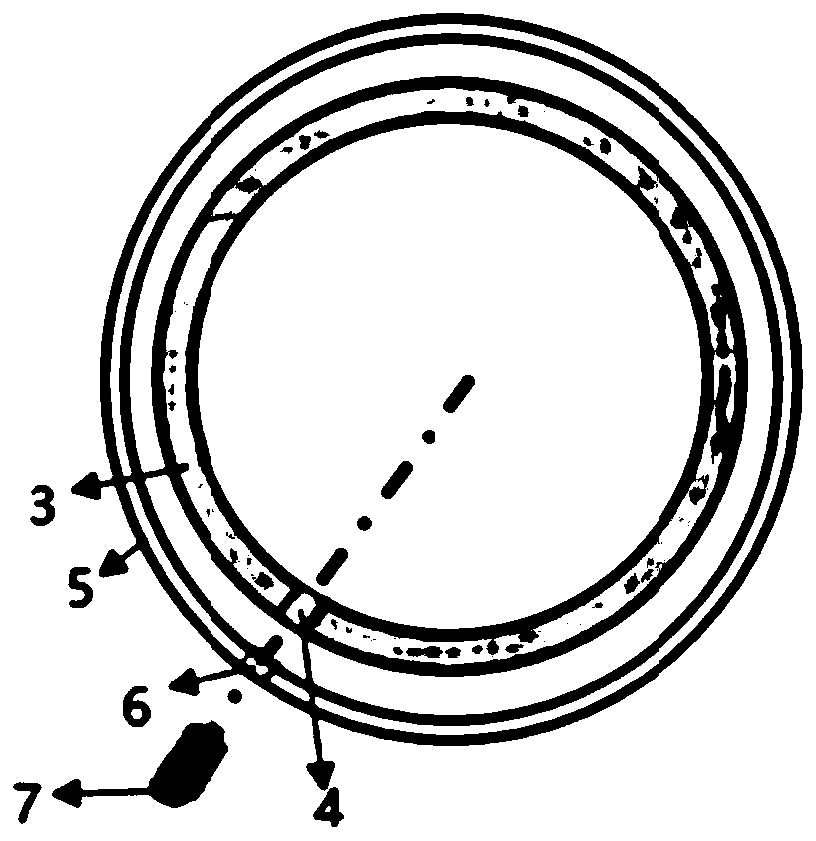

[0038] see Figure 1 to Figure 3 , the Czochralski single crystal furnace of this embodiment includes a crucible and a heater, and the periphery of the heater is provided with an insulating layer. The peripheral support crucible 1-4 outside the quartz crucible 1-3 is made of graphite or carbon-carbon composite material, and the single crystal 1-1 is drawn from the melt 1-2 in the crucible. The heater includes a main heater 2 surrounding the crucible and an auxiliary heater 2-2 arranged at the bottom of the crucible. The insulation layer 3 is provided with a first window 4 in the vertical direction for the infrared thermometer 7 to measure the temperature.

[0039] The thermal insulation layer 3 of the present embodiment comprises a graphite thermal insulation inner cylinder 3-2 and an outer thermal insulation layer 3-1 arranged inside and outside, the main furnace cylinder 5 is arranged outside the thermal insulation layer 3, and the main furnace cylinder 5 is provided with t...

Embodiment 2

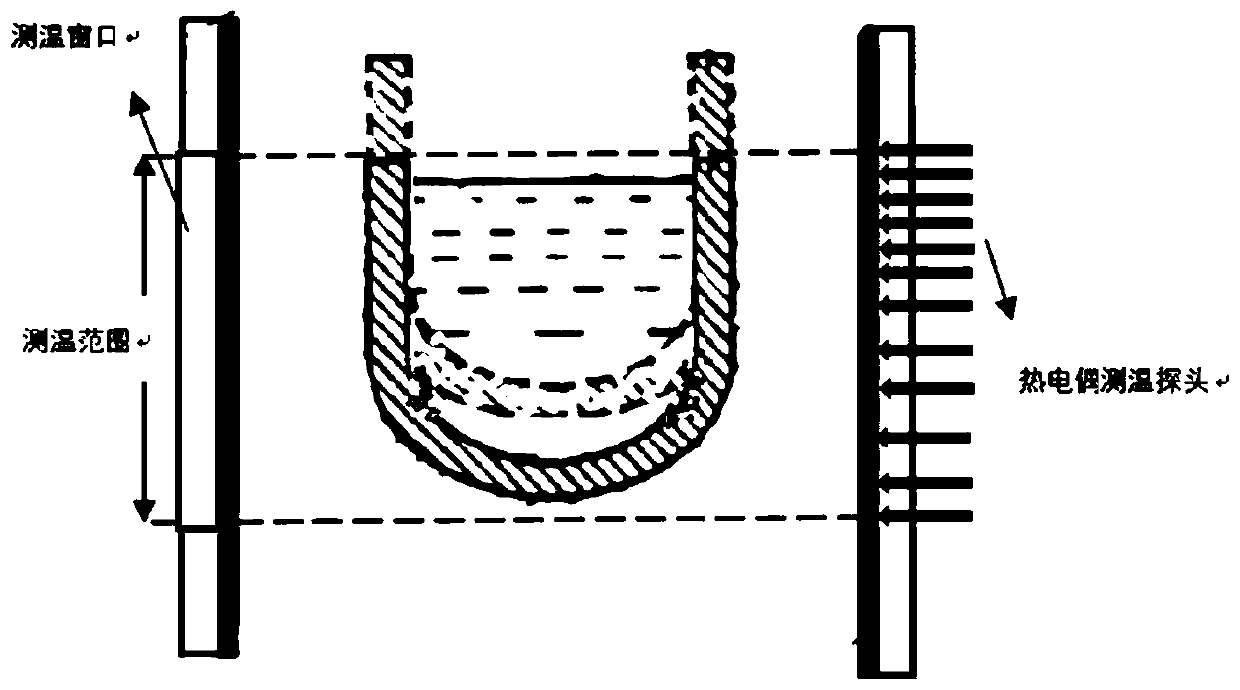

[0061] The Czochralski single crystal furnace and its longitudinal temperature gradient measurement and control method in this embodiment are the same as those in Embodiment 1 except that the temperature measurement structure and method are different from those in Embodiment 1, and will not be repeated here.

[0062] The first window is not provided on the insulation layer of this embodiment, and the second window is not provided on the main furnace shell. Thermocouple temperature measuring probes distributed along the vertical direction are arranged on the outer insulation layer 3-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com