Patents

Literature

35results about How to "Raise the reduction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

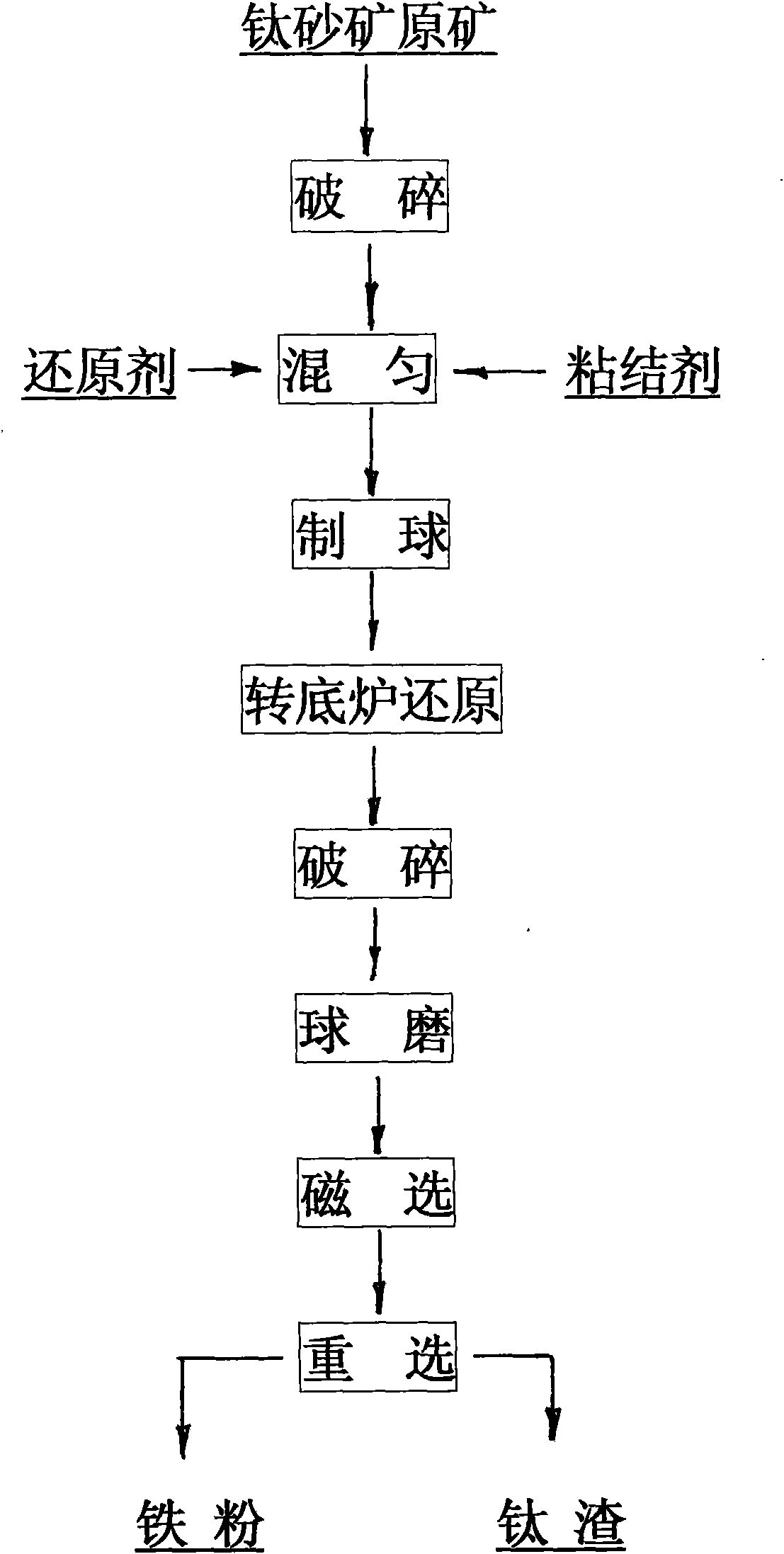

Method for producing ferrous powder and co-production titanium slag by rapidly reducing titanium placer pellets by rotary hearth furnace

InactiveCN101565768AAbandon distracting serious problemsImprove controllabilityRotary drum furnacesWet separationIron powderHearth

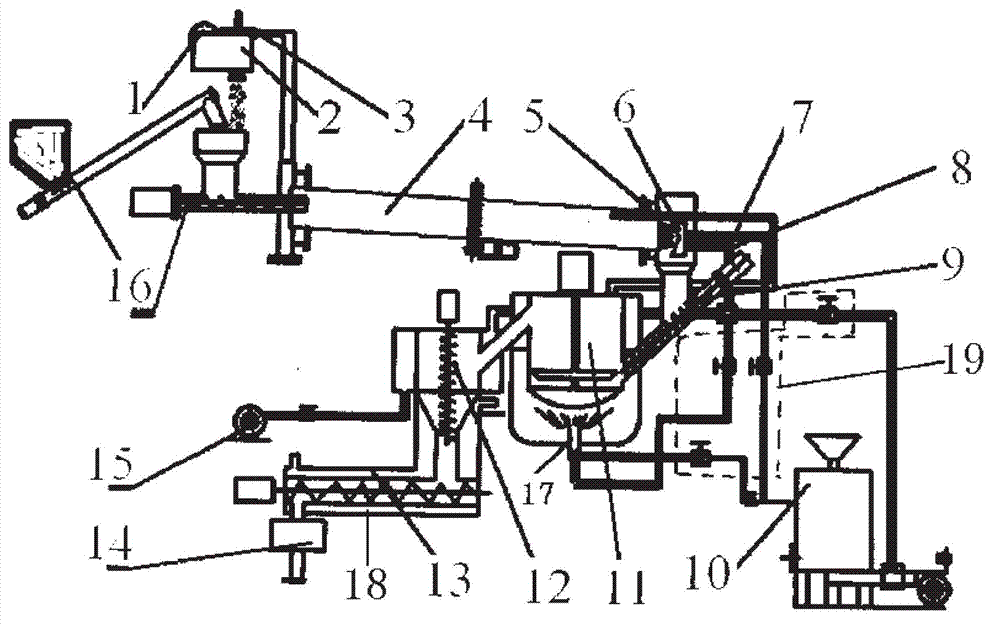

The invention discloses a method for producing ferrous powder and co-production titanium slag by rapidly reducing titanium placer pellets by a rotary hearth furnace, which comprises the following steps of: thinning titanium placer which is then added with a certain proportions of carbonaceous reducing agent, adhesive and concentrate ore and evenly mixing the materials; making pellets with the diameter of 10-40mm by a pellet forming machine; drying the pellets for 4-6 hours at the temperature of 200-500 DEG C and rapidly reducing the pellets in the rotary hearth furnace with the reducing temperature of 1200-1350 DEG C and the reducing time of 20-120min; crashing the pellets after being reduced; and then carrying out ball milling to the crashed pellets according to the grinding ore concentration of 50-80 percent, the ball milling time of 0.5-1.5h and the grinding ore fineness of 80-90 percent of -200 meshes; and after ball milling, carrying out magnetic separation and reelecting to obtain concentrate ore ferrous powder and tailing titanium slag, wherein the magnetic separation strength is 1000-4000 gausses. The invention adopts a method for rapidly reducing titanium placer pellets at the high temperature by the rotary hearth furnace, not only has even furnace temperature field, but also can quicken the reducing reaction speed, shorten the reducing time, improve the reducing efficiency and control the reducing temperature and atmosphere simultaneously.

Owner:KUNMING INST OF PRECIOUS METALS

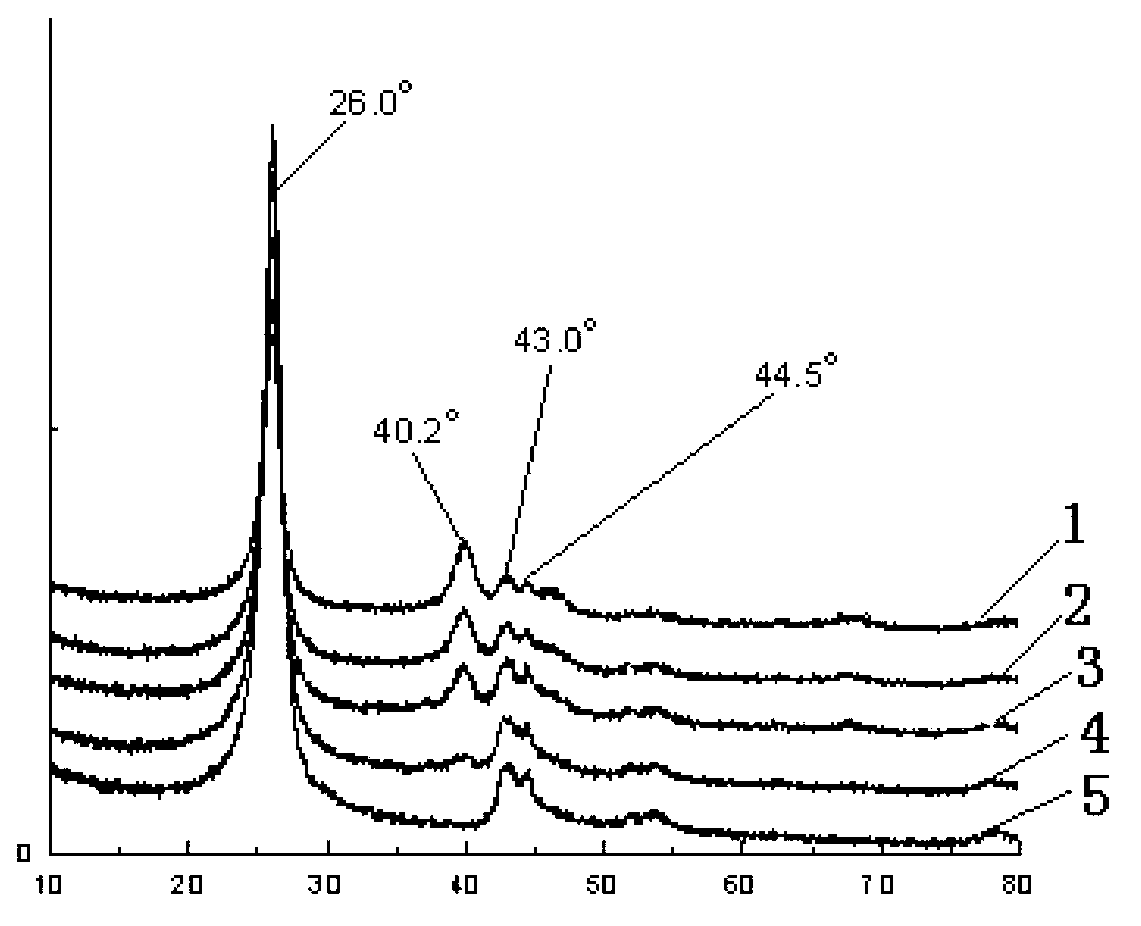

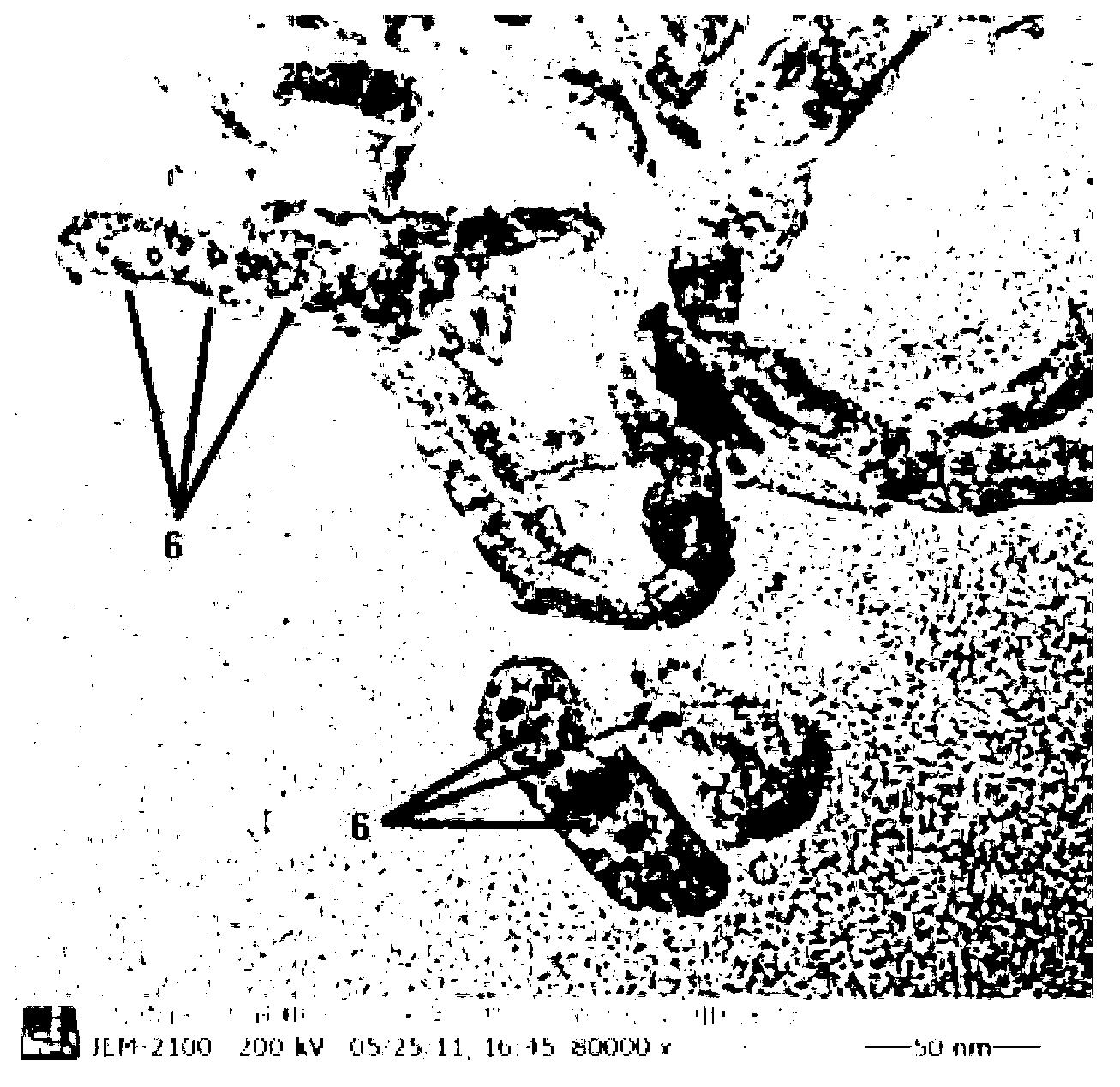

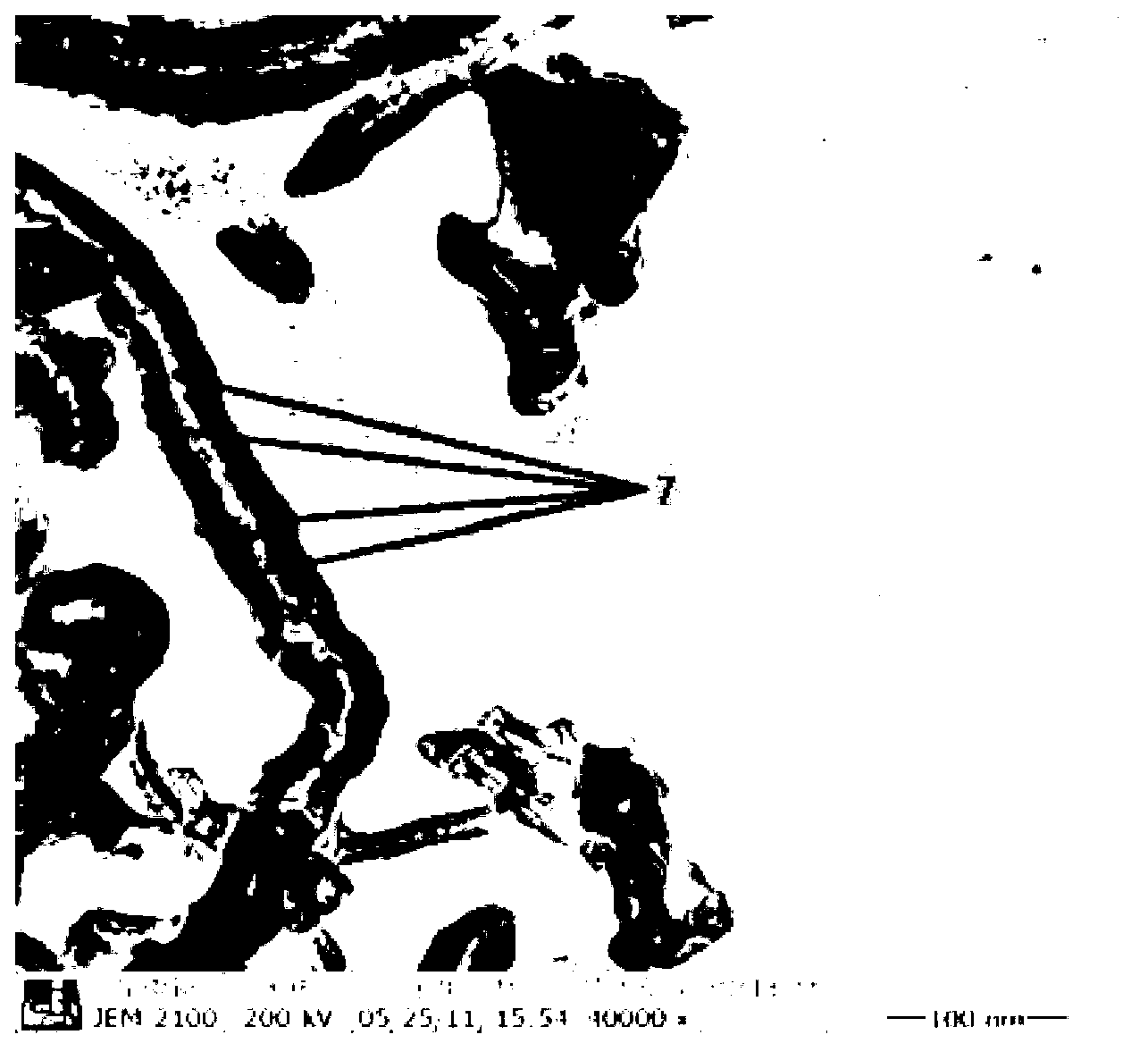

Highly dispersed palladium/carbon nanometer tube catalyst for anthraquinone hydrogenation and preparation method thereof

ActiveCN103055852AReduce dosageReduce storagePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsAnthraquinonesSlurry reactor

The invention discloses a highly dispersed palladium / carbon nanometer tube catalyst for anthraquinone hydrogenation and a preparation method thereof, and relates to a catalyst and a preparation method. According to the invention, a carbon nanometer tube industrial product with good conductivity, heat conductivity, high mechanical strength and huge external specific surface is used as a palladium carrier; simultaneously ultrasonic is utilized to further enhance the dispersity and uniformity of palladium and the carbon nanometer tube; and a nanometer palladium catalyst uniformly loaded on the surface of the carbon nanometer tube is prepared in a slurry reactor by adopting a liquid phase reduction method. The catalyst needs no extrusion molding and can be directly suspended in the liquid phase for normal-pressure or pressurized hydrogenation of anthraquinone; the activity of the catalyst is not reduced after the catalyst is used for a plurality of times by filtration and separation; moisture, acid and alkaline do not influence the use effect; the catalytic activity of the new catalyst is 4-8 times higher than that of the traditional Pd / gamma-Al2O3 catalyst, and the amount of the catalyst used can be greatly reduced. The catalyst can be used for replacing the traditional catalyst, the post treatment of the traditional catalyst is simplified, the treatment capability of a device is greatly increased, and the operation cost is lowered.

Owner:XIAMEN UNIV +2

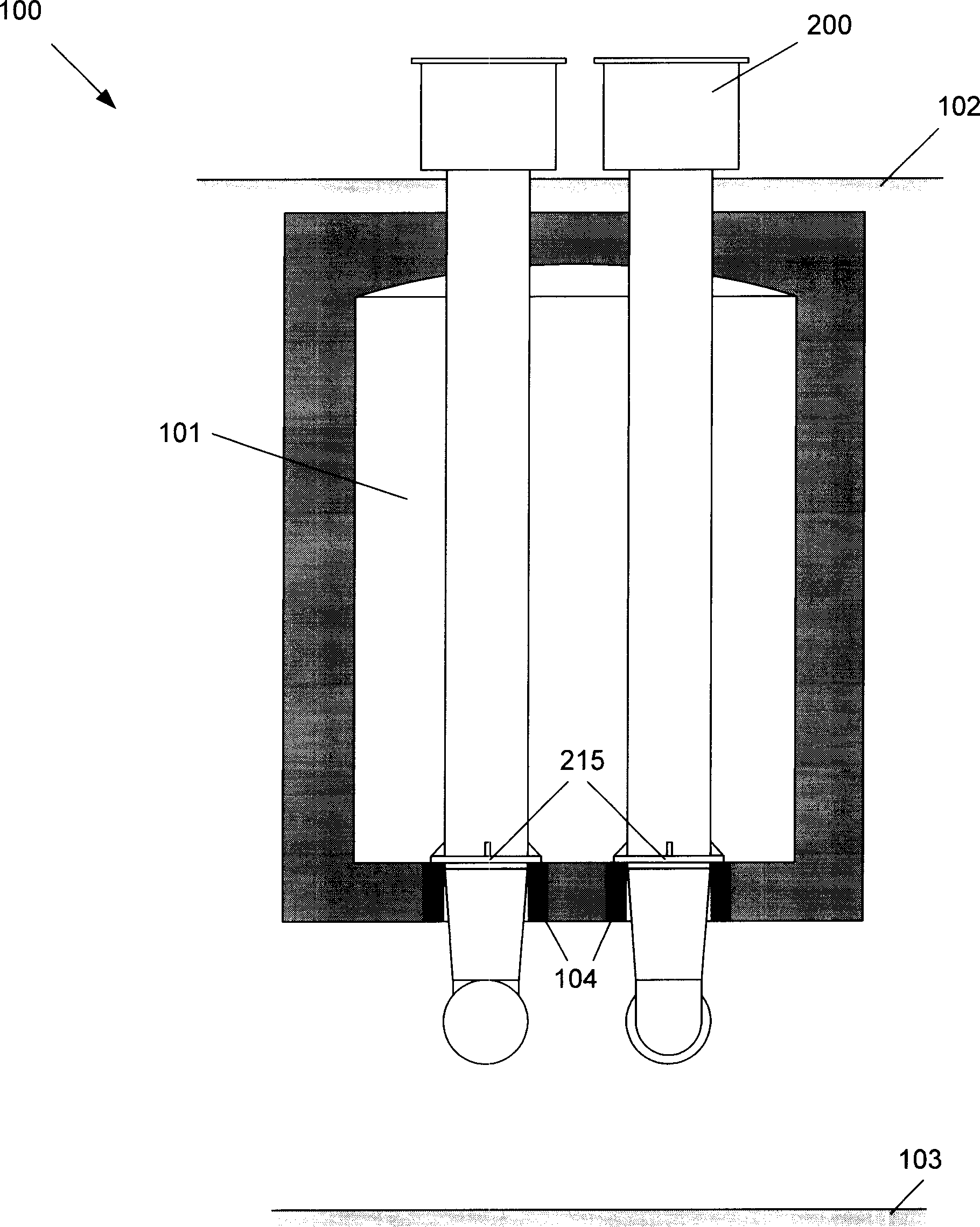

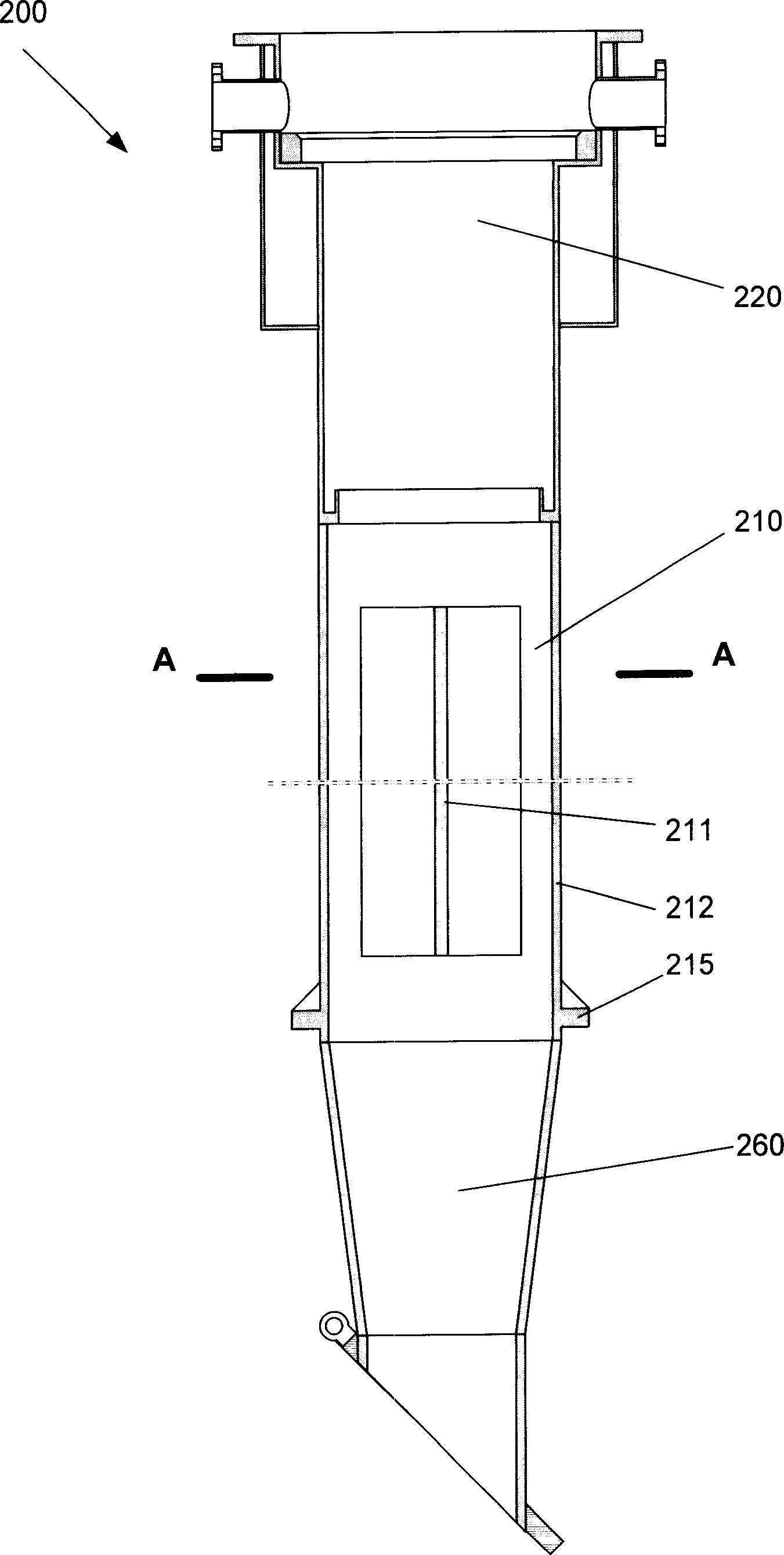

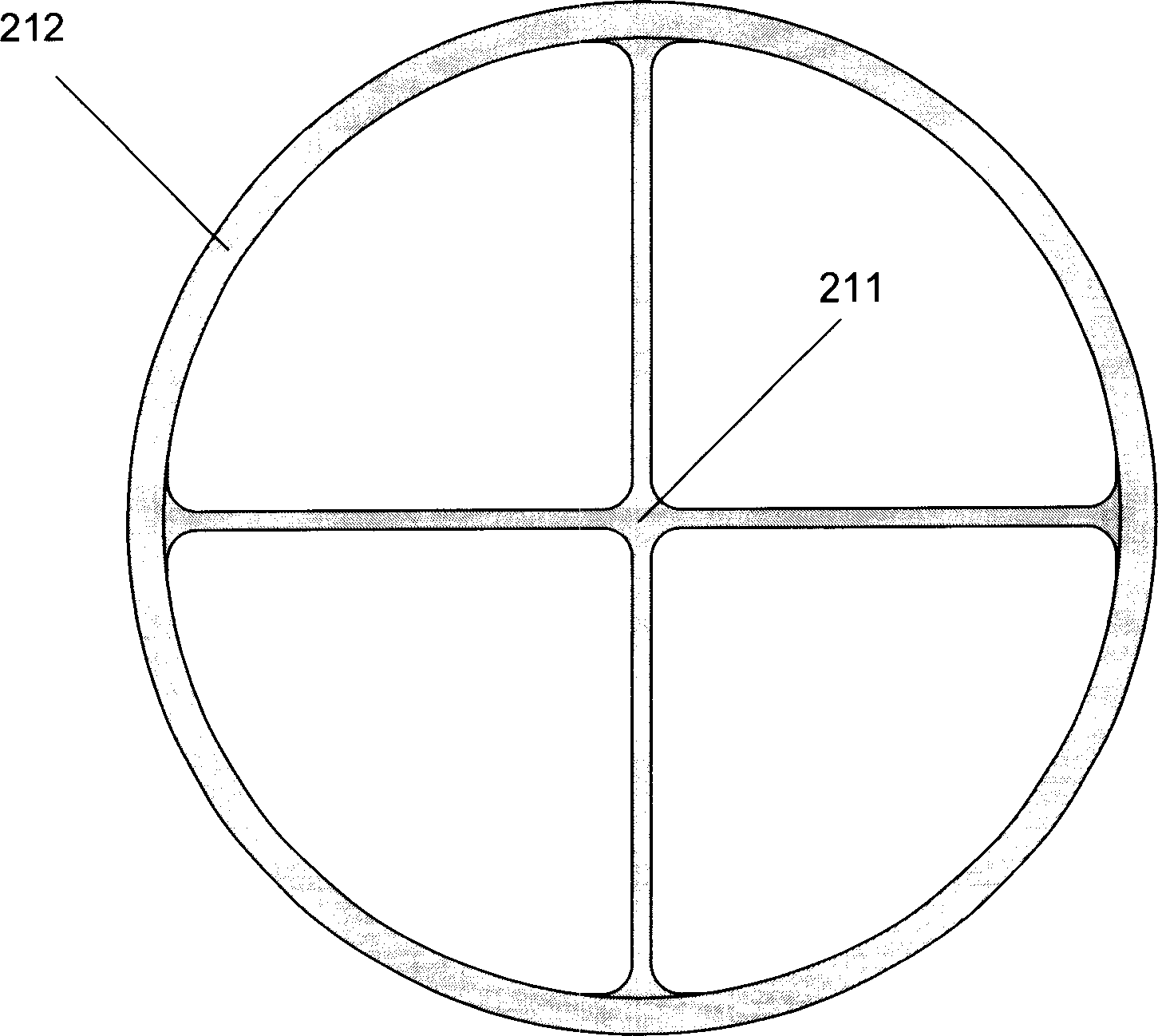

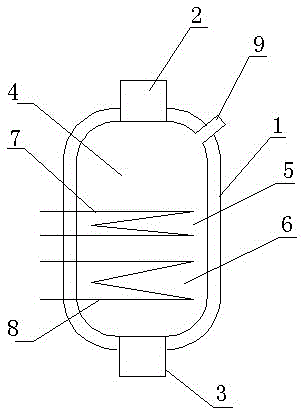

Pijiang metal refining method and device

InactiveCN1704489AImprove creep resistanceExtended service lifeReduction procedureHeat transfer efficiency

The invention discloses a method for reinforcing the heat transfer efficiency and creep-resistance for pidgeon process reduction tanks, a method for realizing pidgeon process reduction tank automatic charging and discharging, a method for continuous monitoring the pidgeon metal reduction procedure, a method for reclaiming reaction by-product base metals, a vertical reduction tank employing the methods and a pidgeon process reduction furnace constructed by employing the vertical reduction tank.

Owner:刘伟杰

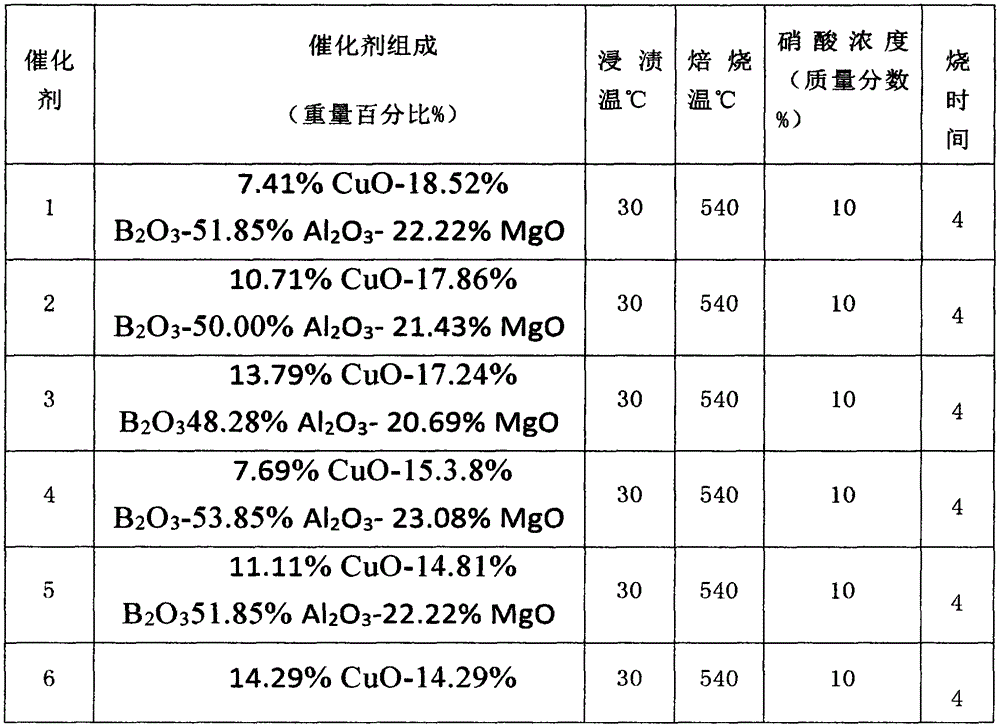

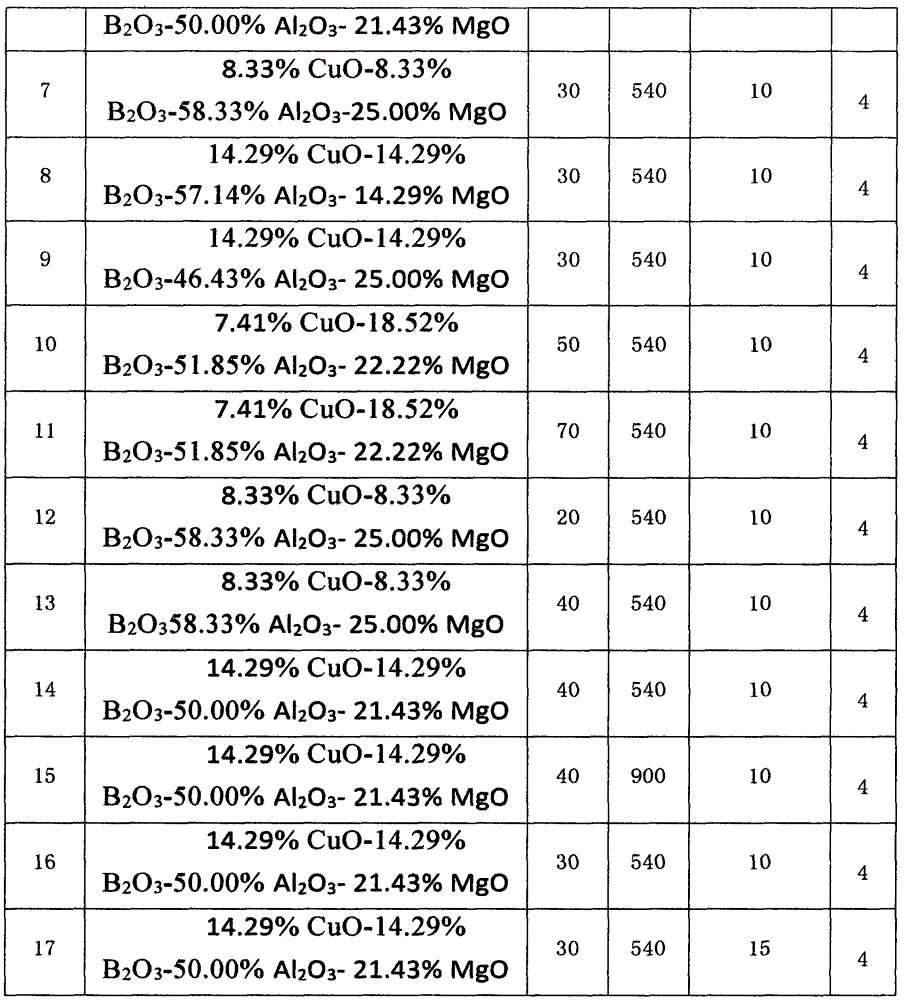

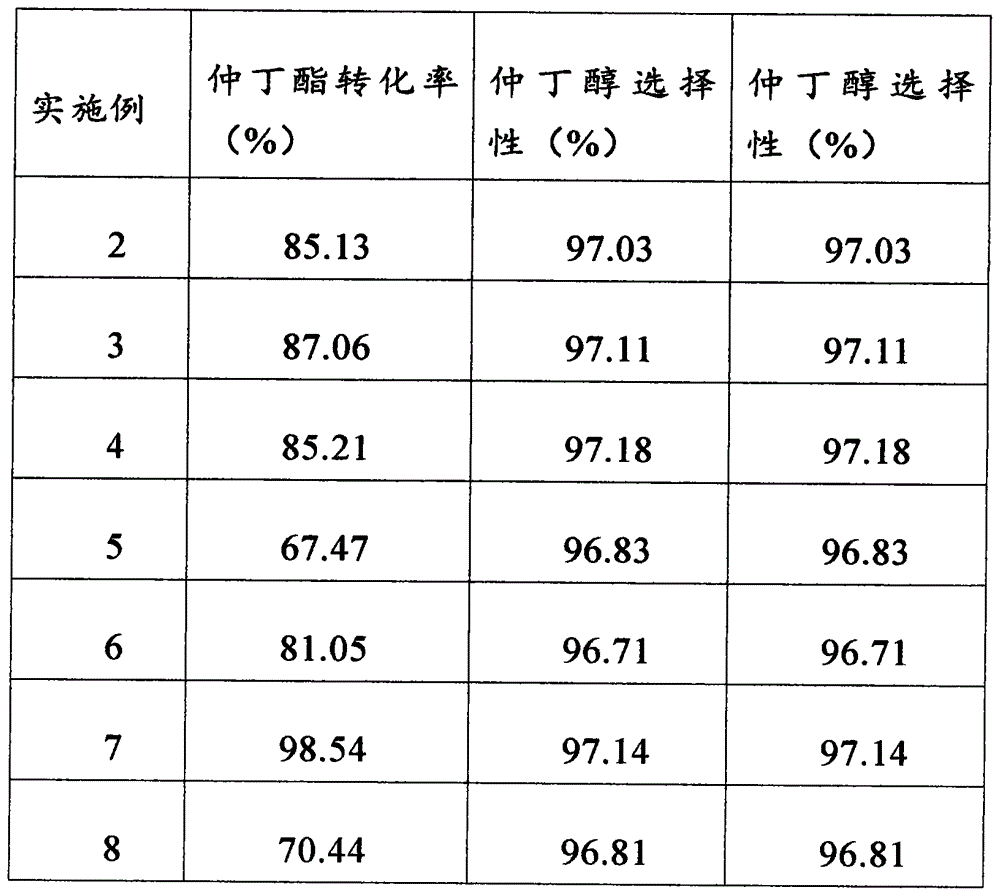

Catalyst for preparing sec-butyl alcohol and preparation method of catalyst

InactiveCN104475109AGood activity and stabilityHigh selectivityOrganic compound preparationHydroxy compound preparationReaction rateBoric acid

The invention relates to a catalyst for preparing sec-butyl alcohol and a preparation method of the catalyst. The catalyst is prepared from the following raw materials by weight percent: 5.0 to 25.0 percent of CuO, 5.0 to 25.0 percent of B2O3, 40.0 to 70.0 percent of Al2O3 and 15.0 to 35.0 percent of at least one of MgO, CaO or K2O. The preparation method of the catalyst comprises the following steps: mixing the at least one of MgO, CaO or K2O with Al2O3 powder to obtain a mixture; extruding and molding the mixture, drying, roasting the mixture to obtain a needed carrier (I); immersing the surface of the carrier (I) by utilizing a boric acid solution, drying the carrier, and roasting the carrier at a high temperature to obtain a modified carrier (II) of the catalyst; and finally immersing the surface of the modified carrier (II) by utilizing a Cu(NO)2 solution, drying, and roasting the modified carrier at high temperature to obtain the needed catalyst. The catalyst is good in activity stability and capable of increasing the yield and conversion ratio of the sec-butyl alcohol; the preparation method of the catalyst is high in selectivity, relatively high in reaction rate, moderate in reaction condition and small in corrosion performance.

Owner:BEIJING ENZE FULAI TECH +1

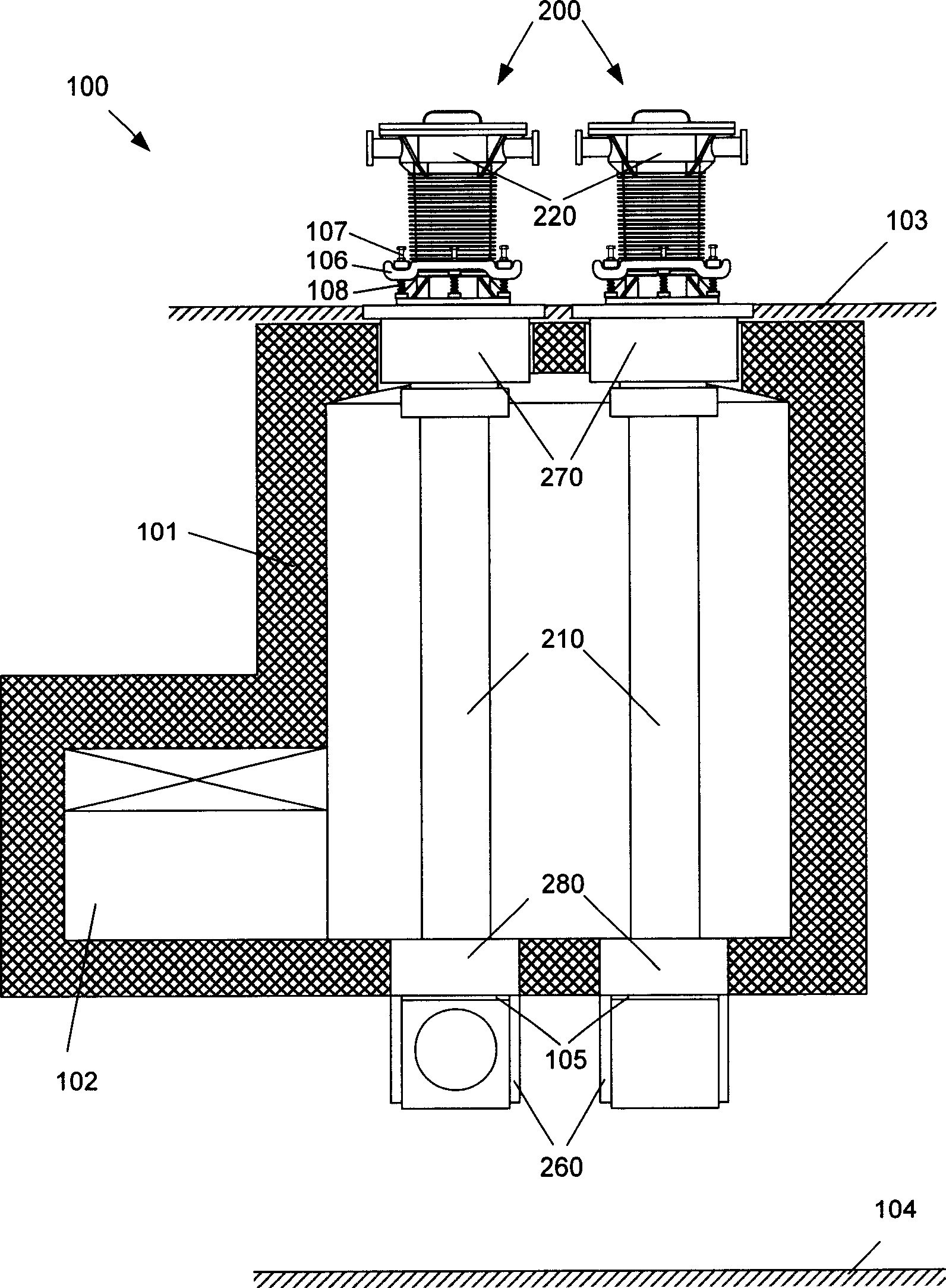

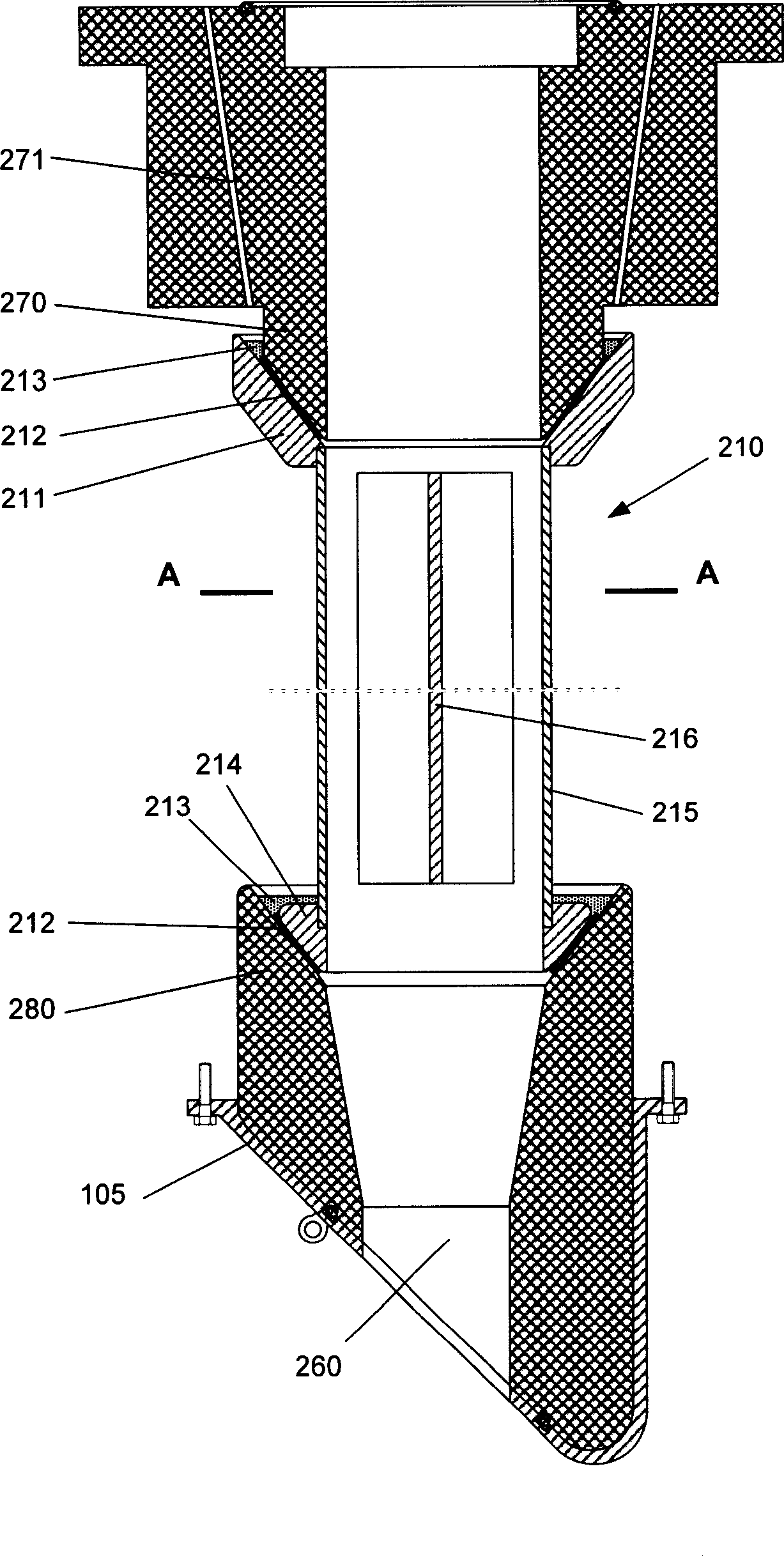

Vertical reduction tank and reduction furnace device for metal smelting

InactiveCN1876856AReduce heat leakageReduce consumptionProcess efficiency improvementHeat transmissionIngot

A leakage method of obstruction reducing furnace intrinsic heat towards the furnace outside along reduction bank; a method which can simultaneously strengthen the coefficient of overall heat transmission and creep resistance of the reduction bank; an air cooling method for metal ingot cylinder of the reduction bank; a method of carrying automatic shipping and delivery of the reduction bank using earth gravity; an on-line continuous monitoring method for matallic reducing process. A vertical reduction bank is built with the said method. A vertical reducing furnace built with the said vertical reduction bank is characterized in that it is of high calorific efficiency, short reduction cycle, long reduction bank age and automatic charge, and can perform on-line observation for reduction process.

Owner:刘伟杰

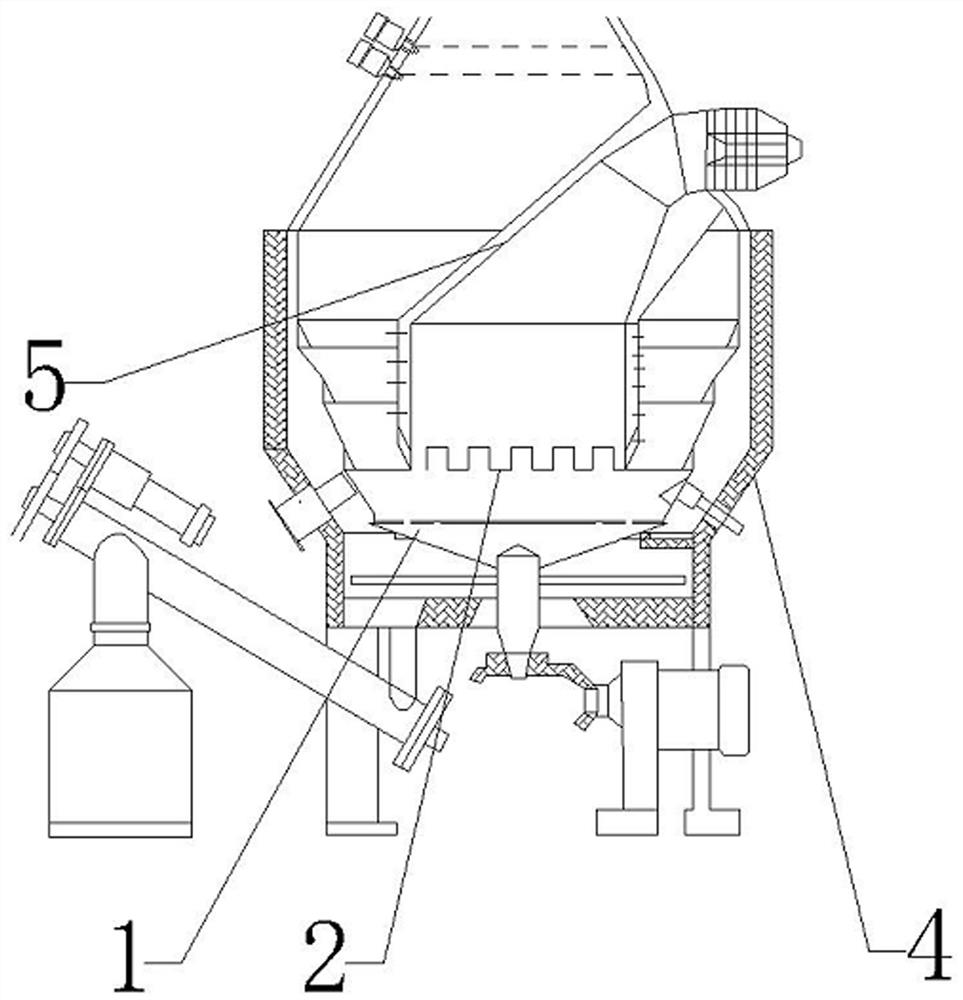

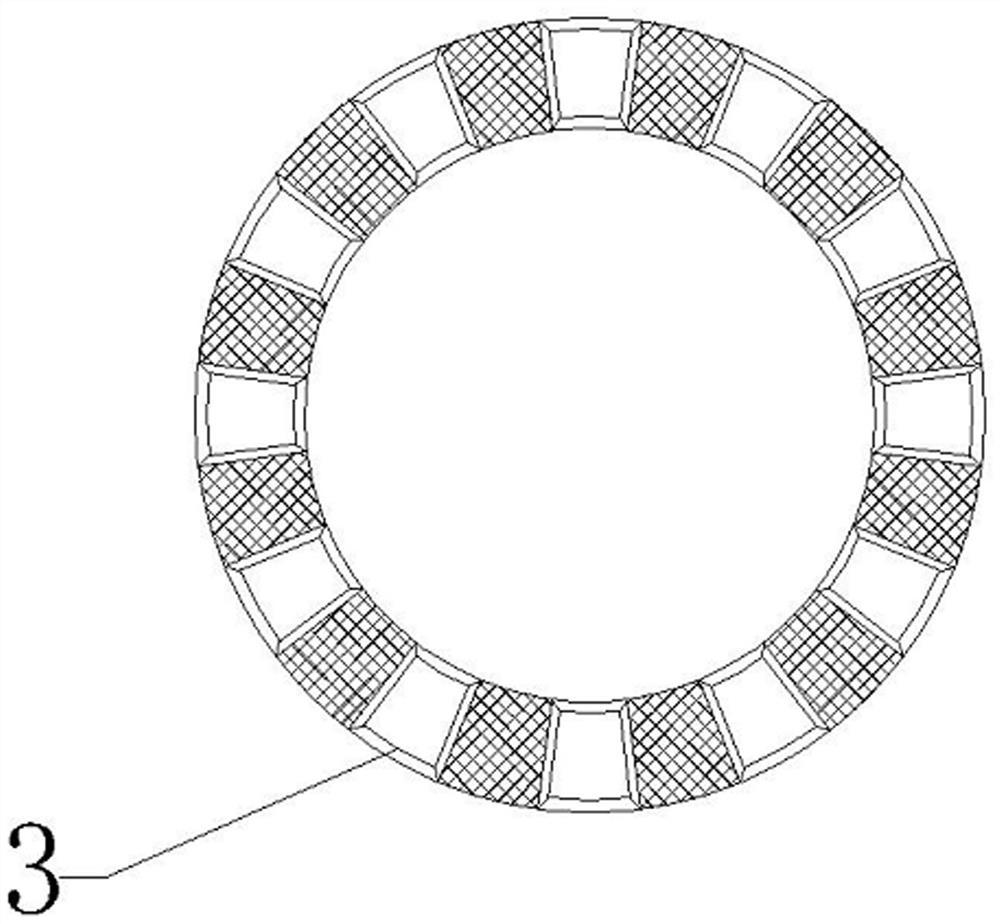

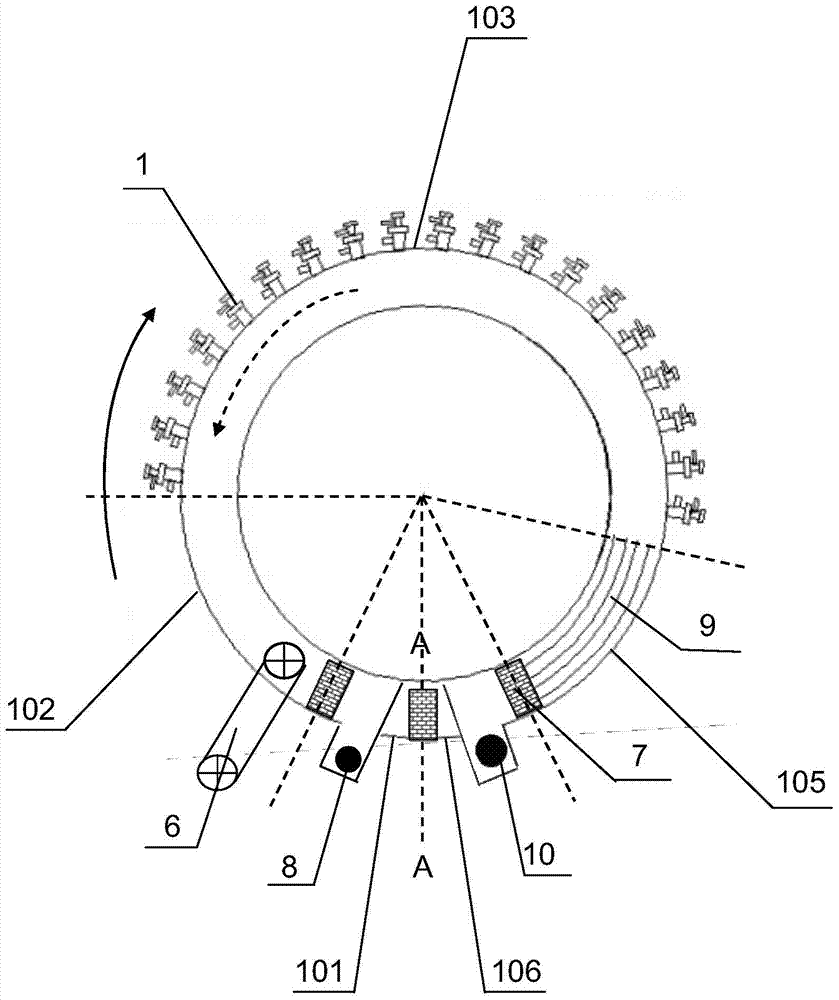

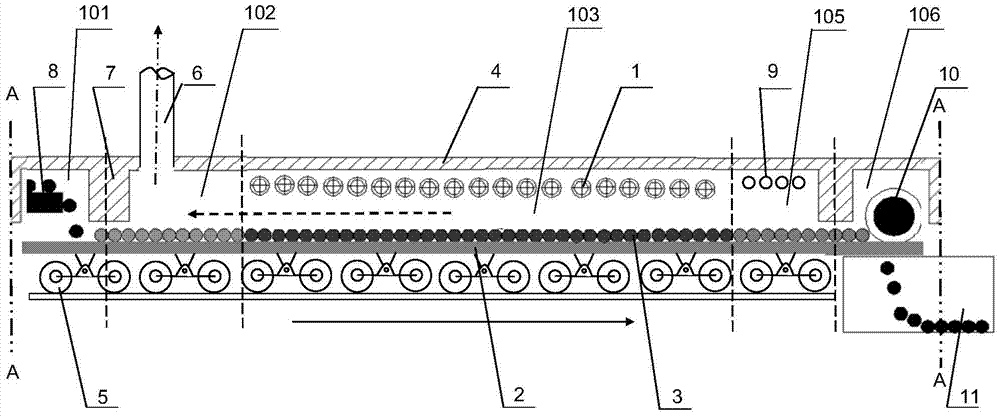

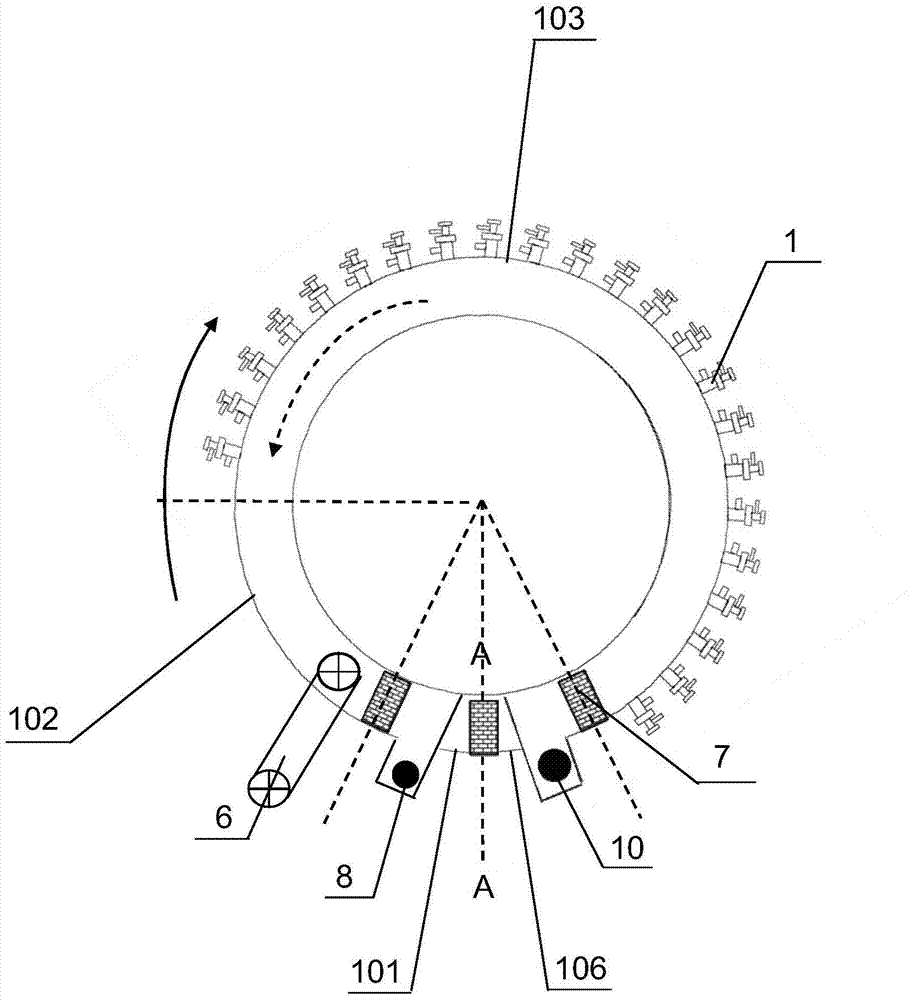

Microwave-fuel combined heating-type coal-based direct reduction method and rotary hearth furnace

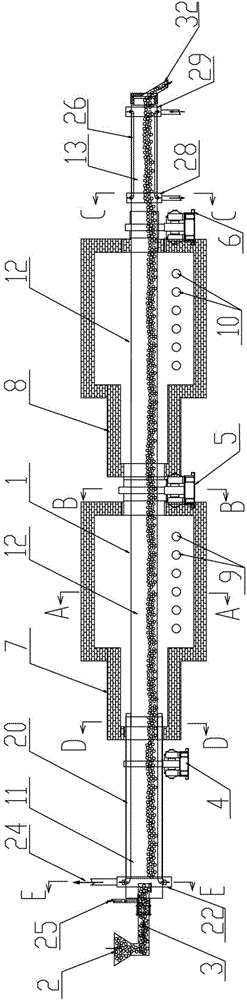

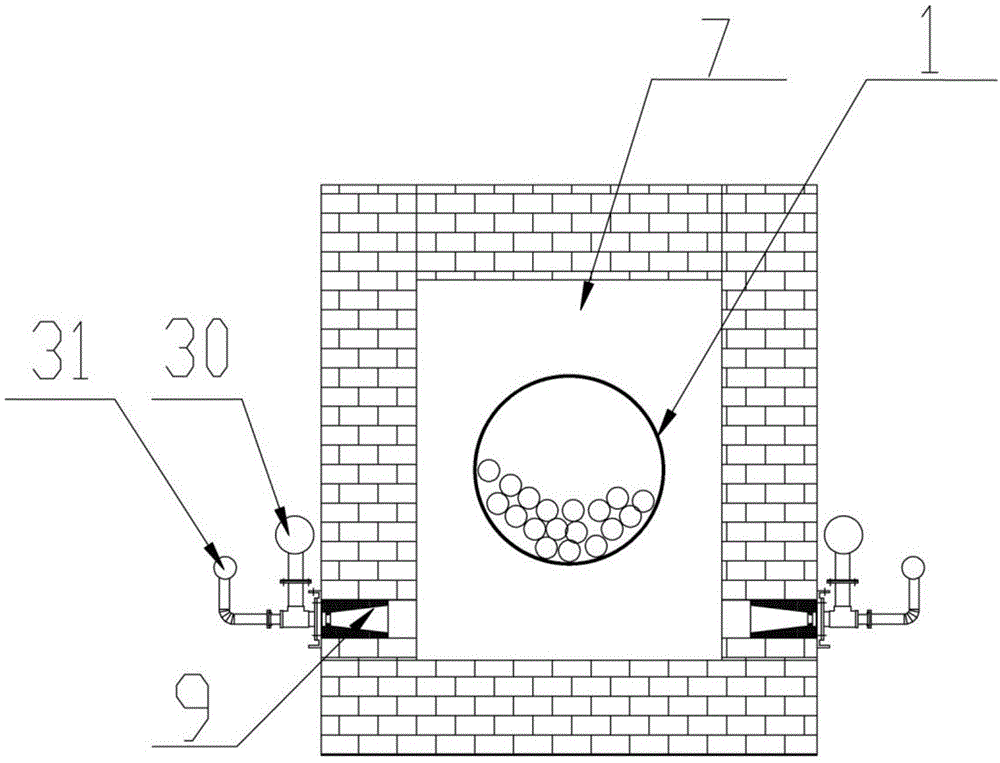

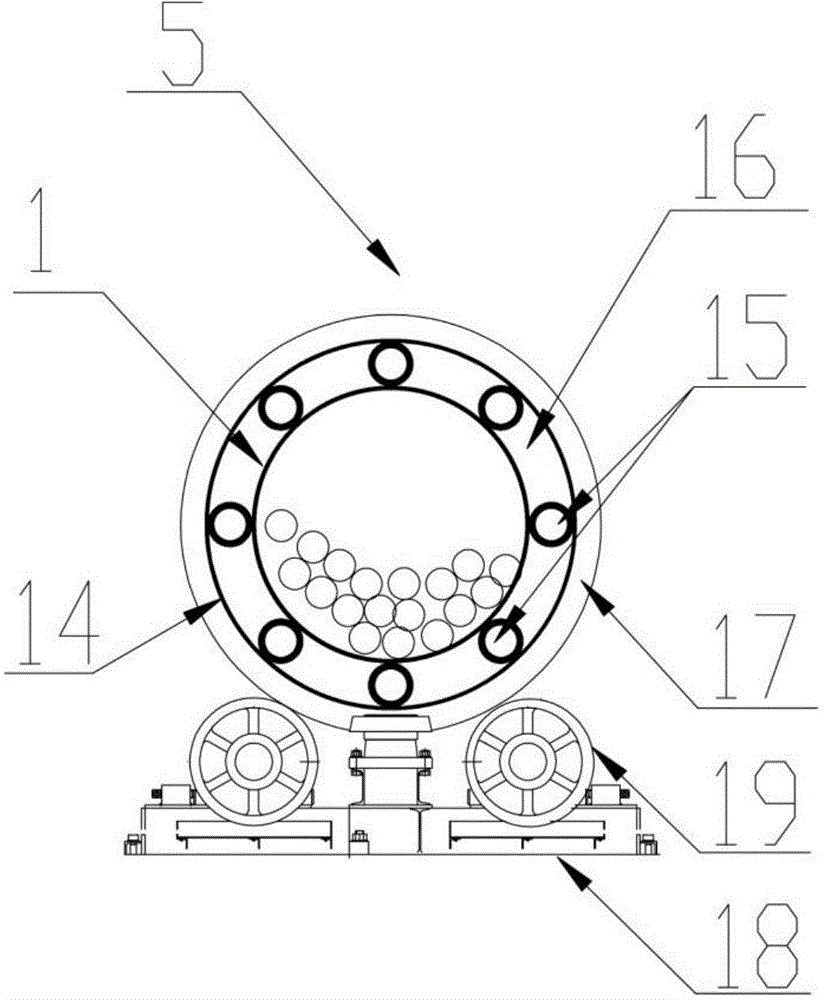

The invention discloses a microwave-fuel combined heating-type coal-based direct reduction method and a rotary hearth furnace. The method comprises the following steps of drying and pre-heating materials, reducing the materials by a fuel combustion method, and further reducing the materials by a microwave radiation method, wherein a reducer for reducing the metal oxide into metal is fixed carbon in the materials. The rotary hearth furnace is used by the above method. The rotary hearth furnace has the advantages of simple structure, low cost, high metallization rate, and realization and popularization easiness.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Oxide briquetting used for steelmaking alloy element and preparation method thereof

The invention discloses an oxide briquetting for steelmaking alloying elements, which includes oxide(s) and reducer(s) containing alloying elements, wherein the oxide(s) is / are one or more than one selected from oxides of chromium, molybdenum, vanadium, tungsten, titanium, nickel, boron, niobium, zirconium and cerium, the reducer(s) is / one or two selected from appropriate carbon, silicon and aluminum. The manufacturing method is adding appropriate reducer and binder to the steelmaking alloying elements oxide powder, mixing the reducer and binder in proportion, press forming, and drying. The invention solves the problems of complicated process, high energy consumption, high pollution and resource waste, which are problems of current iron alloy for steelmaking, at the same time, solves the problem of low utilization rate when the current alloying elements oxide is used as alloying addition.

Owner:谢应旭

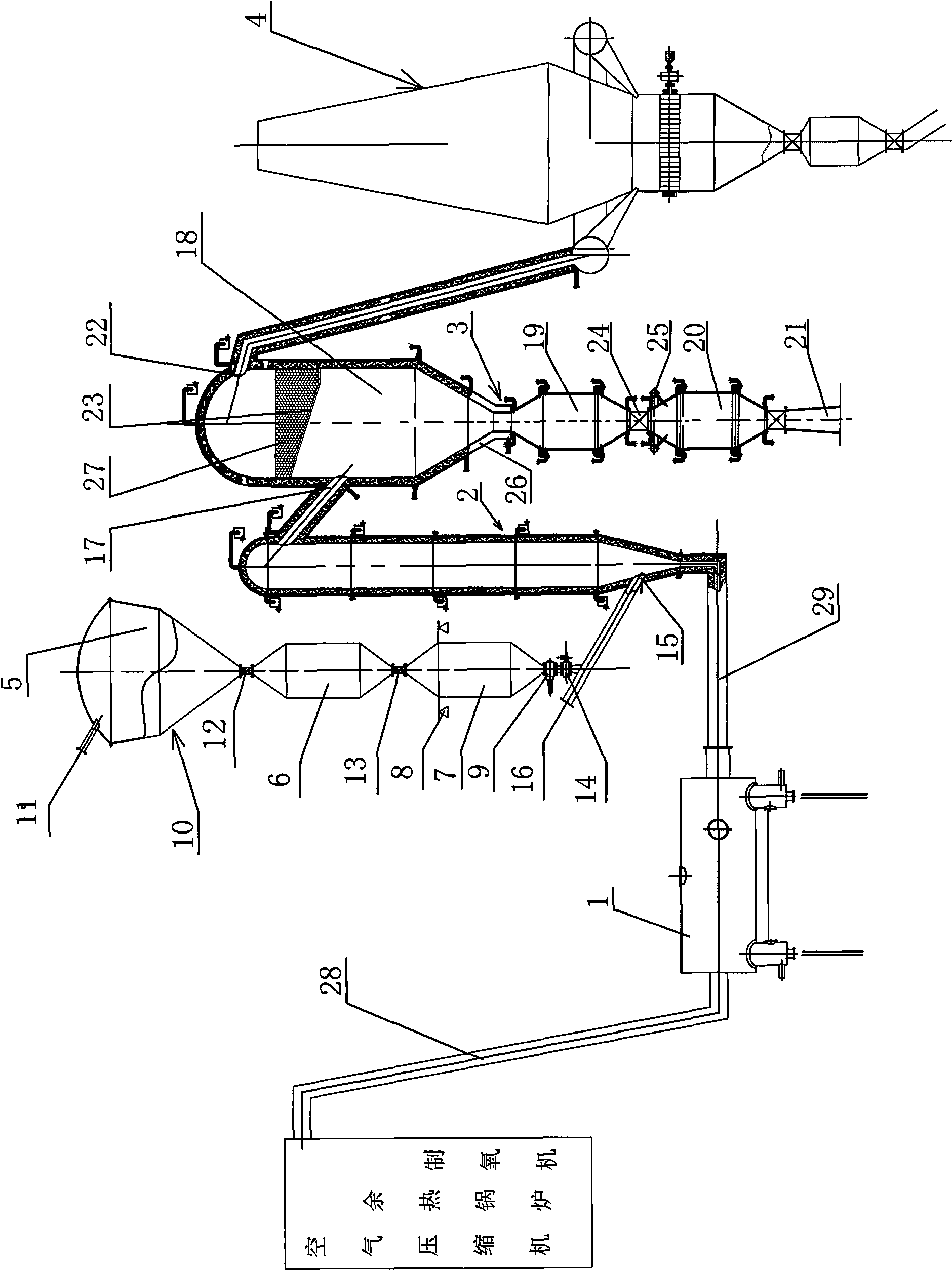

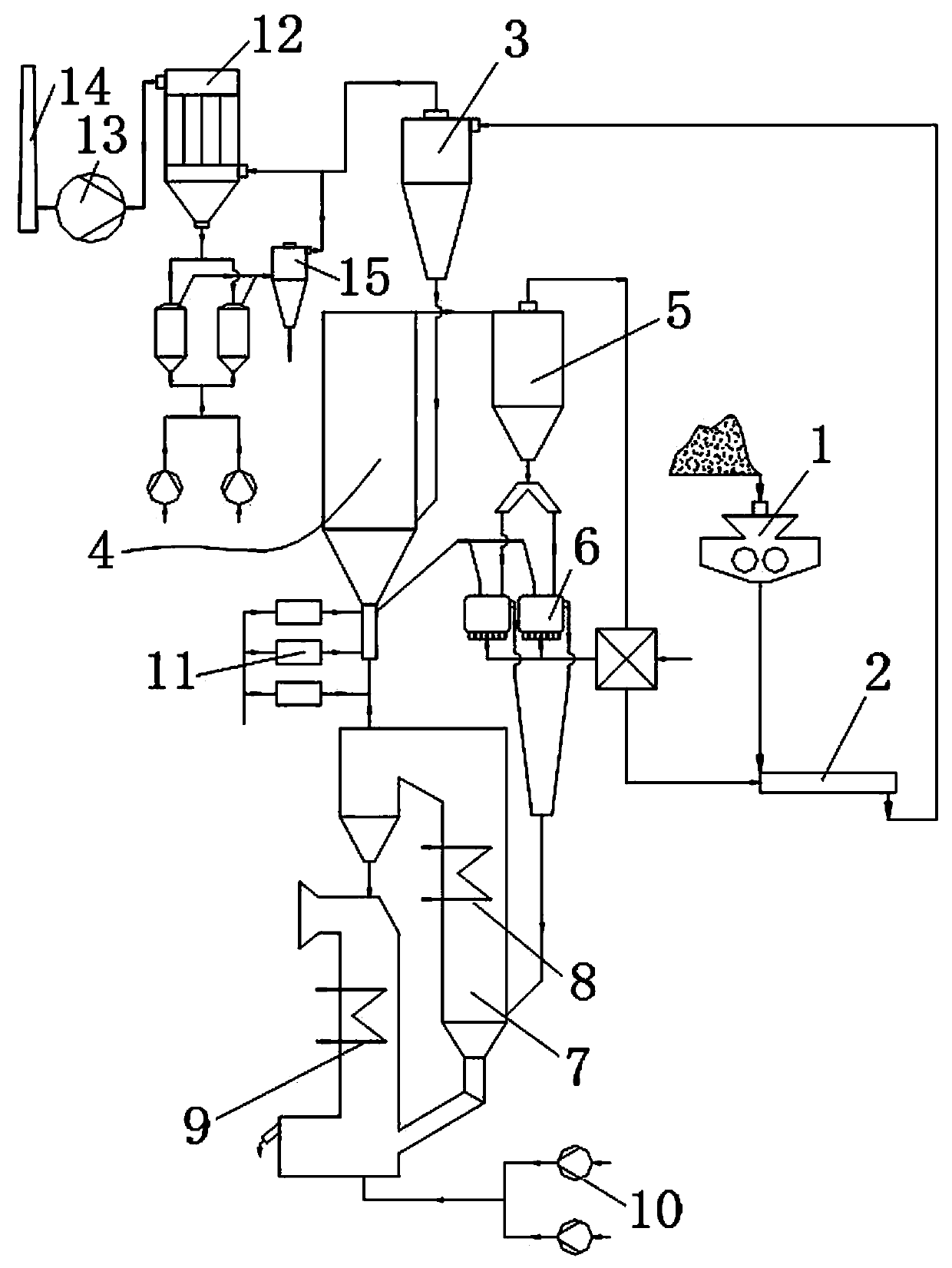

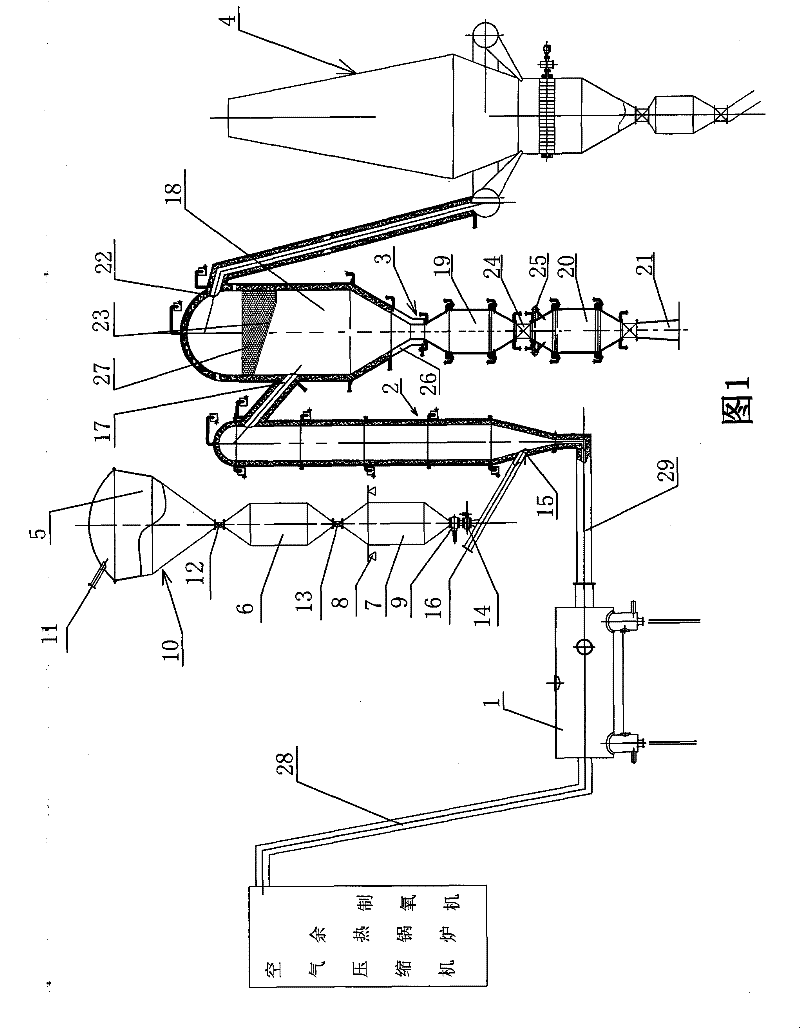

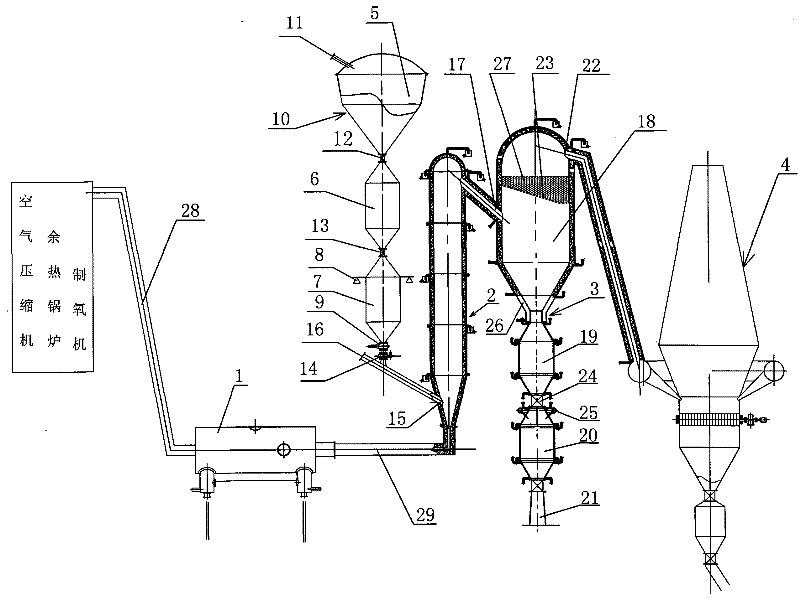

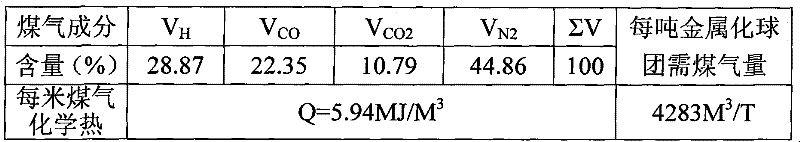

Method and apparatus for reducing metallic pellet by using coal dust in high furnace

The invention discloses a metallized pellets reduction method by pulverized coal and a shaft furnace. The method comprises steps of fabricating pellets of iron ore powder or powder of other metallic oxide ore, putting the pellets into the shaft furnace by a set quantity measurement, raw coal with a lower heating value bigger than or equal to 16MJ / Kg and with an ash dry basic smaller than or equal to 40% being dried and milled by an intermediate-speed coal mill until the mesh number is smaller or equal to 100 and the moisture content is smaller or equal to 0.5%, pre-heating the pulverized coal to the temperature of 80 DEG C - 150 DEG C, transferring the pulverized coal to an air-fluidized bed gas generator,mixing the water vapour and the air in proportion, the high-temperature coal gas produced by the air-fluidized bed gas generator passing through a hot precipitator, directly spraying the coal gas after that 90%-95% dust of the coal gas has been eliminated to the lower part of the shaft furnace, the upper part of a material-discharging roller participating in the reduction reaction in the shaft furnace, reducing the iron or other metallic oxide into metallized pellets.The invention has a high reduction temperature, a high reduction speed, a high exhaust physical heat and a chemical heat which is 1.5 times higher than that of the blast furnace gas, reductive cost is greatly reduced by using the middle coal with a low heating value and a high fugitive constituent as the reductive, therefore, the per-ton cost of the generated energy sources of electrical energy, coal gas and the like is lower than 1500 yuan / t.

Owner:沈阳东方钢铁有限公司

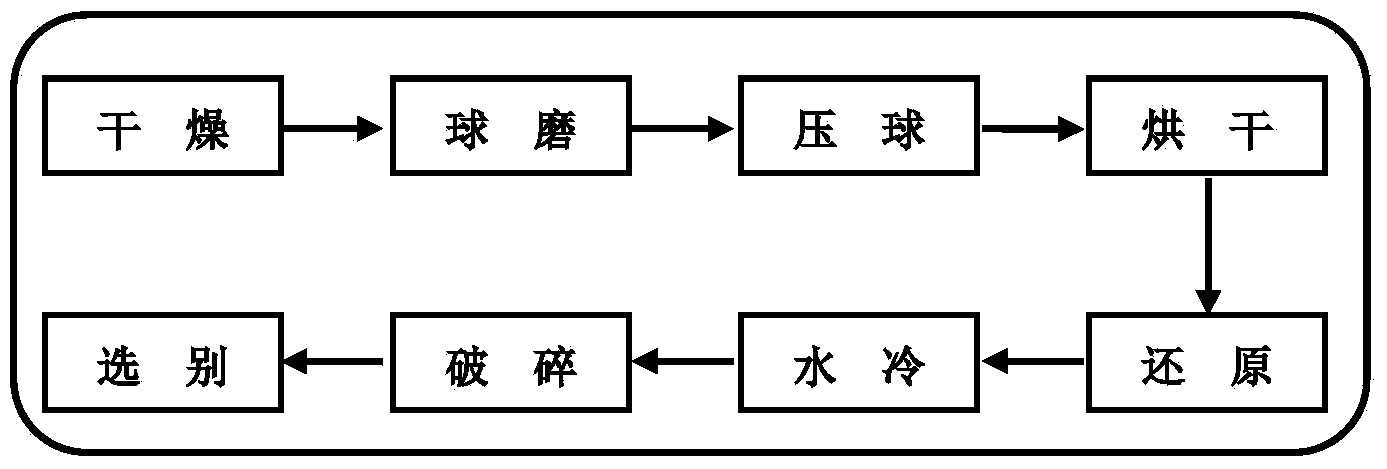

Method for preparing nickel-containing stainless steel raw material from laterite-nickel ore by one-step process

The invention belongs to the field of nonferrous metallurgy, and particularly relates to a method for preparing a nickel-containing stainless steel raw material from laterite-nickel ore by a one-step process. The method comprises the following steps: 1) drying the laterite-nickel ore; 2) performing ball milling on the dried laterite-nickel ore and the reducing agent pulverized coal; 3) adding quick lime and the ball-milled reducing agent pulverized coal into the ball-milled laterite-nickel ore, and pressing into green balls; 4) drying the pressed green balls; 5) quickly reducing the dried green balls; 6) performing water cooling on the balls after reducing roasting; 7) breaking and separating the reduced balls to below 3mm, thereby obtaining the nickel-containing stainless steel raw material by a reselection or magnetic separation way. According to the method provided by the invention, with specific reducing equipment, the reducing temperature is increased, the ball reducing time is greatly shortened, and the nickel recovery rate is improved. Meanwhile, the application range of the raw material is expanded for the dosing and ball pressing method for the low-grade laterite-nickel ore.

Owner:莱芜钢铁冶金生态工程技术有限公司

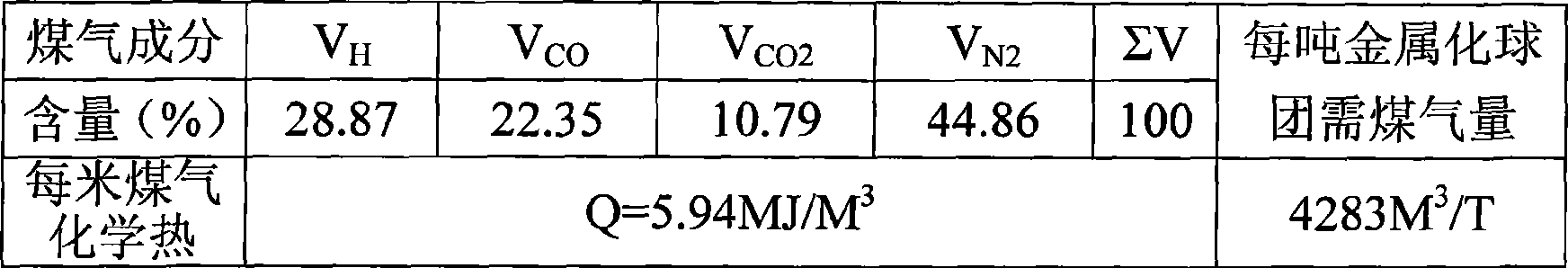

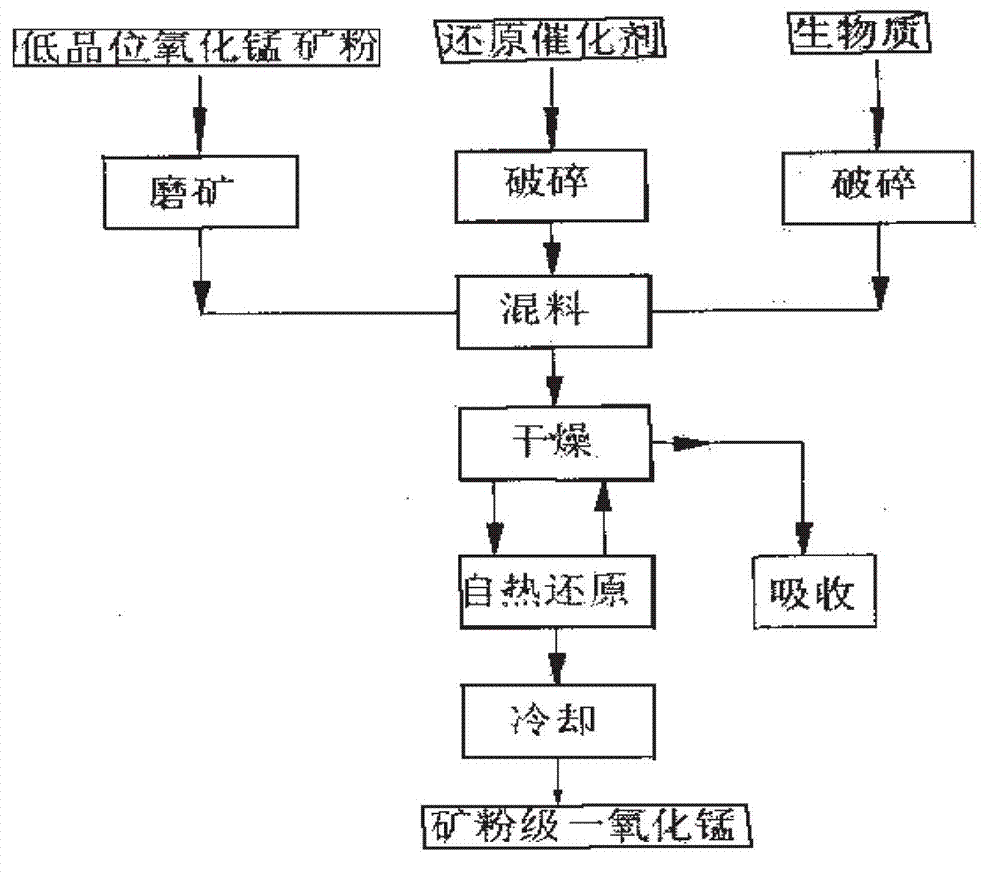

Device and process for producing manganese monoxide through reduction of low-grade manganese oxide ore by using biomass

InactiveCN102849801AReduced activityReduce consumptionManganese oxides/hydroxidesManganese oxideReducing agent

The invention discloses a device and a process for producing manganese monoxide through the reduction of low-grade manganese oxide ore by using biomass. The invention belongs to the technical field of ferrous metallurgy. According to the device, a biomass gas combustor is arranged on the rear of a rotary kiln. The rotary kiln is connected to a reaction furnace through a reaction furnace thruster. The reaction furnace is connected with a stewing tank. The stewing tank is connected with a spiral cooler. The process comprises the steps that: the mineral, a reduction catalyst, and biomass are respectively crushed and are mixed; the mineral, the reduction catalyst, and the biomass are dried in the rotary kiln; through biomass gas combustion, the reduction reaction between the biomass and the mineral is ignited; the raw material is delivered into the reaction furnace; a self-heating reduction reaction is carried out, wherein the reduction upon the mineral is further accelerated with the reaction heat in the reaction furnace; The material is delivered into the stewing tank, such that the reaction can be carried out more sufficiently; the material is cooled to normal temperature, such that mineral-powder-grade manganese monoxide is obtained. Traditionally, coal is adopted as a reducing agent in manganese oxide reduction, the reduction temperature is high, energy consumption is high, and production cost is high. With the device and the process provided by the invention, the defects are overcome.

Owner:TSINGHUA UNIV

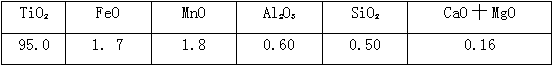

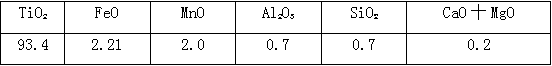

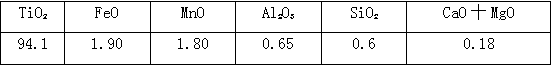

Technological method for improving TiO2 grade of synthetic rutile by reduction rust method

The invention discloses a technological method for improving TiO2 grade of synthetic rutile by a reduction rust method. The method comprises the following steps: 1, selecting high-grade seashore altered titanium concentrate with TiO2 not less than 56%, performing stepped magnetic separation and high tension separation for the titanium concentrate; 2, putting the titanium concentrate obtained in the step 1 into a rotary kiln to be subjected to high-temperature negative-pressure sealing reduction; 3, using a high-temperature material from a reduction kiln to be introduced into a rust tank through high-temperature steam produced by a heat exchanger, and controlling the content of metallic iron below 0.3%; 4, carrying out combined washing on a rusted titanium-rich material by using a horizontal spiral classifier, a vertical spiral chute and a vacuum belt filter press; 5, firstly, carrying out acid leaching on a washed titanium-rich material with dilute hydrochloric acid of which the concentration is 10 to 15%; then adding diluted hydrofluoric acid of which the concentration is 2 to 5% to perform acid leaching for 0.5 to 1 h; and 6, drying the titanium-rich material obtained in the step 5, and then improving the TiO2 grade through dry magnetic separation. The method does not require pelletizing, crushing and ore grinding, and further does not need to perform pre-oxidation treatment, and is simple in treatment process of raw materials before reduction and low in cost.

Owner:MAOMING UBRIDGE GROUP MINERAL IND +1

Coal-base low-temperature quick deep reduction method of high-density metallized pellets

InactiveCN104630408AContinuously stable temperatureNo stickingRotary drum furnacesSteelmakingAdhesive

The invention belongs to the technical field of metallurgy, and particularly relates to a coal-base low-temperature quick deep reduction method of high-density metallized pellets, which comprises the following steps: uniformly mixing iron ore powder or iron scale to be reduced with carbon powder and an adhesive, and spraying water to prepare phi8-phi20mm pellets; drying, preparing a material to be reduced from the pellets and a reducer, adding the material to be reduced into a flame-isolated rotary kiln, carrying out reduction reaction, and carrying out magnetic separation to obtain the high-grade high-density metallized pellets, of which the grade TFe is greater than or equal to 90%, etaFe is greater than or equal to 93% and the density is greater than or equal to 4.3t / m<3>. The reduction apparatus adopts a flame-isolated rotary kiln, thereby saving the energy. The material reaction is more violent, thereby greatly shortening the reaction time. The high-density metallized pellets with the density of greater than or equal to 4.3t / m<3> have the advantages of uniform particle size, high grade, simple components and trace amounts of harmful elements, and is suitable to be used instead of steel scrap, a diluter and a cooling agent for steelmaking.

Owner:泉州寰锋冶金技术有限责任公司

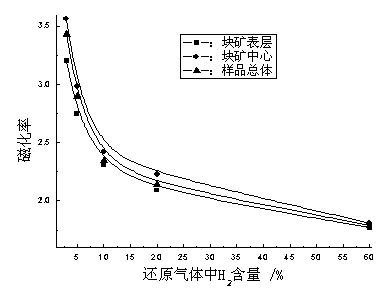

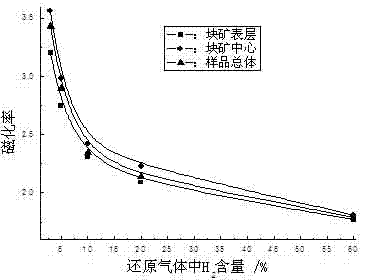

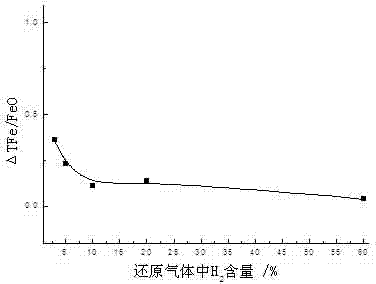

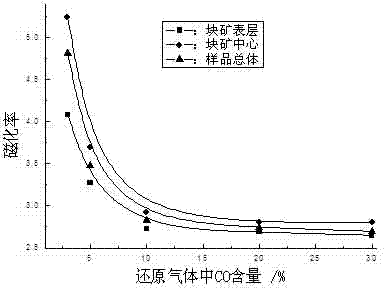

Roasting method of efficiently controlling iron ores to be magnetized

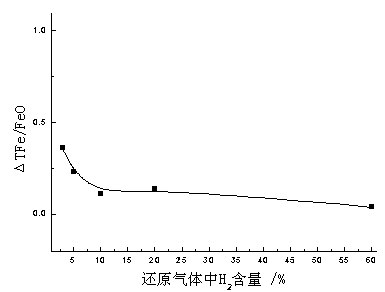

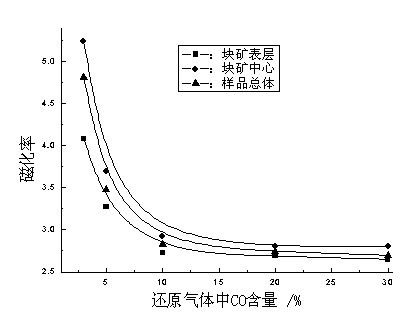

The invention relates to a roasting method of efficiently controlling iron ores to be magnetized. The method comprises the following steps: by virtue of agile adjustment of components, flow and pressure of reduced gas, improving the content of hydrogen in the reduced gas; controlling the content of hydrogen at 15%+ / -3%; greatly improving the diffusivity and thermal conductance of the reduced gas; obtaining the optimal effect of the roasting method of efficiently controlling iron ores to be magnetized. Meanwhile, aiming at the problem that the reduced gas in the roasting method excessive, the reduced gas is reduced from 1800-2000m<3> / h to 1000-1200m<3> / h, the consumption of the reduced gas is reduced by 800m<3> / h, the production cost is lowered, and the environmental pollution by CO in exhaust gases in a shaft furnace is eliminated. The reducing temperature of the iron ores is improved to 680-720 DEG C, and a good reducing temperature is provided for reducing block iron ores. Meanwhile, the pressure of the reduced gas is controlled at 5000Pa+ / 200Pa, so that the iron ores can be fully and uniformly roasted.

Owner:JIUQUAN IRON & STEEL GRP

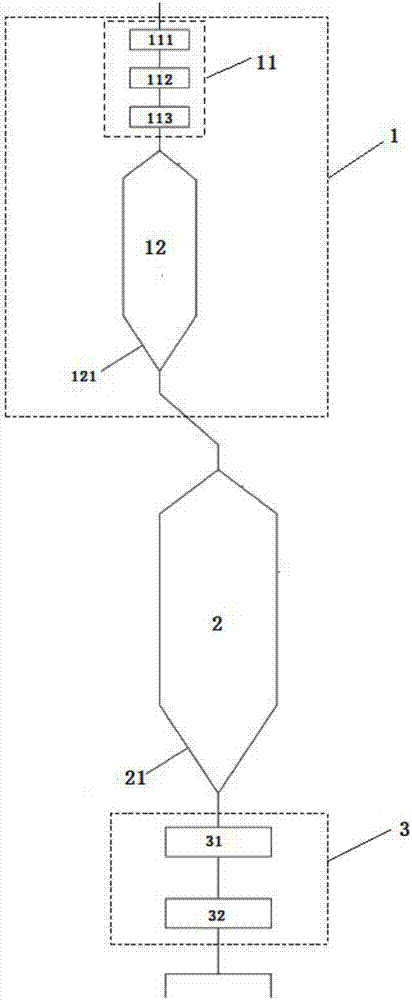

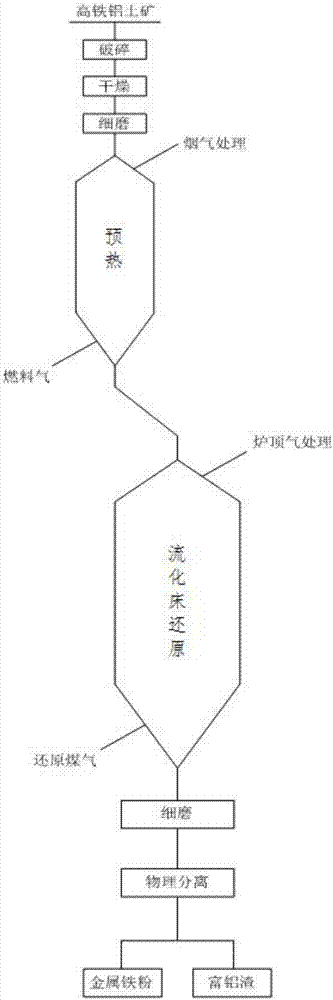

System and method for treating high-iron bauxite

The invention relates to a system and method for processing high-iron bauxite. The system includes a pretreatment unit, a reduction unit and a fine grinding separation unit. The pretreatment unit includes the inlet of high-iron bauxite raw ore, the outlet of preheated high-iron bauxite powder; the reduction unit includes a fluidized bed, and the fluidized bed includes the inlet of preheated high-iron bauxite powder, the inlet of reducing gas, the metallization The high-iron bauxite outlet, the reducing gas inlet is arranged at the lower part of the fluidized bed; the fine grinding separation unit includes a metallized high-iron bauxite inlet, a metal iron powder outlet, and an aluminum-rich slag outlet, and the metallized The high-iron bauxite inlet is connected to the metallized high-iron bauxite outlet. The aluminum-rich slag obtained by the system and method can be used as a raw material for producing alumina, and the metallic iron powder can be used as a raw material for steelmaking, and finally achieves the effects of reducing harmful components of metallic iron, reducing energy consumption and production costs, and simplifying the process.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

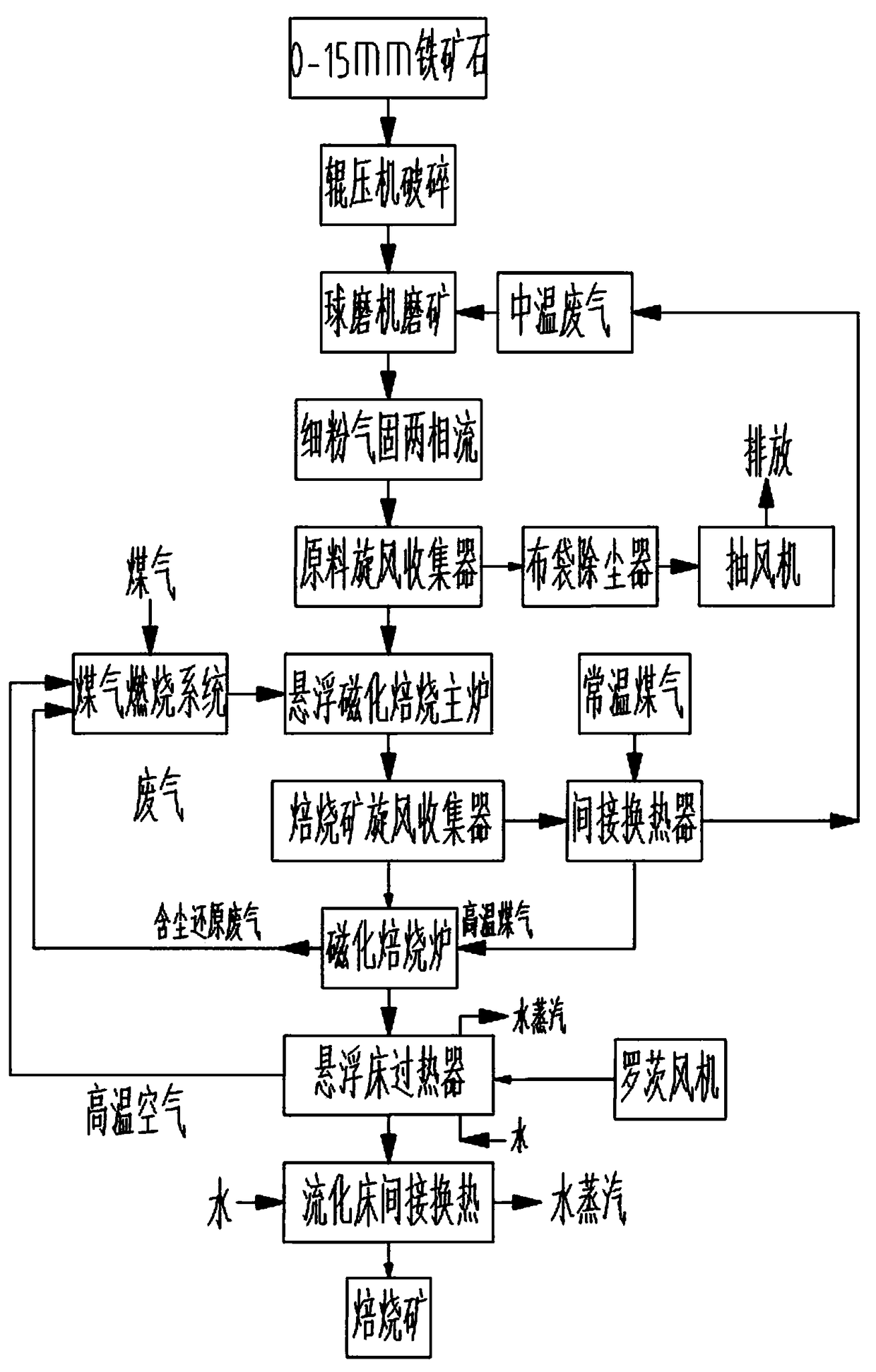

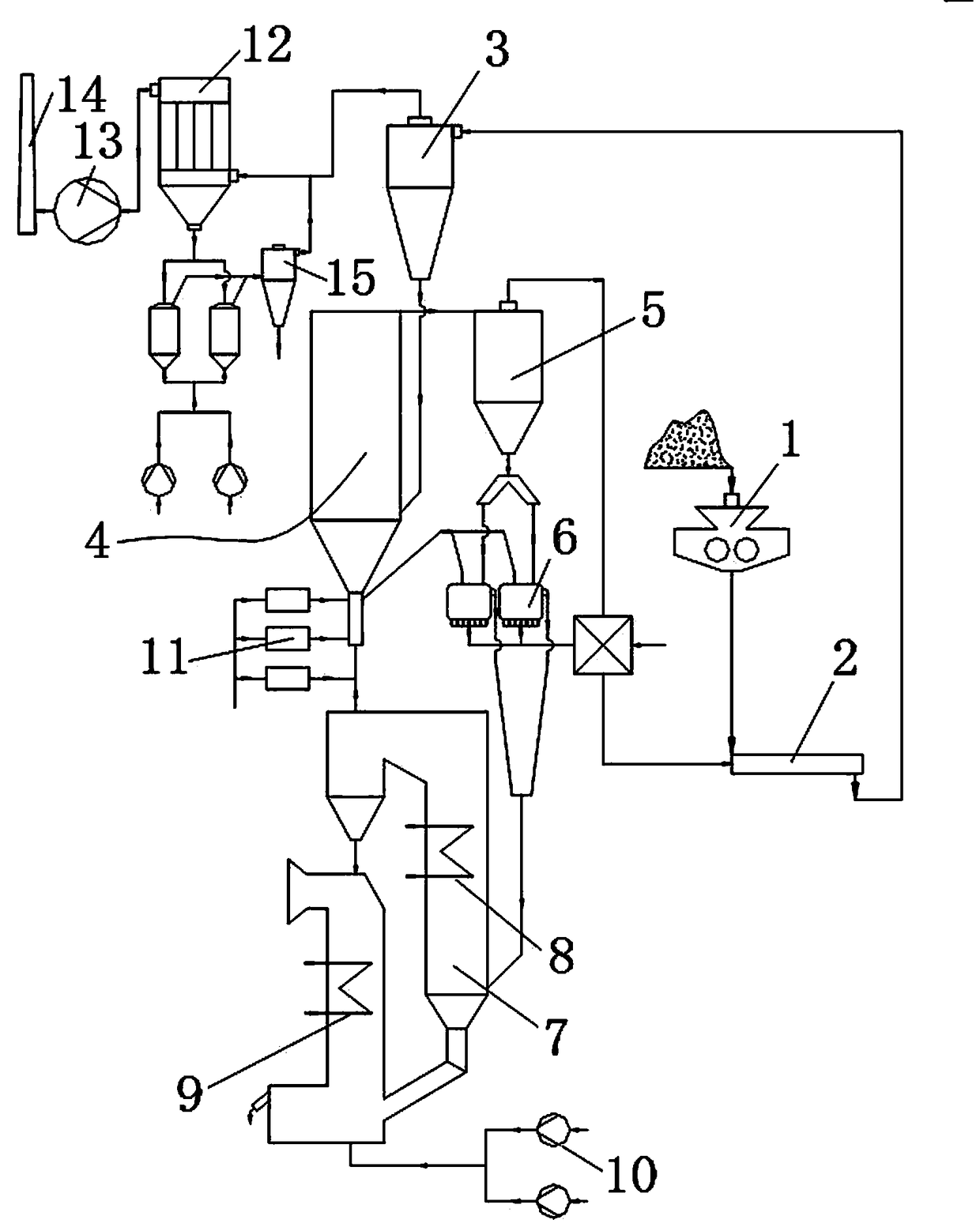

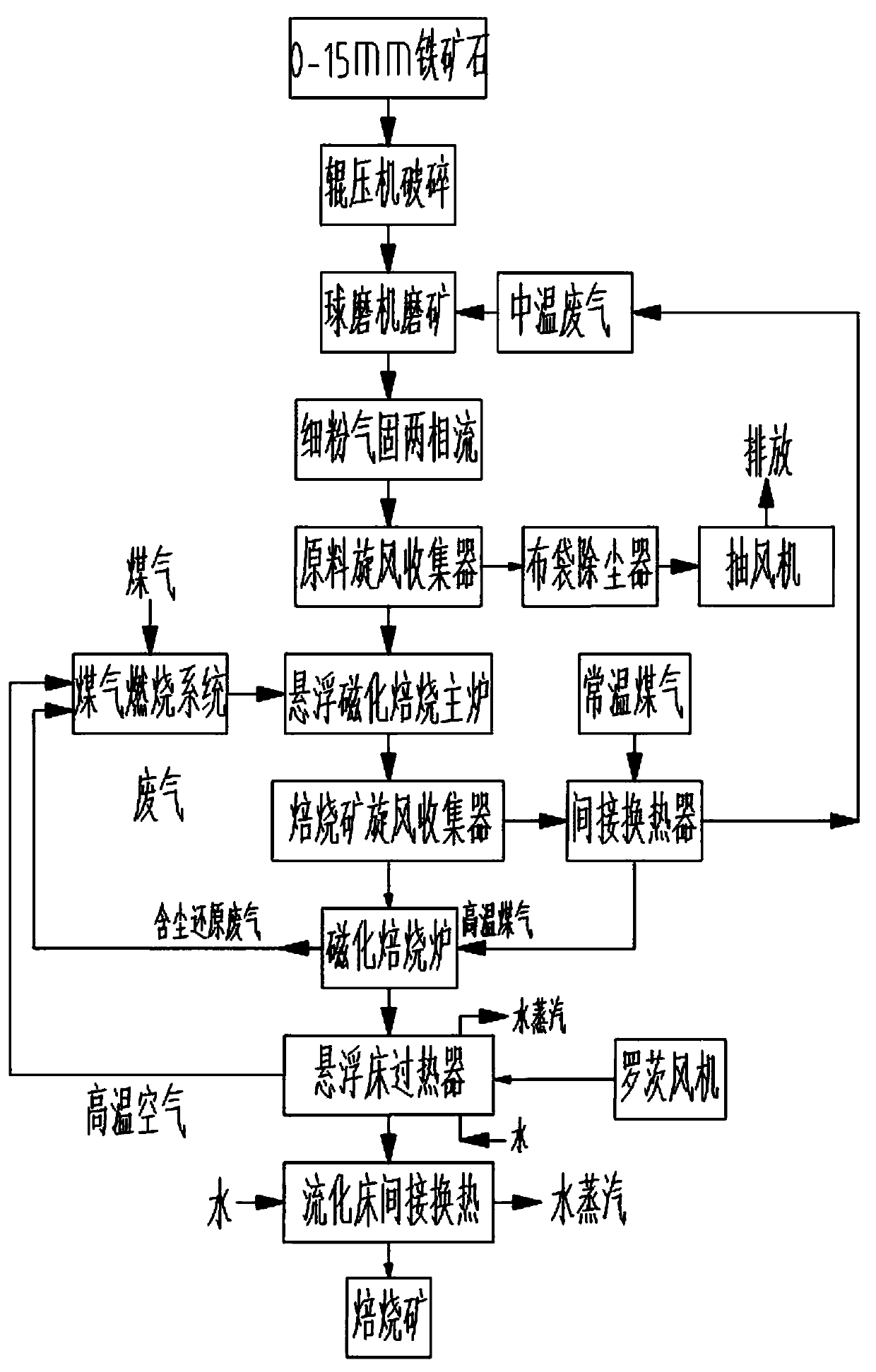

Refractory iron ore dry grinding-suspension roasting integration technology and device

ActiveCN108823400AReduce power consumptionReduce energy consumptionHuman health protectionGrain treatmentsSuperheaterBall mill

The invention provides a refractory iron ore dry grinding-suspension roasting integration technology and device. The refractory iron ore dry grinding-suspension roasting integration technology comprises the following steps of: breaking powder iron ores by a roller press, carrying out ore grinding by a dry-type ball grinder or the roller press, fluidifying to generate fine powder gas-solid two phase flow, then introducing the fine powder gas-solid two phase flow to a raw material cyclone collector for gas-solid separation in a suspension magnetic roasting technology, introducing middle-temperature flue gas discharged by the suspension magnetic roasting technology to a dry-type ore grinding technology for fluidifying, separating to obtain iron ore powder, carrying out oxidizing roasting on iron ore powder in a suspension magnetizing roasting main furnace, preheating coal gas to 450-500 DEG C by using burnt gas discharged by the oxidizing roasting in the suspension magnetizing roasting main furnace, entering a magnetizing roasting furnace so as to carry out iron ore reducing roasting, carrying out indirect heat exchanger cooling on roasted ore produced after reducing coasting to obtain roasting ore with the relatively high magnetism by using a suspended bed supercharger and a fluidized bed. The refractory iron ore dry grinding-suspension roasting integration technology has short technological process, does not consume water, consumes little coal gas, is low in cost, reduces the carbon emission, improves environments and improves economic benefits.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

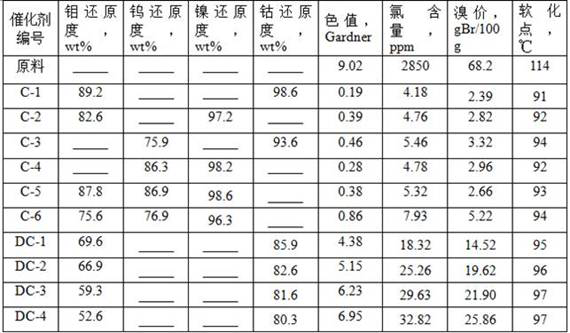

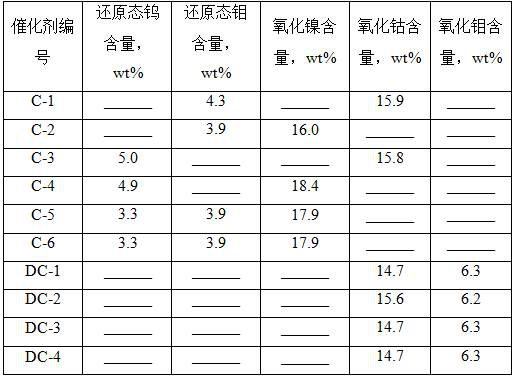

C5 petroleum resin hydrogenation catalyst and preparation method thereof

ActiveCN112973765AHigh crystallinityAvoid destructionMolecular sieve catalystsHeterogenous catalyst chemical elementsMolecular sievePtru catalyst

The invention discloses a C5 petroleum resin hydrogenation catalyst and a preparation method thereof. The catalyst comprises 2 wt%-12 wt% of reduction-state Mo and / or W, 10 wt%-30 wt% of oxidation-state Co and / or Ni and 58 wt%-88 wt% of a carrier, wherein the carrier is one or more selected from aluminum oxide, zirconium oxide, titanium oxide, magnesium oxide and molecular sieve-modified aluminum oxide. The preparation method comprises the following steps: (1) impregnating the carrier with Mo and / or W active metal impregnation liquid, then conducting drying, and carrying out reduction treatment on a dried material to obtain a catalyst precursor; and (2) impregnating the catalyst precursor obtained in the step (1) with Co and / or Ni active metal impregnation liquid, and then carrying out drying and roasting in an inert atmosphere to obtain the C5 petroleum resin hydrogenation catalyst. The catalyst disclosed by the invention has relatively high hydrogenation activity and capability of resisting poisoning of impurities such as sulfur and chlorine, presents very high stability, and is suitable for C5 petroleum resin hydrogenation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

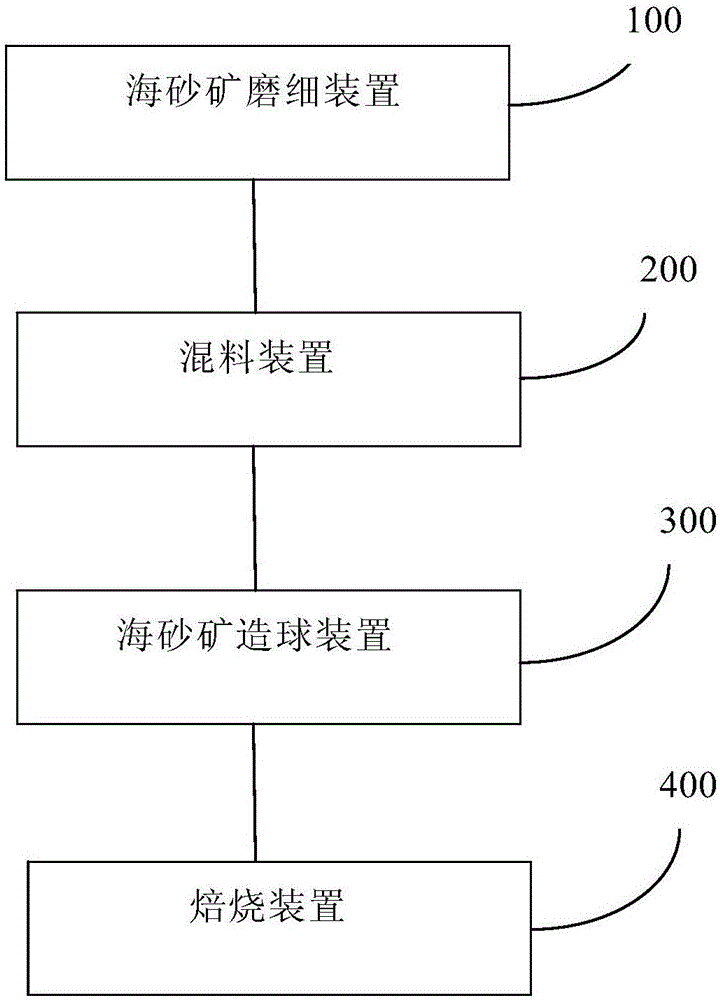

Method for restraining and reducing reduction degradation of iron sand pellets and system special for method for restraining and reducing reduction degradation of iron sand pellets

InactiveCN106591567AIncrease calcium ferrite contentImproved metallurgical propertiesHigh heatCalcium ferrite

The invention discloses a method for restraining and reducing reduction degradation of iron sand pellets and a system special for the method for restraining and reducing the reduction degradation of the iron sand pellets. The method for restraining and reducing the reduction degradation of the iron sand pellets comprises the steps that iron sand is ground to be fine, so that iron sand powder is obtained; the iron sand powder is evenly mixed with bentonite, so that a mixture is obtained; the mixture is made into green pellets in a pelletizer, wherein when the mixture in made into the green pellets in the pelletizer, a boric acid water solution is added in the growing process of the green pellets to be used as a pelletizing solution; and the green pellets are roasted, so that the pellets are obtained. The invention further discloses the system special for the method for restraining and reducing the reduction degradation of the iron sand pellets. According to the method for restraining and reducing the reduction degradation of the iron sand pellets and the system special for the method for restraining and reducing the reduction degradation of the iron sand pellets, by the adoption of the feature that boric acid is low in melting point, the liquid phase forming temperature is lowered, the content of calcium ferrite in the pellets is increased, and the reduction temperature of phosphosiderite pellets is greatly lowered; and in this way, the metallurgical performance of the phosphosiderite pellets in the reduction process is greatly improved, serious degradation at the high temperature is restrained, the problem that reduction degradation is serious during blast furnace smelting of the iron sand is effectively solved, the energy consumption is greatly lowered, the furnace condition is lowered, and economic benefits are increased.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

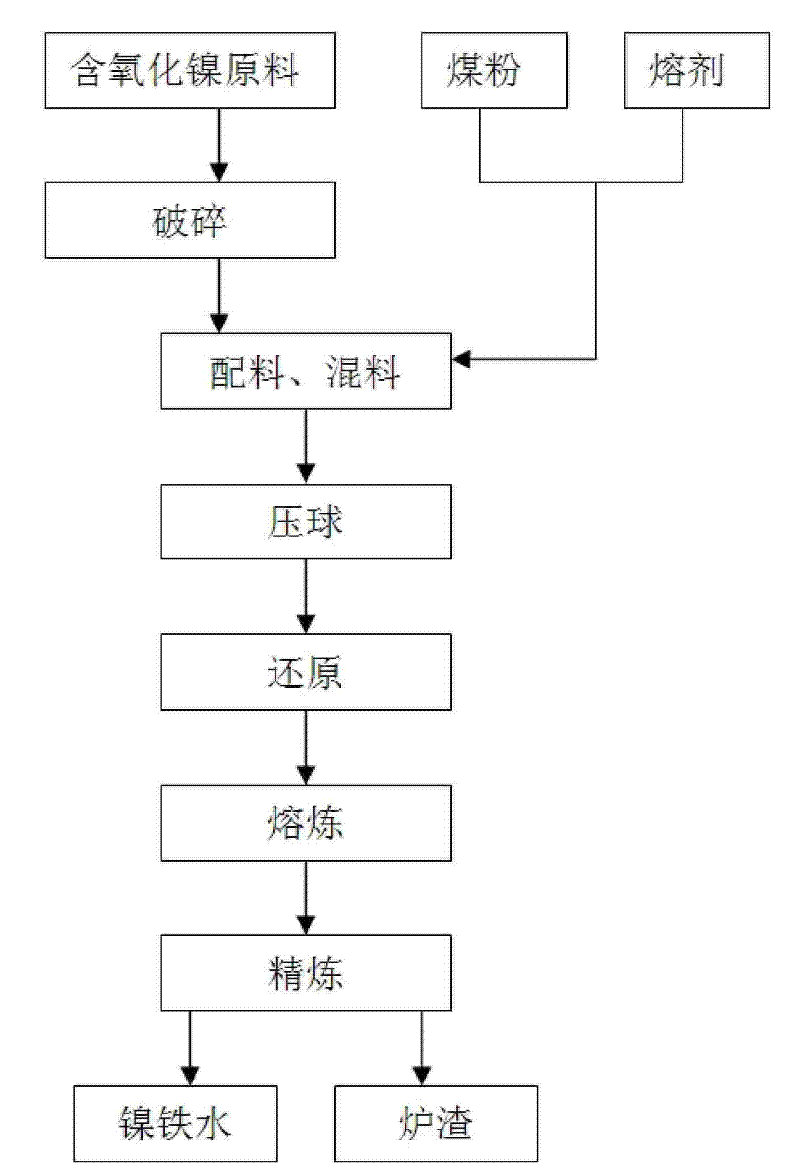

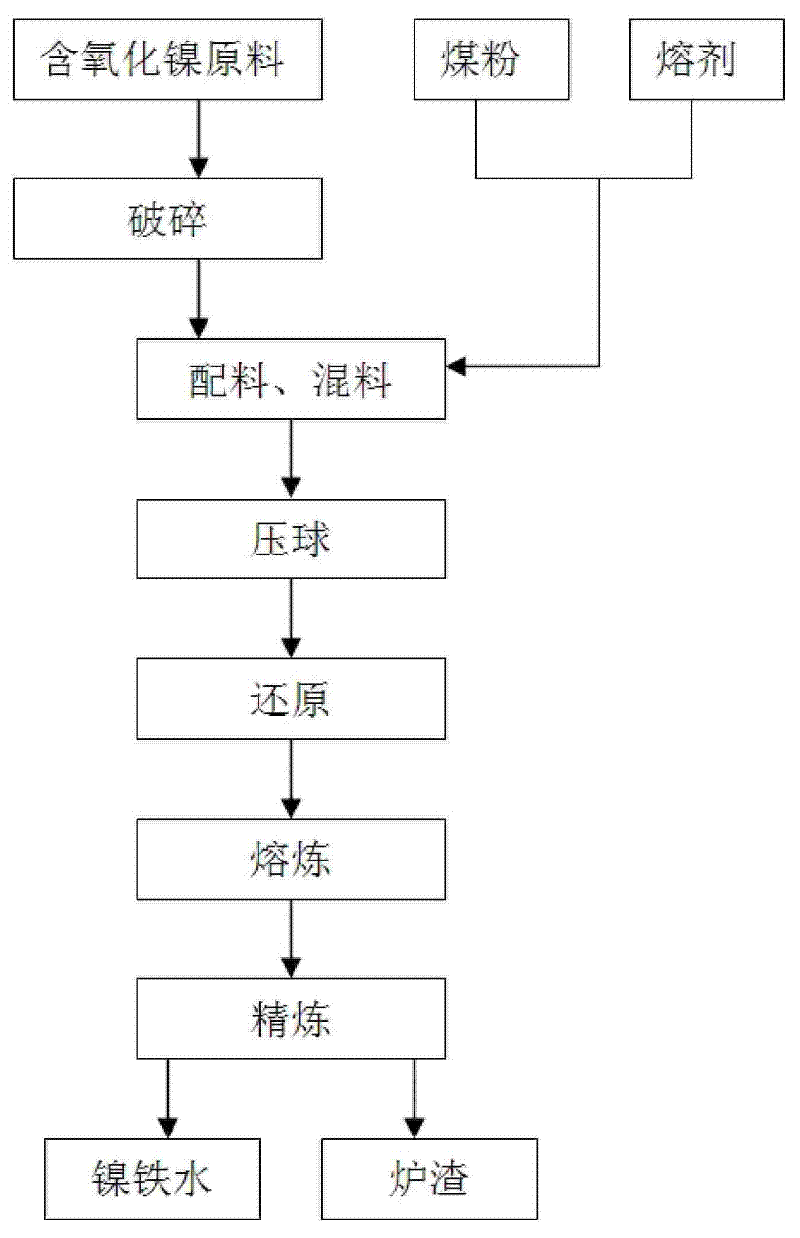

Manufacture method of nickel-iron alloy

The invention belongs to the technical field of metallurgy, in particular to a method for manufacturing a nickel-iron alloy. The technical problem to be solved by the present invention is to provide a nickel-iron alloy manufacturing method with high production efficiency, short process, low energy consumption, common coal as reducing agent, and furnace charge that is not easy to agglomerate. The technical scheme of the present invention comprises the following steps: A. After mixing nickel oxide-containing raw materials, coal powder and flux, press them into pellets; B. Reducing the pellets to obtain metallized pellets; C. Smelting the metallized pellets to obtain rough nickel-iron alloy ; D, crude nickel-iron alloy is refined to obtain refined nickel-iron alloy. The present invention mixes coal powder in the raw material to form pellets, which increases the reaction area, improves the kinetic conditions, and facilitates the reduction process. The reduction time is short, the energy consumption is low; and the pellet furnace charge does not stick to the furnace lining, the dust is less, and the recovery rate of useful elements is high.

Owner:侯霞

Manufacturing method of nickel-iron alloy

The invention belongs to the technical field of metallurgy, and especially relates to a manufacturing method of a nickel-iron alloy. The invention aims to provide a nickel-iron alloy manufacturing method, which has the advantages of high production efficiency, short flow, low energy consumption, and difficulty in clotting of furnace charge, and takes common coal as the reducing agent. The manufacturing method comprises the following steps: step A, mixing nickel oxide, coal powder, and flux, and pressing the mixture into pellets; step B, reducing the pellets to obtain metalized pellets; step C, melting the metalized pellets to obtain coarse nickel-iron alloy; step D, refining the coarse nickel-iron alloy to obtain refined nickel-iron alloy. According to the preparation method, coal powder is added into the raw materials to produce pellets directly, the reaction surface is enlarged, the dynamic conditions are improved, and the reduction reaction is promoted. Furthermore, the reduction time is short, the energy consumption is low, the pellet-shaped furnace charge will not adhere on the furnace lining, the dust is little, and the recovery rate of useful elements is high.

Owner:匡永刚

A technology of iron ore shaft furnace-rotary kiln direct reduction to produce iron powder

ActiveCN104195278BSolve the strength problemRaise the reduction temperatureRotary drum furnacesMagnetic separationIron powderShaft furnace

The invention provides an iron ore shaft furnace-rotary kiln direct reduction process for producing iron powder, which includes the following process steps: (1) after the iron ore is ground, it is enriched by magnetic separation, and the obtained rough concentrate powder is mixed with bentonite Afterwards, carry out grinding and pelletizing to obtain pellets; (2) Pellets are added from the top of the shaft furnace, and the pellets are fully heated, oxidized and consolidated in the shaft furnace; (3) Oxidized pellets Mix it with granular coal and add it to the rotary kiln for reduction; (4) Put the reduced pellets into the waste heat recovery device, so that the pellets and air can perform indirect heat exchange; (5) The materials discharged from the waste heat recovery device are magnetically The metallized iron powder with a metallization rate of more than 85% and an iron grade of more than 80% can be obtained. The invention solves the problems of low pellet strength and easy generation of liquid phase in the direct reduction of refractory low-grade iron ore, improves the reduction temperature of the pellets in the reduction roasting rotary kiln, shortens the reduction time, and reduces the number of pellets. powdering phenomenon.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

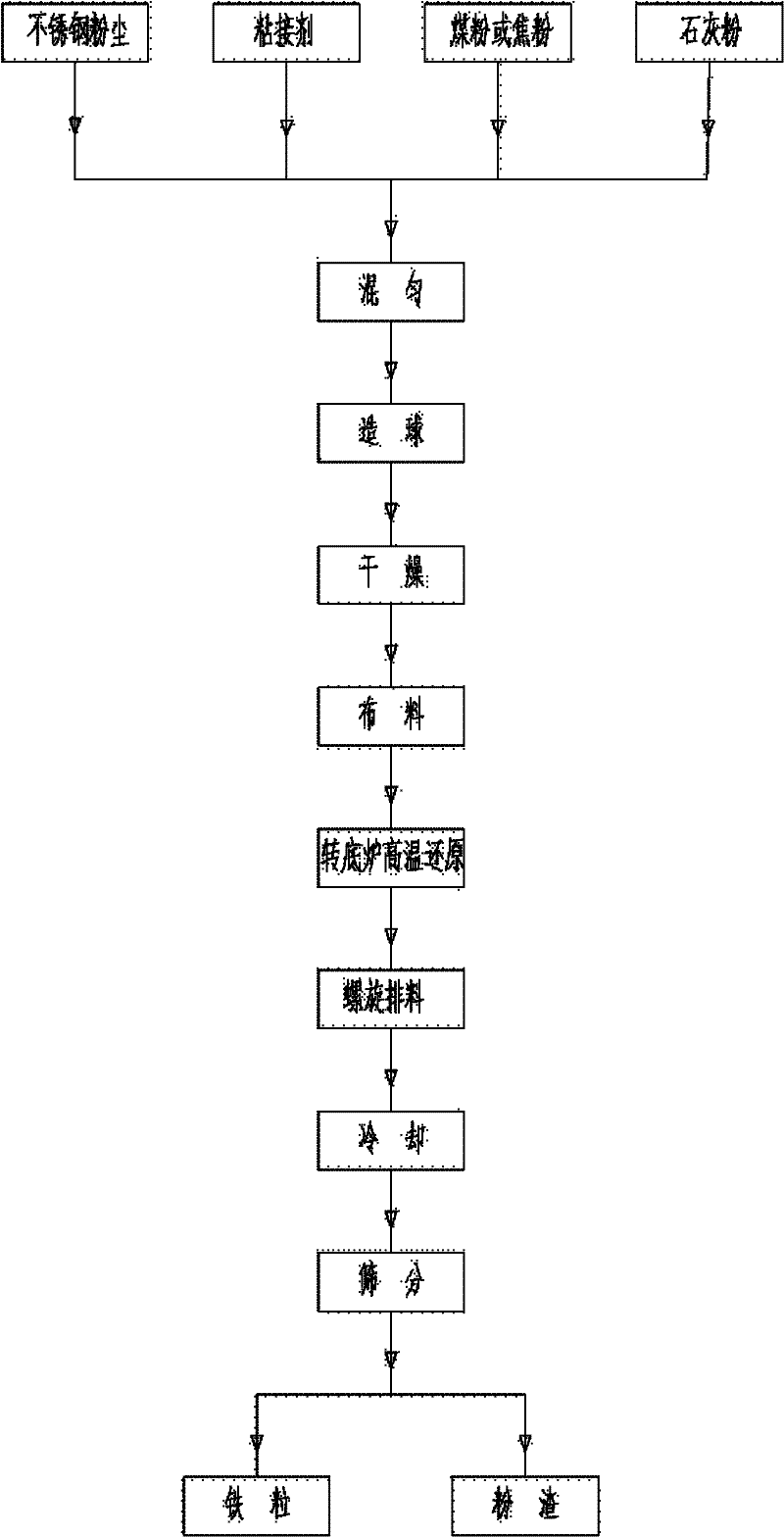

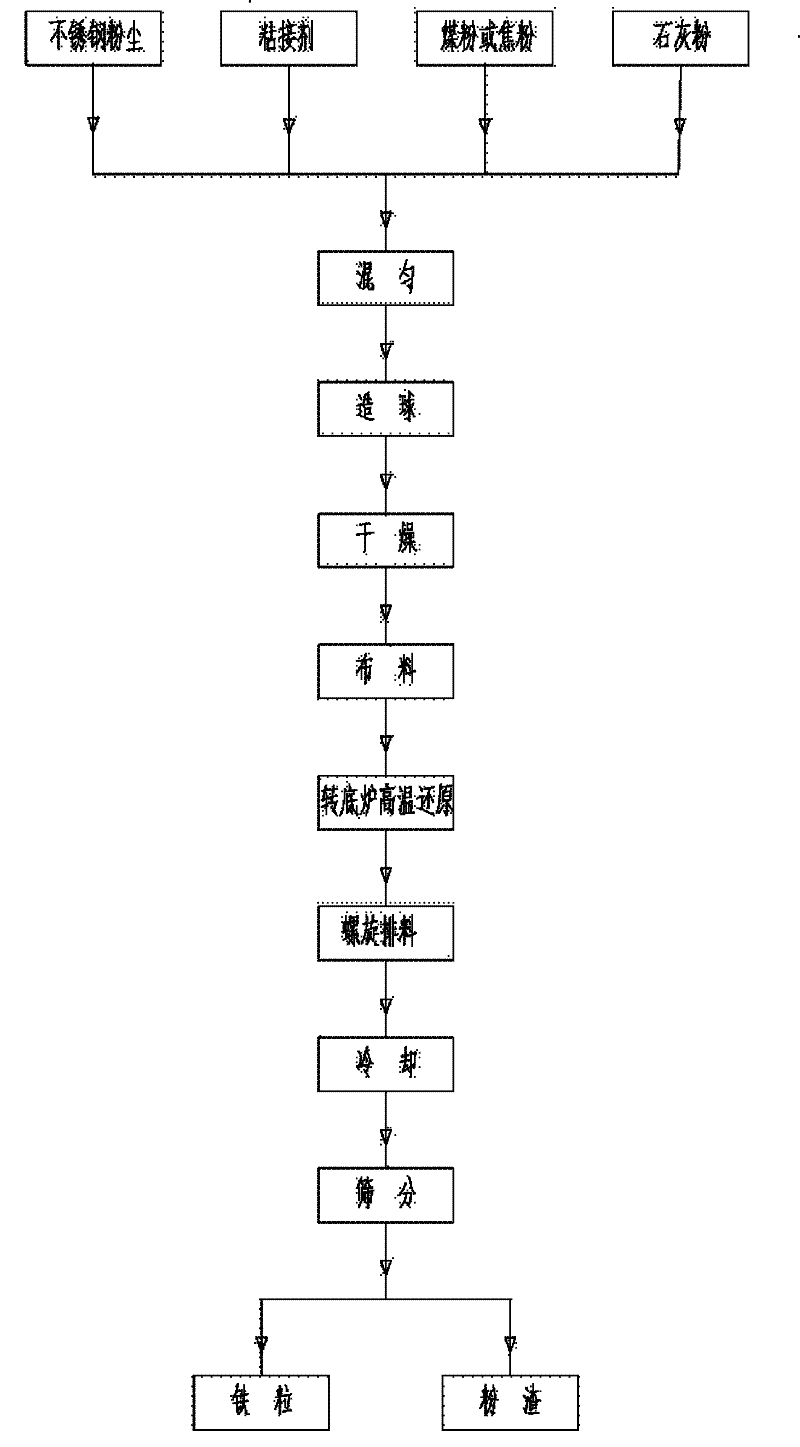

Method for extracting high-content nickel, chromium and iron from stainless steel dust

The invention relates to a method for extracting high-content nickel, chromium and iron from stainless steel dust, which is characterized by comprising the following steps of: mixing the stainless steel dust, coal powder and limestone, then adding an adhesive for manufacturing green balls, adding the obtained green balls into a rotary hearth furnace, firstly oxidizing the green balls rotating along with a hearth through an oxidation zone in the rotary hearth furnace, then reducing the green balls through a high-temperature reduction zone in the rotary hearth furnace, finally reducing the green balls into high-temperature mature balls, discharging the mature balls out of the rotary hearth furnace, then naturally cooling, naturally powdering the slag in the cooled mature balls, naturally powdering iron slag, and sieving to obtain iron grains directly used for steelmaking. The method thoroughly changes a traditional process route, the atmosphere component control in the rotary hearth furnace is optimized by improving the proportion of raw materials, a product can be obtained through one-step smelting, the process route is simplified, the production energy consumption is also greatly reduced, the cost is greatly lowered, and the product is quite competitive.

Owner:WISDRI ENG & RES INC LTD

Technique for preparing nickel-iron alloy

The invention belongs to the field of metallurgical technology, and more particularly relates to a technique for preparing nickel-iron alloy. The technique aims at solving the technical problem of providing the technique which is used for preparing nickel-iron alloy, has high production efficiency, short process flow and low energy consumption, takes common coal as reducing agent and ensures burden not to be easily agglomerated. The technical scheme comprises the steps: A. after mixing nickel oxide-containing raw material, pulverized coal and fusing agent, pelletizing the mixture; B. reducingpellets and obtaining metalized pellets; C. smelting the metalized pellets and obtaining crude nickel-iron alloy; D refining the nickel-iron alloy and obtaining refined nickel-iron alloy. The technique has the raw material which is internally provided with pulverized coal pellets, enlarges the reaction area, improves the dynamical condition and is beneficial to the reduction process. Furthermore,the technique has the advantages of short reduction time, low energy consumption, less dust and high recovery rate of useful elements as well as ensuring the pellet burden not to bond a furnace lining.

Owner:PANZHIHUA UNIV +1

Roasting method of efficiently controlling iron ores to be magnetized

The invention relates to a roasting method of efficiently controlling iron ores to be magnetized. The method comprises the following steps: by virtue of agile adjustment of components, flow and pressure of reduced gas, improving the content of hydrogen in the reduced gas; controlling the content of hydrogen at 15%+ / -3%; greatly improving the diffusivity and thermal conductance of the reduced gas; obtaining the optimal effect of the roasting method of efficiently controlling iron ores to be magnetized. Meanwhile, aiming at the problem that the reduced gas in the roasting method excessive, the reduced gas is reduced from 1800-2000m<3> / h to 1000-1200m<3> / h, the consumption of the reduced gas is reduced by 800m<3> / h, the production cost is lowered, and the environmental pollution by CO in exhaust gases in a shaft furnace is eliminated. The reducing temperature of the iron ores is improved to 680-720 DEG C, and a good reducing temperature is provided for reducing block iron ores. Meanwhile, the pressure of the reduced gas is controlled at 5000Pa+ / 200Pa, so that the iron ores can be fully and uniformly roasted.

Owner:JIUQUAN IRON & STEEL GRP

An upward-sloping trapezoidal wave interface device for a three-swirl biomass gasification burner

ActiveCN108443863BReduce flow rateBurn fullySolid fuel combustionCombustion apparatusThermodynamicsCombustor

The invention relates to an upward-inclined trapezoidal wave interface device applied to a three-cyclone biomass gasification combustor and belongs to the technical field of biomass combustion equipment. When the three-cyclone biomass gasification combustor is in a use process, fuel is combusted to form gas; the gas flows smoothly via annular trapezoidal openings which are uniformly formed in thebottom of an annular trapezoidal wave interface; the flow speed of the gas is reduced; the quantity of sparks carried in the flame in combustion of the three-cyclone biomass gasification combustor canbe effectively reduced; meanwhile, under the effect of a necking type reduction chamber, the speed of the gas is effectively reduced and the gas is gathered at the top of an annular square opening; under a heat accumulation effect, hot gas flow can obtain a relatively high reduction temperature, thus the carbon dioxide in hot smoke which enters the reduction chamber from an annular fire layer anda bottom fire layer can be effectively reduced into carbon monoxide; the fuel is effectively combusted; and smoke emission is reduced.

Owner:春晖新材料科技(江苏)有限公司

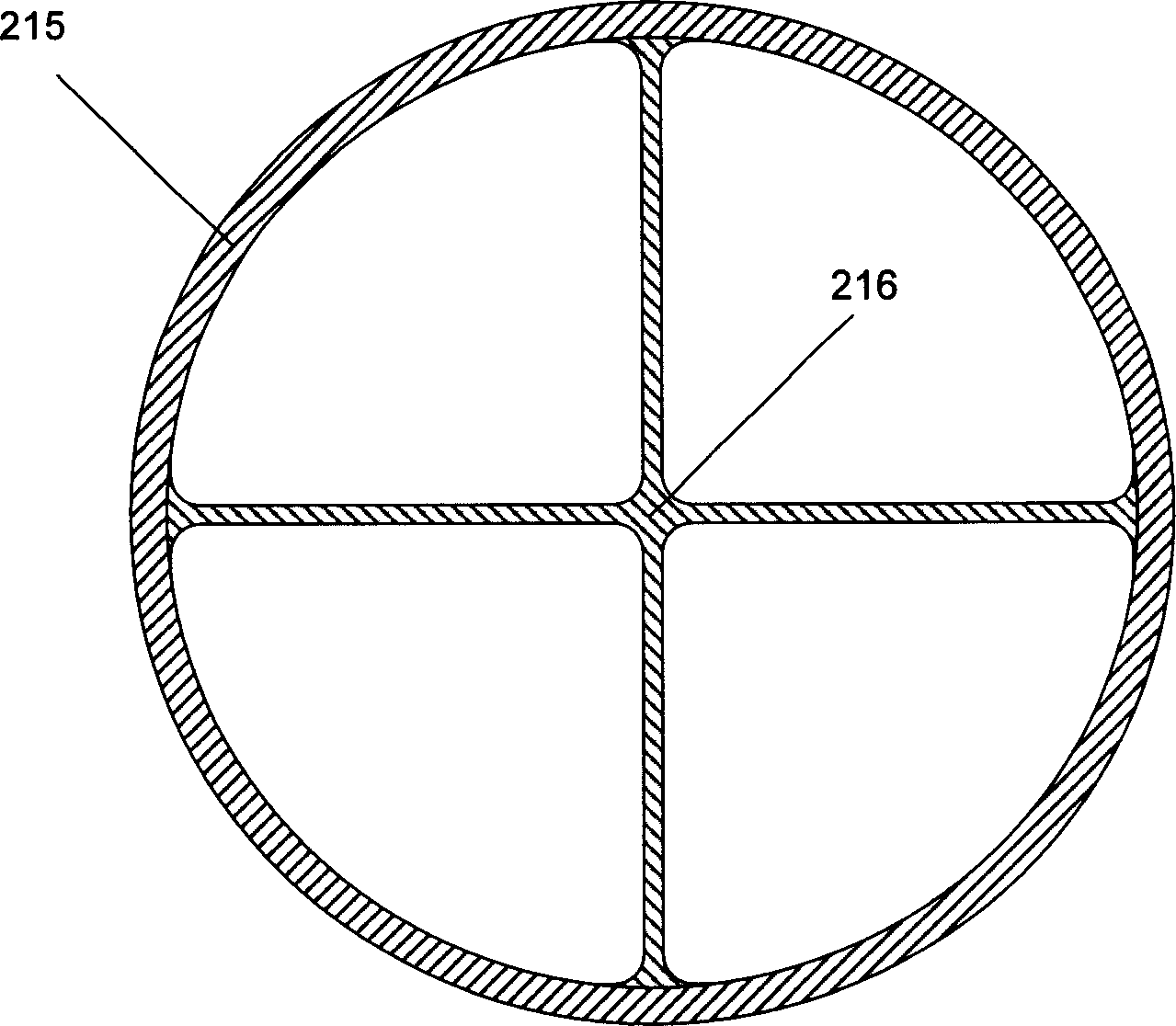

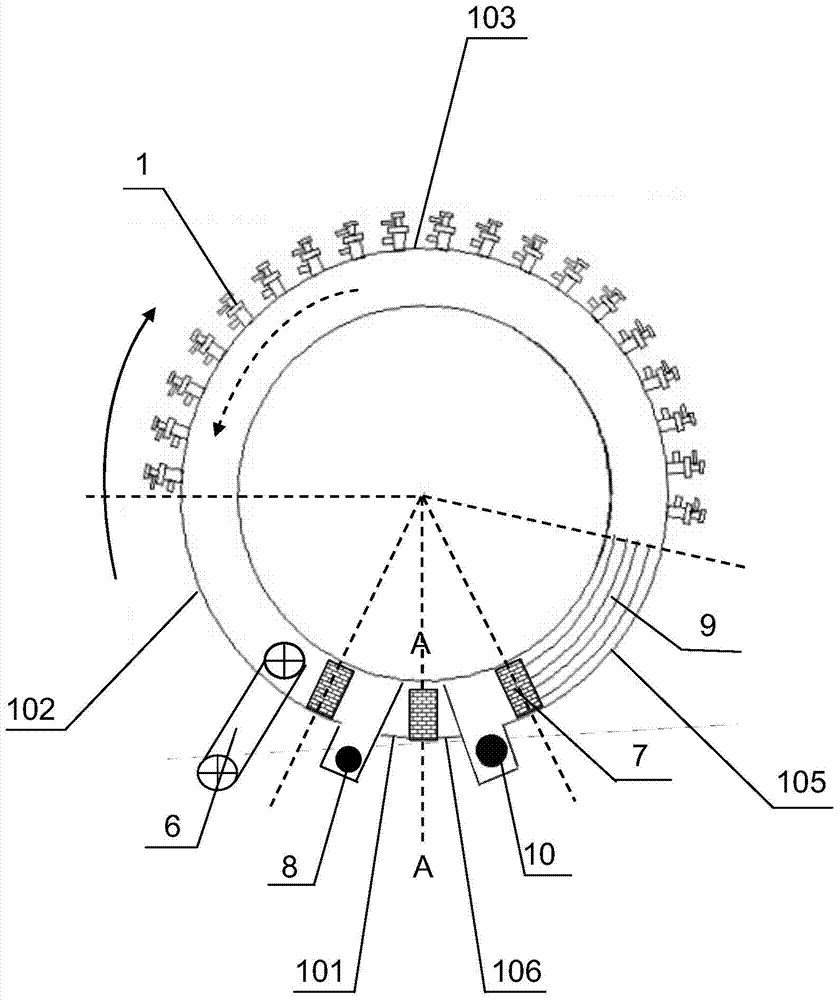

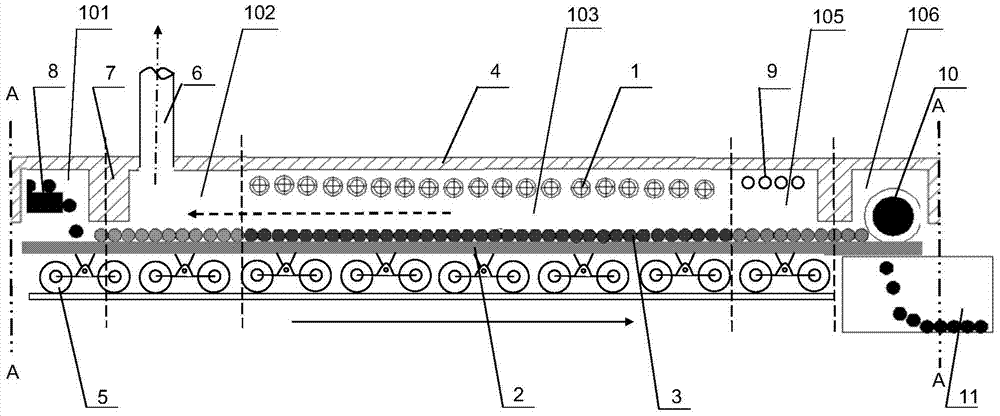

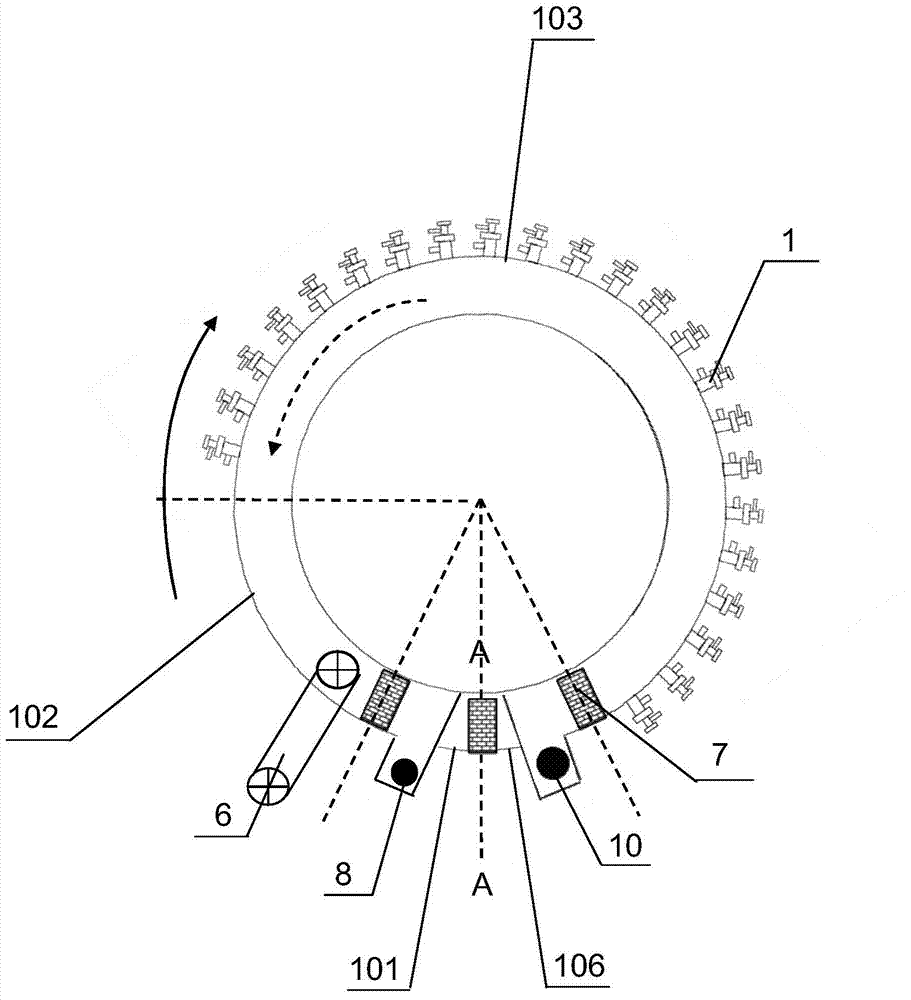

A coal-based direct reduction method and rotary hearth furnace with microwave fuel combined with heating

The invention discloses a coal-based direct reduction method and a rotary hearth furnace with microwave fuel combined with heating. The material is further reduced by radiation; the reducing agent required for metal oxide reduction to metal comes from the fixed carbon in the material. The rotary hearth furnace is an apparatus based on the method described above. The invention has the advantages of simple structure, low cost, high metallization rate, easy realization, popularization and application, and the like.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

An integrated process and device for refractory iron ore dry grinding-suspension roasting

ActiveCN108823400BReduce energy consumptionTake advantage ofHuman health protectionGrain treatmentsGas solidFlue gas

The invention provides a refractory iron ore dry grinding-suspension roasting integration technology and device. The refractory iron ore dry grinding-suspension roasting integration technology comprises the following steps of: breaking powder iron ores by a roller press, carrying out ore grinding by a dry-type ball grinder or the roller press, fluidifying to generate fine powder gas-solid two phase flow, then introducing the fine powder gas-solid two phase flow to a raw material cyclone collector for gas-solid separation in a suspension magnetic roasting technology, introducing middle-temperature flue gas discharged by the suspension magnetic roasting technology to a dry-type ore grinding technology for fluidifying, separating to obtain iron ore powder, carrying out oxidizing roasting on iron ore powder in a suspension magnetizing roasting main furnace, preheating coal gas to 450-500 DEG C by using burnt gas discharged by the oxidizing roasting in the suspension magnetizing roasting main furnace, entering a magnetizing roasting furnace so as to carry out iron ore reducing roasting, carrying out indirect heat exchanger cooling on roasted ore produced after reducing coasting to obtain roasting ore with the relatively high magnetism by using a suspended bed supercharger and a fluidized bed. The refractory iron ore dry grinding-suspension roasting integration technology has short technological process, does not consume water, consumes little coal gas, is low in cost, reduces the carbon emission, improves environments and improves economic benefits.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Process for producing direct reduced iron with coal as reducer

InactiveCN1314817CAvoid sticking to each otherRaise the reduction temperatureFluidised-bed furnacesReaction rateReducer

The invention provides a process for production of direct reduced ferrum with coal as a reducer: covering the surface of pellet with a protective layer made up of inorganic inert substance with disk cuber or cylinder cuber after the iron material is made into pellet basing on the present technology, then covered pellets being produced, sending the covered pellets into the kiln to run reduction reaction, after reduction sending the covered pellets into cooling barrel and cooling them rapidly, then disintegrating or grinding and letting the inorganic inert substance release the pellets, the direct reduced ferrum pellets being obtained after sifting. Producing direct reduced ferrum with the method, pellets don't bind with each other, or with retort, and the temperature of the inside of kiln can be raising to 1100 to 1250 deg, as a result, the reduction reaction rate and metallising ratio are highly increased, and the productive efficiency and productive cost improved.

Owner:北京祥艺互联网信息科技有限公司

Method and apparatus for reducing metallic pellet by using coal dust in high furnace

The invention discloses a metallized pellets reduction method by pulverized coal and a shaft furnace. The method comprises steps of fabricating pellets of iron ore powder or powder of other metallic oxide ore, putting the pellets into the shaft furnace by a set quantity measurement, raw coal with a lower heating value bigger than or equal to 16MJ / Kg and with an ash dry basic smaller than or equalto 40% being dried and milled by an intermediate-speed coal mill until the mesh number is smaller or equal to 100 and the moisture content is smaller or equal to 0.5%, pre-heating the pulverized coalto the temperature of 80 DEG C - 150 DEG C, transferring the pulverized coal to an air-fluidized bed gas generator,mixing the water vapour and the air in proportion, the high-temperature coal gas produced by the air-fluidized bed gas generator passing through a hot precipitator, directly spraying the coal gas after that 90%-95% dust of the coal gas has been eliminated to the lower part of the shaft furnace, the upper part of a material-discharging roller participating in the reduction reaction in the shaft furnace, reducing the iron or other metallic oxide into metallized pellets.The invention has a high reduction temperature, a high reduction speed, a high exhaust physical heat and a chemical heat which is 1.5 times higher than that of the blast furnace gas, reductive cost is greatly reduced by using the middle coal with a low heating value and a high fugitive constituent as the reductive, therefore, the per-ton cost of the generated energy sources of electrical energy, coal gas and the like is lower than 1500 yuan / t.

Owner:沈阳东方钢铁有限公司

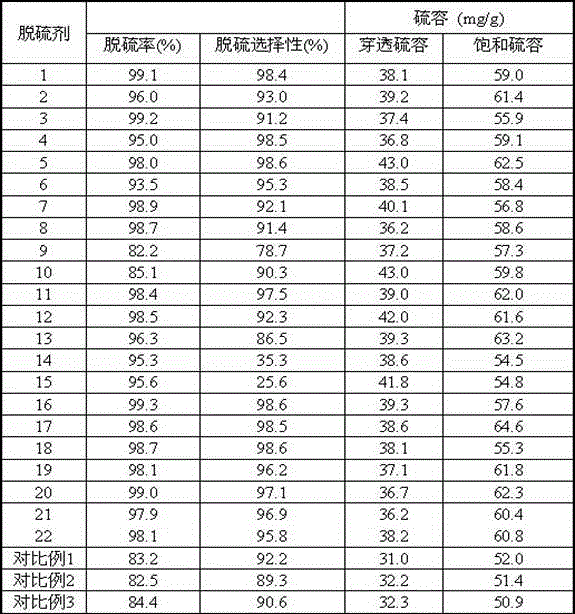

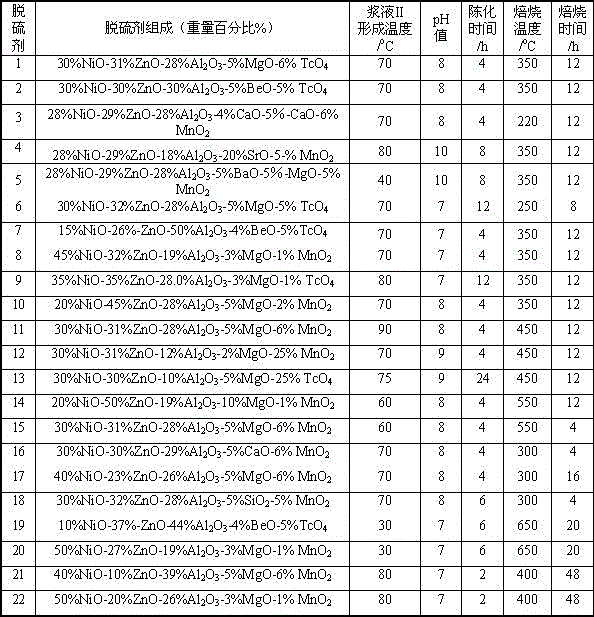

Solid desulfurizer and preparation method thereof

ActiveCN103933927BHigh desulfurization rateHigh breakthrough sulfur capacityOther chemical processesSolid sorbent liquid separationPhysical chemistryAlkene

Owner:CHINA PETROLEUM & CHEM CORP +1

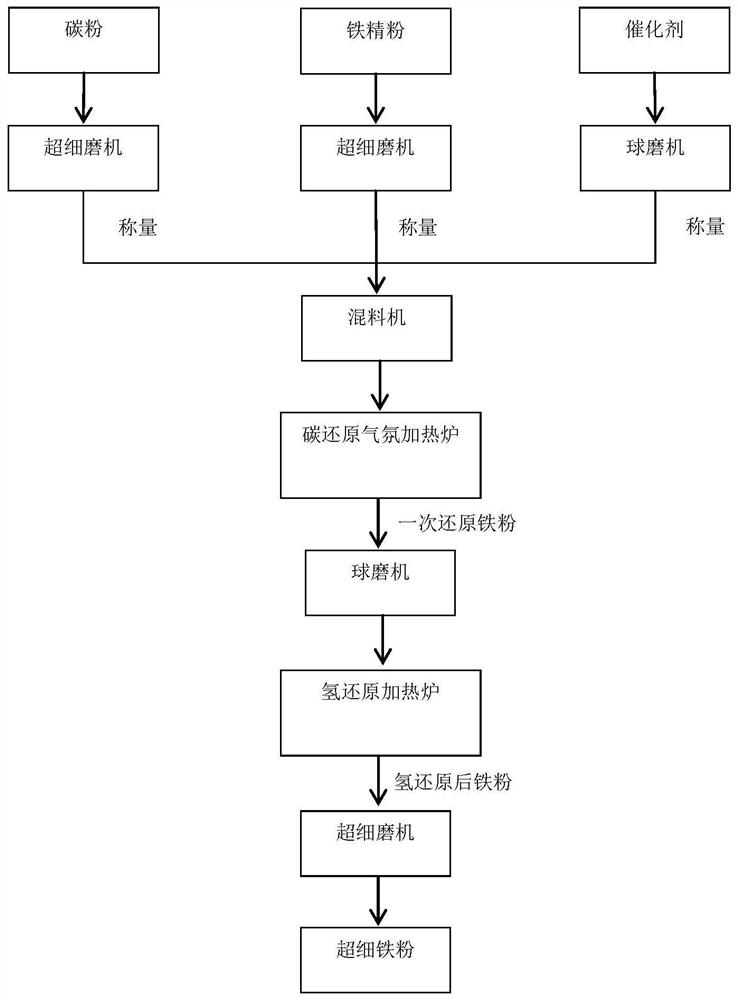

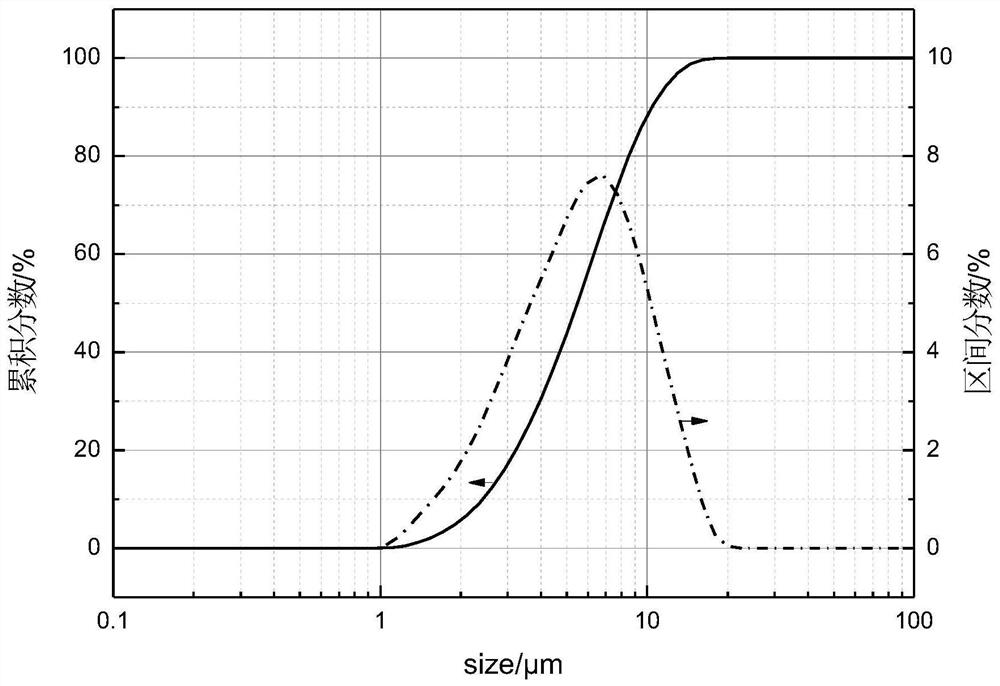

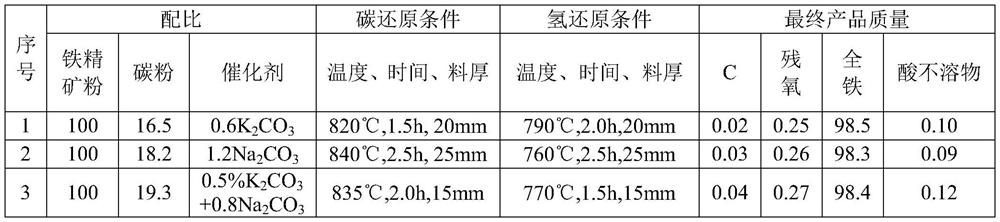

A method for preparing ultra-fine iron powder by low-temperature hydrocarbon double reduction

A method for preparing ultra-fine iron powder through double reduction of low-temperature hydrocarbons, step 1, ball milling iron ore concentrate powder, carbon powder and catalyst with a certain purity; The ratio is evenly mixed; step 3, the material after mixing is placed under a protective atmosphere for heating and reduction, and primary reduced iron is obtained after cooling; step 4, the primary reduced iron described in step 3 is ball milled; step 5, the primary reduced iron in step 4 is The primary reduced iron after ball milling is placed in a hydrogen atmosphere for final reduction, cooled and released from the furnace to obtain reduced iron powder; step 6, ball milling the reduced iron powder described in step 5 to obtain superfine iron powder. Compared with the prior art, the present invention has the advantages of low reaction temperature, low energy consumption, and low hydrogen consumption, and is easy to obtain high-quality ultrafine iron powder, and has simple preparation process, low energy consumption, and low production cost.

Owner:钢研晟华科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com