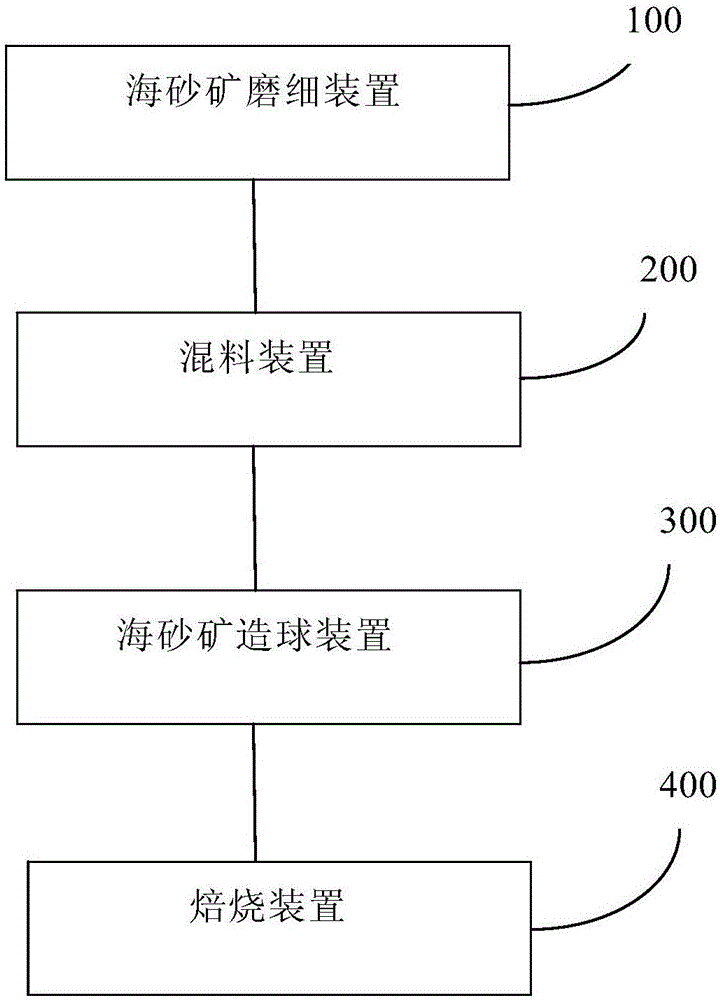

Method for restraining and reducing reduction degradation of iron sand pellets and system special for method for restraining and reducing reduction degradation of iron sand pellets

A sea placer and pellet technology, which is applied in the field of sea placer metallurgical pellet preparation, can solve problems such as reduction and pulverization, and achieve the effects of reducing reduction temperature, increasing strength and improving metallurgical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Grind the sea sand ore in a grinding device until the proportion of the sea sand ore powder with a particle size of less than 0.074mm is 60% to 80% to obtain sea sand ore powder; put the sea sand ore powder and bentonite binder in the mixing device Mix evenly in the medium to obtain the mixture, the mass ratio of sea sand mineral powder and bentonite is 97:3; the mixture is made into green pellets in the pelletizer, and the diameter of the green pellets is 10-18mm; Roasting in a roasting device (rotary kiln with chain grate) at a temperature of 1150°C to obtain sea sand pellets; wherein, when the mixture is made into green pellets in the pelletizer, during the growth process of the green pellets The spraying concentration in the medium is 0.5% boric acid aqueous solution; The quality of sea sand mineral powder and bentonite is 100%, the consumption of the added 0.5% boric acid aqueous solution is 2wt%; Boric acid is added to the water tank where the green balls are adde...

Embodiment 2

[0043] Grind the sea placer ore in a grinding device until the proportion of the sea placer ore powder with a particle size of less than 0.074mm is 60% to 80% to obtain sea placer ore powder; mix the sea placer ore powder and bentonite binder in the mixture Mix evenly in the device to obtain a mixture, the mass ratio of sea sand ore powder to bentonite is 99:1; make the mixture into green pellets in a pelletizer, and the diameter of the green pellets is 10-18mm; Roasting in a roasting device (rotary kiln with chain grate), the roasting temperature is 1350 ° C, to obtain sea sand ore pellets; wherein, when the mixture is made into green pellets in the pelletizer, the length of the green pellets Spray concentration of 1.0% boric acid aqueous solution in the large process; based on 100% of the quality of sea sand mineral powder and bentonite, the amount of 1.0% boric acid aqueous solution added is 3wt%; the adding point of boric acid is the water adding point of the pelletizer Firs...

Embodiment 3

[0046] Grind the sea sand ore in a grinding device until the proportion of the sea sand ore powder with a particle size of less than 0.074mm is 60% to 80% to obtain sea sand ore powder; put the sea sand ore powder and bentonite binder in the mixing device Mix evenly in the medium to obtain the mixture, the mass ratio of sea sand mineral powder and bentonite is 98:2; the mixture is made into green pellets in the pelletizer, and the diameter of the green pellets is 10-18mm; Roasting in a roasting device (rotary kiln with chain grate) at a temperature of 1250°C to obtain sea sand ore pellets; wherein, when the mixture is made into green pellets in the pelletizer, the raw pellets grow The spraying concentration in the process is 2.0% boric acid aqueous solution; the quality of sea sand mineral powder and bentonite is 100%, the consumption of the added 2.0% boric acid aqueous solution is 4wt%; Boric acid is added to the water adding tank where the green balls are added with water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com