Patents

Literature

117results about How to "Reduce surface porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing microcrystalline glass-ceramics composite board with novel microcrystalline phase

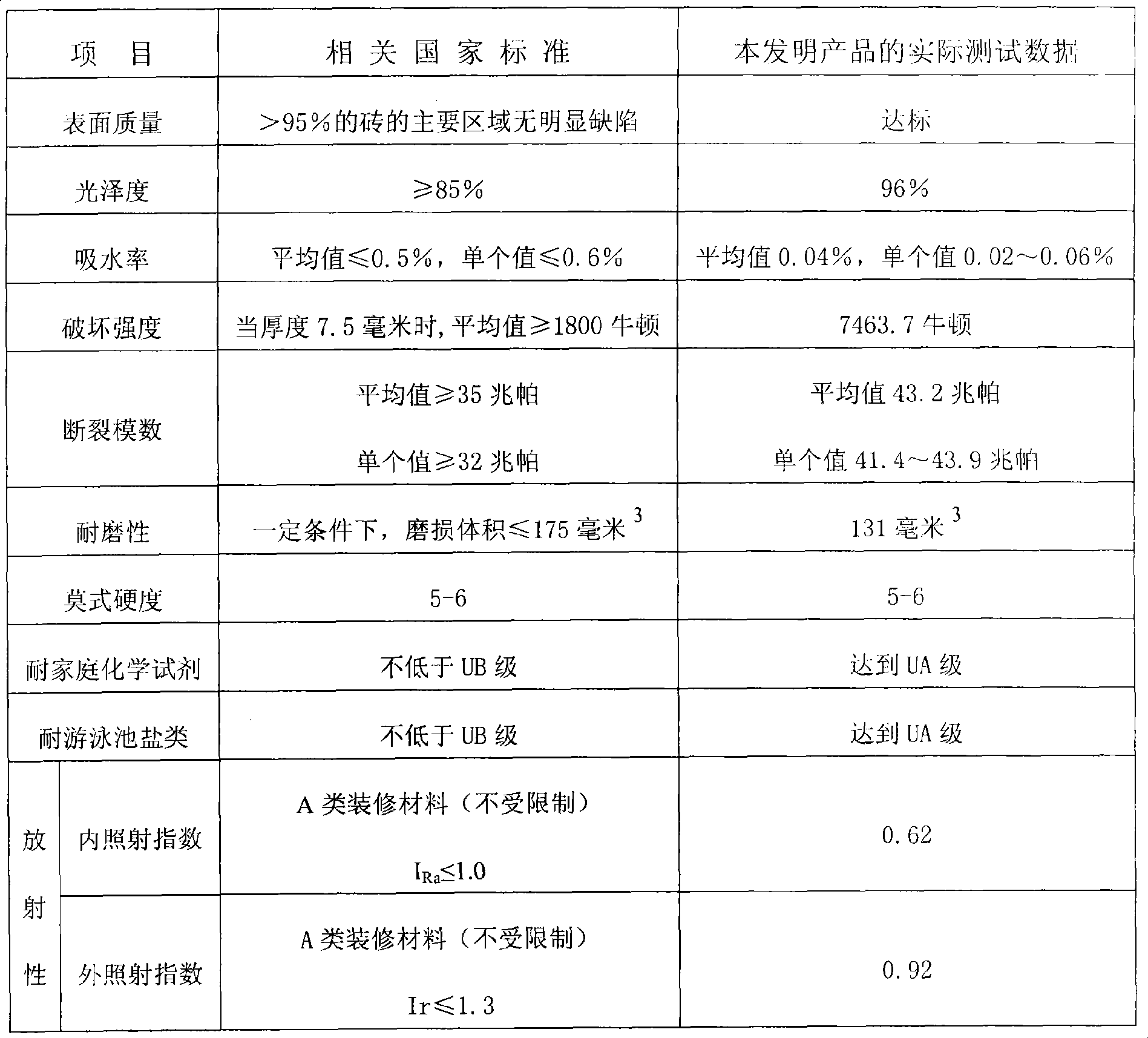

The invention discloses a method for producing a microcrystalline glass-ceramics composite board with novel microcrystalline phase, which is characterized in that the composite board takes diopside-containing pyroxene as microcrystalline phase and the production method thereof comprises the steps as follows: firstly, microcrystalline glass granules are prepared; according to the weight percentage, the microcrystalline glass consist of 50-65% of SiO2, 5-25% of Al2O3, 5-20% OF CaO, 2-10% of MgO, 1-8% of K2O+NaO, 0-1% of Li2O, 0-8% of BaO, 0-8% of B2O3 and the balance of nucleating agent, clarifier and corant with the content ranging from 0 to 20%; secondly, a ceramic palette board is prepared; according to the weight percentage, the ceramic palette board comprises 66-75% of SiO2, 13-23% of Al2O3, 0.3-3% of CaO+MgO, 3-8% of K2O+Na2O and the balance of 0-2% of auxiliary raw material; finally, the raw materials are distributed, sintered and post-processed, thus gaining the finished product of the microcrystalline glass-ceramics composite board. The method has the advantages of low production cost, high product quality, good appearance effect, and the like.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

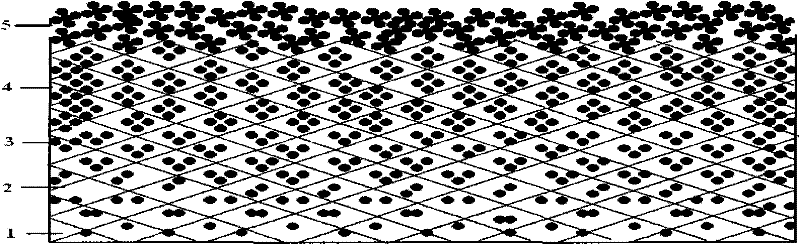

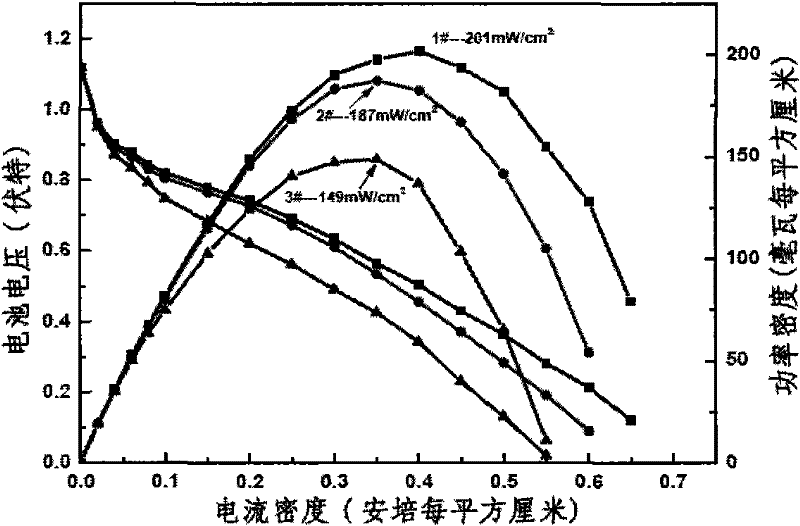

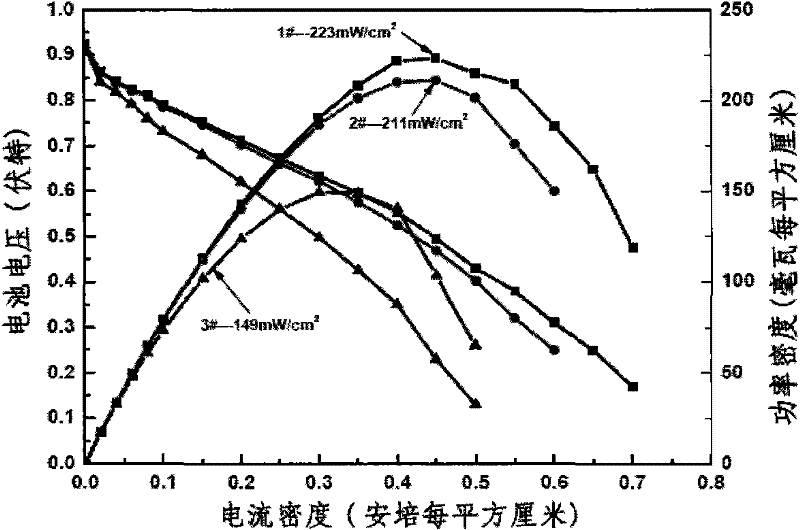

Gas diffusion layer with gradient hole structure and preparation and applications thereof

The invention relates to a gas diffusion layer with a gradient hole structure for fuel batteries and a preparation method and applications thereof. The gas diffusion layer consists of a macroporous carbon-based support body and a micro-porous layer which are overlapped, wherein the material of the micro-porous layer is embedded in the macroporous carbon-based support body from one side, far from the flow field of a battery, of the macroporous carbon-based support body to form a transitional hole layer; the transitional hole layer is composed of the material of the micro-porous layer and the fiber of the macroporous carbon-based support body and is obtained by embedding the material of the micro-porous layer in the side, far from the flow field of a battery, of the macroporous carbon-based support body; and the curvature of reaction gas transfer from the side next to the flow field to the side next to a catalyst layer in the gas diffusion layer increases gradiently and the air permeability gradually reduces from 4-10s / 100ml to 100-900s / 100ml. By adopting the gas diffusion layer with the structure, the mass transfer curvatures of water and the gas in the gas diffusion layer (GDL) can be effectively increased, the transfer path of the product-water can be prolonged and liquid water in the battery can be maintained; and the gas diffusion layer is particularly suitable for fuel batteries working under low humidity and the cathodes of alkaline fuel batteries.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nucleated glass composite material and process for preparing same

InactiveCN1433985AThe level of artistic aesthetics has improvedReduce manufacturing costGlass compositesSurface layer

The present invention relates to a nucleated glass composite material and its preparation method. Said composite material is formed from surface layer nucleated glass and base material. Its surface layer bucleated glass includes ZnO 10-40% (wt%), SiO2, Al2O3, CaO, MgO, Na2O+K2O, Li2O, BaO and ZrO2, and its base material is ceramic or nucleated glass layer. Said nucleated glass is made up by following steps: preparing surface layer nucleated glass granulated raw material, preparing base material, combining them and making them into semi-finished product, edge grinding, scrapping, coarse grinding, polishing, edge grindnig, chamferring and drying, and the pattern of the obtained nucleated glass copmosite material can be various forms of ball, chrysanthemum flower, slag flow, flower cluster, flowing lines, flame and radiation, etc.

Owner:戴长禄 +1

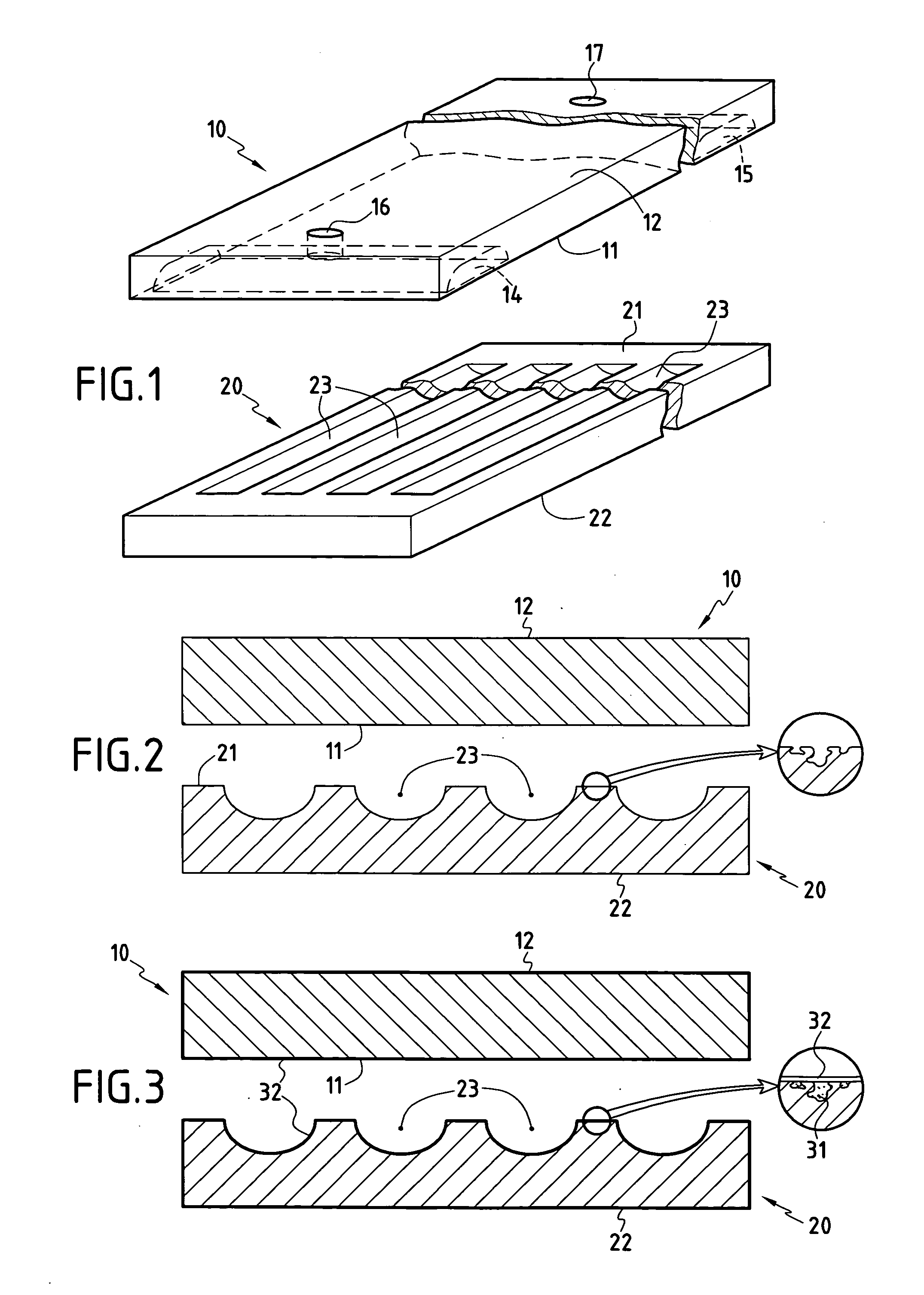

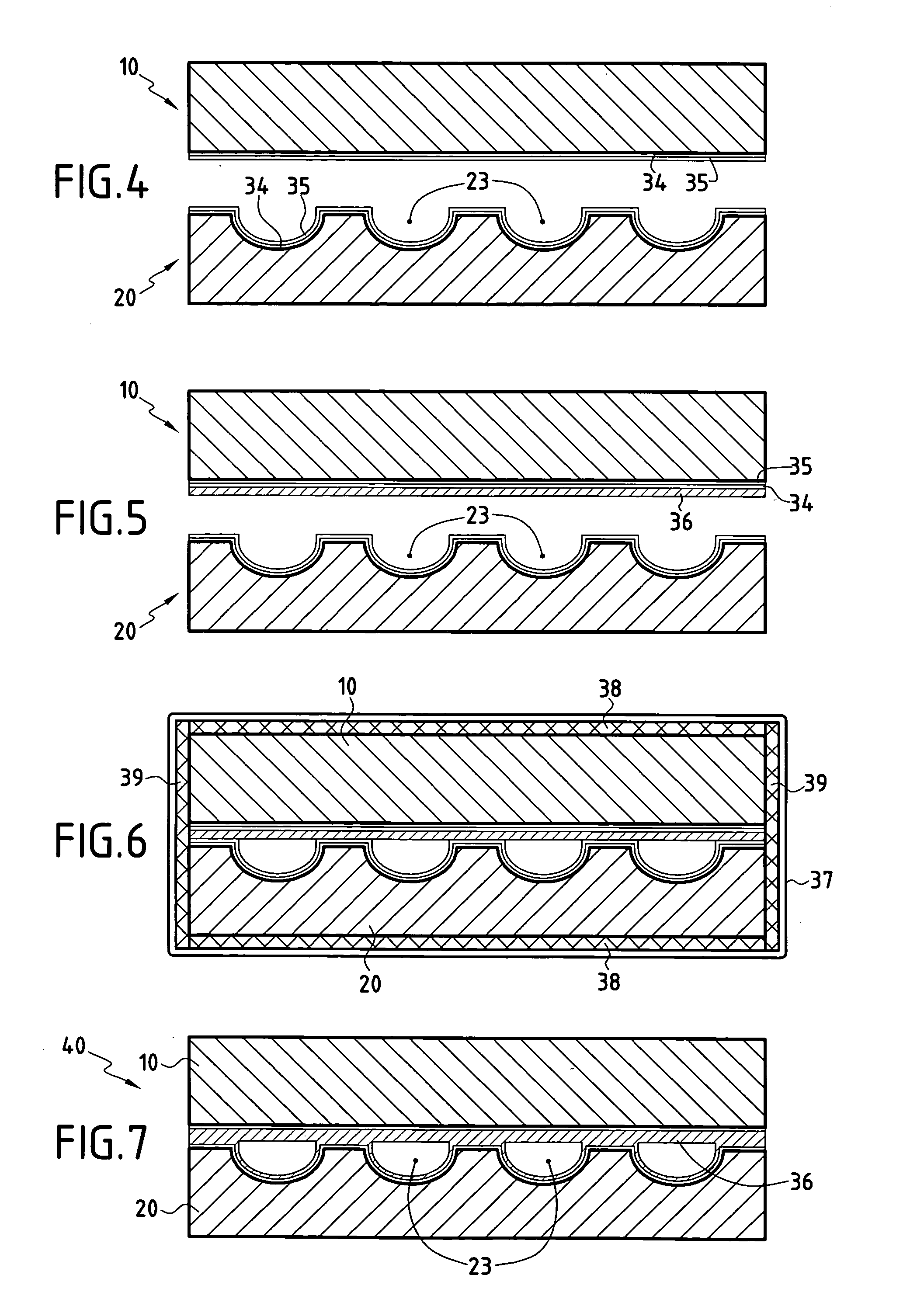

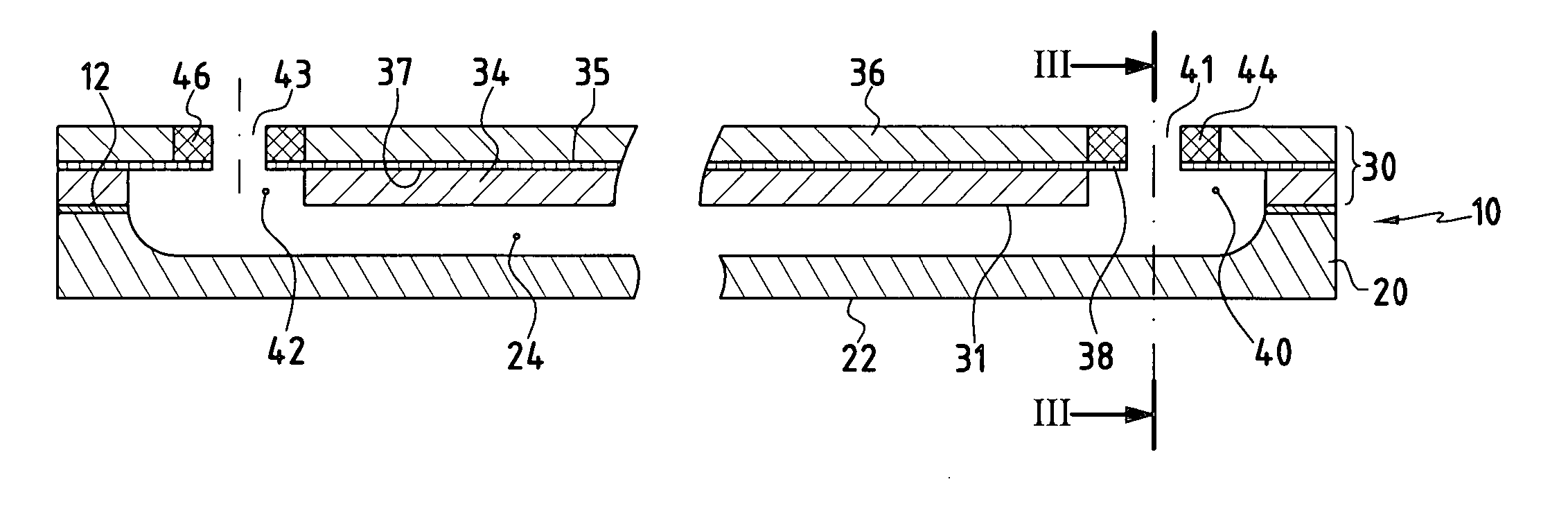

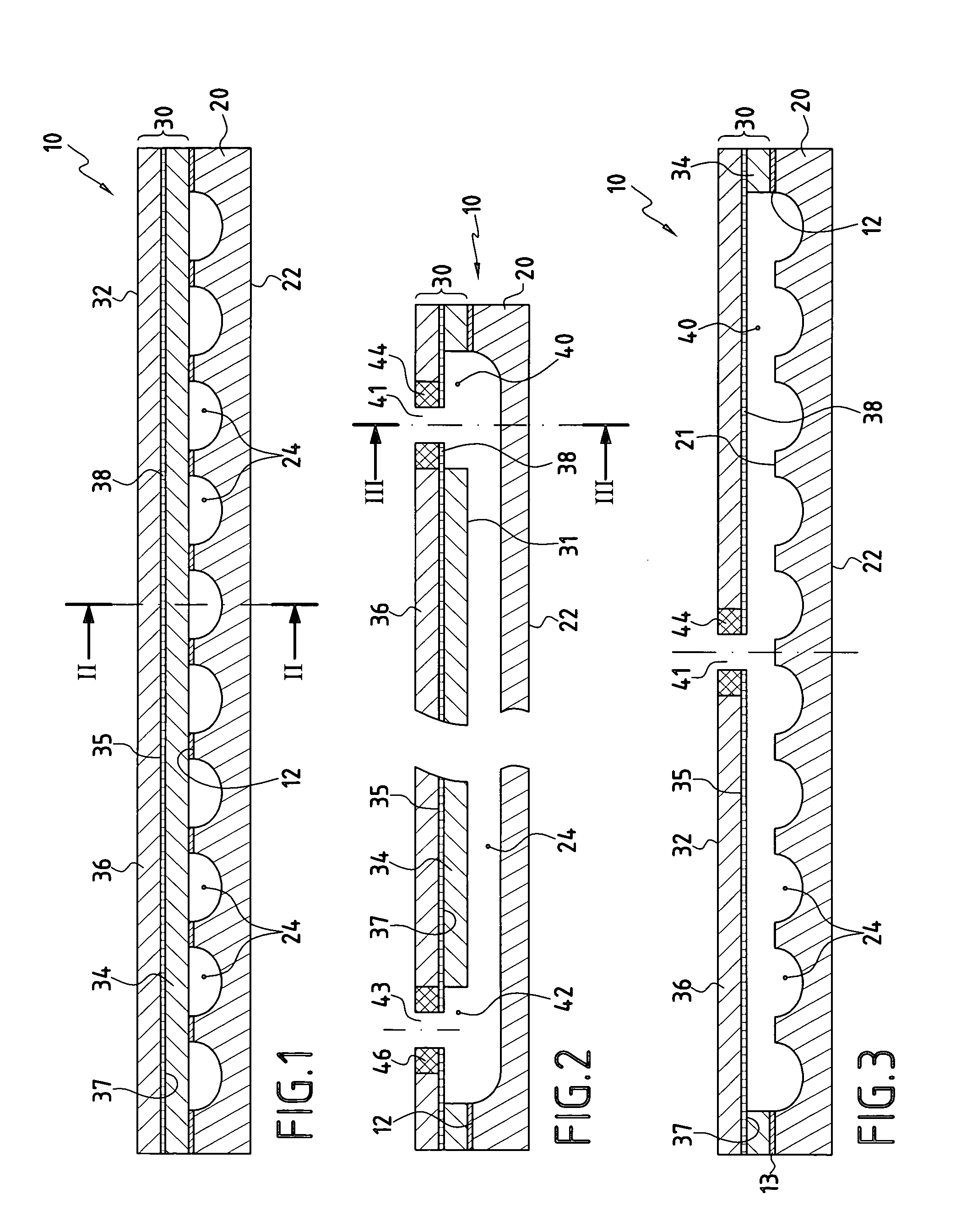

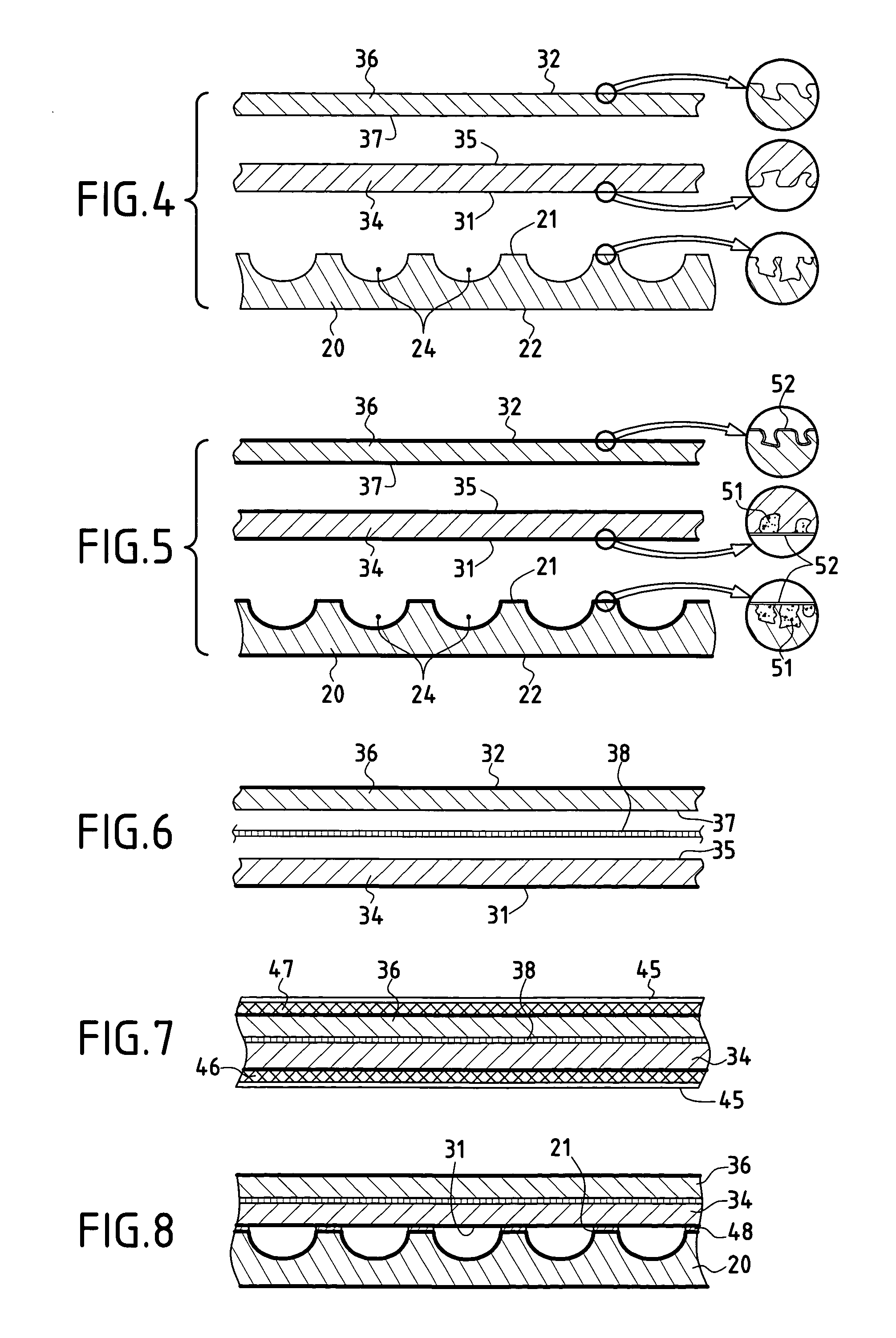

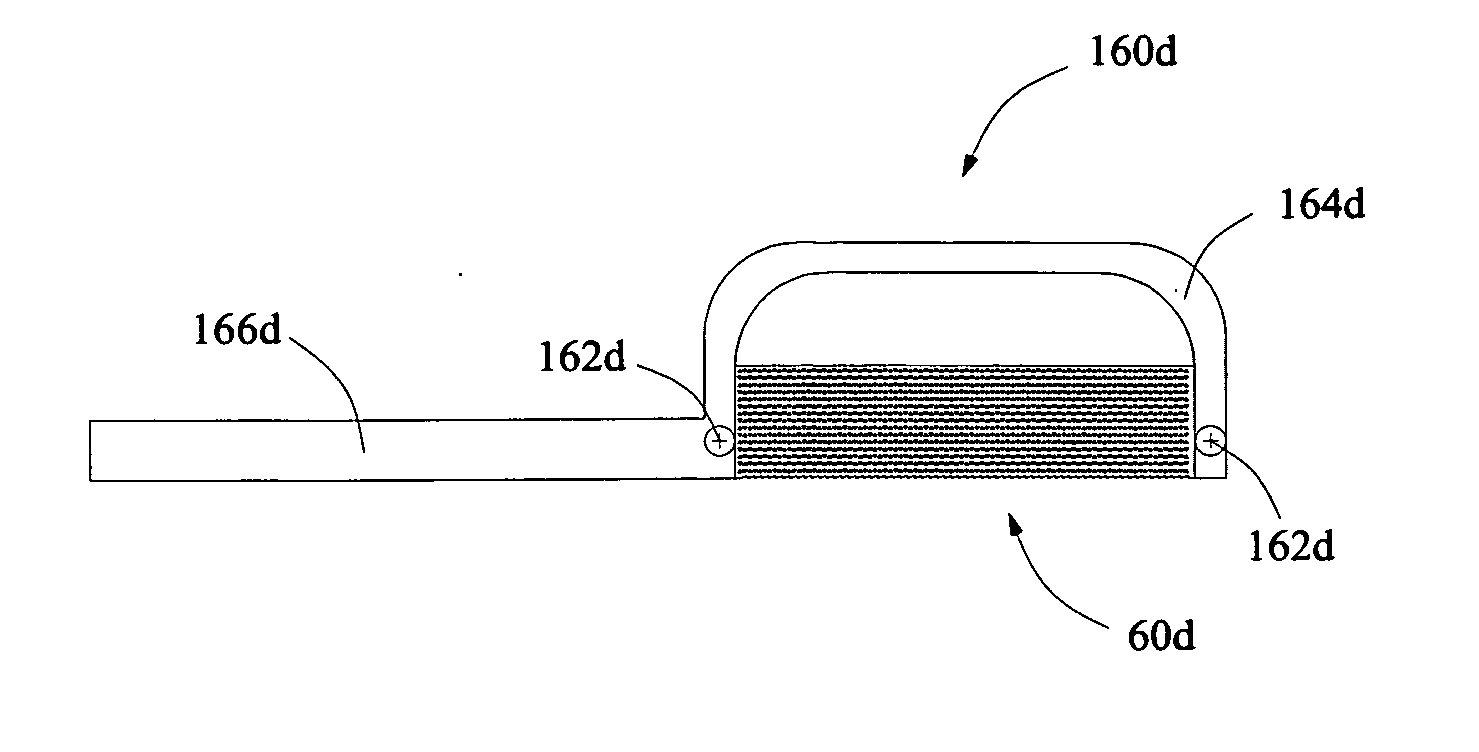

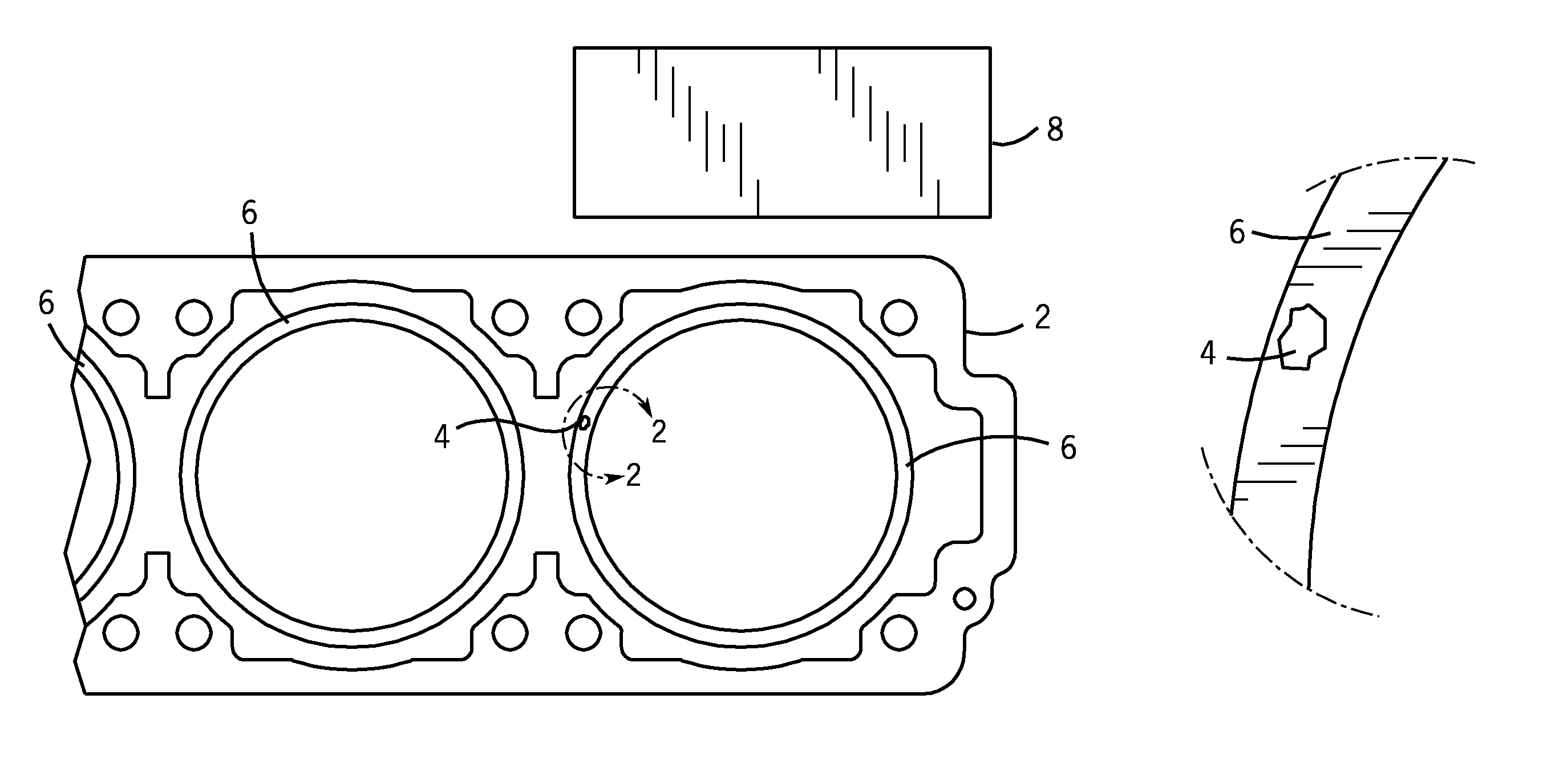

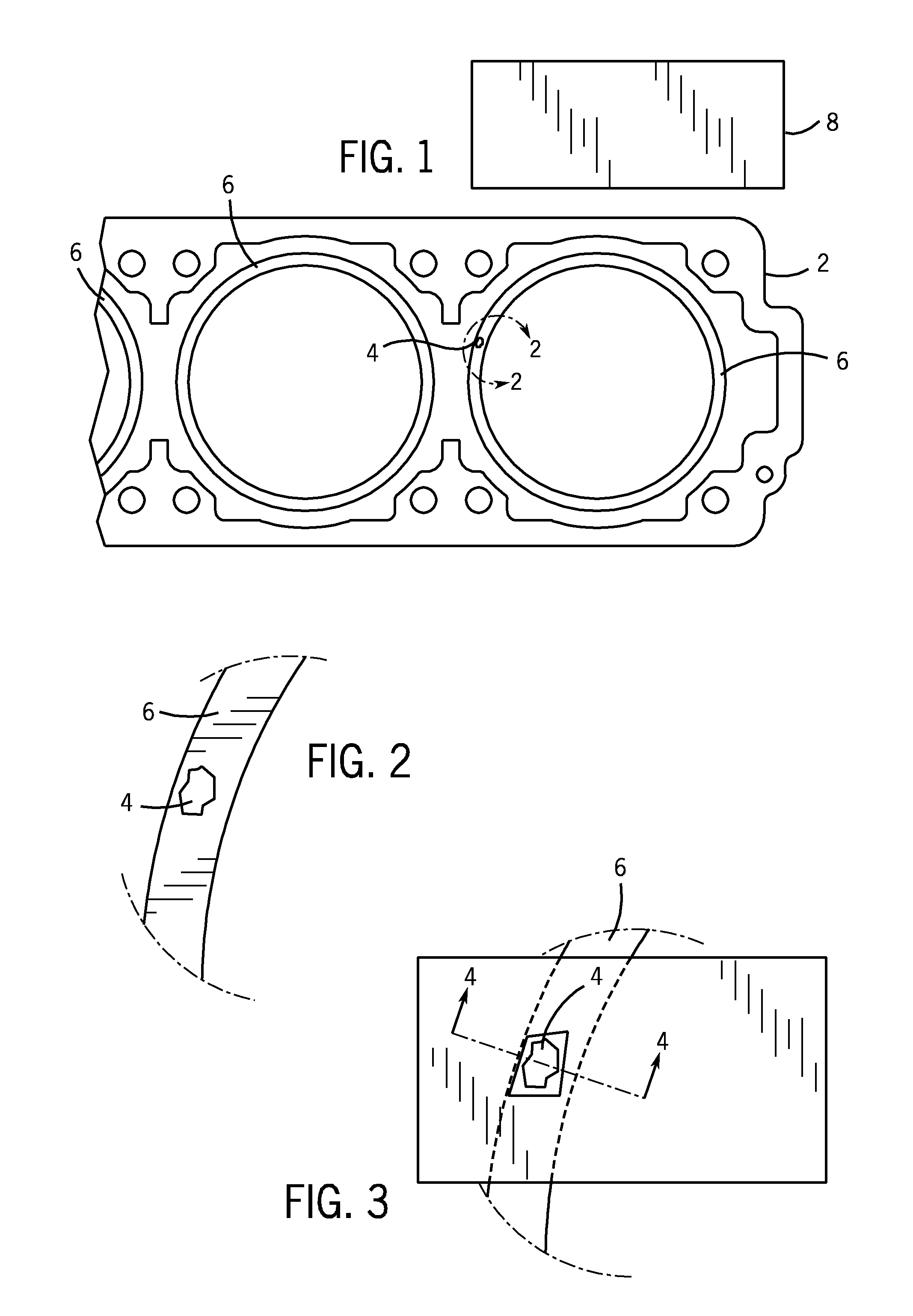

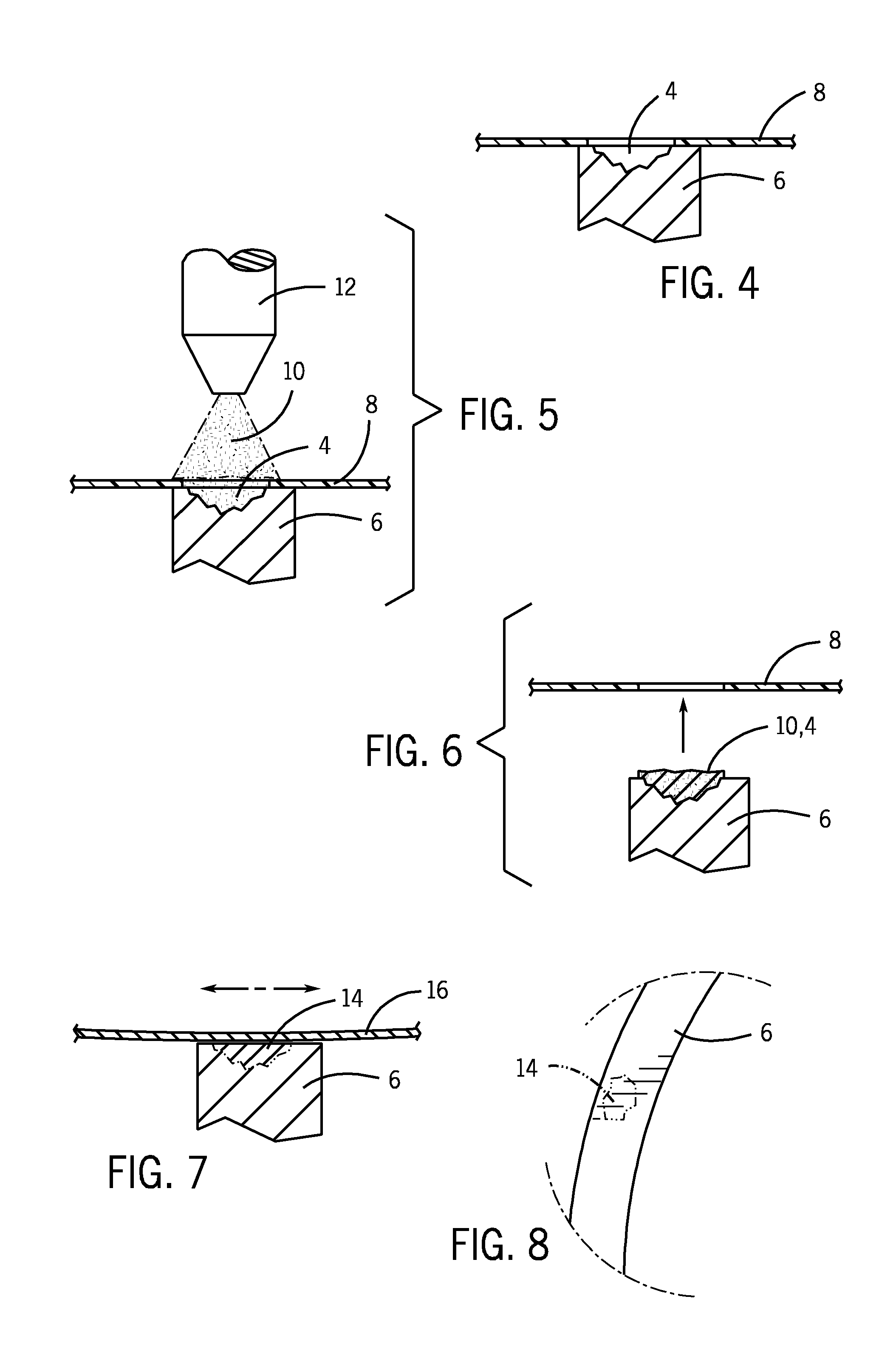

Method of manufacturing an active cooling panel out of thermostructural composite material

InactiveUS20050077341A1Effective and durableReduce usageContinuous combustion chamberNuclear energy generationMetal coatingCombustion chamber

A metal coating is formed on the inside face of a first thermostructural composite material part presenting indentations forming channels, and also on the inside face of a second thermostructural composite material part for being applied against the inside face of the first part, and the first and second parts are assembled together by bonding said inside faces together by hot compression, in particular by hot isostatic pressing, thereby obtaining a thermostructural composite material cooling panel having integrated fluid flow channels. The invention is applicable to making heat exchanger walls such as the walls of combustion chambers in aircraft engines, or the diverging portions of rocket engines, or plasma confinement chambers in nuclear fusion reactors.

Owner:SNECMA PROPULSION SOLIDE

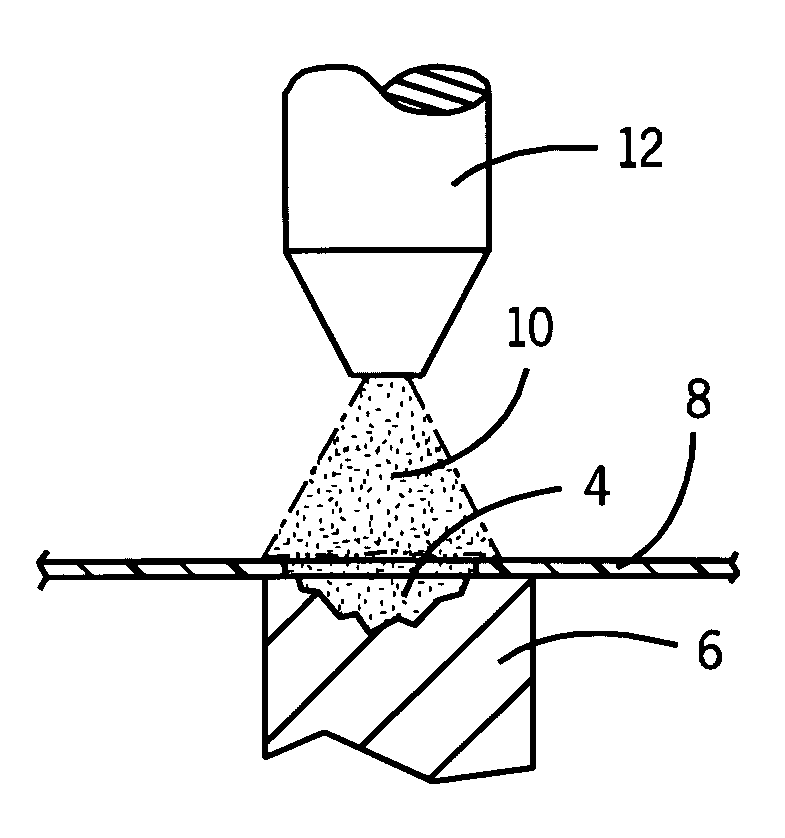

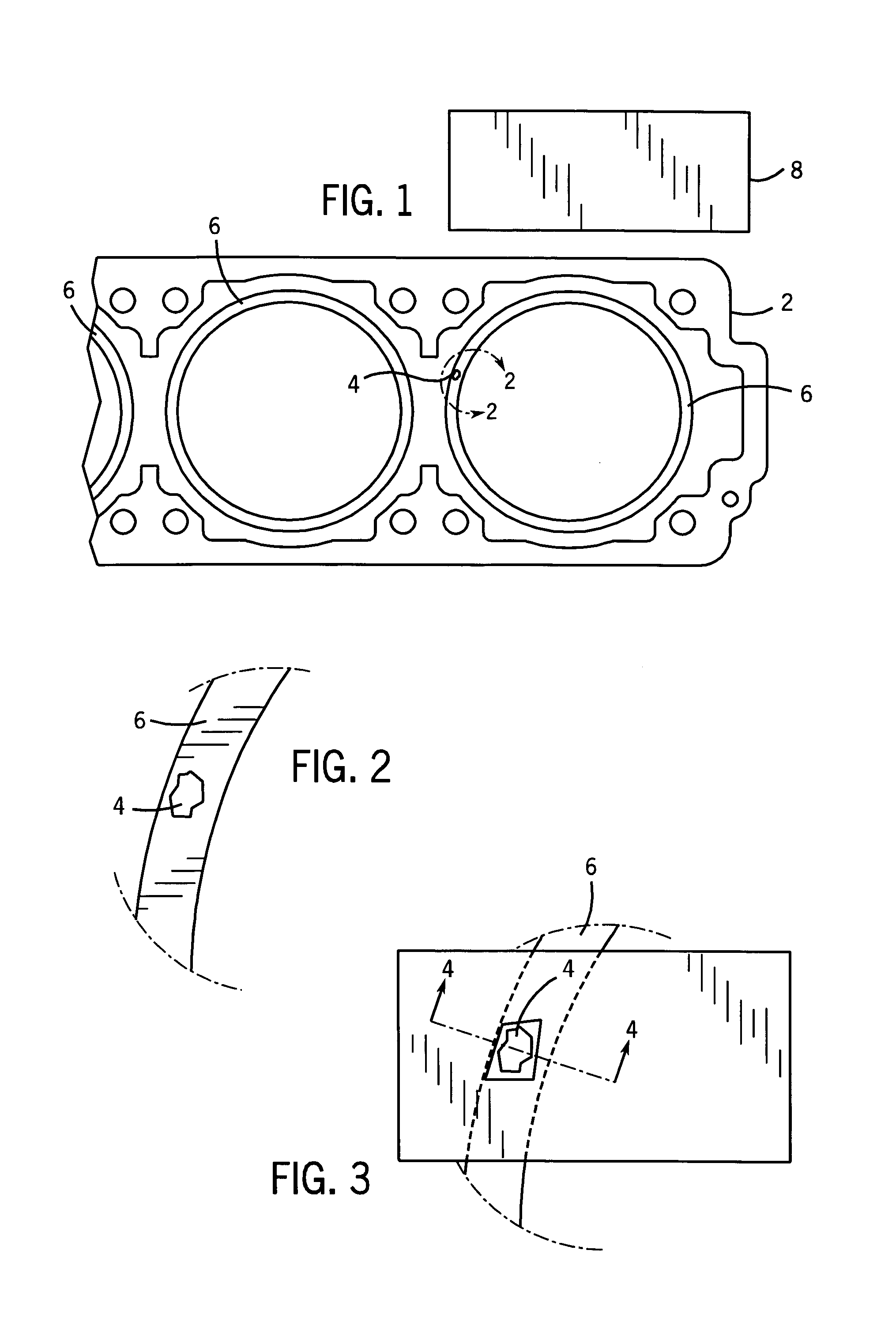

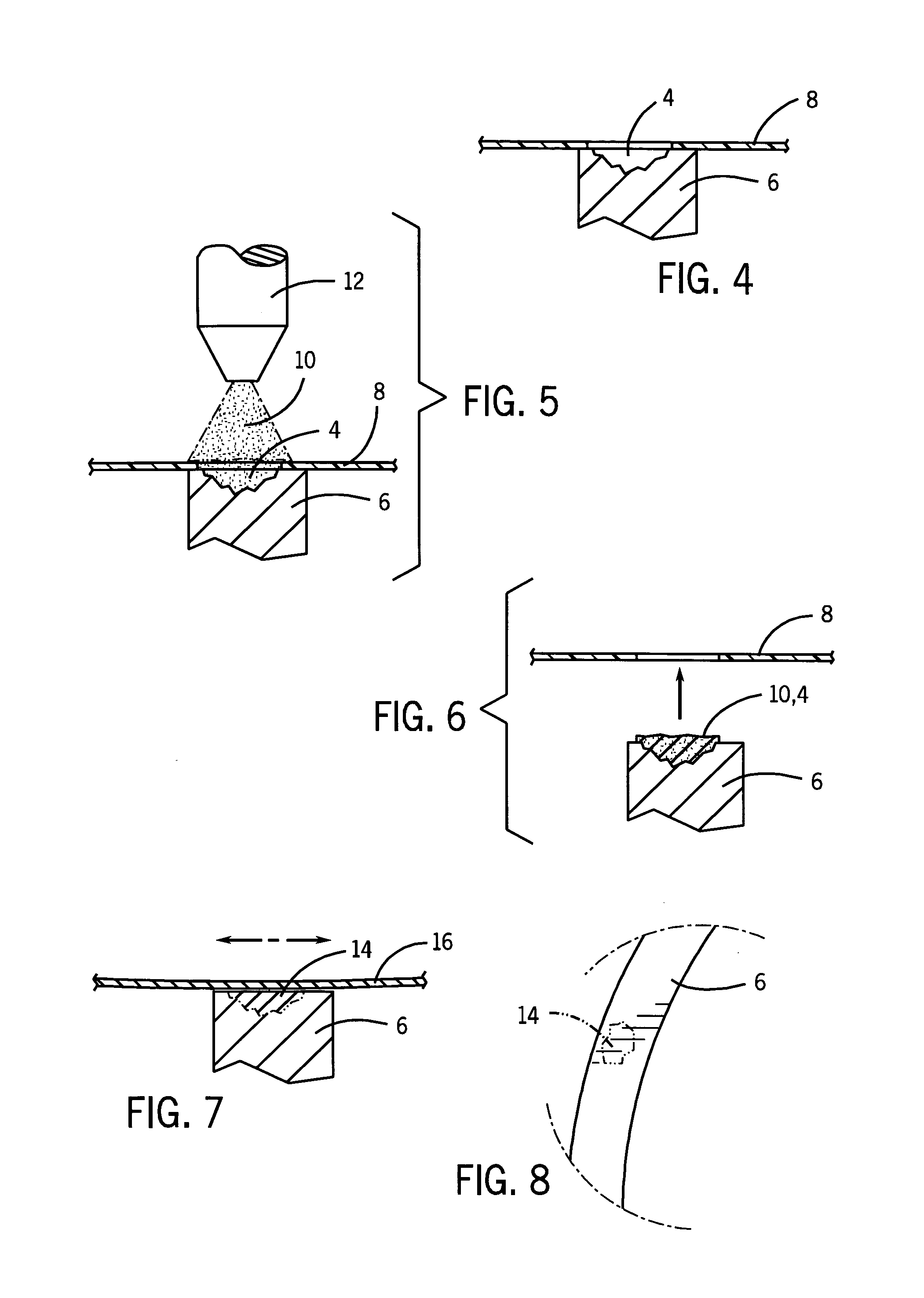

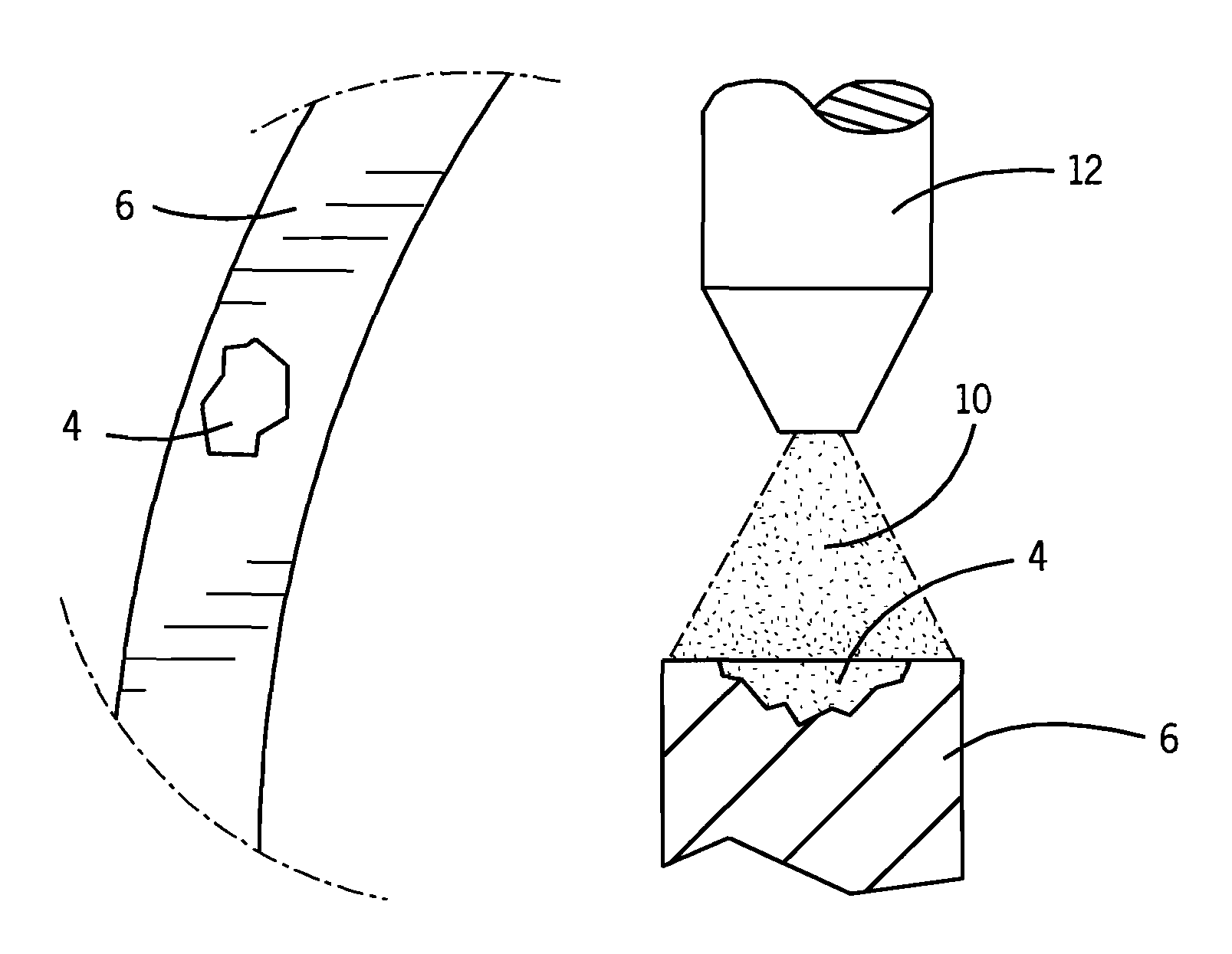

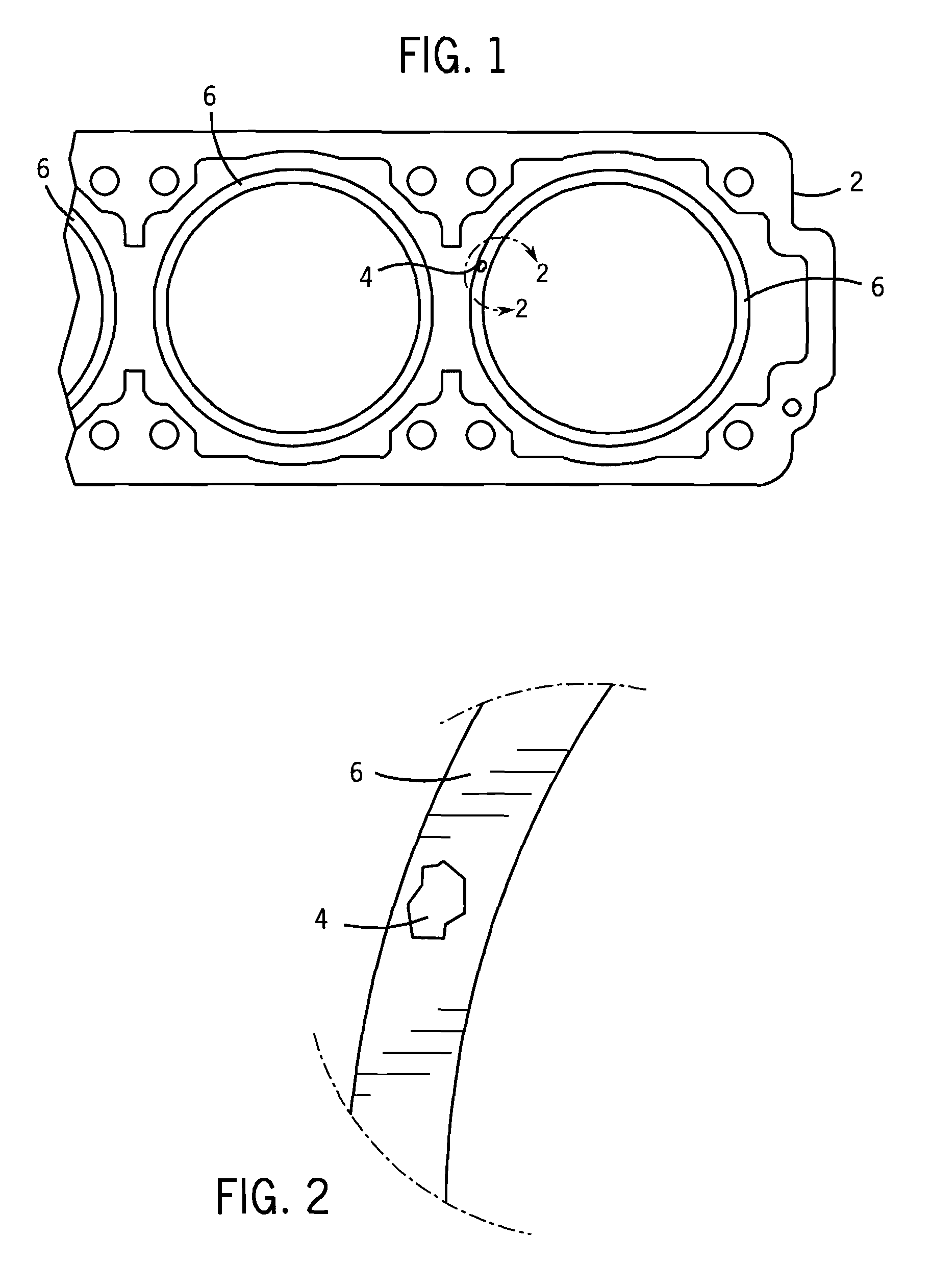

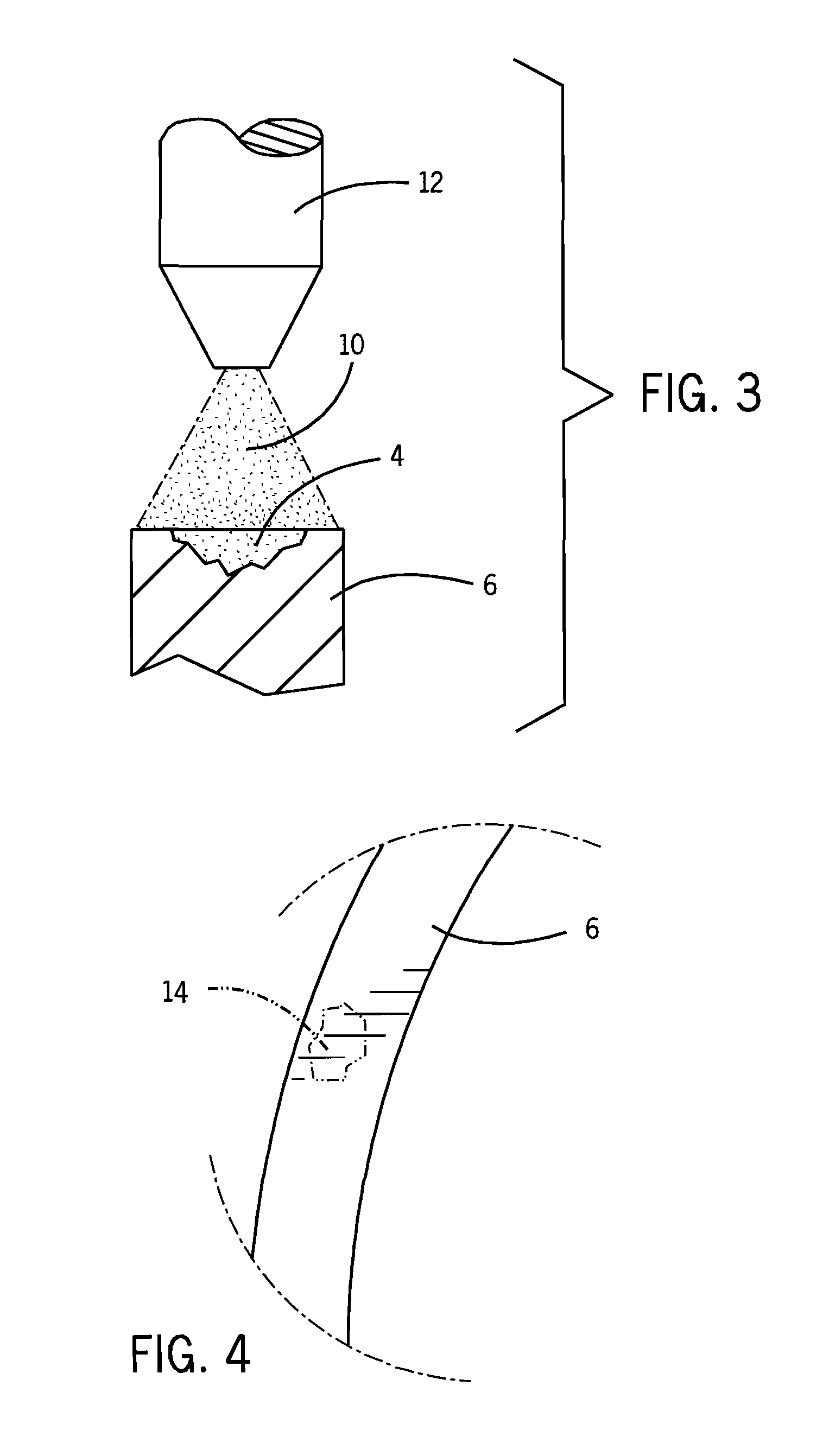

Restoration process for porosity defects in high pressure die cast engine blocks

ActiveUS7188416B1High level of porosityIncrease manufacturing costMolten spray coatingMetal working apparatusPorosityMetallurgy

A restoration process for restoring surface porosity defects in engine blocks cast using a high pressure die cast method. The areas of an engine block having surface porosity defects are identified and the areas not containing surface porosity defects are masked using an adhesive, reusable, rubberized mask. The masked surface is subsequently cleaned and a metal spray is applied to the surface porosity defects. The mask is removed and the restored surface porosity defects are hand finished to create an engine block having less than 0.05% surface porosity.

Owner:BRUNSWICK CORPORATION

Flame-resistant corrosion-resistant coating

The invention discloses a flame-resistant corrosion-resistant coating. The flame-resistant corrosion-resistant coating is an amorphous flame-resistant corrosion-resistant coating for protecting the surface of a liner of an industrial furnace. The flame-resistant corrosion-resistant coating is characterized in that fine powder of tabular corundum and magnesium aluminate spinel, calcined alpha-Al2O3 micro-powder, pure calcium aluminate cement as a curing agent, sodium hexametaphosphate as a sintering assistant, and a phosphoric acid or aluminum dihydrogen phosphate solution as a binder are blended into the flame-resistant corrosion-resistant coating. The flame-resistant corrosion-resistant coating can resist corrosion produced by a high-concentration fluoride and a high-concentration hydrogen fluoride atmosphere, and has the advantages of high purity, good heat stability, application convenience, smooth and compact surface and relatively low cost. The flame-resistant corrosion-resistantcoating is suitable for the surface of a liner of a furnace with fluorides and a hydrogen fluoride atmosphere and also is suitable for the surface of a liner of a high-temperature and low-oxygen content furnace with a strong reduction atmosphere.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

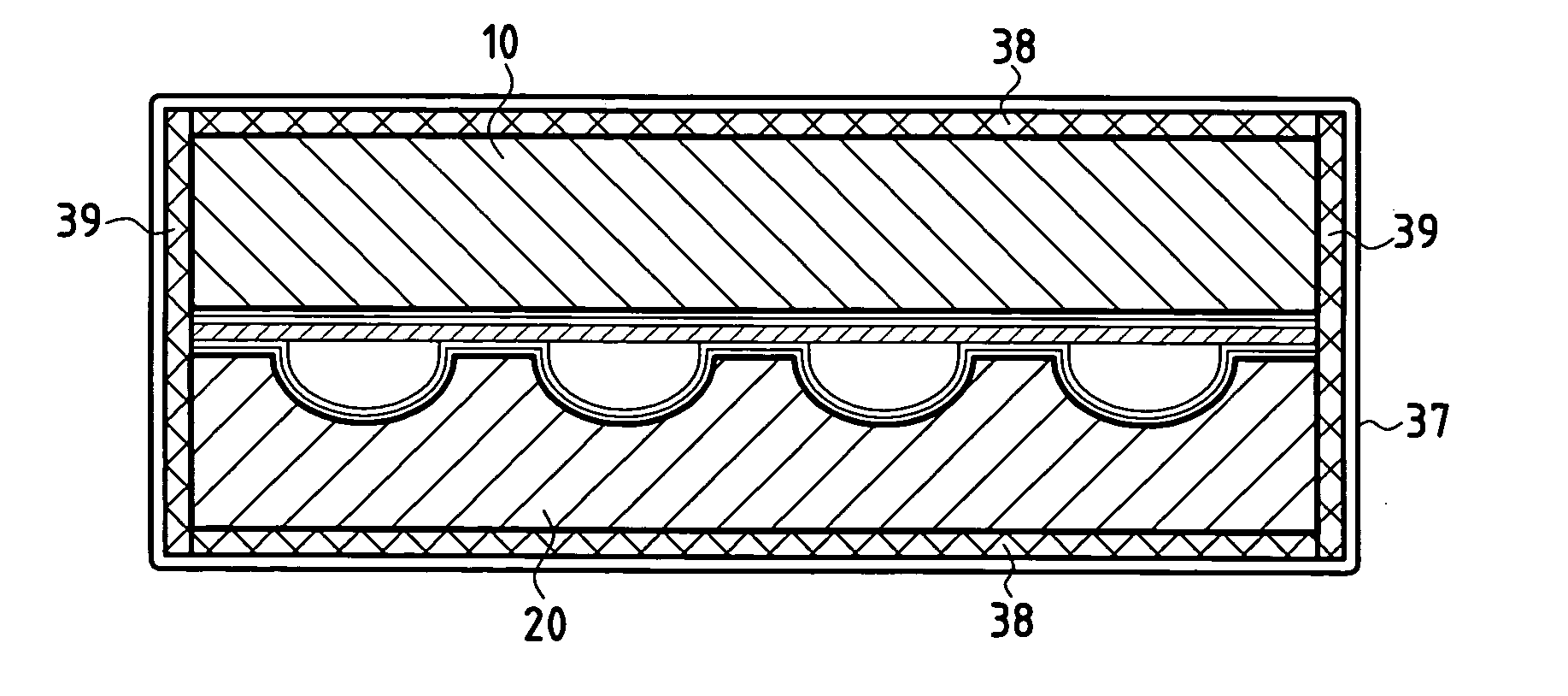

Active cooling panel of thermostructural composite material and method for its manufacture

InactiveUS20040194941A1Reduce thermomechanical stressReduce surface porosityContinuous combustion chamberNuclear energy generationCombustion chamberActive cooling

Owner:SNECMA PROPULSION SOLIDE

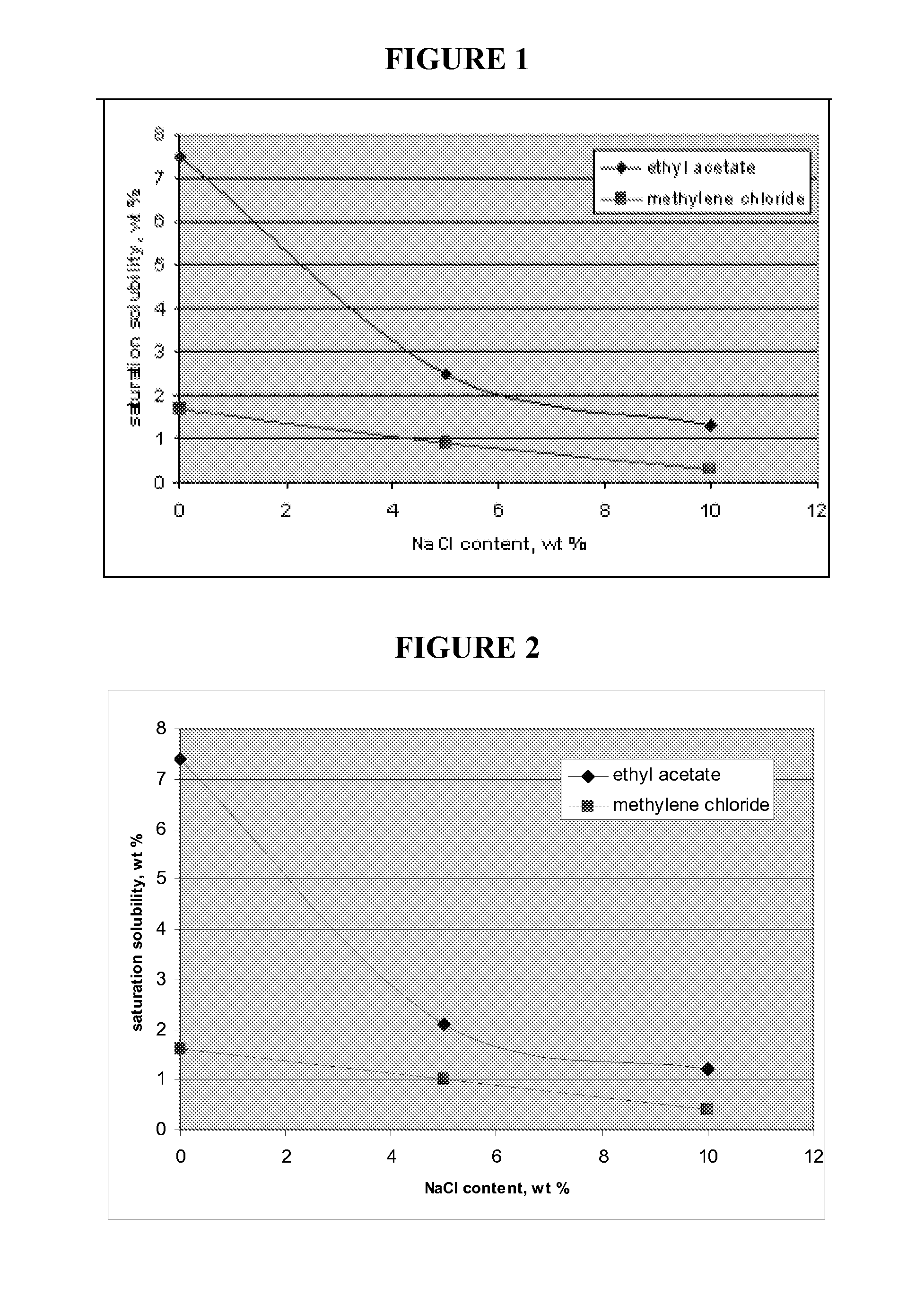

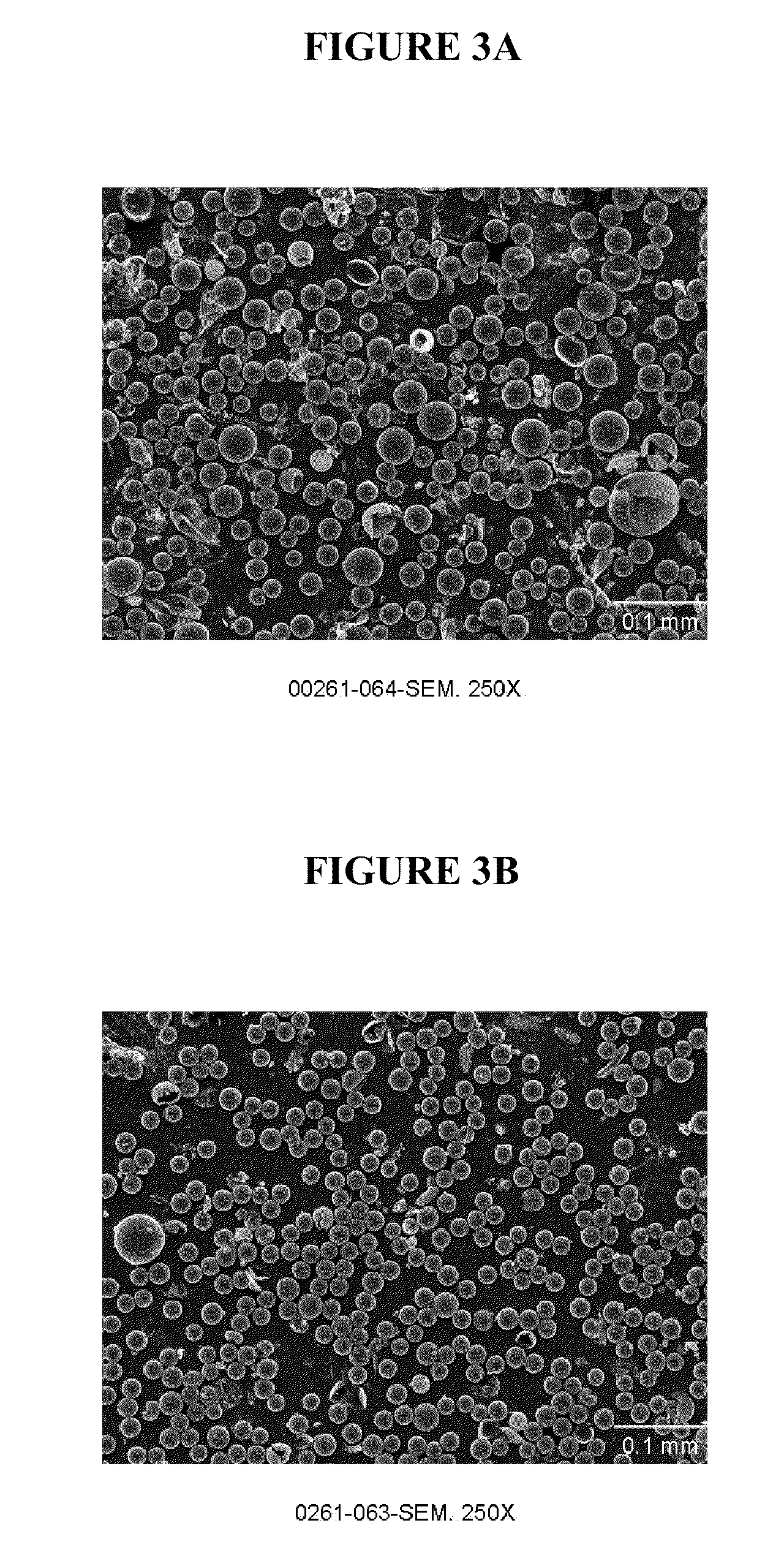

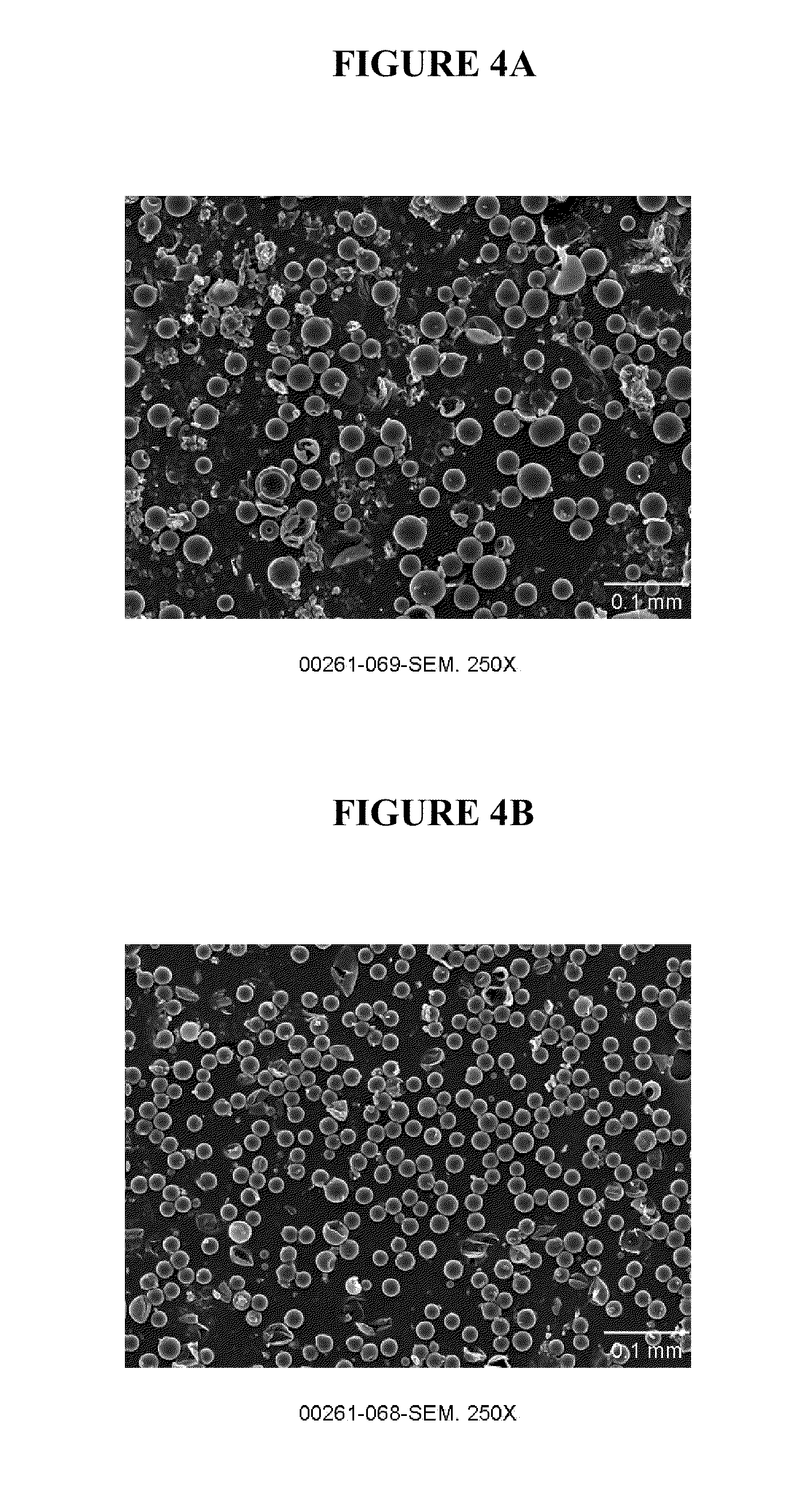

Microencapsulation process with solvent and salt

ActiveUS20100069602A1Safe handlingInexpensive waste disposalGranular deliveryLiposomal deliveryEmulsionMicroparticle

The present disclosure relates to processes for preparing microparticles using an emulsion process where both a solvent and a salt are used in the continuous phase of the emulsion. The present disclosure also relates to micropartices having an angle of repose of ≦35, as measured using a Hele-Shaw cell.

Owner:EVONIK CORP

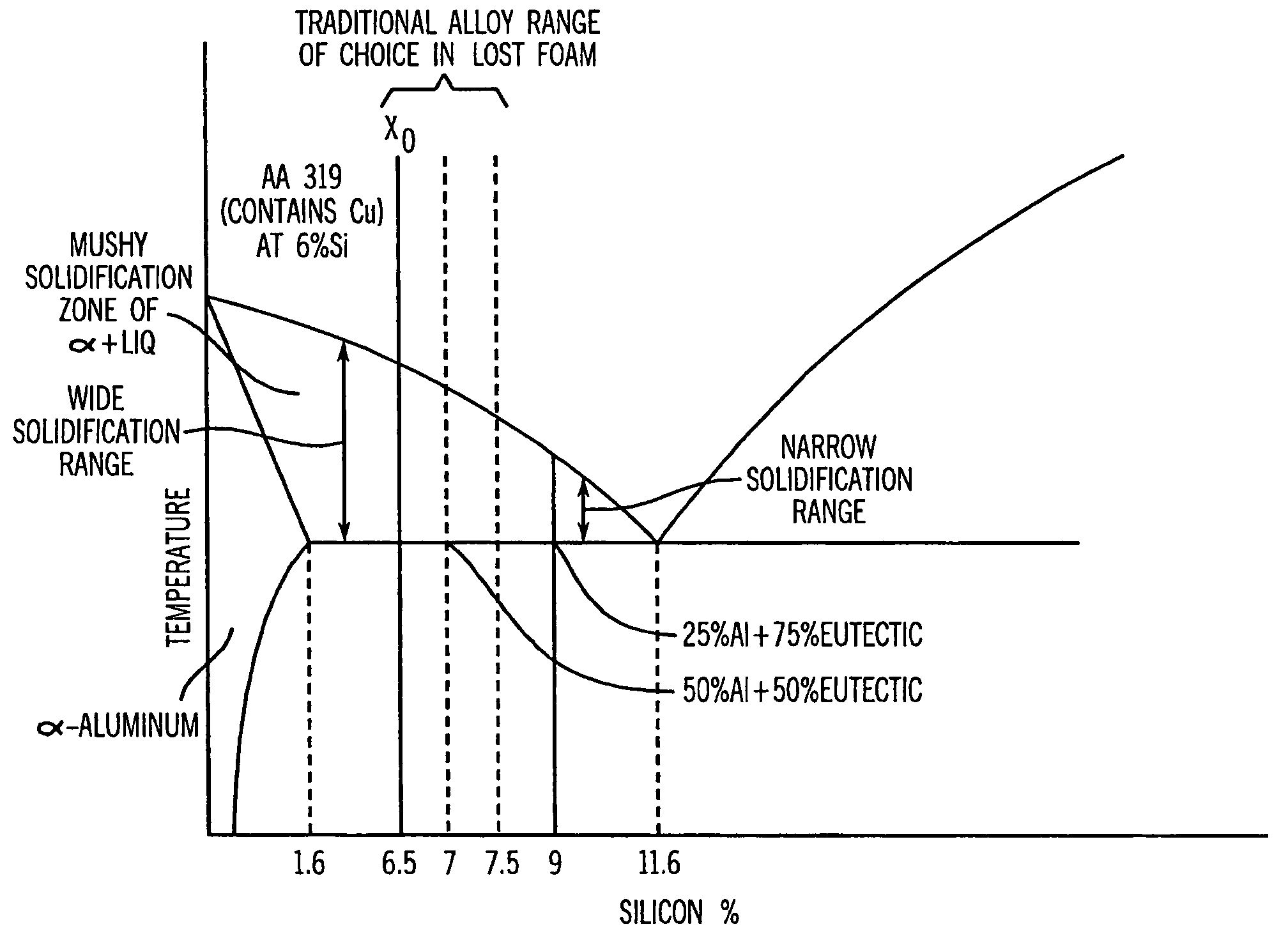

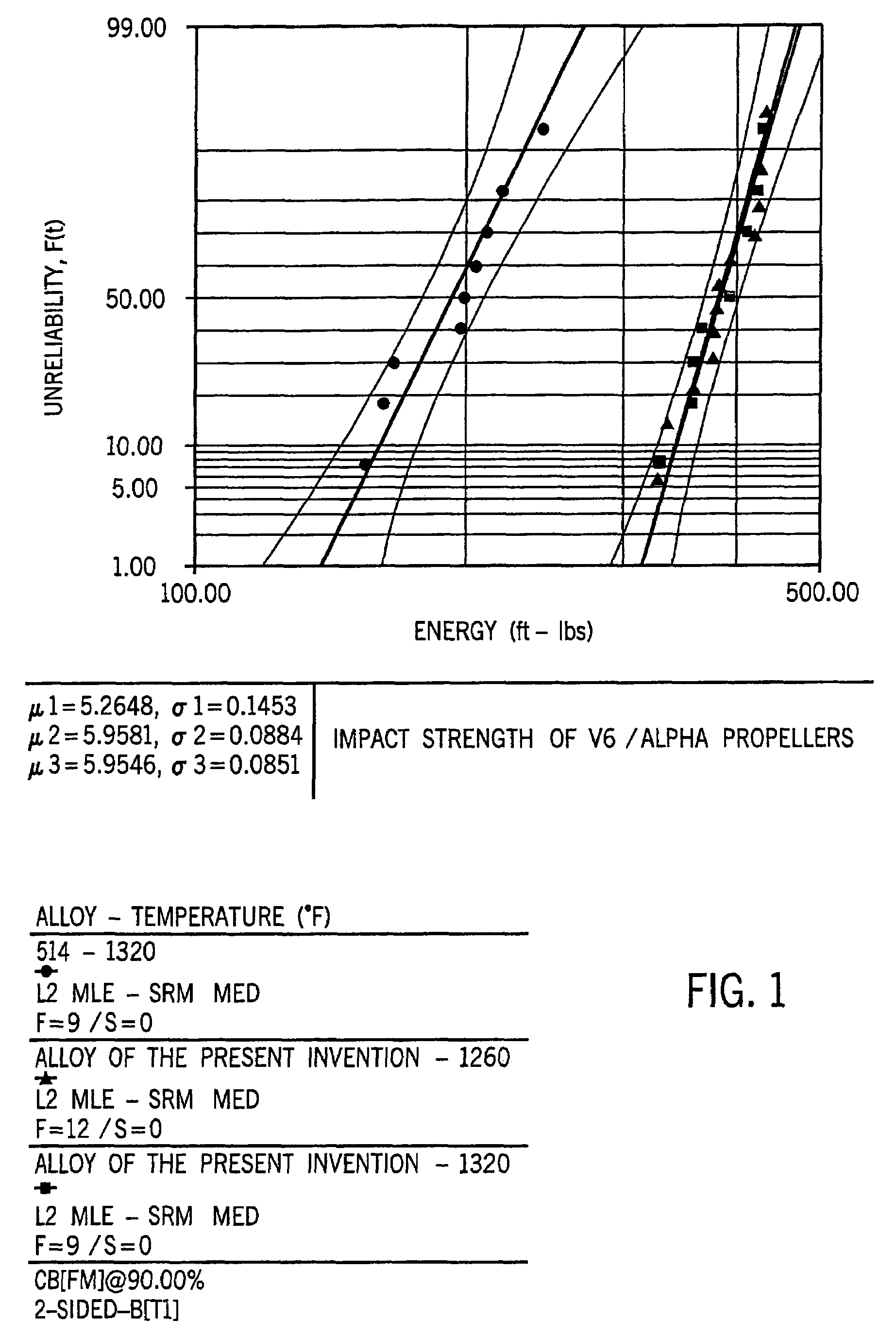

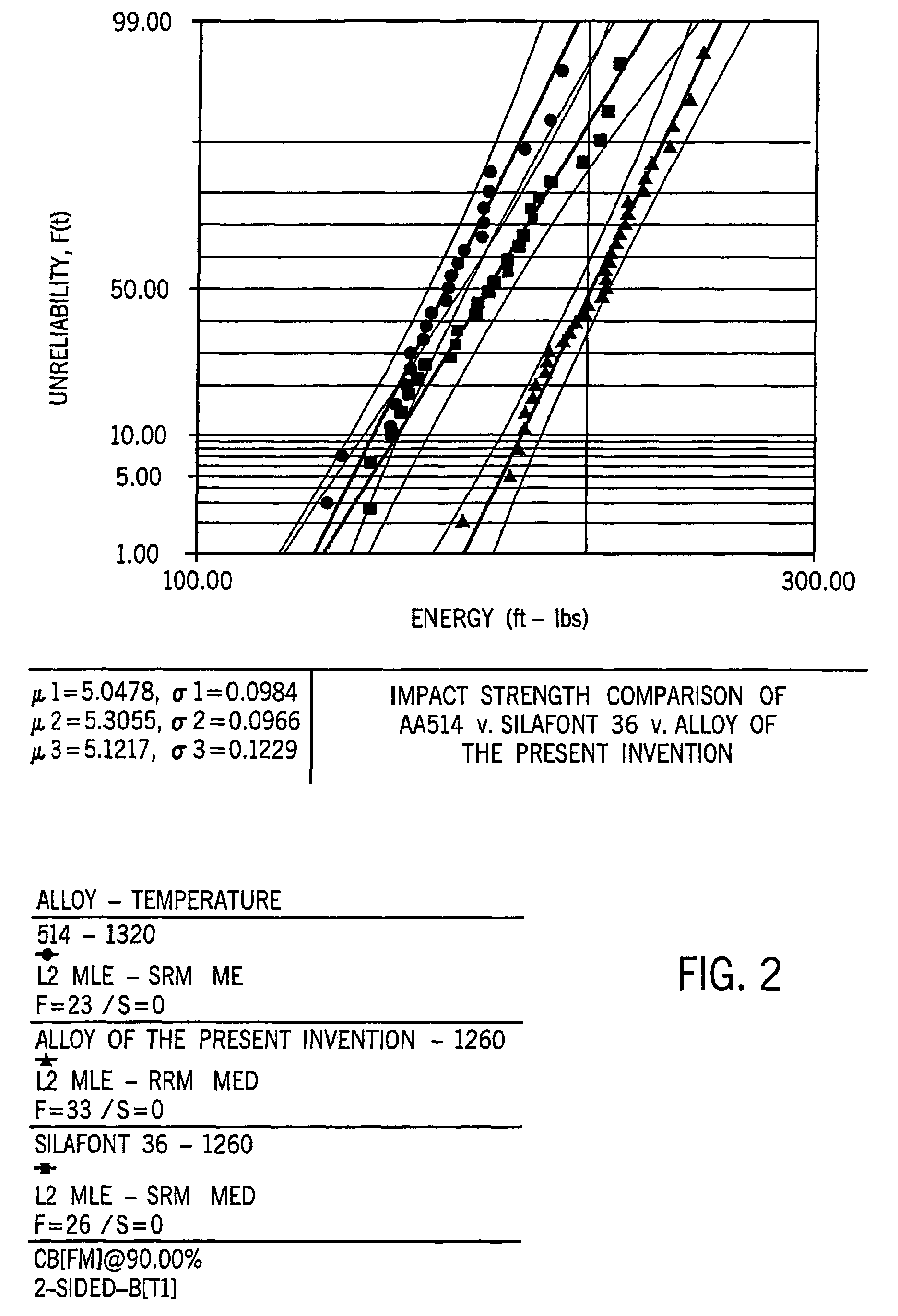

Aluminum-silicon alloy having reduced microporosity and method for casting the same

An aluminum-silicon lost foam casting alloy having reduced microporosity and a method for casting the same is herein disclosed. A preferred lost foam cast alloy consists essentially of 6 to 12% by weight silicon and preferably 9.0 to 9.5% by weight silicon, 0.035-0.30% strontium, 0.40% maximum iron, 0.45% maximum copper, 0.49% maximum manganese, 0.60% maximum magnesium, 3.0% maximum zinc, and the balance aluminum. Most preferably, the lost foam alloy is free from iron, titanium and boron. However, such elements may exist at trace levels. Most preferably, the alloy is lost foam cast with the process that applies at least 10 atmospheres of pressure during solidification. However, the range may be 5 to 60 atmospheres. The strontium addition is greater than 0.005% by weight and most preferably greater than 0.05% by weight. In accordance with the present disclosure, alloys having substantially decreased tensile liquid failure defects and substantially decreased surface puncture defects in comparison to conventional lost foam cast aluminum silicon alloys are obtained. Further, hydrogen porosity formation is substantially completely suppressed and surface porosity defects are substantially decreased in comparison to conventional lost foam silicon alloys when casting lost foam cast alloys in accordance with the claims of the instant disclosure. The instant disclosure further discloses aluminum silicon alloys that may be utilized in both the lost foam with pressure and the die casting processes.

Owner:BRUNSWICK CORPORATION

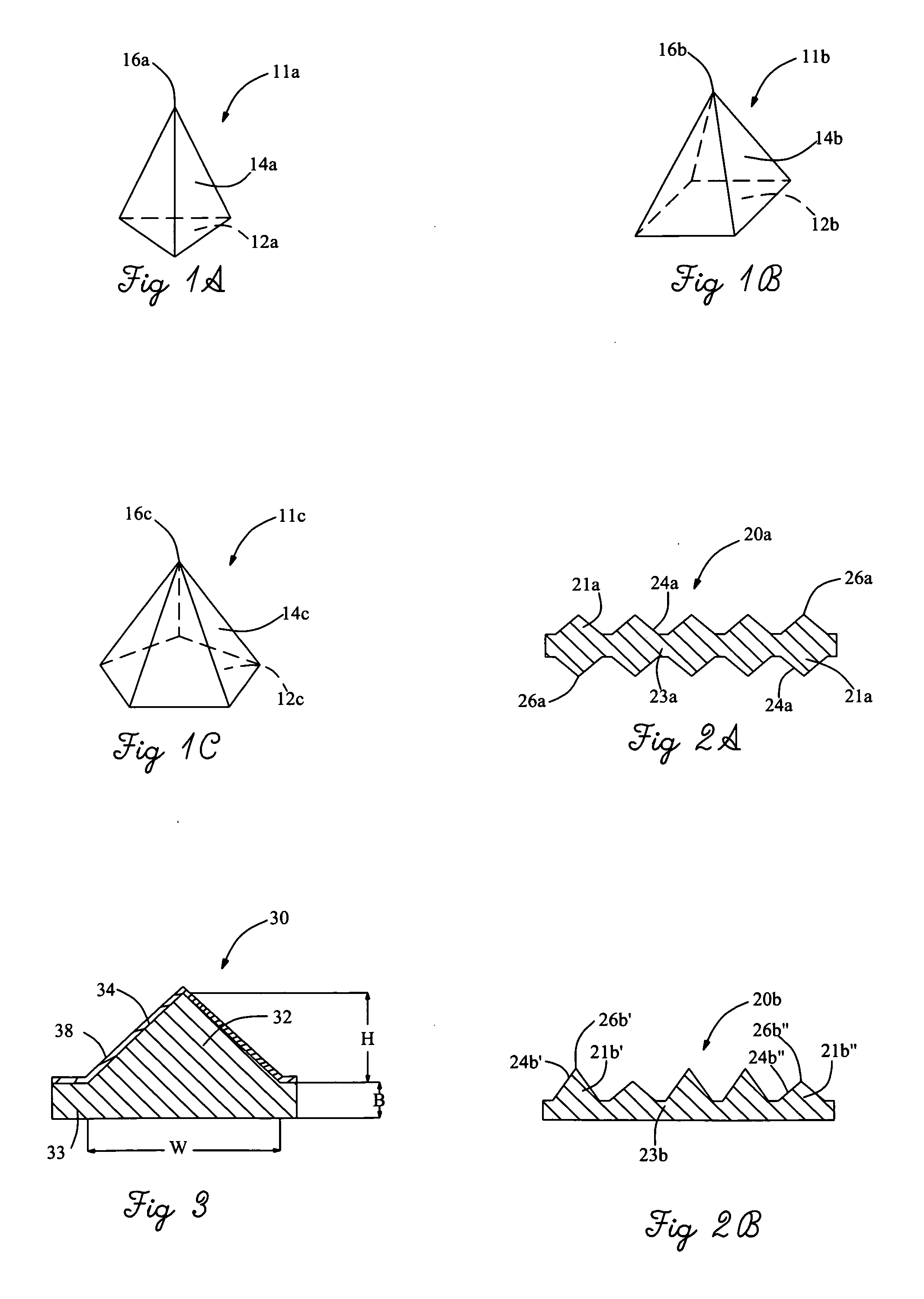

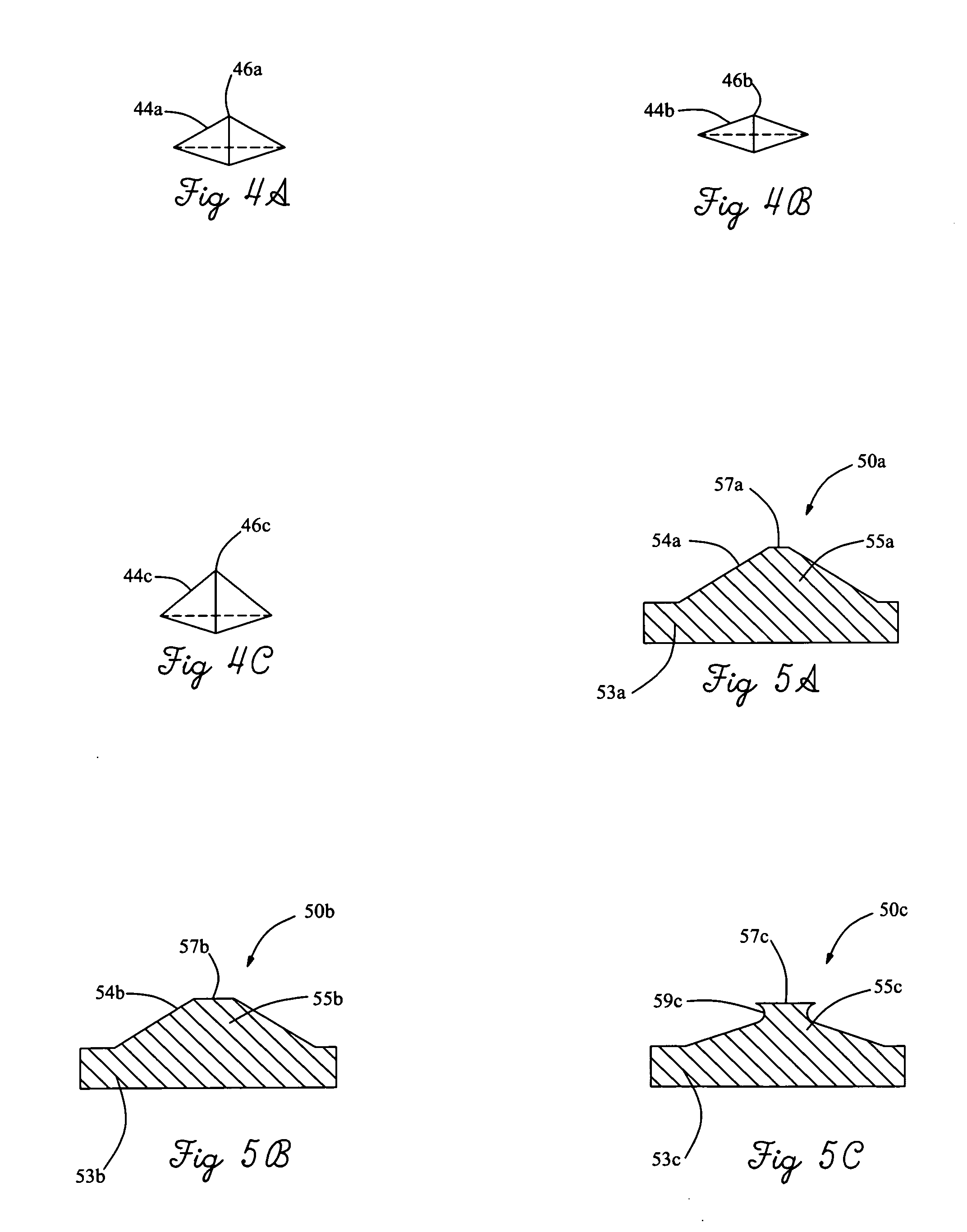

Method for finishing and fitting dental restorations and an abrasive material for doing same

InactiveUS20110081830A1Easy to removeFinishing difficultDental toolsMetal working apparatusSteel abrasiveMaterials science

A method for finishing and fitting dental restorations is provided. The method comprises the steps of contacting the restoration surface with a stainless steel abrasive material and working the stainless steel abrasive material against the restoration surface to shape and smooth the restoration surface. The stainless steel abrasive material comprises a base having a plurality of pyramidal shapes protruding therefrom, a portion of the protrusions having a substantially polygonal base and triangular sides which meet at an apex which substantially forms a point, hereinafter pyramidal protrusions, and a portion of the protrusions having a substantially polygonal base and substantially trapezoidal sides with the portion thereof distant from the base surface forming a plateau such that the protrusions are substantially butte-like in shape, hereinafter termed butte protrusions, the protrusions providing intermixing cutting and planing edges, the ratio of the pyramidal protrusions to the butte protrusions ranging from 100:0 to 0:100. Also provided is the stainless steel abrasive material used to carry out the method.

Owner:POLLASKY ANTHONY DAVID

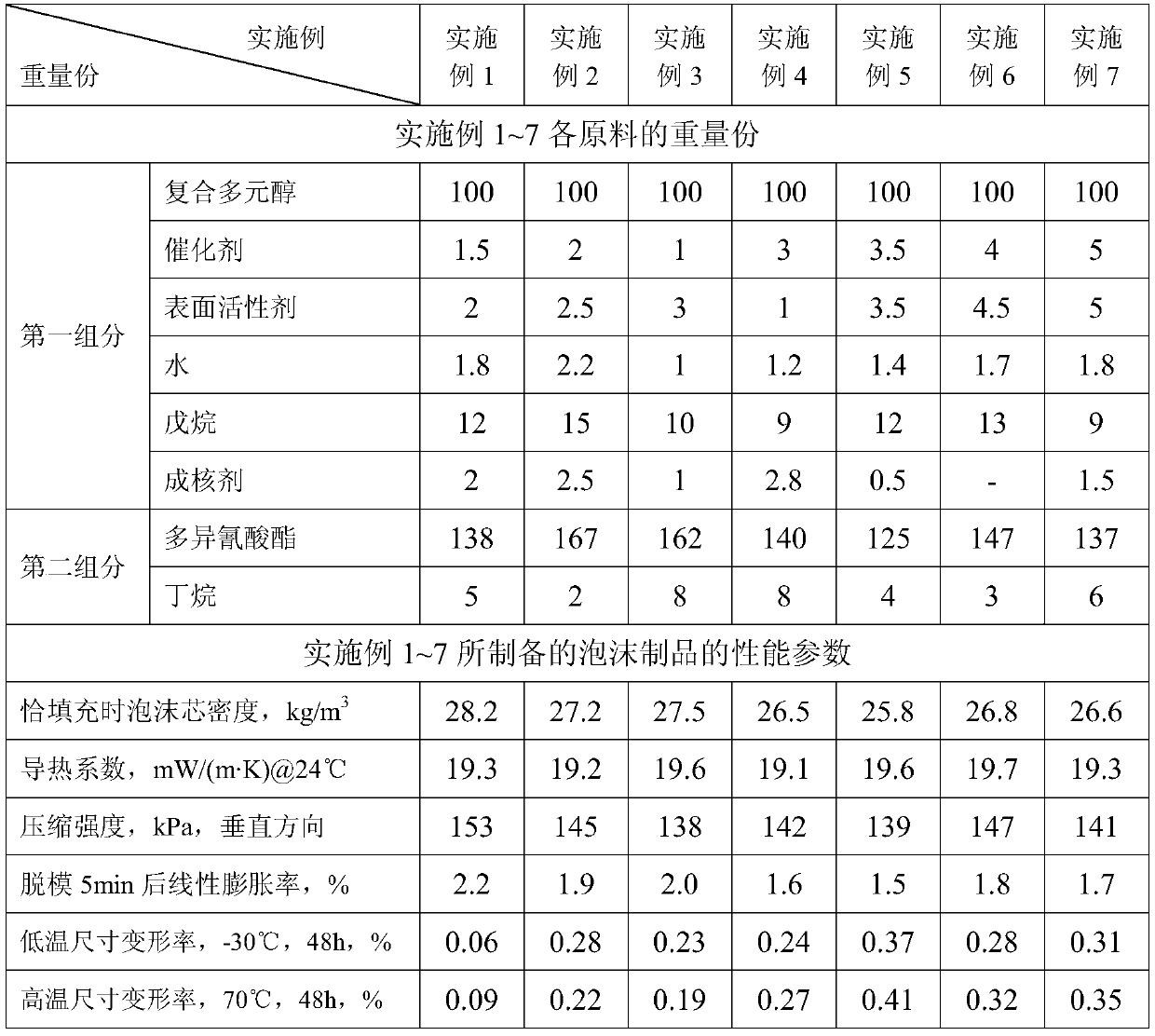

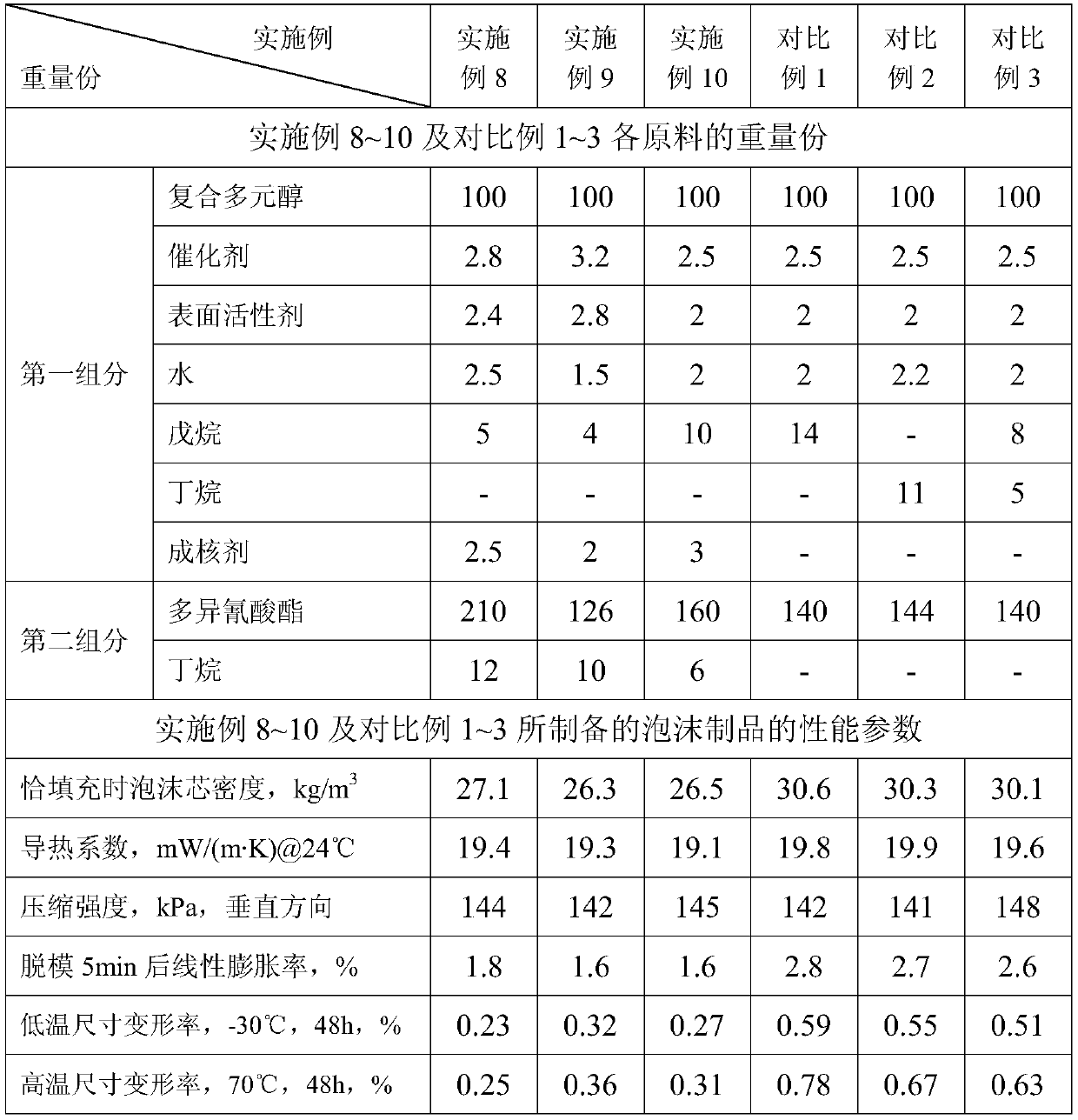

Ultra-low-density rigid polyurethane foam and preparation method thereof

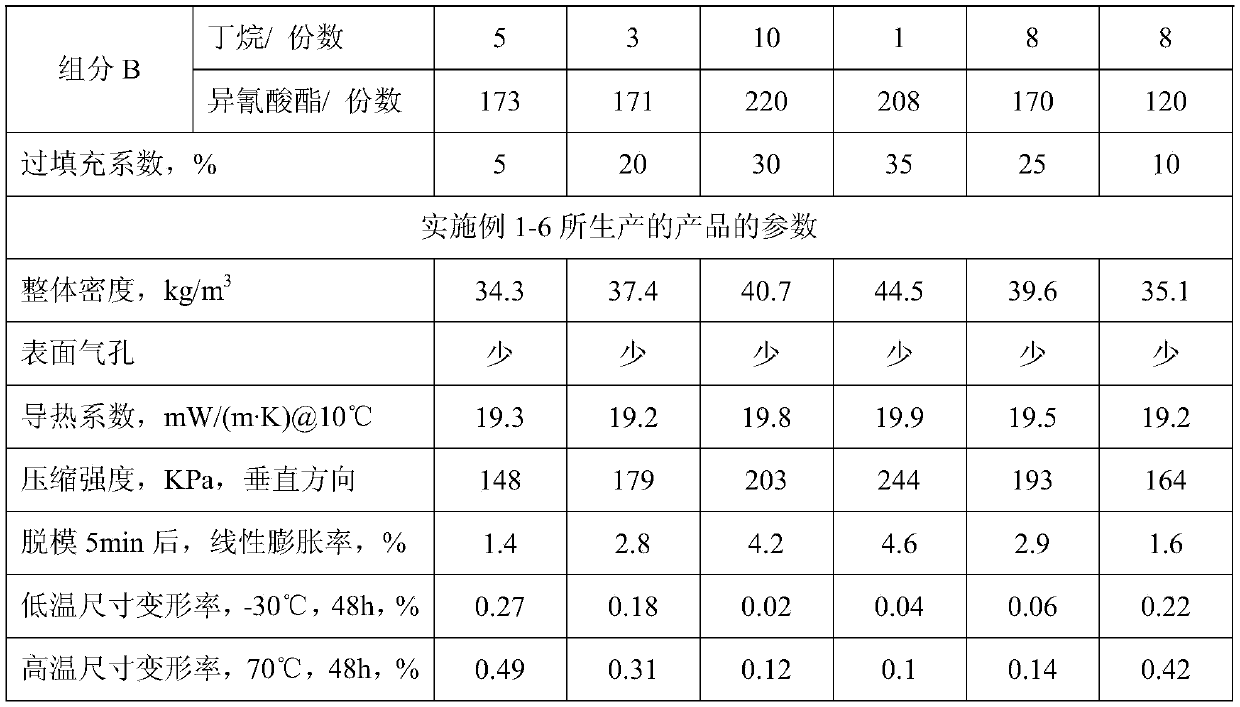

The invention relates to ultra-low-density rigid polyurethane foam with pentane and butane as foaming agents. The ultra-low-density rigid polyurethane foam is prepared by well premixing a component Aand a component B, and then well mechanically mixing and foaming the component A and the component B, wherein the component A is prepared from the components in parts by weight: 100 parts of pluronicpolyols, 4-15 parts of the pentane, 1-5 parts of a catalyst, 1-5 parts of an organosilicon surfactant, 1-2.5 parts of water and 0-3 parts of a nucleating agent, the component B is prepared from the components in parts by weight: 2-12 parts of the butane and 120-210 parts of polyisocyanates, and raw materials are based on 100 parts of pluronic polyols. According to the prepared foam, foam holes arefine and uniform, the heat conductivity coefficient is small, the compression strength is high, and the overall performance is excellent. The invention further discloses a preparation method of the rigid polyurethane foam.

Owner:NANJING HONGBAOLI POLYURETHANE

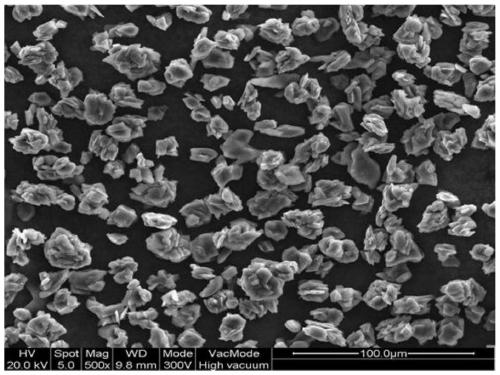

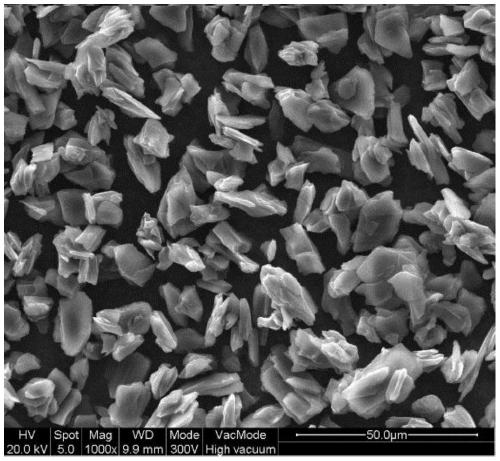

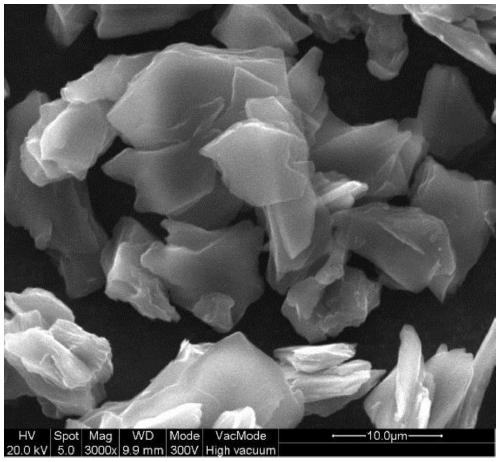

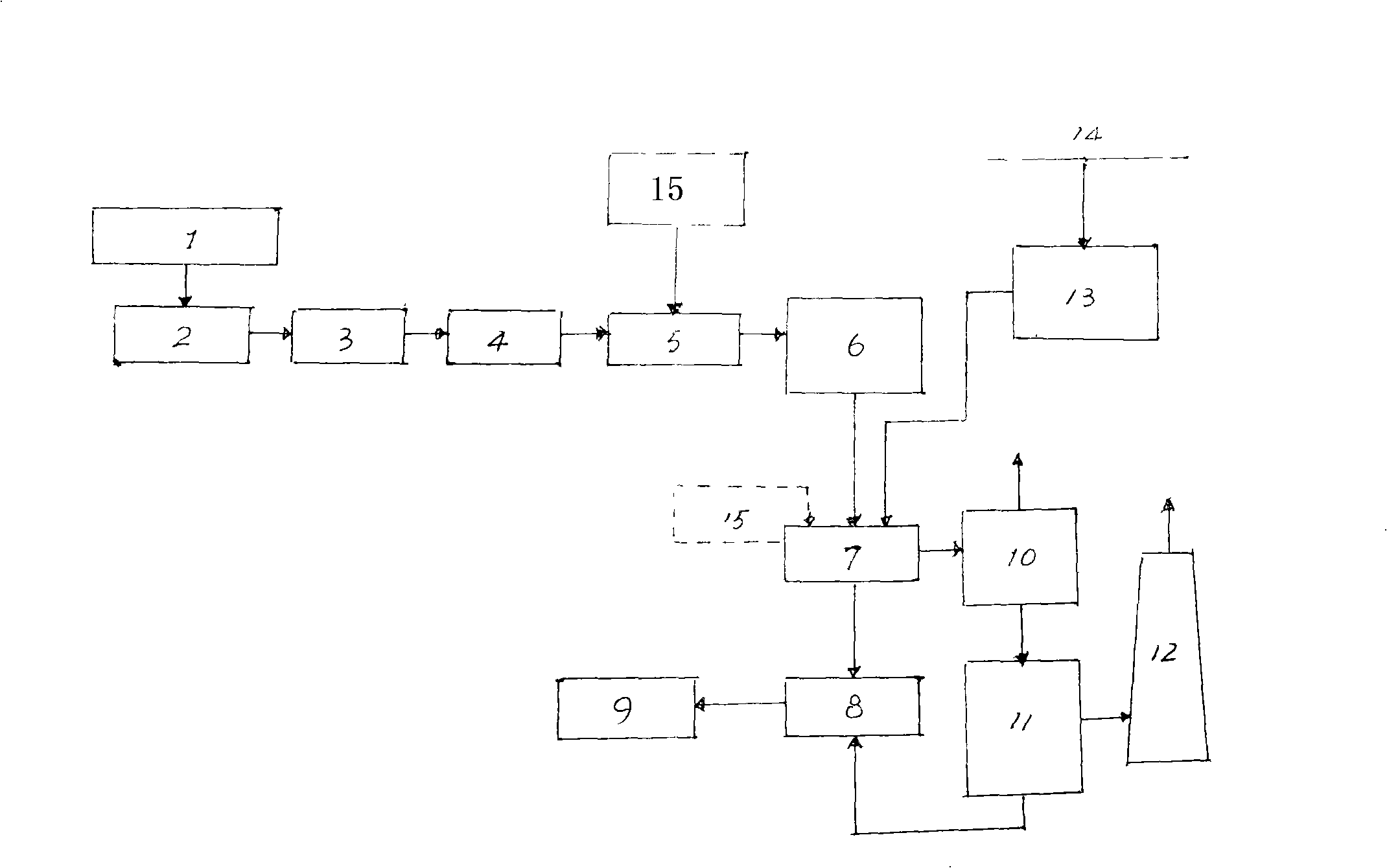

Graphite negative electrode material, lithium ion battery, preparation method and application

ActiveCN111384367AHigh tap densityIncrease battery capacityCell electrodesSecondary cellsGraphiteElectrical performance

The invention discloses a graphite negative electrode material, a lithium ion battery, a preparation method and application. The preparation method of the material comprises the steps of (1) crushingand shaping an artificial graphite raw material to prepare powder; 2, graphitizing the powder to obtain a material A; 3, screening the material A to obtain a material B; (4) carrying out surface coating modification treatment on a mixture of the material B and a binder to obtain a material C; and (5) carbonizing the material C to obtain the product. The graphite negative electrode material disclosed by the invention has relatively high tap density and relatively high battery capacity, various characteristics interact with one another, the comprehensive advantages of the material are improved,the characteristics of high capacity and high compaction are ensured, and the high-rate performance of the material is improved; and the preparation method facilitates improvement of the low-temperature electrical performance of the graphite negative electrode material of the lithium ion battery, and is simple in process, low in production cost and suitable for industrial production.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

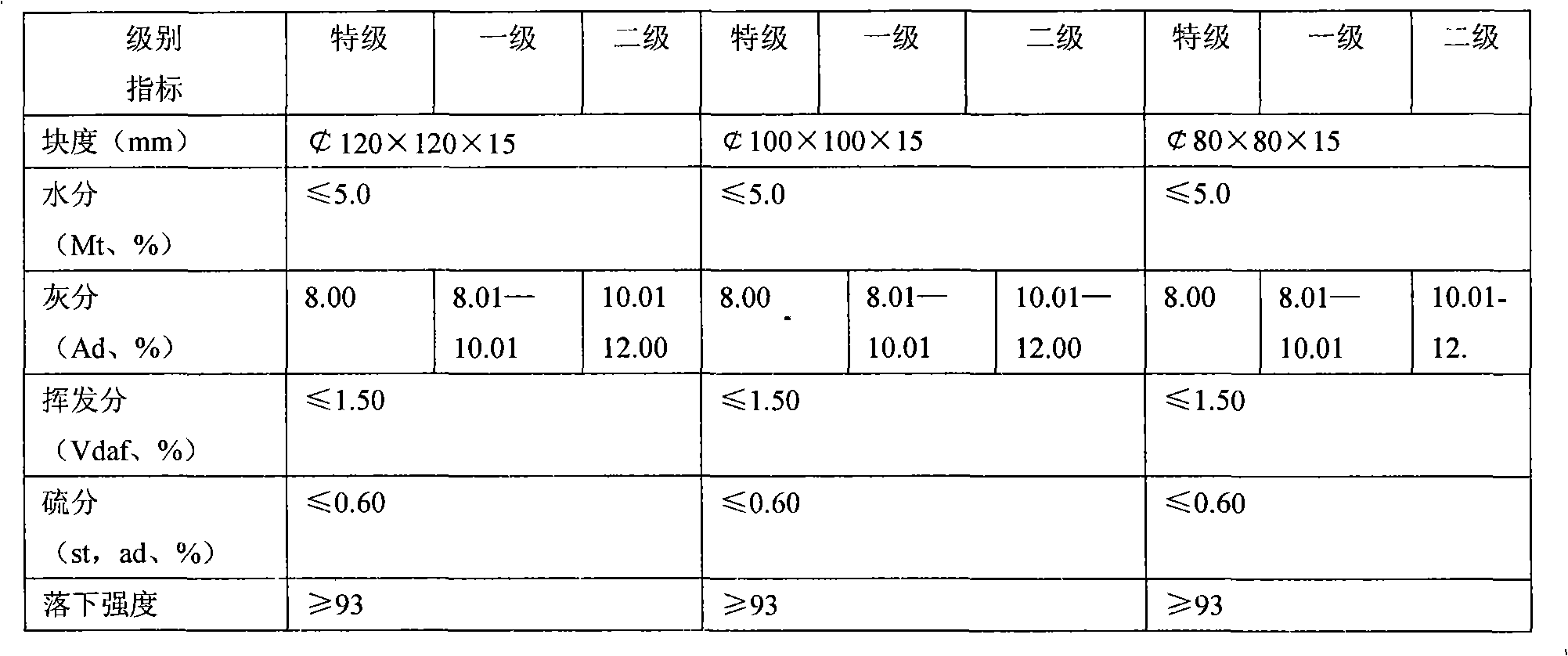

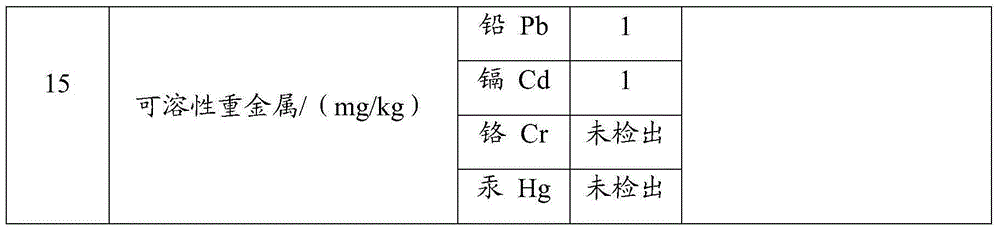

Anthracite carbon casting formed coke

InactiveCN101280203ARealize protection and meet emission standardsHigh carbon contentSpecial form destructive distillationFoundryHigh carbon

Disclosed is anthracite carbon foundry formed coke which solves the disadvantages of uneven granularity, insufficient oxygen-adding, high broken rate and environment pollution found in the formed coke in the prior art; the anthracite carbon foundry formed coke is characterized in that the anthracite or non-coking coal is used to produce the anthracite carbon foundry formed coke; the steps include that the raw coal is conveyed to the factory, crushed and grinded to powder; the binder is added to the grinded powder and the mixture is stirred under the cooling condition, and then stirred evenly after being heated; the mixture is conveyed to the pressing machine for the extruding formation; the formed material is conveyed to the carbonization chamber and then is processed with dry distillation and carbonization under the conditions of air-isolation and the temperature ranging from 950 DEG C-1050 DEG C; finally, the formed material is cooled and the finished product is outputted to be stored in the storehouse for sale; the process of comprehensive utilization of the coke-oven gas generated in the carbonization chamber is set for the lime joint production; the process of dust removal and desulfurization is set for the flue gas and SO2 in the exhausted gas; based on the special binder formula and the special product structure and compared with the traditional coking method, the anthracite carbon foundry formed coke has the advantages of high carbon content, high calorific value, low ash content and sulfur content, crush resistance, abrasion resistance, good intensity, moderate reactivity, high intensity after reaction, good cold and heat intensity, reasonable and simple structure, small investment, low expense and specially being applicable to the coking and the mechanical casting industries.

Owner:YANGQUAN YANGMEI FORMED COKE TECH DEV CENT

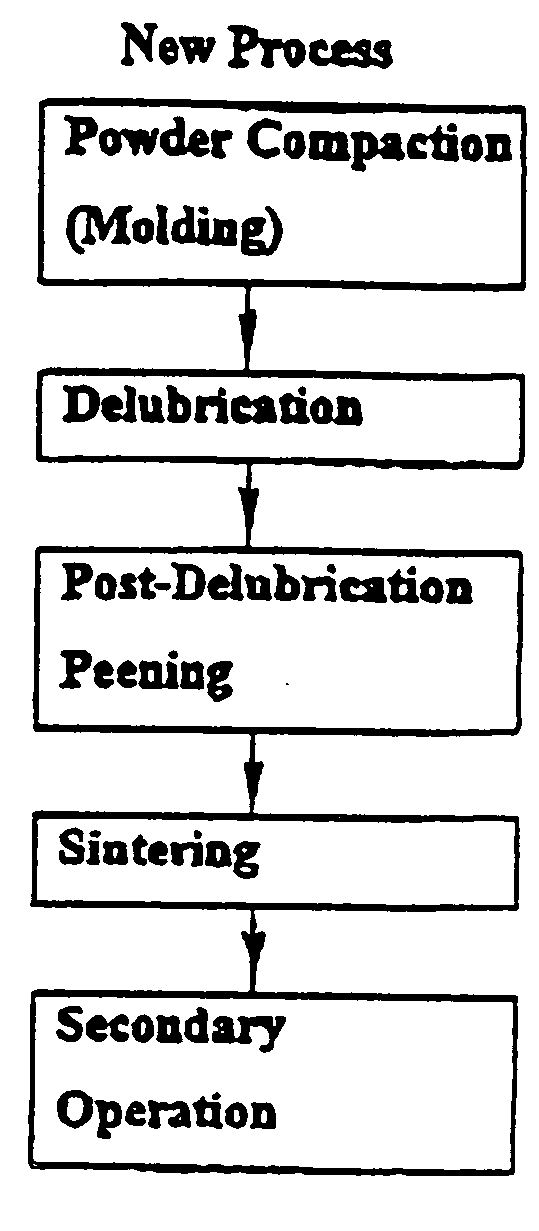

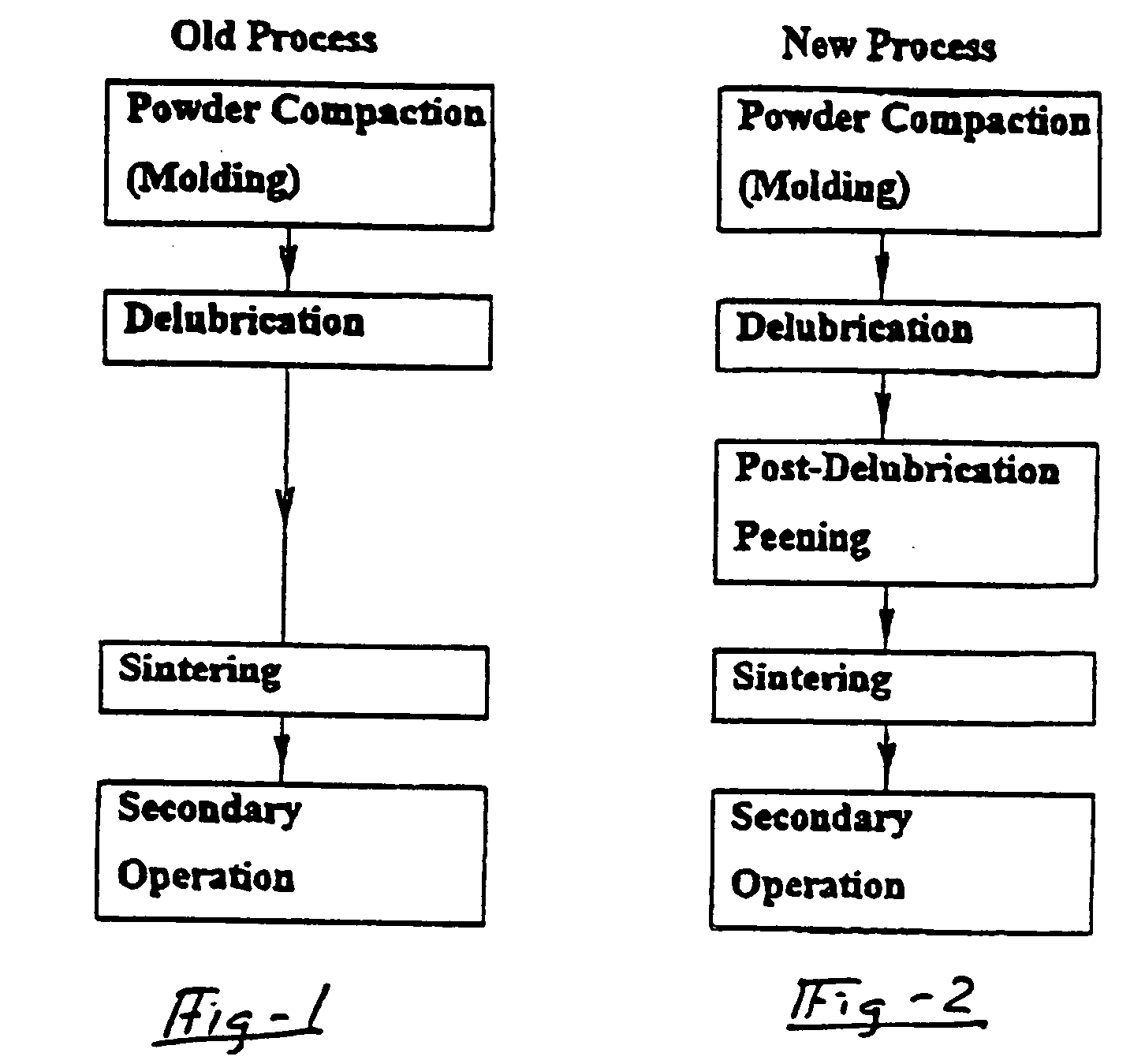

Post-delubrication peening for forged powder metal components

A process of forming powder metal components which minimizes decarburization and oxidation of the component prior to final forging. The process begins by molding powder metal material into a preform configuration. The preform is delubricated to extract lubricant found in the pores of the preform. Passing the preform through a shot peening operation closes a majority of the surface pores creating a densified layer within which interconnected pores are eliminated. Following post-delubrication peening (PDP), the component is sintered and then forged into its final configuration.

Owner:LIU FUPING

Restoration process for porosity defects in metal cast products

ActiveUS8220124B1Reduce surface porosityImprove efficiencyMolten spray coatingPlate printingPorosityMaterials science

A restoration process for restoring surface porosity defects on a component surface. The areas of a component surface having surface porosity defects are identified for restoration. The restoration surface is subsequently sprayed with a restoration spray to restore the surface porosity defects. The component surface is then finished to create a final component substantially free of surface porosity.

Owner:BRUNSWICK CORPORATION

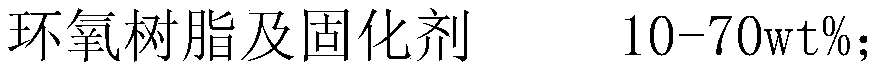

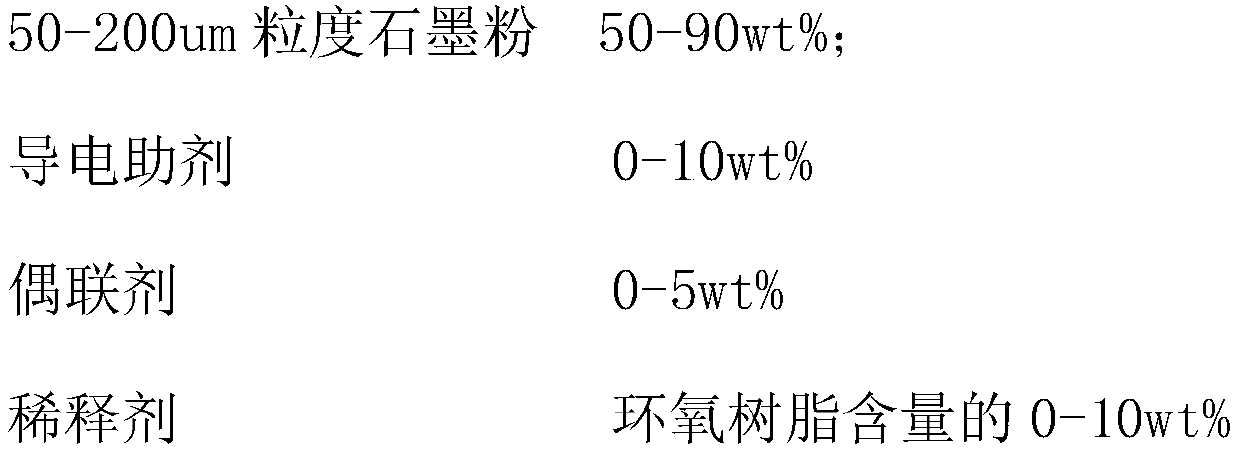

All-vanadium redox flow battery bipolar plate and preparation process thereof

ActiveCN109768296AGood product performanceImprove conductivityRegenerative fuel cellsElectro conductivityCorrosion

An all-vanadium redox flow battery bipolar plate and a preparation process thereof. The all-vanadium redox flow battery bipolar plate comprises a silane coupling agent solution, mesh carbon cloth treated with the silane coupling agent solution, a flexible graphite plate and a conductive adhesive. The conductive adhesive is a graphite-filled conductive adhesive. The bipolar plate is prepared by heating and pressing the flexible graphite plate, the graphite-filled conductive adhesive, the mesh carbon cloth, the graphite-filled conductive adhesive and the flexible graphite plate in sequence withthe vacuum molding technology; and the graphite-filled conductive adhesive is used as a binder. The invention reduces the use of an organic solvent; the preparation process adopts an internal mixer and a open mill for the conductive adhesive preparation and the vacuum molding for the composite bipolar plate preparation so that the operation process is more automatic and the product performance isbetter and more stable; the prepared vanadium battery composite bipolar plate material has the advantages of high electrical conductivity, good corrosion resistance, excellent mechanical properties and good product stability; and the defects of pure graphite plate and conductive plastic as a bipolar plate material in a vanadium battery are solved.

Owner:杭州德海艾科能源科技有限公司

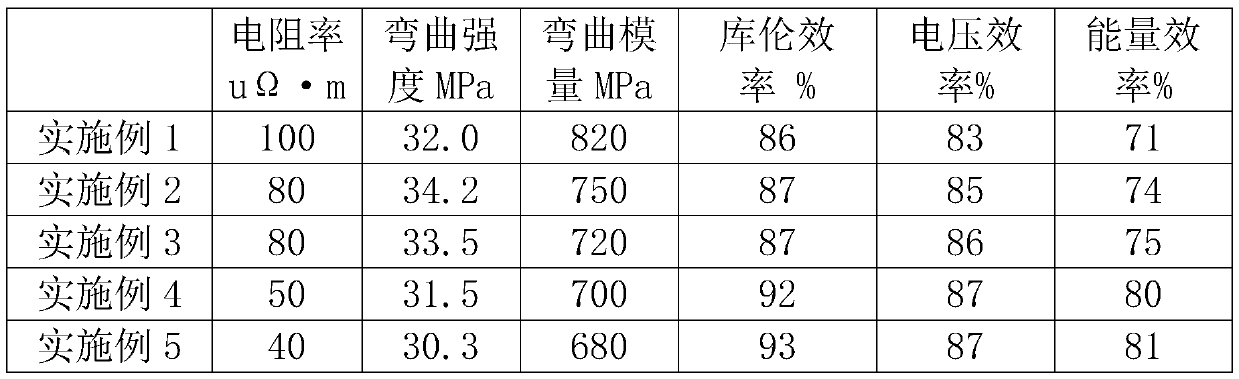

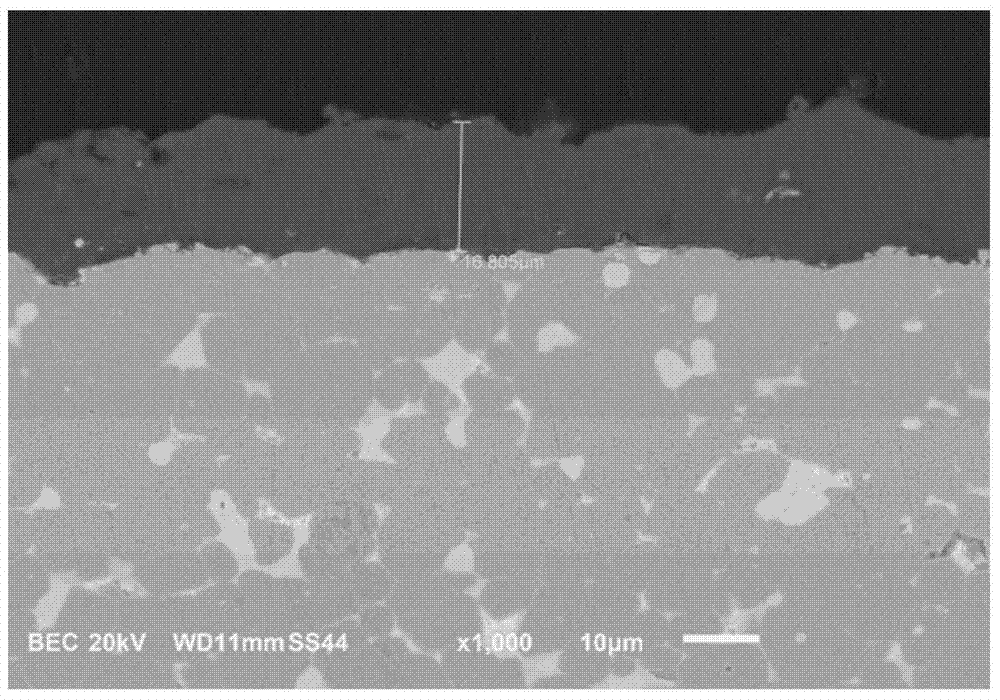

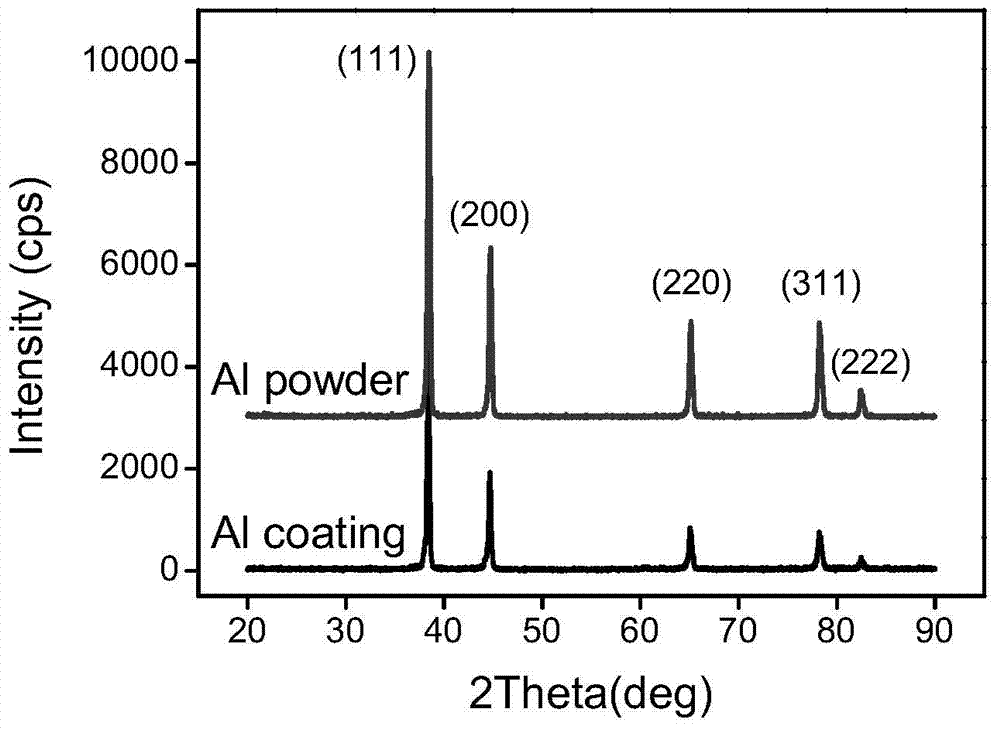

Method for preparing Al coating on surface of sintered NdFeB by adopting detonation spraying

The invention discloses a method for preparing an Al coating on the surface of sintered NdFeB by adopting detonation spraying. The micron-sized Al coating obtained by virtue of the method disclosed by the invention is closely combined with an NdFeB substrate material, is in a pure aluminum phase and has the advantages of high uniformity and compactness and low porosity. The corrosion current density of the sintered NdFeB with the Al coating in a saline solution is only one fifth of that of the sintered NdFeB; an Al2O3 oxidation film layer is formed on the surface of the Al coating, so that the sintered NdFeB substrate can be effectively protected.

Owner:BEIHANG UNIV

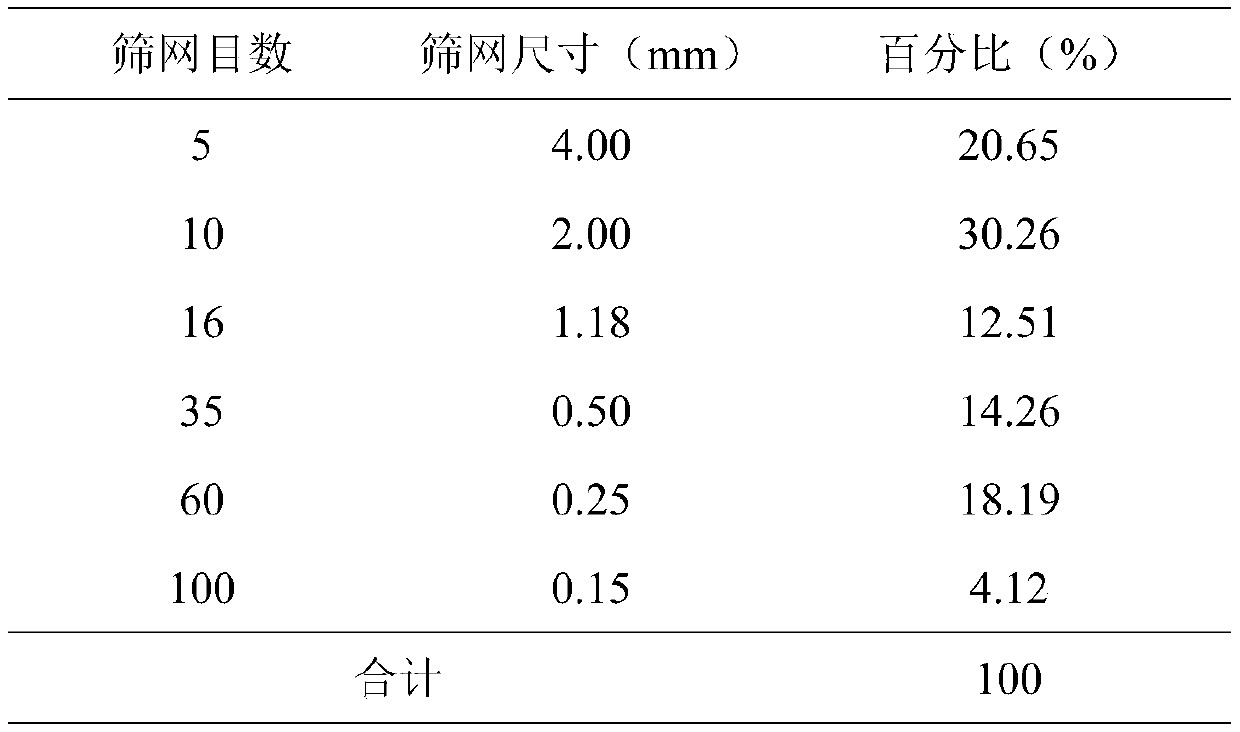

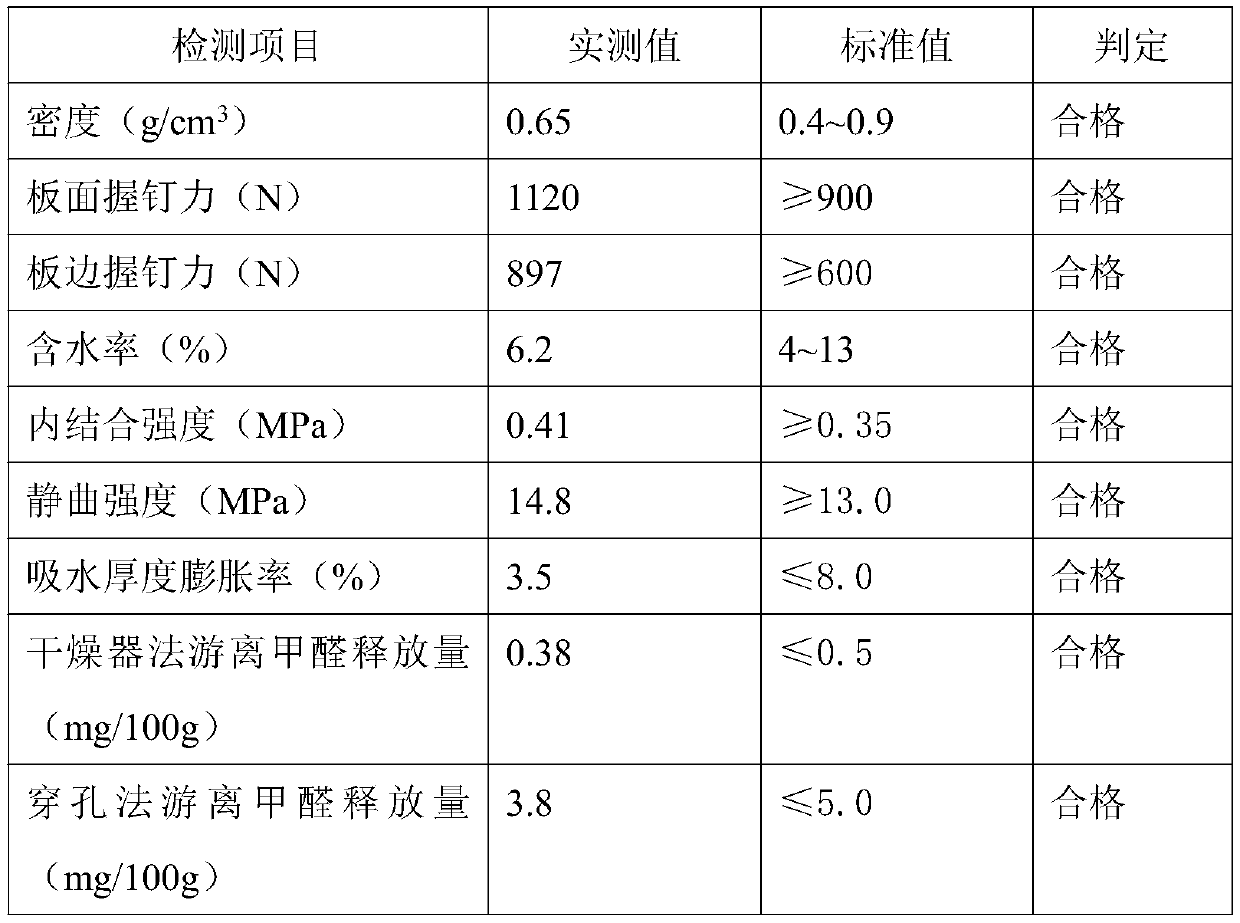

Particle board and preparation method and application thereof

ActiveCN111113607AAvoid preprocessingReduce pollutionDomestic articlesFlat articlesWood shavingsCamellia oleifera

The invention belongs to the technical field of composite materials, and provides a particle board and a preparation method and application thereof. The preparation method of the particle board comprises the steps that oil-tea camellia husk particles are dried and then sieved to obtain oil-tea camellia husk particles for surface layers and oil-tea camellia husk particles for core layers, the oil-tea camellia husk particles for the surface layers and the oil-tea camellia husk particles for the core layers are separately mixed with wood particles to obtain mixed particles for the surface layersand mixed particles for the core layers, an urea formaldehyde adhesive, an isocyanate adhesive and an beeswax emulsion hybrid adhesive are added, after the mixture is atomized by a pressurization nozzle, sizing treatment is carried out on the mixed particles for the surface layers and the mixed particles for the core layers, then pavement is carried out in a layered mode, layered pavement slabs ofthe lower surface layers / core layers / upper surface layers, then the pavement slabs are subjected to pre-pressing, high-frequency heating steam-injection heating, hot pressing, pressure maintaining and pressure relief forming, and the particle board is obtained. Compared with traditional wood raw materials, the particle board manufactured by using an oil-tea camellia husk has good physical and mechanical properties, the raw materials are easy to obtain, and the cost is zero, so that large-scale resource utilization of the oil-tea camellia husk is achieved.

Owner:SOUTH CHINA AGRI UNIV

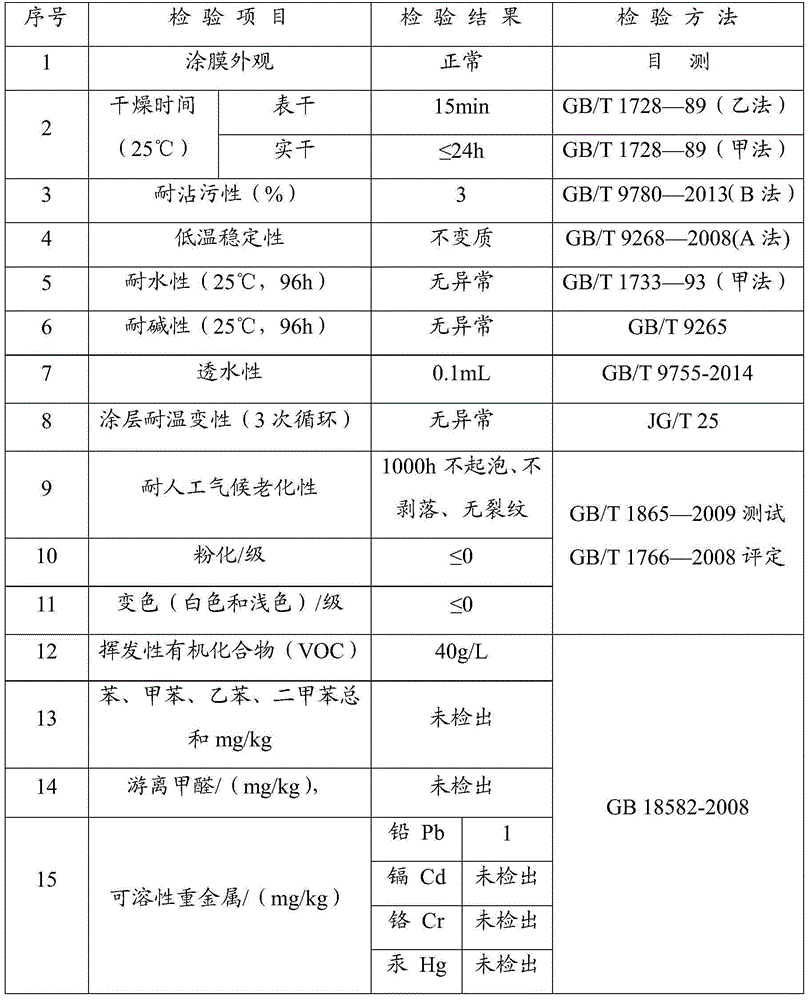

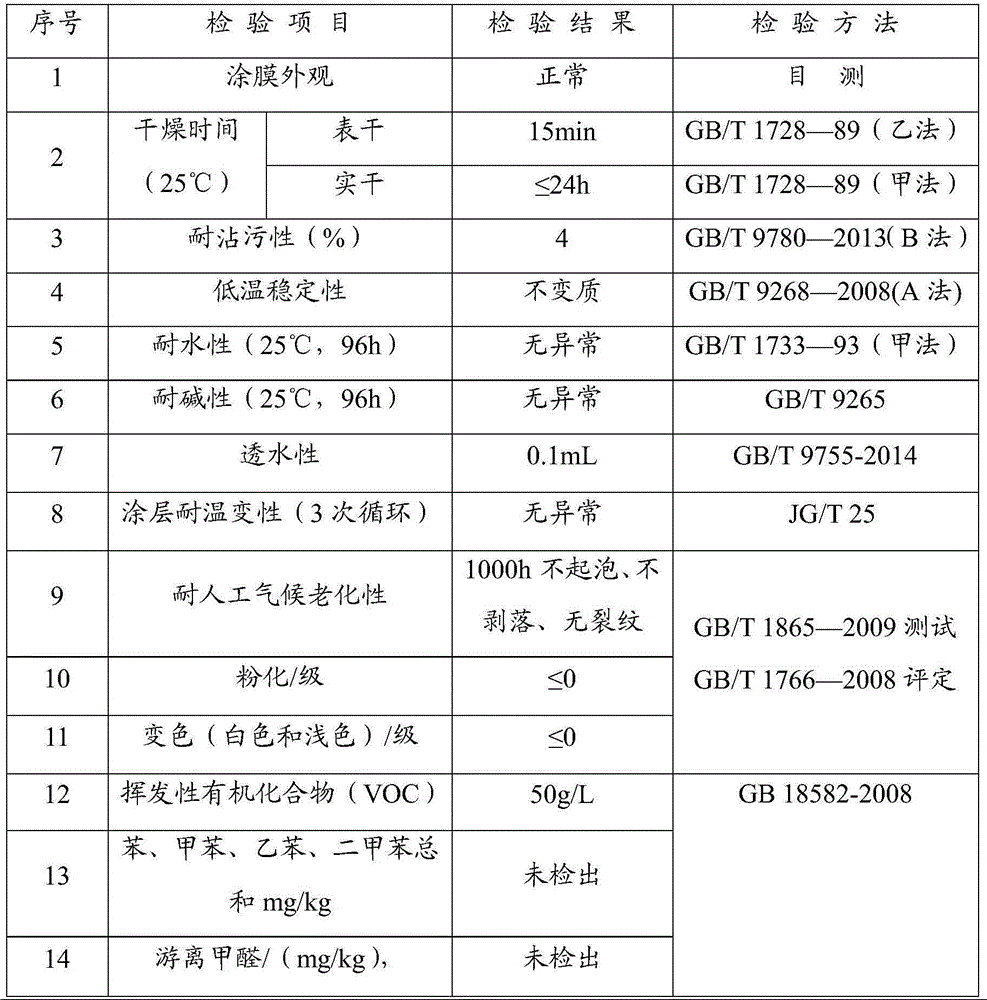

Organic and inorganic compound finish for outer walls

ActiveCN105111870AImproves stain resistanceImprove hydrophilicityAntifouling/underwater paintsPaints with biocidesWater basedInorganic compound

The invention provides organic and inorganic compound finish for outer walls. The finish comprises components in parts by weight as follows: 40-50 parts of an inorganic compound acrylic polymer emulsion, 10-15 parts of an alkyl-ZnO2 modified organic silicon material, 0-15 parts of a nano silicone emulsion and 0.1-1 part of a fluorocarbon surfactant. According to the finish, the inorganic compound acrylic polymer emulsion is used as a main film forming matter, the alkyl-ZnO2 modified organic silicon material and the fluorocarbon surfactant are compatible, so that the outer layer of a finish film has excellent hydrophilia, the lyophobic inner layer of the finish film can effectively prevent further intrusion of a pollution source, and the finish for the outer walls has higher pollution resistance; the finish has the self-cleaning effect. The finish is a water-based material, is lower in carbon, more environment-friendly and more energy-saving and has good air permeability and waterproofness and higher ageing resistance. Experimental results indicate that the stain resistance of the finish is 3%-5%; the stain resisting effect is still below 5% after the finish is aged for 1000 h.

Owner:珠海展辰新材料股份有限公司

Low-density hard polyurethane foam and preparation method thereof

The invention discloses low-density hard polyurethane foam which is prepared by respectively premixing components A and components B, jointly mixing and foaming. The components A include, by weight, 100 parts of composite polyol, 5-15 parts of cyclopentane, 1.5-6 parts of amine catalyst, 1-5 parts of silicon surfactant and 0.8-2.5 parts of water, and the components B include, by weight, 1-10 partsof butane and 120-220 parts of isocyanate, wherein each raw material above is based on 100 parts of composite polyol. The preparation method includes following steps: (1), preparing the components A;(2), preparing the components B; (3), injecting the components A and the components B into a closed mold, allowing sufficient reaction, and demolding to obtain the hard polyurethane foam. The low-density hard polyurethane foam is environment-friendly and excellent in performance.

Owner:HONGBAOLI GRP CO LTD

Flame-retardant smoke-suppression type bamboo fiber/polylactic acid composite material and preparation method thereof

The invention relates to a preparation method of a flame-retardant smoke-suppression type bamboo fiber / polylactic acid composite material, belonging to the technical field of material processing. The preparation method comprises the steps of adding low polymerization degree ammonium polyphosphate into absolute ethyl alcohol, stirring, adding a silane coupling agent, carrying out constant-temperature water bath, continuing to stir, and carrying out reduced pressure distillation until reaching a dry state so as to obtain modified ammonium polyphosphate; spraying a urea solution to the surface of sieved bamboo powder, uniformly mixing, airing, putting the mixture into a fermentation tank, carrying out sealed standing, spraying bacterial liquid for aerobic fermentation, and drying after the fermentation so as to obtain modified bamboo powder; adding magnesium nitrate and aluminum nitrate into deionized water, carrying out constant-temperature water bath, stirring, then adding modified bamboo powder, stirring, adjusting the pH value by virtue of a sodium hydroxide solution, standing, filtering to obtain filter residue, washing the filter residue, and drying to constant weight, so as to obtain flame-retardant modified bamboo powder; and uniformly mixing polylactic acid, modified ammonium polyphosphate, the flame-retardant modified bamboo powder and the like, blending, transferring the mixture into a hot-press formation machine, carrying out hot-pressing, and cooling to the room temperature, so as to obtain the flame-retardant smoke-suppression type bamboo fiber / polylactic acid composite material.

Owner:刘凡领

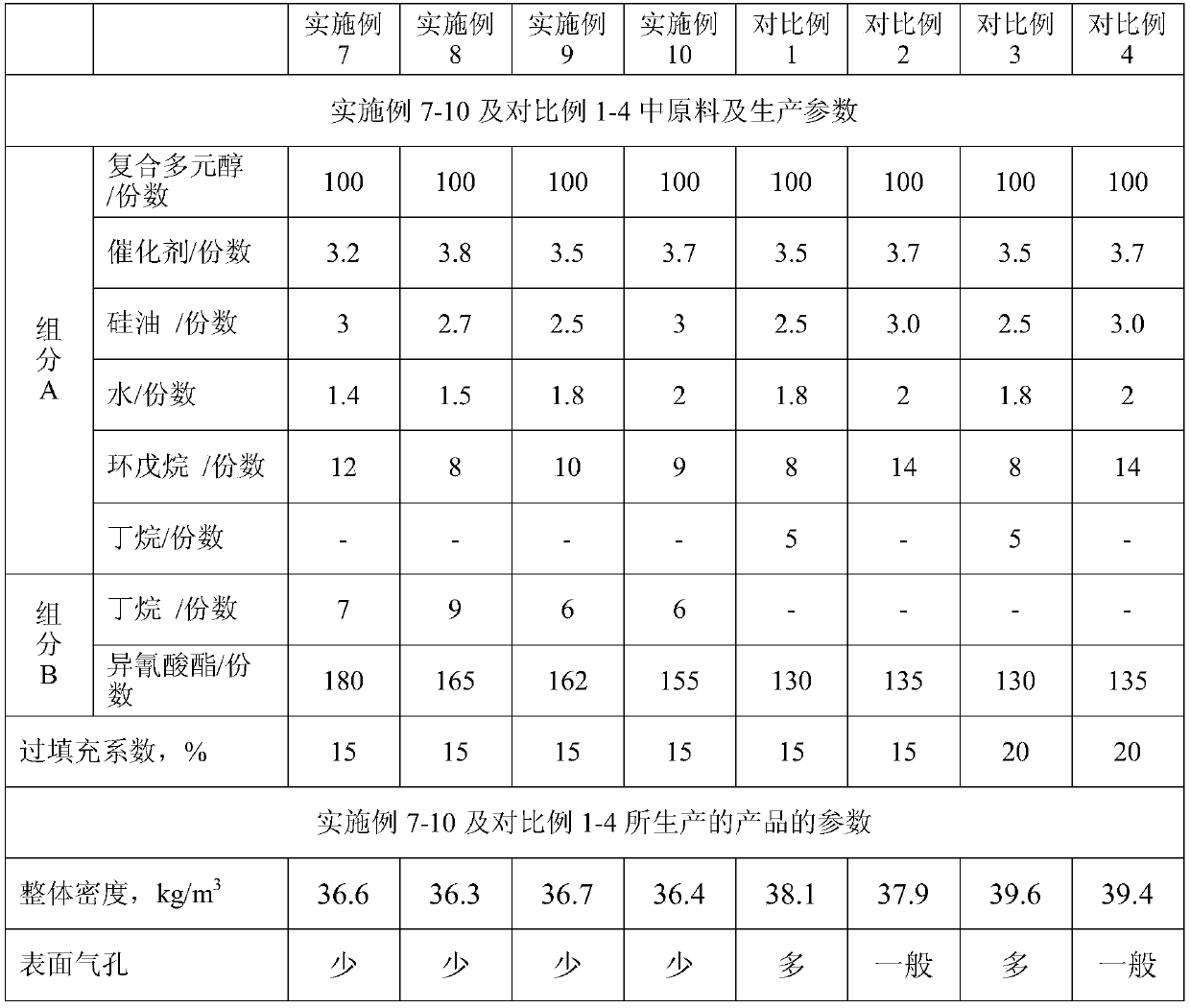

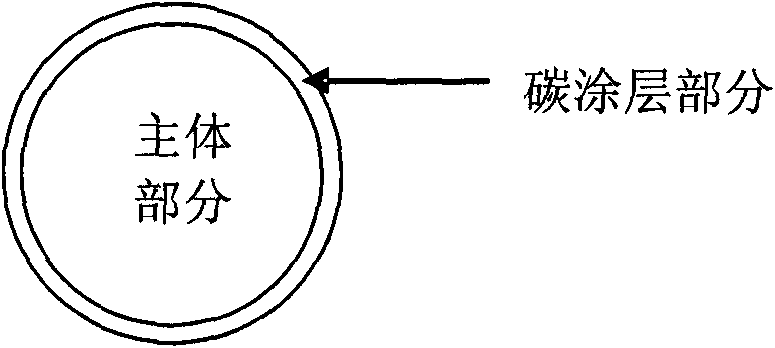

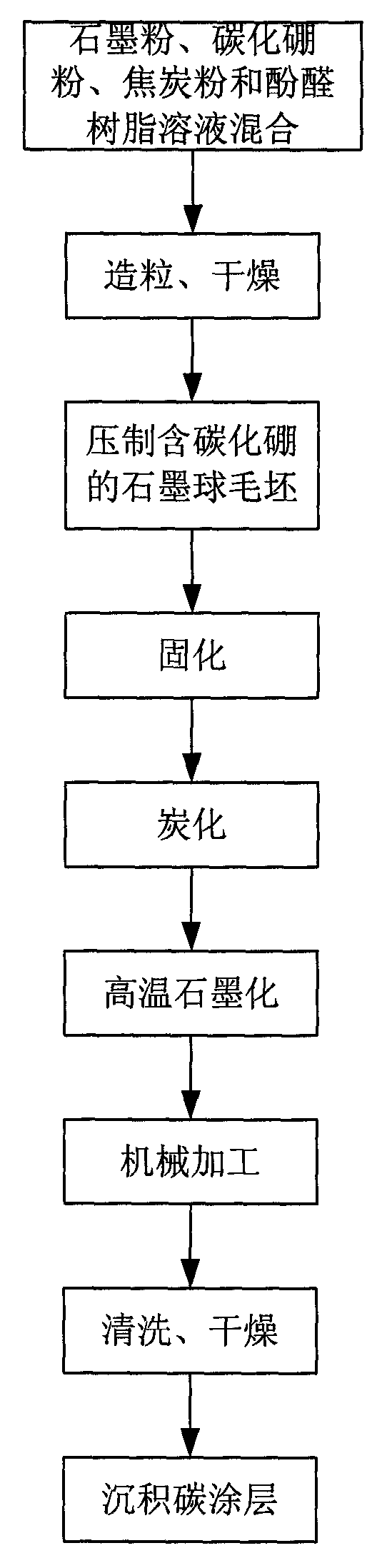

Boron-carbide-containing graphite absorber ball and preparation process thereof

InactiveCN102214488AHigh strengthHigh degree of automationNuclear energy generationReactors manufactureCarbon coatingPorosity

The invention provides a boron-carbide-containing graphite absorber ball and a preparation process thereof. The boron-carbide-containing graphite absorber ball consists of a main structure and a carbon coating attached to the surface of the main structure, wherein the main structure is boron-carbide-containing graphite which comprises the flowing components in percentage by mass: 5-50% of boron carbide and 50-95% of graphite or carbon. Coke powder is added to the formula of the boron-carbide-containing graphite absorber ball, therefore the strength of the product is improved. In the press forming process of the boron-carbide-containing graphite absorber ball, a continuous press is used for pressing and forming a ball-shaped product directly, equipment is simple, the degree of automation is high, and labor cost is low; in addition, since a coating is attached to the surface of the boron-carbide-containing graphite absorber ball disclosed by the invention, the surface porosity is reduced by more than 50%; since no coating is attached to surface of the traditional common boron-carbide-containing graphite absorber ball, the surface porosity is higher. The coating of the boron-carbide-containing graphite absorber ball provided by the invention is prepared by a chemical vapor deposition technology, has good combinability with the main structure and high carbon element content being more than 99.99999% and almost does not contain other impurity elements; the anti-moisture absorption property of the boron-carbide-containing graphite absorber ball provided by the invention is improved about 10-100 times higher than that of the traditional common boron-carbide-containing graphite absorber ball; and the wear resistance of the boron-carbide-containing graphite absorber ball provided by the invention is improved by about 2-10 times.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

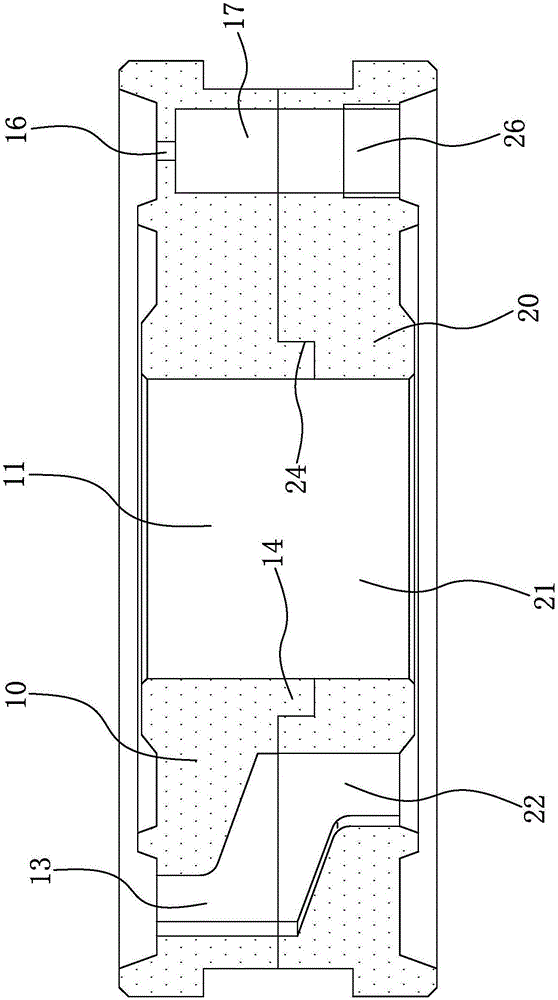

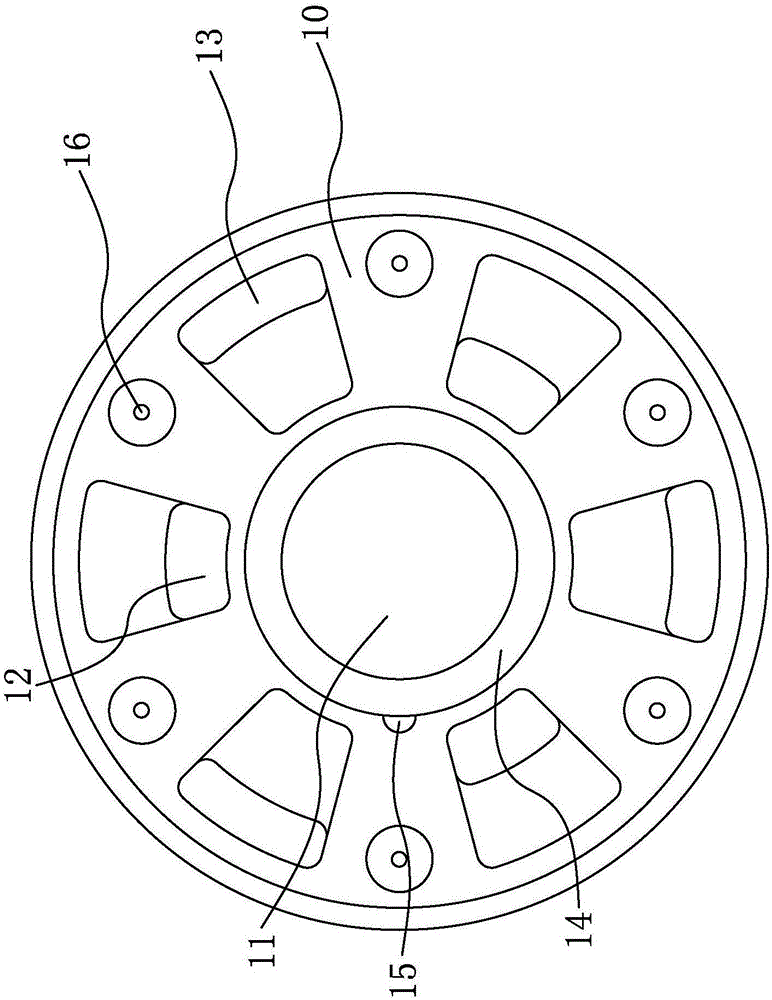

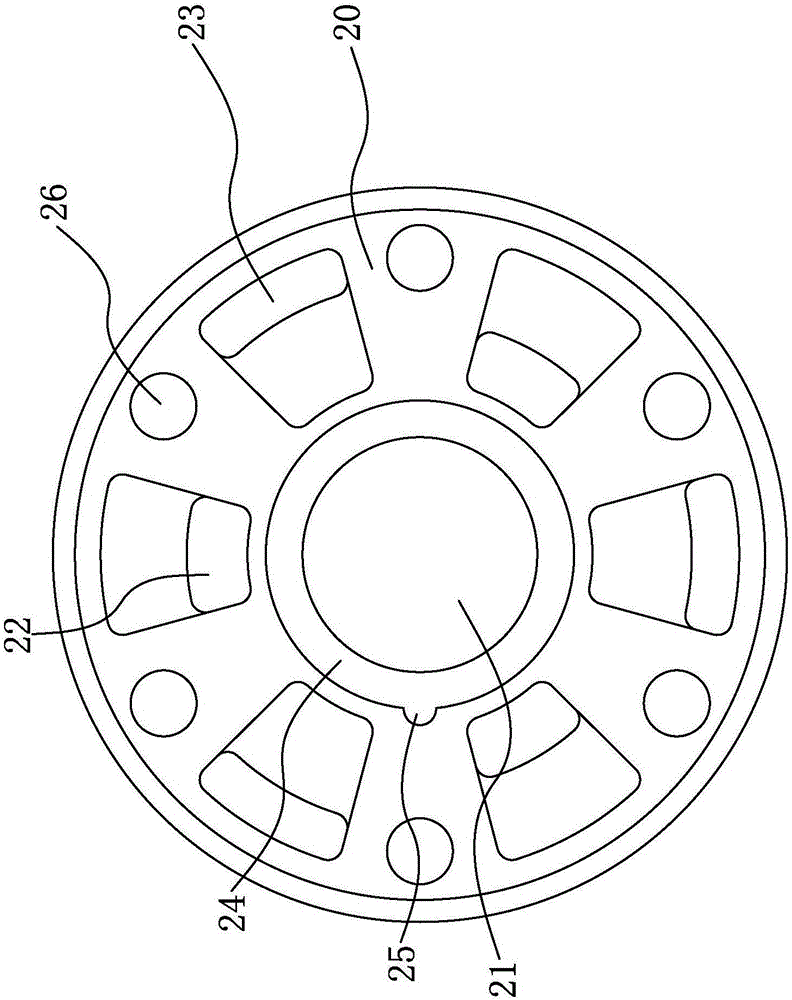

Piston valve for motor car damper

The invention provides a piston valve for a motor car damper, and belongs to the technical field of dampers. The piston valve comprises an upper valve body and a lower valve body connected with the upper valve body. An upper mounting hole is formed in the middle of the upper valve body. Three first inwards-bent holes are formed in the upper valve body. Three first outwards-bent holes are formed in the periphery of the upper valve body. A lower mounting hole is formed in the middle of the lower valve body. Three second inwards-bent holes are formed in the lower valve body. Second outwards-bent holes are evenly formed in the periphery of the lower valve body. The first inwards-bent holes communicate with the second inwards-bent holes. The first outwards-bent holes communicate with the second outwards-bent holes. The piston valve for the motor car damper is made from powder metallurgical sintered steel. The powder metallurgical sintered steel is mainly composed of 0.3-0.6% of C, 1.5-3.9% of Cu and the balance Fe. The powder metallurgical sintered steel adopts iron-based powder alloy as a basal body, and is obtained through infiltration treatment with a copper infiltration agent. By adopting the structure, the inclined load of the damper is faster, the response is rapider, the damping effect is good, and the service life is long.

Owner:NINGBO RUIFENG AUTO PARTS

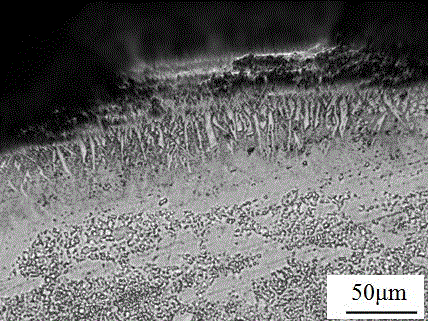

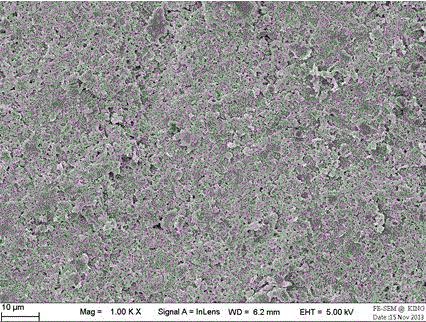

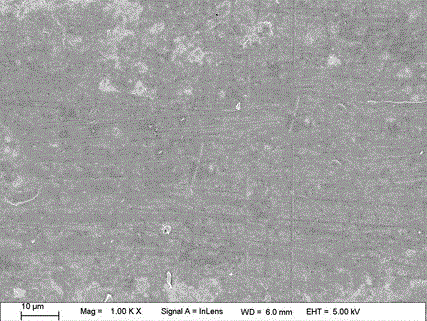

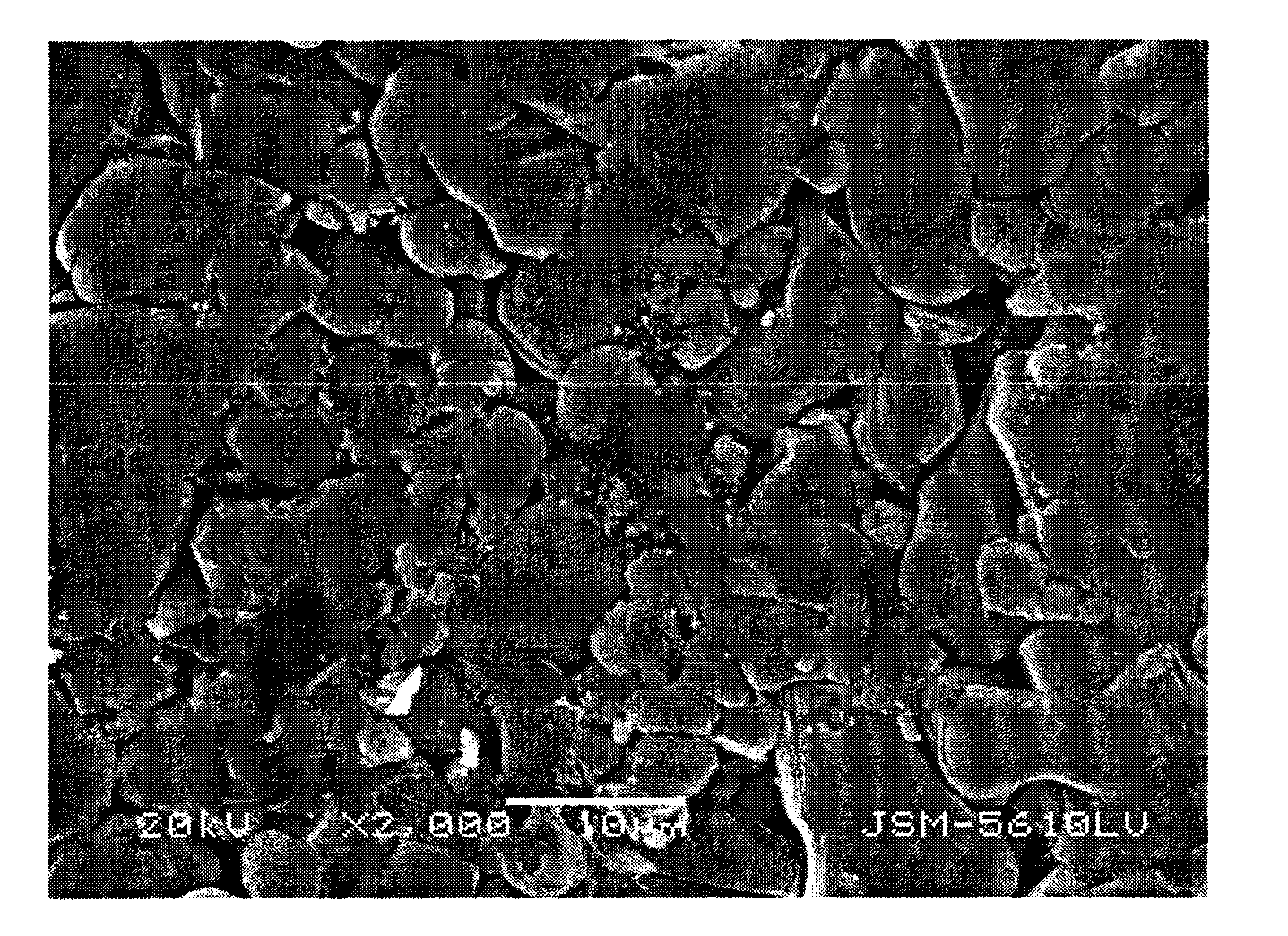

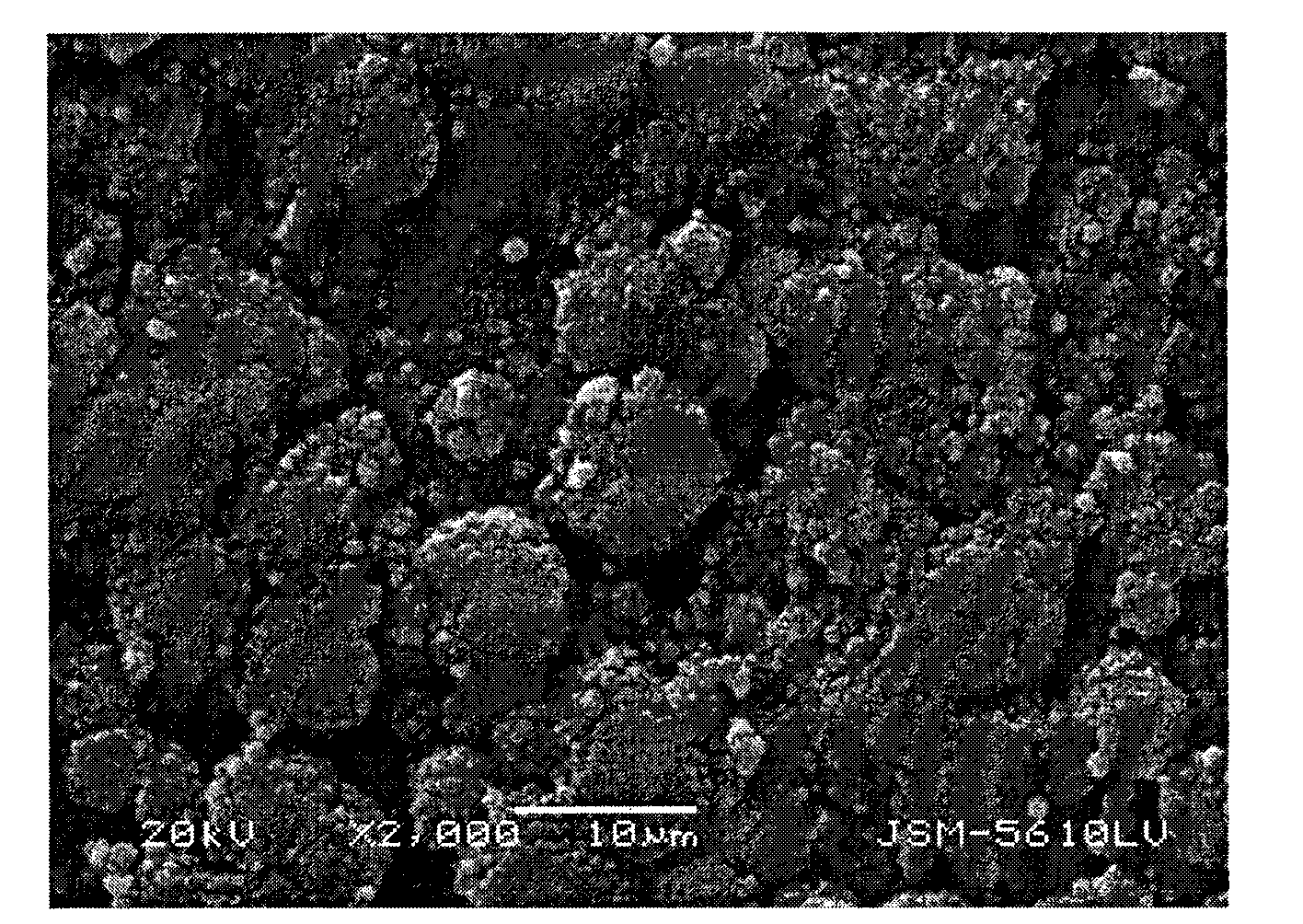

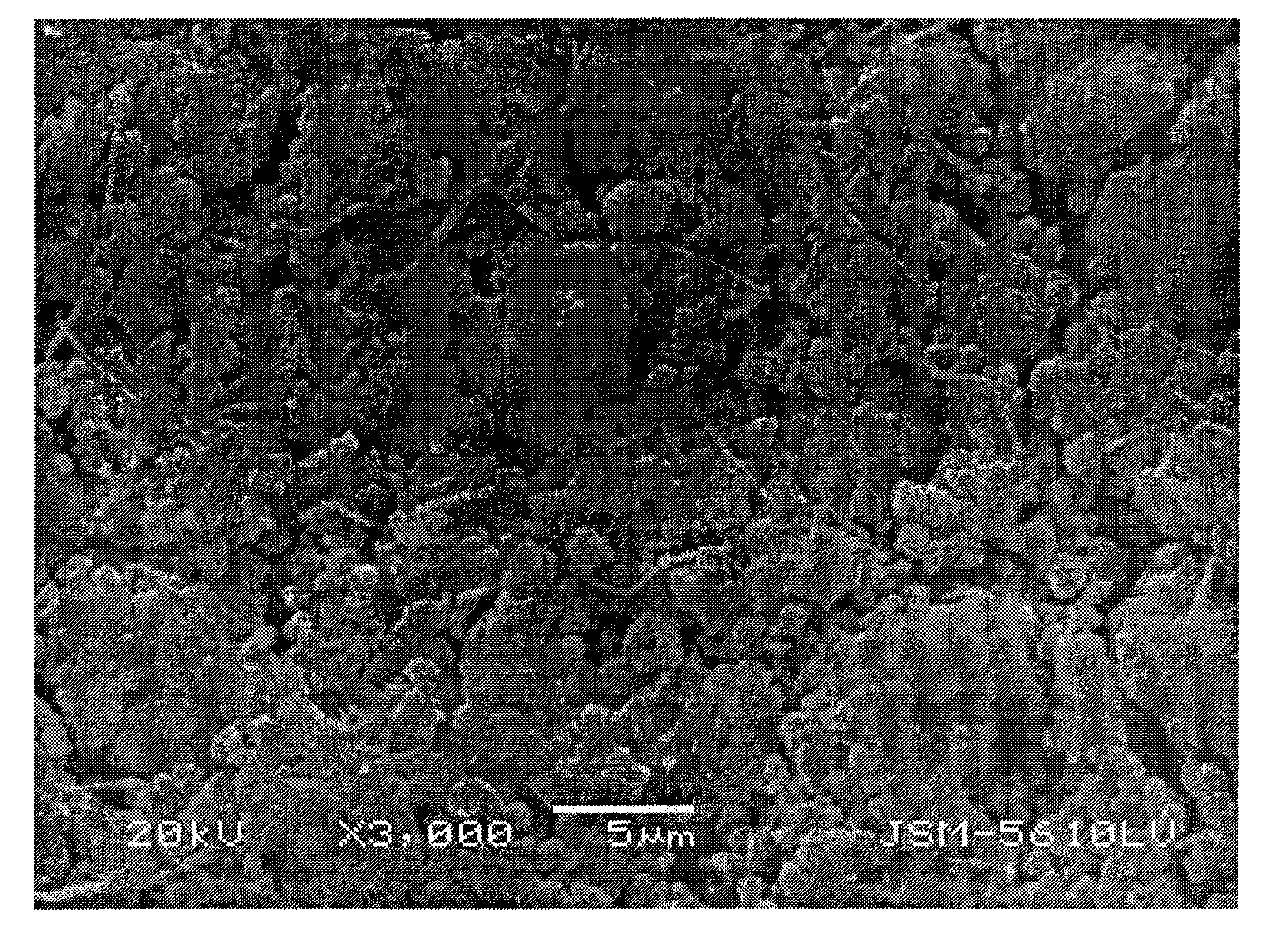

Treatment method for improving mold steel surface frictional wear resistance

The invention belongs to the field of advanced material surface modification treatment, in particular to a treatment method for improving mold steel surface frictional wear resistance. The treatment method is characterized in that a boriding layer is formed on the surface of mold steel; and then, the laser quenching is performed on the boriding layer to eliminate defects of the boriding layer so as to improve the frictional wear resistance of the boriding layer. Hole and piece structures on the surface of the boriding layer are reduced after the laser quenching treatment, so that the stress concentration can be effectively prevented, the strength and the toughness of the boriding layer are improved, the defects of easy wear and stripping of the boriding layer are solved, and the mold service life is prolonged.

Owner:CHANGZHOU UNIV

PVC (polyvinyl chloride) mixture for PVC foam wood-plastic production

The invention relates to a PVC (polyvinyl chloride) mixture for PVC foam wood-plastic production. The PVC mixture is prepared from raw materials in parts by weight as follows: 50-60 parts of PVC, 15-20 parts of light calcium carbonate, 10-18 parts of wood flour, 1-2 parts of a stabilizer, 1-1.5 parts of tribasic lead sulfate, 3.5-4.5 parts of a foaming regulator, 0.1-0.5 parts of an AC foaming agent, 0.2-0.8 parts of an NC foaming agent, 0.2-0.6 parts of an internal lubricating agent, 0.3-0.5 parts of PE wax, 1-1.5 parts of an ACR-175, 2-3 parts of ACR-401 and 2-3 parts of CPE-135A. A production method comprises steps as follows: the raw materials are subjected to hot mixing at 120-140 DEG C and cold mixing at 30-50 DEG C, and a final finished product is obtained. A plate made of the PVC mixture has the advantages of being high in hardness and strength, water-proof, damp-proof, antibacterial, insect-removing and the like.

Owner:武汉立尔飞贸易有限公司

Preparation method of antibacterial conductive cotton fiber

The invention relates to a preparation method of antibacterial conductive cotton fiber. Cotton fiber short fiber loose wool is used as a raw material. The method comprises the following steps that the cotton short fiber is deoiled, coarsened and subjected to sensitization pretreatment, a low concentration silver nitrate-ammonia water solution is added for activation, then chemical silvering is carried out, a chelating ligand agent is added during chemical silvering to replace some ammonia water, and high-temperature solidifying treatment is carried out after chemical silvering. The operation is simple, the technological performance is stable, energy consumption is small, and industrial production is easy. By the adoption of the antibacterial conductive cotton fiber, the plating layer combining firmness degree is high, the conductivity is good, the specific surface area resistance reaches 10-100 ohm / cm, the properties of common cotton fiber are reserved, and the cotton fiber can be used as the antibacterial and conductive cotton fiber, and can be made into antibacterial conductive cotton yarn after being matched with different proportions of common cotton short fiber to be used for various textiles.

Owner:SUZHOU TEKTRONIX SILVER FIBER TECH CO LTD

Battery electrode, preparation method thereof and battery

ActiveCN102054979ALower internal resistanceImprove rate charge and discharge performanceElectrode carriers/collectorsLi-accumulatorsMicro nanoPower flow

The invention provides a battery electrode, a preparation method thereof, and a battery. The battery electrode comprises a current collector and an active substance layer coated on the current collector; a micro-nano particle layer is adhered to the surface of the active substance layer; the active substance layer comprises electrode active substance and electrode binder; the micro-nano particle layer comprises micro-nano dry powder particles; and the micro-nano dry powder particles comprise dry powder particles of the micro-nano electrode active substance. Interface impedance between the electrode and electrolyte is reduced and rate discharge performance of the battery is improved; a micro-nano active material reduces serious volume effect of the material; and specifically, the micro-nano particle layer may not comprise the binder preferably, so that the large-current discharge characteristic of the battery is improved further. The method is simple and is easy to implement; and the combinability between the micro-nano particle layer and the active substance layer is high, and the surface of the active substance layer is not polluted by the substances of an upper layer.

Owner:SHANGHAI BYD

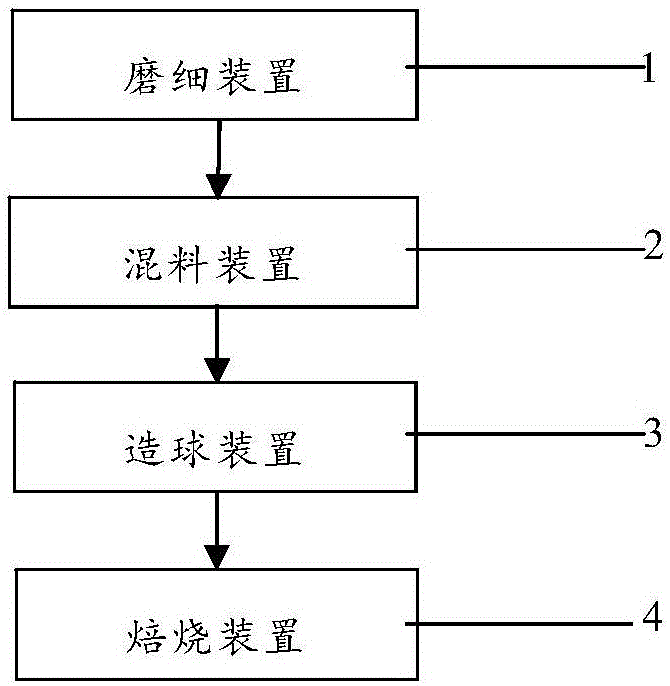

Method and system for reducing reduction degradation of vanadium-titanium magnet pellets

The invention discloses a method and system for reducing reduction degradation of vanadium-titanium magnet pellets. The method for reducing reduction degradation of the vanadium-titanium magnet pellets includes the following steps that firstly, vanadium-titanium magnetite is ground to be fine, and vanadium-titanium magnetite powder is obtained; secondly, the vanadium-titanium magnetite powder is mixed with bentonite, and a mixture is obtained; thirdly, the mixture is pelletized, and green pellets are obtained, wherein a boric acid water solution is added in the pelletizing process to serve as water for pellet pelletizing; and fourthly, the green pellets are roasted, and the vanadium-titanium magnet pellets are obtained. The invention further discloses a system implementing the method, and the system includes a fine grinding device, a material mixing device, a pelletizing device and a roasting device. According to the method and the device, in the pelletizing process, the boric acid water solution is evenly sprayed into the green pellets, the reduction degradation rate of the vanadium-titanium magnet pellets is effectively reduced, and the metallurgical performance in the pellet smelting reduction process is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Restoration process for porosity defects in metal cast products

A restoration process for restoring surface porosity defects resulting from the casting process in metal cast products. The areas of a cast product having surface porosity defects are identified and the areas not containing surface porosity defects are masked using an adhesive, reusable, rubberized mask. The masked surface is subsequently cleaned and a metal spray is applied to the surface porosity defects. The mask is removed and the restored surface porosity defects are hand finished to create a cast product having less than 0.05% surface porosity.

Owner:BRUNSWICK CORPORATION

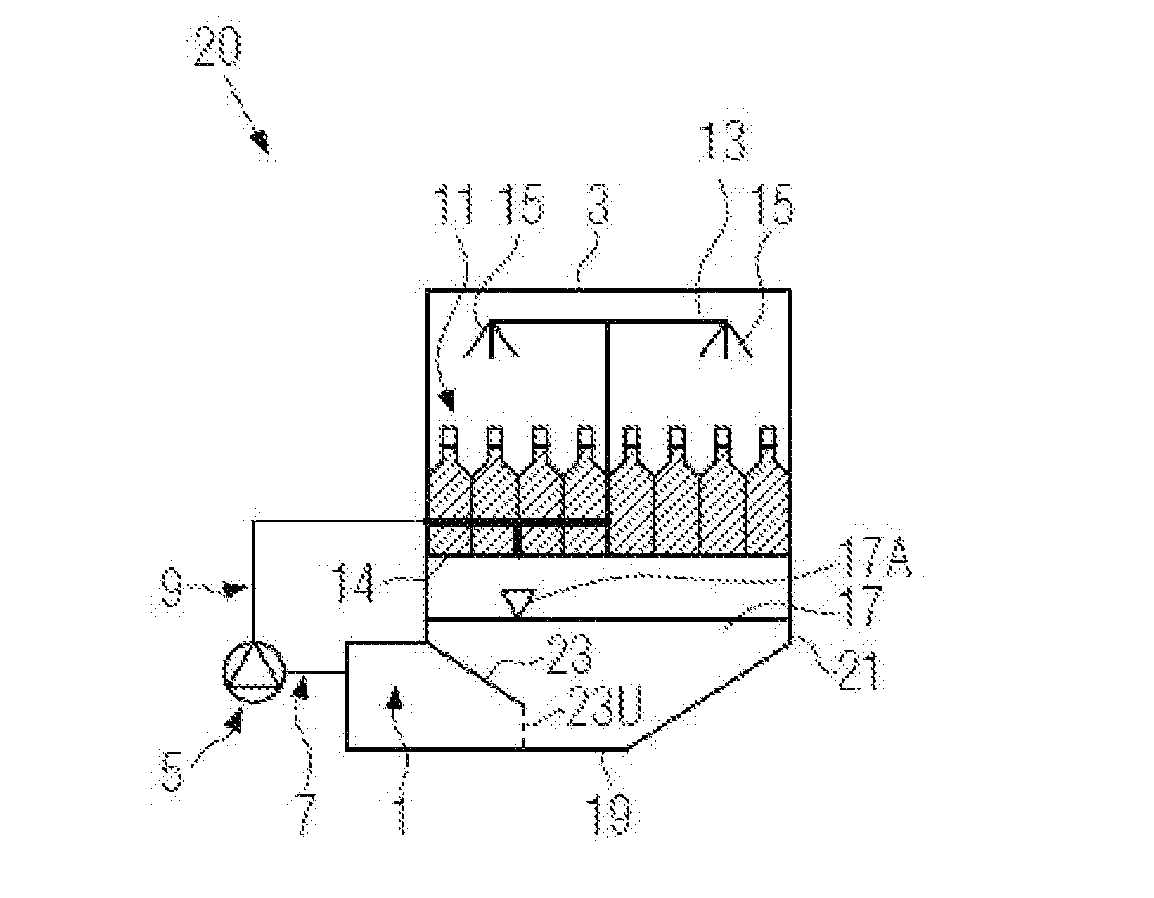

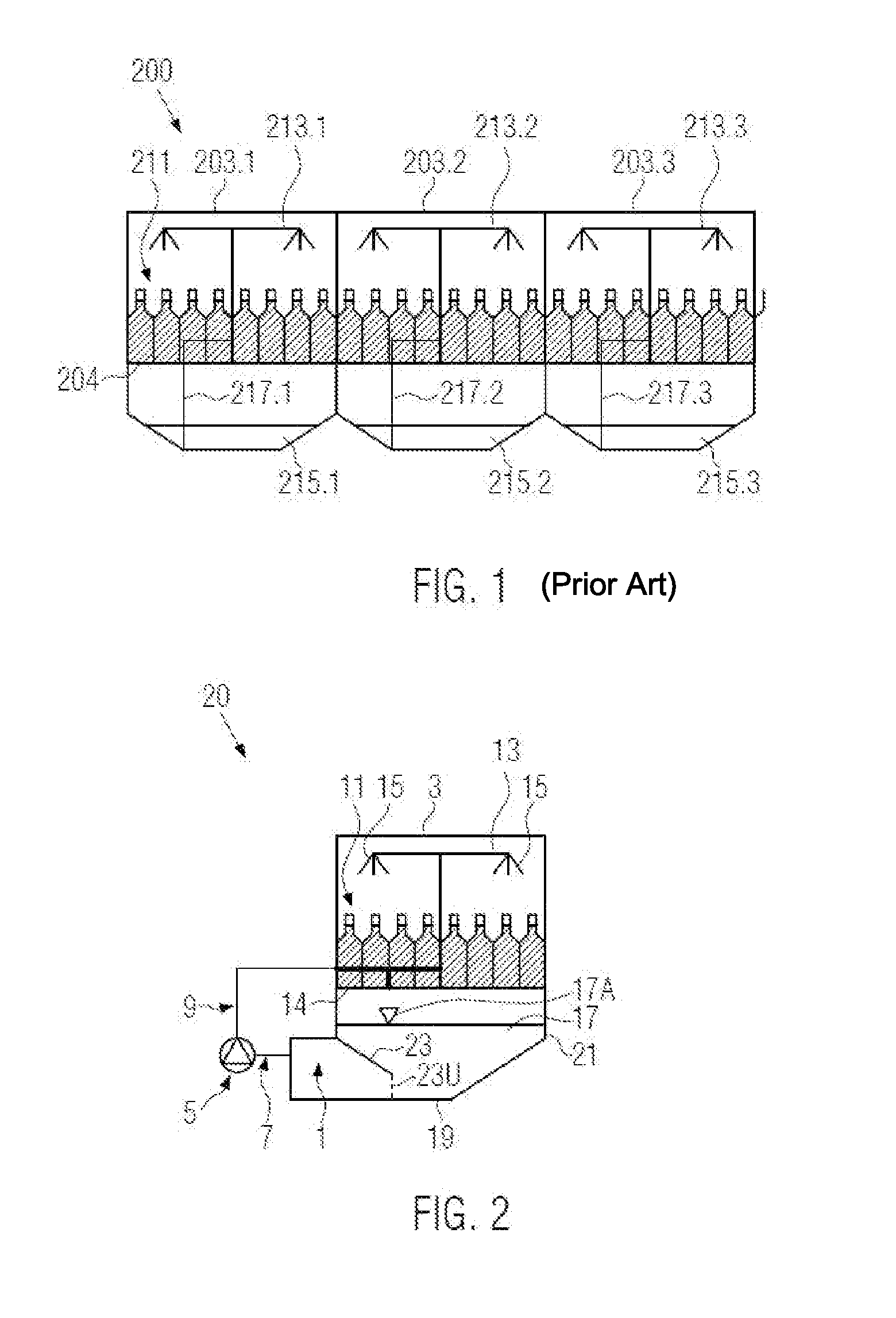

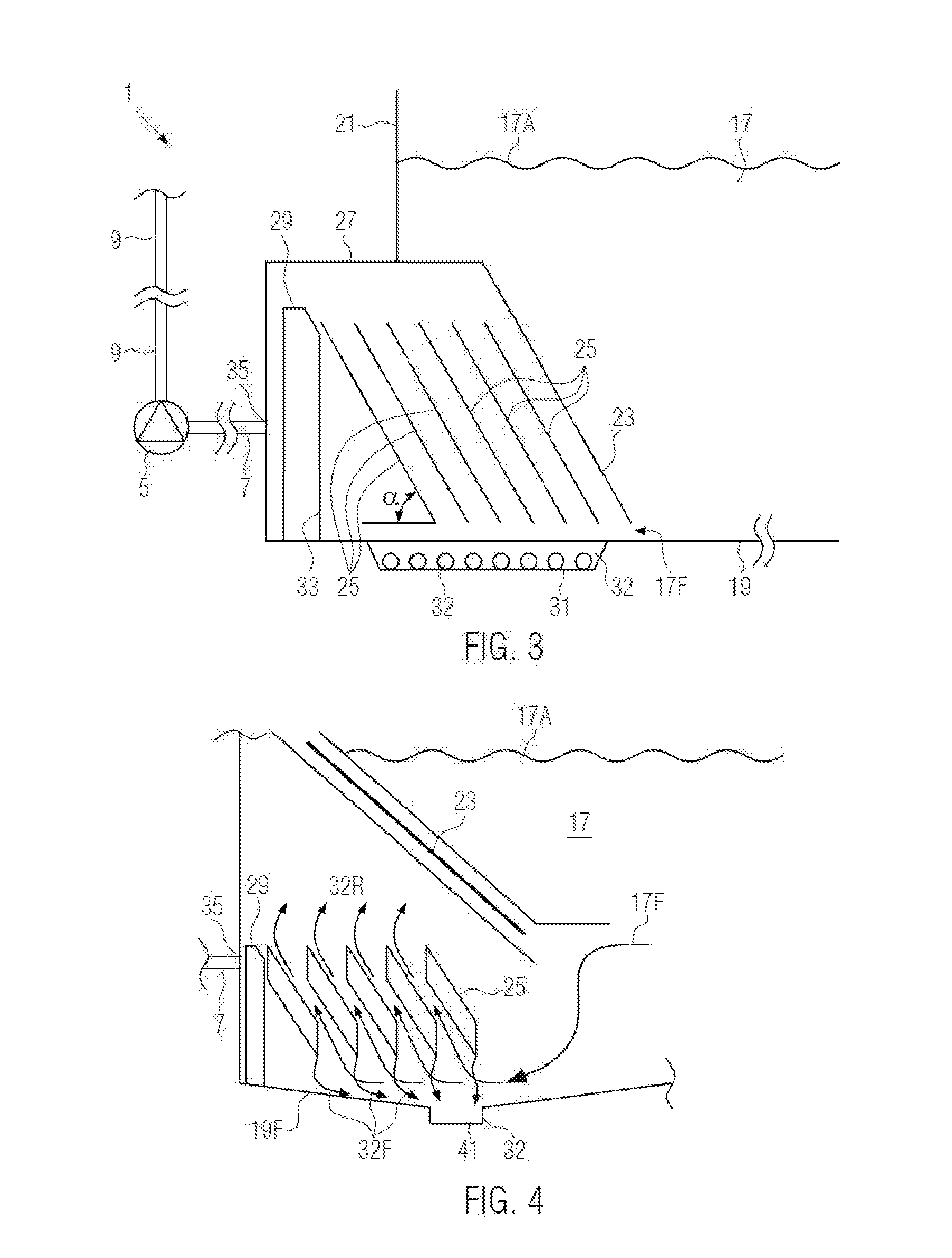

Device for thermally treating products with cleaning of the process liquid

InactiveUS20140110360A1Robust and inexpensive provisionLittle maintenanceLiquid separation auxillary apparatusPackage sterilisationProcess engineeringHeat treated

A device for thermally treating products in containers, including supply and discharge conveyors for containers; with at least one irrigation or spraying zone for irrigating or spraying the containers with a process liquid, for example water; and a circulation circuit for at least partially reusing said process liquid, the circulation circuit including at least one pump; with at least one separation unit with several essentially parallel lamellae for cleaning the process liquid from particles, for example broken glass and / or sand, and the pump pumps the process liquid along the lamella.

Owner:KRONES AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com