Battery electrode, preparation method thereof and battery

A battery electrode and electrode active material technology, which is applied to battery electrodes, electrode carriers/collectors, lithium batteries, etc., can solve the problems of unsatisfactory high-power output and large-capacity supply of batteries, and achieve electrode capacity and cycle performance. Effects of improving large current discharge characteristics and improving rapid discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a preparation method for preparing the above-mentioned battery electrode, the steps include

[0026] a, coating the slurry containing electrode active material, electrode binder and solvent on the current collector, drying, and coating the active material layer on the current collector;

[0027] b, attaching micronanoscale dry powder particles containing dry powder particles of micronanoscale electrode active materials to the surface of the active material layer to prepare a battery electrode. The method of the invention is simple and easy to realize, overcomes the problem of compatibility between layers, and reduces the influence on the active material layer.

[0028] Among them, the preparation of the slurry containing the electrode active material, electrode binder and solvent adopts various techniques known to those skilled in the art. The active material of the positive electrode can be common active material in this field, such...

Embodiment 1

[0038] (1) Production of positive electrode:

[0039] 940 grams of positive electrode active material LiCoO2 (94%), 30 grams of binder PVDF (3%), 30 grams of conductive agent acetylene black (3%) are added in 600 grams of solvent NMP (nitrogen methyl pyrrolidone), and then Stir in a mixer to form a stable and uniform cathode slurry. The slurry was evenly and intermittently coated on both sides of an aluminum foil (aluminum foil size: width 160 mm, thickness 16 microns), and then dried at 120° C. to prepare a battery positive electrode with a 0.120-0.130 mm thick active material layer.

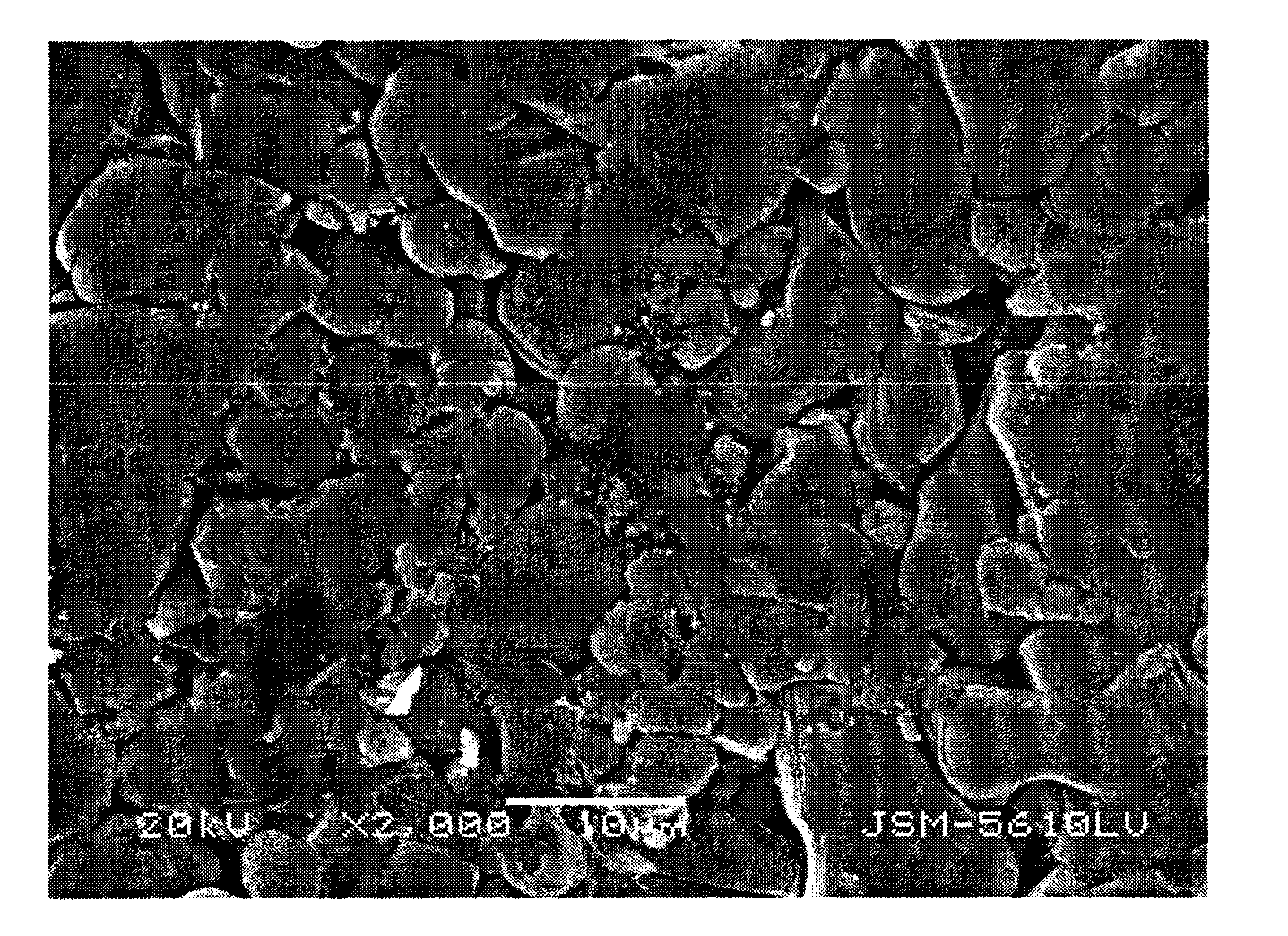

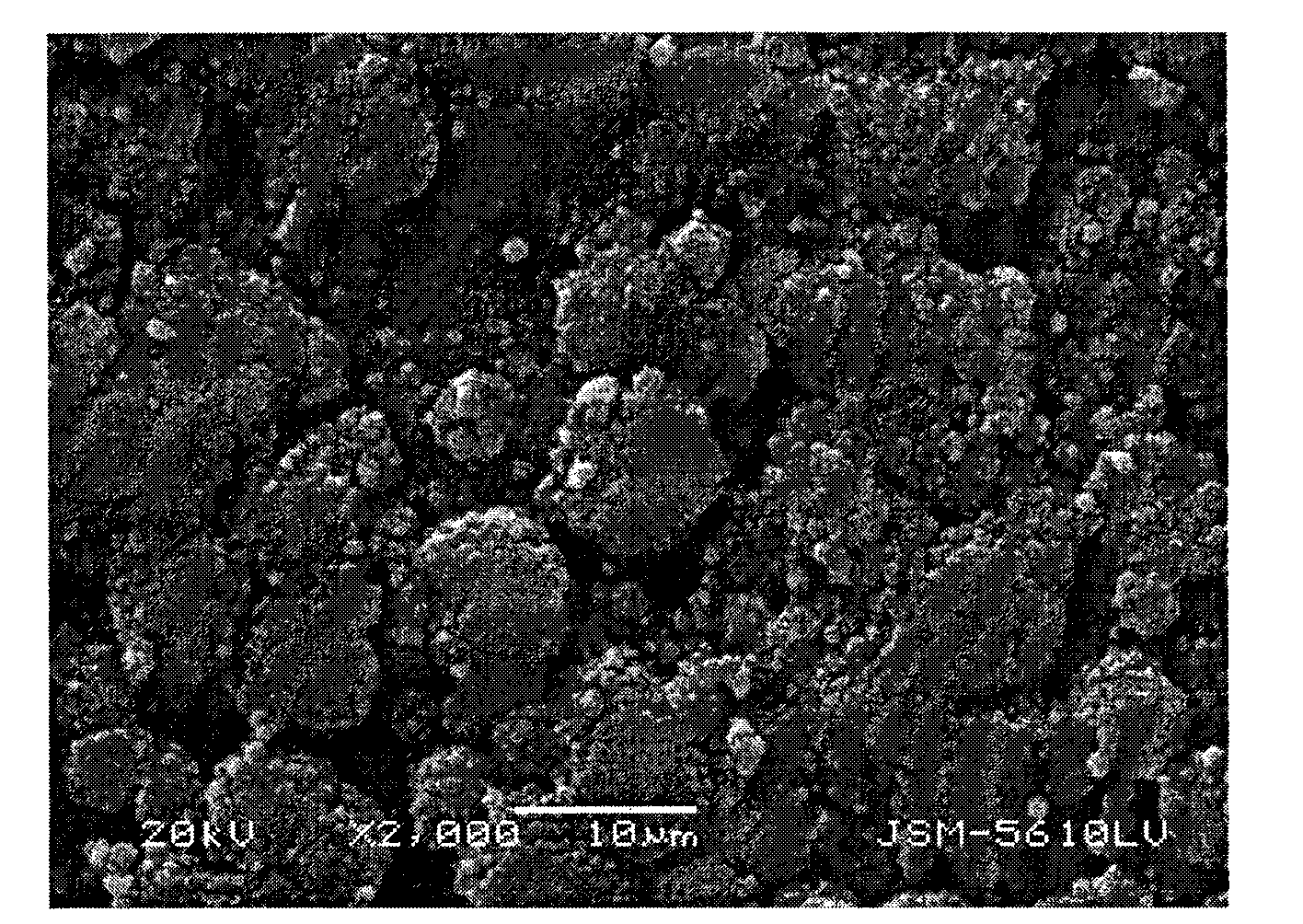

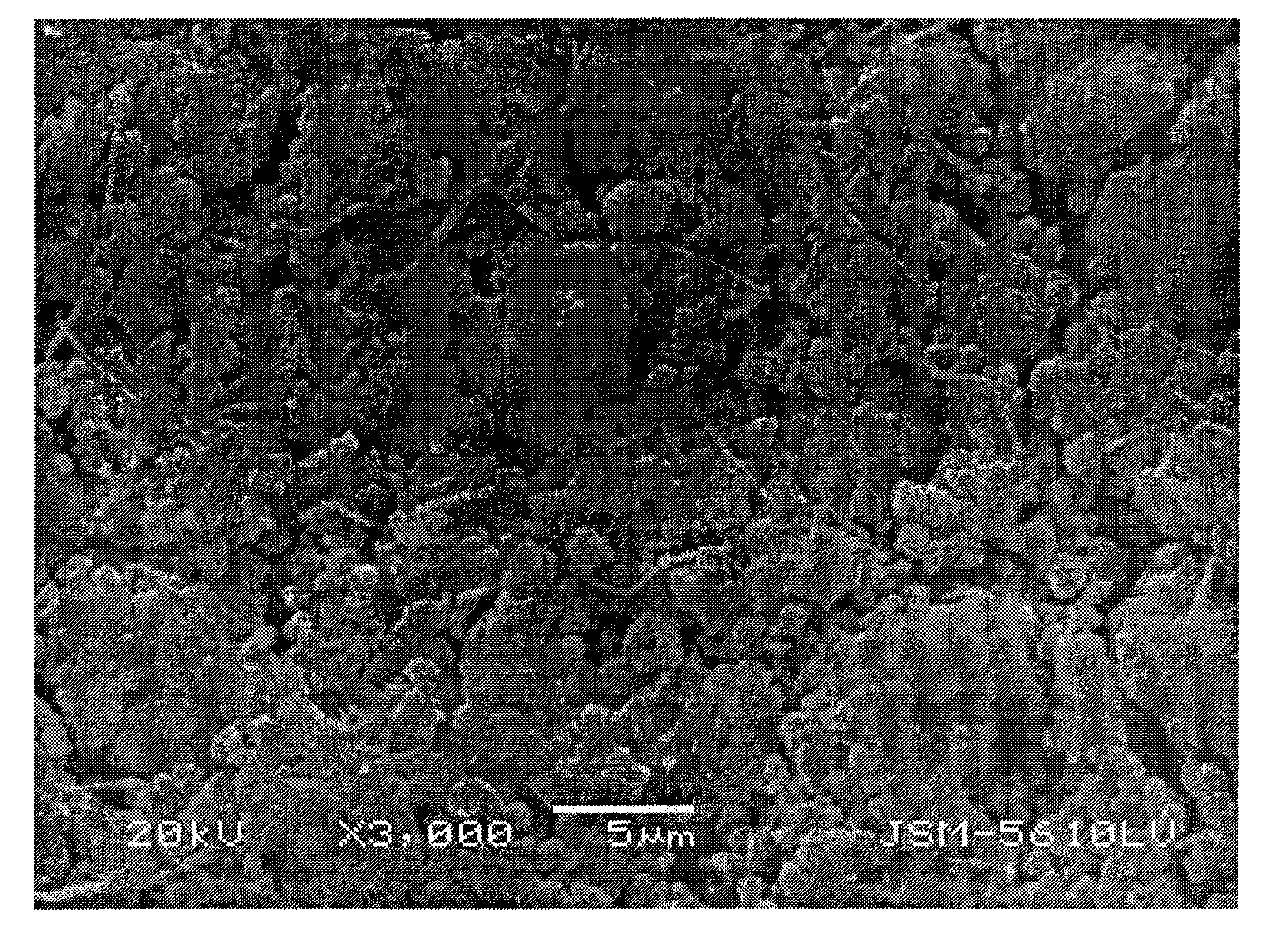

[0040] 50 grams (5%) of acetylene black with an average particle size of 0.08 μm and 950 grams (95%) of LiCoO with an average particle size of 5 μm were stirred to form a uniform powder mixture, and the powder mixture was put into the powder spraying system In the powder supply device, adjust the voltage of the electrostatic generator to 55,000 volts, spray the above-mentioned dried electrodes...

Embodiment 2

[0047] The same method as in Example 1 was used to prepare the positive electrode, negative electrode and battery, except that the thickness of the active material layer was increased by 10 μm. During the preparation of the positive electrode and negative electrode of the battery, the voltage of the electrostatic generator was adjusted to 55,000 volts. Spraying treatment, control flow rate pressure 0.15MPa, spraying distance 200mm, powder output 80g / min, atomization pressure 0.3MPa and spraying speed 4.0m / min, spray a layer of micro-nano particles with a thickness of 5μm on the above electrode, obtained from the SEM image The average distance between the micron-sized particles of the positive electrode is about 8 microns, and the average distance between the micron-sized particles of the negative electrode is about 6 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com