PVC (polyvinyl chloride) mixture for PVC foam wood-plastic production

A polyvinyl chloride and mixed material technology, applied in the field of wood-plastic materials, can solve the problems of high rejection rate, inaccurate weighing of ingredients, low yield of finished products, etc., and achieves high bending strength and modulus, good waterproof performance, and porosity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The PVC compound used in the production of polyvinyl chloride foamed wood plastics in the present invention consists of the following raw materials in parts by weight: PVC: 60 parts; light calcium carbonate: 20 parts; wood powder: 12 parts; stabilizer: 2 parts ; Lead sulfate tribasic: 1.5 parts; Foam regulator: 3.8 parts; AC foaming agent: 0.2 parts; NC foaming agent: 0.4 parts; Internal lubricant 60: 0.3 parts; PE wax: 0.3 parts; 175: 1.2 parts; ACR-401: 2.4 parts; CPE-135A: 2.8 parts, the wood powder is camphor wood powder.

[0014] Crush camphor wood to 80 meshes, dry to obtain wood powder, mix PVC, wood powder, light calcium carbonate, stabilizer, tribasic lead sulfate, foam regulator, AC foaming agent, NC foaming agent, internal Lubricant 60, PE wax, ACR-175, ACR-401, and CPE-135A are put into the mixing mixer for stirring, and the heating device is used to heat the material for 15 minutes while stirring the material at 1250 rpm, so that the temperature of the mate...

Embodiment 2

[0016] The PVC compound that is used for polyvinyl chloride foamed wood-plastic production among the present invention is made up of the raw material of following weight part: is made up of the raw material of following weight part: PVC: 55 parts; Light calcium carbonate: 18 parts; Wood powder: 14 parts; Stabilizer: 1.8 parts; Tribasic lead sulfate: 1.2 parts; Foam regulator: 3.6 parts; AC foaming agent: 0.15 parts; NC foaming agent: 0.4 parts; Internal lubricant 60: 0.3 parts; PE wax: 0.3 parts; ACR-175: 1.2 parts; ACR-401: 2.2 parts; CPE-135A: 2.5 parts, and the wood powder is bamboo powder.

[0017] Bamboo is crushed to 80 mesh, dried to obtain wood powder, PVC, wood powder, light calcium carbonate, stabilizer, tribasic lead sulfate, foam regulator, AC foaming agent, NC foaming agent, internal lubrication Put agent 60, PE wax, ACR-175, ACR-401, CPE-135A into the stirring mixer for stirring, and use a heating device to heat the material for 15 minutes while stirring the mate...

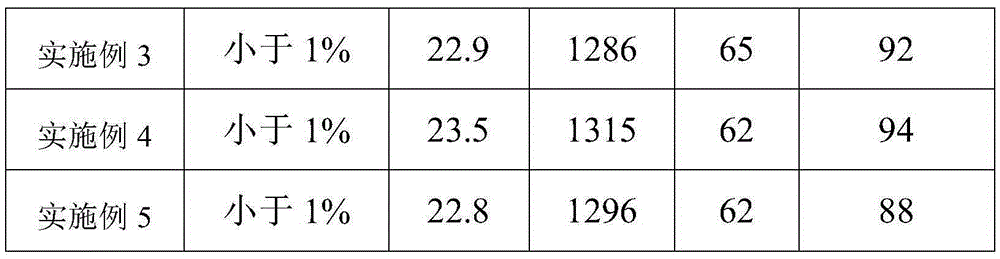

Embodiment 3

[0019] The PVC compound used in the production of polyvinyl chloride foamed wood plastics in the present invention consists of the following raw materials in parts by weight: PVC: 55 parts; light calcium carbonate: 16 parts; wood flour: 12 parts; stabilizer: 1.5 parts ; Lead sulfate tribasic: 1 part; Foam regulator: 3.5 parts; AC foaming agent: 0.2 parts; NC foaming agent: 0.2 parts; Internal lubricant 60: 0.3 parts; PE wax: 0.3 parts; 175: 1 part; ACR-401: 2.5 parts; CPE-135A: 2.5 parts. The wood powder is mixed with straw powder, bamboo powder and bitter bark powder in a mass ratio of 3:2:1.

[0020] Grind 6 parts of straw, 4 parts of bamboo and 2 parts of bitter bark to 80 meshes respectively, mix them evenly after drying to obtain wood powder, mix PVC, wood powder, light calcium carbonate, stabilizer, tribasic lead sulfate, foam Regulator, AC foaming agent, NC foaming agent, internal lubricant 60, PE wax, ACR-175, ACR-401, CPE-135A are put into the mixing mixer for stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com