Particle board and preparation method and application thereof

A technology of particleboard and shavings, which is applied in the field of particleboard and its preparation, can solve the problems of insufficient initial viscosity of isocyanate adhesives, moisture absorption thickness expansion, etc., and achieve the effect of avoiding pretreatment process, reducing expansion rate and reducing release amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

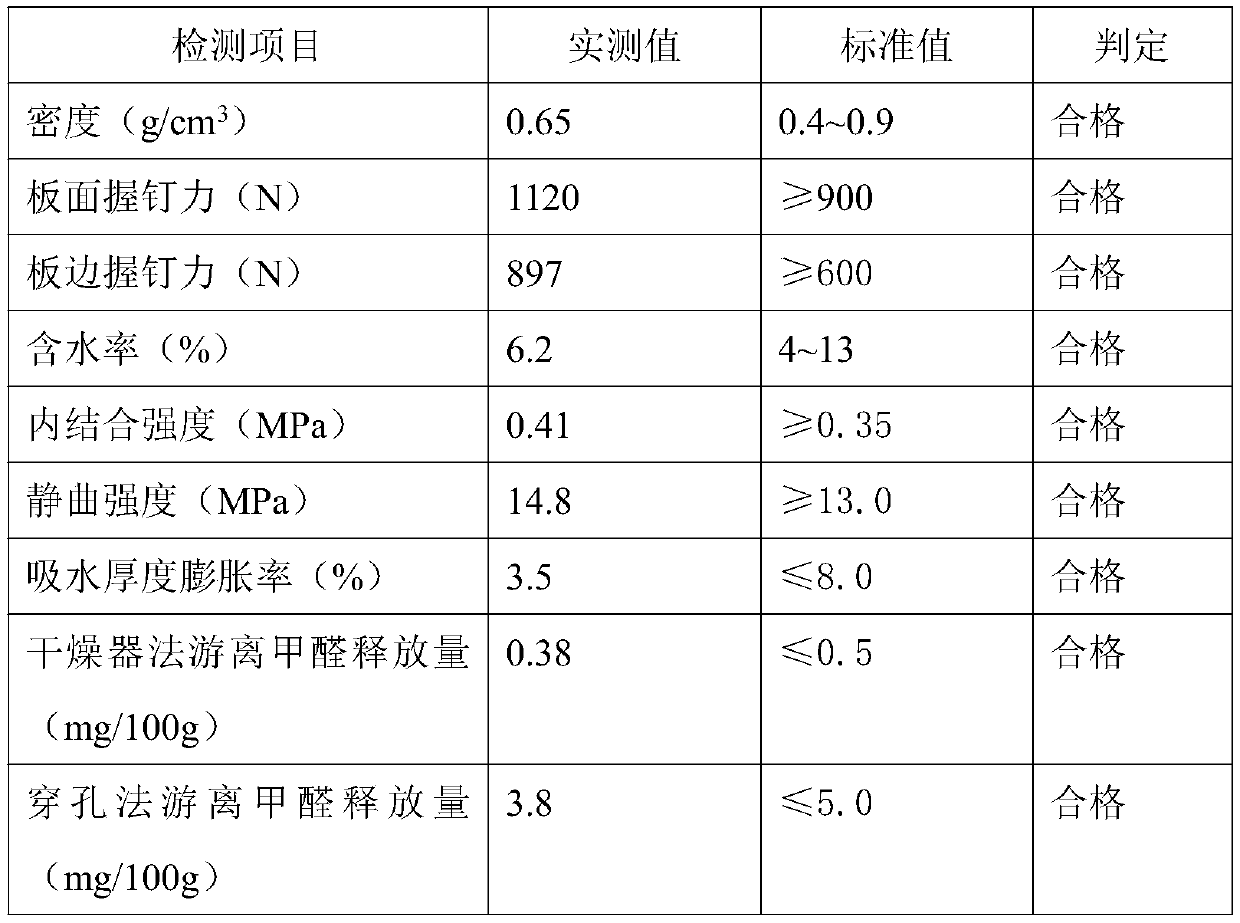

Embodiment 1

[0029] 1. Shavings: use a ring-type flaking machine to shavings to obtain powdery and massive shavings, and the size distribution of the shavings ranges from 0.15 to 4.00mm.

[0030] 2. Drying: Dry the Camellia oleifera husk shavings obtained by flaking to a moisture content of less than 4.0% in a single-channel drum-type hot-smoke dryer. is 130°C.

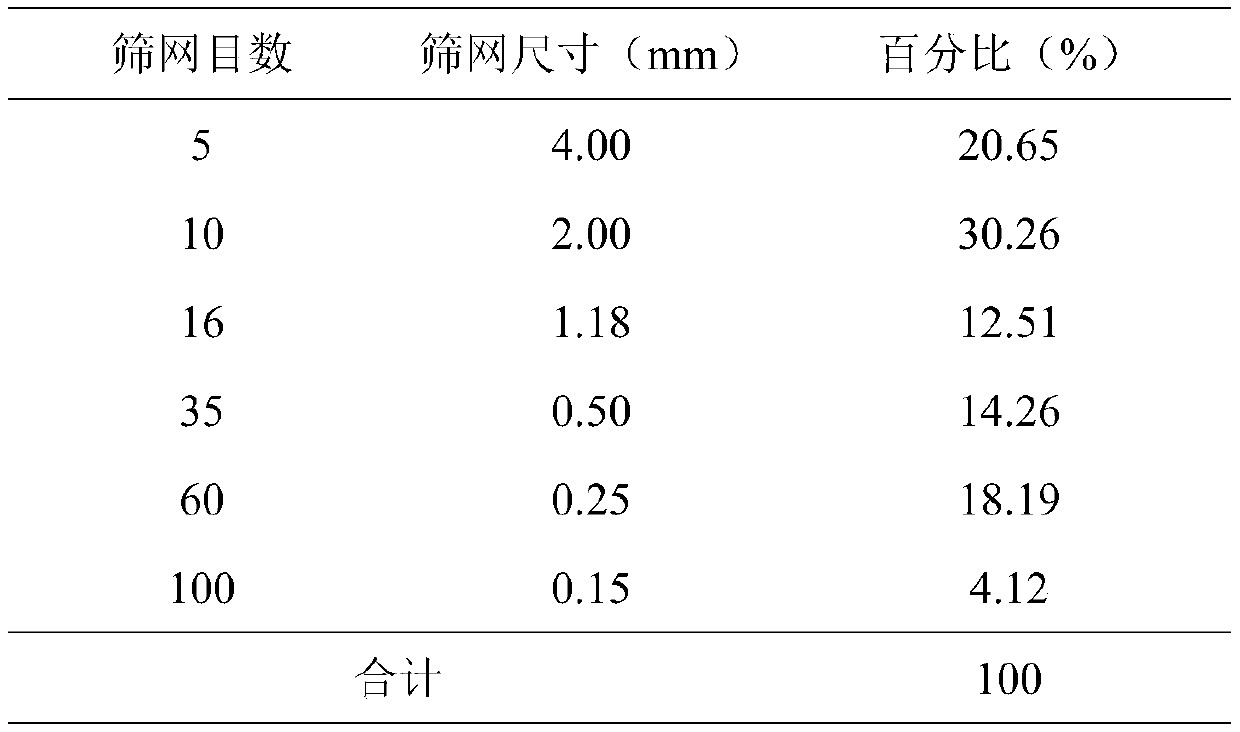

[0031] 3. Sieving: Sieve the dried shavings to obtain 35-140 mesh shavings for the surface layer and 5-60 mesh shavings for the core layer. The sizes of the shavings for the surface layer and the core layer are respectively 0.15~0.5mm and 0.25~4mm, the sieving statistics of shavings are shown in Table 1 below.

[0032] 4. Pneumatic separation: The sieved surface shavings and core shavings are separated by air to remove impurities, stones and metal blocks, and then transported to the surface shavings silo and core shavings silo for standby.

[0033] 5. Mixing and sizing: After the air-sorted shavings are quantitatively measured, ...

Embodiment 2

[0042] 1. Shavings: Use a hammer flaker to shave to obtain powdery and blocky shavings, and the size distribution of the shavings ranges from 0.15mm to 4.00mm.

[0043] 2. Drying: Dry the Camellia oleifera husk shavings obtained by shavings to a moisture content of less than 4.0% in a single-channel drum-type hot-smoke dryer. is 125°C.

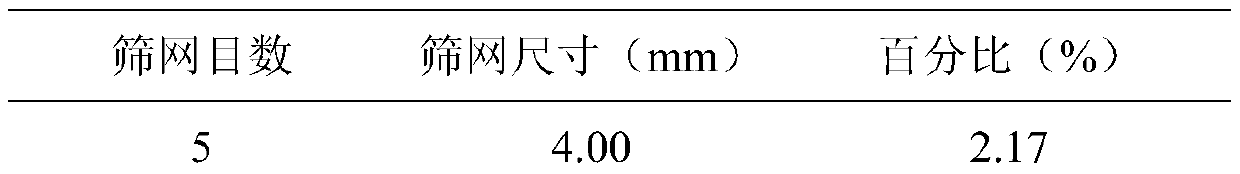

[0044] 3. Sieving: Sieve and sieve the dried shavings to obtain 35-140 mesh shavings for the surface layer and 5-60 mesh shavings for the core layer. 0.15~0.5mm and 0.25~4mm, the sieving statistics of shavings are shown in Table 3 below.

[0045] 4. Pneumatic sorting: The sieved surface and core shavings are separated by pneumatic separation to remove impurities, stones and metal blocks, and then transported to the surface shaving silo and core shaving silo for standby.

[0046] 5. Mixing and sizing: After the air-sorted shavings are quantitatively measured, the mass ratio of camellia oleifera shell surface shavings to wood surface shavings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com