Trace heavy metal detecting system based on chronopotentiometric stripping analysis method, and detection method thereof

A technology of trace heavy metals and chronopotentiometry, which is used in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of cumbersome pretreatment process and unsuitable for on-site use, avoid electrode pretreatment, and be easy to miniaturize. , the effect of a wide range of potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

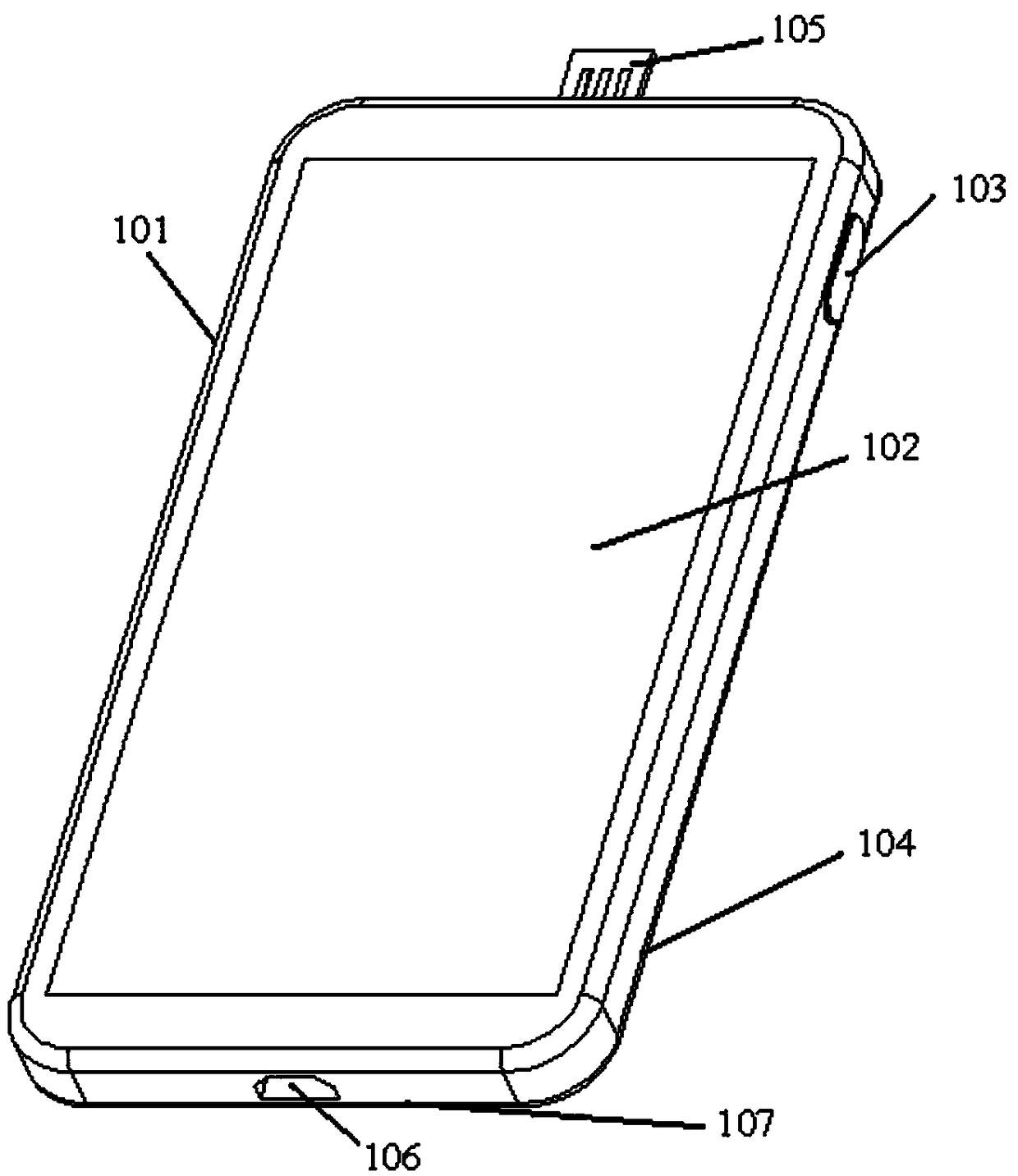

[0060] Embodiment 1: A trace heavy metal detection system based on the chronopotential stripping method, including a chronopotential stripping apparatus and a screen-printed electrode.

[0061] The chronopotential dissolution apparatus includes a housing 101. The front of the housing 101 is a touch screen 102. The right side of the housing is provided with a switch button 103. The lower part of the back of the housing 101 is a battery box 104 with a built-in rechargeable battery. The upper end of the housing 101 has a wire The electrode socket 105 of the screen-printed electrode is provided with a data interface 106 and a bluetooth communication port 107 at the lower end of the side of the housing 101 , and the housing 101 has a built-in working motherboard 108 . The switch button 103 is used to turn on / off the instrument, and the touch screen 102 is used to set the working parameters and display on the display unit (touch screen) 102 for confirmation. The power adapter is con...

Embodiment 2

[0069] Embodiment 2: adopt the same detection system and detection steps as embodiment 1 to detect the heavy metal cadmium sample:

[0070] Preparation of cadmium sample: add 0.2ml of cadmium water intermediate treatment solution to 0.8ml of testing solution, and mix well; testing solution and testing operation steps are the same as in Example 1, except that the setting of the chronopotential dissolution apparatus is changed to the parameters of cadmium. The graph obtained by the test analysis is as follows Figure 9 shown. It shows that the chronopotential stripping method of the present invention has a good response to heavy metal cadmium ions.

Embodiment 3

[0071] Embodiment 3: adopt the detection system and detection step identical with embodiment 1 to detect metal zinc sample:

[0072] Preparation of zinc sample: add 0.2ml of zinc water intermediate treatment solution to 0.8ml of testing solution, and mix well; testing solution and testing operation are the same as in Example 1, except that the setting of the chronopotential dissolution apparatus is changed to the parameters of cadmium. The graph obtained by the test analysis is as follows Figure 10 shown. It shows that the chronopotential stripping method of the present invention for detecting trace heavy metals has a good response to heavy metal zinc ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com