Organic and inorganic compound finish for outer walls

A finish paint, inorganic technology, applied in latex paint, paint containing biocide, antifouling/underwater paint, etc., can solve the problem of weak stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In the present invention, the preparation method of the organic-inorganic compound exterior wall finish paint preferably comprises the following steps:

[0054] Inorganic composite acrylic polymer emulsion, alkyl-ZnO 2 The modified organosilicon material, nano silicon emulsion and fluorocarbon surfactant are mixed to obtain an organic-inorganic composite exterior wall finish paint.

[0055] In the present invention, the inorganic composite acrylic polymer emulsion, alkyl-ZnO 2 The type, source and amount of the modified organosilicon material, nano-silicon emulsion and fluorocarbon surfactant are the same as those of the inorganic composite acrylic polymer emulsion, alkyl-ZnO 2 The type, source and dosage of the modified silicone material, nano-silicon emulsion and fluorocarbon surfactant are the same, and will not be repeated here.

[0056] The above-mentioned method for preparing the finish paint is simple and easy to implement, and is easy to realize industrial pro...

Embodiment 1

[0068] 32mL tetramethyl orthosilicate was hydrolyzed in a mixed solvent composed of 21mL n-hexane and 26mL water to obtain a hydrolyzate;

[0069] The hydrolyzate, 0.4g of ZnO with a particle size of 10-50nm 2 Cocondensation with 27mL organosilane compound to obtain alkyl-ZnO 2 Modified silicone material.

[0070] 0.5 parts of ethylene glycol, 1.8 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate of TEXANOL, 0.1 parts of pH stabilizer AMP-950, fluorocarbon surfactant FS6100.6 parts, the alkyl-ZnO prepared above 2 15 parts of the modified silicone material were mixed, and evenly stirred by a certain shear; then 45 parts of inorganic composite acrylic polymer emulsion RS-2520DC, 0.3 parts of thickener RM-2020, 36.7 parts of deionized water were added, and mixed and stirred evenly to obtain organic Inorganic compound exterior wall finish paint.

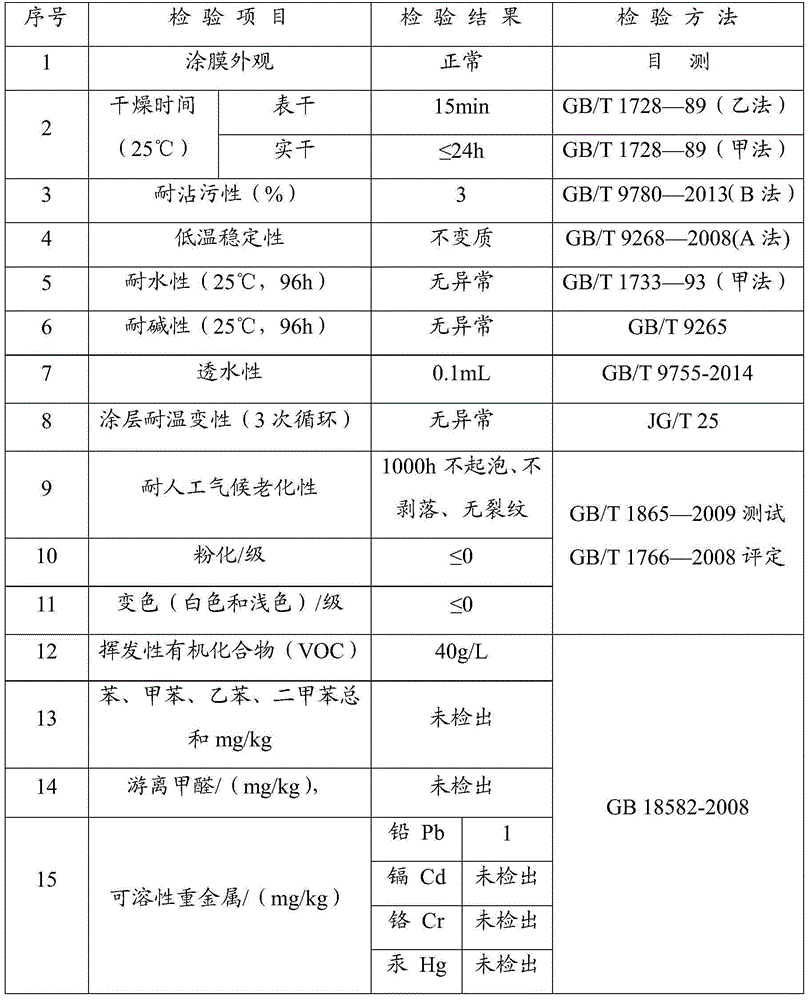

[0071] The present invention carries out the performance test to the obtained organic-inorganic composite exterior wall fini...

Embodiment 2

[0075] 33mL tetramethyl orthosilicate was hydrolyzed in a mixed solvent composed of 21mL n-hexane and 27mL water to obtain a hydrolyzate;

[0076] The hydrolyzate, 0.5g of ZnO with a particle size of 10-50nm 2 Cocondensation with 27mL organosilane compound to obtain alkyl-ZnO 2 Modified silicone material.

[0077] 1 part of ethylene glycol, 2 parts of film-forming aid TEXANOL, 0.2 parts of pH stabilizer AMP-65, 1 part of fluorocarbon surfactant FS6101, the above-mentioned alkyl-ZnO 2 Mix 15 parts of the modified silicone material, and stir evenly through a certain shear; then add 50 parts of inorganic composite acrylic polymer emulsion RS-2520DC, 5 parts of nano-silicon emulsion JYD-0115 parts, 0.5 parts of thickener RM-20200, 15.4 parts of deionized water parts, mixed and stirred evenly to obtain an organic-inorganic compound exterior wall finish paint.

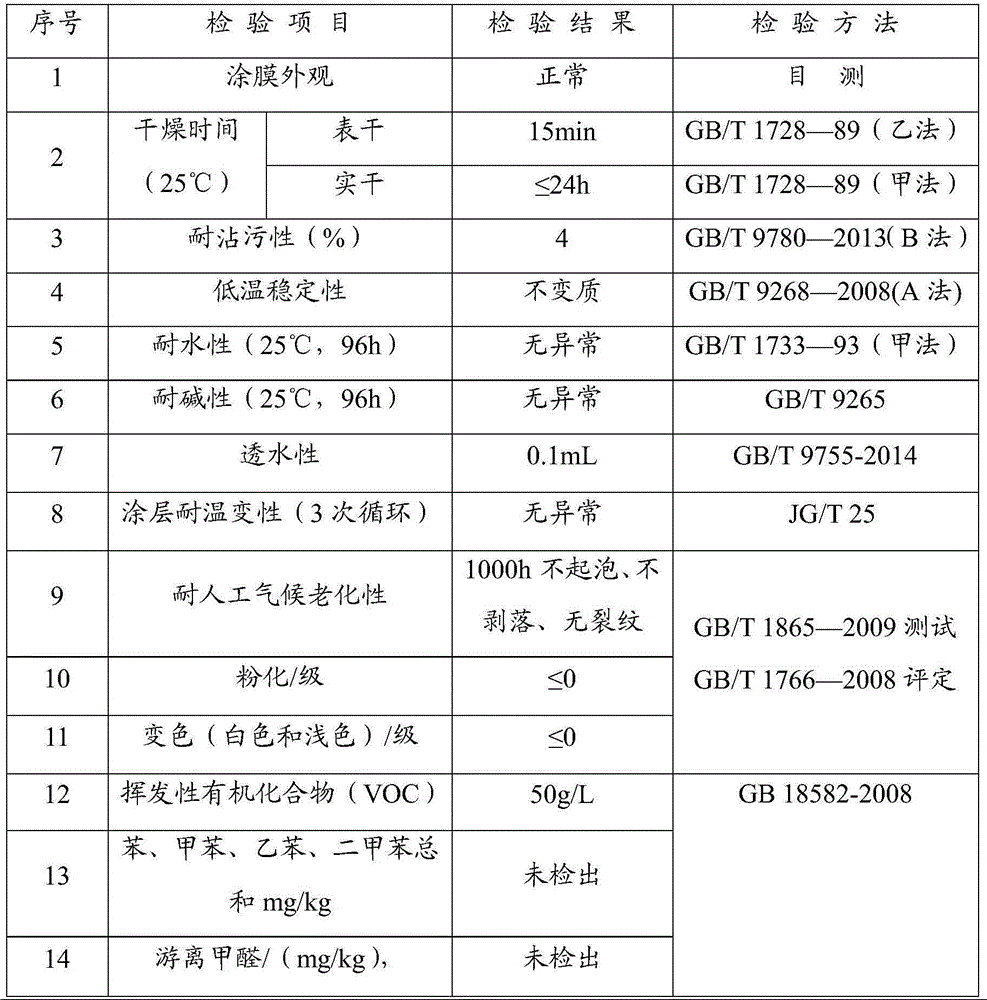

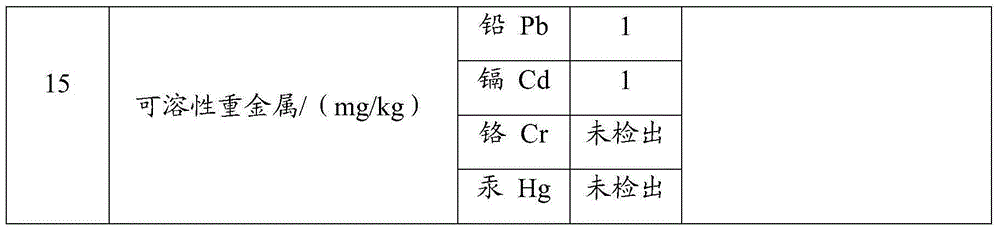

[0078] The present invention carries out the performance test to the obtained organic-inorganic composite exterior wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com