Preparation method of amphoteric polyether sulphone separation membrane

A polyethersulfone ultrafiltration membrane and polyethersulfone technology are used in the preparation of polymer separation membranes and the preparation of amphoteric polyethersulfone separation membranes. Difficult to control and other problems, to achieve the effects of easy control of the preparation process, improved hydrophilicity, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

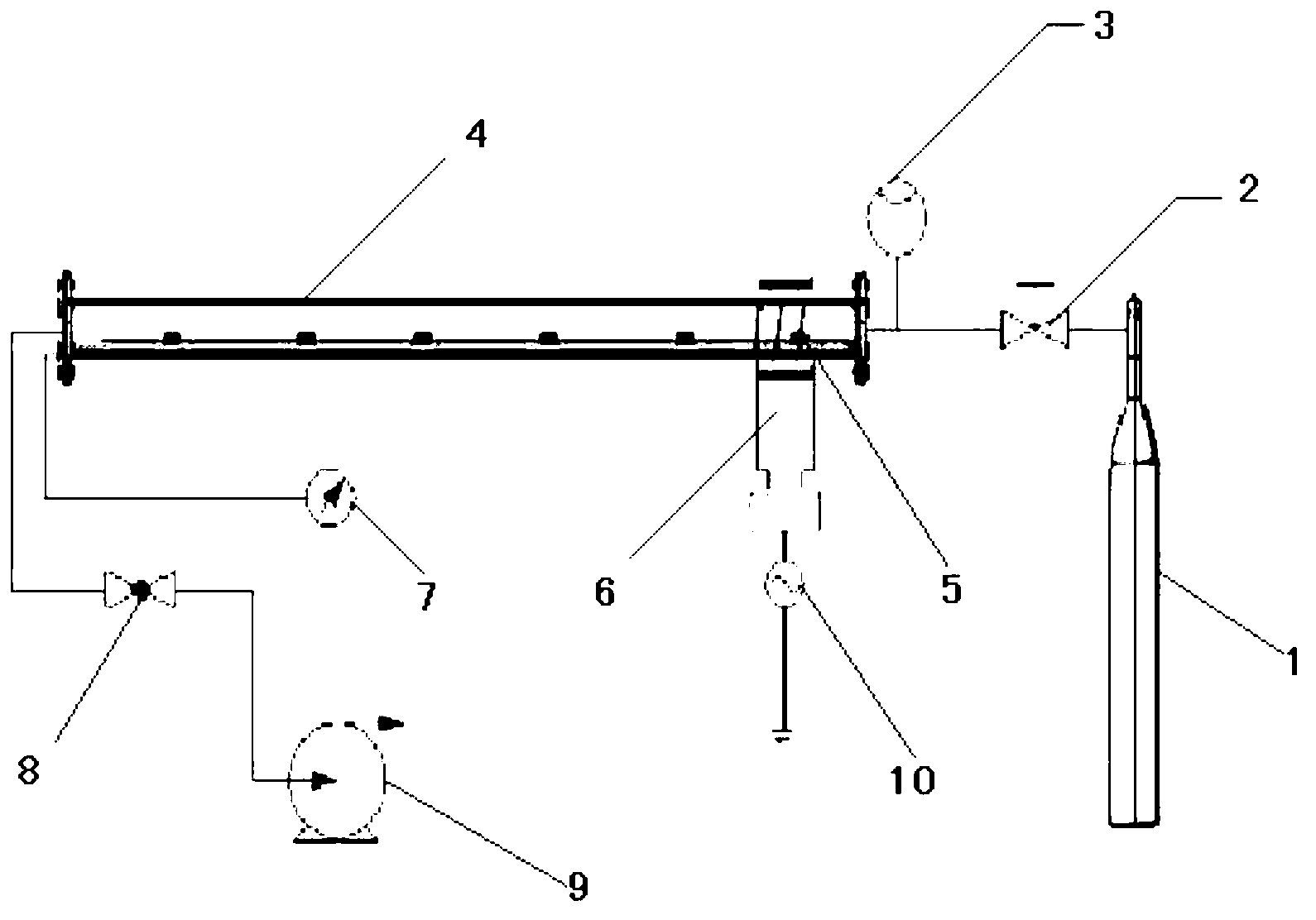

[0036] The preparation method of the amphoteric polyethersulfone separation membrane of the present invention is specifically implemented according to the following steps:

[0037] Step 1, take the polyethersulfone flat ultrafiltration membrane, remove the additives contained in the polyethersulfone flat ultrafiltration membrane, and obtain a clean polyethersulfone flat ultrafiltration membrane:

[0038] Step 1.1, take polyethersulfone flat ultrafiltration membrane, the polyethersulfone flat ultrafiltration membrane is a commercial product of Shenzhen Jiaquan Membrane Filtration Co., Ltd., with an average pore size of 0.2 μm;

[0039] Step 1.2, wash the polyethersulfone flat ultrafiltration membrane in step 1.1 with distilled water, wherein the amount of distilled water and polyethersulfone flat ultrafiltration membrane is: 50L / m 2 ~80L / m 2 , that is, 50L to 80L of distilled water should be added to each square meter of polyethersulfone flat ultrafiltration membrane;

[0040...

Embodiment 1

[0075] Take the polyethersulfone flat ultrafiltration membrane, wash the polyethersulfone flat ultrafiltration membrane with distilled water, add 50L of distilled water per square meter of polyethersulfone flat ultrafiltration membrane, and place the cleaned polyethersulfone flat ultrafiltration membrane in a vacuum In a drying oven, dry at room temperature for 11 hours to obtain a polyethersulfone flat ultrafiltration membrane, and weigh the quality of the polyethersulfone flat ultrafiltration membrane;

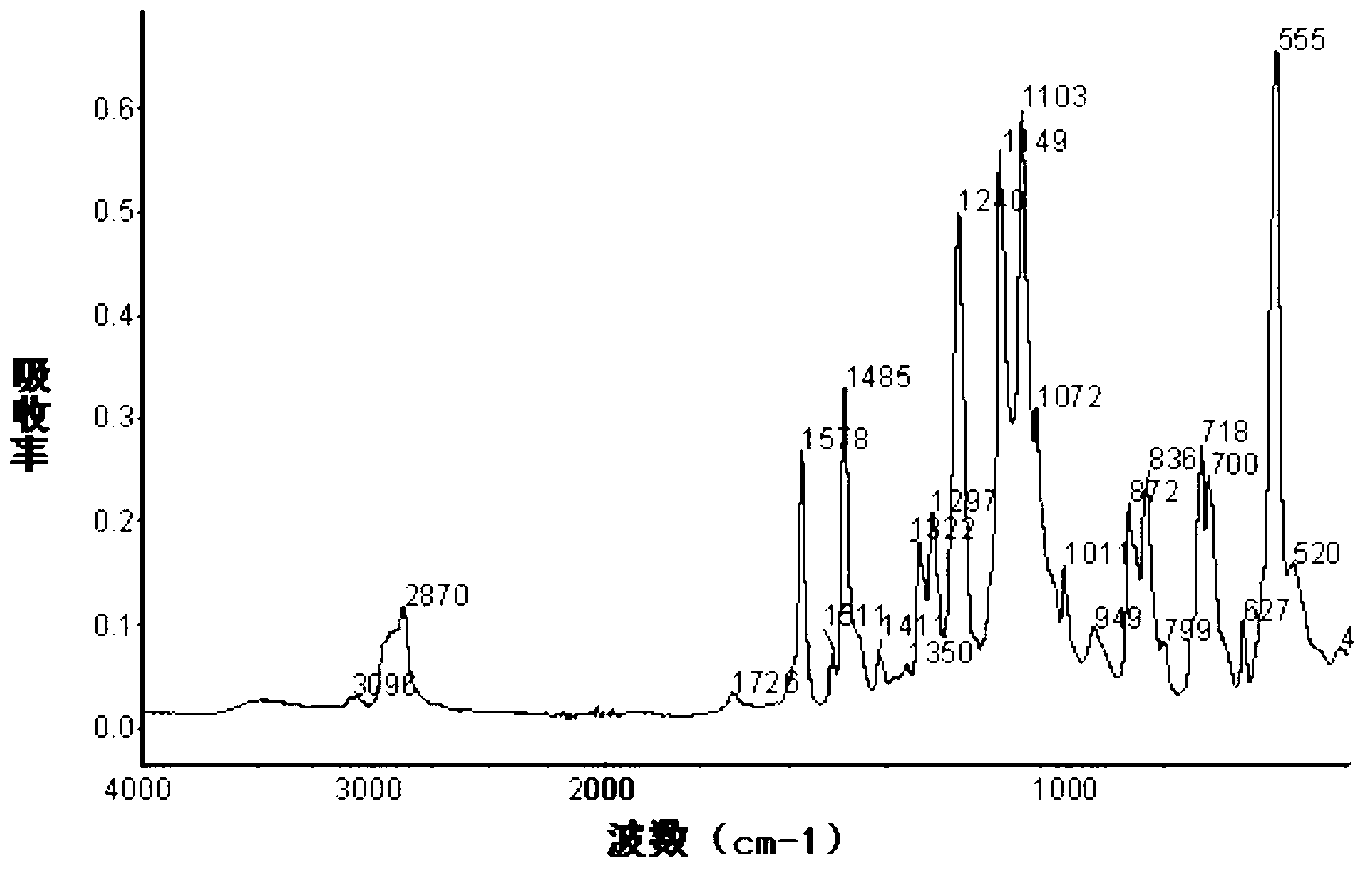

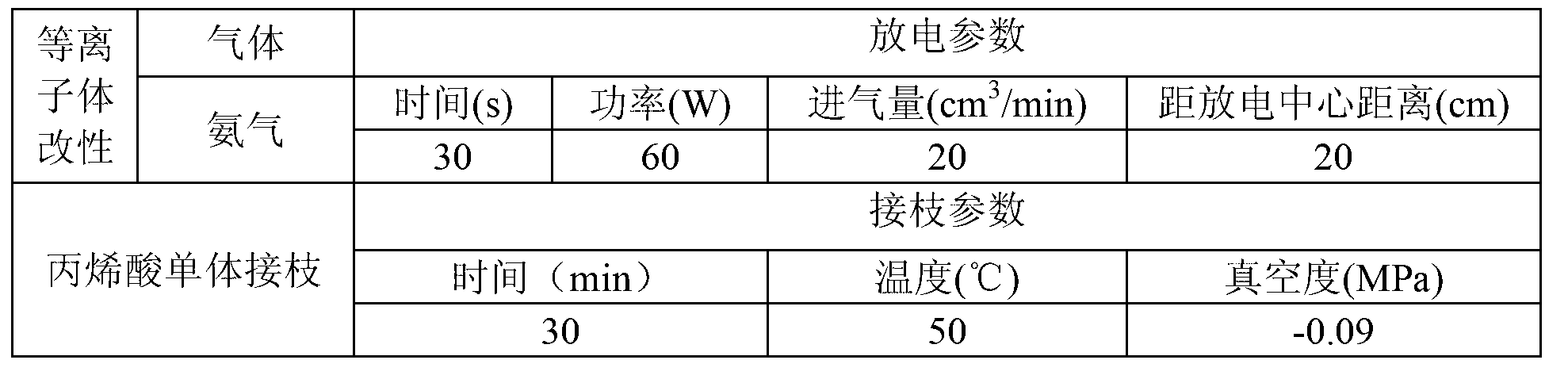

[0076] First place the cleaned polyethersulfone flat ultrafiltration membrane in the discharge reaction tube of the controllable low-temperature plasma discharge device, 20cm away from the discharge center, and then adjust the discharge parameters of the controllable low-temperature plasma discharge device. The discharge parameters are: The working gas is ammonia, the discharge power is 60W, and the gas flow rate is 20cm 3 / min, after adjusting the discharge parameters, star...

Embodiment 2

[0083] Take the polyethersulfone flat ultrafiltration membrane, clean the polyethersulfone flat ultrafiltration membrane with distilled water, add 55L of distilled water per square meter of polyethersulfone flat ultrafiltration membrane, and place the cleaned polyethersulfone flat ultrafiltration membrane in a vacuum In a drying oven, dry at room temperature for 12 hours to obtain a polyethersulfone flat ultrafiltration membrane, and weigh the quality of the polyethersulfone flat ultrafiltration membrane;

[0084] First place the cleaned polyethersulfone flat ultrafiltration membrane in the discharge reaction tube of the controllable low-temperature plasma discharge device, 40cm away from the discharge center, and then adjust the discharge parameters of the controllable low-temperature plasma discharge device. The discharge parameters are: The working gas is ammonia, the discharge power is 60W, and the gas flow rate is 20cm 3 / min, after adjusting the discharge parameters, sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com