Composite reverse osmosis membrane as well as preparation method and application thereof

A technology of reverse osmosis membrane and cross-linking reaction, which is applied in the fields of semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., which can solve the problems of poor pollution resistance of reverse osmosis membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing a composite reverse osmosis membrane, the method comprising forming a separation layer on a support layer using cross-linked polyamide, and then passing a hydroxyl-containing polymer and a zwitterion-containing polymer on the separation layer The cross-linking reaction of the silane coupling agent forms a hydrophilic stain-resistant layer.

[0036] The present invention does not specifically limit the thickness of the support layer, separation layer and hydrophilic pollution-resistant layer, which can be a conventional choice in this field, but in order to make these three layers play a better synergistic effect, the obtained The composite reverse osmosis membrane can better have higher water flux and desalination rate and excellent pollution resistance performance. Preferably, the thickness of the support layer is 90-150 microns, and the thickness of the separation layer is 0.05- 0.5 microns, the thickness of t...

preparation example 1

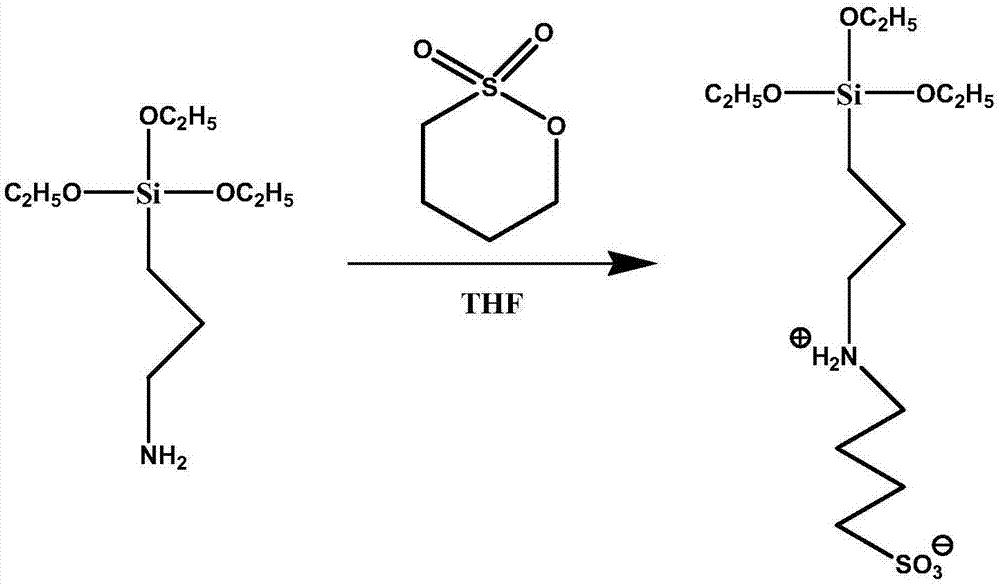

[0059] This preparation example is used to illustrate the preparation method of the silane coupling agent (SKH550) containing zwitterions.

[0060] Add 5g of KH550 and 50mL of tetrahydrofuran into a three-necked flask equipped with magnetic stirring, condenser and nitrogen protection, then add 3g of 1,4-butyl sultone dropwise under stirring, then react at 60°C for 12h Finally, the silane coupling agent SKH550 containing zwitterions was obtained. The synthesis process is as figure 1 shown.

preparation example 2

[0062] This preparation example is used to illustrate the preparation method of the silane coupling agent (SKH540) containing zwitterions.

[0063] Add 5g of KH540 and 50mL of tetrahydrofuran into a three-necked flask equipped with magnetic stirring, condenser and nitrogen protection, then add 2g of 1,3-propyl sultone dropwise under stirring, then react at 60°C for 24h Finally, the silane coupling agent SKH540 containing zwitterions was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com