Preparation and catalytic regeneration of functionalized graphene oxide/polyether sulfone blended ultrafiltration membrane

A graphene and polyethersulfone technology, which is applied in the modification of polyethersulfone ultrafiltration membrane and its catalytic regeneration field, can solve the problems of poor hydrophilicity, low flux, low cleaning and recovery efficiency, etc., and achieve enhanced pollution resistance. , simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

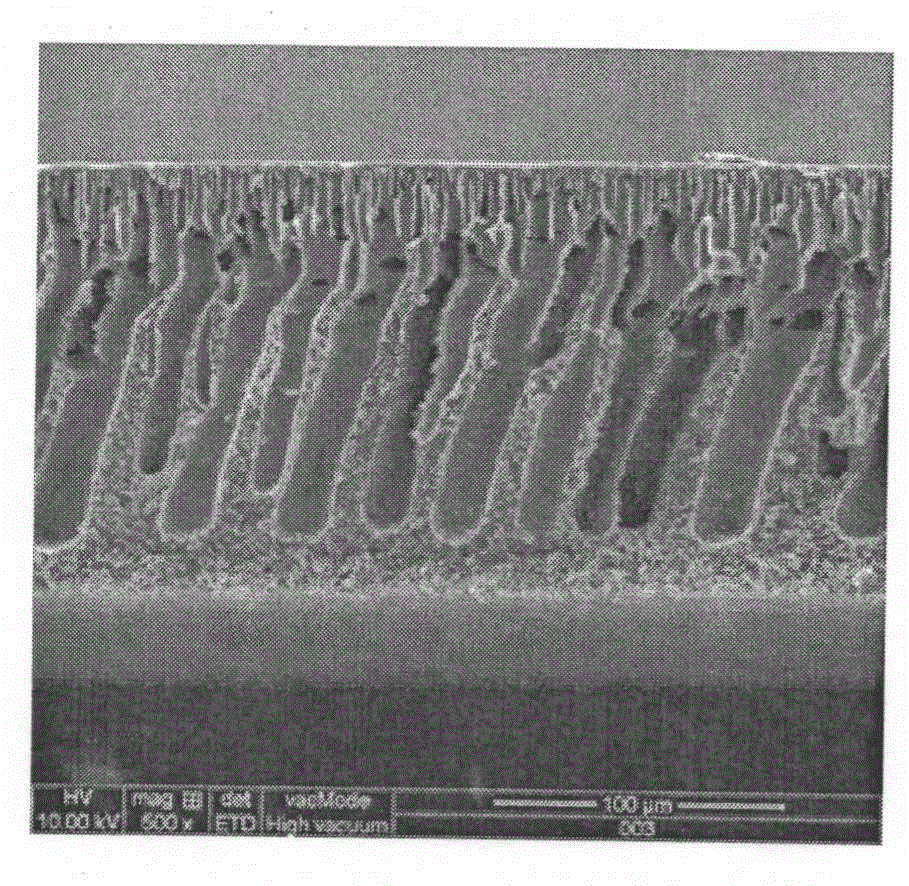

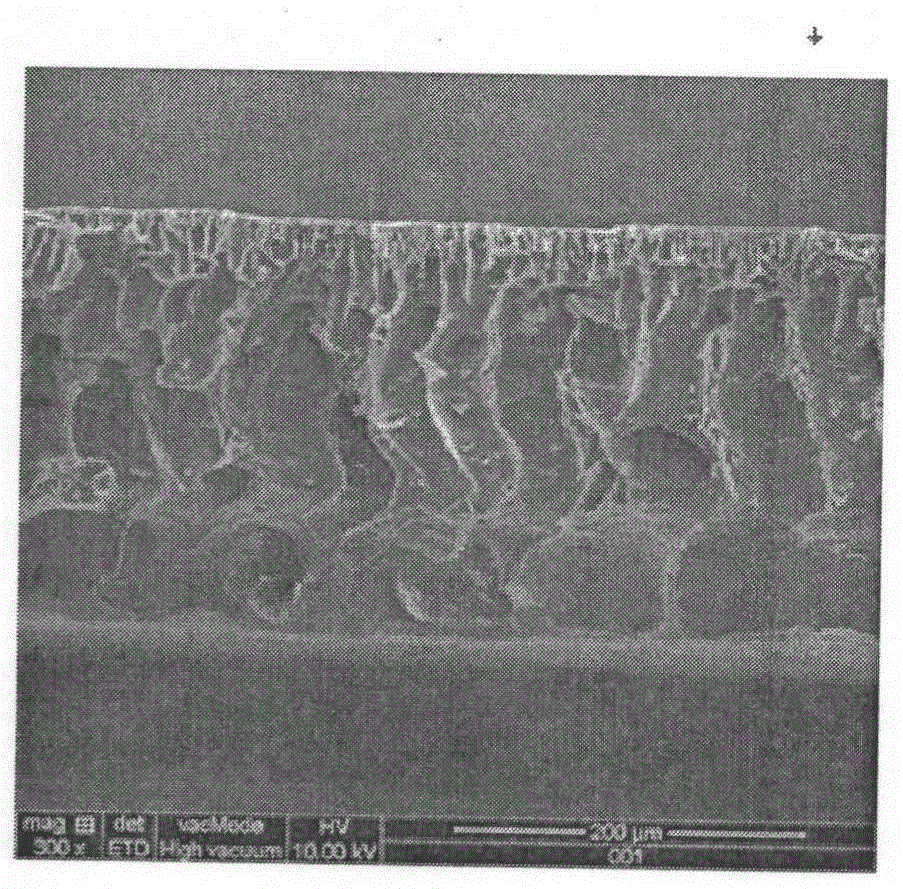

[0032] A preparation method of functionalized graphene oxide / polyethersulfone blended ultrafiltration membrane, the specific steps are:

[0033] Ultrasonic dispersion of functionalized graphene oxide and porogen polyvinylpyrrolidone in the organic solvent N,N-dimethylacetamide for 2 hours, adding polyethersulfone to the resulting dispersion, and placing it in a water bath at a constant temperature of 80°C Stir and dissolve, leave to stand for 1 hour for defoaming, and obtain the casting solution; the mass percent concentration of graphene oxide loaded with tricobalt tetroxide in the casting solution is 0%, and the mass percent concentration of polyethersulfone in the casting solution is 15%. The polyvinylpyrrolidone of polyvinylpyrrolidone is 5%;

[0034] At room temperature and ambient humidity of 50-55%, keep the temperature of the clean scraping plate, flat scraper panel and casting solution consistent, set the thickness and speed of the scraping film, and the thickness of ...

Embodiment 2-7

[0036] Similar to Example 1, the difference is that the concentration of graphene oxide loaded with tricobalt tetroxide in the casting solution in Examples 2-7 is 0.1%, 0.3%, 0.5%, 0.7%, 1.0%, and 2.0%.

[0037] The functionalized graphene oxide / polyethersulfone blended ultrafiltration membrane in Examples 1-7 was measured under 0.1MPa pressure for its pure water flux and BSA rejection rate (%), specifically as follows:

[0038]The bovine serum albumin (BSA) of 1g / L is adopted as a pollutant, and the functionalized graphene oxide / polyethersulfone blended ultrafiltration membrane in Examples 1-7 is evaluated for pollution resistance, and the test process is: at room temperature , Prepress the membrane with distilled water for 40min at 0.15MPa, then change the pressure to 0.1MPa to calculate the pure water flux by measuring the volume of pure water passing through, record the volume of pure water passing through every 5min, and the experiment time is 30min ; Then replace the ult...

Embodiment 2

[0043] The preparation method of the functionalized graphene oxide / polyethersulfone blended ultrafiltration membrane in Example 5 The catalytic regeneration method of the prepared functionalized graphene oxide / polyethersulfone blended ultrafiltration membrane, the specific steps are:

[0044] Get a piece of functionalized graphene oxide / polyethersulfone blended ultrafiltration membrane prepared in Example 5 and put it into an ultrafiltration cup, pre-press for 20min under a pressure of 0.15MPa, and test the pure water flux J at 0.1MPa 1 382.57L·m -2 h -1 Add sewage from the secondary sedimentation tank to the ultrafiltration cup for ultrafiltration operation, maintain the pressure at 0.1MPa, measure a flux data every 5 minutes, and continue to run for 6 hours. At this time, the ultrafiltration membrane has a certain degree of pollution, and then use distilled water The pure water flux of the test membrane is denoted as J 2 141.29L·m -2 h -1 ;Use a damp sponge to wipe off t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com