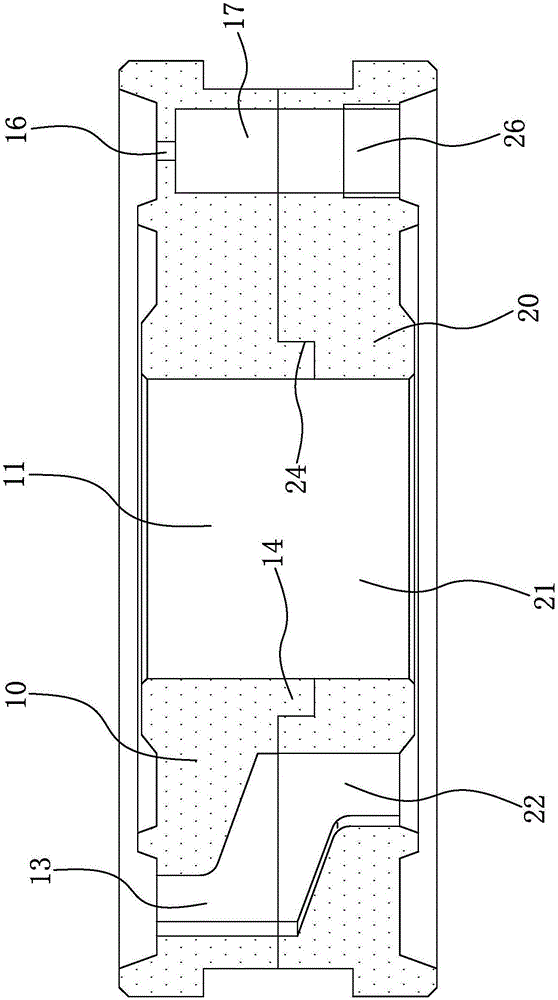

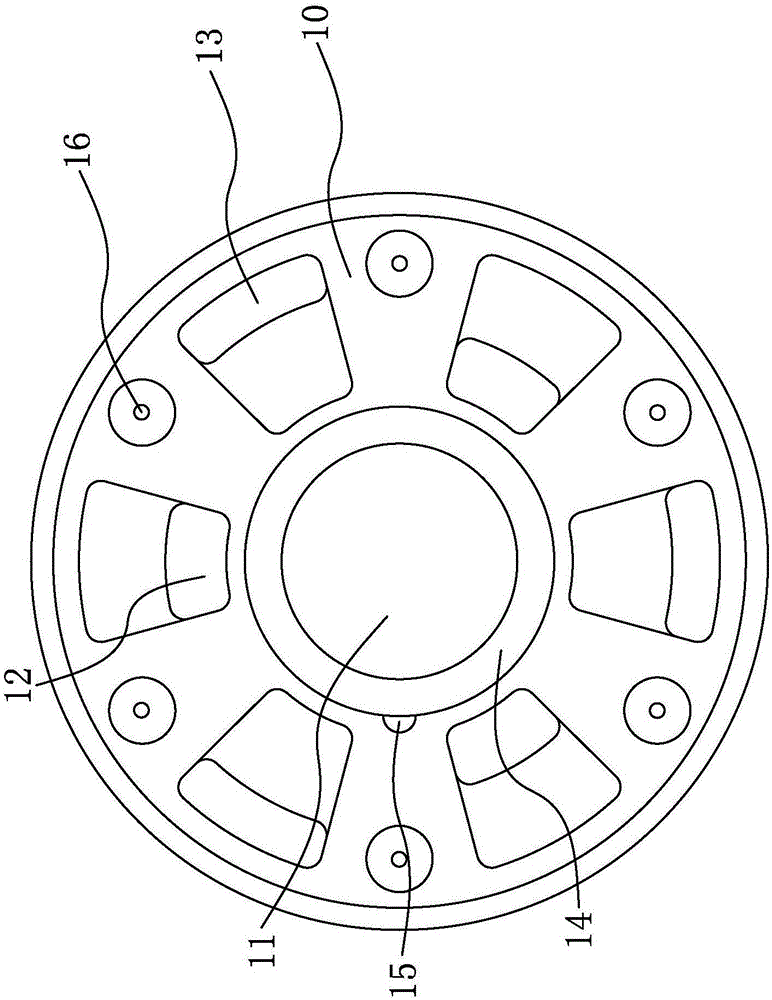

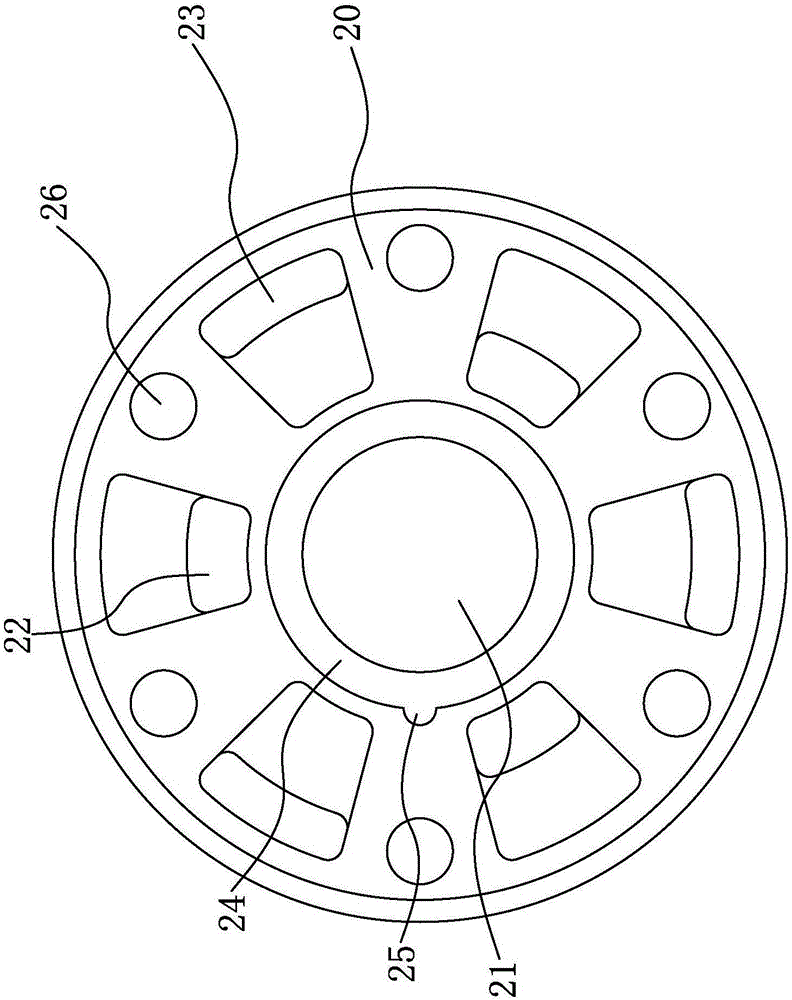

Piston valve for motor car damper

A shock absorber, piston valve technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of low use frequency of shock absorbers, slow load of shock absorbers, and small damping force, etc. Achieve the effect of increasing Rockwell hardness, improving flexural strength and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Powder mixing: water-atomized iron powder (50-120 μm water-atomized iron powder accounts for 30% of the total mass of water-atomized iron powder, and the balance is water-atomized iron powder with a particle size of 10-30 μm), copper powder, The colloidal graphite is uniformly mixed and pressed at 760MPa and 94°C for 10s to obtain the iron-based powder alloy piston valve blank.

[0043] Sintering: The iron-based powder alloy piston valve blank is sintered at 1150° C. for 40 minutes in a mixed gas of hydrogen and nitrogen (the volume percentage of hydrogen and nitrogen is 2%:98%) to obtain a semi-finished iron-based powder alloy piston valve.

[0044] The iron-based powder alloy piston valve semi-finished product is successively subjected to resonance grinding, oil immersion, rolling, cleaning, heat treatment, cleaning, and oil immersion to obtain the iron-based powder alloy piston valve substrate. Among them, the abrasive used in resonance grinding is silica abrasive, a...

Embodiment 2

[0047] Powder mixing: water-atomized iron powder (50-120 μm water-atomized iron powder accounts for 40% of the total mass of water-atomized iron powder, and the balance is water-atomized iron powder with a particle size of 10-30 μm), copper powder, The colloidal graphite is uniformly mixed and pressed at 750MPa and 92°C for 16s to obtain the iron-based powder alloy piston valve blank.

[0048] Sintering: The iron-based powder alloy piston valve blank was sintered at 1160° C. for 50 minutes in a mixed gas of hydrogen and nitrogen (the volume percentage of hydrogen and nitrogen was 3%:97%) to obtain a semi-finished iron-based powder alloy piston valve.

[0049] The fixed block semi-finished product and the movable block semi-finished product are respectively subjected to resonance grinding, oil immersion, rolling, cleaning, heat treatment, cleaning, and oil immersion respectively to obtain fixed block finished products and movable block finished products. Among them, the abrasiv...

Embodiment 3

[0052] Powder mixing: water-atomized iron powder (50-120 μm water-atomized iron powder accounts for 20% of the total mass of water-atomized iron powder, and the balance is water-atomized iron powder with a particle size of 10-30 μm), copper powder, The colloidal graphite was mixed evenly, and pressed at 770MPa and 96°C for 5s to obtain the iron-based powder alloy piston valve blank.

[0053] Sintering: The iron-based powder alloy piston valve blank was sintered at 1120° C. for 60 minutes in a mixed gas of hydrogen and nitrogen (the volume percentage of hydrogen and nitrogen was 3.8%:96.2%) to obtain a semi-finished iron-based powder alloy piston valve.

[0054] The fixed block semi-finished product and the movable block semi-finished product are respectively subjected to resonance grinding, oil immersion, rolling, cleaning, heat treatment, cleaning, and oil immersion respectively to obtain fixed block finished products and movable block finished products. Among them, the abras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com