Method for preparing Al coating on surface of sintered NdFeB by adopting detonation spraying

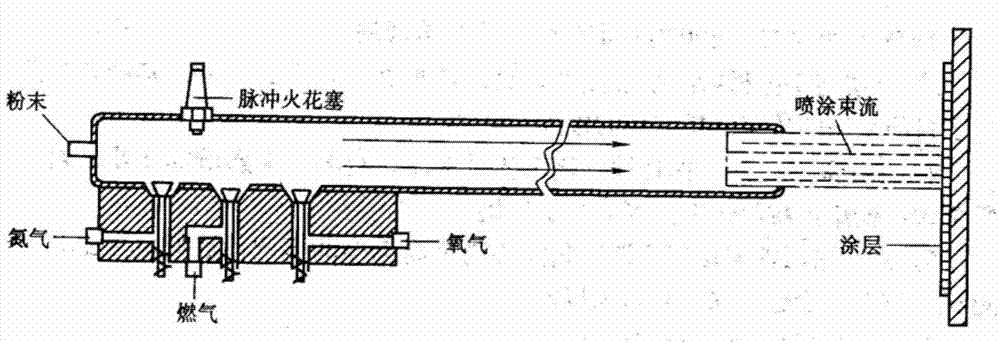

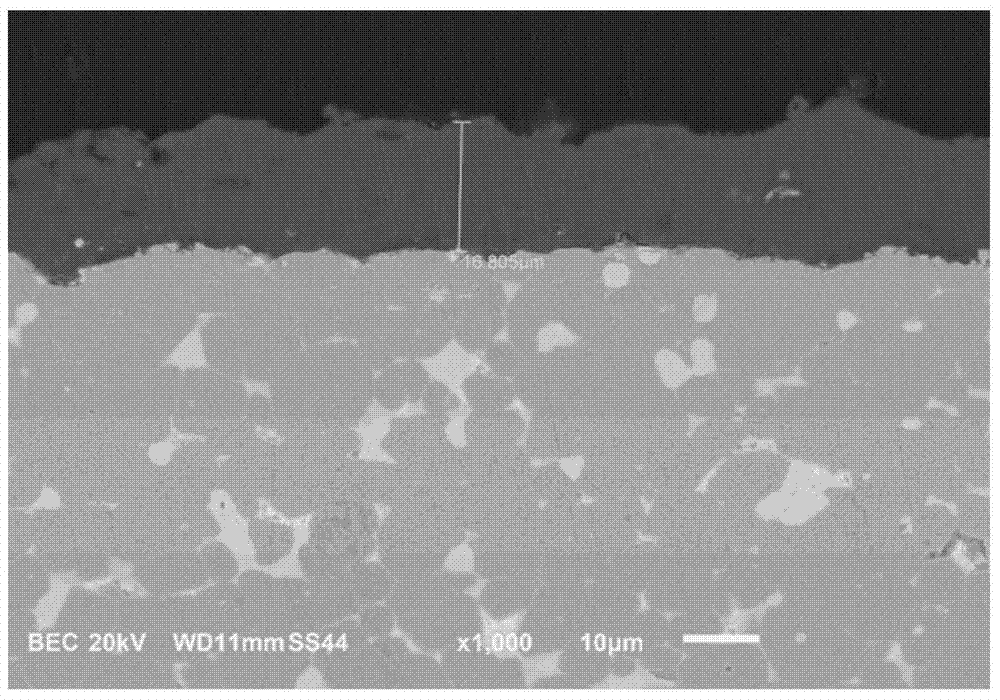

A technology of explosive spraying and coating, applied in the direction of coating, metal material coating process, molten spraying, etc., can solve the problems of complex process, high cost, unfavorable ecological environment, etc., achieve low surface porosity and improve corrosion resistance sex, combined with good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The first step: substrate pretreatment

[0038] (A) A sintered NdFeB sample whose brand name is N35 is not magnetized is used as the base material, the hardness Hv=6.20, and the density D is 7.6;

[0039] Place the substrate in alcohol with a mass fraction of 99.7% for degreasing treatment by ultrasonic cleaning. Under the condition of a frequency of 30KHz, after ultrasonic cleaning for 5 minutes, naturally dry to obtain the first substrate;

[0040] (B) Install the first substrate on a DB-1 sandblasting machine, adjust the pressure to 0.7 MPa, select 60 mesh corundum sand for sandblasting, and obtain a second substrate with a roughness of Ra=3;

[0041] Step 2: Preparation of Al coating by detonation spraying process

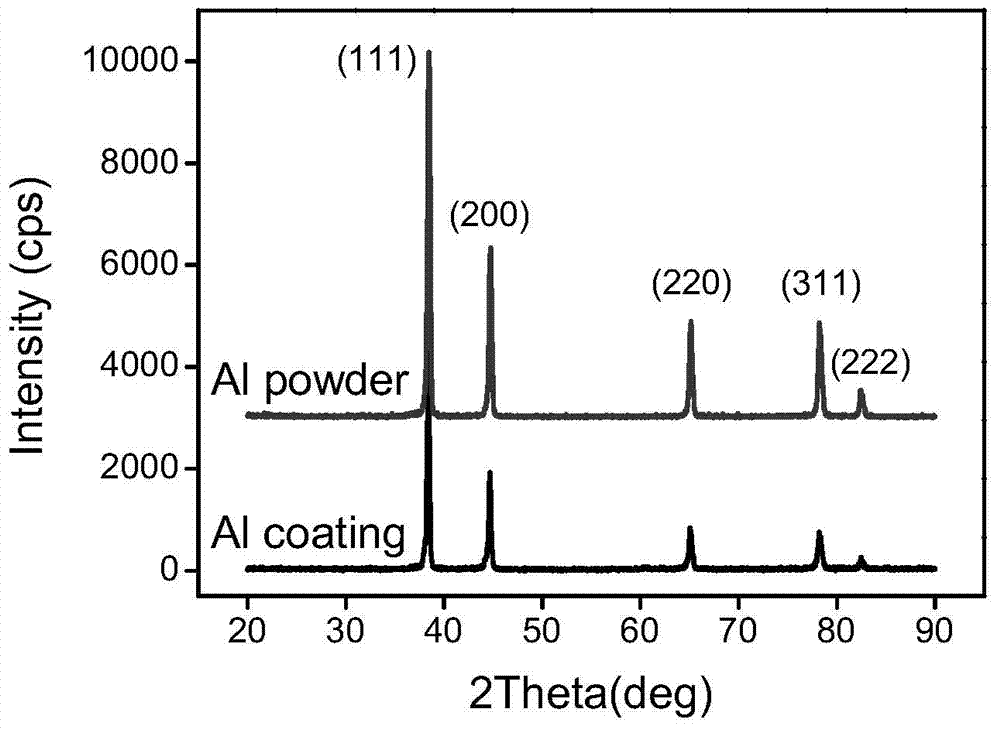

[0042] Explosion spraying material selects industrial pure aluminum (mass percentage purity is 99.99%) powder, and average particle diameter is 38 microns; The XRD photograph of aluminum powder is as follows image 3 As shown, the abscissa is the angle...

Embodiment 2

[0053] The first step: substrate pretreatment

[0054] (A) A sintered NdFeB sample whose brand name is N35 is not magnetized is used as the base material, the hardness Hv=6.20, and the density D is 7.6;

[0055] Place the substrate in alcohol with a mass fraction of 99.7% for degreasing treatment by ultrasonic cleaning. Under the condition of frequency of 40KHz, after ultrasonic cleaning for 5 minutes, naturally dry to obtain the first substrate;

[0056] (B) Install the first substrate on a DB-1 sandblasting machine, adjust the pressure to 0.7 MPa, select 60 mesh corundum sand for sandblasting, and obtain a second substrate with a roughness of Ra=3.5);

[0057] Step 2: Preparation of Al coating by detonation spraying

[0058] The explosive spraying material is made of industrial pure aluminum (mass percentage purity is 99.99%) powder, and the average particle size is 38 microns;

[0059] Loading detonation spray material into gas detonation spray equipment;

[0060] mounti...

Embodiment 3

[0067] The first step: substrate pretreatment

[0068] (A) A sintered NdFeB sample whose brand name is N35 is not magnetized is used as the base material, the hardness Hv=6.20, and the density D is 7.6;

[0069] Place the substrate in alcohol with a mass fraction of 99.7% for degreasing treatment by ultrasonic cleaning. Under the condition of frequency of 30KHz, after ultrasonic cleaning for 15 minutes, naturally dry to obtain the first substrate;

[0070] (B) Install the first substrate on a DB-1 sandblasting machine, adjust the pressure to 0.7 MPa, select 60 mesh corundum sand for sandblasting, and obtain a second substrate with a roughness of Ra=3.3;

[0071] Step 2: Preparation of Al coating by detonation spraying

[0072] The explosive spraying material is made of industrial pure aluminum (mass percentage purity is 99.99%) powder, and the average particle size is 38 microns;

[0073] Loading detonation spray material into gas detonation spray equipment;

[0074] mounti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com