Preparation method of antibacterial conductive cotton fiber

A technology of conductive cotton and cotton fiber, which is applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of formaldehyde poisonous and volatile, pollution, etc., achieve high bonding fastness of coating, less energy consumption, and reduce porosity and roughness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

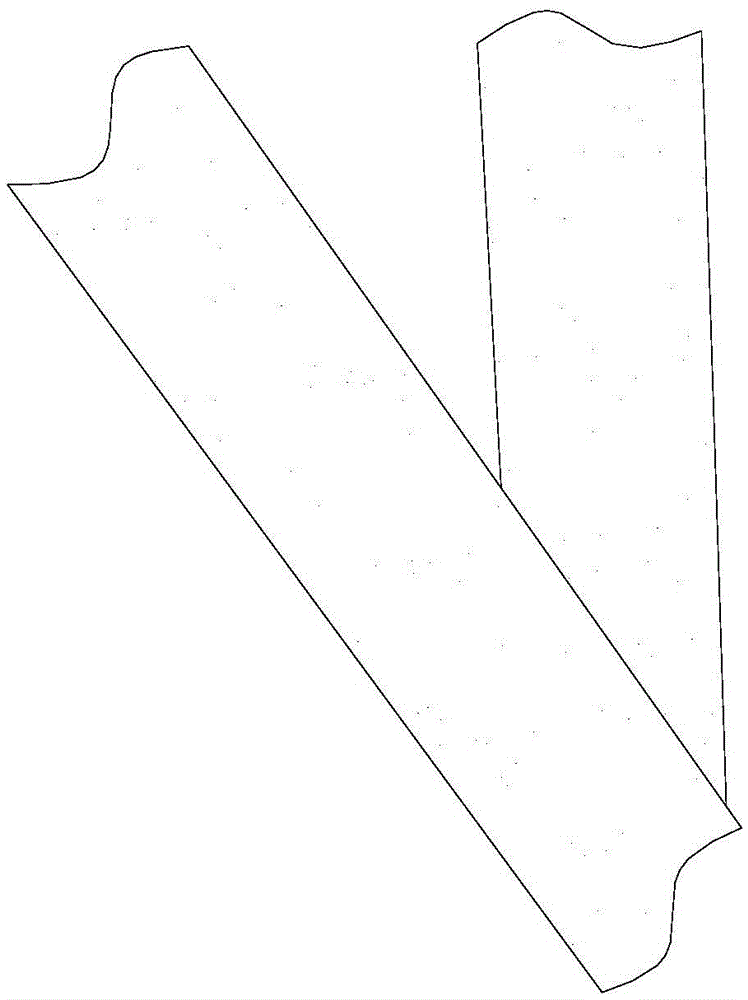

Image

Examples

Embodiment 1

[0027] In this embodiment, 1 g of cotton staple fiber is used as the base fiber.

[0028] The first step: degreasing. Add 0.1g of sodium hydroxide, 0.1g of OP emulsifier, and 0.1g of Omo washing powder into 50mL of deionized water to dissolve, the temperature of the water bath is 50°C, stir well, then add the weighed cotton staple fiber (1g) and stir for 30min , and then rinse well.

[0029] The second step: coarsening. Add 7mL of sodium hydroxide to 50mL of deionized water, and then add the cotton staple fiber treated in the previous step. The temperature of the water bath is 50°C, stir for 30min, and then fully wash with water.

[0030] The third step: sensitization. Weigh 0.5g of stannous chloride and dissolve it in 0.5mL of hydrochloric acid, and then add it to 50mL of deionized water after it is completely dissolved, and finally add the cotton staple fiber treated in the previous step and stir for 10min at a temperature of 30°C. After sensitization, use Soak in 1g / L s...

Embodiment 2

[0039] In this embodiment, 1 g of cotton staple fiber is used as the base fiber.

[0040] The first step: degreasing. Add 0.1g of sodium hydroxide, 0.1g of OP emulsifier, and 0.1g of washing powder into 50mL of deionized water to dissolve. The temperature of the water bath is 50°C. Stir well, then add 1g of cotton staple fiber and stir for 30min. Then rinse well.

[0041] The second step: coarsening. Add 5mL of sodium hydroxide to 50mL of deionized water, and then add the cotton staple fiber treated in the previous step. The temperature of the water bath is 55°C, stir for 30min, and then fully wash with water.

[0042] The third step: sensitization. Weigh 0.4g of stannous chloride and dissolve it in 0.5mL of hydrochloric acid, add it to 50mL of deionized water after it is completely dissolved, and finally add the nylon fiber treated in the previous step and stir for 10min at a temperature of 30°C. After sensitization, use 1g / L sodium bicarbonate solution for 3 minutes, an...

Embodiment 3

[0051] In this embodiment, 1 g of nylon is used as the base fiber.

[0052] The first step: degreasing. Add 0.1g of OP emulsifier and 0.1g of washing powder into 60mL of deionized water to dissolve, the temperature of the water bath is 50°C, stir well, then add 1g of nylon fiber and stir for 30min, then fully wash with water.

[0053] The second step: coarsening. Add 6mL of sodium hydroxide to 50mL of deionized water, and then add the nylon fiber treated in the previous step. The temperature of the water bath is 55°C, stir for 30min, and fully wash with water.

[0054] The third step: sensitization. Weigh 0.6g of stannous chloride and dissolve it in 0.5mL of hydrochloric acid, and then add it into 50mL of deionized water after it is completely dissolved, and finally add the nylon fiber treated in the previous step and stir for 10min at a temperature of 30°C. After sensitization, use 1g / L sodium bicarbonate solution for 3 minutes, and then fully washed with water.

[0055] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com