Graphite negative electrode material, lithium ion battery, preparation method and application

A graphite anode and raw material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low charging capacity and poor low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

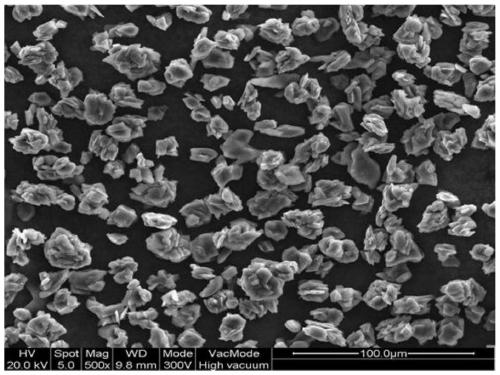

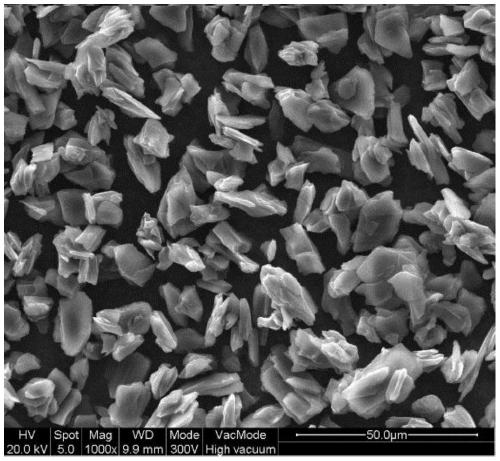

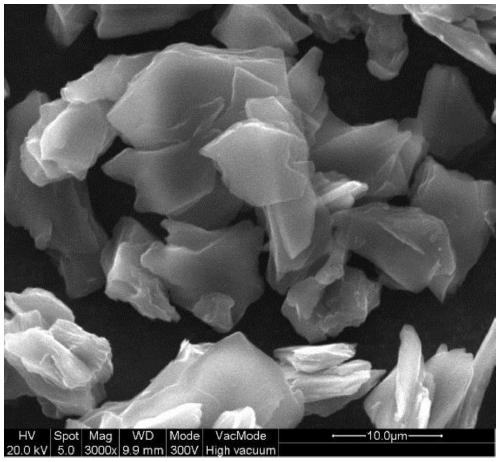

Image

Examples

Embodiment 1

[0056] In the crushing equipment, the calcined needle coke is crushed to obtain powder, the median particle size of the powder is controlled at 8-8.5 μm, the crushed material is shaped, and the shaped powder is mixed evenly . Under the protection of chlorine gas, the mixed powder was subjected to graphitization treatment. The graphitization temperature is 2900°C, and the graphitization time is 90h. The material after graphitization treatment is screened, and the mesh number of the screen is 250 mesh, to remove the lumps that coke quickly at high temperature during the graphitization process. Fully mix the sieved material with the binder asphalt according to the ratio of 100:3, and mix for 45 minutes, so that the asphalt is evenly distributed in the sieved material to prepare a mixture. The mixture was subjected to surface coating modification treatment, including two stages. The temperature of the first stage was 350°C and the time was 3h; the temperature of the second stage...

Embodiment 2

[0058] In the crushing equipment, the calcined needle coke is crushed to obtain powder, the median particle size of the powder is controlled at 8-8.5 μm, the crushed material is shaped, and the shaped powder is mixed evenly . Under the protection of chlorine gas, the mixed powder was subjected to graphitization treatment. The graphitization temperature is 2900°C, and the graphitization time is 90h. The material after graphitization treatment is screened, and the mesh number of the screen is 250 mesh, to remove the lumps that coke quickly at high temperature during the graphitization process. Fully mix the sieved material with the binder asphalt according to the ratio of 100:4, and mix for 45 minutes, so that the asphalt is evenly distributed in the sieved material to prepare a mixture. The mixture was subjected to surface coating modification treatment, including two stages. The temperature of the first stage was 350°C and the time was 3h; the temperature of the second stage...

Embodiment 3

[0061] In the crushing equipment, the calcined needle coke is crushed to obtain powder, the median particle size of the powder is controlled at 8-8.5 μm, the crushed material is shaped, and the shaped powder is mixed evenly . Under the protection of chlorine gas, the mixed powder was subjected to graphitization treatment. The graphitization temperature is 2900°C, and the graphitization time is 90h. The material after graphitization treatment is screened, and the mesh number of the screen is 250 mesh, to remove the lumps that coke quickly at high temperature during the graphitization process. Fully mix the sieved material with the binder asphalt according to the ratio of 100:5, and mix for 45 minutes, so that the asphalt is evenly distributed in the sieved material to prepare a mixture. The mixture was subjected to surface coating modification treatment, including two stages. The temperature of the first stage was 350°C and the time was 3h; the temperature of the second stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com