Patents

Literature

61results about How to "Slow down recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintered ore pulverization inhibitor and adding method thereof

The invention provides sintered ore pulverization inhibitor and an adding method thereof. The sintered ore pulverization inhibitor comprises the following chemical components by weight percentage: 65-85% of MgCl2, 3-7% of CaCl2, 5-15% of H3BO2 and 5-15% of CaO B2O3 4H2O. The adding method comprises the following steps that: pulverization inhibitor which is prepared and uniformly mixed is stored in a liquid storage pool; at a first spraying point, a 4.5kw pump and a spray tube are adopted for spraying sintered ores in a circular cooler; at a second spraying point, a 4.5kw pump and a spray nozzle are adopted for spraying a finished sintered ore belt; and at a third spraying point, a 7.5kw pump and an atomizing spray gun are adopted for spraying a finished product belt. After the pulverization inhibitor is sprayed to the finished sintered ores, the low-temperature reduction degradation index of the sintered ores is reduced, the breathability of a blast furnace is improved, the comprehensive coke ratio is reduced, and the yield of ferrum is improved; the content of chlorine is reduced, so the corrosion on a bag-type dust collector of the blast furnace is relieved; and simultaneously, the generation amount of TCDD (tetrachlorodibenzo-p-dioxin) is reduced, so the environmental pollution is avoided.

Owner:ANGANG STEEL CO LTD

Method for directly reducing laterite-nickel into nickel-bearing ball iron in tunnel kilns

InactiveCN101538628AImprove heat transfer performanceRestore fastFluidised-bed furnacesTunnel kilnDesiccant

The invention relates to a method for directly reducing laterite-nickel into nickel-bearing ball iron in tunnel kilns, which is completed according to the following steps: firstly, laterite-nickel containing absorption water is added with dryers, then stirred uniformly and dewatered and dried; secondly, the mixture is broken up and added with reducing agents and particle ferronickel aggregation agents, mixed uniformly and sent onto a tunnel kiln trolley spread with coke powder, and then covered with a layer of coke powder for reducing roasting; the materials after reducing roasting are cooled and hardened by water, broken up, ball ground and subjected to magnetic separation, and then high-quality nickel-bearing ball iron alloy is obtained. The method does not use the traditional reduction pot, has the advantages of simple production, short reduction time, high yield, convenient operation, low energy consumption, low cost and high recovery ratio of nickel, and the produced nickel-bearing ball iron alloy particles can be directly used as the high-quality raw material for smelting stainless steel; and the method is applicable to laterite-nickel of various grades and various types.

Owner:毛黎生

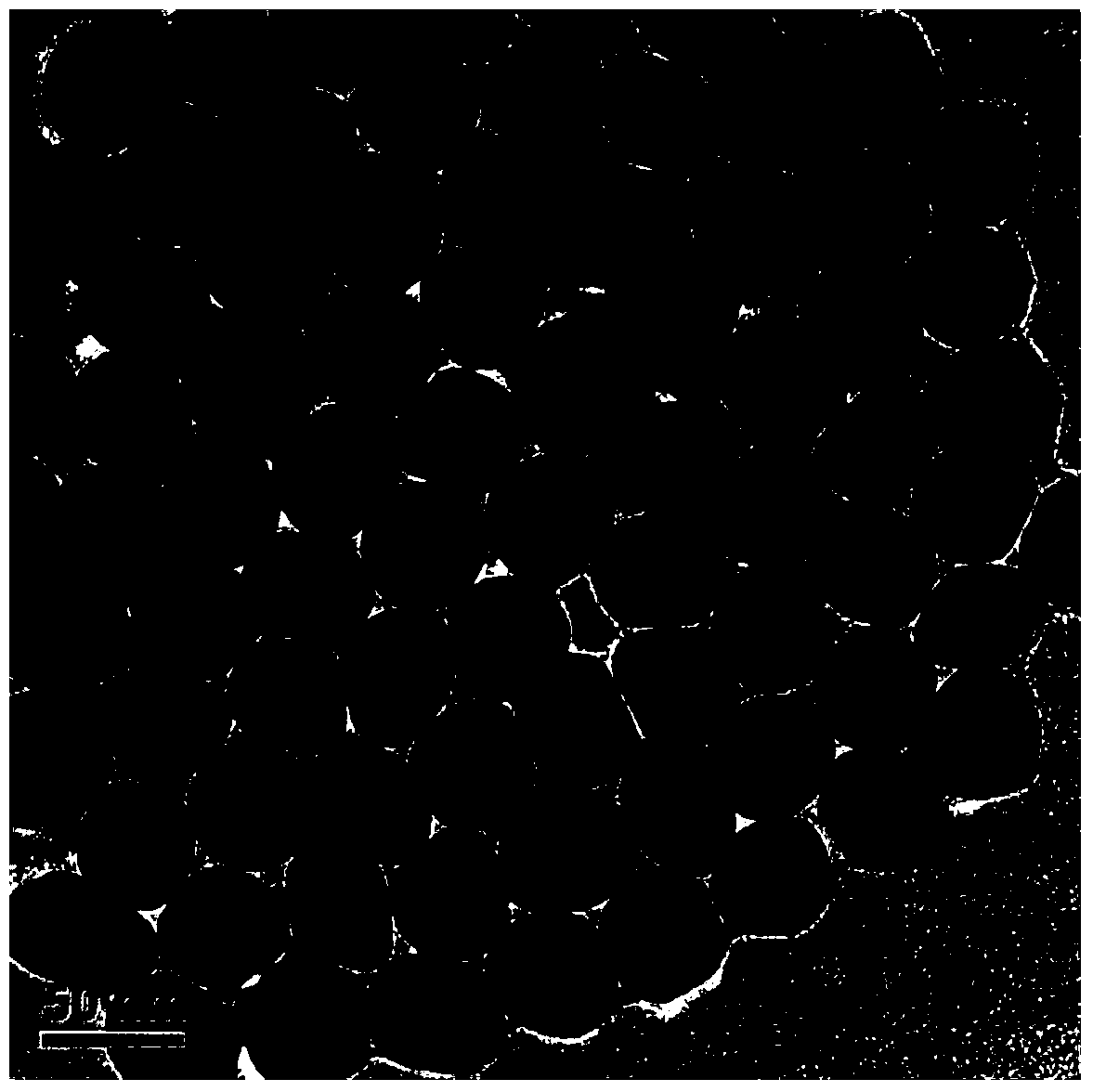

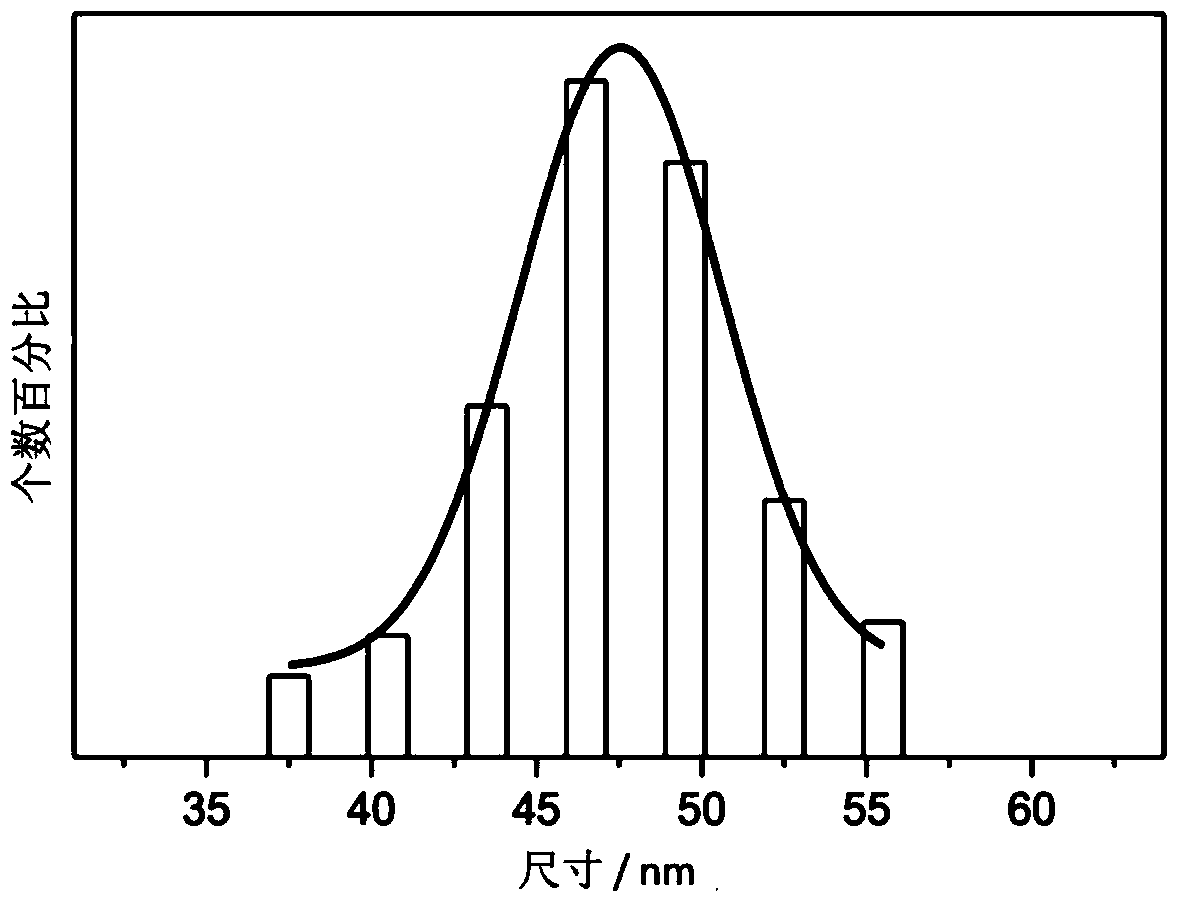

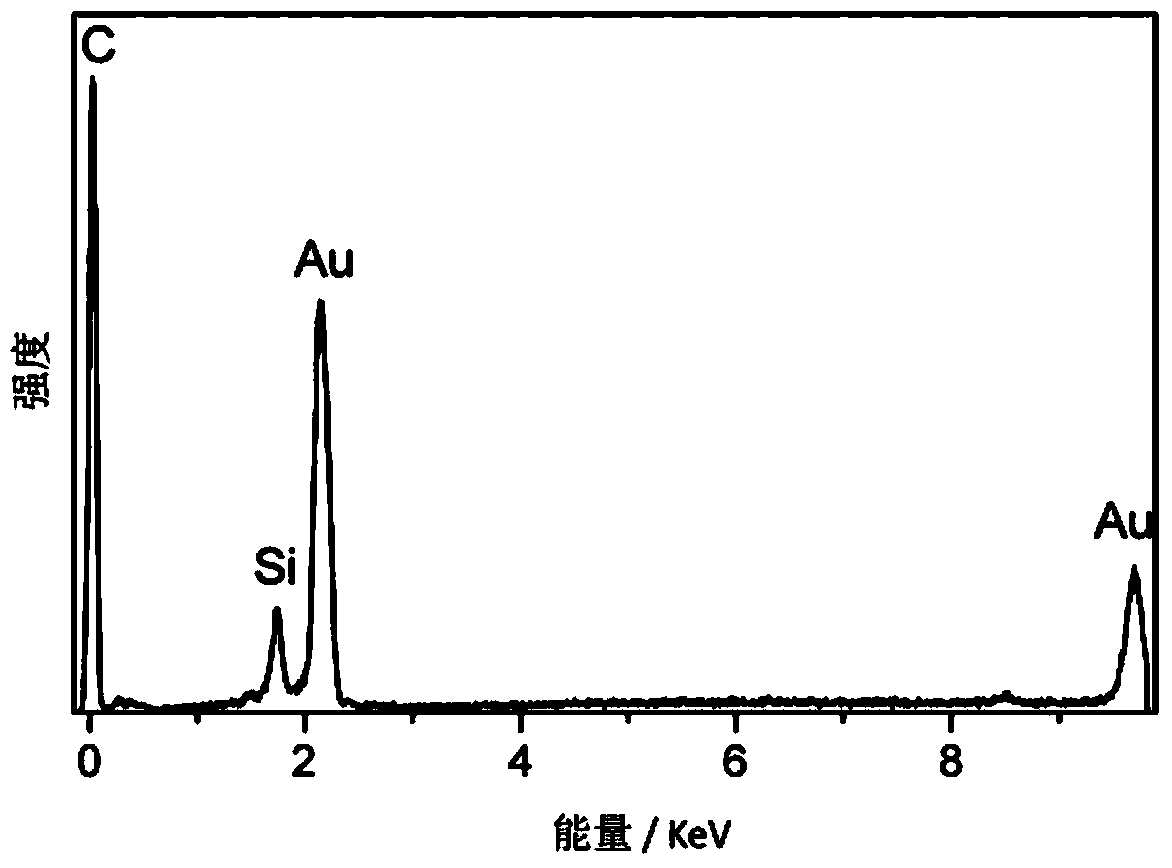

Method for synthesizing oil-soluble gold nanoparticles

The invention relates to gold nanoparticles, and provides a method for synthesizing high-concentration and high-stability oil-soluble gold nanoparticles with the particle sizes of 30-100 nm in an oil phase system under mild conditions. The method comprises the following steps: adding seed crystals into a growth solution and adding a precursor of Au to obtain the oil-soluble gold nanoparticles with the particle sizes of 30-100 nm. Short-chain organic amine is introduced into the growth solution in a seed crystal growth method, on one hand, the surfaces of small-sized Au seed crystals are exchanged to reduce the protection degree of the surfaces thereof, so that a salt precursor of the Au continues to grow more easily, on the other hand, the reduction speed of the salt precursor of the Au is reduced so as to reduce the growth speed to obtain large-sized Au nanoparticles; the method has the advantages of mild reaction conditions, good reproducibility and high yield.

Owner:XIAMEN UNIV

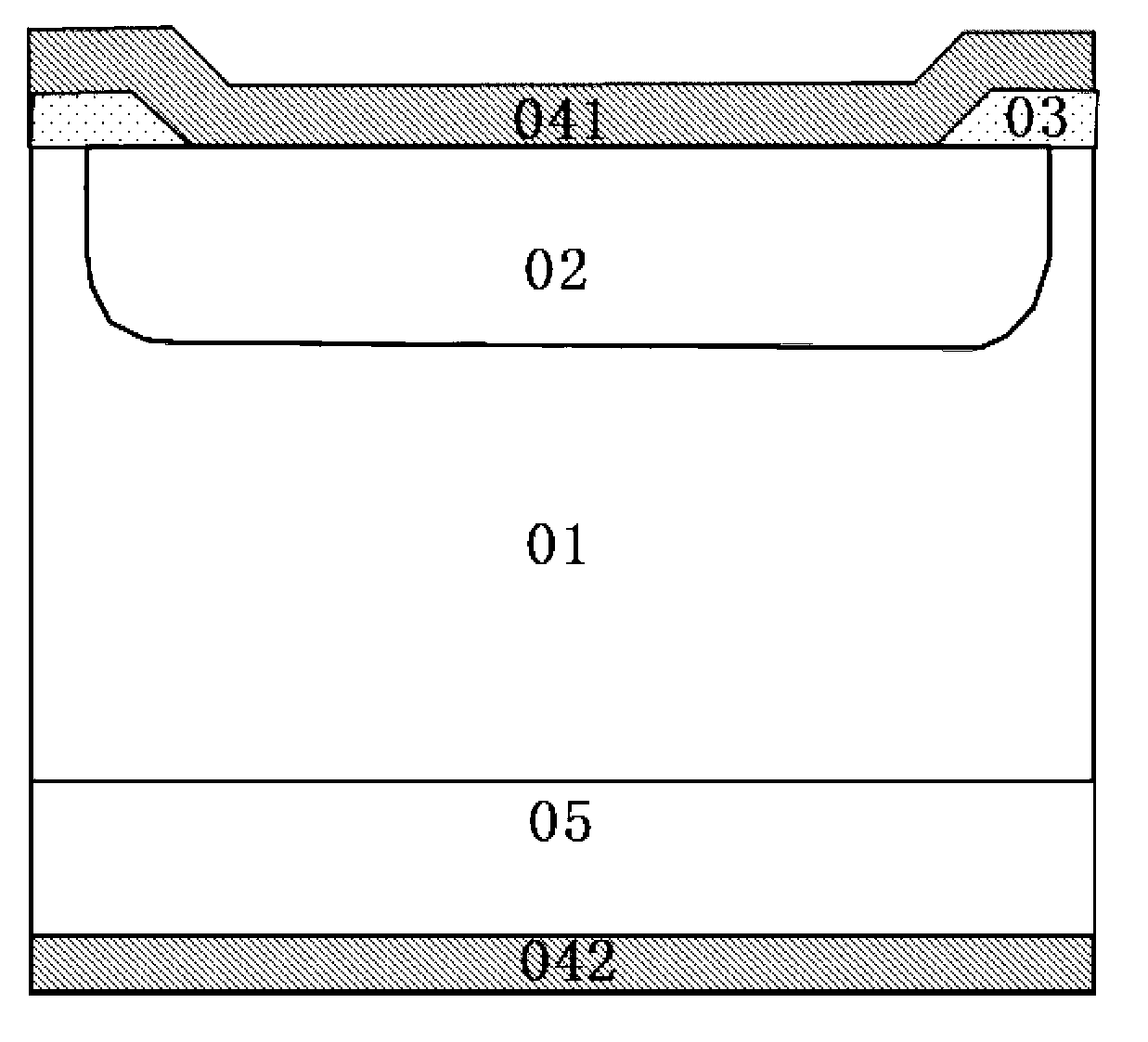

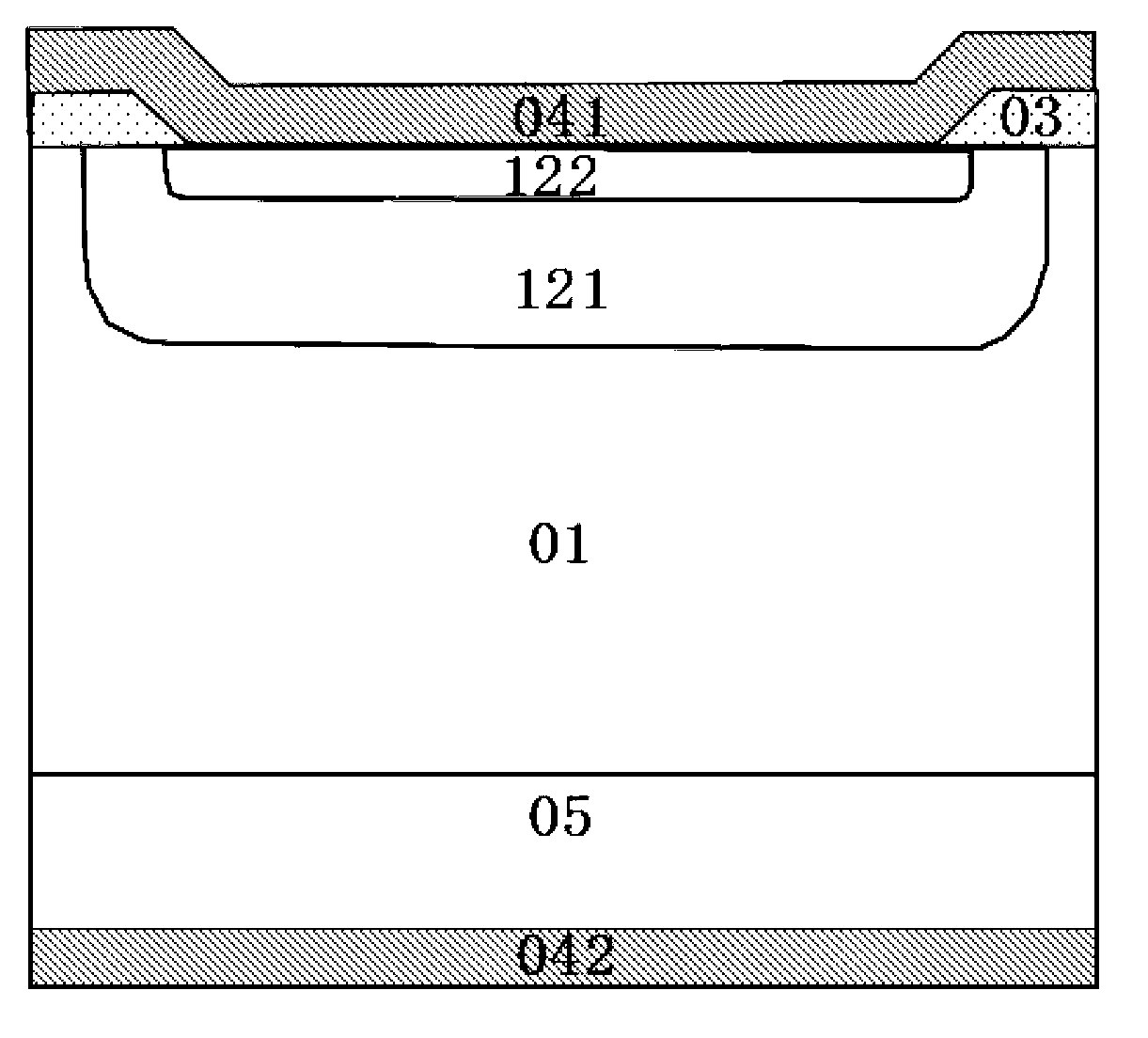

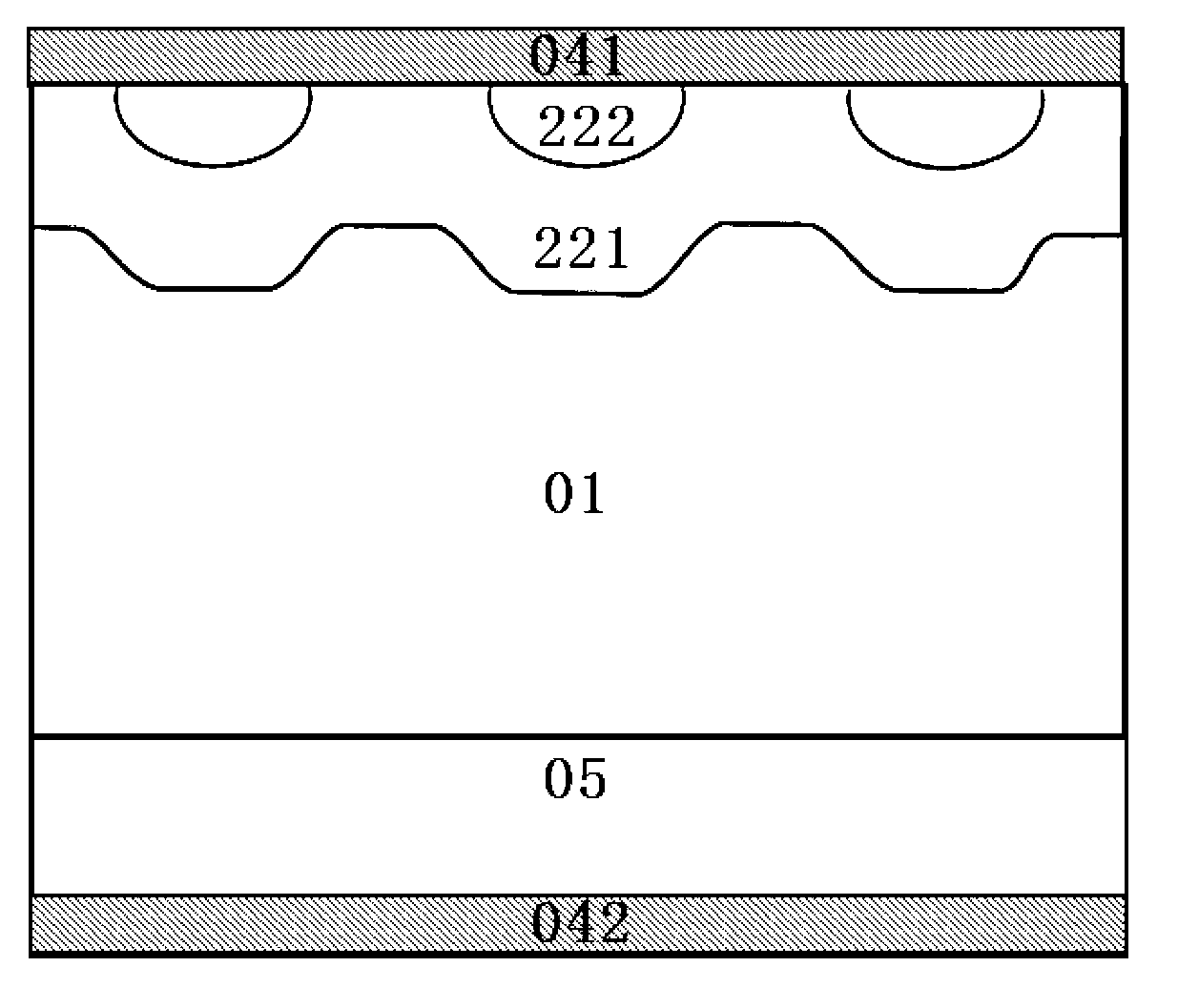

Fast recovery diode and manufacturing method thereof

ActiveCN103022154AReduce shockImprove safe work areaSemiconductor/solid-state device manufacturingSemiconductor devicesReverse recoveryIntrinsics

The invention discloses a fast recovery diode and a manufacturing method of the fast recovery diode. The diode disclosed by the invention comprises an anodic diffusion P-type doped region, an evenly-doped intrinsic region, a cathodic diffusion N-type region, anode and cathode metal layers, wherein the anodic diffusion P-type doped region is a P-type doped region provided with alternated high and low concentrations and formed by locally pouring through a mask plate. Compared with the prior art, the diode disclosed by the invention has the characteristics of low inverse peak current IRRM, short reverse recovery time trr and high reverse recovery softness.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

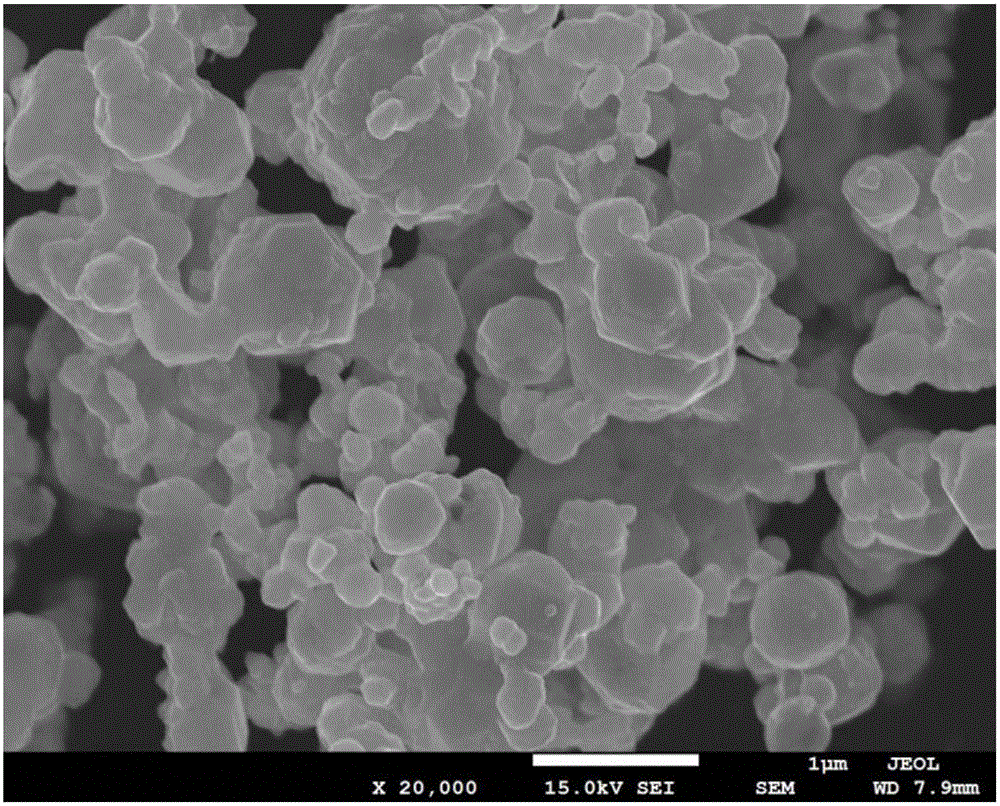

Preparing method of antioxidant silvering copper powder

InactiveCN106086837AImprove stabilityImprove the problem of too fast releaseTransportation and packagingMetal-working apparatusSilver plateAmmonium hydroxide

The invention relates to a preparing method of antioxidant silvering copper powder. Sodium hypophosphite is adopted to serve as a reducing agent, deionized water is adopted to serve as a solvent, sodium hypophosphite reduction liquid is prepared, copper powder is adopted to serve as a base material to be added into the reduction liquid, PVP is added, ammonium hydroxide is added to adjust the pH value, and the pH value is stabilized to 11; silver nitrate serves as a silver source, the deionized water serve as a solvent to prepare oxidation liquid, an EDTA-2Na complexing agent is added, stability of plating liquid is improved, and the problem that in the silvering process, silver ions are released too fast is obviously solved; solutions are mixed, meanwhile, magnetic stirring is carried out, the adding temperature is kept to range from 30 DEG C to 80 DEG C, reaction is carried out for 20 min, centrifuging is carried out, and one-time-silvering copper powder is obtained; the one-time-silvering copper powder serves as the base material, the above steps are repeated twice, and third-time-silvering copper powder is obtained. High-temperature oxidation resistance of silver plated copper powder prepared through the method is excellent, and the method is suitable for replacing conductive phase silver powder of electronic paste.

Owner:JINLING INST OF TECH

Reducing roasting method for powdered iron ores in tunnel kiln

The invention discloses a reducing roasting method for powdered iron ores in a tunnel kiln, which is designed for solving the problems of low heat transfer efficiency, long reducing time, non-uniform material reduction quality, and the like when powdered iron ores are subjected to reducing roasting in a tunnel kiln. According to the invention, by reasonably selecting the particle size range and distribution of iron ores, iron ores with different particle sizes and reducing coal are mixed and distributed in layers, and then the obtained object is subjected to reducing roasting, so that the iron ores with different particle sizes achieve a same roasting effect, thereby increasing the metal recovery rate of roasted iron ores, improving the quality of roasting, shortening the roasting time, reducing the roasting temperature, and lowering the production cost.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

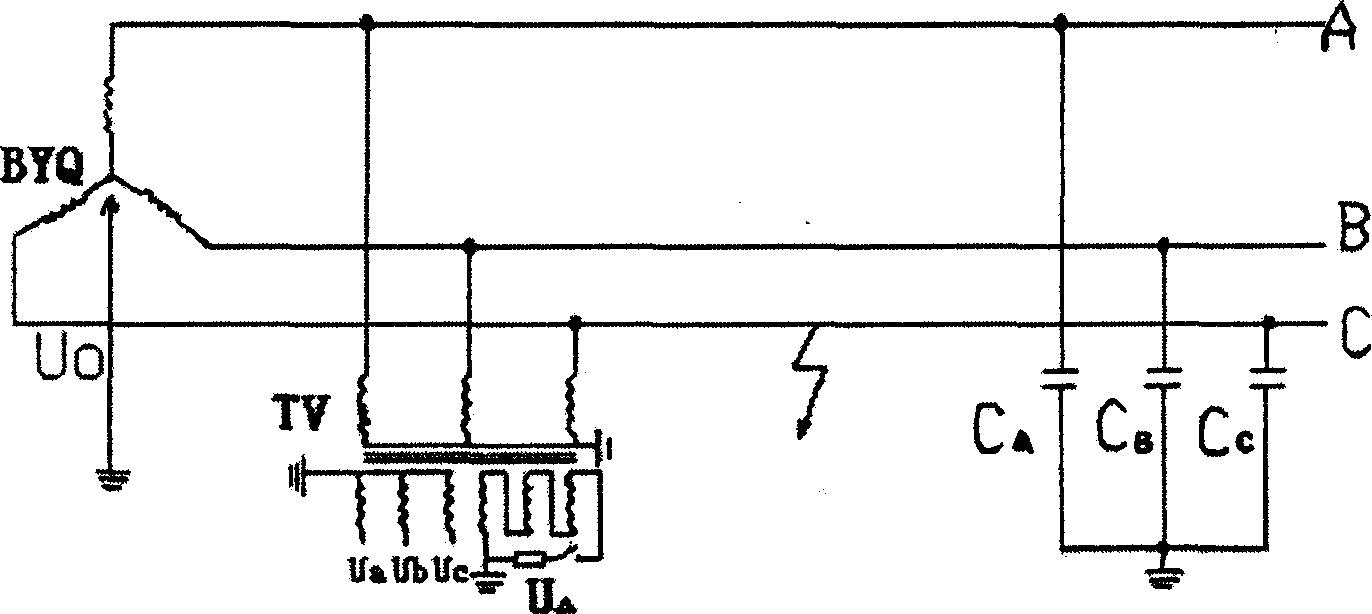

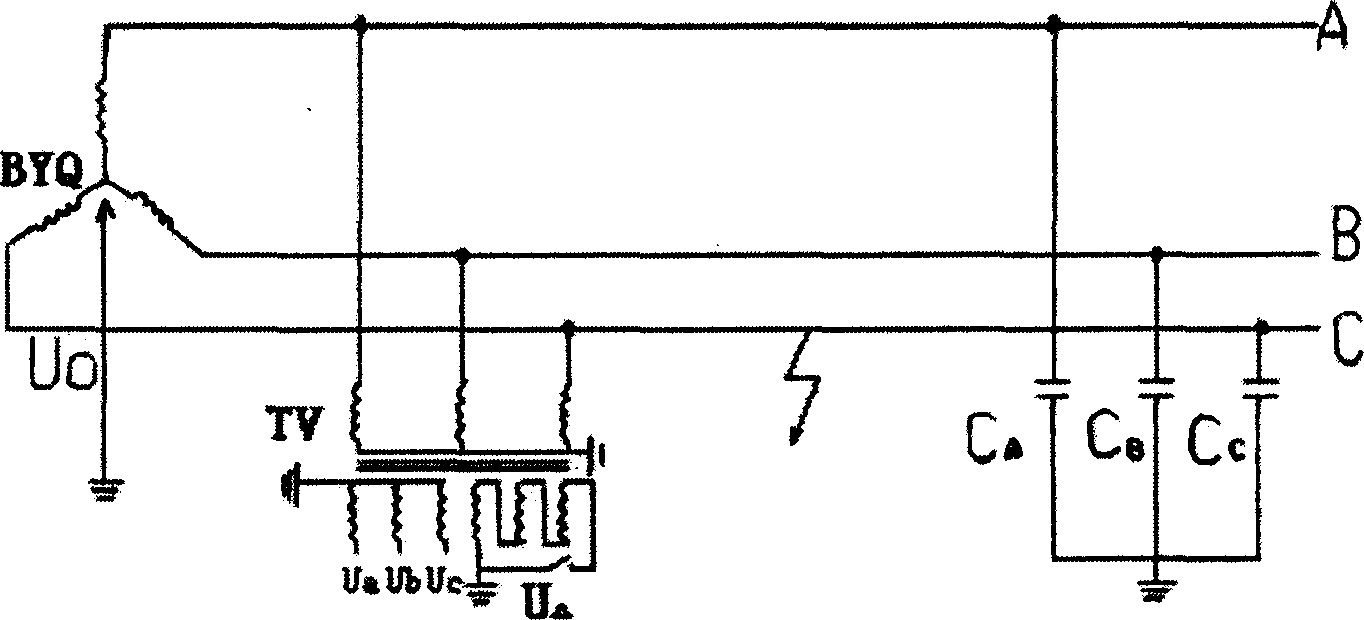

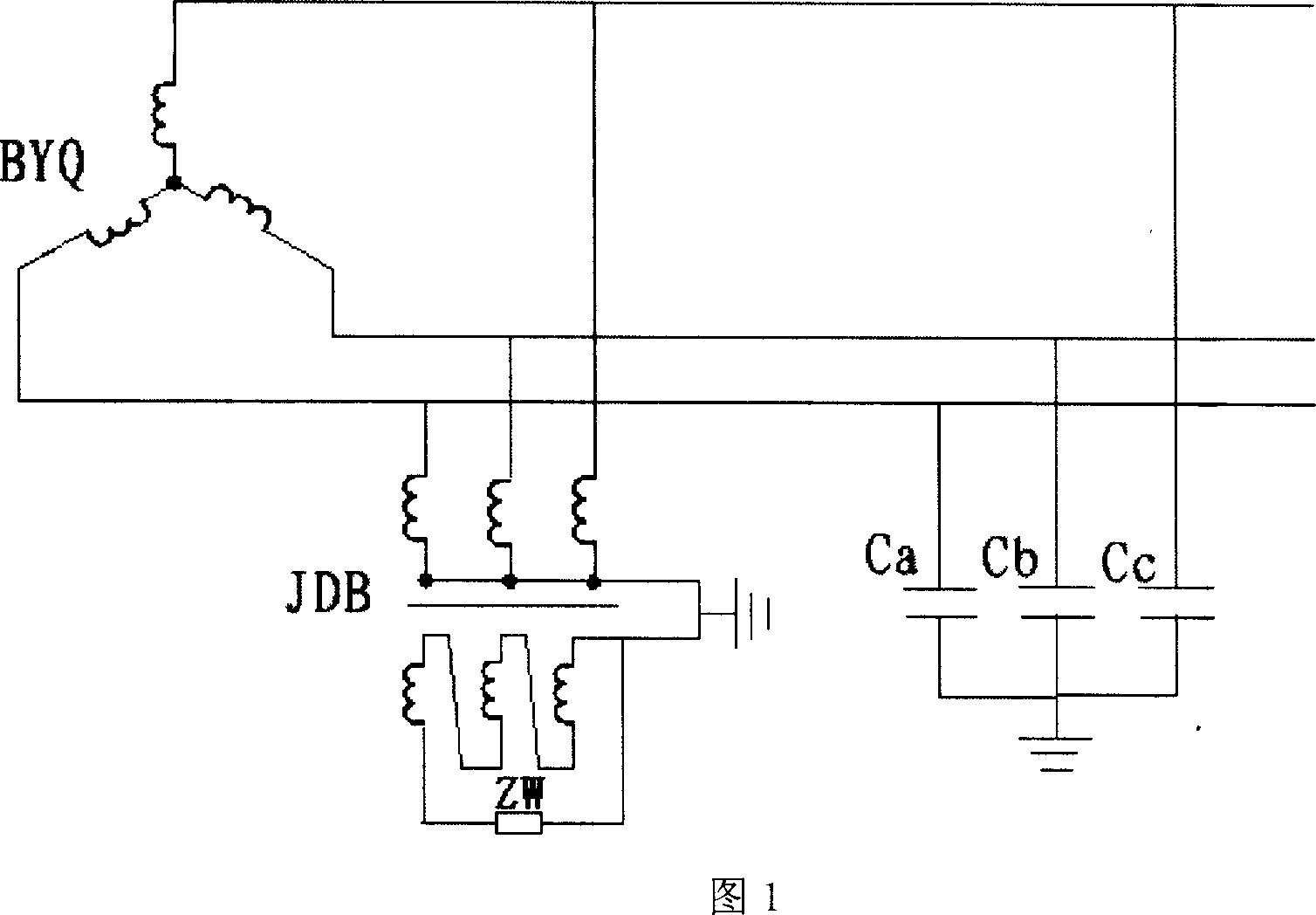

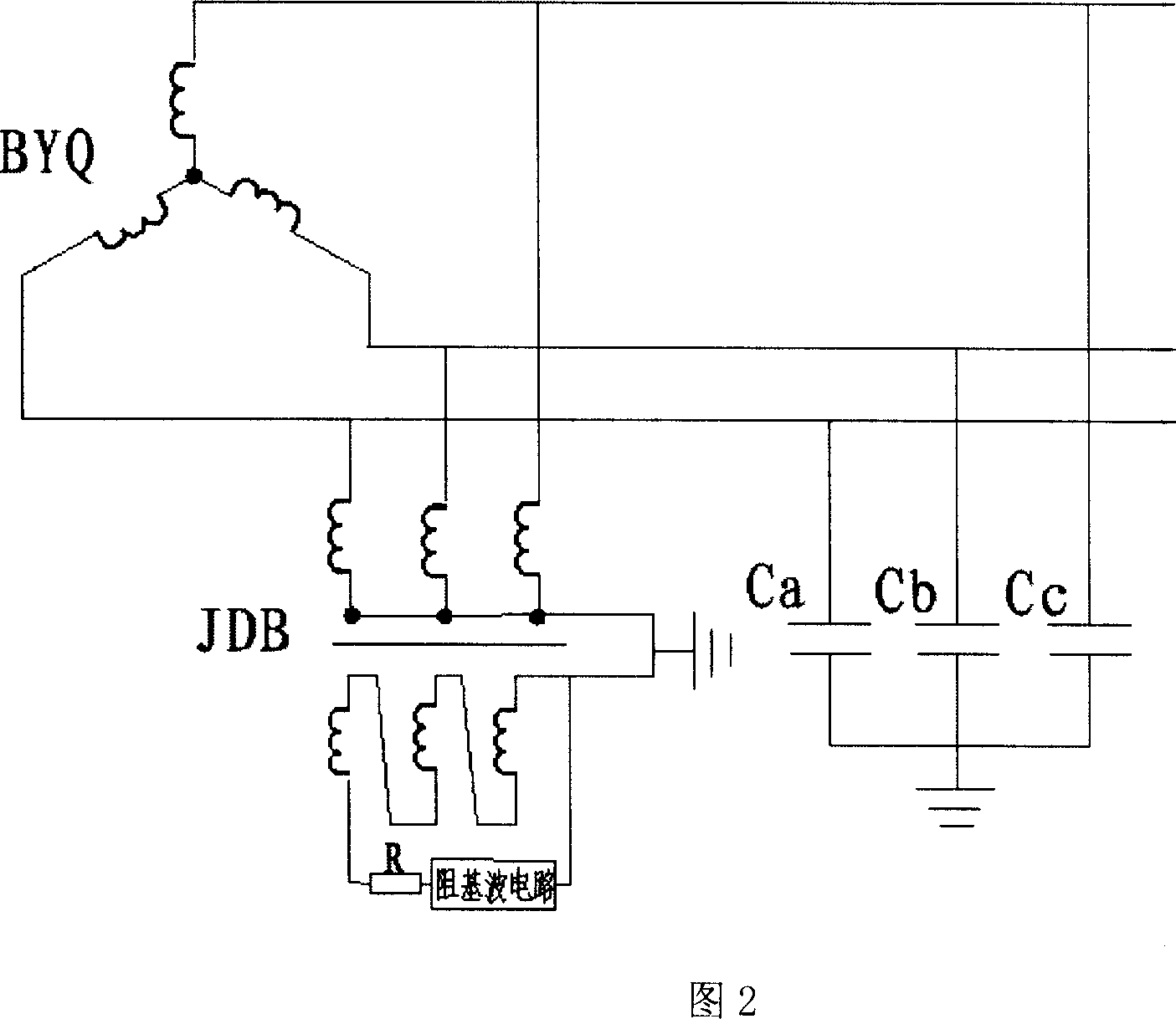

Power transmission and distribution system of leakage for earth capicitance storage charge and system control method

ActiveCN1913271AAvoid ferroresonanceDelayed recoveryTransformers/inductances coils/windings/connectionsElectric component structural associationSingle phaseCapacitance

This invention relates to a transmission and distribution system releasing earth capacitor storage charges and a system control method characterizing in setting a releasing transformer in the system, in which, the three phase winding of the secondary side is connected end to end in series, an open-end is set between any adjacent two windings to form a releasing channel by bridging resistor elements at the two ends of the open-end or short-connecting the open-end directly to form a triangle connection of the secondary side, which provides a releasing channel to charges stored to the earth capacitor when the earth system of small current is faulty in earth to prevent from generating over voltage and ferro-resoanace induced in the resuming process of the earth voltage of the faulty phase and sanity phase.

Owner:合肥溢鑫电力科技有限公司

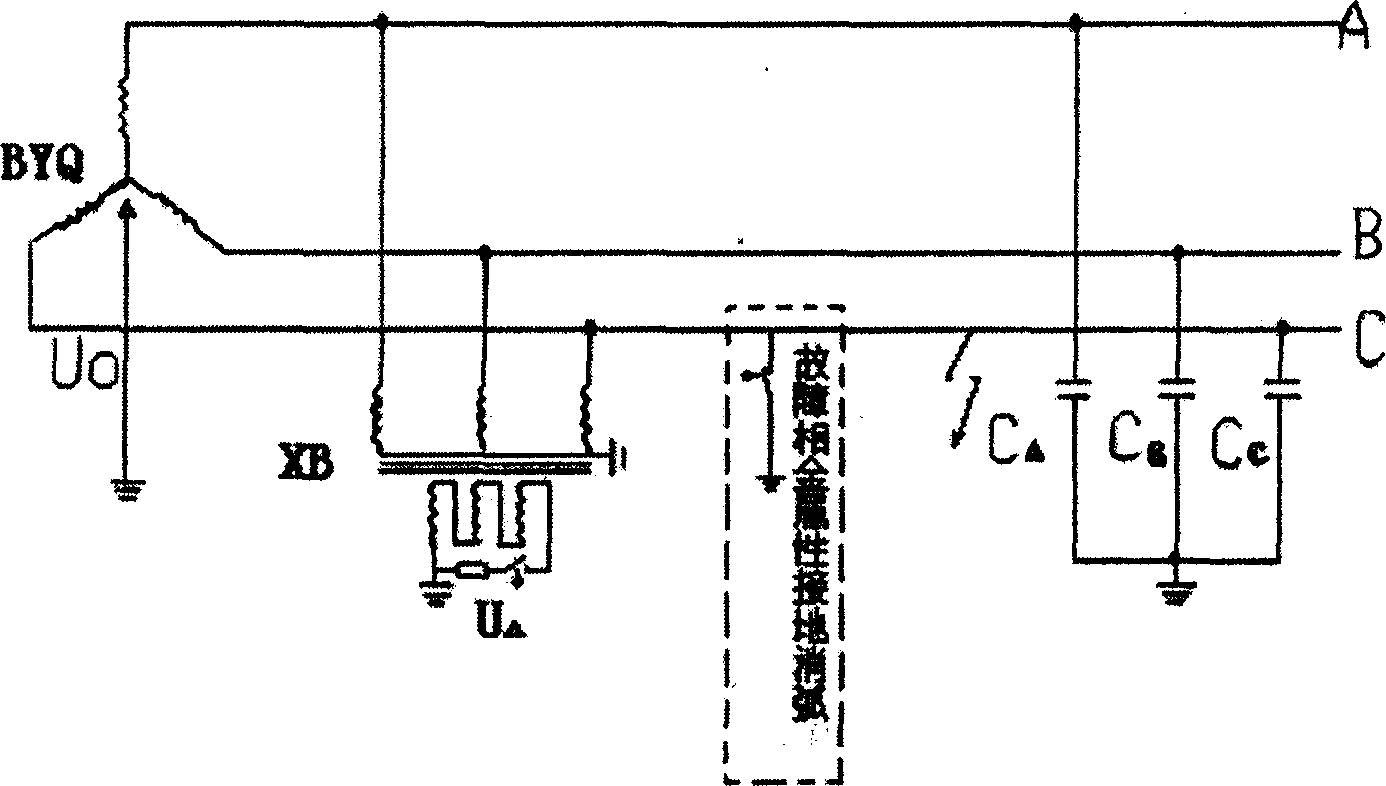

Automatically recovery long ruler

Owner:NINGBO GREAT WALL PRECISION INDAL

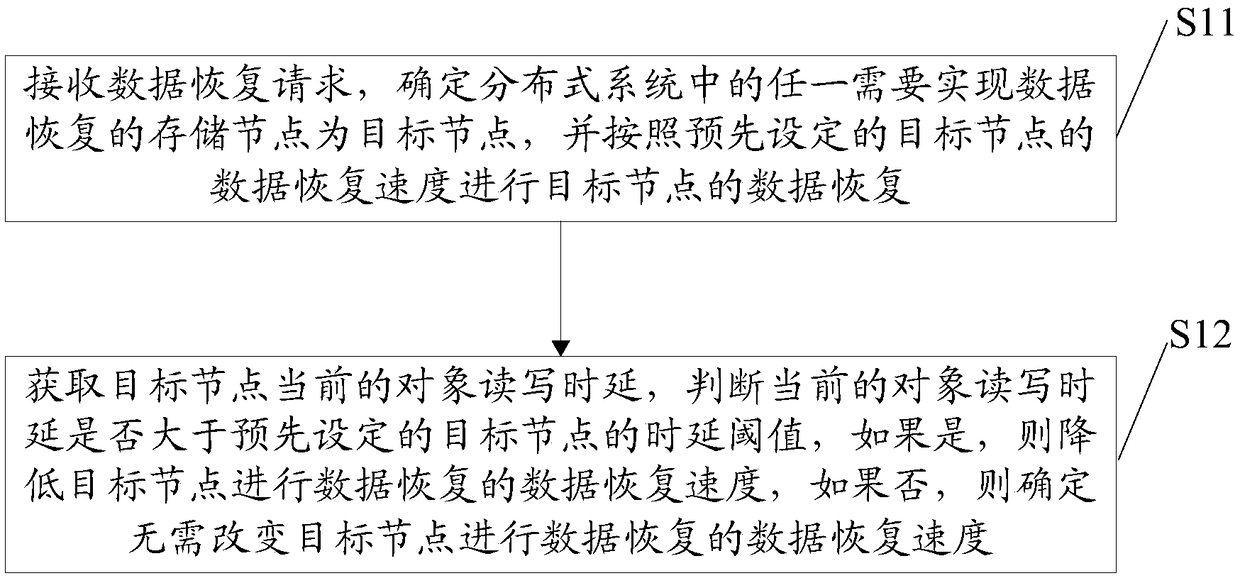

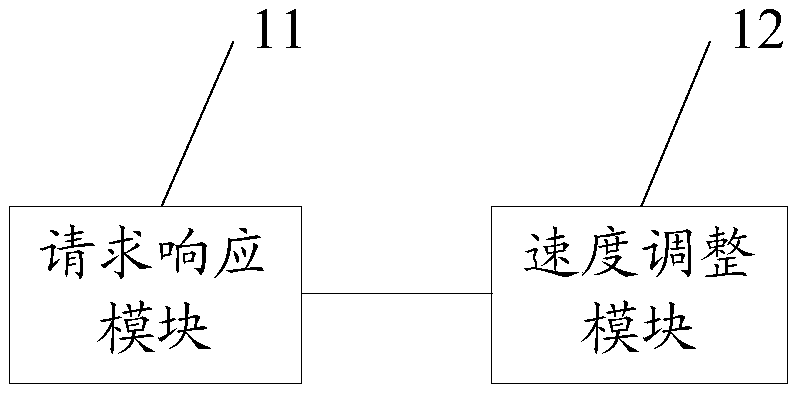

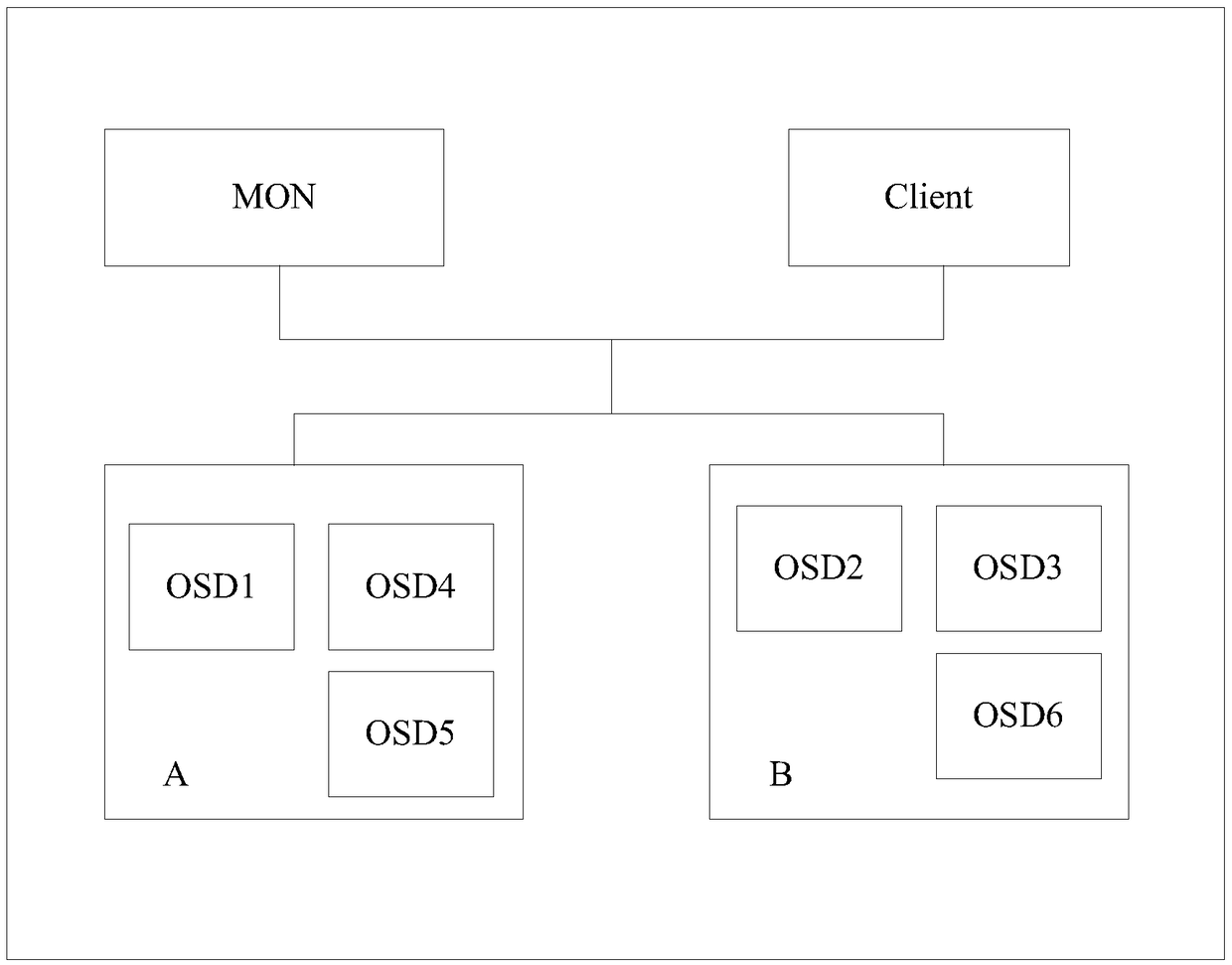

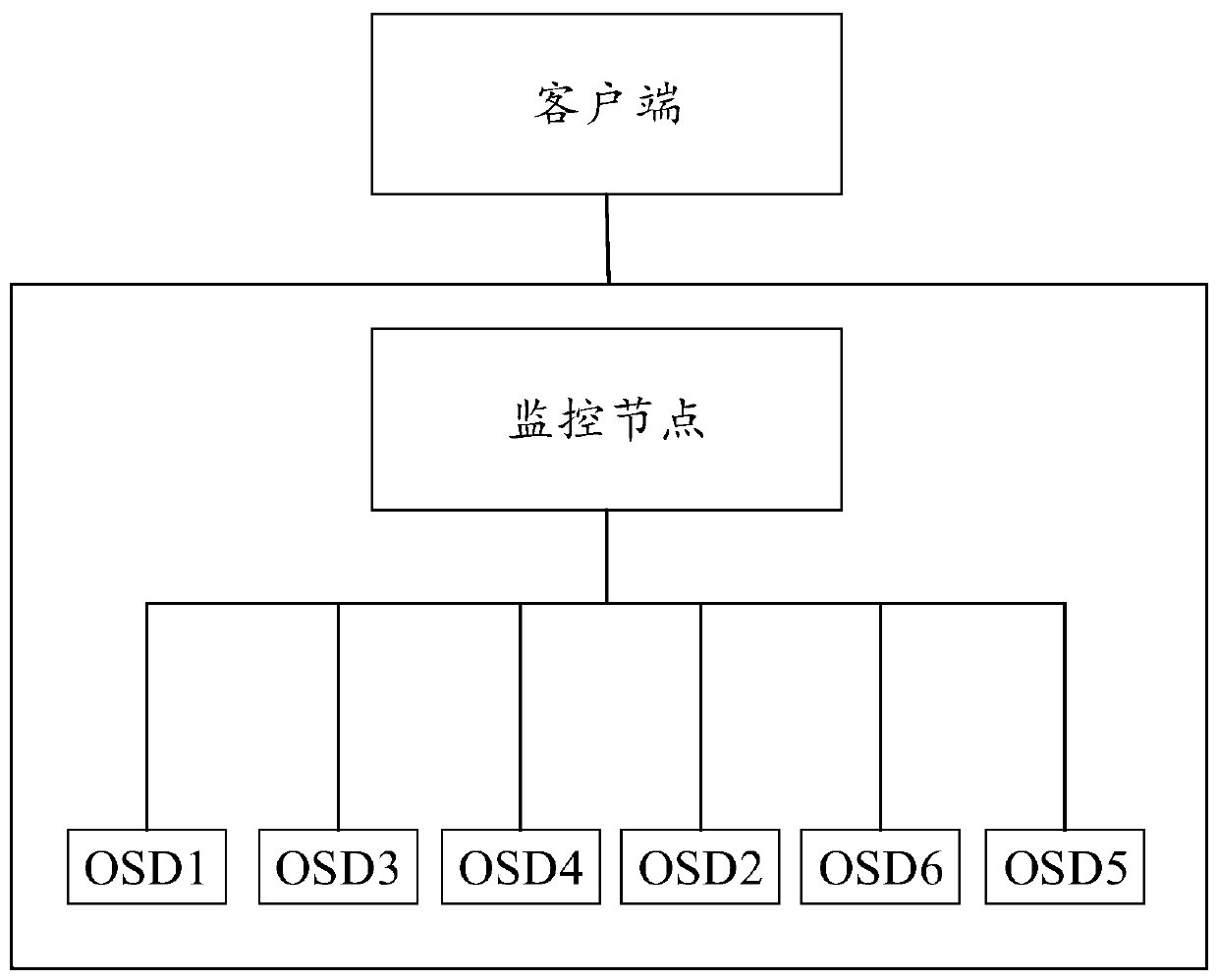

Method and apparatus for adjusting data recovery speed based on object read/write delay

InactiveCN109117306ASlow down recoveryNo need to change adverse effectsRedundant operation error correctionTime delaysData access

The invention discloses a method, a device, an apparatus and a computer readable storage medium for adjusting data recovery speed based on object read / write time delay. The method comprises the following steps: receiving a data recovery request, determining any storage node in a distributed system that needs to realize data recovery as a target node, and performing data recovery of the target nodeaccording to a preset data recovery speed of the target node; and performing data recovery of the target node according to the preset data recovery speed of the target node; obtaining the current object read / write delay of the target node, judging whether the current object read / write delay is greater than the preset delay threshold of the target node, if so, decreasing the data recovery speed ofthe target node for data recovery, if not, determining that the data recovery speed of the target node for data recovery does not need to be changed. As a result, when the data restoration has adverse effects on the data access service, the speed of the data restoration is reduced to ensure the normal data access service, and when the data restoration has no adverse effects on the data access service, the fast data restoration is realized.

Owner:GUANGDONG INSPUR BIG DATA RES CO LTD

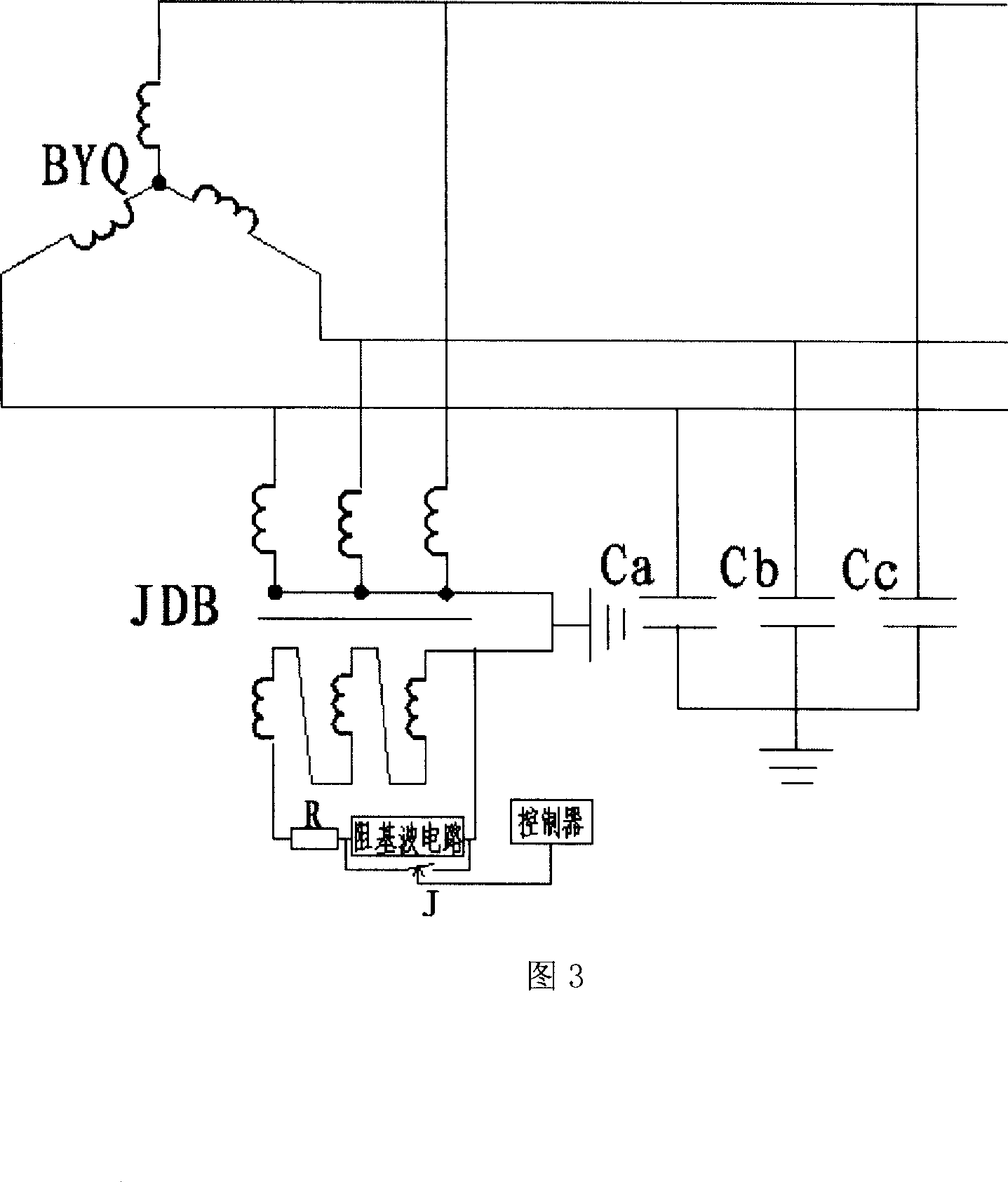

Virtual grounding power transmission and distribution system

InactiveCN101055989AMaintain propertiesProtection insulation safetyTransformers/inductances coils/windings/connectionsEmergency protective arrangements for limiting excess voltage/currentElectric power transmissionCapacitance

A virtual grounding transmission and distribution system is charactered in that a virtual grounding transformer is set up in the system. Three phases of its primary side are respectively connected in the corresponding lines of the system; the three phases of the secondary side are connected in series, wherein openings are disposed between any one of those neighboring two-phase windings; the formation of the virtual grounding is by bridging impedance at both ends of the openings, or directly shorts the openings to form a triangle connection at the secondary side of the virtual grounding transformer. The invention provides a virtual grounding manner for a neutral point non-grounding system, which can quickly consume the charge stored in the capacitance relative to the grounding, thus effectively preventing the over-voltage in the restoration process of the fault phase and the sound phase to a normal grounding voltage, preventing the ferromagnetic resonant, while at the same time delaying the restoration speed of the fault voltage relative to grounding, which is propitious to not re-ignite.

Owner:张云一

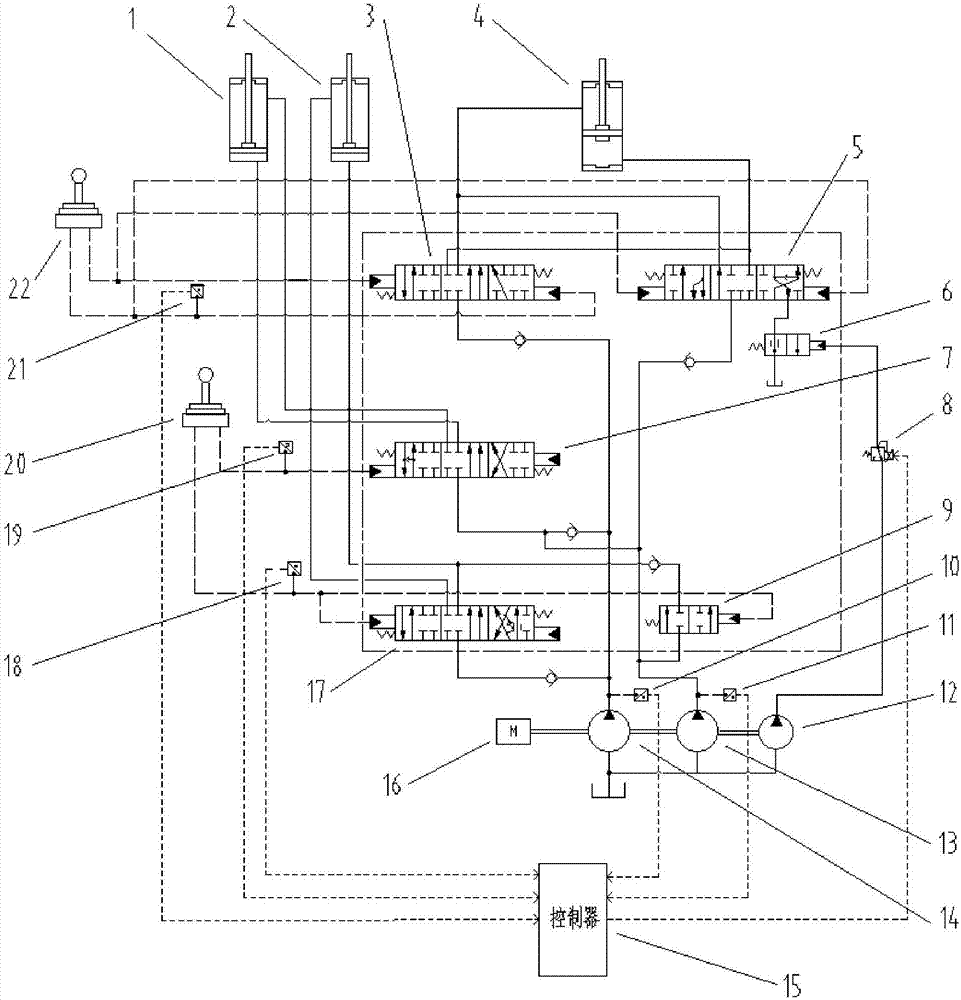

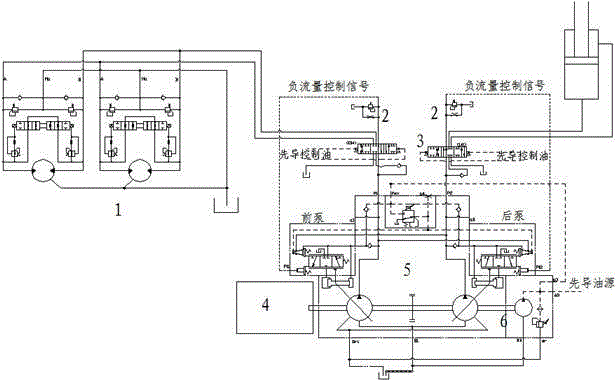

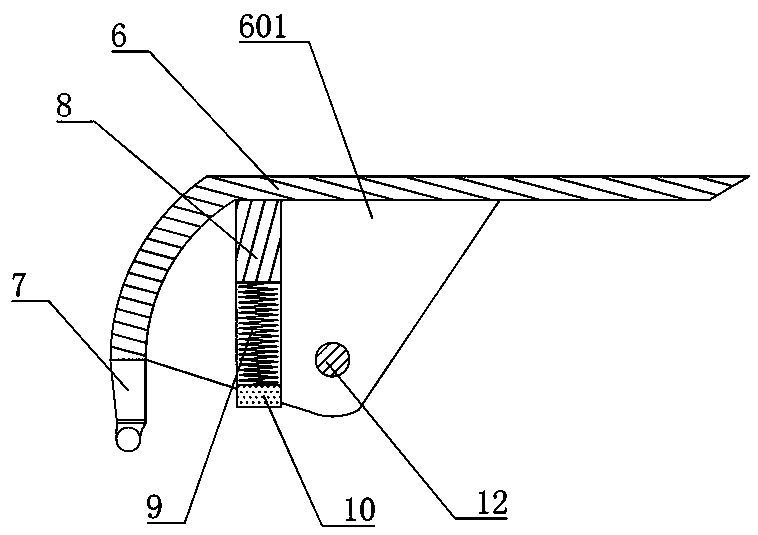

Hydraulic control method and control system for excavator

ActiveCN107882100ASlow down recoveryImprove motor coordinationSoil-shifting machines/dredgersControl systemControl valves

The invention relates to a hydraulic system of an excavator. In order to solve the problem that an existing excavator has a nodding phenomenon during working on a flat ground, the invention provides ahydraulic control method for the excavator. A bucket rod regeneration control valve is arranged on an oil return oil path of a bucket rod control valve of the excavator; and when the excavator is ina state of working on the flat ground, the opening degree of a valve port of the bucket rod regeneration control valve is controlled to meet the requirement that the opening degree of the valve port of the bucket rod regeneration control valve at the initial stage of bucket rod recycling is greater than that of the valve port of the bucket rod regeneration control valve at the later stage of bucket rod recycling. According to the hydraulic control method for the excavator, when the excavator is in the state of working on the flat ground, the opening degree of the valve port of the bucket rod regeneration control valve is controlled to meet the requirement that the opening degree of the valve port of the bucket rod regeneration control valve at the initial stage of bucket rod recycling is greater than that of the valve port of the bucket rod regeneration control valve at the later stage of bucket rod recycling, so that the bucket rod regeneration amount can be adjusted to achieve effects of slowing down the bucket rod recycling, improving the harmoniousness of operation and eliminating the nodding phenomenon on the flat ground.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

Al-Si alloy preplating bi-coordinating agent acidic zinc dipping solution and preparation method thereof

The invention provides Al-Si alloy preplating bi-coordinating agent acidic zinc dipping solution and a preparation method thereof. The solution is characterized in that: the solution is prepared from 90 to 110g / L of zinc chloride, 10 to 30g / L of sodium citrate, 15 to 30g / L of ammonium bifluoride, 20 to 30g / L of boric acid, 15 to 20g / L of thiocarbamide, 1.5 to 2g / L of sodium dodecyl sulfate, 0.2 to 0.5 mL / L of 30 percent hydrogen peroxide, 1 to 3g / L of activated carbon and distilled water. The zinc chloride is taken as major salt, the sodium citrate and the ammonium bifluoride are taken as double coordinating agents, the boric acid is taken as a buffering agent and pH modifier, the thiocarbamide is taken as a hydrogen inhibitor, and the sodium dodecyl sulfate is taken as a wetting agent. Compared with other methods, the method of the invention has the advantages of simple process, easy control, low cost, little corrosion to a Al-Si alloy substrate, and quite good shape, evenness, density and coverage of zinc grains. The coordinating agents do not contain cyanides, which is beneficial to the environmental protection and the good health of operators, and can realize green production.

Owner:HARBIN ENG UNIV

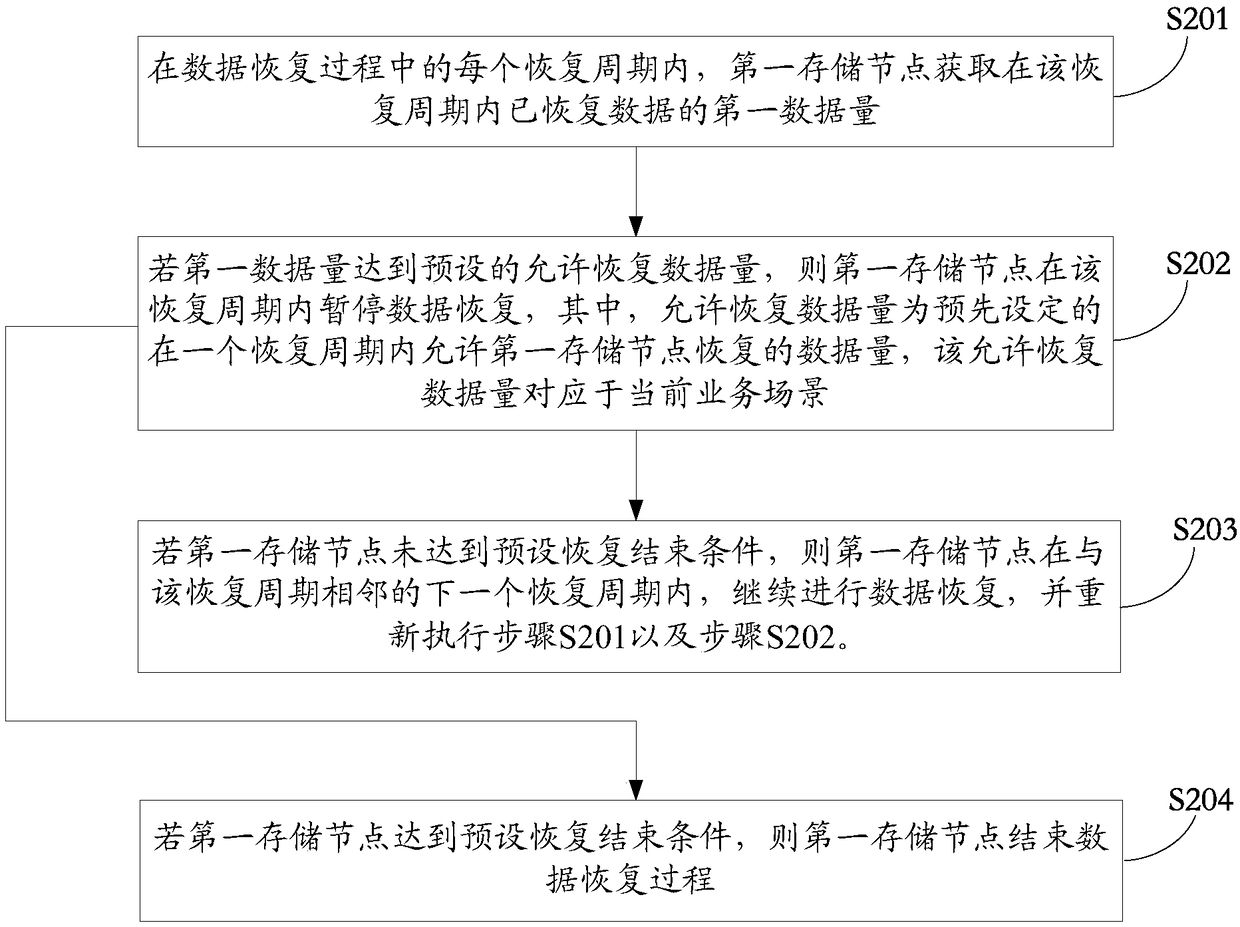

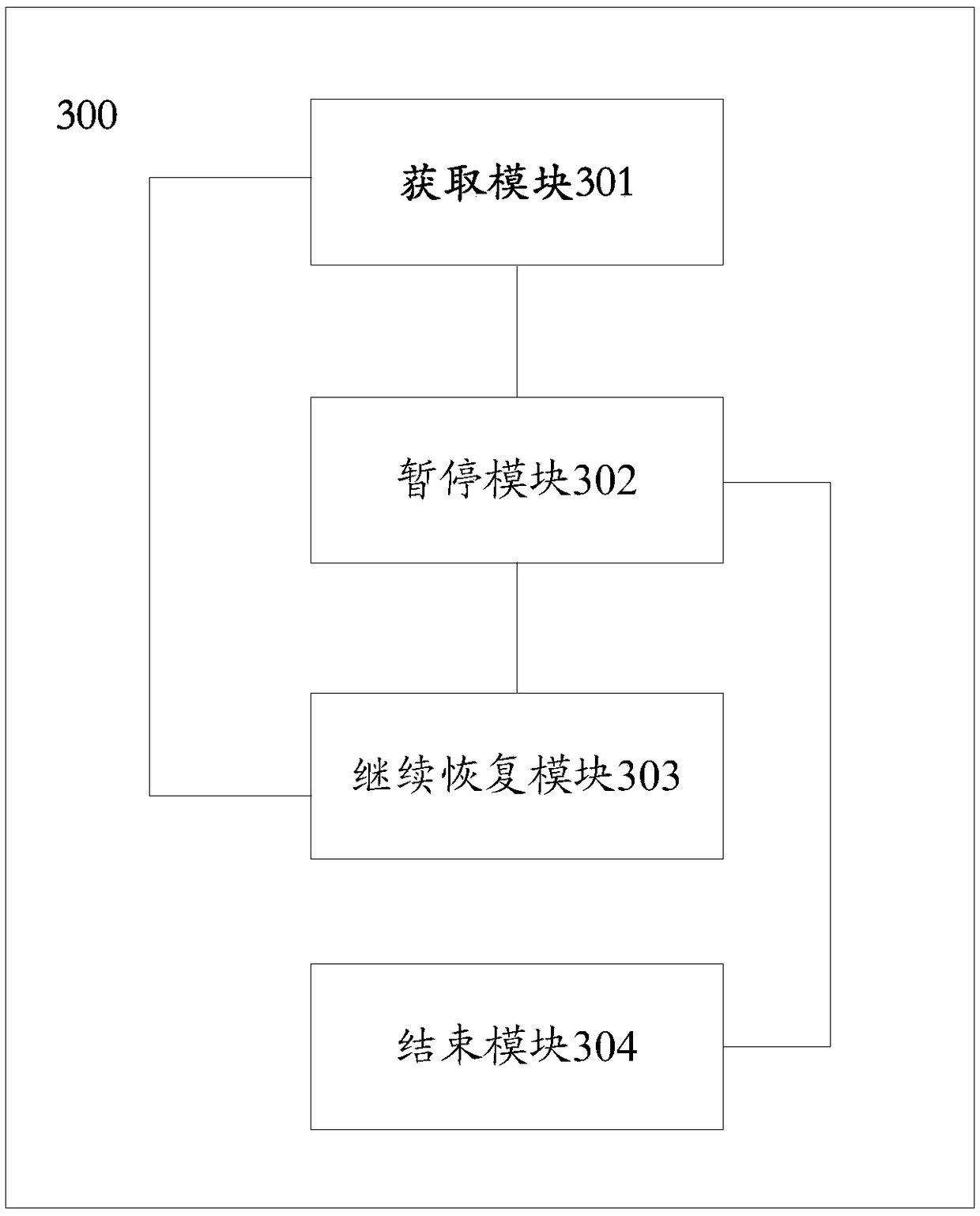

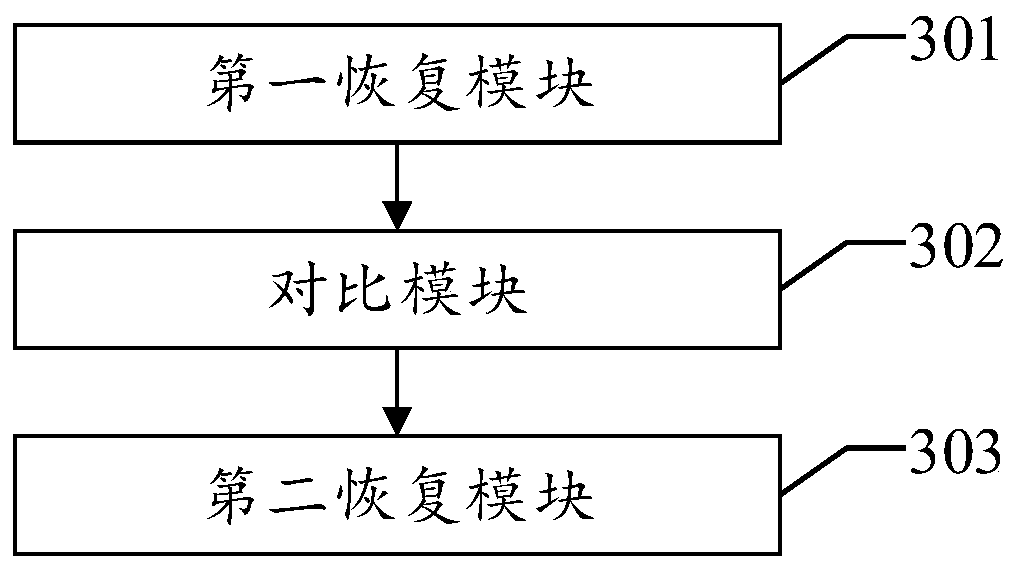

A method and apparatus for data recovery

ActiveCN109144782ARecovery speed limitSlow down recoveryRedundant operation error correctionSoftware engineeringData recovery

The invention discloses a method and apparatus for data recovery, the method including: during each recovery cycle of the data recovery process, the first storage node obtains the first data amount ofthe recovered data, it is judged whether it reaches the preset allowable recovered data amount, and if so, the data recovery pauses, wherein the allowable data amount corresponds to the current business scenario, and the allowable recovered data amount is the preset data amount allowed to be recovered in a recovery cycle; it is judged whether the first storage node reaches the preset recovery completion condition or not, if the preset recovery end condition is not reached, the data recovery is continued in the next recovery cycle adjacent to the recovery cycle, and the above steps are executed again, and if the preset recovery end condition is reached, the data recovery process is ended. Visible, in the data recovery, for the current business scenario, the data recovery speed of the firststorage node is limited, so that the impact of the data recovery process on user traffic can be reduced as much as possible.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Arc-extinguishing voltage limiting device based on electronic switch

InactiveCN102457058AQuick releaseSlow down recoveryEmergency protective arrangements for limiting excess voltage/currentContactorElectric arc

The invention discloses an arc-extinguishing voltage limiting device based on an electronic switch, belonging to the technical field of a power distribution network. The device comprises a high voltage isolation electronic switch, a controllable combined voltage limiter, a voltage sensor and a microcomputer controller, wherein the high voltage isolation electronic switch consists of a switching transformer and an electronic control switch; the controllable combined voltage limiter consists of a zinc oxide non-liner resistor and a quick vacuum contactor; a primary of the switching transformer is connected with the primary of the voltage sensor in parallel, then connected with the controllable combined voltage limiter in parallel and connected between a system bus and the ground; a secondary of the switching transformer is connected with a turn-off quick thyristor by a rectification circuit; the control end of the quick thyristor is connected with the control output end of the microcomputer controller; and the input end of the microcomputer controller is connected with the secondary of the voltage sensor. The arc-extinguishing voltage limiting device is suitable for 6 kV, 10 kV and 35 kV neutral-point non-effectively grounded systems, can effectively inhibit ground arc and different overvoltages of the power system, and has the characteristics of quick action, flexible operation, safety and stability.

Owner:徐成飞

Method for directly reducing nickel containing pig iron by lateritic nickel in tunnel kiln

InactiveCN101638703AImprove heat transfer performanceRestore fastFluidised-bed furnacesTunnel kilnDesiccant

The invention relates to a method for directly reducing nickel containing pig iron by lateritic nickel in a tunnel kiln, which is finished according to the following steps: firstly, adding desiccant into the lateritic nickel which contains adsorbed water, uniformly stirring and mixing for dehydrated desiccation; secondly, crushing the mixture, adding a reducing agent and a pig iron aggregation agent into the mixture, uniformly mixing, delivering the mixture on a tunnel kiln trolley on which an isolating agent is sprayed, and coating a layer of coke powder for carrying out reduction roasting;and thirdly, after reduction roasting, water quenching and cooling, crushing and sorting big iron blocks and small iron slag, self-milling the big iron blocks and the small iron slag in an autogenousmill, thereby leading iron containing pig iron alloy and mineral slag to completely separate to obtain nickel containing pig iron alloy. The invention does not use the traditional reduction jar and has simple production, short reduction time, high yield, convenient operation, energy consumption reduction, low cost and high recovery rate of nickel. The produced nickel containing pig iron can be directly used as high quality raw materials for smelting stainless steel.

Owner:毛黎生 +1

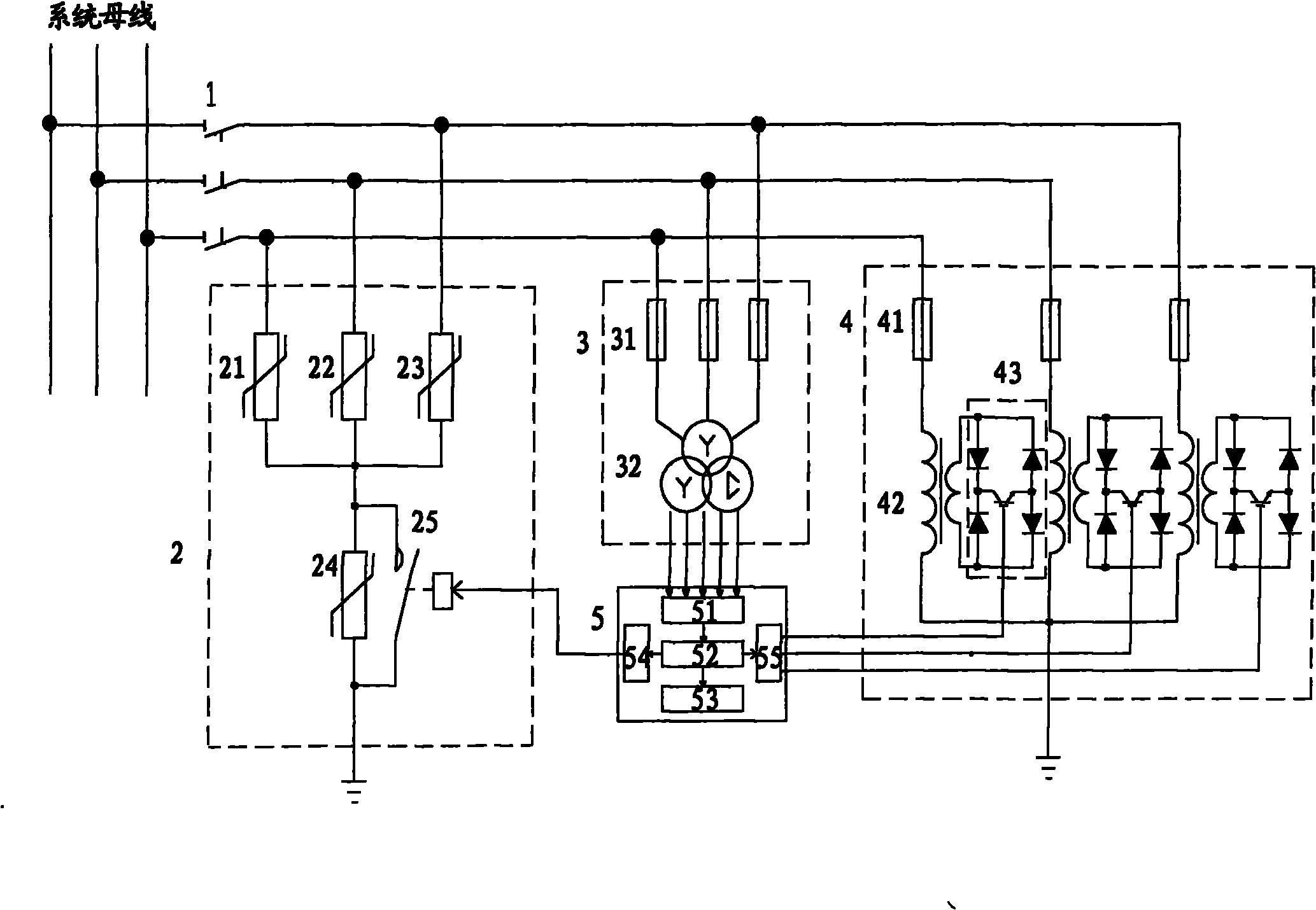

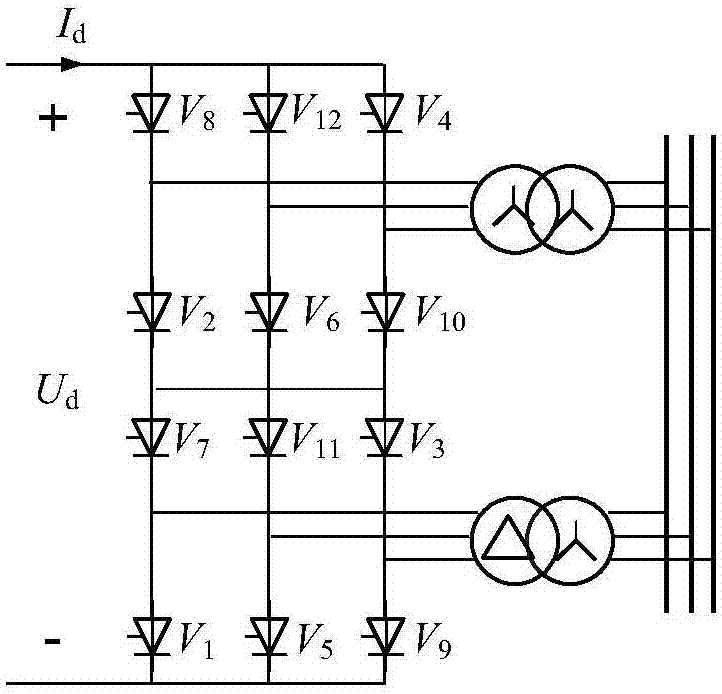

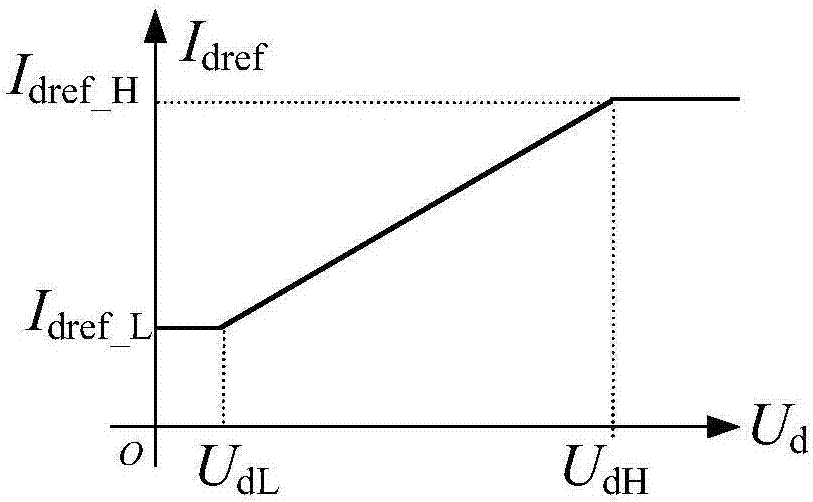

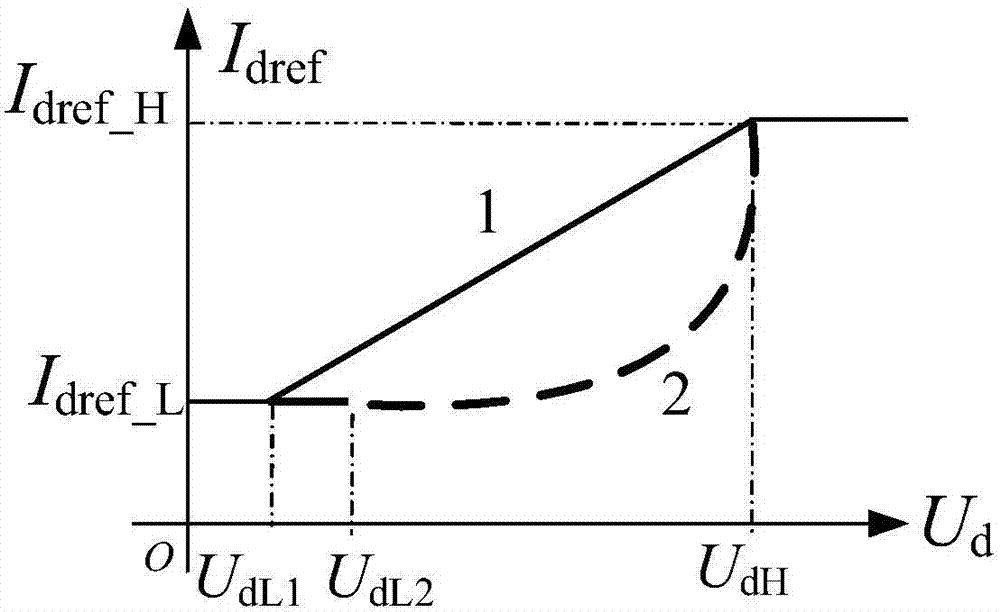

Method for suppressing subsequent phase commutating failure of 12-pulse inverter of thyristor and system thereof

InactiveCN106998075ASmall rate of changeSlow down recoveryElectric power transfer ac networkContigency dealing ac circuit arrangementsCurrent limitingLow voltage

The embodiment of the invention provides a method for suppressing subsequent phase commutating failure of a 12-pulse inverter of a thyristor and a system thereof. The method comprises the steps that compensation voltage is acquired; VDCOL voltage is generated according to the compensation voltage and DC voltage; and the VDCOL voltage is inputted to a high voltage DC power transmission circuit. According to the method, the characteristics of difference changes of DC current in the recovery process of an AC-DC system after fault elimination are fully utilized, the VDCOL voltage is acquired firstly, and then the VDCOL voltage is inputted to the high voltage DC power transmission circuit to be led into low voltage current limiting control (VDCOL). The degree of influence on the DC current is the highest, the change rate of the DC current is the highest and the VDCOL voltage is the lowest at the moment of fault elimination, and the recovery rate of the DC current is correspondingly limited at the low level and the recovery speed of the DC power can be reduced so that reactive power consumption of a current converter can be reduced, the receiving end power grid is enabled to recover the voltage support capacity and the probability of subsequent phase commutating failure of the 12-pulse inverter can be reduced.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

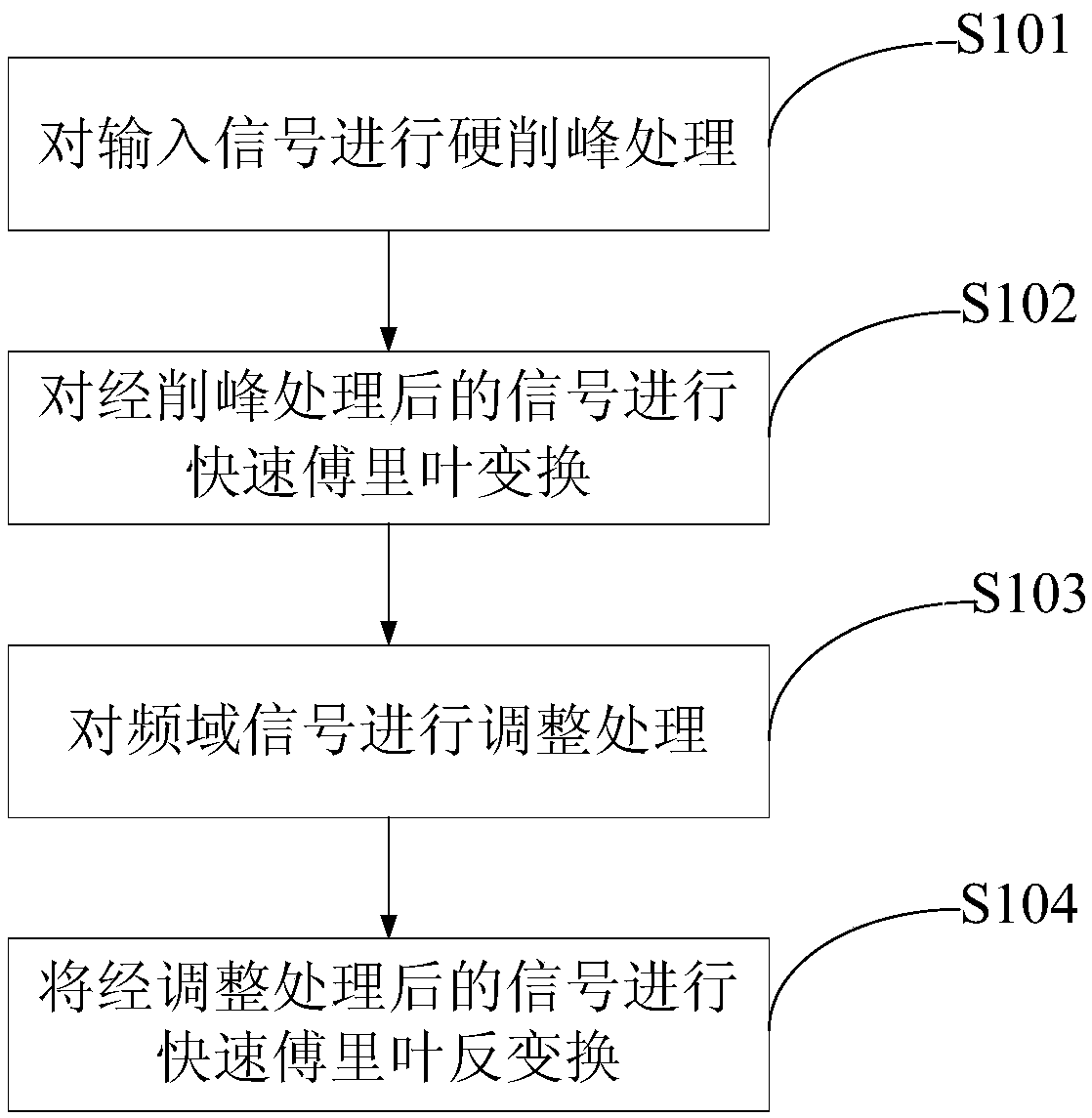

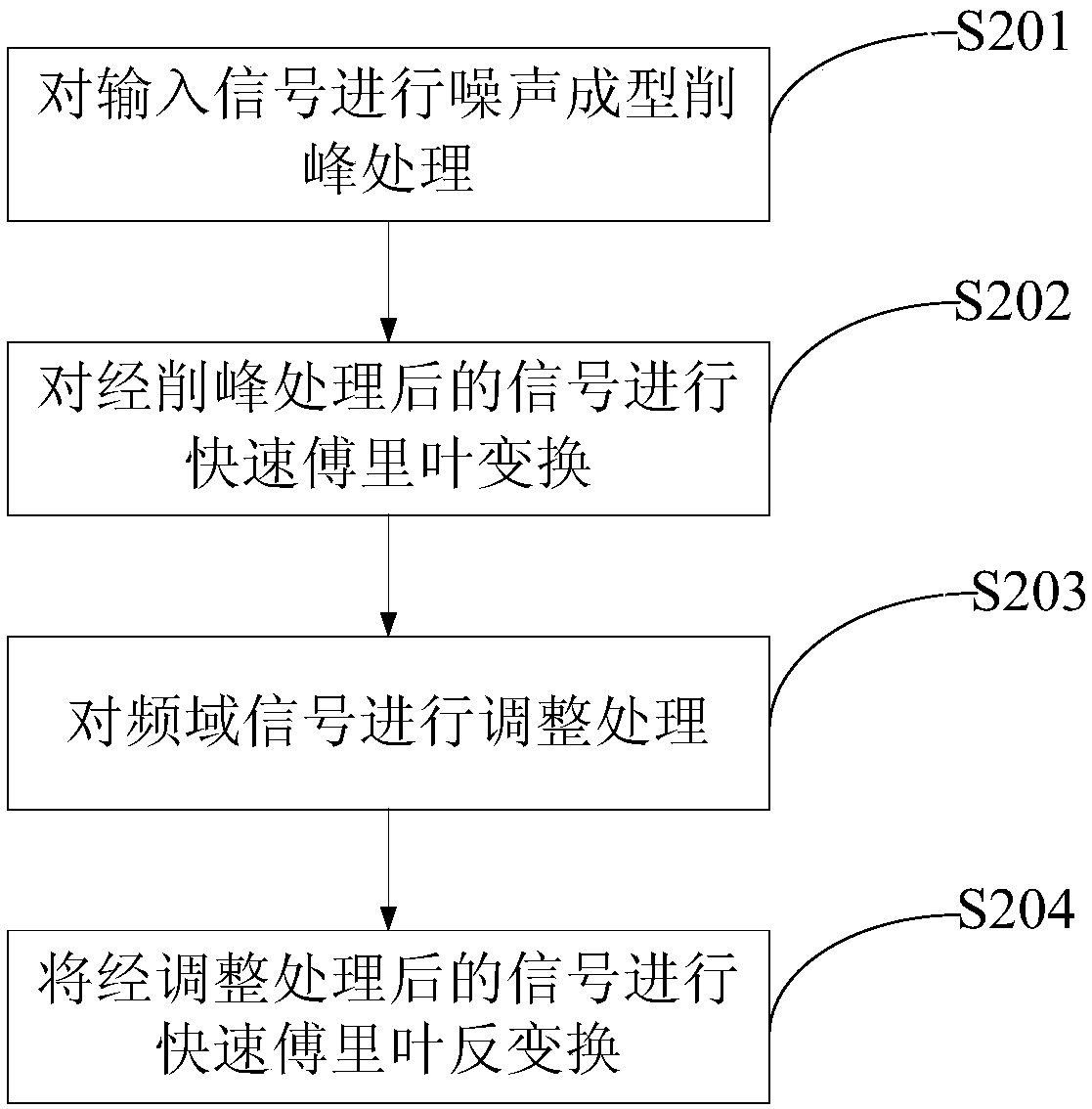

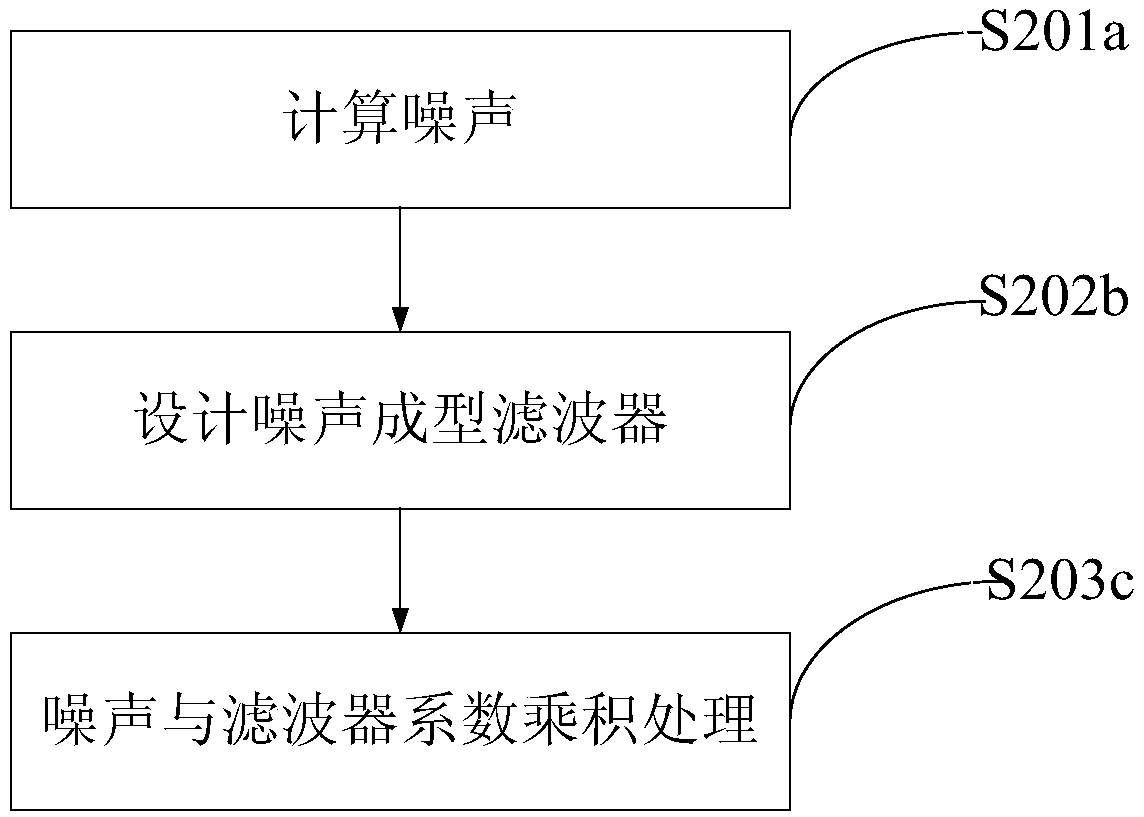

Method and device for reducing signal peak-to-average ratio based on frequency domain processing

PendingCN110891037AEffective regulationSlow down recoveryMulti-frequency code systemsFast Fourier transformTime domain

The invention provides a method and a device for reducing a signal peak-to-average ratio based on frequency domain processing. The method comprises the following steps: performing peak clipping processing on an input signal, converting the signal subjected to peak clipping processing from a time domain to a frequency domain through fast Fourier transform, performing in-band and out-band processingon the signal in the frequency domain respectively, and converting the peak clipping signal into the time domain through inverse fast Fourier transform on the signal subjected to in-band and out-bandprocessing, thereby obtaining a peak clipping signal. The peak-to-average ratio of the signal is reduced in the frequency domain, the error vector amplitude can be controlled, and the requirement ofthe adjacent channel power leakage ratio is considered.

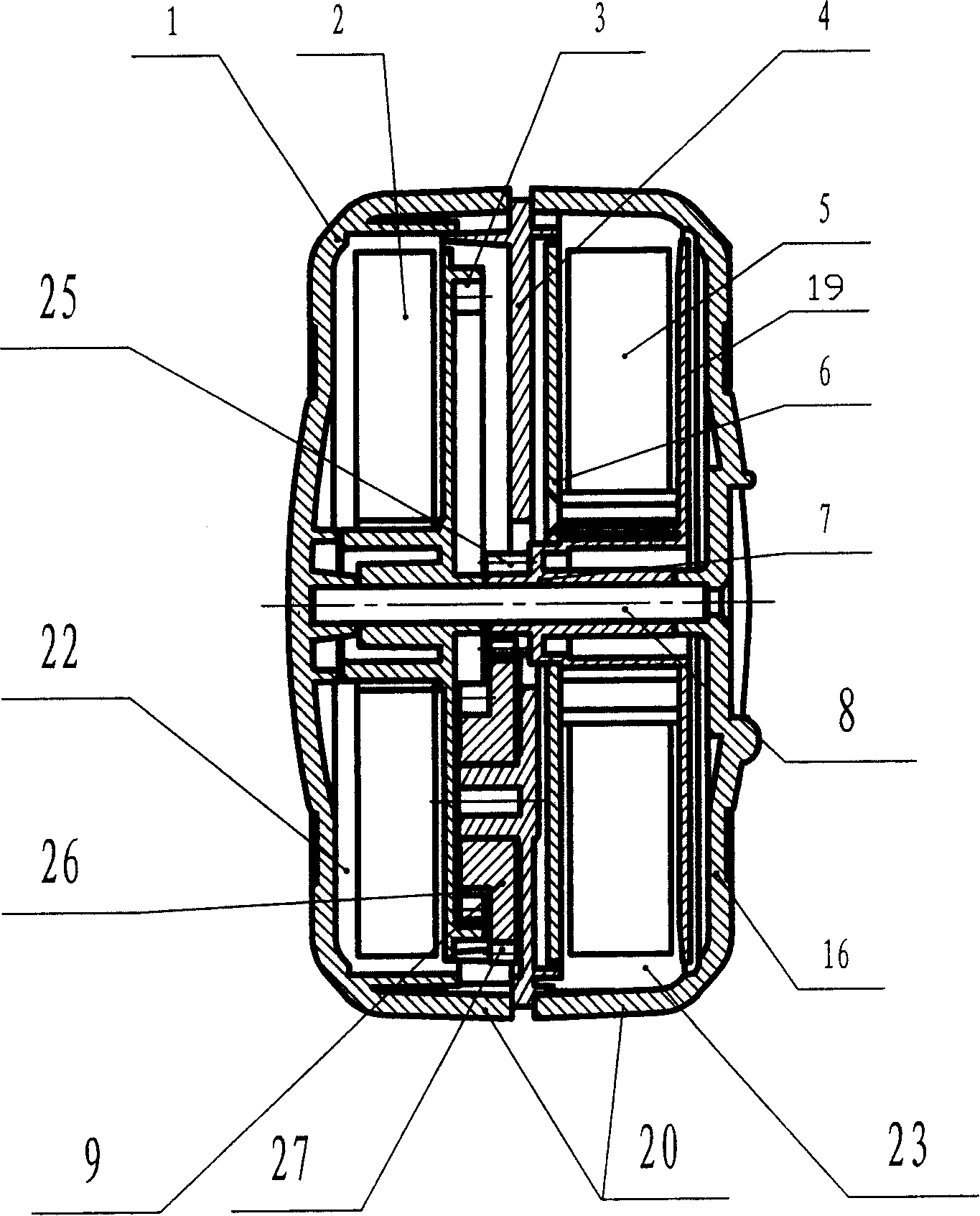

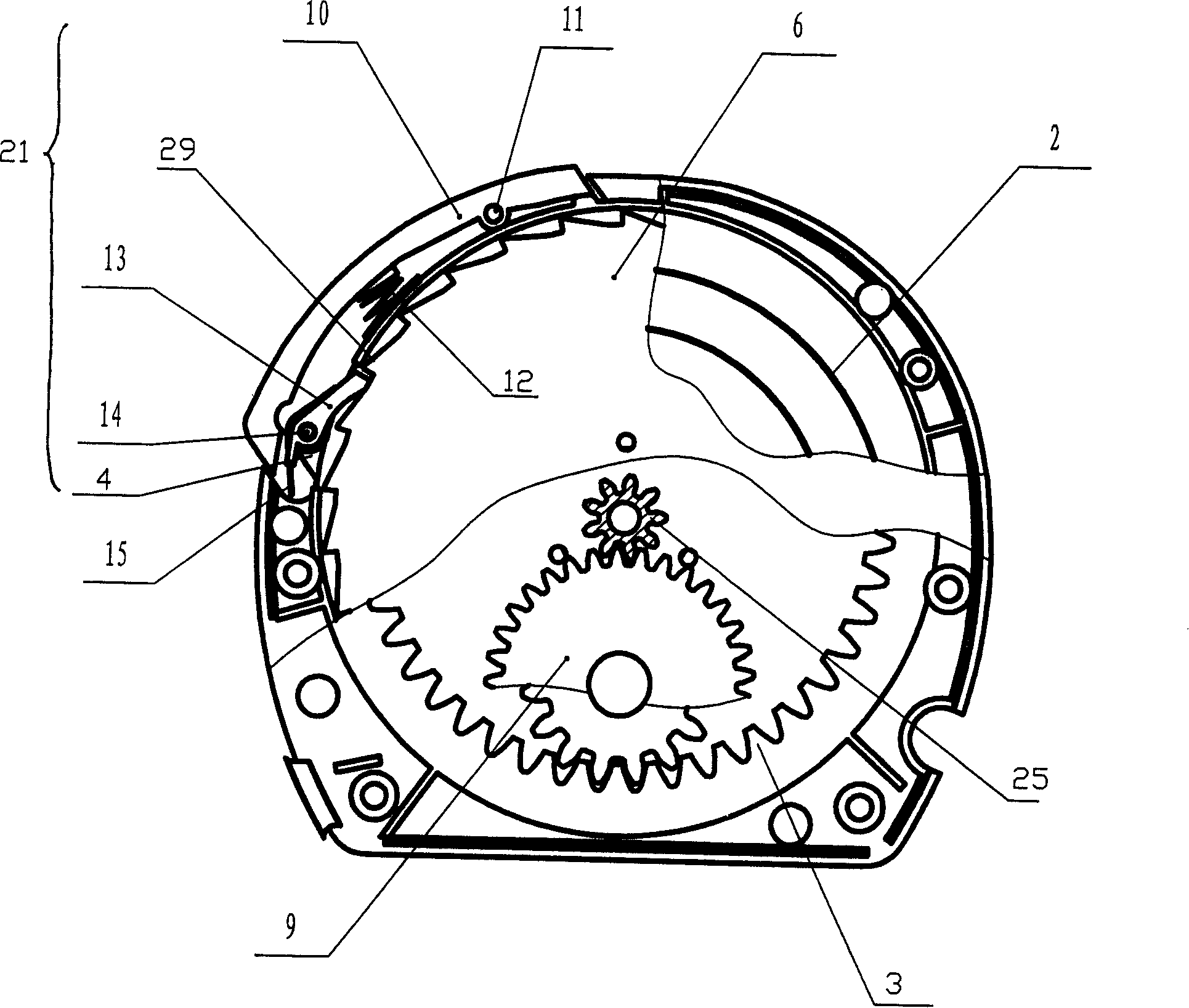

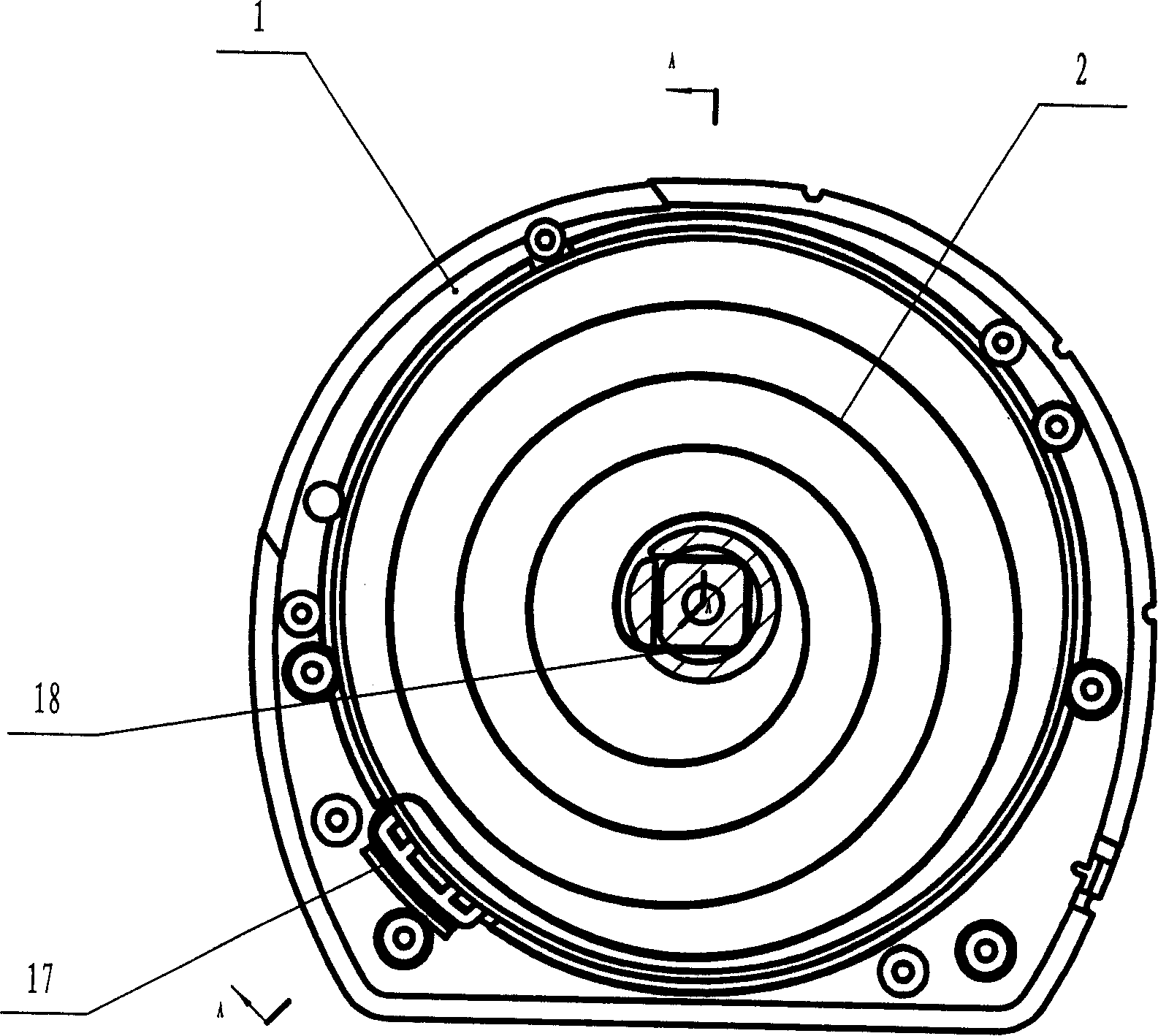

Long ruler

The invention relates to a long ruler, comprising a casing, a ruler core disk, a ruler spring, a ruler belt, a braking device, a middle dividing mounting plate and a driving device, which is characterized in that: the ruler core disk, the ruler spring and the ruler belt are arranged in the casing; the ruler core disk can rotate; the ruler belt is wound on the ruler core disk; one end of the ruler belt extends out of the casing; the ruler spring is connected with the ruler core disk through the driving device; the braking device is arranged between the button of the casing and the ruler core disk; the casing cavity is divided into a left arranging cavity and a right arranging cavity through the middle dividing mounting plate, wherein the ruler spring is arranged in one arranging cavity and the ruler core disk arranged in the other; one end of the driving device is connected with one end of the ruler spring and the other end is connected with the ruler core disk. The invention has the advantages of simple and reasonable structure, convenience for handheld usage, easy assembly and production, suitable for popularizing and applying in long ruler.

Owner:NINGBO GREAT WALL PRECISION INDAL

Configuration of hydraulic element of excavator

PendingCN105113570AExtended service lifeReduce contact areaMechanical machines/dredgersControl valvesExcavator

The invention discloses configuration of a hydraulic element of an excavator. The configuration comprises a main pump, a rotary motor and a main control valve. The main pump is connected with an engine through a spline of a main shaft. The main pump is connected with the main control valve through a hydraulic pipeline. A work oil opening of the main control valve is connected with large cavities and small cavities of all oil cylinder openings of the excavator and oil inlet and return openings of the rotary motor and a walking motor, and the rotary motor is a double rotary motor. The double rotary motor is adopted, displacement and starting torque are large, and when the excavator rotates, time consumed from a static state to a constant speed state is short, and work efficiency is greatly improved. Meanwhile, the contact area of the double rotary motor and a gear ring of the excavator is large, the borne unit area is small, and the service life of the excavator can be greatly prolonged. Internal oil channel design is optimized, the sealing mode of a one-way valve and the like is changed, so that the leakage amount becomes small, and energy waste is reduced.

Owner:SHANDONG CHANGLIN MACHINERY GRP

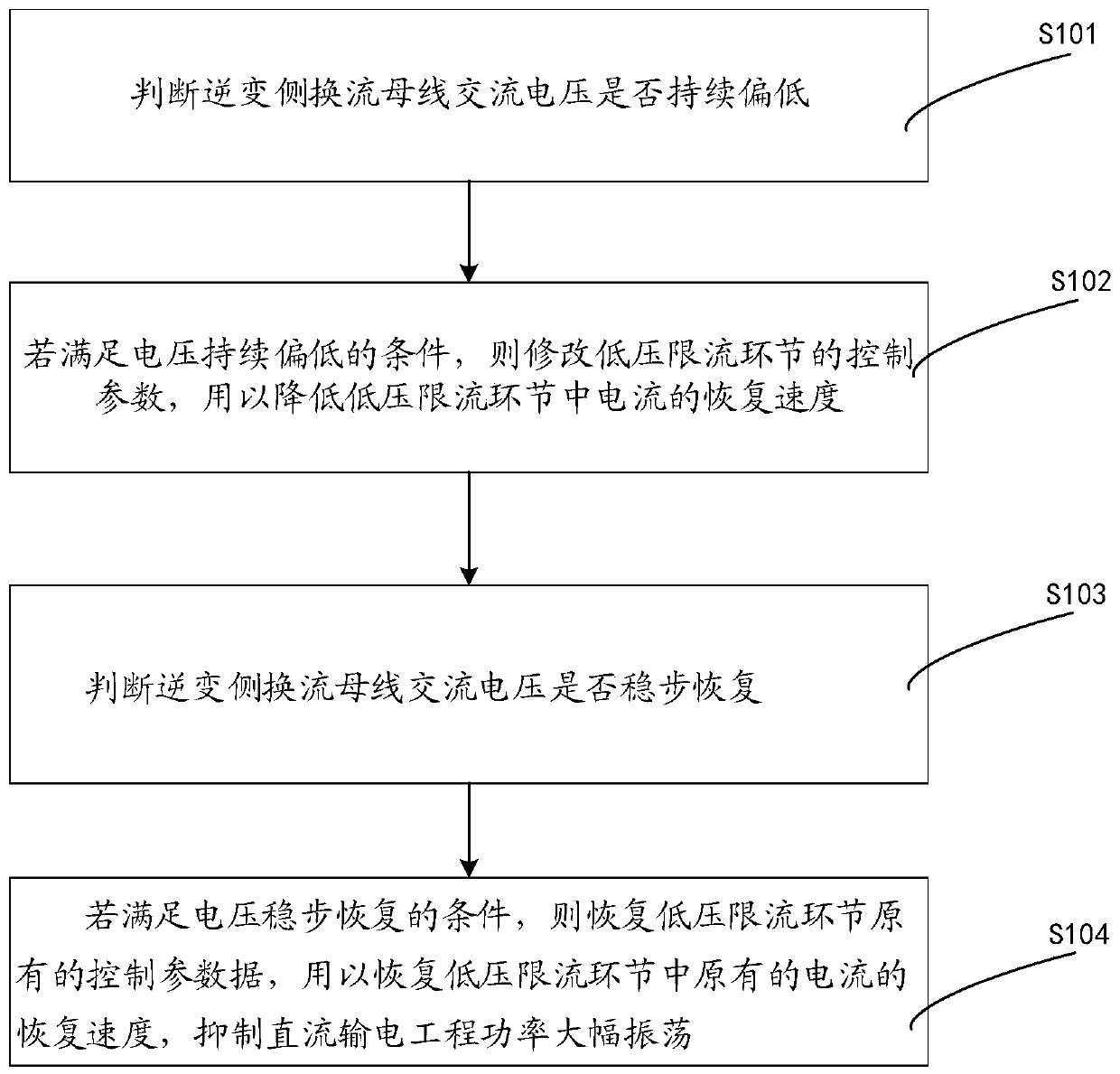

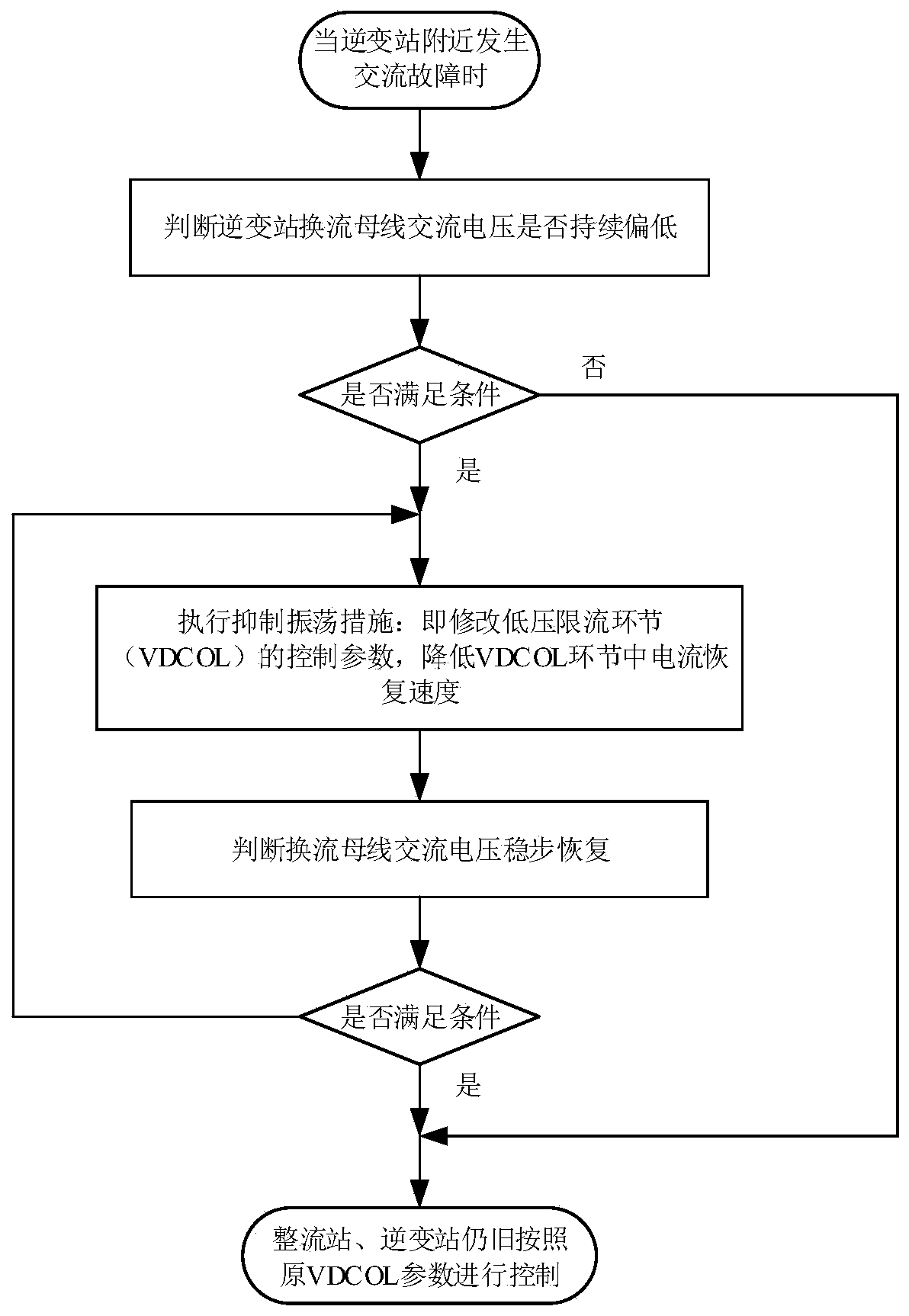

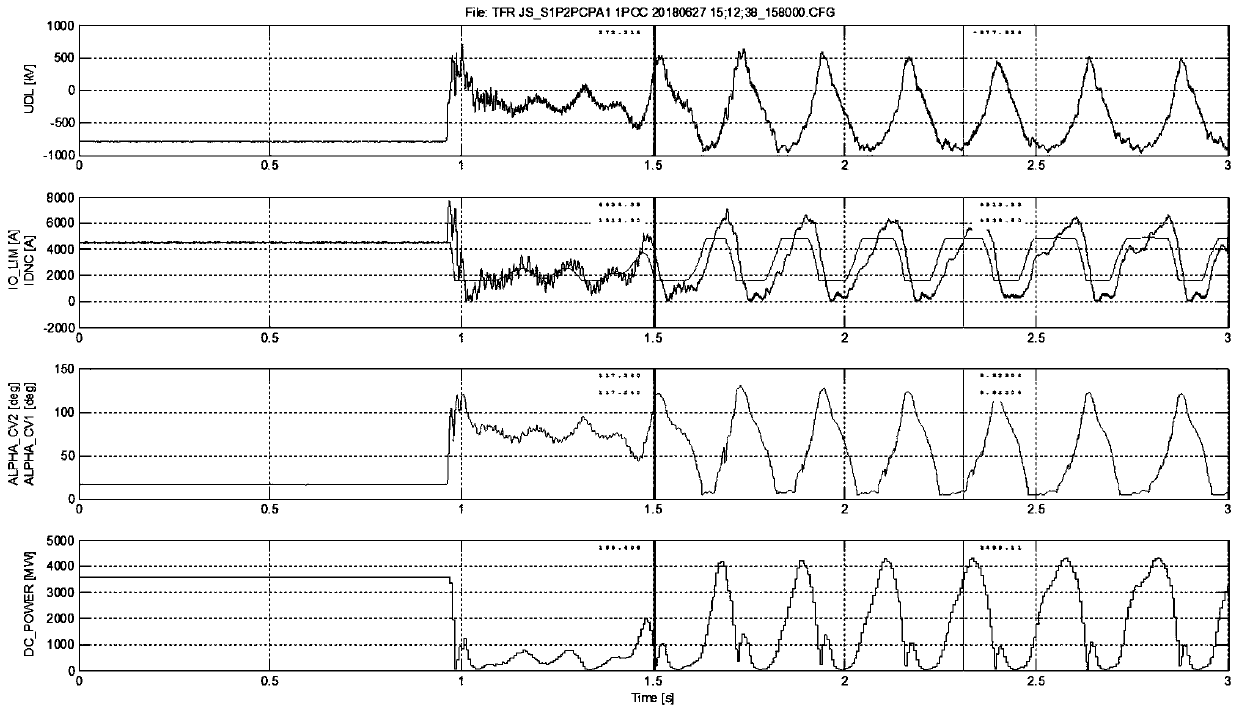

Method for suppressing large-amplitude power oscillation of direct-current power transmission project

PendingCN110994641AThreats to safe and stable operationSlow down recoveryElectric power transfer ac networkPower oscillations reduction/preventionCurrent limitingControl engineering

The invention discloses a method for suppressing large-amplitude power oscillation of a direct-current power transmission project. The method comprises the following steps: judging whether the alternating-current voltage of an inverter-side converter bus is continuously low or not; if the condition that the voltage is continuously low is met, modifying the control parameters of a low-voltage current limiting link to reduce the recovery speed of the current in the low-voltage current limiting link; judging whether the alternating-current voltage of the inverter-side converter bus is stably recovered or not; and if the condition of stable voltage recovery is satisfied, recovering the original control parameter data of the low-voltage current-limiting link to recover the recovery speed of theoriginal current in the low-voltage current-limiting link, suppress the large-amplitude power oscillation of a direct-current power transmission project under the serious fault of an alternating-current side, and prevent the huge threat to the safe and stable operation of the power grid.

Owner:CHINA ELECTRIC POWER RES INST +1

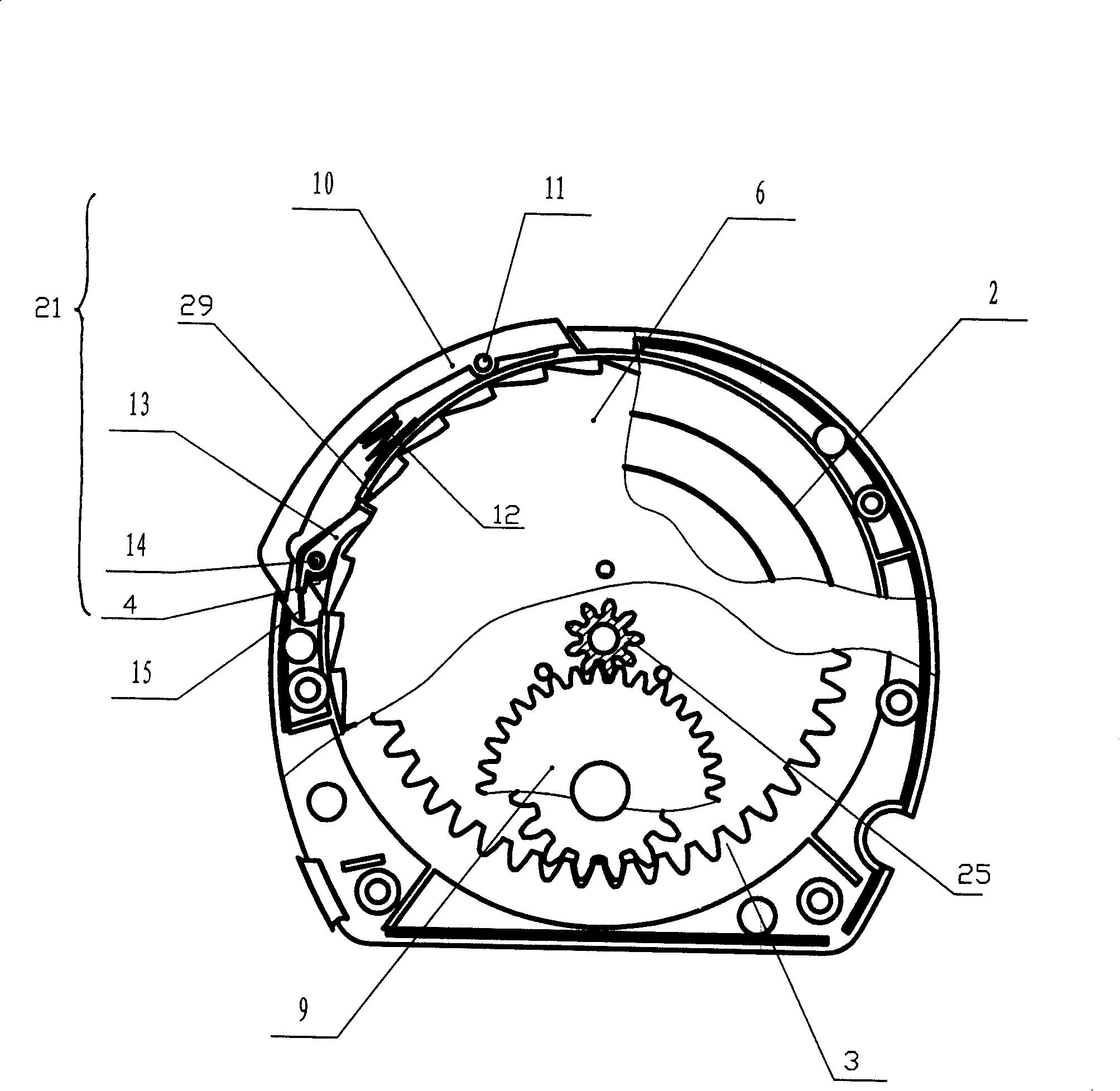

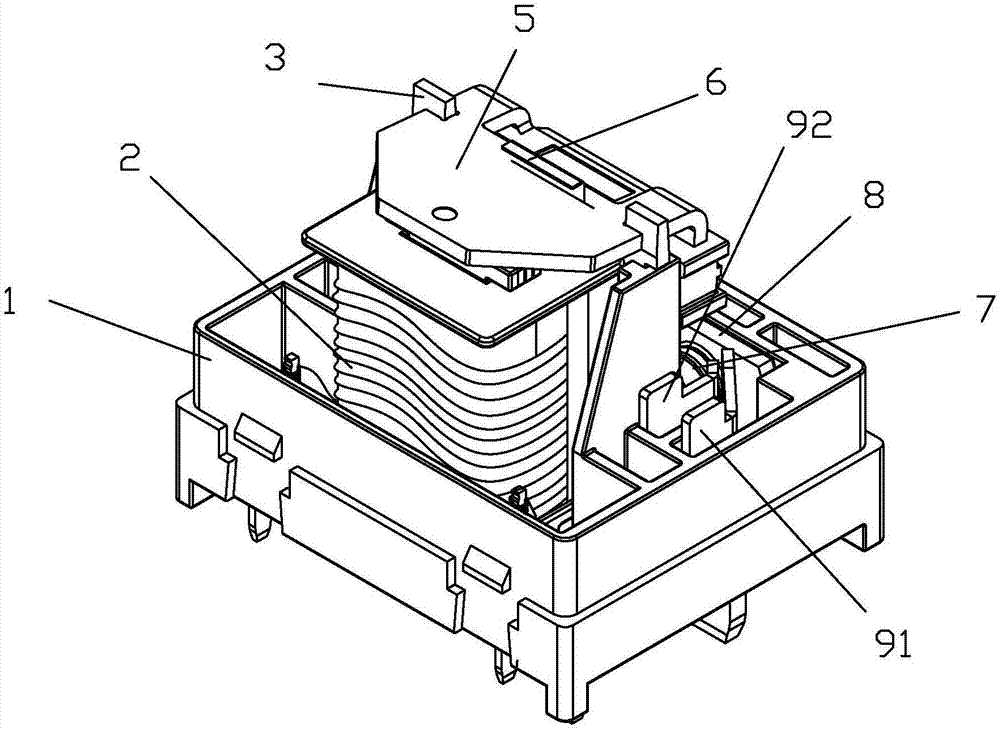

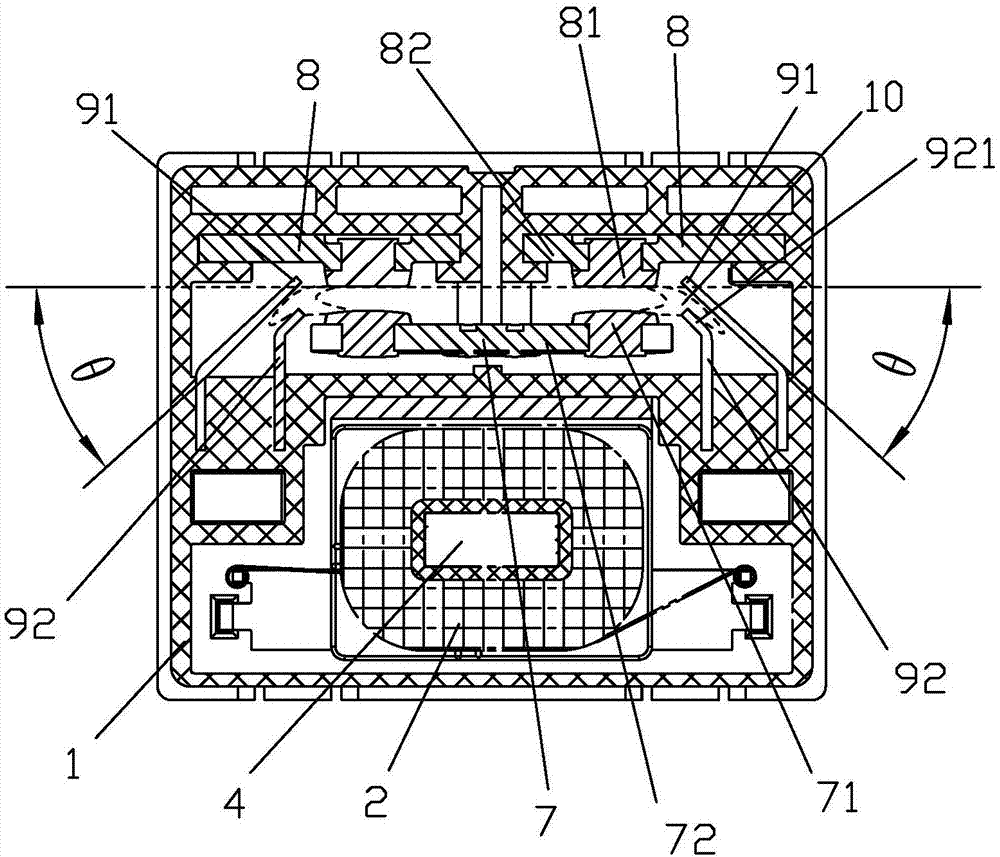

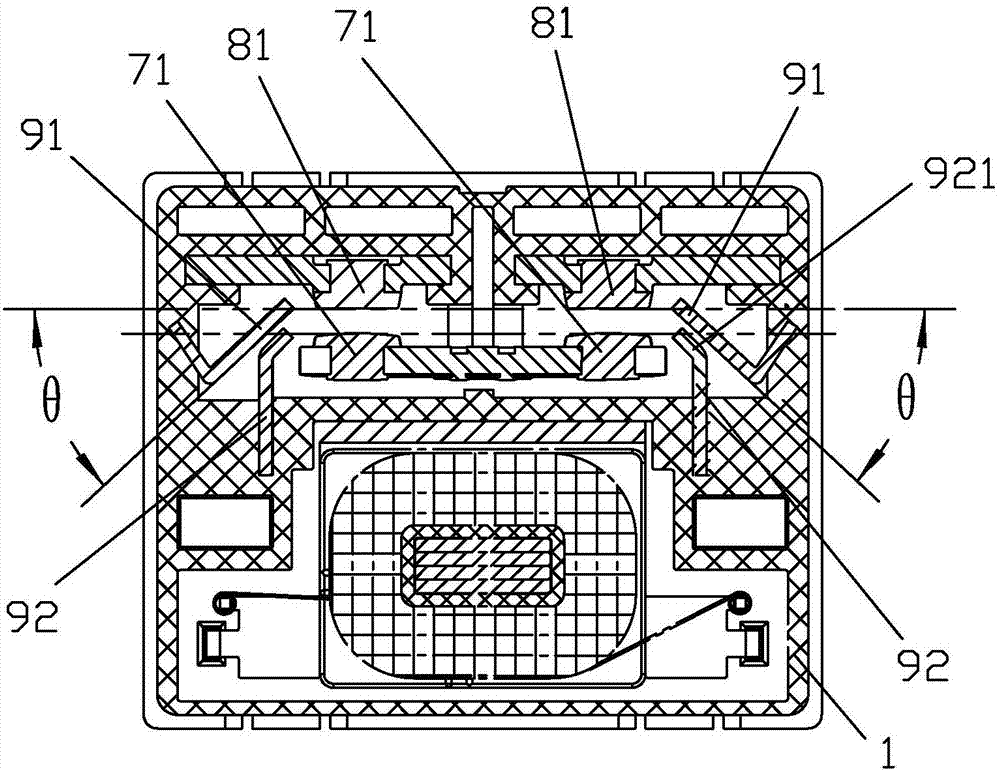

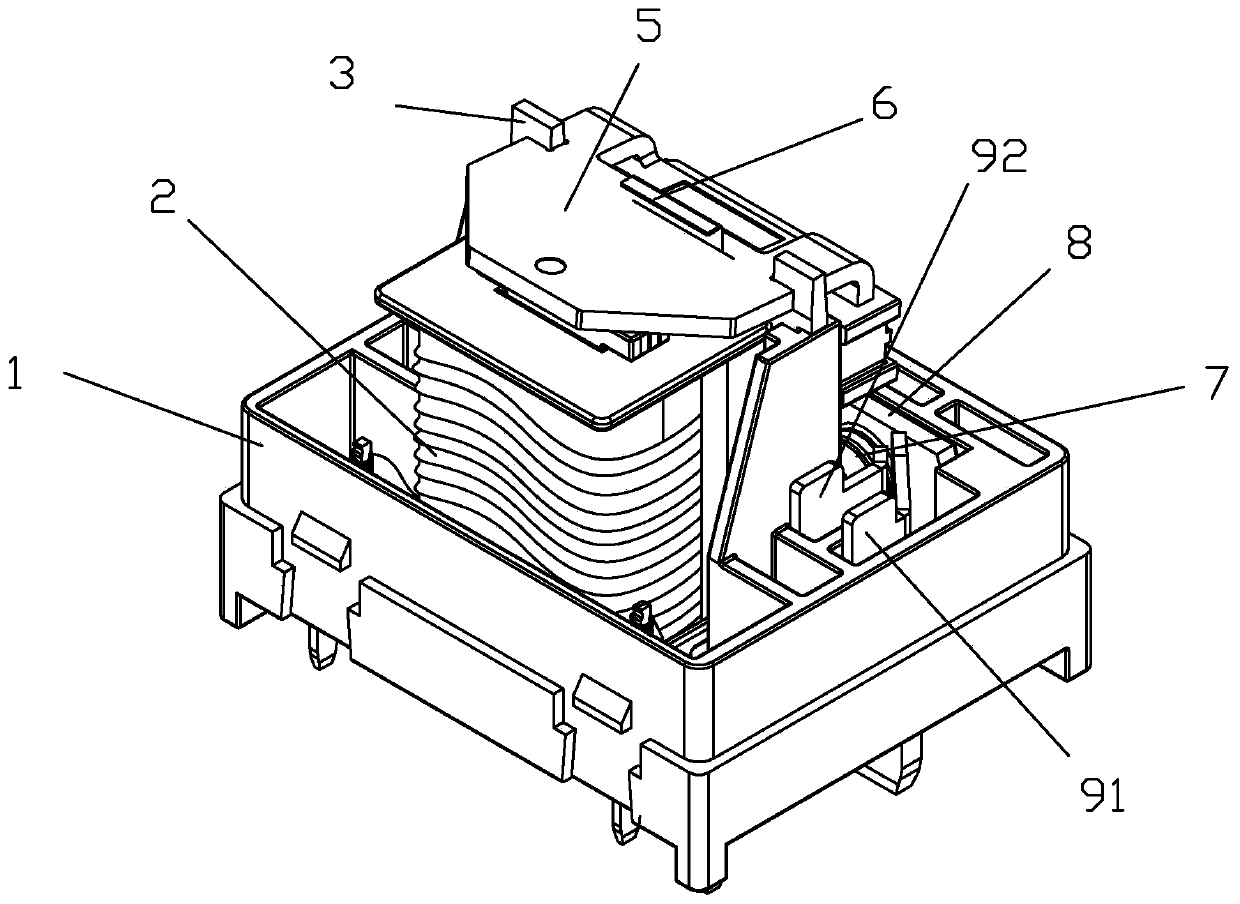

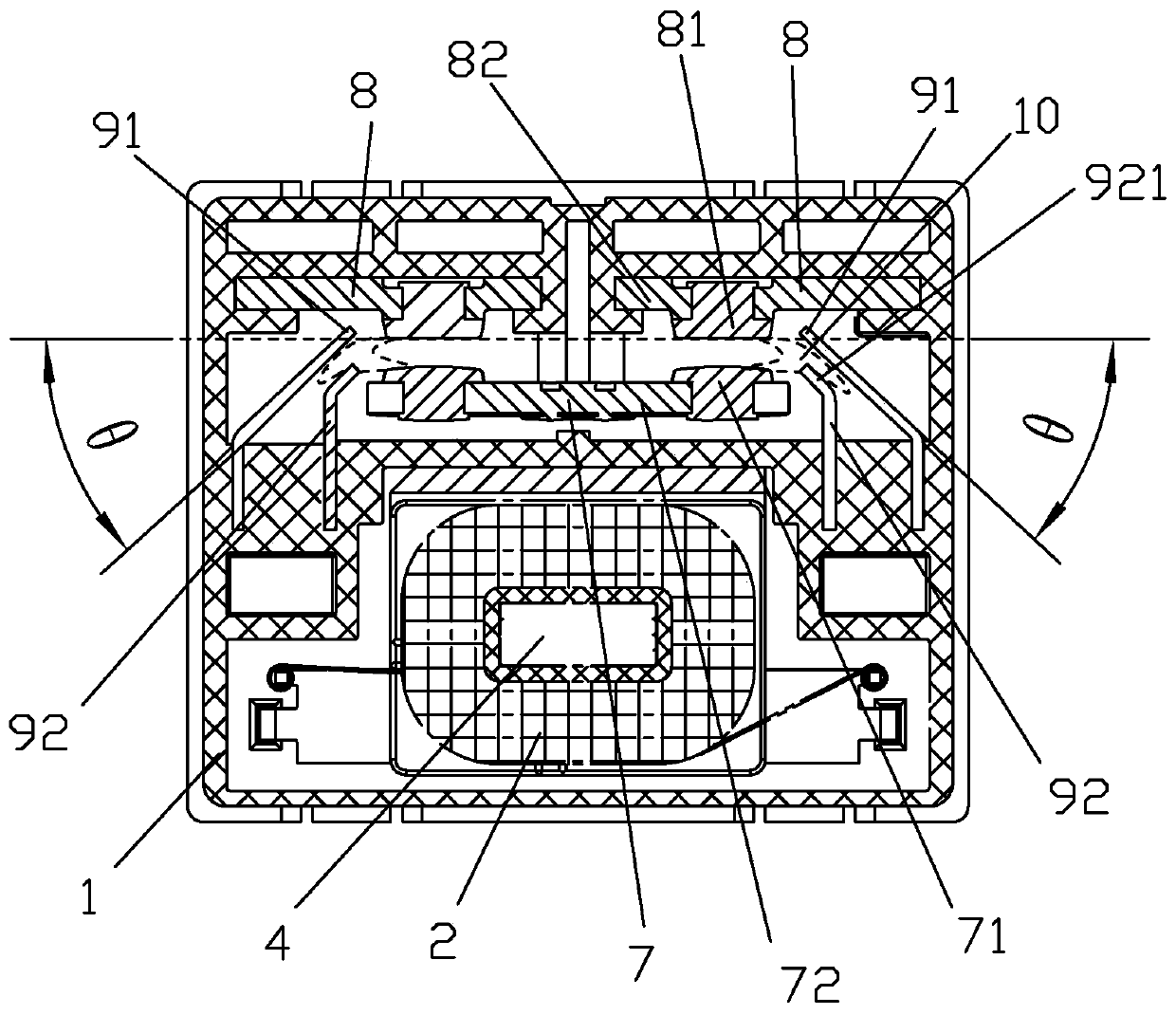

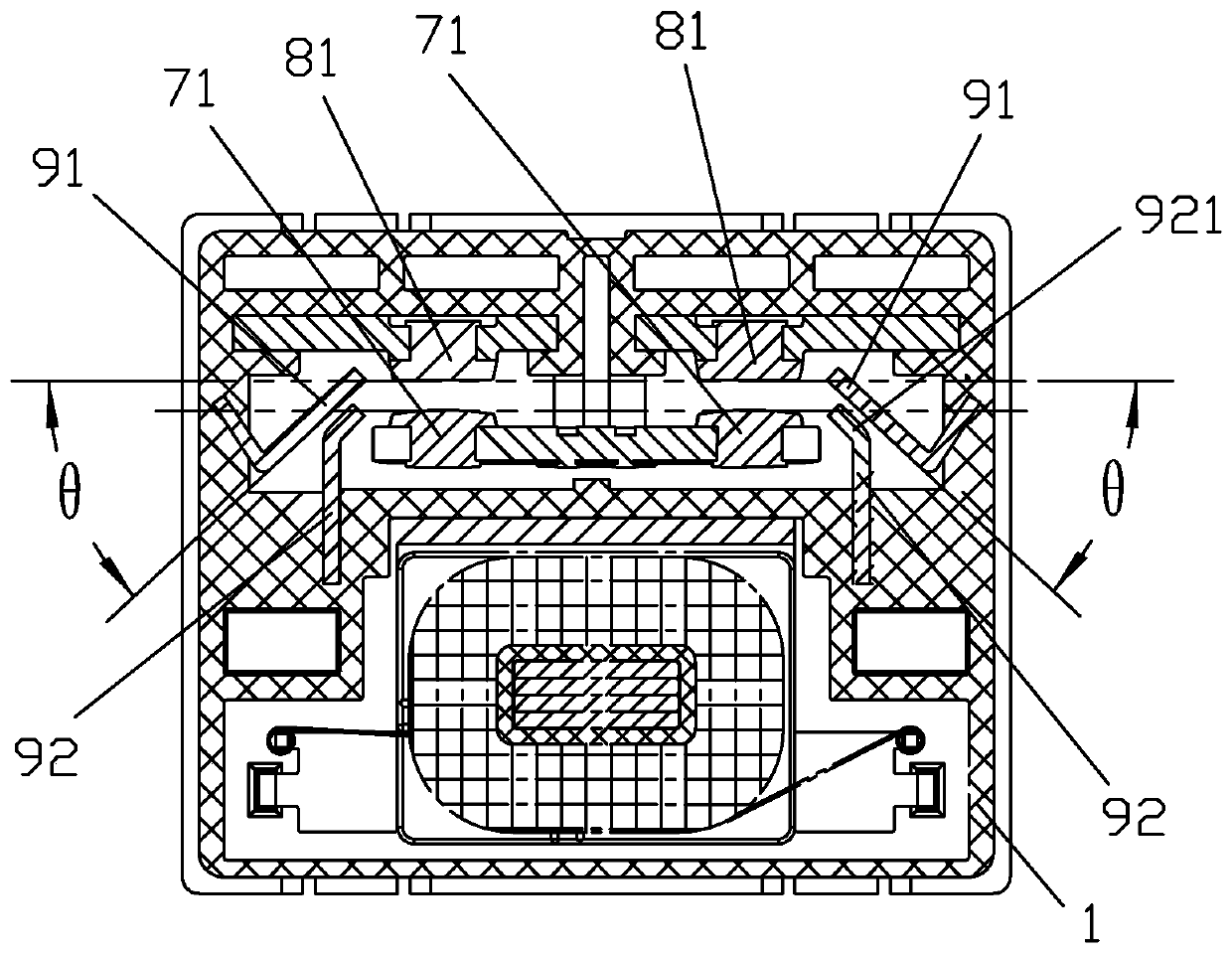

Electromagnetic relay for high-voltage-withstanding and heavy-current load

ActiveCN107045955ASlow down recoverySpeed up recoveryElectric switchesElectromagnetic relay detailsCurrent loadEngineering

The invention discloses an electromagnetic relay for a high-voltage-withstanding and heavy-current load. The electromagnetic relay comprises two moving contacts, a moving reed in bridge connection with the two moving contacts, and two static contacts matching the two moving contact correspondingly. One of the static contacts is set to be a current flowing-in side and the other of the static contacts is set to be a current flow-out side, so that arcs generated between the two pairs of contacts splatter outwardly along connecting lines of gaps of the two pairs of contacts. First arc-guiding pieces for stopping corresponding arcs from splattering towards the outer sides along connecting lines of gaps of the two pairs of contacts are arranged at the outer sides of the connecting lines of gaps of the two pairs of contacts; the first arc-guiding pieces made of conductive metal materials are arranged obliquely relative to the connecting lines of gaps of the two pairs of contacts, so that the stopped arcs can be guided to move along the preset arc guiding directions of the first arc-guiding pieces. Therefore, cutting off of the high-voltage and heavy-current load can be realized; plastic burning by arcs can be avoided; and the arc energy can be reduced. The electromagnetic relay is also suitable for alternating-current and direct-current loads.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

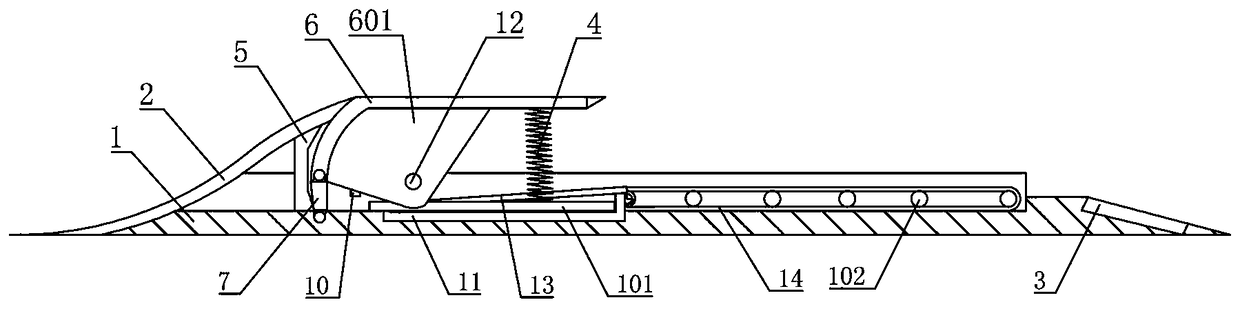

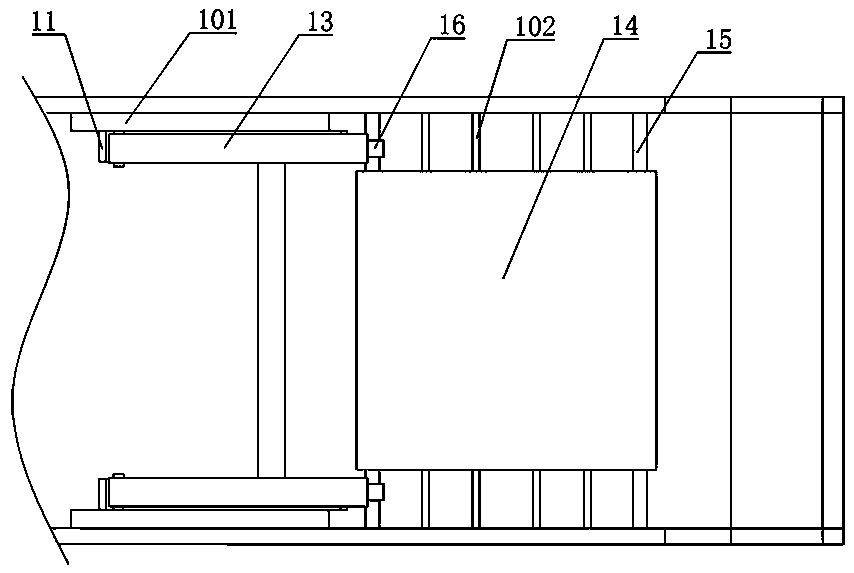

Speed bump with function of preventing driving wrong way

ActiveCN109468901ASlow down recoveryReduce the impact of vibrationTraffic signalsRoad signsSpeed bumpWrong-way driving

The invention discloses a speed bump with a function of preventing driving the wrong way. The speed bump comprises a base, a front slope, a reflector, a first spring and a wrong way driving movement preventing assembly, wherein the front slope is fixedly arranged at the front end of the base and comprises an inclined section and a horizontal section located at the rear end of the inclined section,a support plate is fixedly arranged between the inclined section of the front slope and the base, an overturning face plate is arranged at the rear end of the front slope on the base, two rotating plates are fixedly arranged on two sides of the overturning face plate, arranged on two side walls of the base and rotationally connected with the base, and front ends of the two side walls of the baseare flush with the front end of the inclined section of the front slope; a support rib plate is arranged at the lower part of the overturning face plate, the first spring is arranged at the rear end,the rear end of the base is glidingly connected with a baffle plate, the baffle plate is in drive connection with the wrong way driving movement preventing assembly, and the reflector is fixedly arranged on the rear end surface of the base. The speed bump can effectively prevent vehicle from driving the wrong way to snatch the path and guarantees smooth traffic order.

Owner:合肥龙智机电科技有限公司

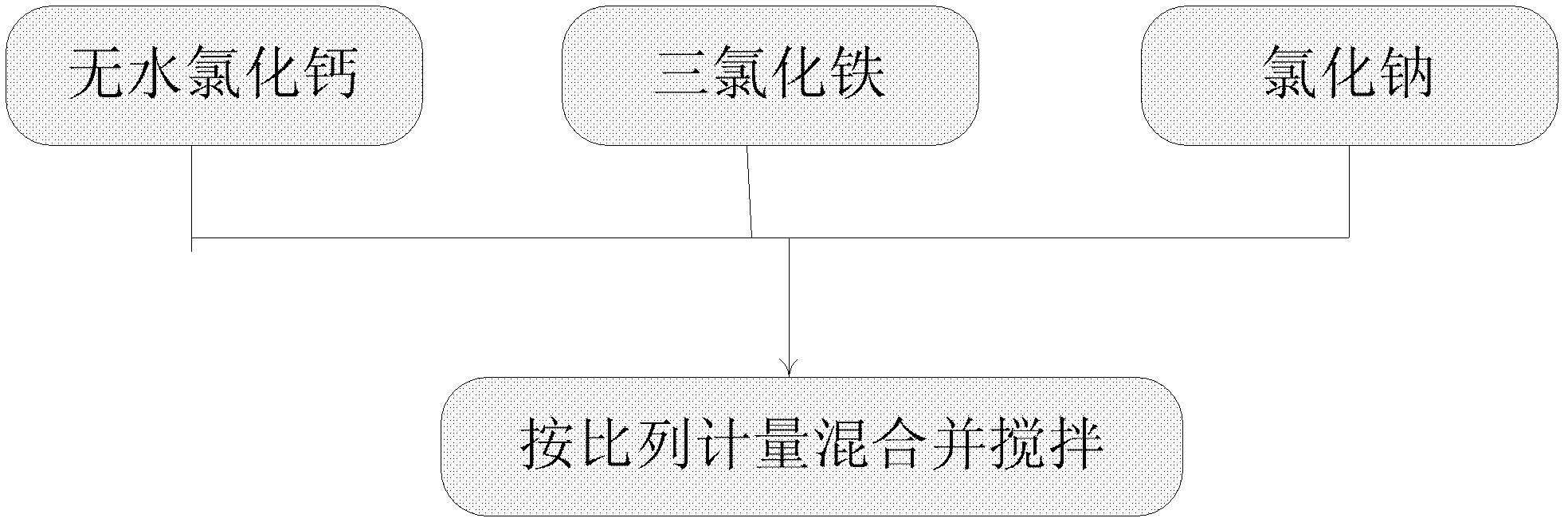

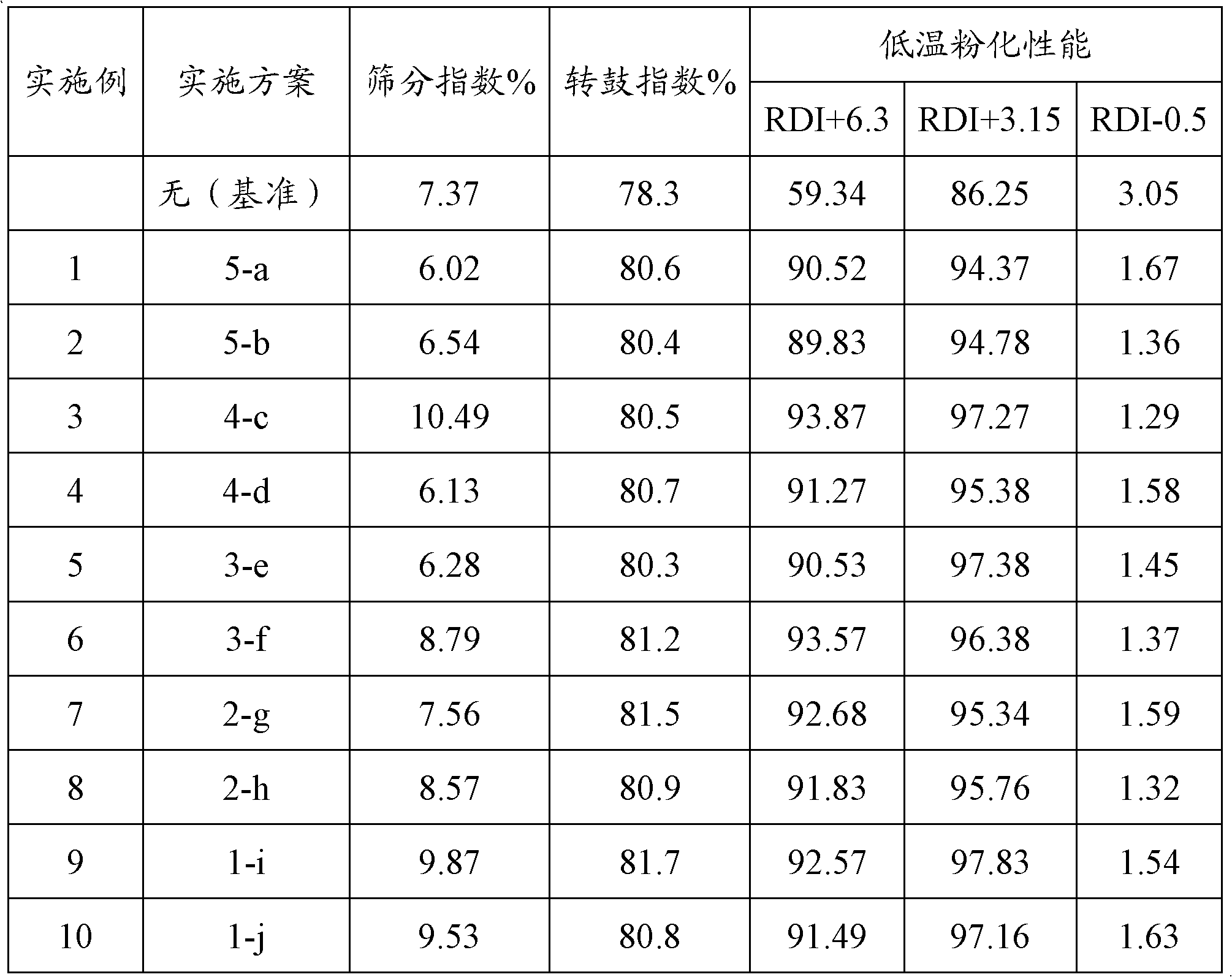

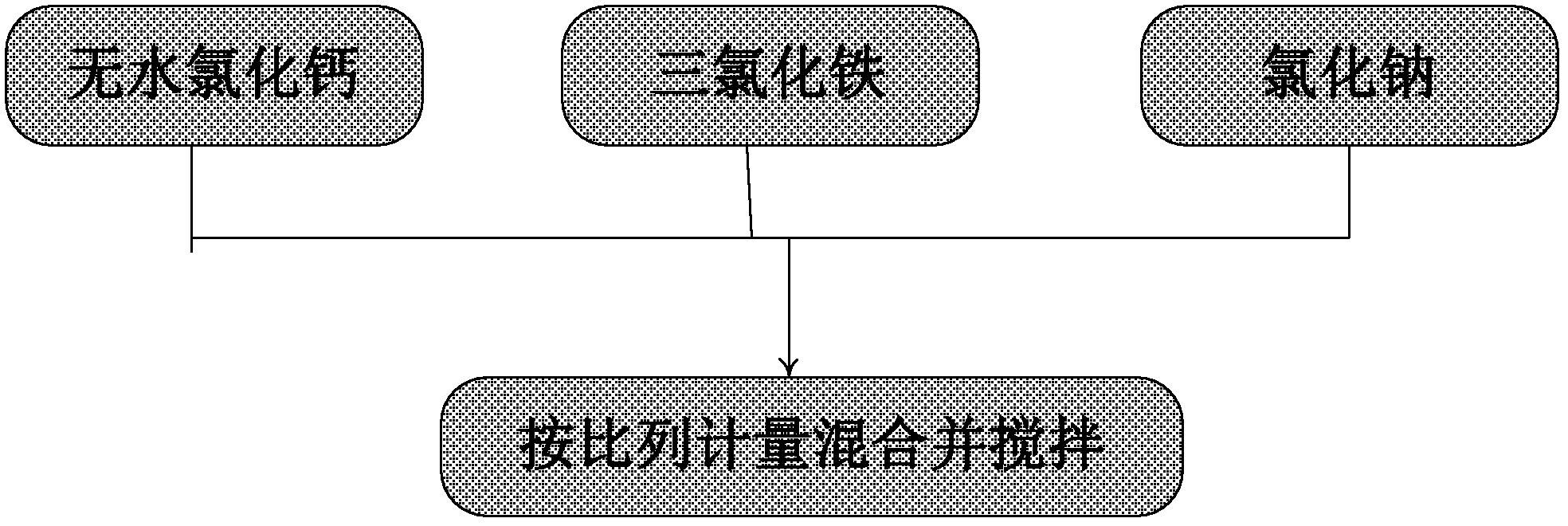

Sintered ore modifier and preparation method and iron-making method

InactiveCN102560092ASlow down recoveryThe purpose of reducing low temperature reduction pulverizationBlast furnace detailsAlkalinityHalogen

The invention discloses a sintered ore modifier and a preparation method. The sintered ore modifier comprises CaCl2, FeCl3 and NaCl. As the FeCl3 added to the sintered ore modifier is effectively bonded with an iron to ensure that a halogen ellement is adhered to the sintered ore surface and is simultaneously and effectively bonded with the sintered ore, pulverization of sintered ores is reduced; in addition, as NaCl is added to the sintered ores, the alkalinity of the sintered ores is improved, the pulverization of the sintered ores is further reduced and the purpose of improving the metallurgical performance of the sintered ores is achieved; and the components of the sintered ore modifier are convenient to obtain and simple to prepare and are beneficial for industrial production. Based on the sintered ore modifier and the preparation method, the invention discloses an iron-making method. The iron-making method comprises the following steps: mixing the sintered ore modifier with water to prepare a sintered ore modifier solution of a certain concentration; spraying the sintered ore modifier solution to the sintered ore surface according to a certain proportion; and reducing the sintered ores at a high temperature via a reducing agent to obtain iron. The low temperature pulverization rate of the sintered ores is decreased in the iron-making process, the energy utilization rate is improved, and the energy consumption is reduced, so that the efficiency is improved.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

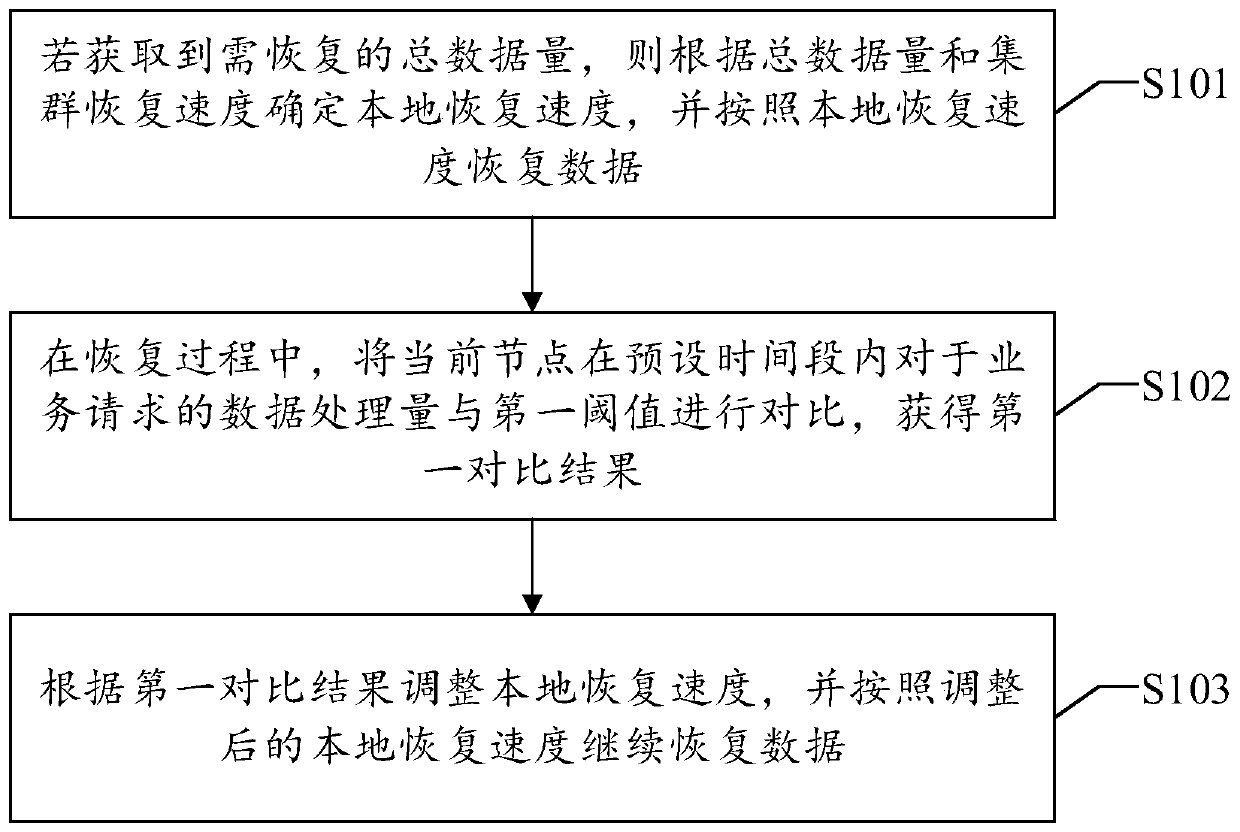

Data recovery method, device and equipment and readable storage medium

InactiveCN111061585ASpeed up recoveryImprove recovery efficiencyNon-redundant fault processingRedundant operation error correctionComputer resourcesReal-time computing

The invention discloses a data recovery method, device and equipment and a readable storage medium. The method disclosed by the invention is applied to any node in a distributed cluster, and comprisesthe steps of determining a local recovery speed according to a total data size and a cluster recovery speed if the total data size needing to be recovered is obtained, and recovering data according to the local recovery speed; in the recovery process, comparing the data processing amount of the current node for the service request in a preset time period with a first threshold value to obtain a first comparison result; and adjusting the local recovery speed according to the first comparison result, and continuing to recover the data according to the adjusted local recovery speed. According tothe method, the front-end service and the data recovery can be prevented from scrambling for computer resources, and the balance of the two can be realized, so that the response speed of the front-end service is increased, and the data recovery speed and efficiency are improved. The invention also discloses a data recovery device and equipment and the readable storage medium, which also have theabove technical effects.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

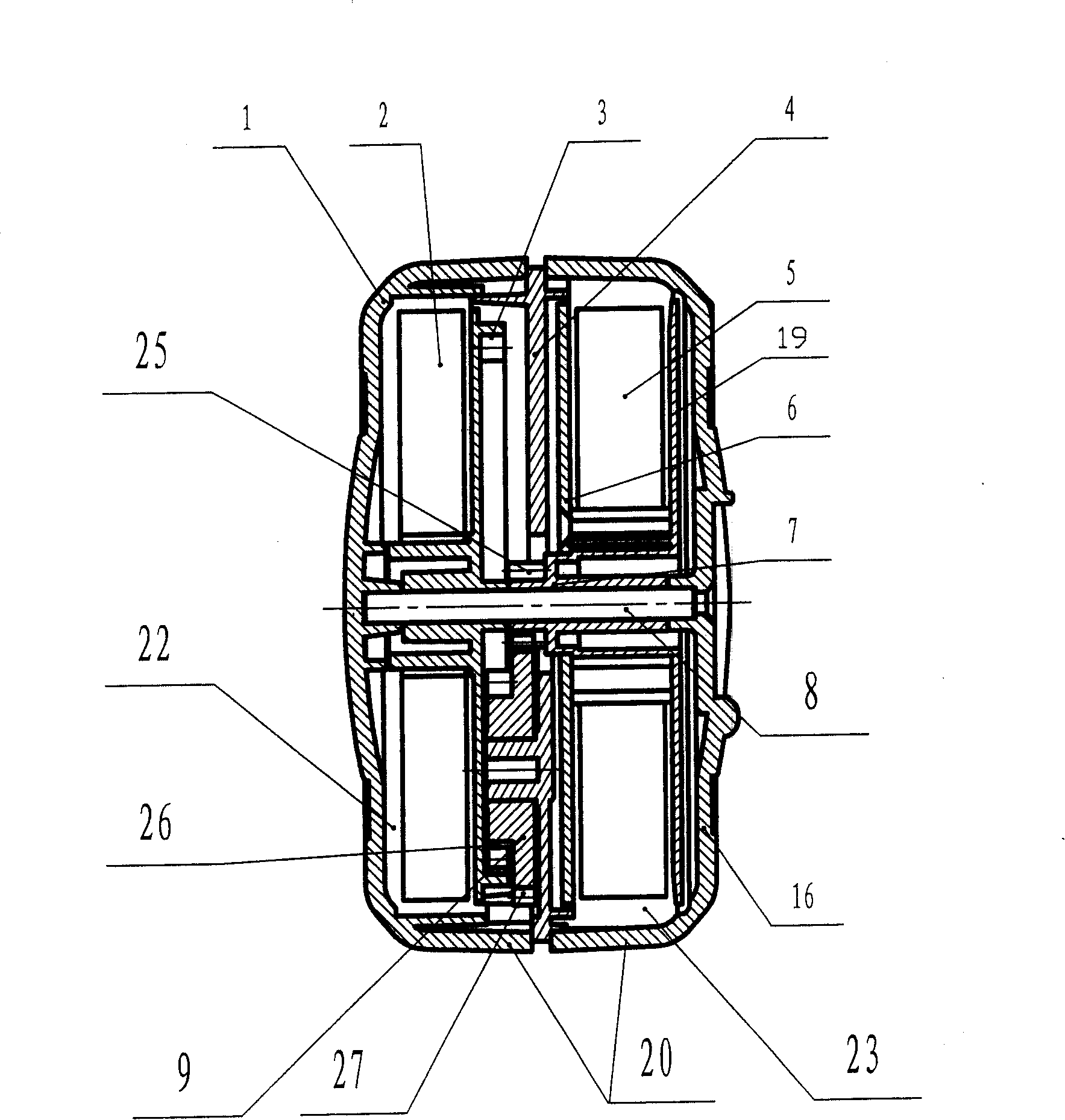

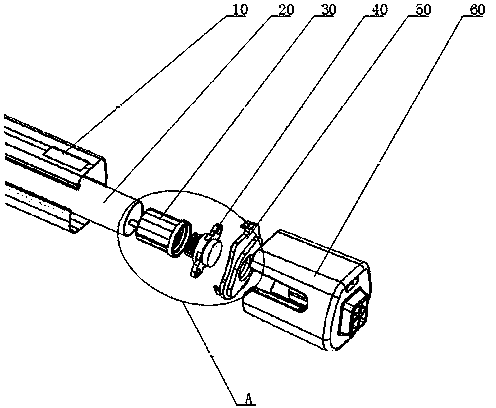

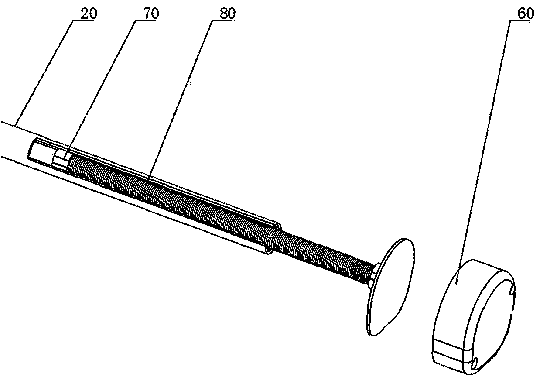

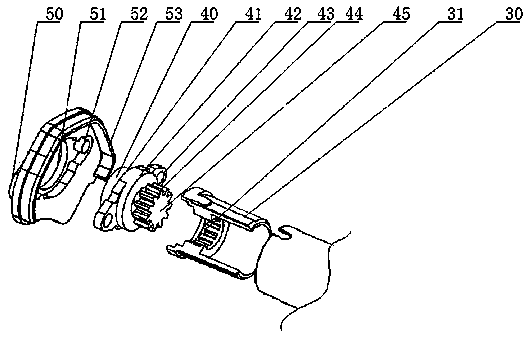

Covering curtain winding device capable of buffering

ActiveCN103670254ADoes not affect the operationSlow down recoveryDoor/window protective devicesVehicle componentsEngineeringConductor Coil

The invention discloses a covering curtain winding device capable of buffering. The covering curtain winding device comprises an inner tube (20), an outer tube (10), and outer seal covers (60), wherein the outer seal covers are used for sealing two ends of the outer tube (10). The covering curtain winding device is characterized in that the inner tube (20) is rotatably connected inside the outer tube (10). A covering curtain is wound on the outer surface of the inner tube (20). A spring set (80) is fixed in the inner cavity of the inner tube (20). A buffering device for slowing down the rotation of the inner tube (20) is disposed between the inner tube (20) and one of the outer seal covers (60). Due to the fact that the winding device is provided with the buffering device, application operations is unaffected during pulling out, the retraction speed is reduced by 1.5-2.0 seconds during retraction, and impact is buffered effectively.

Owner:KUSN HUANGTIAN AUTO PARTS INDAL

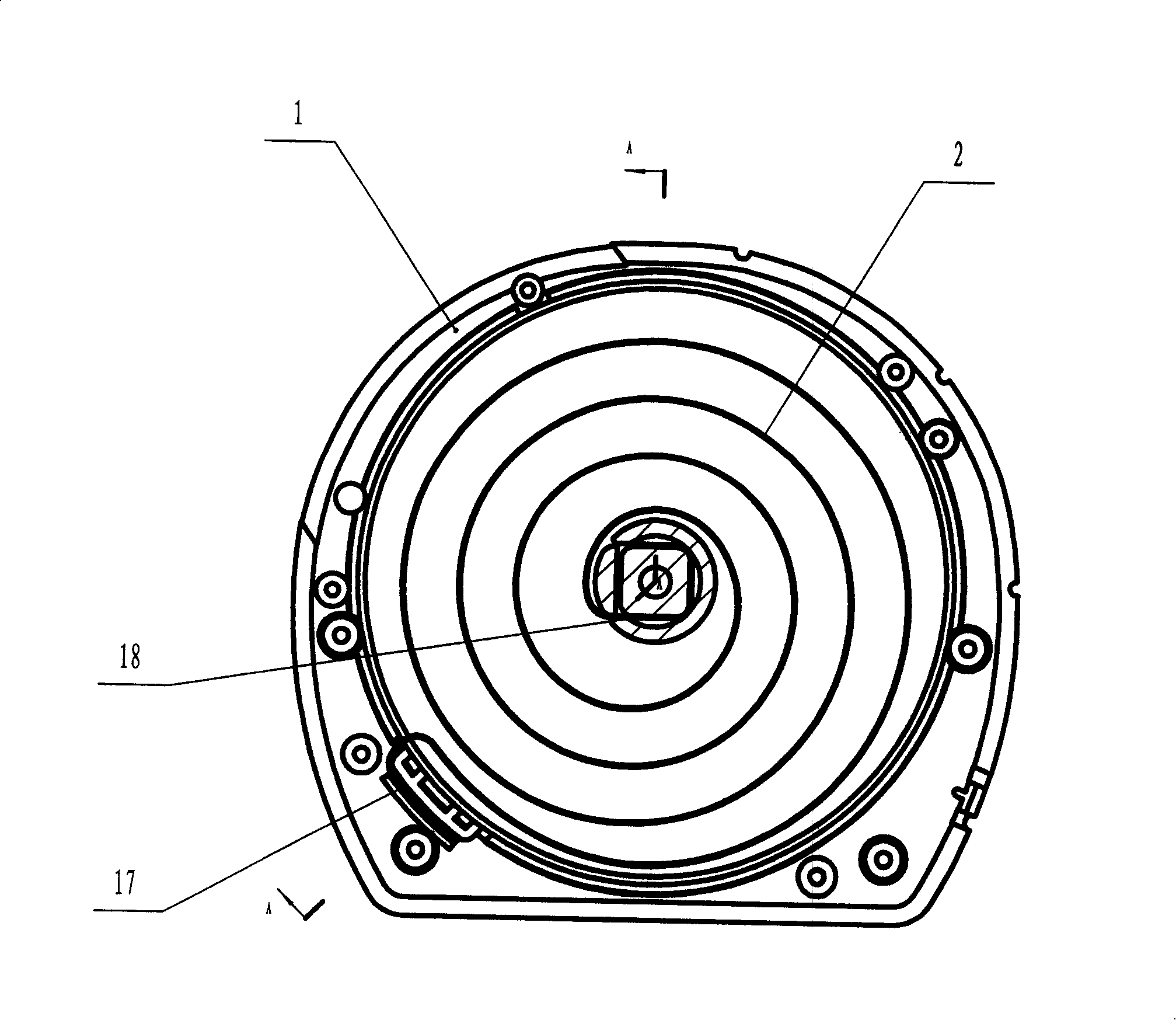

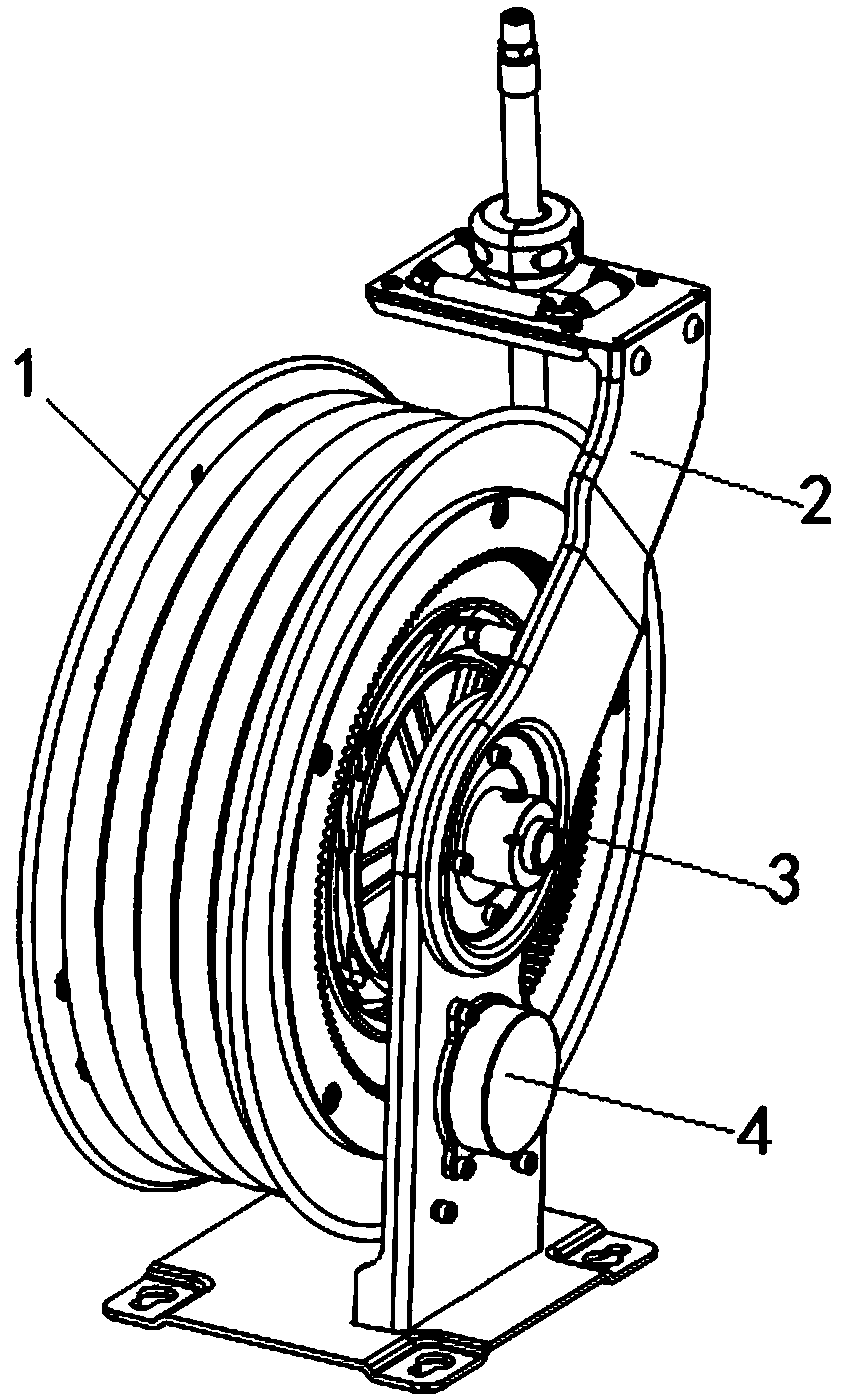

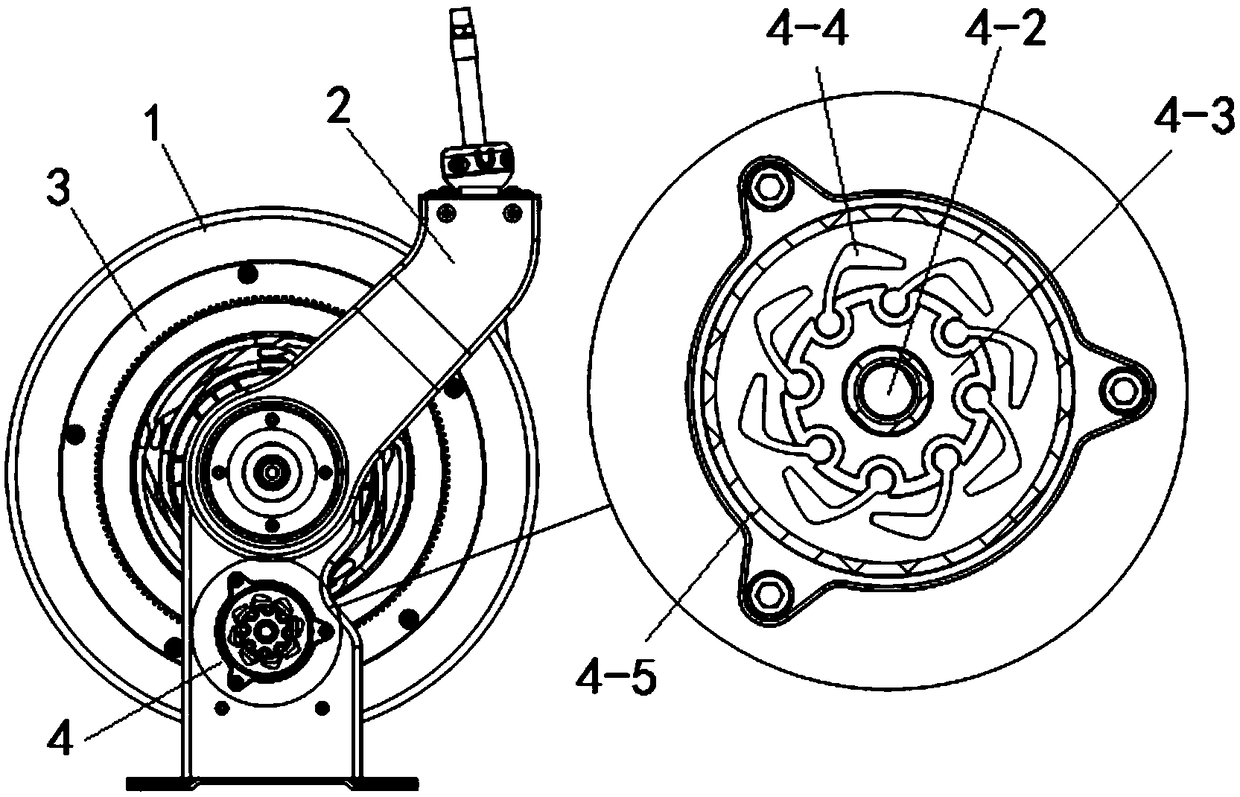

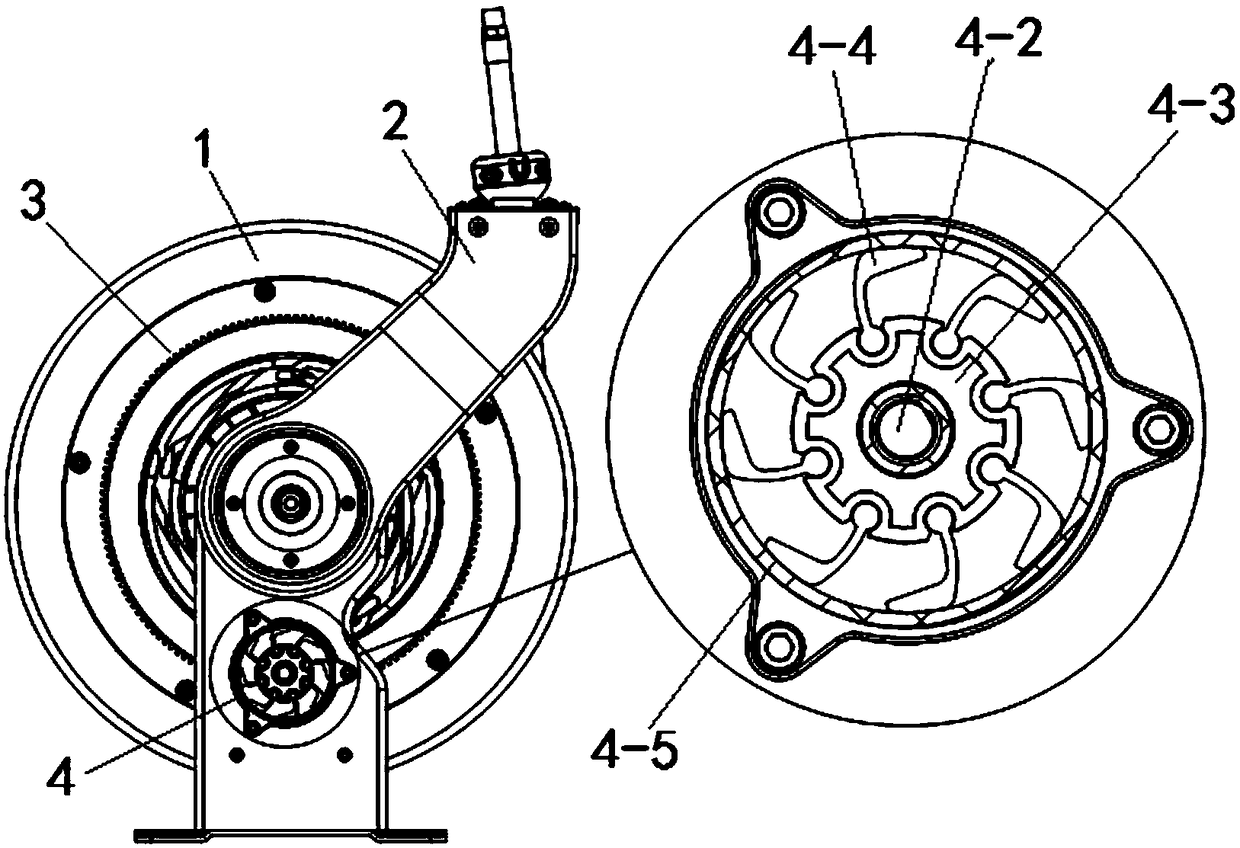

Slow recovering mechanism for metal pipe winding device

The invention relates to a slow recovering mechanism for a metal pipe winding device. The mechanism comprises a plate body, a connecting cover plate, a support and a slow recovering device, wherein the plate body is mounted on the support through a central shaft; one side of the plate body is coaxially fixedly connected to the connecting cover plate, and the connecting cover plate can rotate together with the plate body; an inner gear is arranged on the connecting cover plate; the slow recovering device is mounted on the side surface of the support; a transmission gear in the slow recovering device is in engaging connection with inner teeth of the connecting cover plate; and the transmission gear is driven through the inner gear on the connecting cover plate to drive the slow recovering device to work. According to the mechanism, the slow recovering mechanism is mounted on the support; when the plate body drives a pipe to recover, a gear on a main shaft of the slow recovering mechanismis driven to rotate through the inner teeth on the connecting cover plate mounted on the plate body, and then a throwing block of the slow recovering mechanism is further driven to open to be subjected to friction with the inner wall of a fixed housing, and thus the plate body recovering speed is decreased, and the use safety of the metal pipe winding device is ensured; in addition, the mechanismis simple in structure and can be mounted and used in an existing metal pipe winding device.

Owner:士商(湖州)精密技术有限公司

An electromagnetic relay with high voltage and high current load

ActiveCN107045955BSlow down recoverySpeed up recoveryElectric switchesElectromagnetic relay detailsCurrent loadMetallic materials

The invention discloses an electromagnetic relay for a high-voltage-withstanding and heavy-current load. The electromagnetic relay comprises two moving contacts, a moving reed in bridge connection with the two moving contacts, and two static contacts matching the two moving contact correspondingly. One of the static contacts is set to be a current flowing-in side and the other of the static contacts is set to be a current flow-out side, so that arcs generated between the two pairs of contacts splatter outwardly along connecting lines of gaps of the two pairs of contacts. First arc-guiding pieces for stopping corresponding arcs from splattering towards the outer sides along connecting lines of gaps of the two pairs of contacts are arranged at the outer sides of the connecting lines of gaps of the two pairs of contacts; the first arc-guiding pieces made of conductive metal materials are arranged obliquely relative to the connecting lines of gaps of the two pairs of contacts, so that the stopped arcs can be guided to move along the preset arc guiding directions of the first arc-guiding pieces. Therefore, cutting off of the high-voltage and heavy-current load can be realized; plastic burning by arcs can be avoided; and the arc energy can be reduced. The electromagnetic relay is also suitable for alternating-current and direct-current loads.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

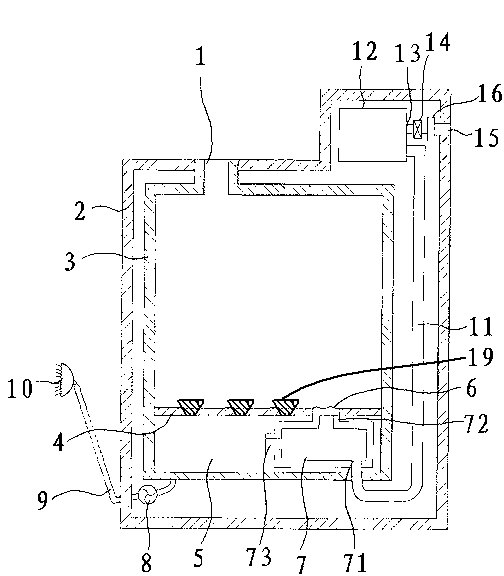

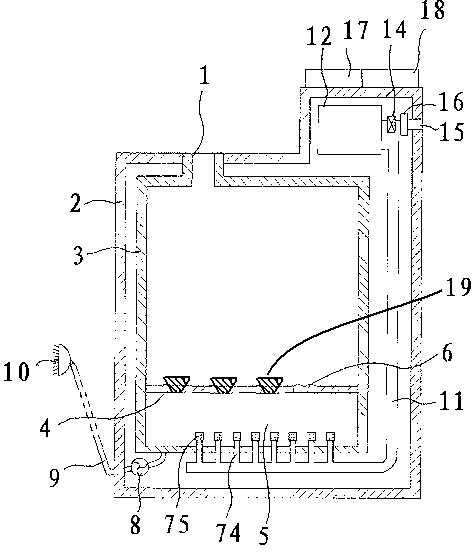

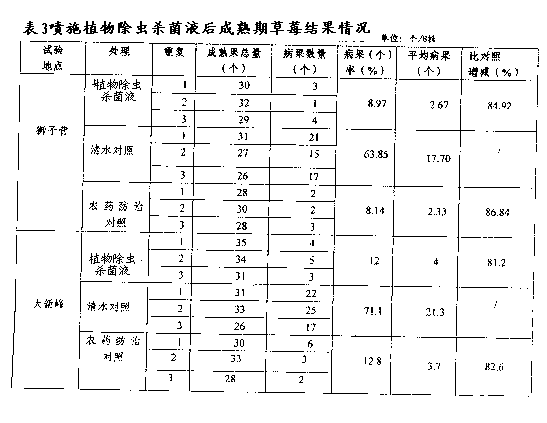

Plant disinsecting and sterilizing solution and special sprayer for preparing and spraying same

ActiveCN103262856AHas insecticidal and bactericidal effectSlow down recoveryBiocideFungicidesAcid waterPesticide residue

The invention relates to the technical field of plant disinsecting and sterilizing solutions and sprayers, and discloses a plant disinsecting and sterilizing solution and a special sprayer for preparing and spraying the same. The plant disinsecting and sterilizing solution is mainly technically characterized by comprising 60-800mg of ozone, 100kg of water and acid liquor for enabling the PH value of a mixture to reach 2-3. A working chamber with a gas-liquid mixing mechanism, which is partitioned by using a baffle plate, is arranged below a liquid storage barrel of the sprayer, the gas-liquid mixing mechanism is connected with an ozone generator through a gas guide pipe, and a generation gas inlet of the ozone generator is communicated with the outer part of a shell through a first gas inlet pipe with a gas pump. When the PH value is 2-3 and the content of the ozone reaches 0.6-8ppm, the reduction speed of the ozone is reduced, the disinsecting and sterilizing effect is improved so that no pesticide is remained on agricultural products, the production cost is lowered, leaves of plants are not easy to age so that the photosynthesis is enhanced, the yield of crops are increased and the quality of the crops are increased; and acidic water has a disinsecting and sterilizing function, and the ozone is added, and thus the disinsecting and sterilizing effect is greatly enhanced.

Owner:山东惠生现代农业有限公司

Preparation method of marine organism health-care peptide preparation

InactiveCN111281963AIncrease the degree of hydrolysisSimple processHydrolysed protein ingredientsNatural extract food ingredientsBiotechnologyOyster

The invention belongs to the field of production methods of biological protein products, and provides a preparation method of a marine organism health-care peptide preparation. According to the invention, a double-enzyme step-by-step hydrolysis mode is adopted; the hydrolysis degree of oyster protein and sea cucumber protein is improved; the defect that the biological activity of protein polypeptide is reduced due to loss of functional components in the protein polypeptide in the traditional process is overcome; medicinal and edible food materials are added, so multiple health-care effects areincreased, and the protein peptide preparation with liver protecting activity and health-care effects is prepared; and in virtue of a microencapsulation technology, the bad smell of the oyster protein peptide is masked, the high activity of the polypeptide is maintained, and product quality is improved.

Owner:聂威

Feed for postpartum parent percocypris pingi

InactiveCN104397497AMeet nutritional requirementsSlow down recoveryAnimal feeding stuffAnimal scienceBetaine

The invention relates to a feed for fish, and in particular relates to a feed for postpartum parent percocypris pingi. The feed is prepared from the following raw materials in parts by weight: 30-33 parts of Peru super fish meal, 8-10 parts of soy protein concentrate, 25-28 parts of bean pulp, 22-25 parts of common flour, 1-3 parts of soybean oil, 1-3 parts of soybean lecithin, 1-3 parts of high-quality fish oil, 0.5-1.5 parts of calcium dihydrogen phosphate, 0.2-0.5 part of ocean fish vitamins, 0.5-1 part of complex mineral salt, 0.1-0.3 part of yeast active peptide, 0.1-0.3 part of astaxanthin, 0.1-0.5 part of choline, 0.1-0.5 part of betaine, 0.1-0.2 part of a mould inhibitor, 0.1-0.3 part of immunopolysaccharide and 3-4 parts of bentonite. After the feed for the postpartum parent percocypris pingi is used, the demand of the postpartum parent percocypris pingi for the nutrition can be met, the postpartum recovery speed of the parent percocypris pingi can be accelerated, and the reproductive capacity of the parent percocypris pingi can be improved.

Owner:FISHERIES INST SICHUAN ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com