Preparing method of antioxidant silvering copper powder

A silver-plated copper powder and anti-oxidation technology, which is applied in liquid chemical plating, metal processing equipment, coating, etc., can solve the problems of high cost, non-dense and uneven silver coating layer, and easy agglomeration of powder, etc. Achieve excellent high temperature oxidation resistance, improve silver ion release too fast, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

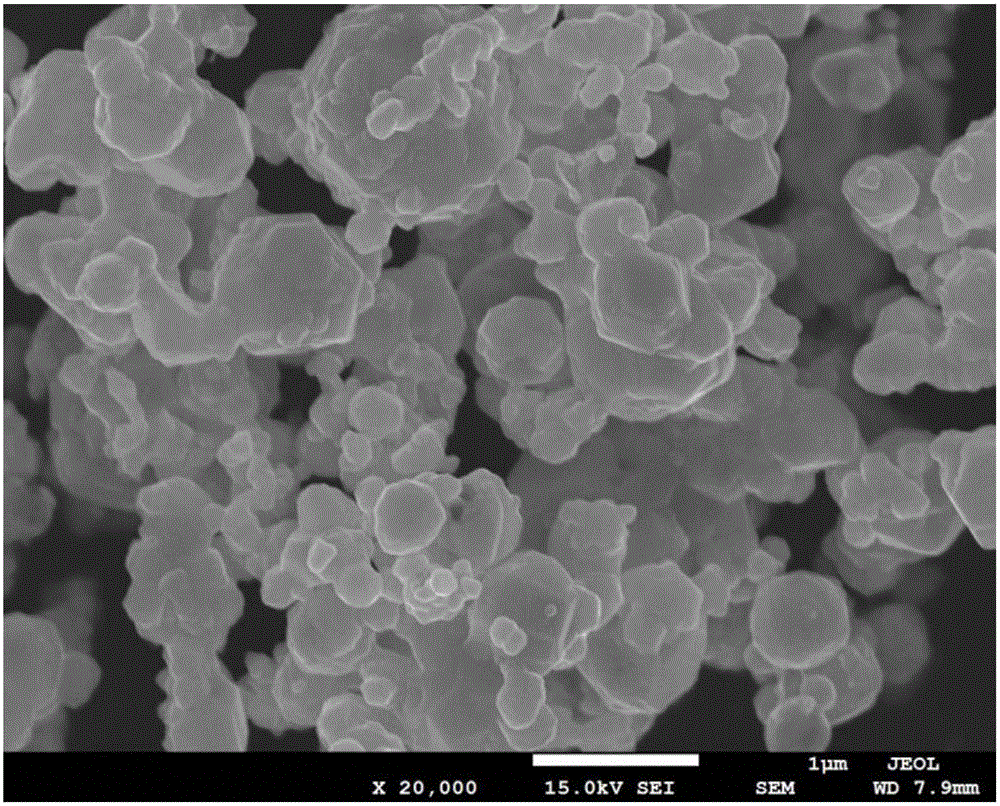

Embodiment 1

[0024] Add 100g of copper powder, 10.3g of sodium hypophosphite, and 10g of PVP into 500mL of deionized water to prepare a reducing solution containing copper substrates, add ammonia water to adjust its pH value to be stable at 11; add 15.9g of silver nitrate, 0.5g of EDTA- 2Na was added to 500mL deionized water to prepare an oxidation solution; the oxidation solution was slowly added to the reduction solution, the temperature was raised to 30°C, and after 20 minutes of reaction, the primary silver-plated copper powder was separated by a centrifuge; the primary silver-plated copper powder was used as the base material to repeat The silver-plated copper powder was prepared three times through the above silver-plated steps twice, washed three times with deionized water, washed once with absolute ethanol, and the silver-plated copper powder after centrifugation was vacuum-dried at 60° C., and the obtained silver-plated copper powder was placed in a horse. Heating in a furnace at 3...

Embodiment 2

[0026] Add 100g of copper powder, 10.3g of sodium hypophosphite, and 10g of PVP into 500mL of deionized water to prepare a reducing solution containing copper substrates, add ammonia water to adjust its pH value to be stable at 11; add 15.9g of silver nitrate, 2g of EDTA-2Na Add 500mL of deionized water to prepare an oxidation solution; slowly add the oxidation solution to the reducing solution, raise the temperature to 30°C, react for 20 minutes, and separate the primary silver-plated copper powder with a centrifuge; repeat the above with the primary silver-plated copper powder as the base material The silver-plated copper powder is prepared twice, and the silver-plated copper powder is prepared three times, washed three times with deionized water, washed once with absolute ethanol, and the silver-plated copper powder after centrifugation is vacuum-dried at 60°C. Heating in the furnace at 300°C for 20 minutes, the mass weight gain rate reaches 2.3%.

Embodiment 3

[0028] Add 100g of copper powder, 10.3g of sodium hypophosphite, and 10g of PVP into 500mL of deionized water to prepare a reducing solution containing copper substrates, add ammonia water to adjust its pH value to be stable at 11; add 15.9g of silver nitrate, 2g of EDTA-2Na Add 500mL of deionized water to prepare an oxidation solution; slowly add the oxidation solution to the reducing solution, raise the temperature to 50°C, react for 20 minutes, and separate the primary silver-plated copper powder with a centrifuge; repeat the above with the primary silver-plated copper powder as the base material The silver-plated copper powder is prepared twice, and the silver-plated copper powder is prepared three times, washed three times with deionized water, washed once with absolute ethanol, and the silver-plated copper powder after centrifugation is vacuum-dried at 60°C. Heating in a furnace at 300°C for 20 minutes, the mass weight gain rate reaches 0.5%. The obtained silver-plated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com