Sintered ore modifier and preparation method and iron-making method

A technology of ore modifier and sintered ore, which is applied in the field of ironmaking, can solve the problems of increasing the pressure difference at the upper part of the blast furnace, deteriorating the gas permeability of the material layer, and affecting the forward movement of the blast furnace, so as to achieve the effect of reducing low-temperature reduction pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

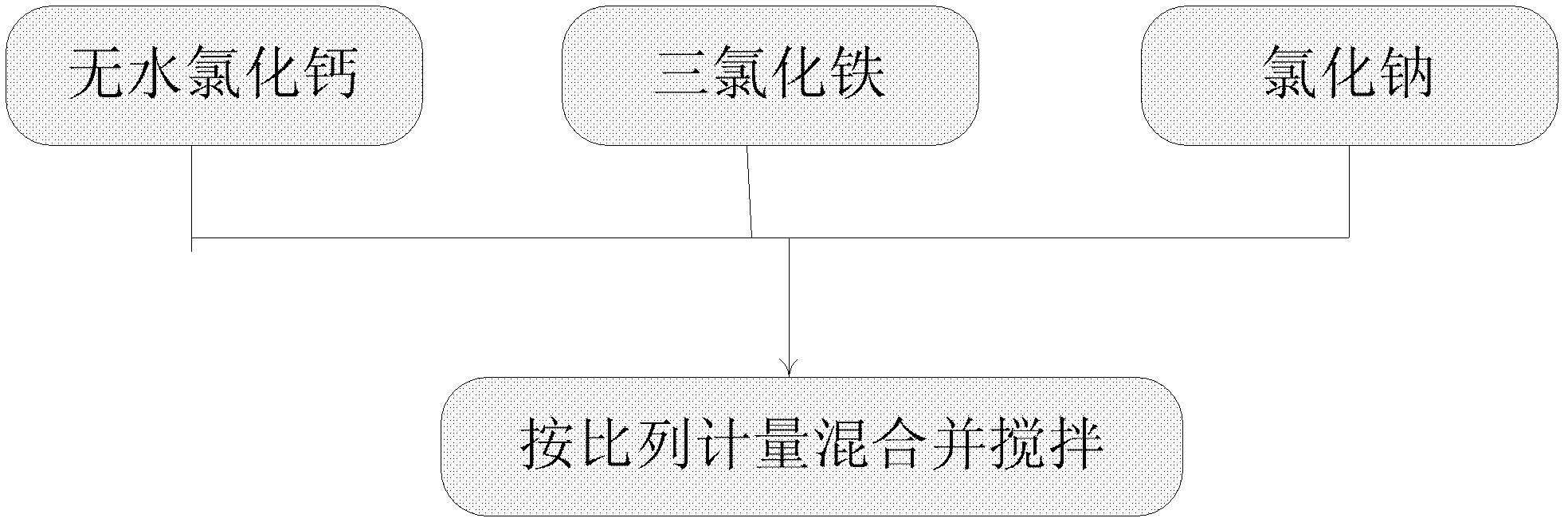

Method used

Image

Examples

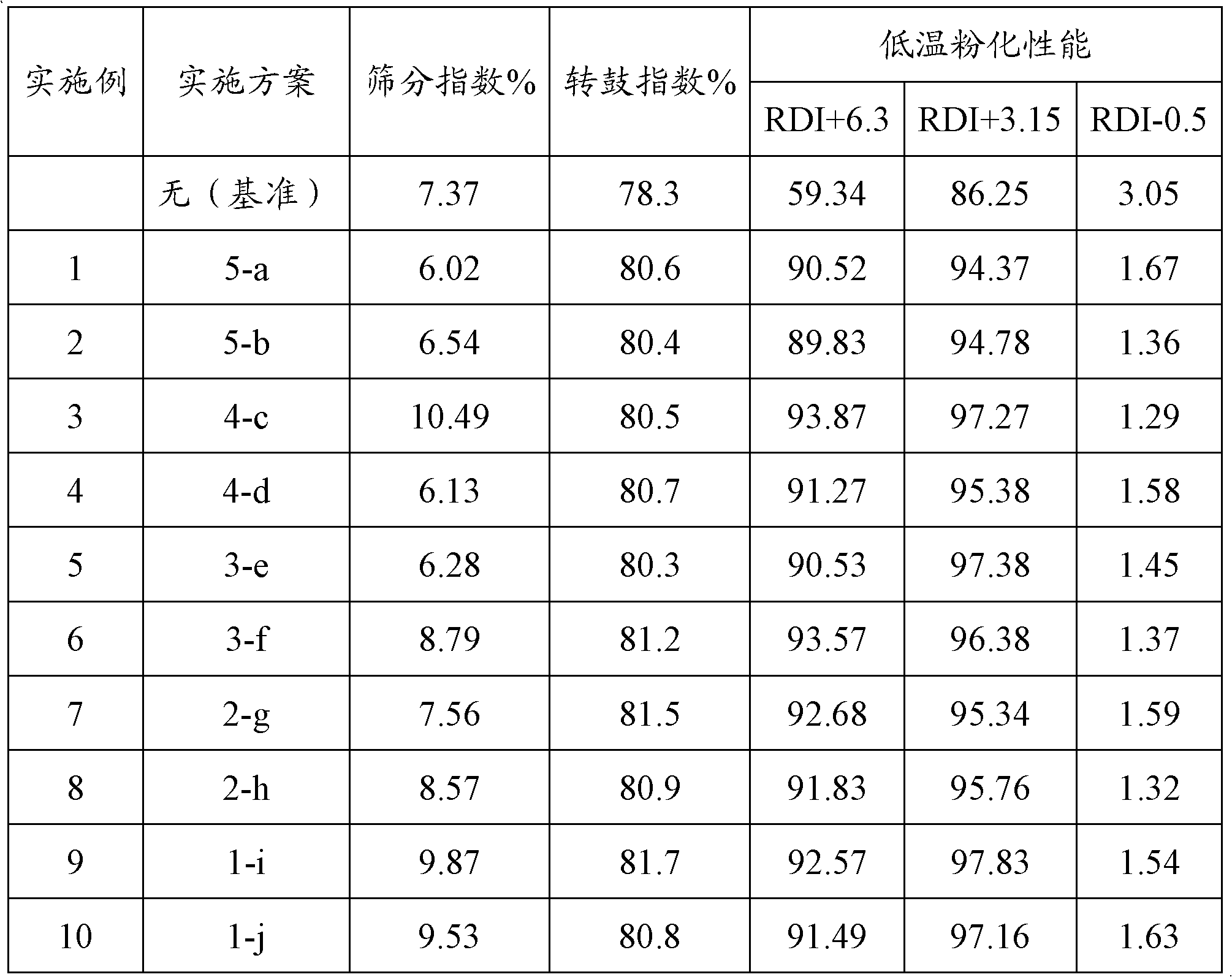

Embodiment 1

[0045] The number of this example is 5-a, and it is measured and weighed according to the ratio of formula 5 in Table 1, wherein the concentration of the sinter modifier in the sinter modifier solution is prepared according to the formula of a in Table 2, and the prepared The sinter modifier is dissolved in the spray amount according to the formula a in Table 2 and is sprayed on the surface of the sinter, and then put into the reaction furnace for reduction reaction. It can be seen from Table 3 that the low-temperature pulverization performance of the sinter is better than that of no (Benchmark) The low-temperature pulverization performance of sintered ore has been significantly improved.

Embodiment 2

[0047] The number of this example is 5-b, and it is measured and weighed according to the proportion of formula 5 in Table 1, wherein the concentration of the sinter modifier in the sinter modifier solution is prepared according to the formula of b in Table 2, and the prepared The sinter modifier is dissolved in the spray amount according to the formula b in Table 2 and sprayed on the surface of the sinter, and then put into the reaction furnace for reduction reaction. It can be seen from Table 3 that the sinter is at a low temperature at RDI+3.15 The pulverization performance is the best, and the low temperature pulverization performance at RDI-0.5 is also ideal.

Embodiment 3

[0049] The number of this example is 4-c, and it is measured and weighed according to the proportion of formula 4 in Table 1, wherein the concentration of the sinter modifier in the sinter modifier solution is prepared according to the formula of c in Table 2, and the prepared The sinter modifier is dissolved in the spray amount according to the formula c in Table 2 and sprayed on the surface of the sinter, and then put into the reaction furnace for reduction reaction. It can be seen from Table 3 that the low-temperature pulverization performance of the sinter is better than that of no (Benchmark) The low-temperature pulverization performance of sintered ore has been significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com