Plant disinsecting and sterilizing solution and special sprayer for preparing and spraying same

A bactericidal liquid, sprayer technology, applied in the directions of botanical equipment and methods, fungicides, plant growth regulators, etc., can solve the problems of increasing the resistance of insects and bacteria, shortening the spraying cycle, and poor insecticidal and bactericidal effects, and achieves improved Crop yield and quality, enhanced insecticidal and bactericidal effects, and improved insecticidal and bactericidal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

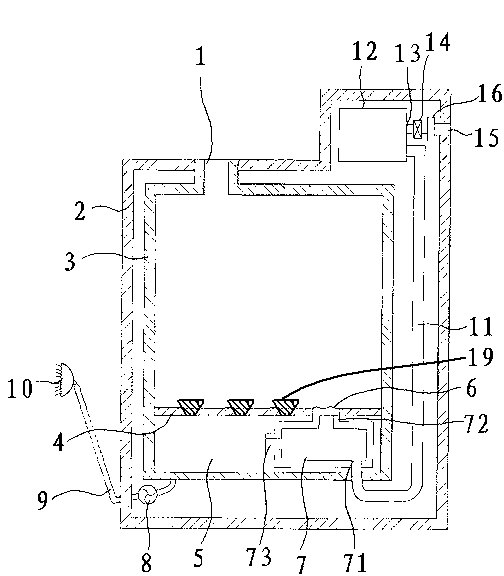

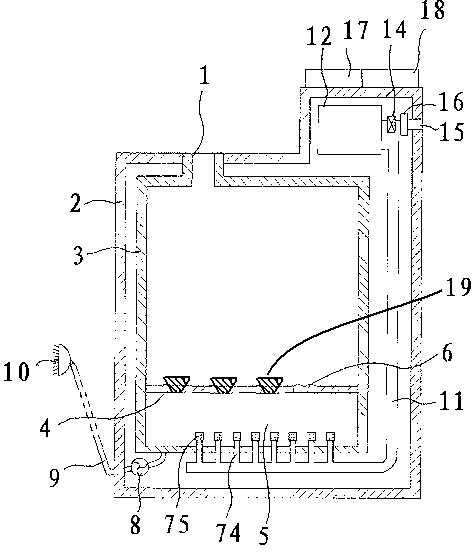

[0028] Add 100 kilograms of water in the liquid storage barrel 3, add about 8 milliliters of concentrated hydrochloric acid that the mass percent concentration is 38%, fully stir, be made into the solution that pH value is 3, open air pump 14 and ozone generator 12, pass through the first The air pipe 15 inputs oxygen into the ozone generator 12, adjusts the ozone concentration in the working room to 8ppm through the gas-liquid mixing structure 7, then opens the nozzle 10 at the end of the water pump 8 and the liquid spray pipe 9, starts spraying, and sprays while working Ozone was introduced into the chamber to keep the ozone concentration at 8ppm.

Embodiment 2

[0030] Add 100 kilograms of water in the liquid storage tank 3, add about 80 milliliters of concentrated hydrochloric acid that the mass percent concentration is 38%, fully stir, be made into the solution that pH value is 2, open air pump 14 and ozone generator 12, pass through the first inlet Air pipe 15 imports air in the ozone generator 12, and the ozone concentration in the working room is adjusted to 0.6ppm by gas-liquid mixing structure 7, then opens the nozzle 10 of water pump 8 and liquid spray pipe 9 ends, starts to spray, sprays while spraying to Ozone is introduced into the studio to keep the ozone concentration at 0.6ppm.

Embodiment 3

[0032] Add 100 kilograms of water in the liquid storage tank 3, add about 25.2 milliliters of concentrated hydrochloric acid with a mass percent concentration of 38%, fully stir, be made into a solution with a pH value of 2.5, open the air pump 14 and the ozone generator 12, and pass through the first inlet The air pipe 15 inputs oxygen into the ozone generator 12, adjusts the ozone concentration in the working room to 7ppm through the gas-liquid mixing structure 7, then opens the nozzle 10 at the end of the water pump 8 and the liquid spray pipe 9, starts spraying, and sprays while working Ozone was introduced into the chamber to keep the ozone concentration at 7ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com