Patents

Literature

87results about How to "Restore evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrocatalyst of MOFs (Metal-organic Frameworks)/graphene composite carrier and preparation method of electrocatalyst

InactiveCN103178273ARestore evenlyNot easy to reuniteCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsMicrowaveSynthesis methods

The invention discloses electrocatalyst of MOFs (Metal-organic Frameworks) / graphene composite carrier and a preparation method of the electrocatalyst. The electrocatalyst is composed of the MOFs / graphene composite carrier and an active component. The preparation method of the MOFs / graphene composite carrier comprises the following steps of: preparing MOFs / graphene composite carrier through a hydrothermal reaction method; and loading the active component on the composite carrier by adopting a microwave synthesis method. The preparation method disclosed by the invention is simple in preparation steps, short in time and small in product loss; and the prepared catalyst is small in grain size, unlikely to cluster, uniformly distributed and high in electrochemical catalytic activity.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

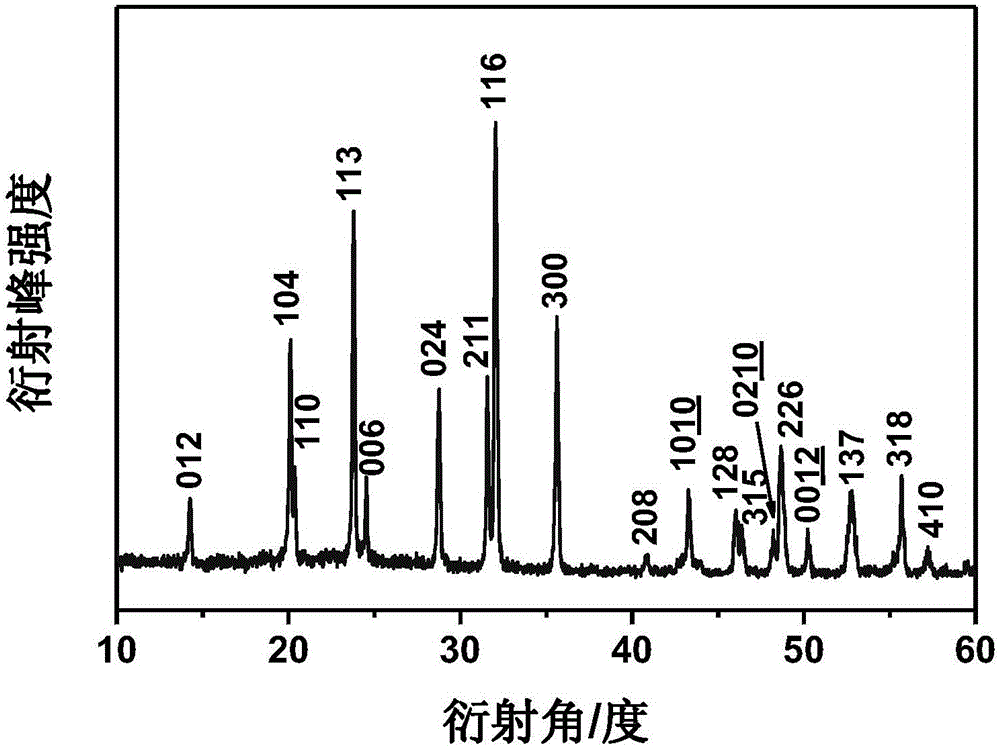

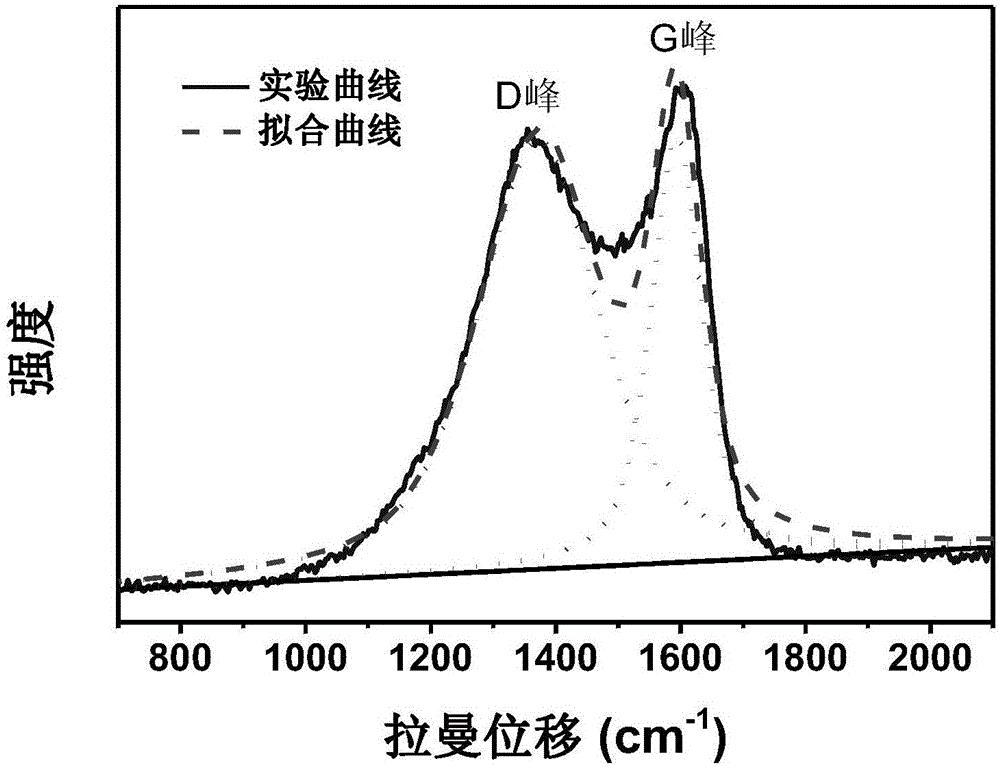

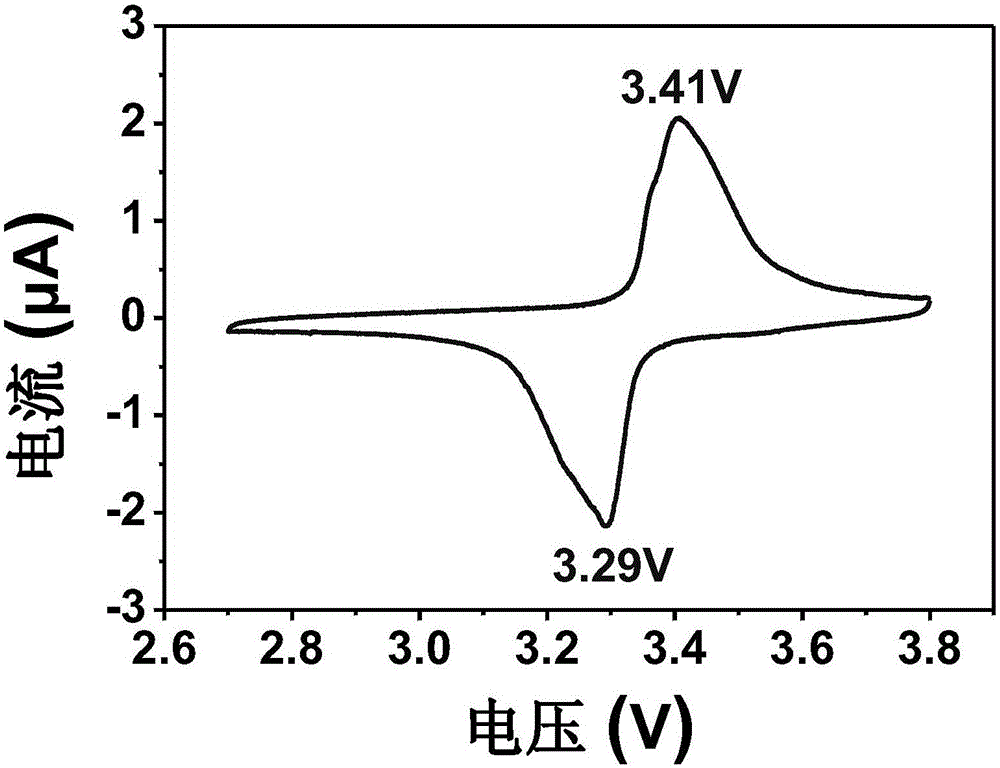

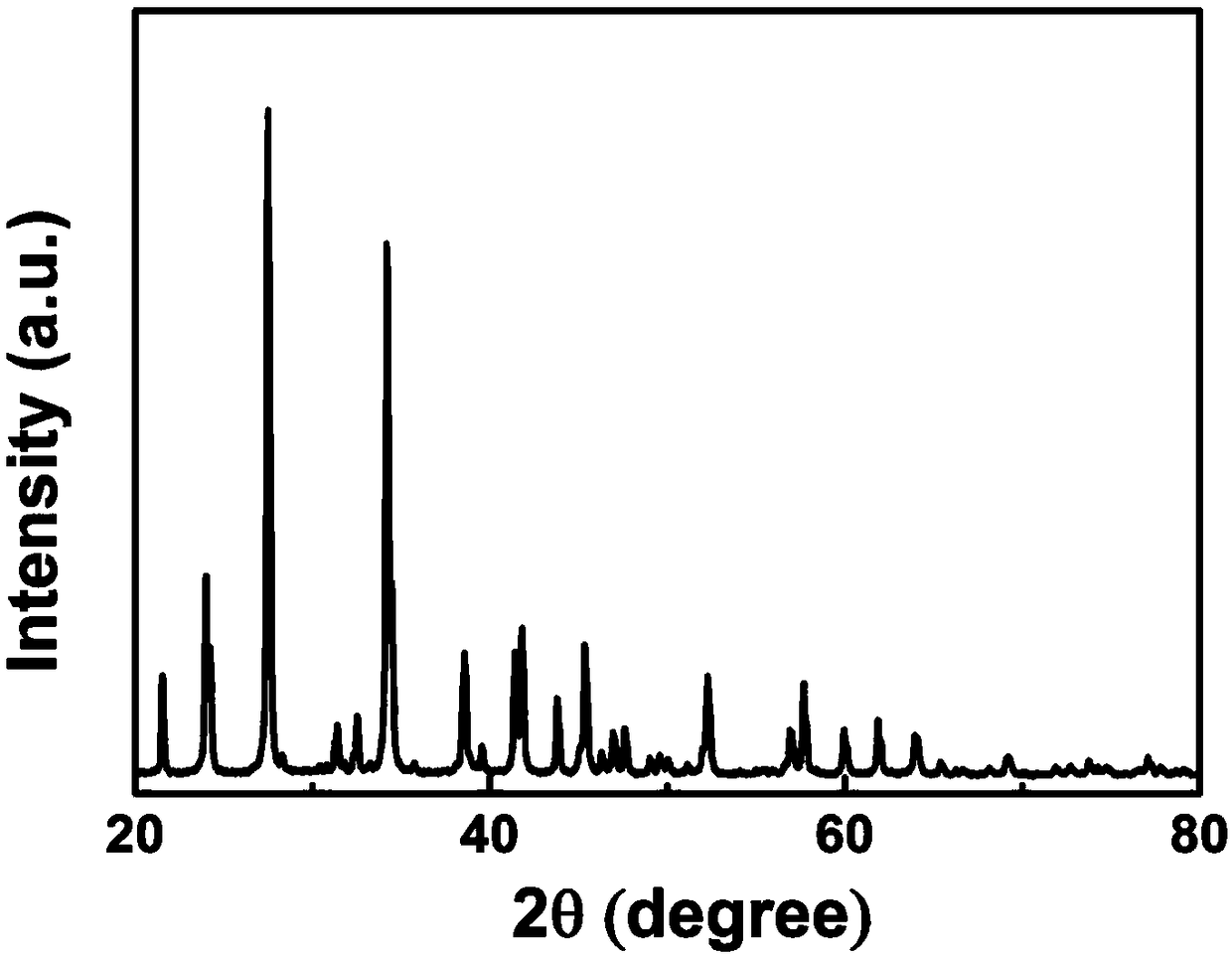

Preparation method for cathode material Na3V2(PO4)3/C of sodium ion battery

InactiveCN105140468ARestore fully and evenlyMix well and evenlyCell electrodesSecondary cellsSodium-ion batteryReducing atmosphere

The invention discloses a preparation method for a cathode material Na3V2(PO4)3 / C of a sodium ion battery. The preparation method comprises the following steps of: (1) taking a high-valent vanadium source compound, a sodium source compound, a phosphorus source compound and a reducing agent as raw materials, weighing the reaction raw materials according to the molar ratio of a sodium element, a vanadium element and a phosphorus element of being 3:2:3 and the molar ratio of the reducing agent and the high-valent vanadium source compound of being 3:1 to 15:1, carrying out mechanical ball grinding for 2 to 20 hours, and reducing high-valent vanadium into low-valent vanadium at a normal temperature; and (2) forwarding a precursor obtained through ball grinding in the step (1) into an inert atmosphere or a reducing atmosphere, and carrying out heat preservation for 4 to 20 hours at 600-900 DEG C to obtain the Na3V2(PO4)3 / C. The method has the advantages of short flow and low cost, and is easy to control, the prepared Na3V2(PO4)3 / C is high in purity and crystallinity, and the production of the cathode material Na3V2(PO4)3 / C of the sodium ion battery at a large scale is easy to realize.

Owner:WUHAN UNIV

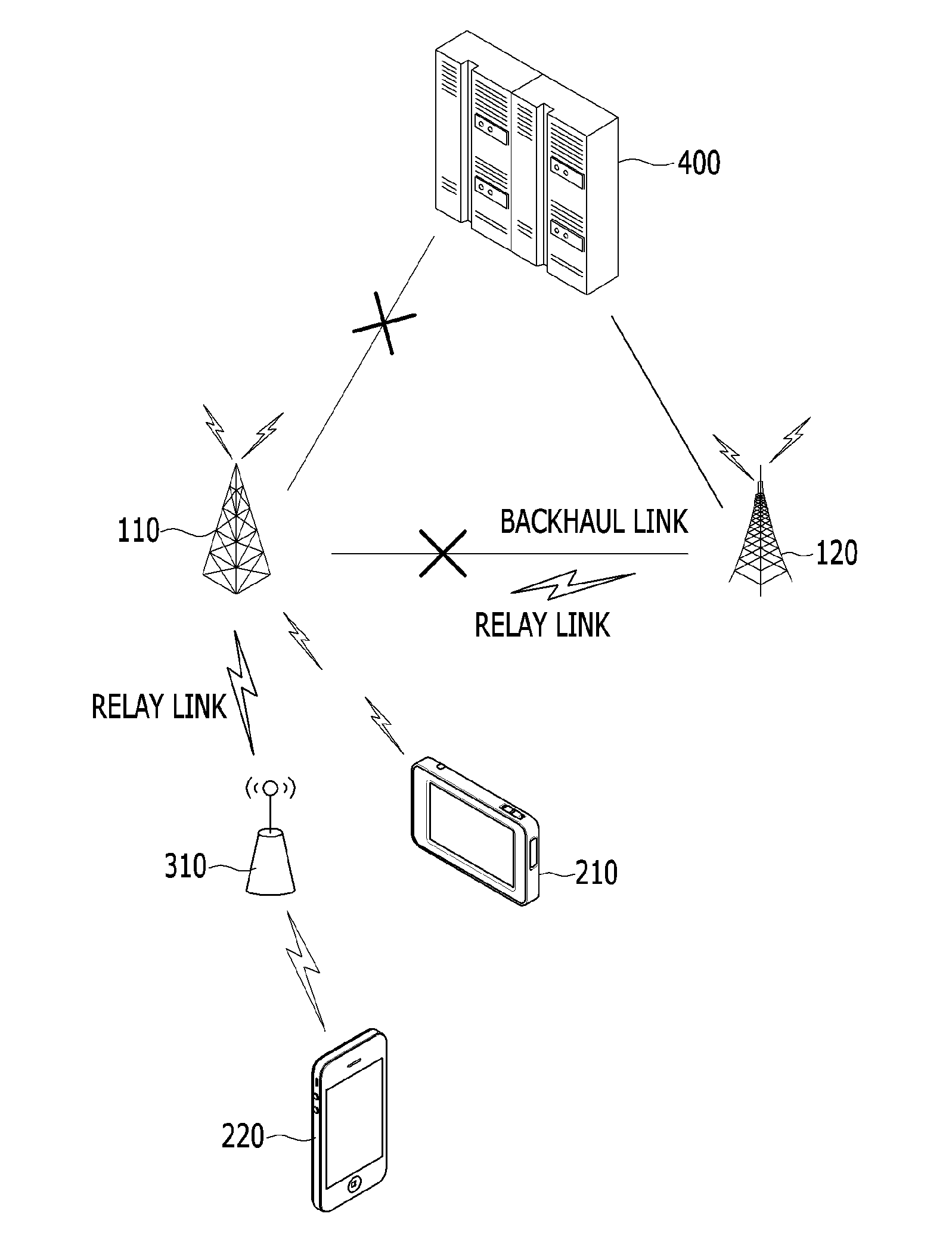

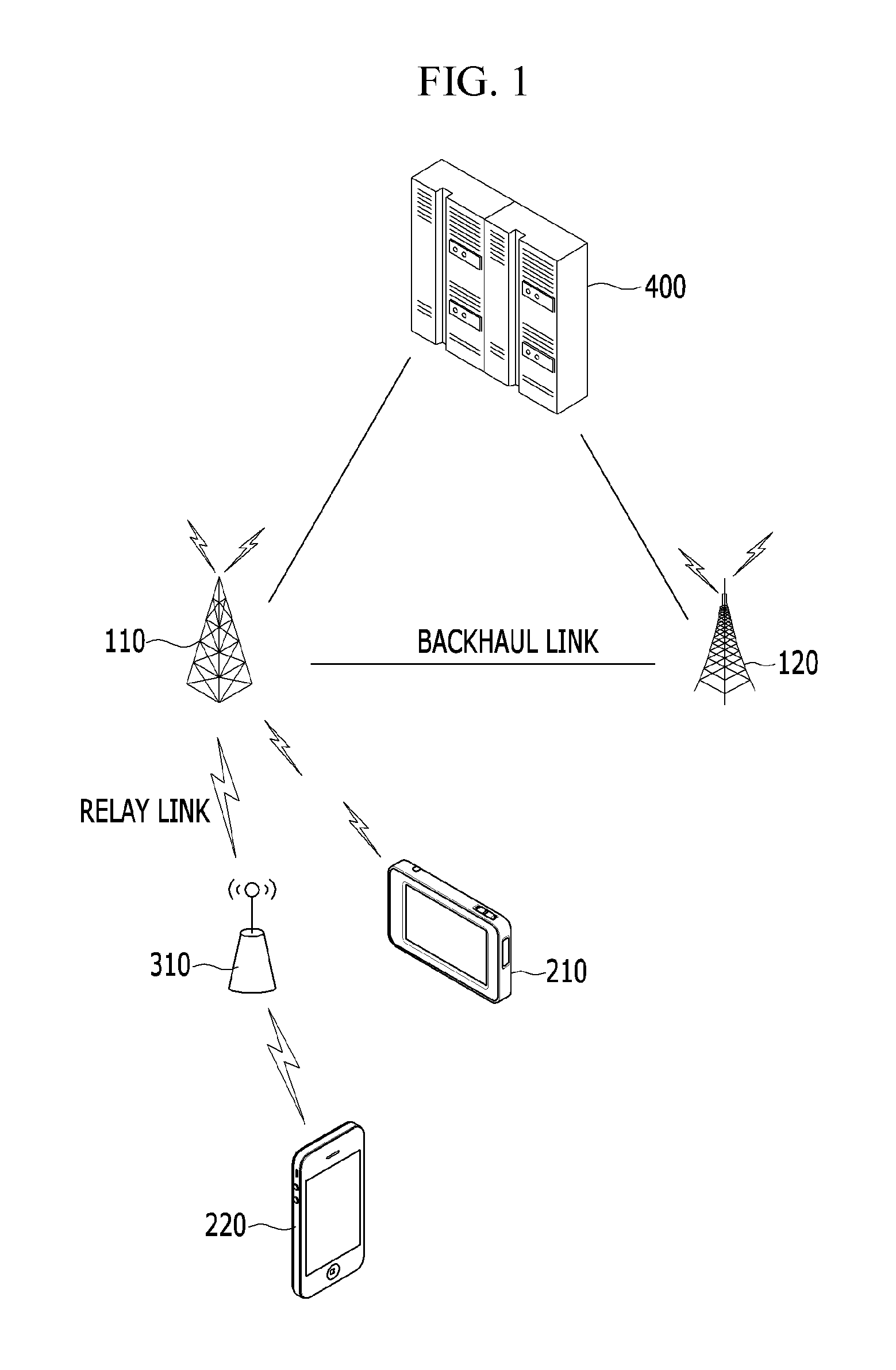

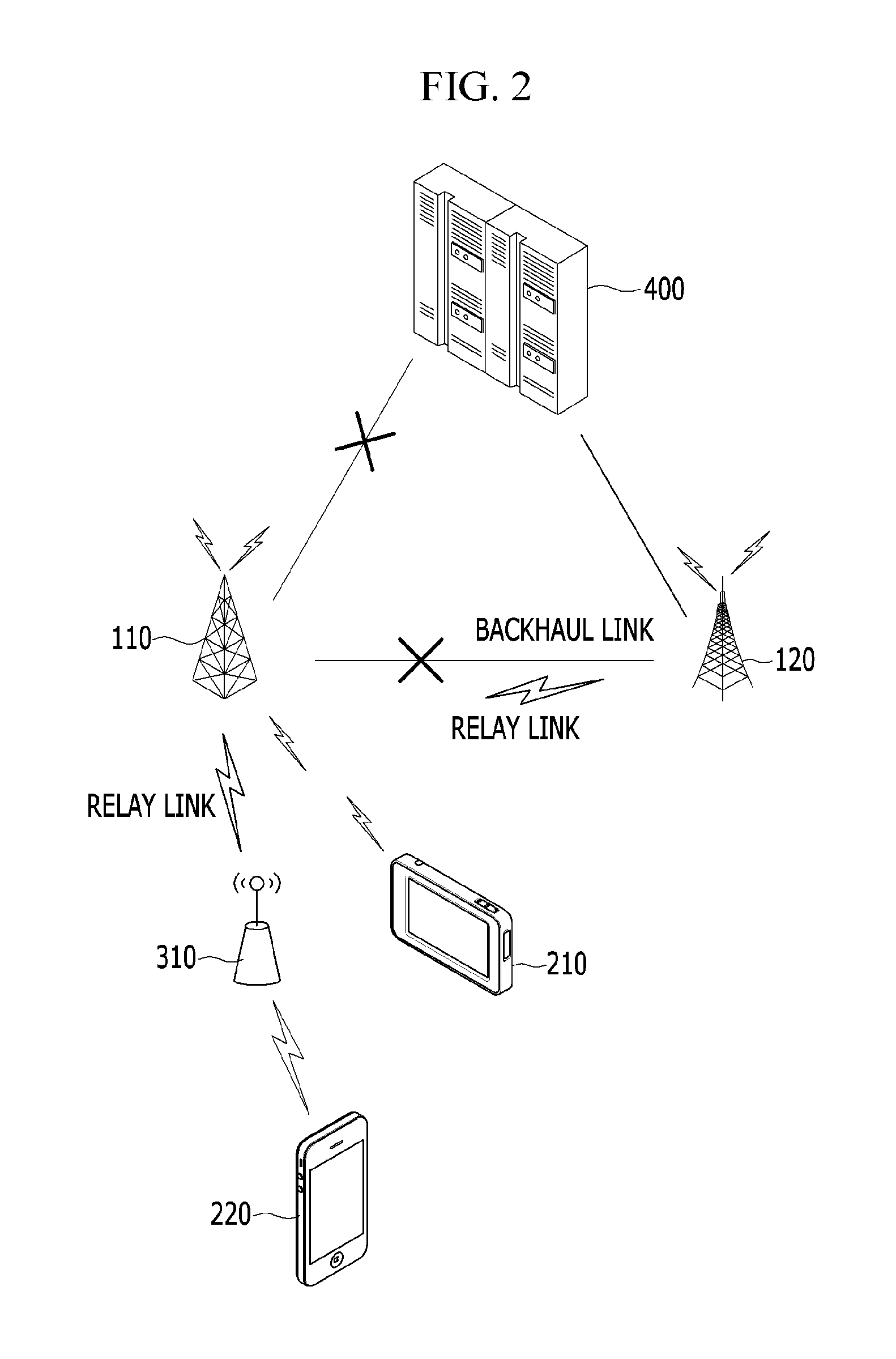

Method for relaying of base station, method for relaying of terminal and method for transmitting

A method of relaying in a base station (BS) includes: setting, when a backhaul link of a first BS is damaged, a relay link using a second BS, which is an adjacent BS of the first BS as a serving BS; and releasing the relay link after the backhaul link is recovered.

Owner:ELECTRONICS & TELECOMM RES INST

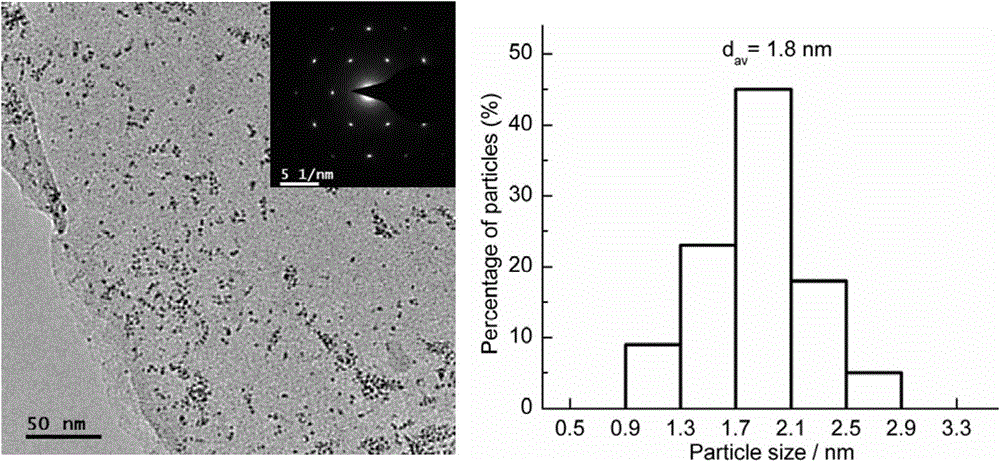

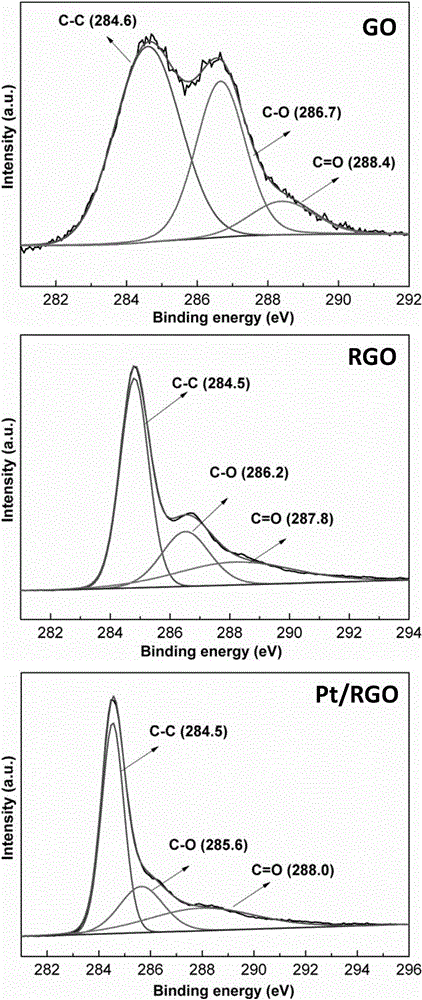

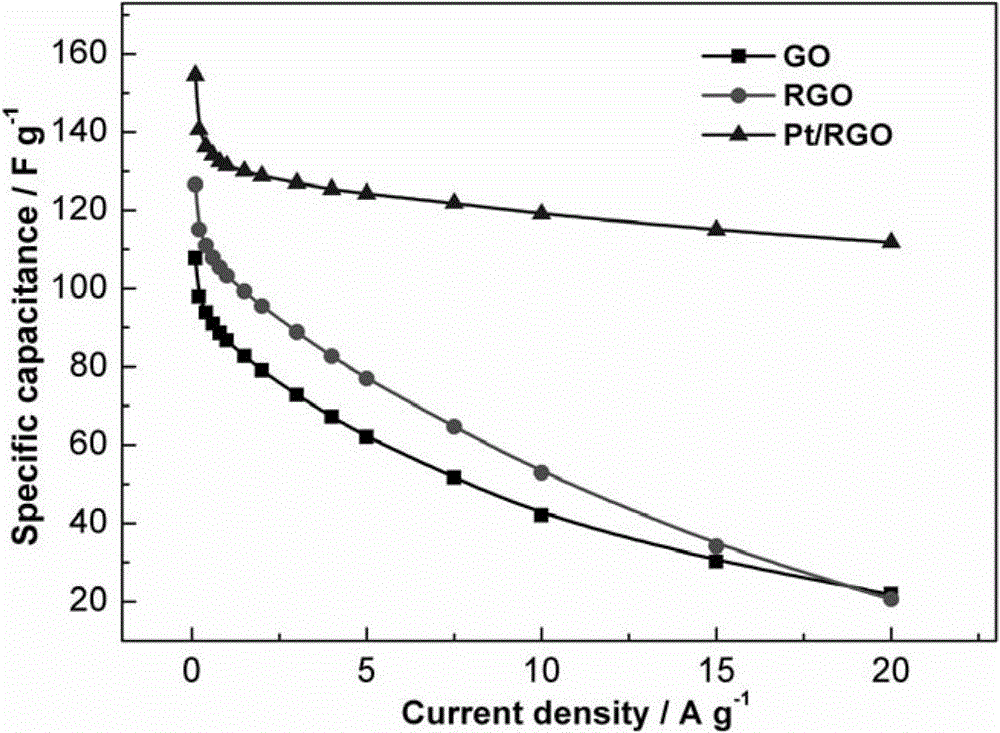

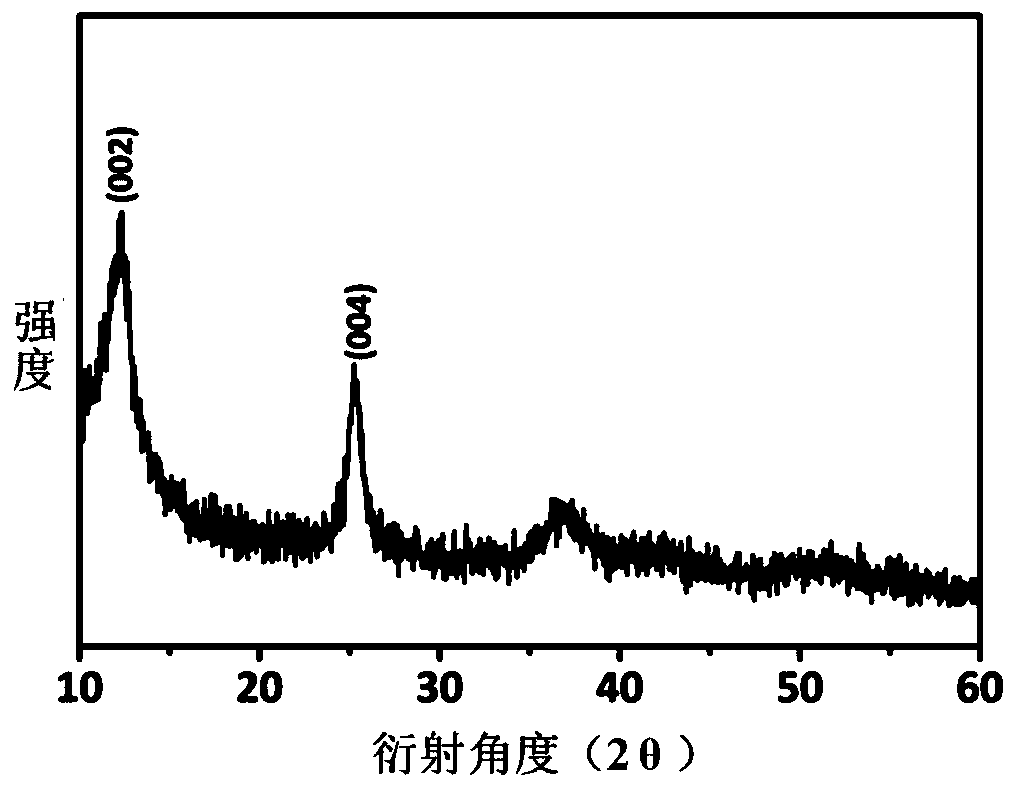

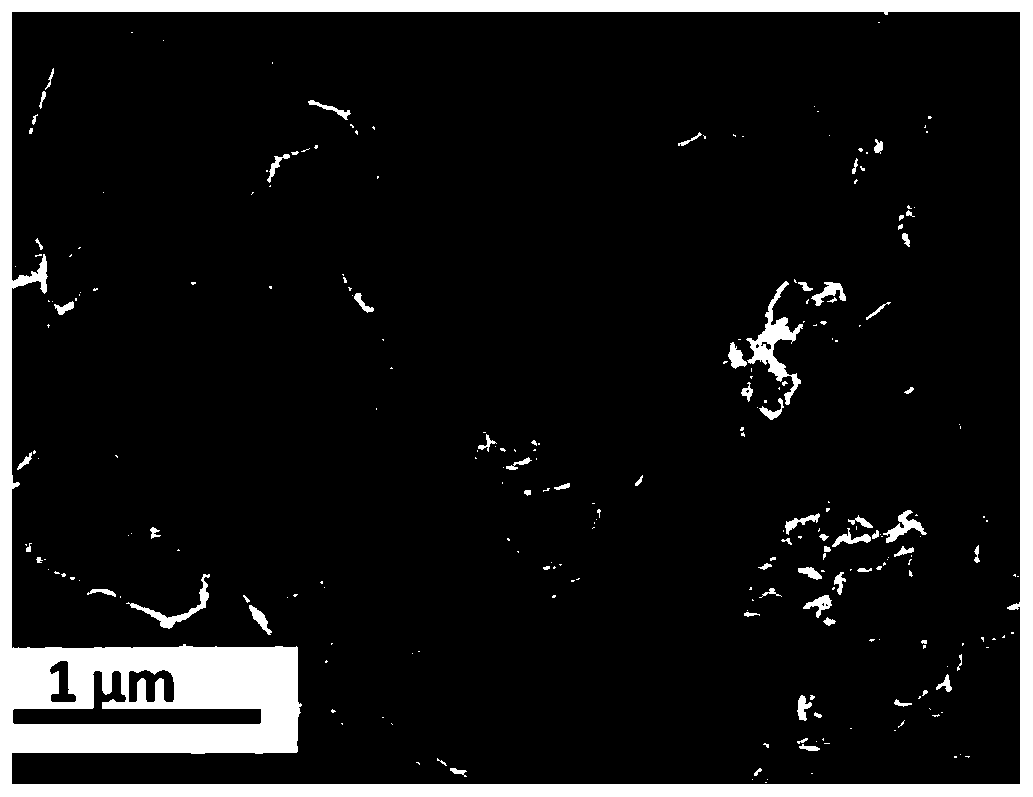

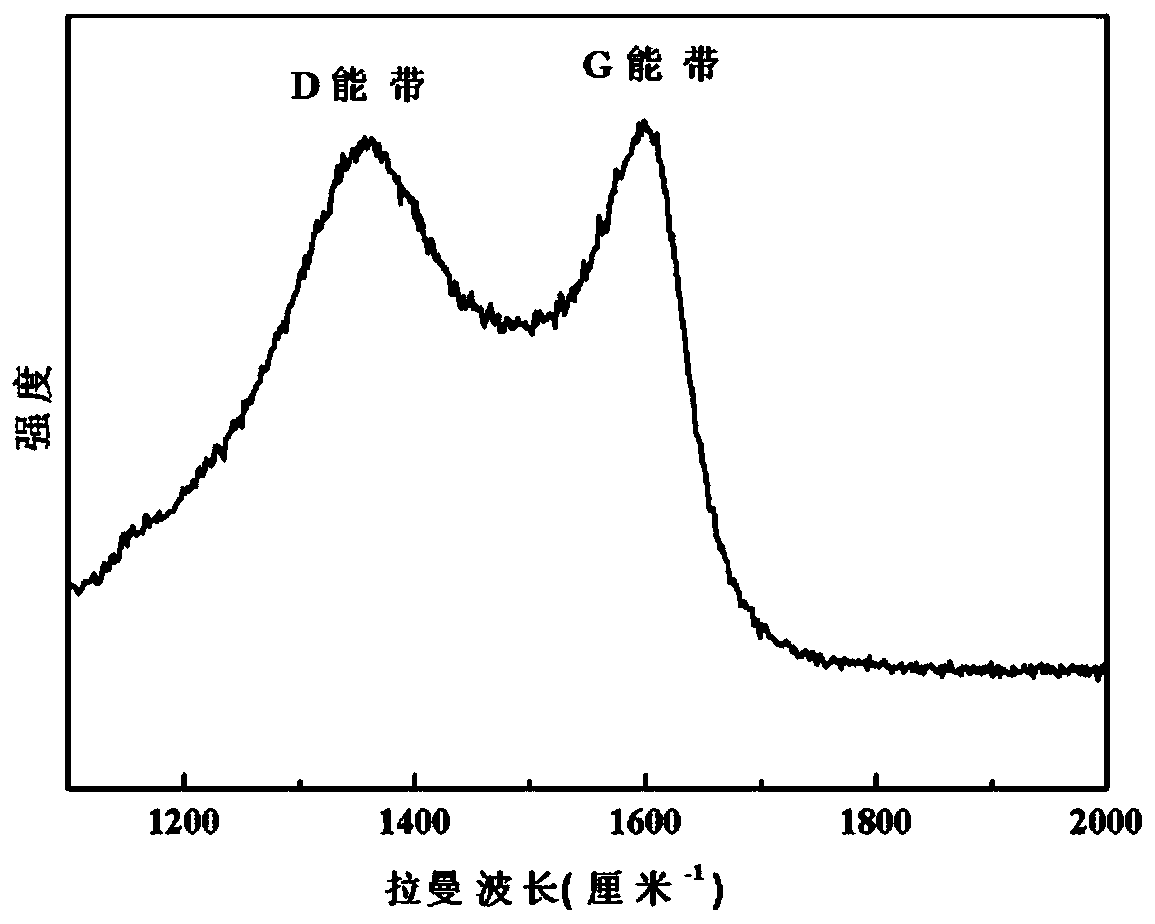

Platinum (Pt)/reduced graphite oxide (RGO) nano composite material and preparation method and application thereof

ActiveCN102751101ACheap and easy to getImprove securityElectrolytic capacitorsCapacitanceGraphene nanocomposites

The invention discloses a platinum (Pt) / reduced graphite oxide (RGO) nano composite material and a preparation method and application thereof. According to the preparation method, graphite oxide (GO) and a platinum metal precursor are reduced in one step by radiation and induction of a gamma ray or an electronic beam, thus obtaining the Pt / RGO nano composite material with the Pt load capacity being 1.0wt% to 15wt%; Pt nano particles are uniformly distributed on an RGO sheet layer, and the average diameter of the Pt nano particles is 1.8 nanometers; and the particle sizes of the Pt nano particles are within 2 nanometers. By virtue of the load capacity of the nano particles of platinum metal, the reducing degree of the GO can be increased, the conductivity of a product is improved, and the surface utilization rate of the RGO sheet layer is increased. Compared with the GO and pure graphene, the nano composite material prepared by the method has higher specific capacitance and higher high-current multiplying power when being applied to a super-capacitor electrode material.

Owner:PEKING UNIV

Reduction method for copper-radic catalyst for reforming methanol vapour to produce hydrogen

The present invention discloses a reduction method of catalyst for reforming hydrogen production by using methyl alcohol aqueous vapour. Said method includes the following several stages: a, dehydration stage of catalyst; b, initiation stage of catalyst reduction; and c, reduction stage of catalyst. Said invention also provides the concrete steps of the above-mentioned every stage and its concrete requirements.

Owner:HAO HUA CHENGDU TECH

Preparation method of metal organic framework loaded Pt-base catalyst

InactiveCN103191778ADistribute quicklySmall particlesOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystAlcohol

The invention discloses a preparation method of a metal organic framework loaded Pt-base catalyst. The method comprises putting the metal organic framework into an alcoholic solution, vibrating with ultrasonic, adding drop by drop a mixed solution of chloroplatinic acid and cobalt oxide, adding NaOH, stirring, putting into a microwave oven for intermittent heating, cooling, filtering by pumping, and drying under vacuum to obtain the metal organic framework loaded Pt-base catalyst. The catalyst is small in particle, not easy to agglomerate, good in dispersibility and high in electrochemical catalytic activity.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

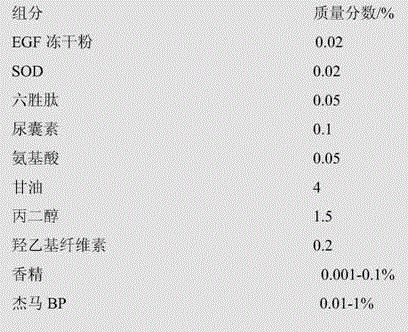

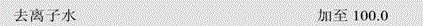

Composition for facial repair and preparation method thereof

ActiveCN103976891APromote growthScavenging oxygen free radicalsCosmetic preparationsToilet preparationsChemistryLiposome

The invention provides a composition for facial repair. The composition is composed of the following components in percentage by weight: 0.01 to 1% of EGF freeze-dried powder, 0.01 to 5% of SOD, 0.1 to 5% of active peptide, 0.01 to 2% of allantoin, and the balance being water; wherein the active components are all individually buried in liposome or covered by nano microcapsules before the mixing. The active effective components of the composition are individually buried in or covered by transfer vectors. Then the active effective components are transported to the corium layer or shallow corium layer by the transfer vectors to promote the cell metabolism, growth, proliferation, and differentiation, remove the free radicals and harmful substances, and improve the skin problems such as dull and yellow skin color, dryness, wrinkles, skin allergy, and the like.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

Aqueous zinc ion battery and preparation method and application thereof

ActiveCN110867579AImprove conductivityImproved magnification performanceFinal product manufactureElectrode carriers/collectorsCarbon compositesElectrolytic agent

The invention relates to an aqueous zinc ion battery and a preparation method and application thereof. A birnessite / carbon composite cathode active material is synthesized by a co-precipitation method. Metal zinc powder is used as an anode active material, and a zinc sulfate-water-urea mixed solution is used as an electrolyte. A pole piece is prepared by using a slurry method. A battery cell is prepared by a winding method. The battery is prepared by a conductive adhesive bonding method. In the method, a carbon material and the birnessite are synthesized in situ. The battery prepared by the method can suppress the dissolution of the cathode material Mn. The urea-modified electrolyte can suppress the generation of dead zinc and zinc dendrites and extend the battery cycle life. A nylon net or chinlon net cathode current collector can reduce the cost and increase the energy density of the battery. A conductive adhesive bonding bus bar can prolong the battery life. The method of the invention is suitable for pilot scale-up production. The battery of the invention can be used as an electric bicycle power battery.

Owner:JIANGSU UNIV OF TECH

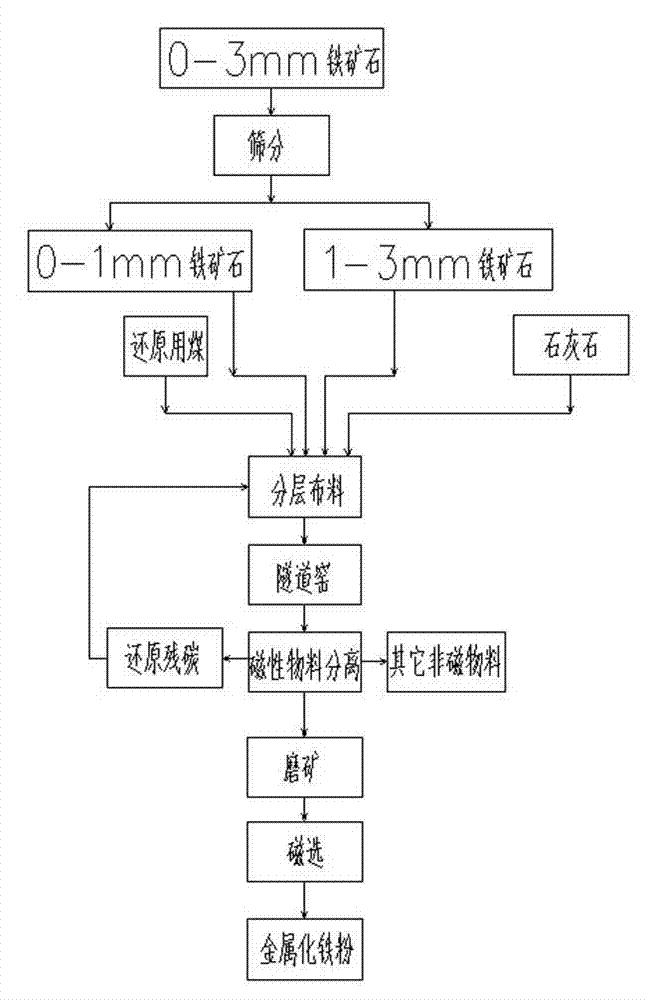

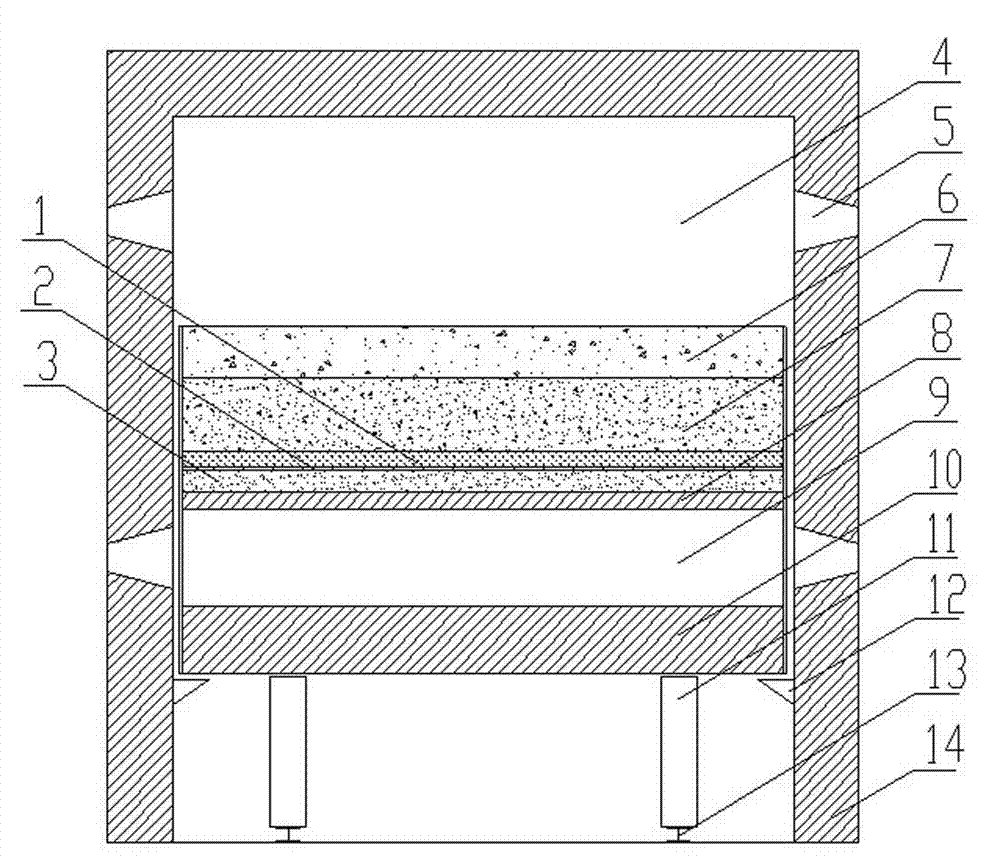

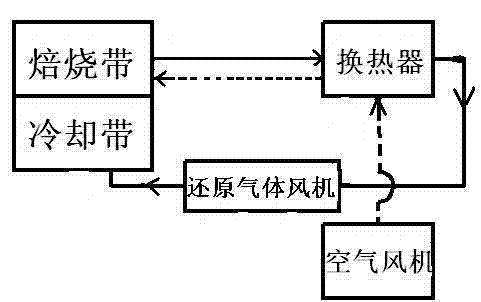

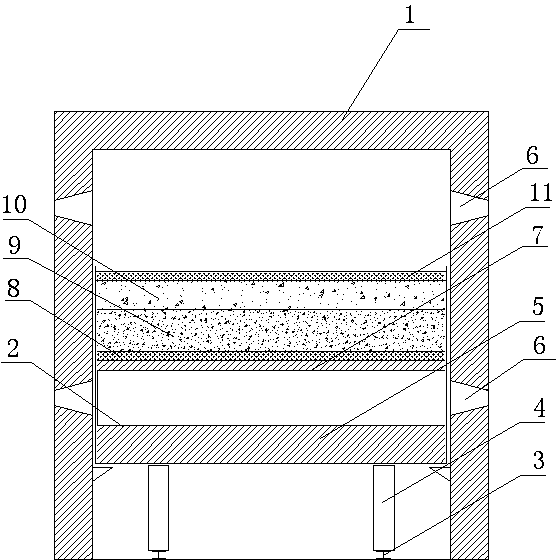

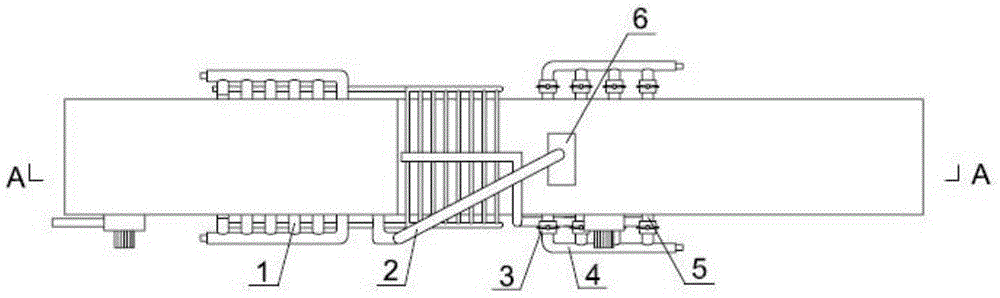

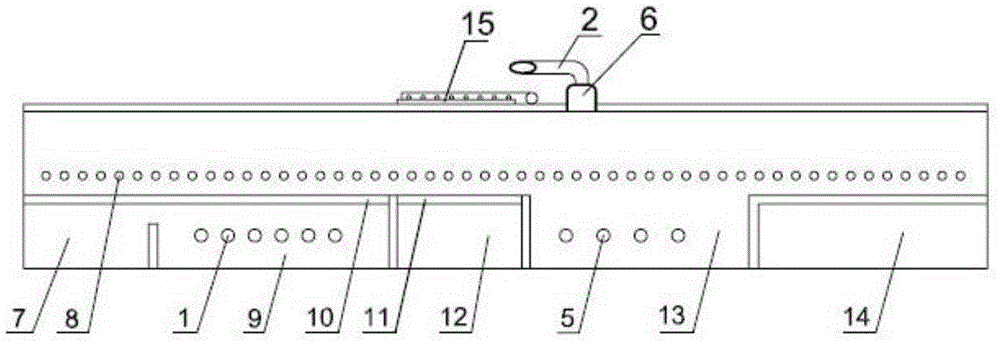

Hierarchical material distribution reduction method for sponge iron tunnel kiln and tunnel kiln applying same

ActiveCN103937921ARestore evenlySolve the problem of using external gas fuel for normal productionFurnace typesTunnel kilnCarbon layer

The invention discloses a hierarchical material distribution reduction method for a sponge iron tunnel kiln and the tunnel kiln applying the hierarchical material distribution reduction method. Materials to be reduced are divided into different grades according to the particle size range, the materials, in different grades, to be reduced are respectively mixed with reducers to form mixed materials, the mixed materials are tiled on a table board of a tunnel kiln car in layers, the particle size range of the materials to be reduced in each layer is gradually increased from the bottom layer to the top layer, and the kiln car carries out reduction by passing through a preheating zone, a roasting zone and a cooling zone in the tunnel kiln after the materials are tiled. By adopting the hierarchical material distribution reduction method, iron ores in different particle sizes can be uniformly reduced during reduction from the upper layer to the bottom layer and in a process of oxygenating for the upper layer by the lower layer in the tunnel kiln; ash of a reduced carbon layer can leak into the lower part from an isolation pore plate, and magnetic separation quantity of a magnetic separation step for the reduced materials after drawing is reduced; and a heat exchanger specially used for the tunnel kiln and a fan are arranged, so that a reducing gas is fully utilized, burning gas does not need to be additionally supplemented, and cost is reduced.

Owner:JIUQUAN IRON & STEEL GRP

Preparation method for metal-organic-framework-loaded platinum-based catalyst

InactiveCN105958085ADistribute quicklySmall particlesMaterial nanotechnologyCell electrodesNano catalystFiltration

The invention discloses a preparation method for a metal-organic-framework-loaded platinum-based catalyst. The metal organic framework is added to an alcoholic solution and the mixture is subjected to ultrasonic oscillation; then a mixed solution of chloroplatinic acid and cobalt oxide is added in a dropwise manner; next, NaOH is added and stirred, and the mixture is placed in a microwave oven to be heated intermittently; and next, the mixture is subjected to cooling, suction filtration and vacuum drying to obtain the metal-organic-framework-loaded platinum-based catalyst. The catalyst prepared by the invention is small in granules, hard to agglomerate, high in dispersibility and high in electrochemical catalytic activity.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Reducing roasting method for powdered iron ores in tunnel kiln

The invention discloses a reducing roasting method for powdered iron ores in a tunnel kiln, which is designed for solving the problems of low heat transfer efficiency, long reducing time, non-uniform material reduction quality, and the like when powdered iron ores are subjected to reducing roasting in a tunnel kiln. According to the invention, by reasonably selecting the particle size range and distribution of iron ores, iron ores with different particle sizes and reducing coal are mixed and distributed in layers, and then the obtained object is subjected to reducing roasting, so that the iron ores with different particle sizes achieve a same roasting effect, thereby increasing the metal recovery rate of roasted iron ores, improving the quality of roasting, shortening the roasting time, reducing the roasting temperature, and lowering the production cost.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Combined direct reduction technology of blast furnace gas ash and refractory low-grade iron ore in tunnel kiln

ActiveCN104004874AEfficient use ofImprove carbon use efficiencyRecycling and recovery technologiesTunnel kilnIron powder

The invention provides a combined direct reduction technology of blast furnace gas ash and refractory low-grade iron ore in a tunnel kiln. The combined direct reduction technology mainly comprises the following processing steps: (1) burdening and mixing the iron ore with grain sizes of 0-3mm and the blast furnace gas ash so as to obtain fine-graded materials; grading the iron ore with grain sizes of above 1mm according to different grain size ranges, burdening and mixing the iron ore and reduced coal in the same grain size range so as to obtain coarse-graded materials; (2) sequentially laying the fine-graded materials and the coarse-graded materials on a fire-resistant thermal conducting plate of a kiln car of a tunnel kiln from top to bottom; and (3) placing the materials in the tunnel kiln along with the kiln car so as to carry out high temperature reduction. The combined direct reduction technology has the advantages that the blast furnace gas ash is effectively utilized, and the utilization efficiency of carbon in the blast furnace gas ash is greatly improved; by adopting a layering distribution step-by-step oxygenation reduction method, the metallization ratio of iron ore direct reduction is increased, and the reduction time is shortened; and the iron grade of metallizing iron powder produced by the technology reaches above 84%, and the metallization ratio reaches above 88%.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

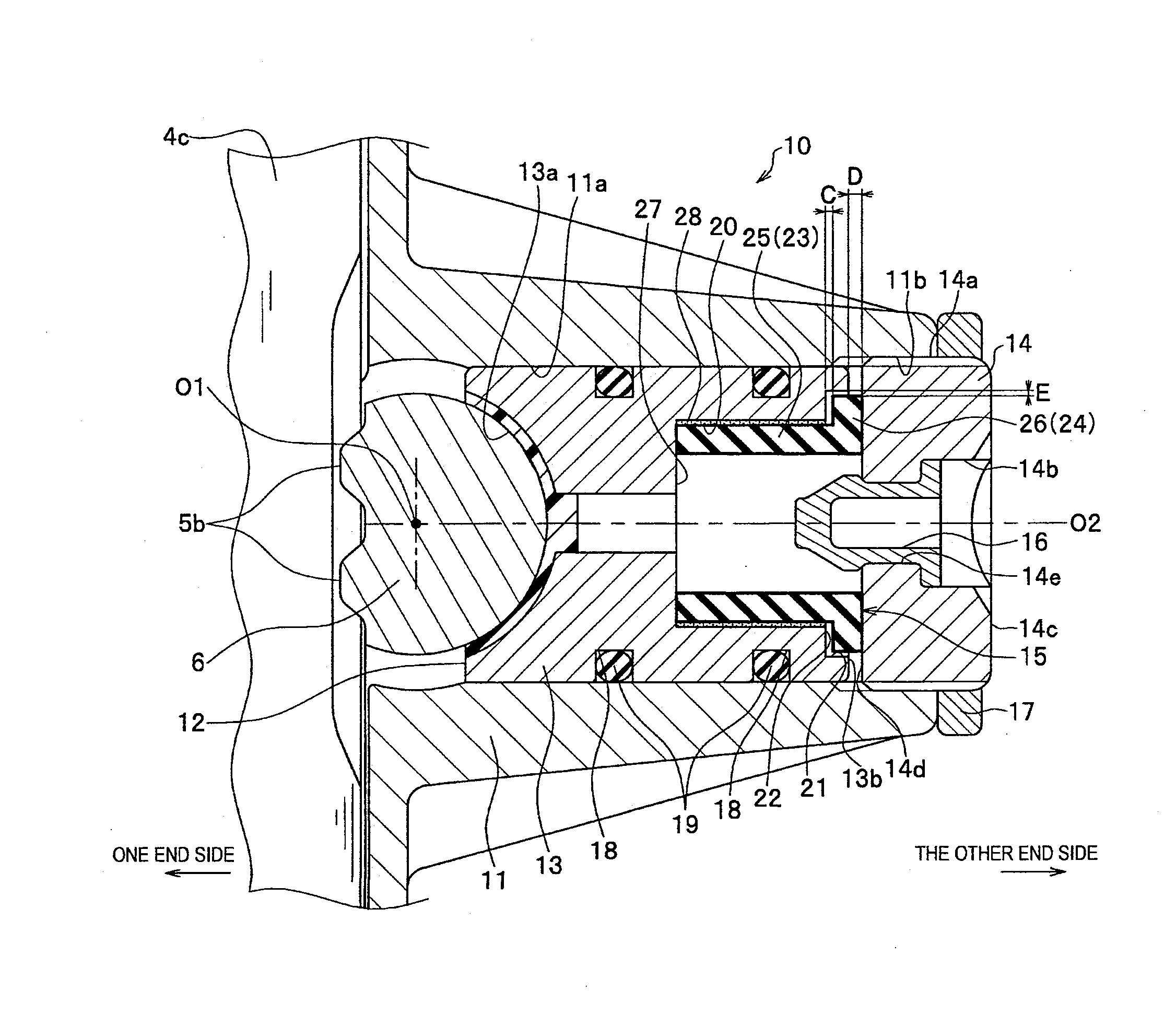

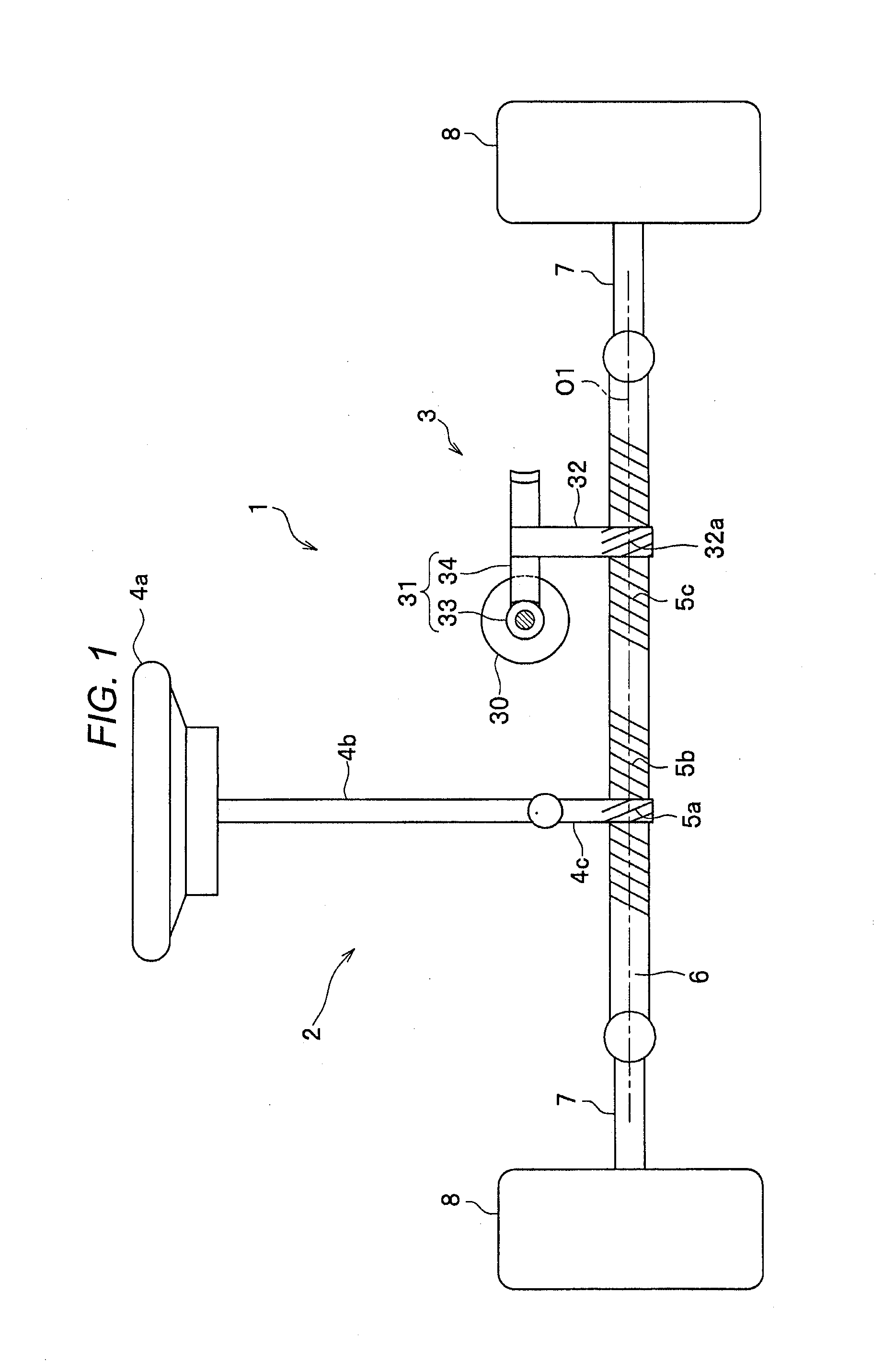

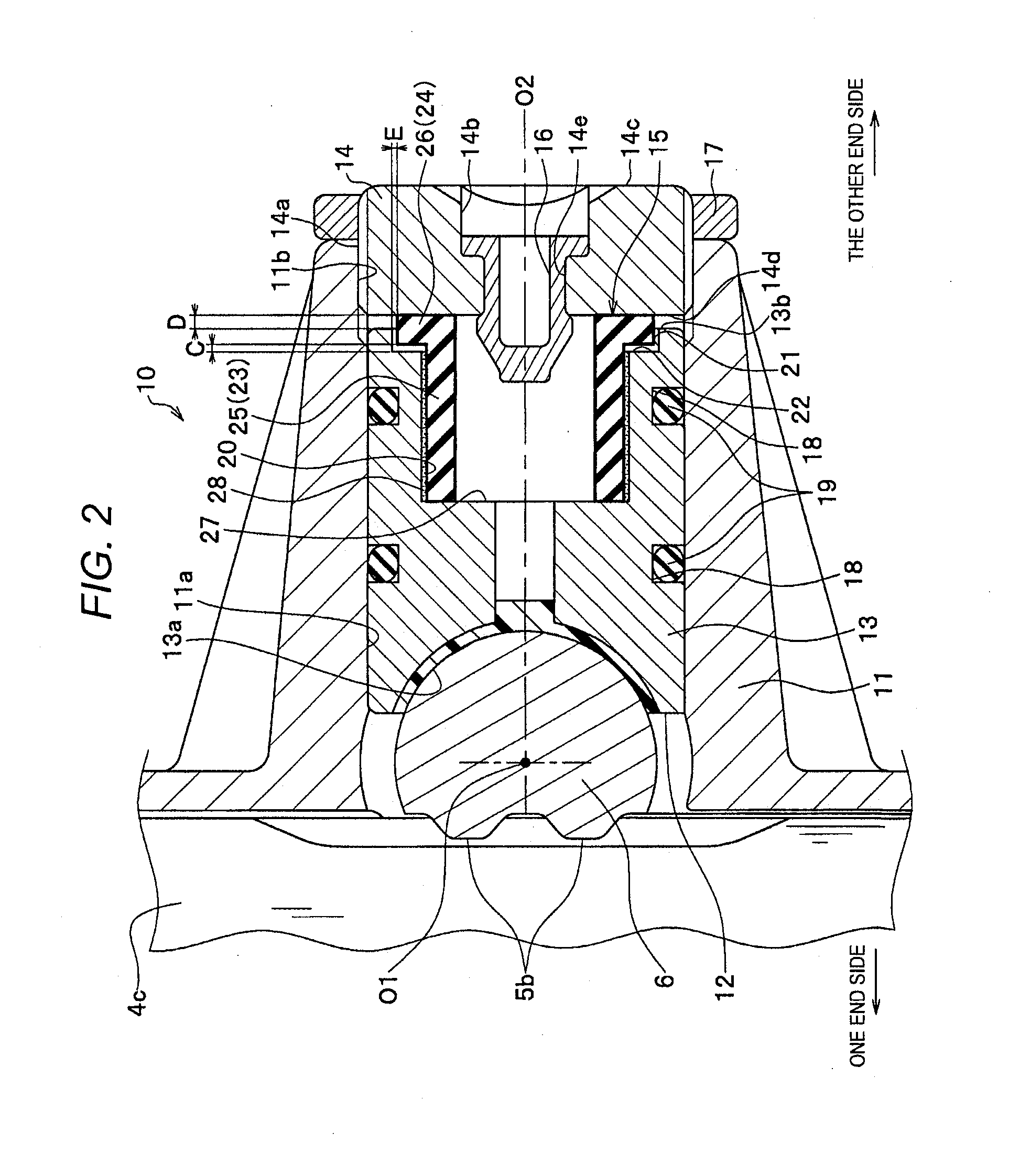

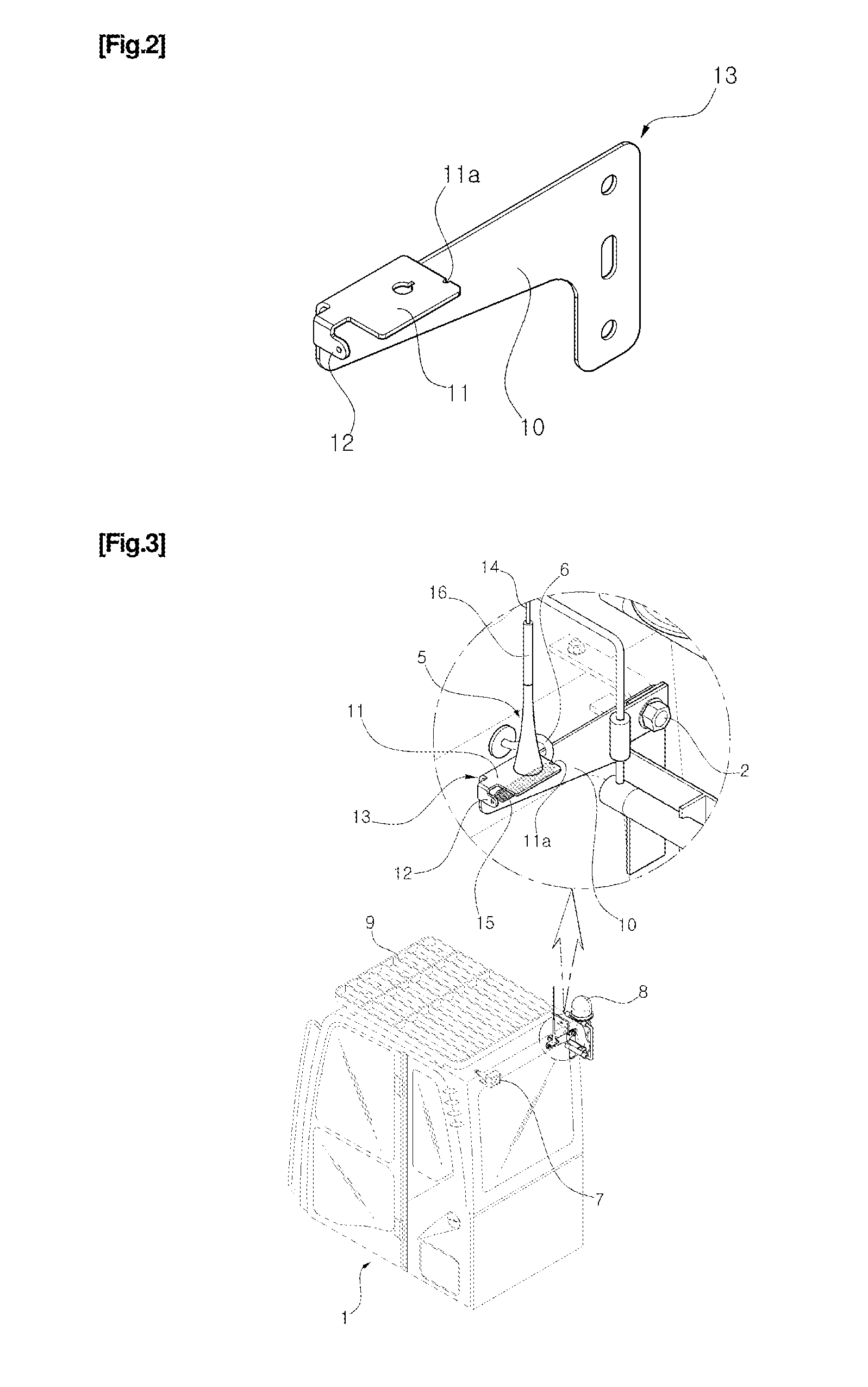

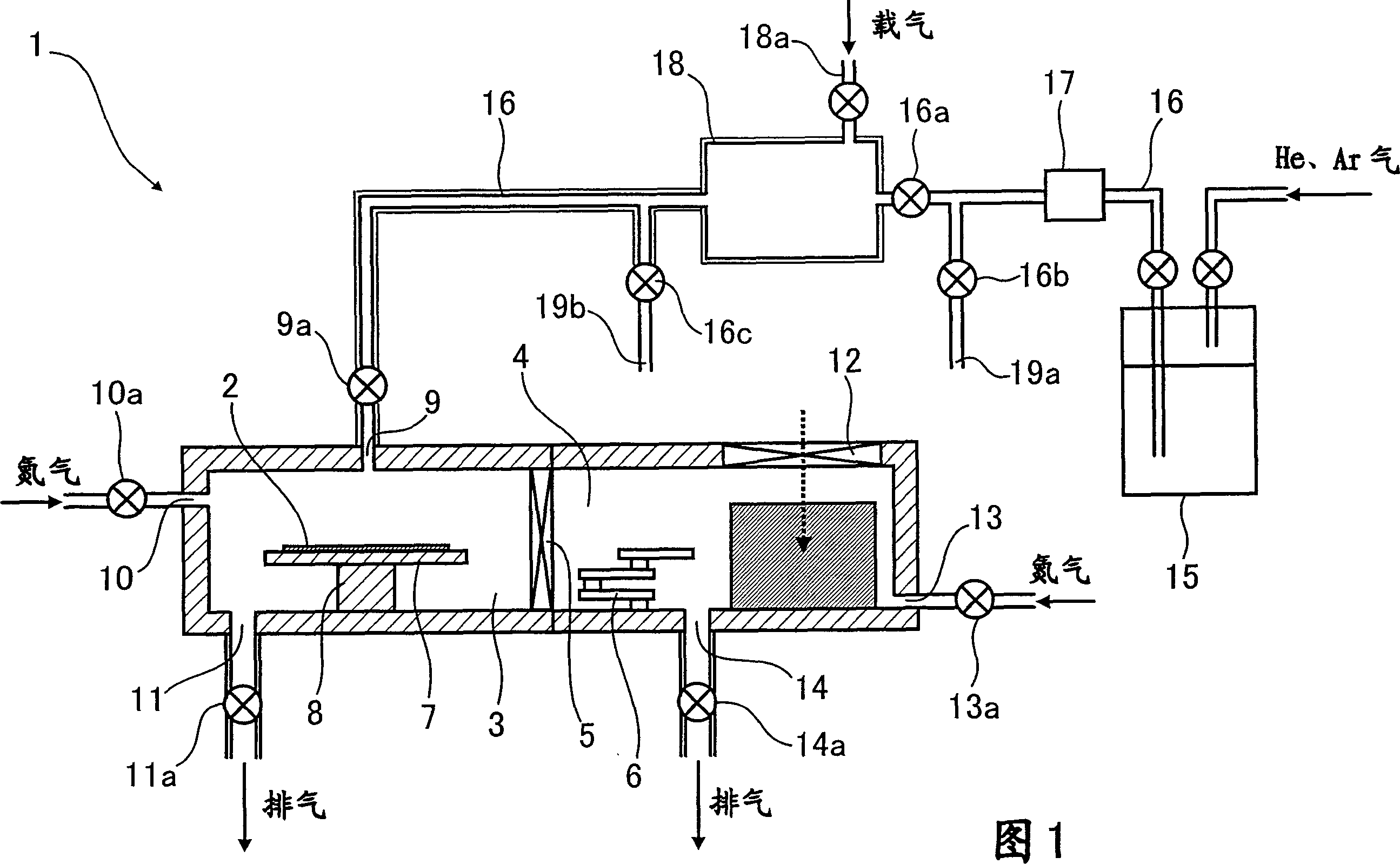

Rack guide mechanism

InactiveUS20160223066A1Sliding resistanceAssembly property can be improvedPortable liftingMechanical steering gearsMechanical engineeringRack and pinion

Owner:SHOWA CORP

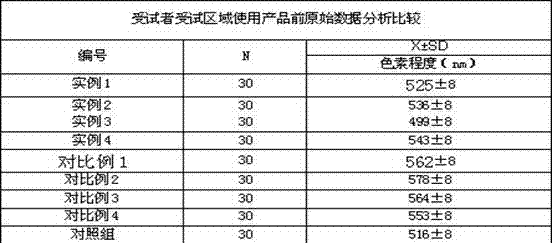

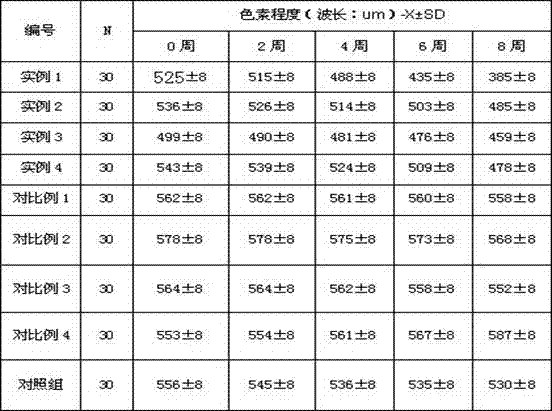

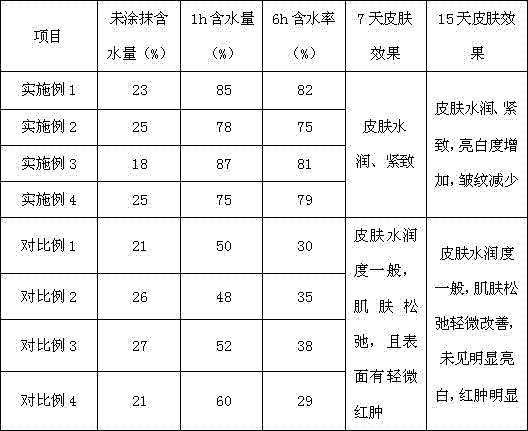

Whitening cosmetic composition

InactiveCN107149578AGood conditionRestore evenlyCosmetic preparationsToilet preparationsWrinkle skinL-Pyroglutamic Acid

The invention discloses a whitening cosmetic composition, mainly comprising PCA (pyroglutamic acid) zinc, chlorella / white lupin protein fermented product, watercress flower / leaf / stem extract, vitamin C ethyl ether and other components. The whitening cosmetic composition can brighten and white the skin and can also moisturize the skin and fade wrinkles.

Owner:广东创美抗衰老研究有限公司

Blue brick firing method

The invention discloses a blue brick firing method. The blue brick firing method disclosed by the invention is implemented through slurrying, pulverizing and compacting raw materials so as to obtain green bodies, feeding the green bodies into a kiln to fire, and in the kiln, sequentially preheating, firing, quenching, coloring and slowly cooling the green bodies, so that finished blue brick products are obtained. In the blue brick firing method disclosed by the invention, in the process of firing, heating is performed by using fuel gas, so that the firing temperature can be conveniently controlled; in the process of coloring, reduction is performed by using mixed reducing colored fuel gas, and a coloring burner is provided with a coloring valve, so that the supply amount of the colored fuel gas is conveniently adjusted, thereby accurately controlling the color of finished blue brick products; after the fuel gas is adopted for firing and reduction, the energy utilization rate is improved, and the pollution emission is greatly reduced; in the process of firing, preheated air subjected to quenching or slow cooling is used, so that the energy consumption is reduced; and the fuel gas reduced in the process of coloring, after being collected by a collecting tank, returns to the process of firing, so that the fuel gas utilization rate is further improved.

Owner:马建明

Horizontal movement - fixed bed magnetization reduction roasting process

ActiveCN102268533AAvoid loopsSimple production processProcess efficiency improvementMagnetizationFixed bed

The invention relates to a horizontal moving-fixed bed type magnetization reduction roasting process, which comprises the following steps: (1) briquetting and pelletizing fine ore after sieving to obtain raw materials; (2) moving raw materials through horizontal moving-fixing The distribution machine of the ore bin in the bed type magnetization reduction roasting device distributes it to the horizontal moving bed, so that the lower layer is ore and the upper layer is balls; (3) The ore and balls on the horizontal moving bed are magnetized reduction roasted with gas or coal powder ;After the ore is fully reduced, the magnetization roasting process is completed; (4) The ore and balls roasted in step (3) are discharged by the scraper at the end of the bed surface, and discharged into the water cooling device. After cooling by water, the unloading machine moves out The ore is sent to the grinding and sorting process. The preheating, heating and reduction processes of powder ore magnetization reduction roasting in the present invention are all completed on the horizontal moving-fixed bed roasting device, which not only simplifies the production process, reduces investment costs, but also avoids the process similar to rotary kilns, etc. The ring formation problem of roasted fine ore.

Owner:JIUQUAN IRON & STEEL GRP +1

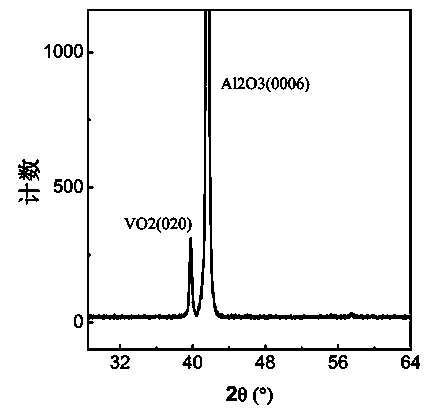

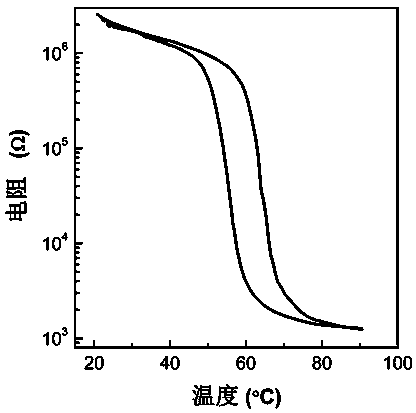

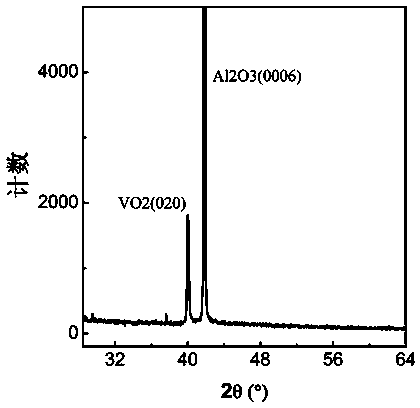

Liquid-phase preparation method of high-oriented vanadium dioxide film

ActiveCN104060241AAct as a reducing agentRestore evenlyLiquid/solution decomposition chemical coatingVanadium dioxidePhase change

The invention discloses a liquid-phase preparation method of a high-oriented vanadium dioxide film, belonging to the field of chemical function materials. The preparation method comprises the following steps: preparing precursor liquid by taking triisopropoxyvanadium oxide as solute, coating a sapphire substrate with the obtained precursor liquid to prepare a precursor film, and finally sintering the precursor film in a vacuum environment. According to the preparation method, the vanadium dioxide film is prepared by controlling vacuum sintering conditions on the basis of a liquid-phase method, the obtained film is good in growth orientation, the phase change temperature of the film is about 60 DEG C, and the change of electrical resistivity before and after the phase change is more than three orders of magnitude; in addition, the preparation process is simple and suitable for large-range popularization.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

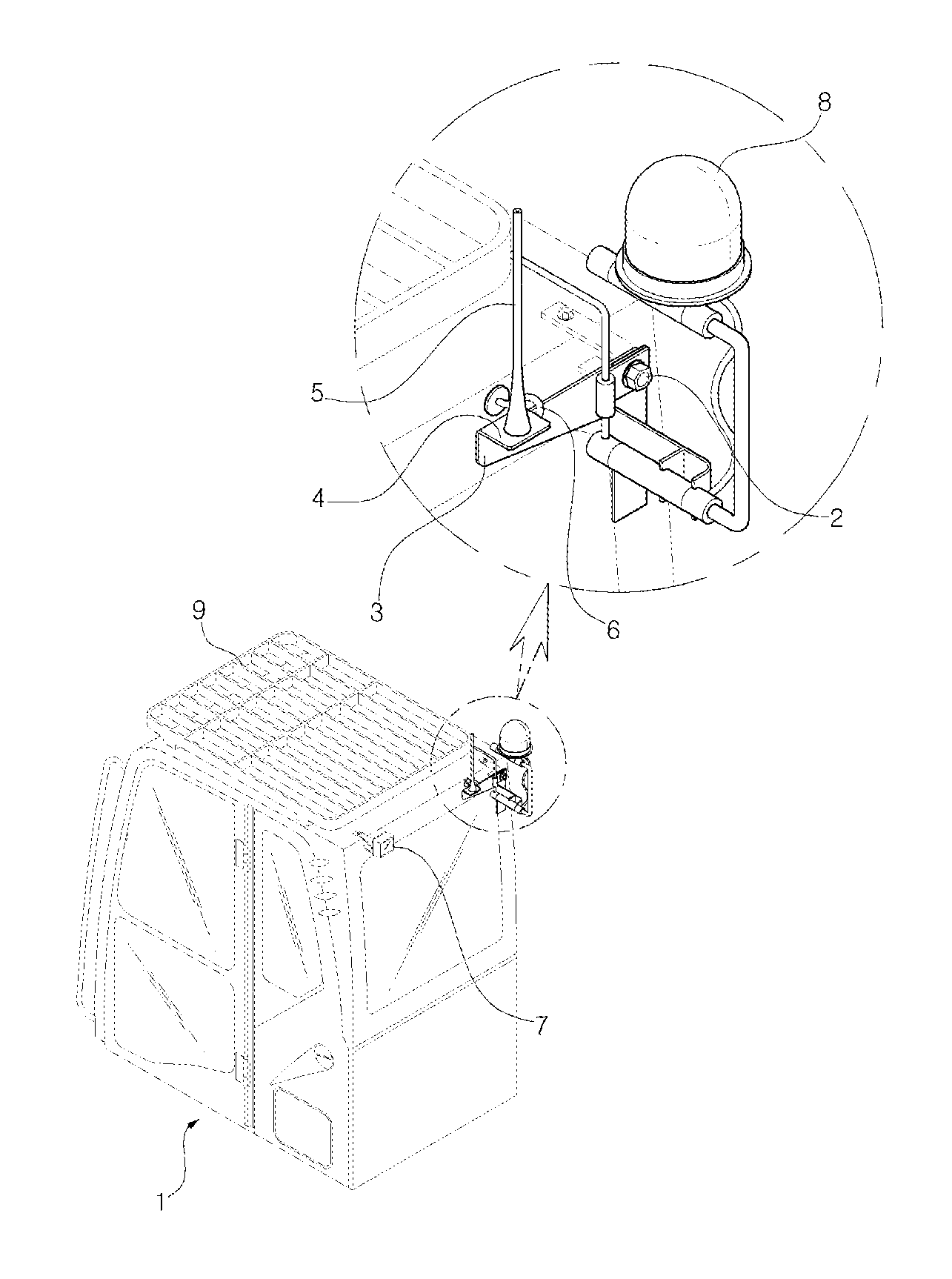

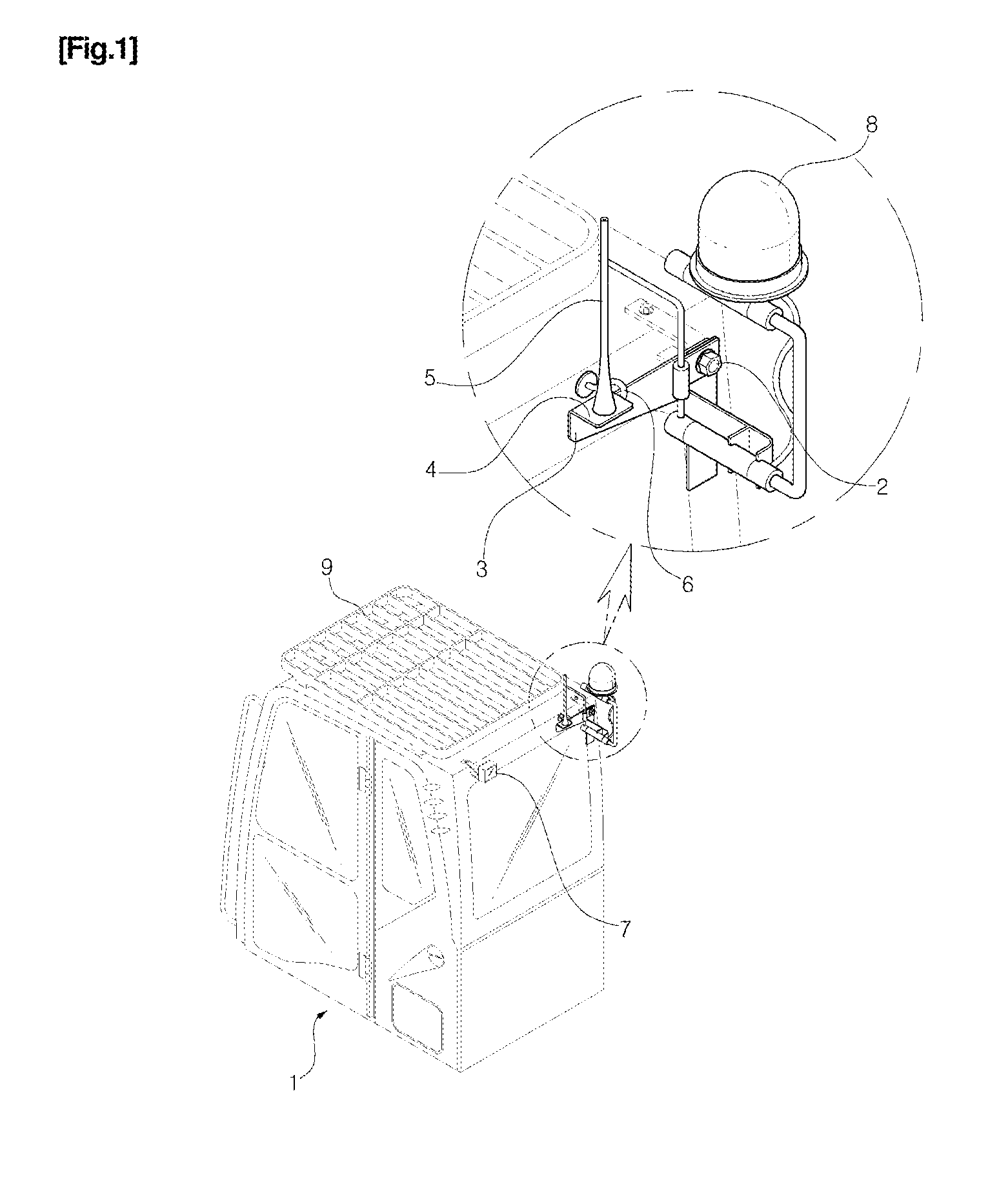

Device for fixing a satellite antenna for construction equipment

ActiveUS20140022129A1Restore evenlyReduce the overall heightAntenna supports/mountingsAntenna adaptation in movable bodiesSatelliteElectrical and Electronics engineering

An apparatus for fixing a satellite antenna for a construction machine is disclosed, which can adjust the height of the satellite antenna that is installed outside a cab to receive a signal of a satellite receiver installed inside the cab when the equipment is transported or operated in a workshop having a low ceiling. The apparatus for fixing a satellite antenna for a construction machine that is mounted outside a cab to receive a signal of a satellite receiver installed inside the cab, includes a bracket composed of a first mount portion mounted on an outer surface of the cab, a second mount portion formed to extend from the first mount portion to be bent, and a third mount portion formed to be bent against the second mount portion; a satellite antenna mounted on the second mount portion to receive a satellite signal; and a hanger fixing a pole, which is laid down to prevent the damage of the satellite antenna due to contact with an obstacle when the equipment is transported or operated, to the third mount portion.

Owner:VOLVO CONSTR EQUIP AB

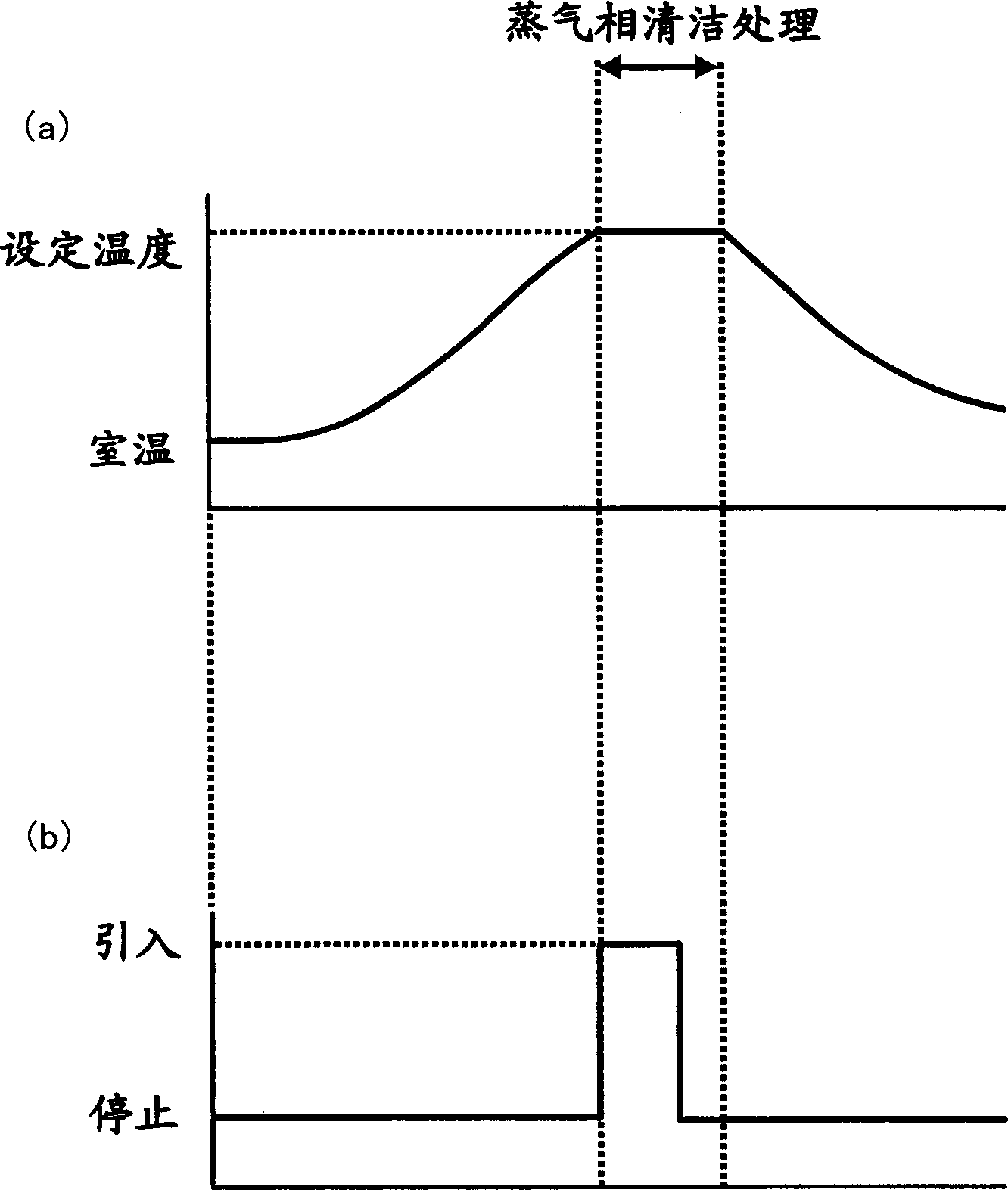

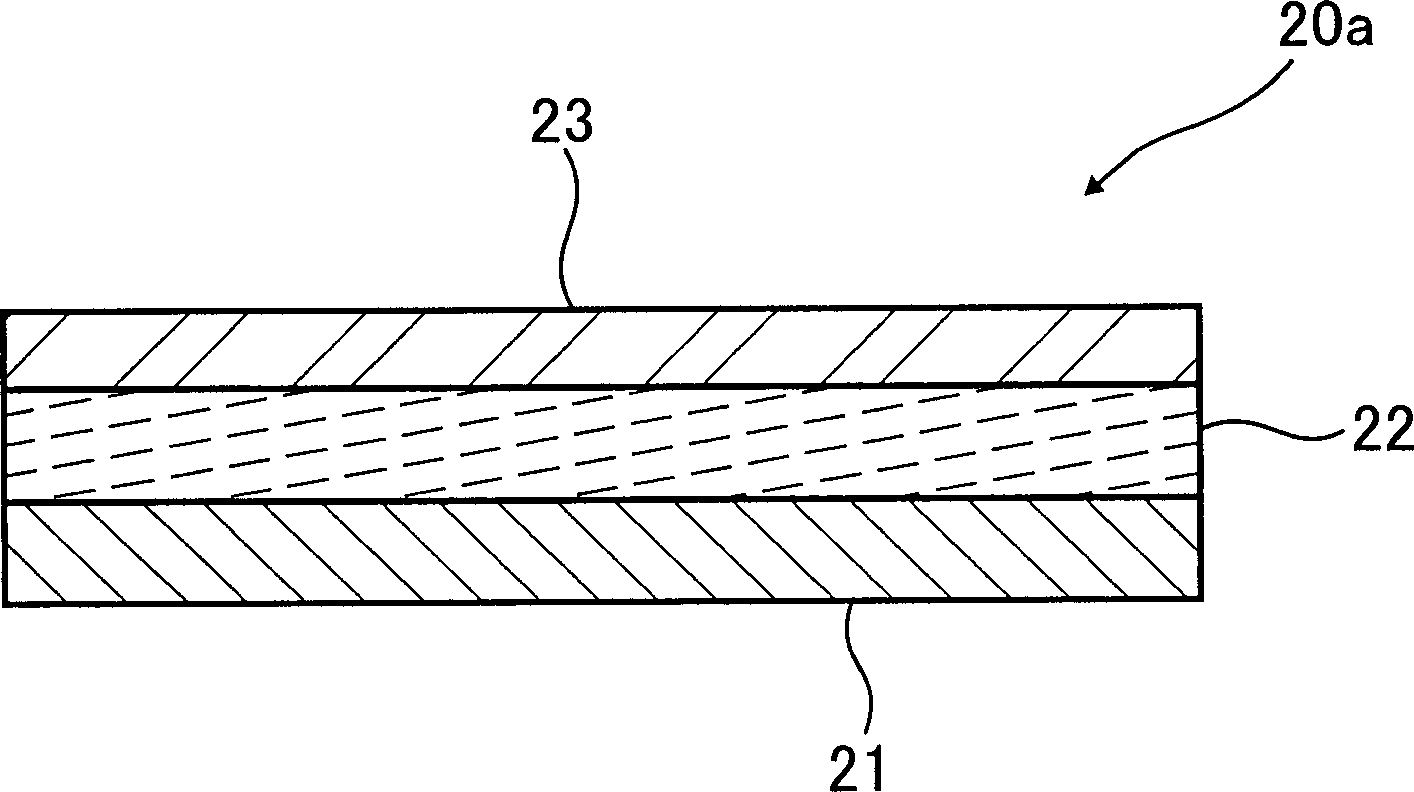

Semiconductor device manufacturing process and equipment

InactiveCN1433053ARestore evenlyEffective recoverySemiconductor/solid-state device manufacturingCleaning processes and apparatusCarburetorCopper oxide

A semiconductor device production method that is used to uniformly and efficiently reduce metal oxides produced on metal (copper, for example) which forms electrodes or wirings on a semiconductor device. An object to be treated on which copper oxides are produced is put into a process chamber and is heated by a heater to a predetermined temperature. Then carboxylic acid stored in a storage tank is vaporized by a carburetor. The vaporized carboxylic acid, together with carrier gas, is introduced into the process chamber via a treating gas feed pipe to reduce the copper oxides produced on the object to be treated to metal copper. As a result, metal oxides can be reduced uniformly without making the surfaces of electrodes or wirings irregular. Moreover, in this case, carbon dioxide and water are both produced in a gaseous state. This prevents impurities from remaining on the surface of copper.

Owner:SOCIONEXT INC

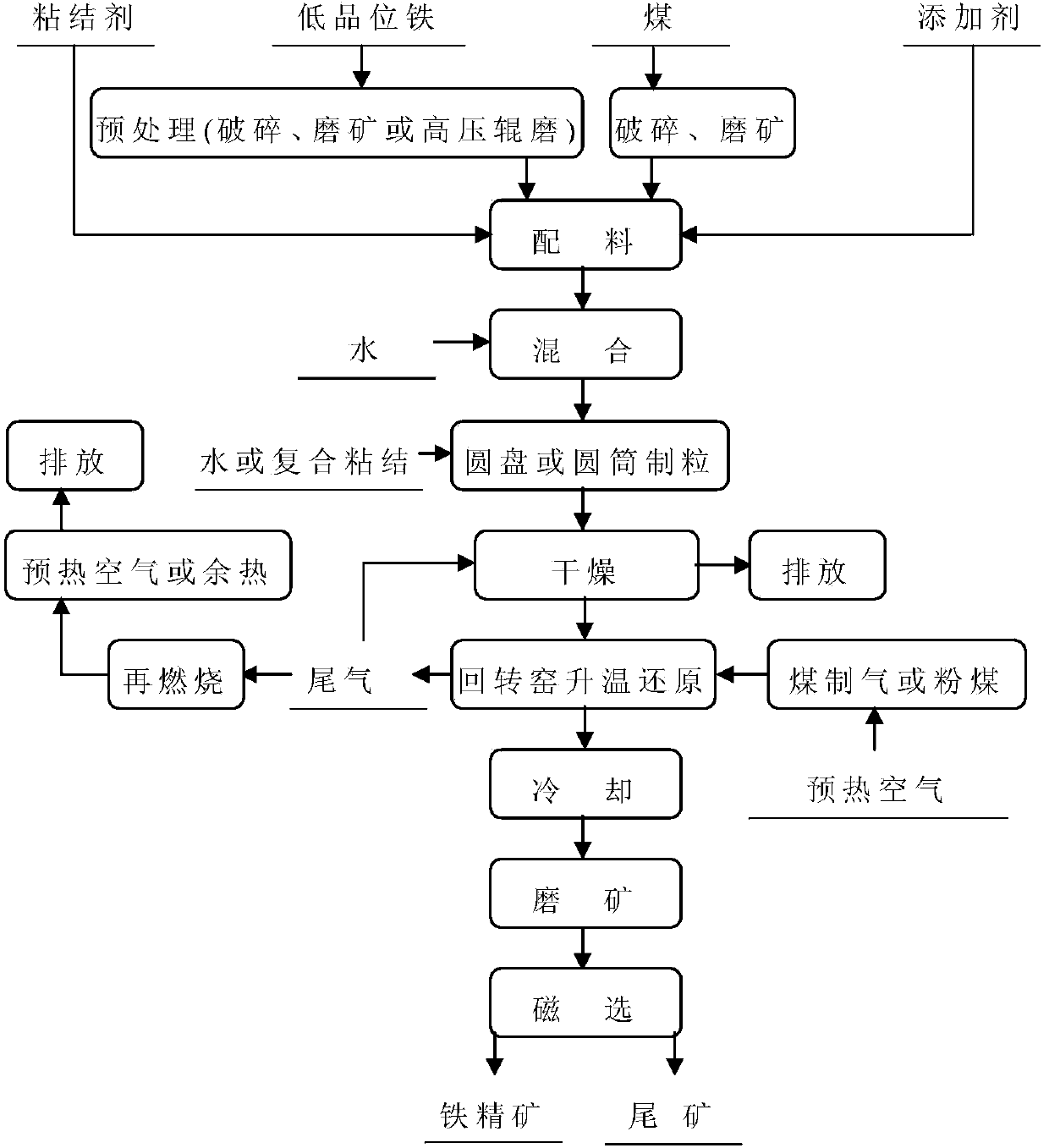

Method for improving grade of low-grade iron ore

ActiveCN103993166AAvoid problems such as lossGood ball formingProcess efficiency improvementClay mineralsLower grade

The invention provides a method for improving the grade of low-grade iron ore. The method comprises the following steps: respectively pretreating low-grade iron ore and coal, adding coal dust and an additive according to a certain proportion and preparing small balls with particle sizes of 3 to 8 mm by using a disc or drum balling machine after the content of treated iron ore and coal with a particle size of 0.074 mm is more than 50%, wherein clay minerals in the low-grade iron ore are used as a binder, or a small amount of binders like bentonite is added and uniformly mixed with treated iron ore and coal; and drying the prepared balls with a belt or cylindrical dryer, carrying out reduction by using a rotary kiln and then successively carrying out cooling and magnetic separation so as to obtain high-grade iron ore concentrate. With the method, low-grade iron ore can be effectively treated, the high-grade iron ore concentrate is obtained through granulation of the coal and the additive, direct reduction and magnetic separation, and the characteristics of energy conservation, high efficiency and rapidness are obtained.

Owner:CENT SOUTH UNIV +2

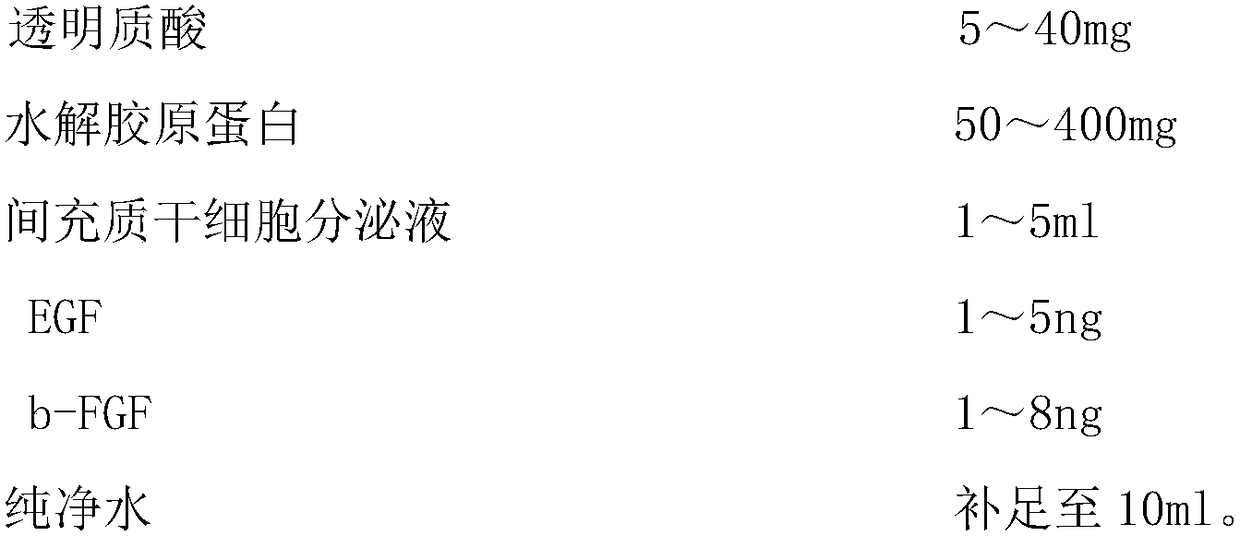

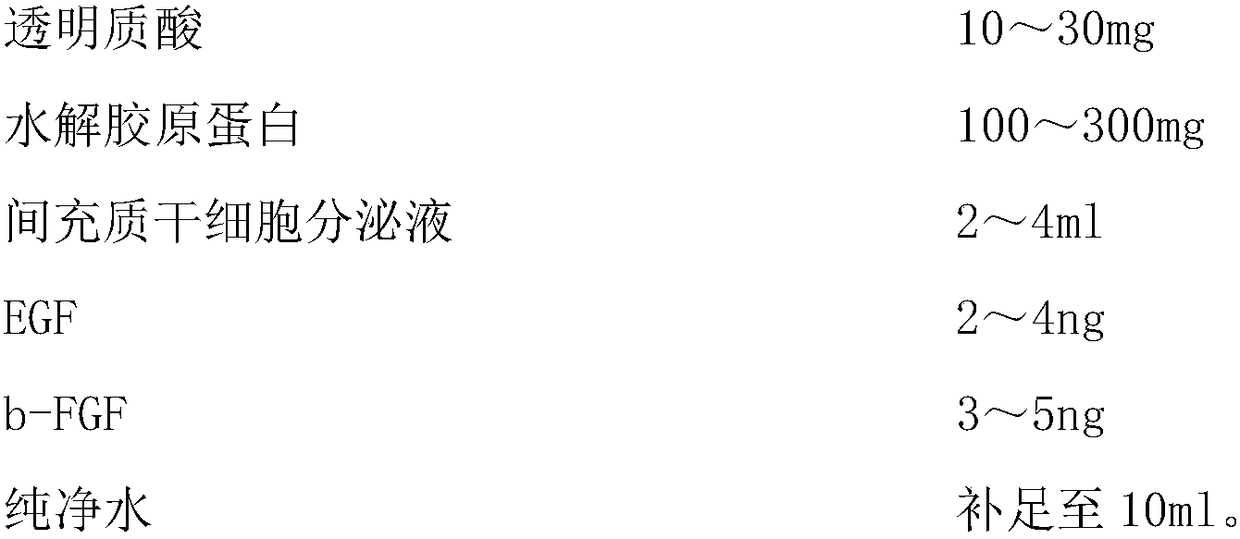

Skin anti-ageing composition

InactiveCN109125246AEnergeticEfficient regenerationCosmetic preparationsToilet preparationsWrinkle skinAdditive ingredient

The invention relates to a skin anti-ageing composition, in particular to a skin care product containing kinds of biological factors, and belongs to the fields of cosmetics and biotechnologies. Every10 ml of composition is composed of, by content, 5-40 mg of transparent hyaluronic acid, 50-400 mg of hydrolyzed collagen, 1-5 ml of mesenchymal stem cell secretion, 1-5 ng of EGF, 1-8 ng of b-FGF1 and 10 ml of sufficiently-supplemented purified water. The skin anti-ageing composition has the advantages that a formula is safe and effective, there are no allergic substances and preservative, ageingresistance and wrinkle removal are effective, the premature ageing of the skin is improved greatly, meanwhile, it is avoided that nutrition excess makes the skin burdened, and new skin problems appear, and the skin anti-ageing composition is particularly suitable for allergic skin.

Owner:灏灵赛奥(天津)生物科技有限公司

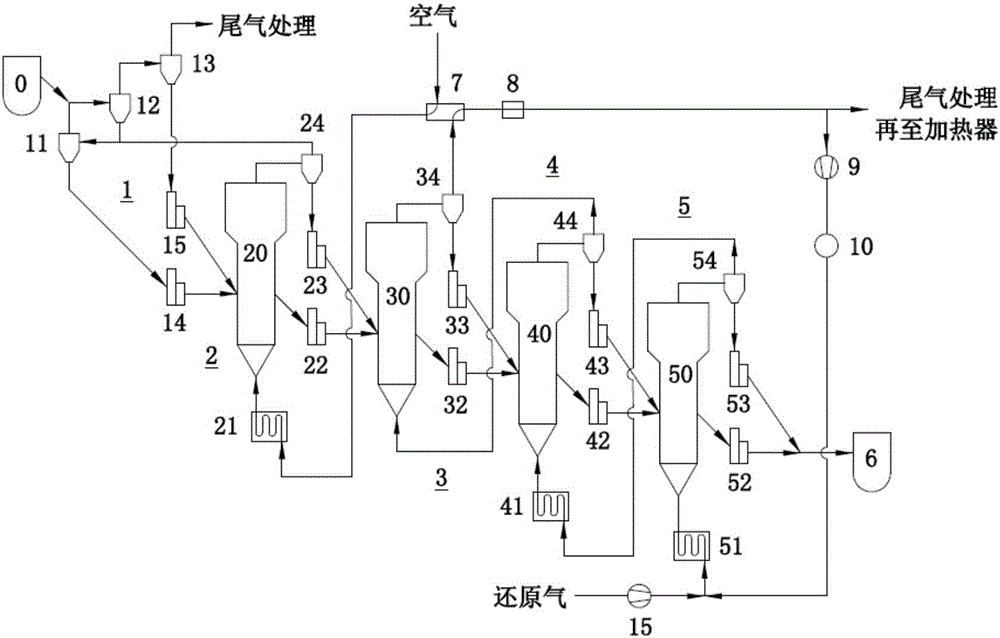

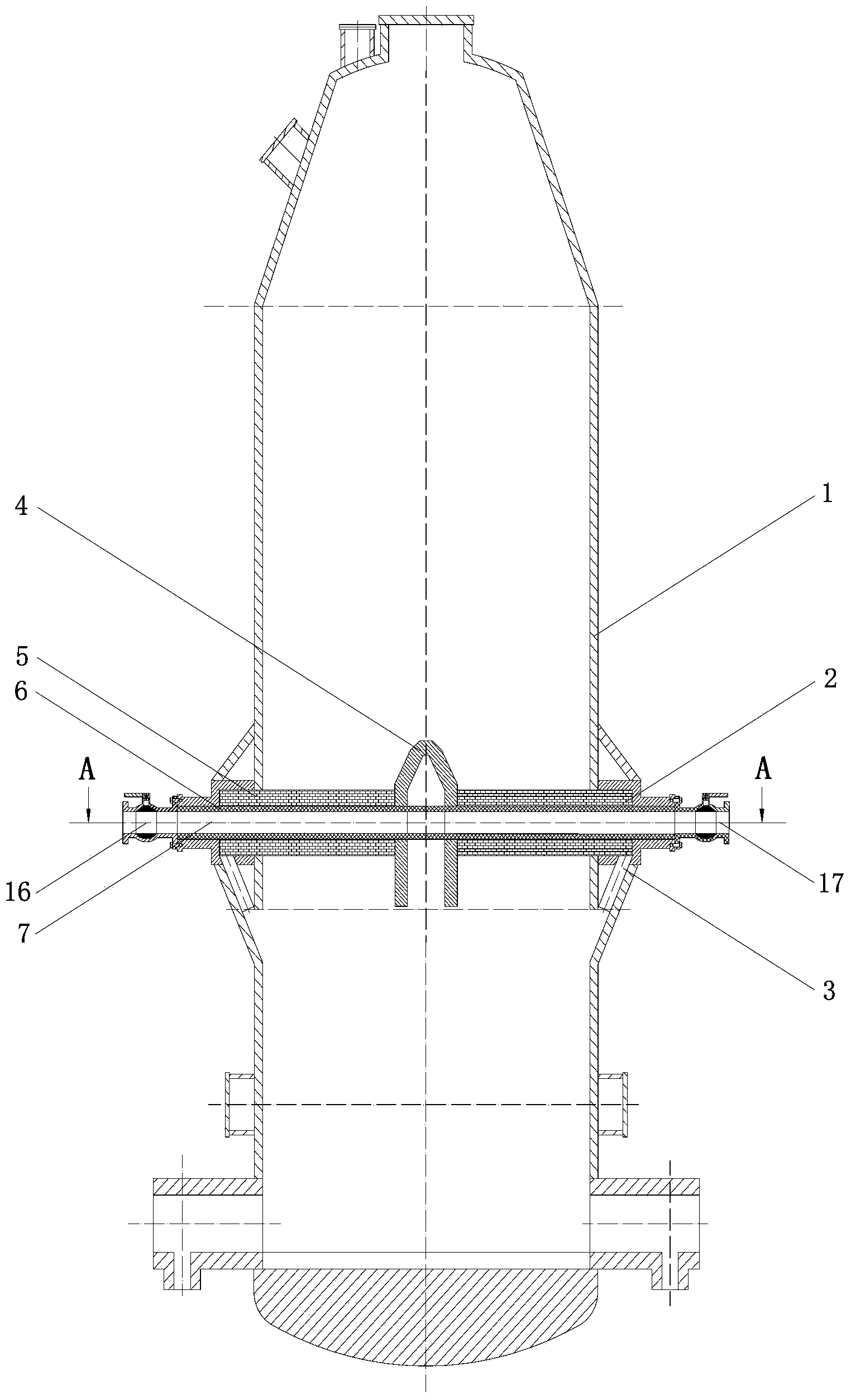

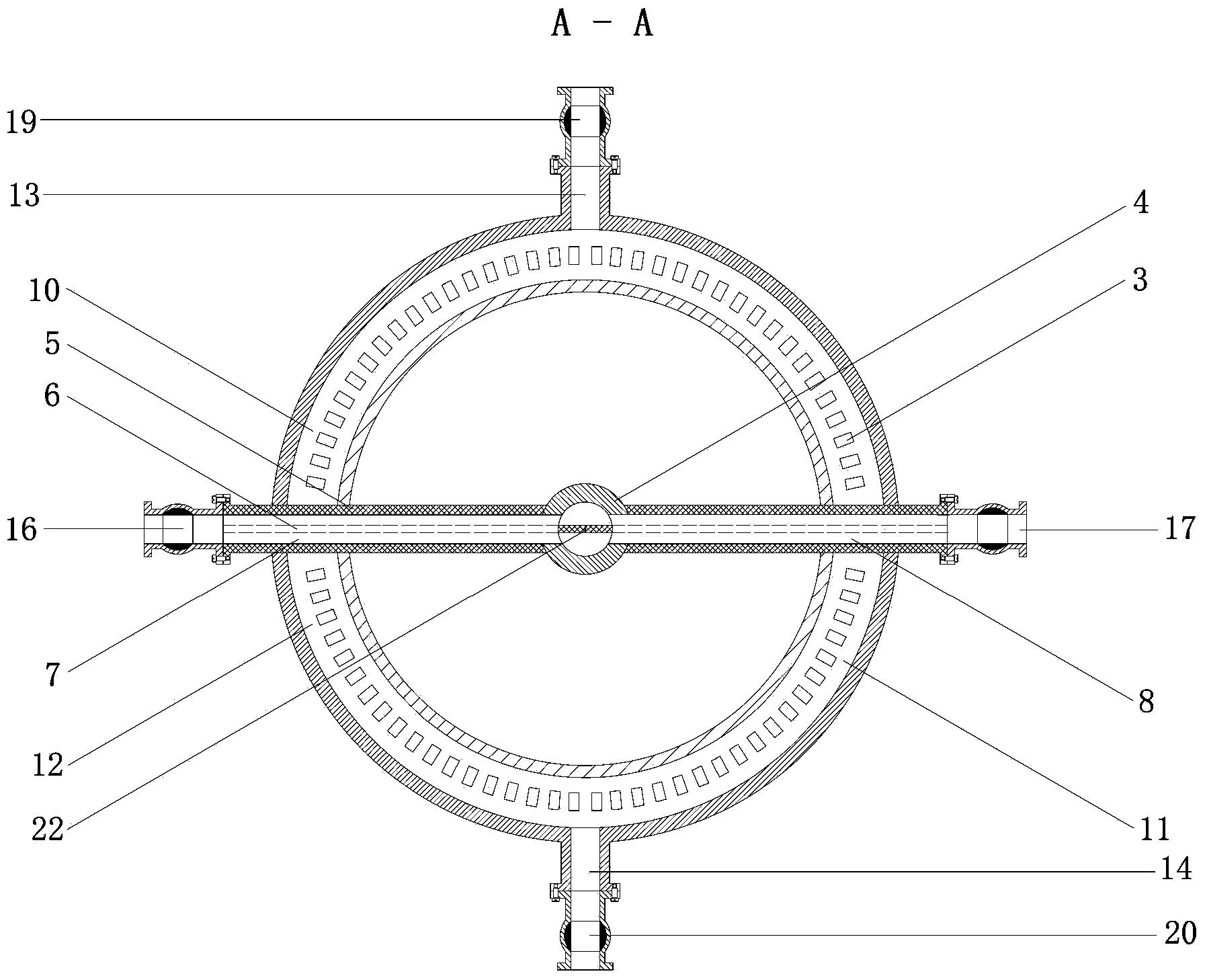

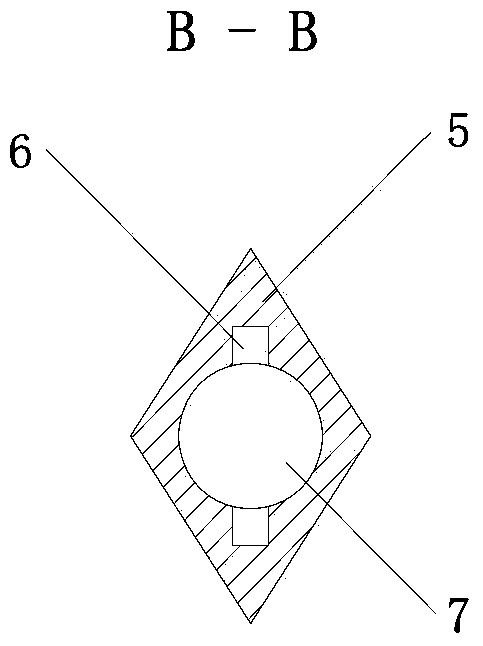

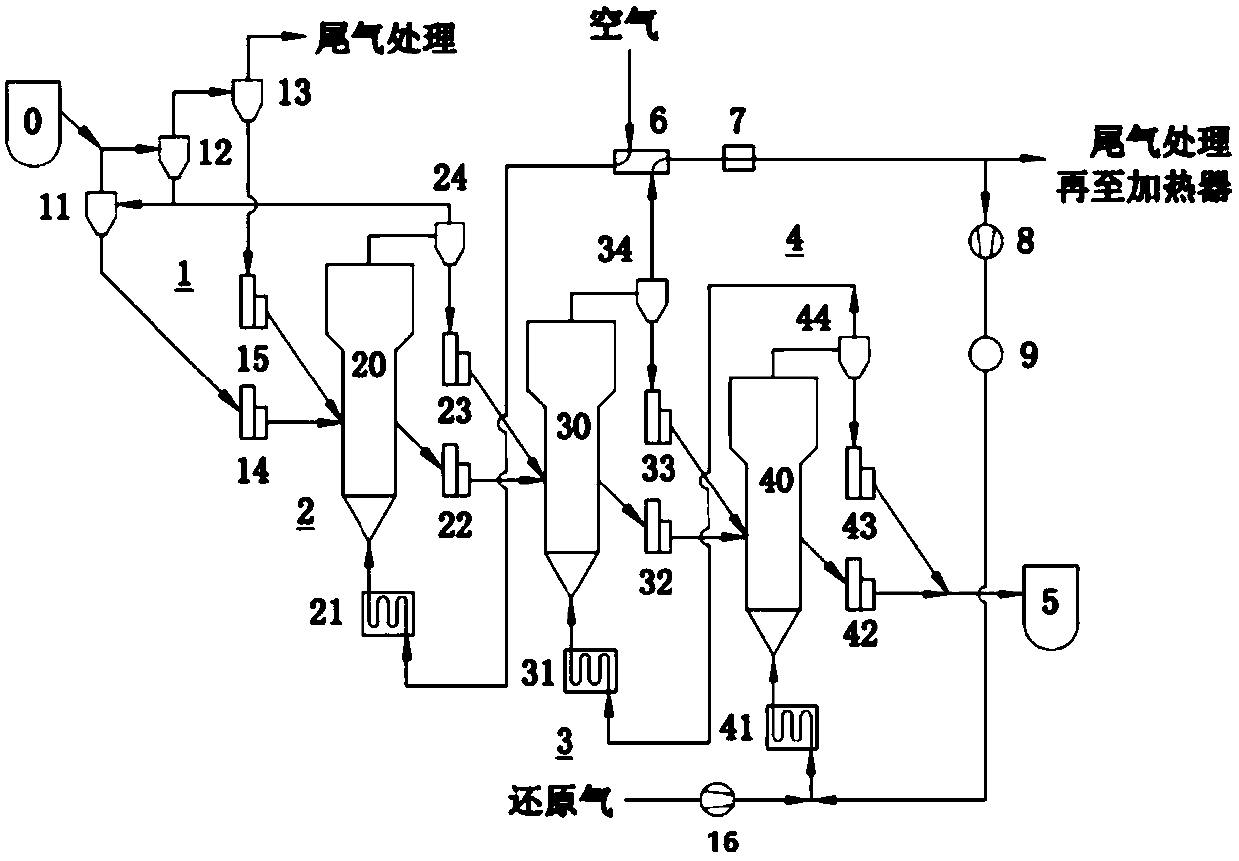

System and method for vanadium titano-magnetite fluidization oxidation and reduction

ActiveCN106319126AImprove reaction efficiencyImprove fluidization stabilityFluidised-bed furnacesHigh energyPhysical chemistry

The invention discloses a system and a method for vanadium titano-magnetite fluidization oxidation and reduction. A four-section fluidized bed is adopted to carry out fluidization oxidation and reduction on vanadium titano-magnetite fine ore; and a fluidized bed reaction body is formed by boiling beds connected in series. Through the technological design of a pre-oxidation treatment and low-gas-velocity reaction fluidized bed, the vanadium titano-magnetite powder fluidization performance can be obviously improved, the reaction efficiency is improved, and the process energy consumption is reduced. The vanadium titano-magnetite fine ore is firstly preheated and dried, enters a low-temperature oxidation bed so as to be subjected to oxidation treatment, then enters a prereduction bed so as to be subjected to prereduction, and finally complete final reduction through a two-stage high-temperature final reduction bed; oxidization tail gas is used for preheating and drying the vanadium titano-magnetite fine ore; after reduction tail gas is heat-exchanged with oxidization air, oxidization components are cleaned and removed, and the reduction tail gas is recycled; and a gas utilization scheme has the advantages of high reaction efficiency and high energy utilization ratio.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Device promoting reasonable distribution of coal gas flow in shaft furnace

InactiveCN103966381AReasonable distributionReduce hindranceShaft furnaceProcess engineeringShaft furnace

The invention discloses a device promoting reasonable distribution of coal gas flow in a shaft furnace. The device is provided with a surrounding pipe and a slot pipe, and is characterized by further comprising 2-3 inner gas supply pipes and a tapered gas distributing device; each two adjacent inner gas supply pipes form an angle of 120 DEG C or an angle of 180 DEG C mutually; the inner gas supply pipes extend into the center of the shaft furnace; the outer opening of each inner gas supply pipe is communicated with a coal gas generating device; the inner opening of the inner gas supply pipe is communicated with the tapered gas distributing device at the central position in the shaft furnace; the outside of the inner gas supply pipes separates the surrounding pipe into 2-3 independent surrounding pipe gas feeding areas; a surrounding pipe gas supply pipe communicated with the outer coal gas generating device is arranged in each surrounding pipe gas feeding area. The device enables coal gas extending into the shaft furnace to be distributed more uniformly, and improves utilization ratio of the coal gas remarkably.

Owner:NORTHEASTERN UNIV

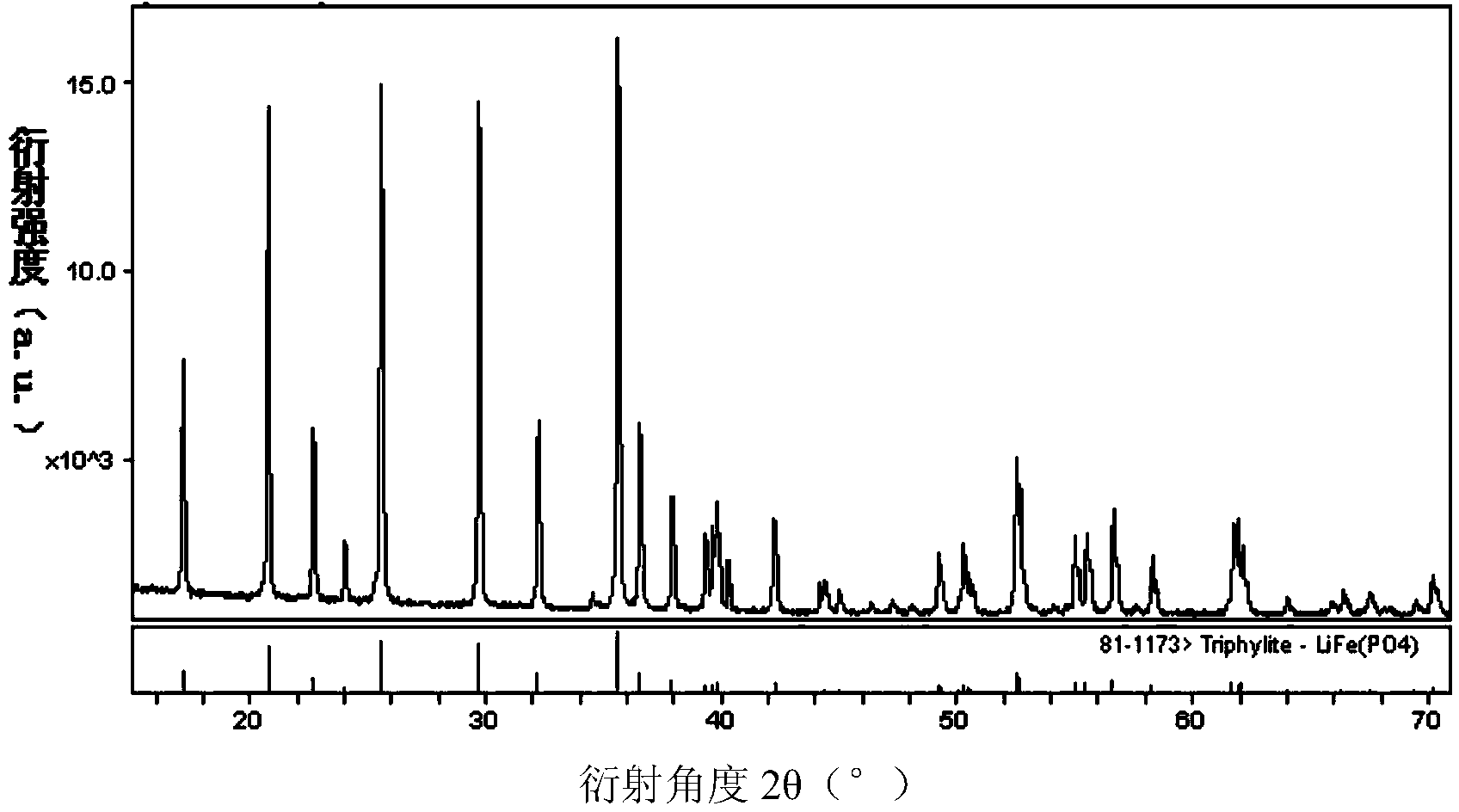

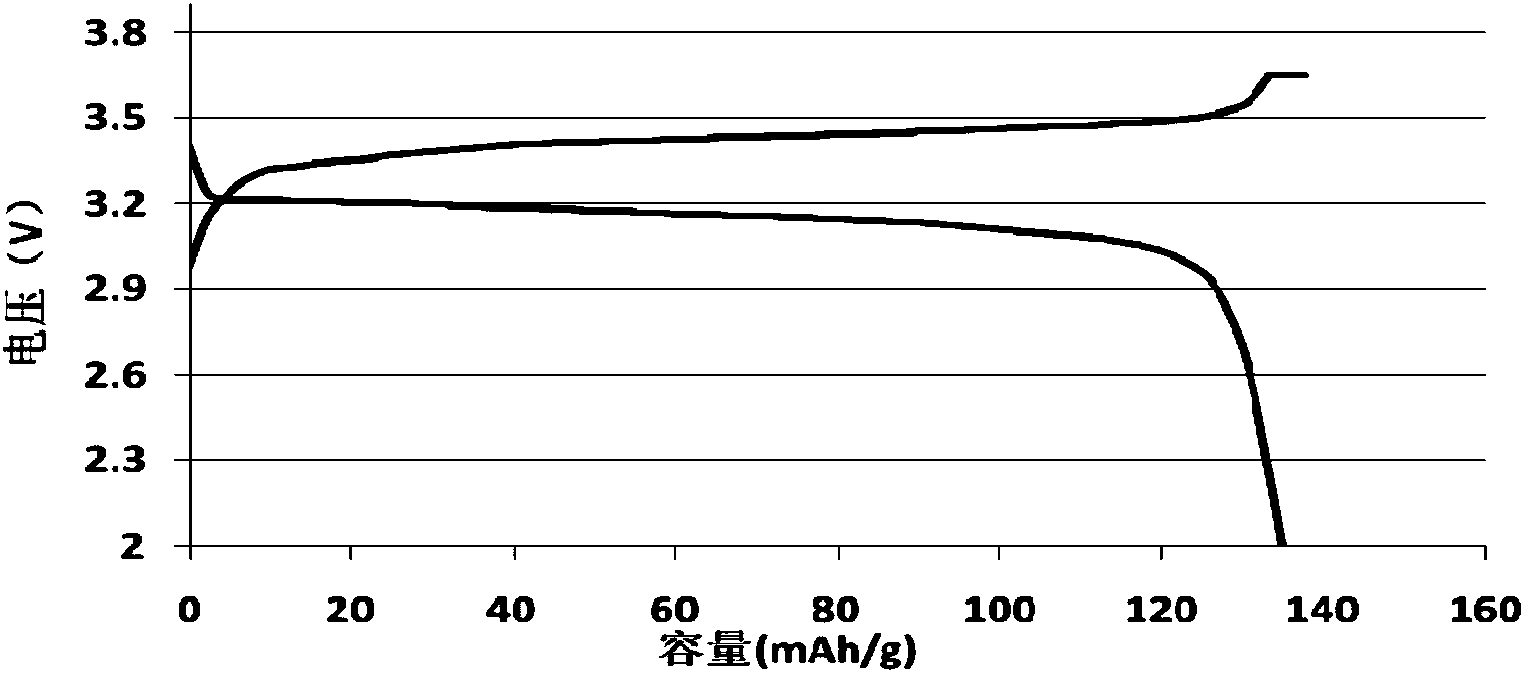

Synthesizing method for lithium ion anode material LiFePO4/C

ActiveCN103840159AImprove electrical performanceAvoid reunionCell electrodesSecondary cellsSesquioxideLithium hydroxide

The invention provides a synthesizing method for a lithium ion anode material LiFePO4 / C and relates to lithium ion battery anode materials. The synthesizing method comprises the following steps: (1) adding water into iron sesquioxide, a doped metal ion oxide and an organic carbon source and mixing; carrying out ball milling and spraying and granulating to prepare powder; pre-treating the obtained powder in an inert atmosphere to obtain carbon coated iron source powder; (2) dissolving a phosphorus source into the water and adding the carbon coated iron source powder obtained by the step (1); adding lithium hydroxide; carrying out the ball milling and spraying and granulating to prepare dry powder; and (3) treating the dry powder obtained by the step (2) into the inert atmosphere to be treated, and carrying out high-temperature heat treatment; and carrying out air flow grading to obtain the lithium ion anode material LiFePO4 / C. According to the synthesizing method, the surfaces of the LiFePO4 / C are coated with carbon and doped ions are introduced into a LiFePO4 / C structure to change the semiconductor property and improve the electronic conductivity; the grain diameter of a LiFePO4 / C crystal is reduced so that the diffusion speed of the lithium ions in a charging and discharging process is improved.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

A system and method for fluidized redox of vanadium-titanium magnetite

ActiveCN106319126BImprove reaction efficiencyImprove fluidization stabilityFluidised-bed furnacesHigh energyOxidation-Reduction Agent

The invention discloses a system and a method for vanadium titano-magnetite fluidization oxidation and reduction. A four-section fluidized bed is adopted to carry out fluidization oxidation and reduction on vanadium titano-magnetite fine ore; and a fluidized bed reaction body is formed by boiling beds connected in series. Through the technological design of a pre-oxidation treatment and low-gas-velocity reaction fluidized bed, the vanadium titano-magnetite powder fluidization performance can be obviously improved, the reaction efficiency is improved, and the process energy consumption is reduced. The vanadium titano-magnetite fine ore is firstly preheated and dried, enters a low-temperature oxidation bed so as to be subjected to oxidation treatment, then enters a prereduction bed so as to be subjected to prereduction, and finally complete final reduction through a two-stage high-temperature final reduction bed; oxidization tail gas is used for preheating and drying the vanadium titano-magnetite fine ore; after reduction tail gas is heat-exchanged with oxidization air, oxidization components are cleaned and removed, and the reduction tail gas is recycled; and a gas utilization scheme has the advantages of high reaction efficiency and high energy utilization ratio.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

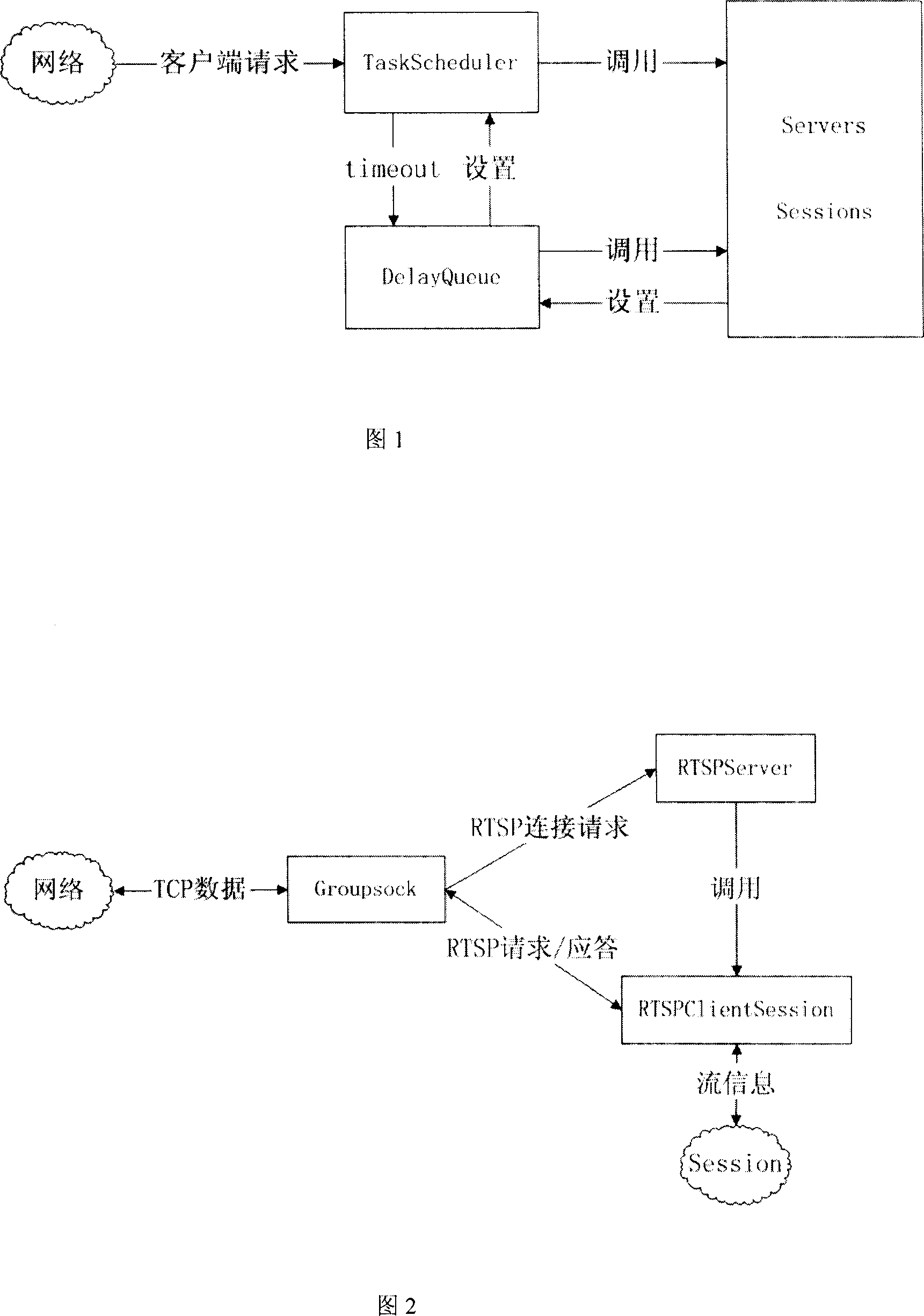

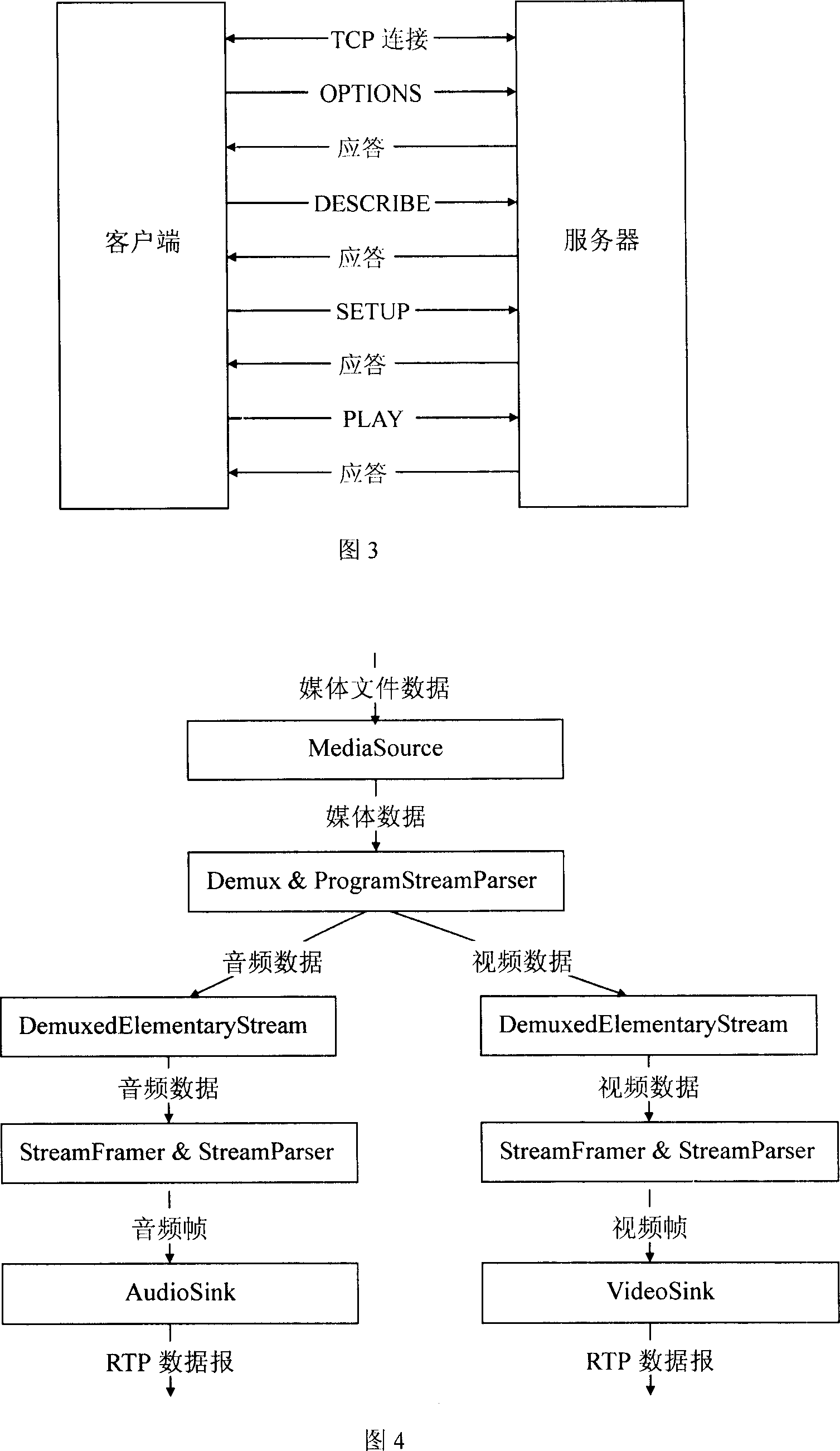

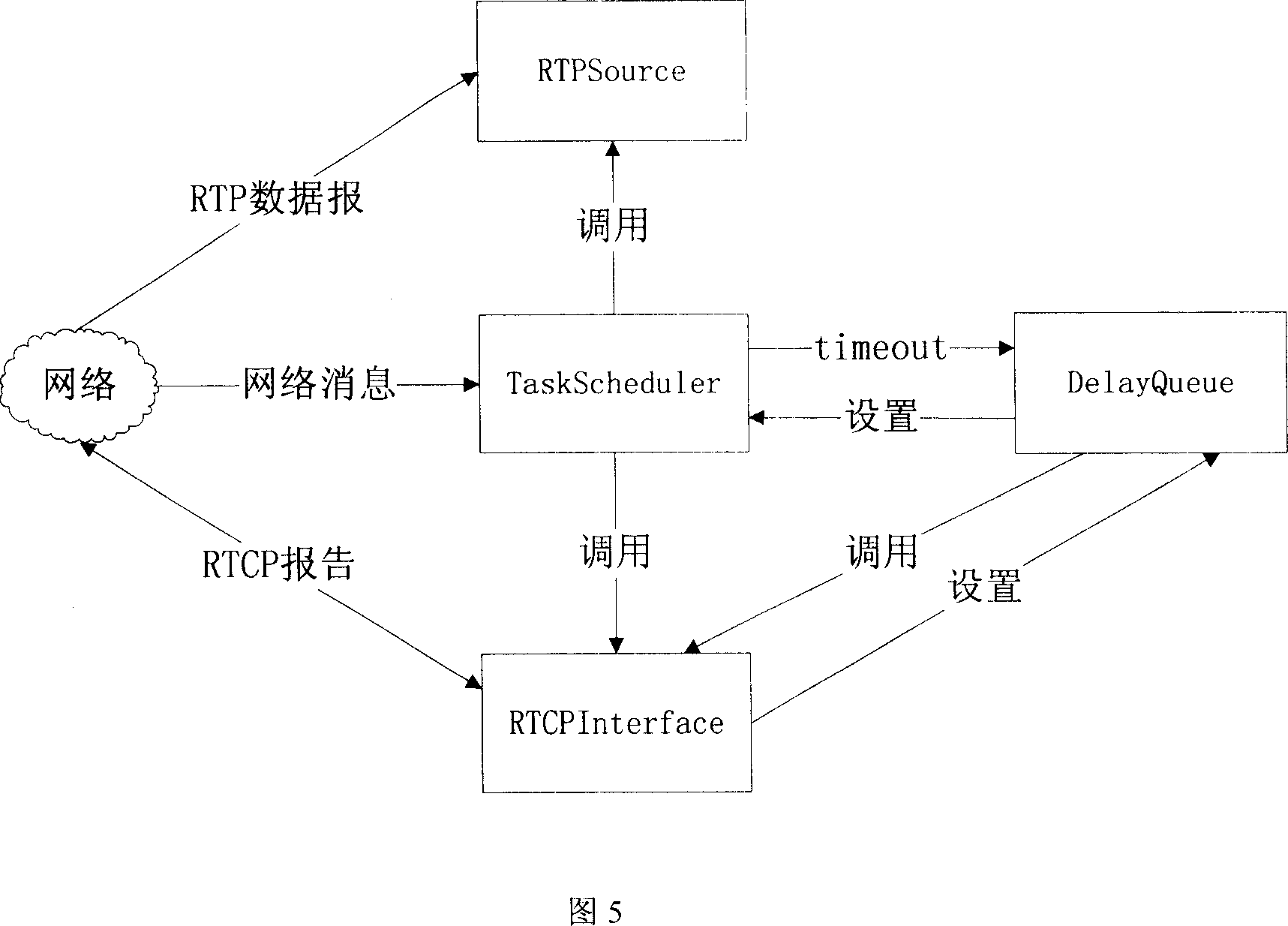

Wireless video on-demand system, method and AVI file analysis, fluidizing method

InactiveCN1972439AAvoid bugs that consume a lot of system resourcesReduce data transfer rateTwo-way working systemsTransmissionWireless videoMedia server

This invention relates to visual frequency play system and method based on wireless local network, which comprises interface wireless local network flow media servo and at least customer end by use of RTP, RTCP and RTSP agreement communication, wherein, the servo adopts single wire process servo; the customer end adopts PDA with each composed of one task manager through its task manager transfer to fulfill customer end RTP data receive and RTCP report receive and send.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

A system and method for fluidized high-temperature rapid redox of vanadium-titanium magnetite

ActiveCN106467930BImprove reaction efficiencyImprove fluidization stabilityFluidised-bed furnacesReduction treatmentHigh energy

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

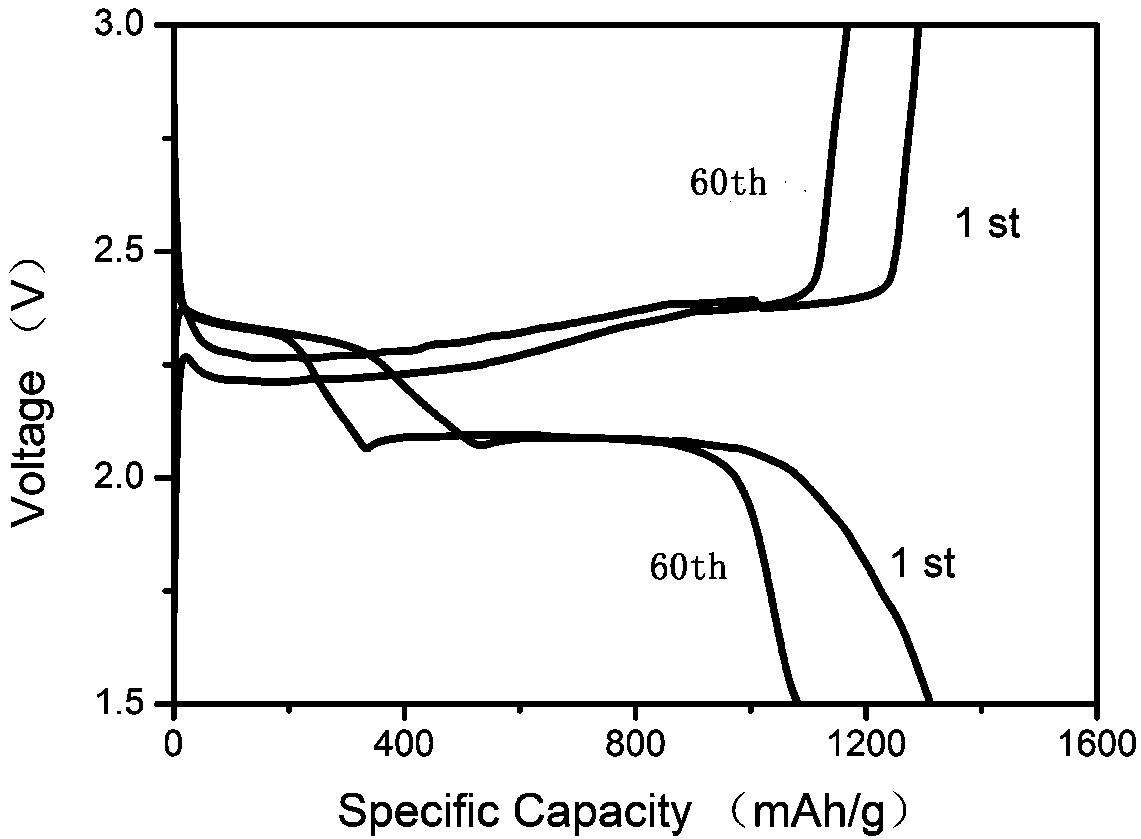

Preparation method of Sb<2>Se<3> composite material used for lithium-sulfur battery diaphragm

ActiveCN108172744AHighlight substantiveImprove cycle performanceCell component detailsElectrical batteryLithium–sulfur battery

The invention discloses a preparation method of a Sb<2>Se<3> composite material used for a lithium-sulfur battery diaphragm. According to the method, rod-like Sb<2>Se<3> is introduced to be used as asupporting framework of a graphene lamination layer, and a coating material structure is modified; Sb<2>Se<3>-pvp and graphene oxide are mixed at a certain proportion, and graphene oxide is reduced through hydrazine hydrate to obtain a dispersion liquid of the Sb<2>Se<3>-pvp and reduced graphene oxide; the dispersion liquid is subjected to spray drying to obtain solid powder, and then the solid powder is glued with a Celgard2400 diaphragm through a binder to prepare a Sb<2>Se<3>-pvp-rGO composite material diaphragm. The electrochemical performance of the lithium-sulfur battery is improved through a simple, convenient and low-cost method.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

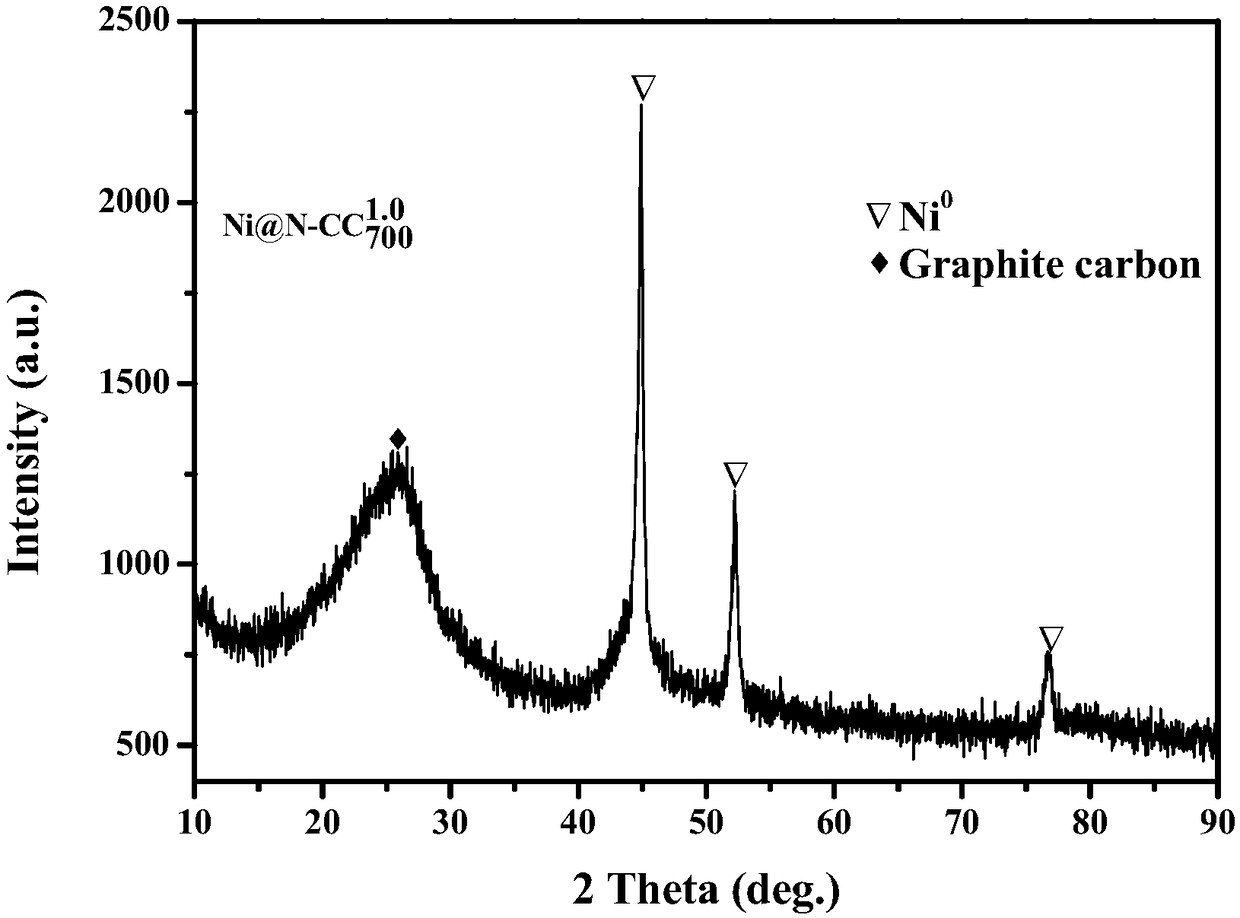

Preparation method of non-metallic element doped nano zero-valent nickel loaded carbon fiber composite material

ActiveCN108479832ALarge specific surface areaHigh temperature resistantCatalyst activation/preparationN dimethylformamideMetal particle

The invention discloses a preparation method of a non-metallic element doped nano zero-valent nickel loaded carbon fiber composite material. The method includes the steps of: firstly impregnating nitric acid modified activated carbon fiber in a N, N-dimethylformamide solution containing nickel ions for pre-oxidation to obtain a precursor; then transferring the obtained precursor and an inorganic non-metallic salt into a tubular furnace together, and conducting calcination and pyrolysis under inert gas protection to obtain the target product. According to the invention, the nitric acid modifiedcarbon fiber surface has a lot of highly dispersed active centers, and provides favorable conditions for dispersion, growth and nucleation of metal particles; the in-situ controlled synthesis effectively avoids the agglomeration and oxidation of zero-valent nickel and the loss of active centers in the reaction process; and the composite material prepared by the method provided by the invention has excellent properties, and can be used for purification of volatile organic gases, catalytic hydrogenation, magnetic materials, supercapacitors and other fields.

Owner:HEFEI UNIV OF TECH +1

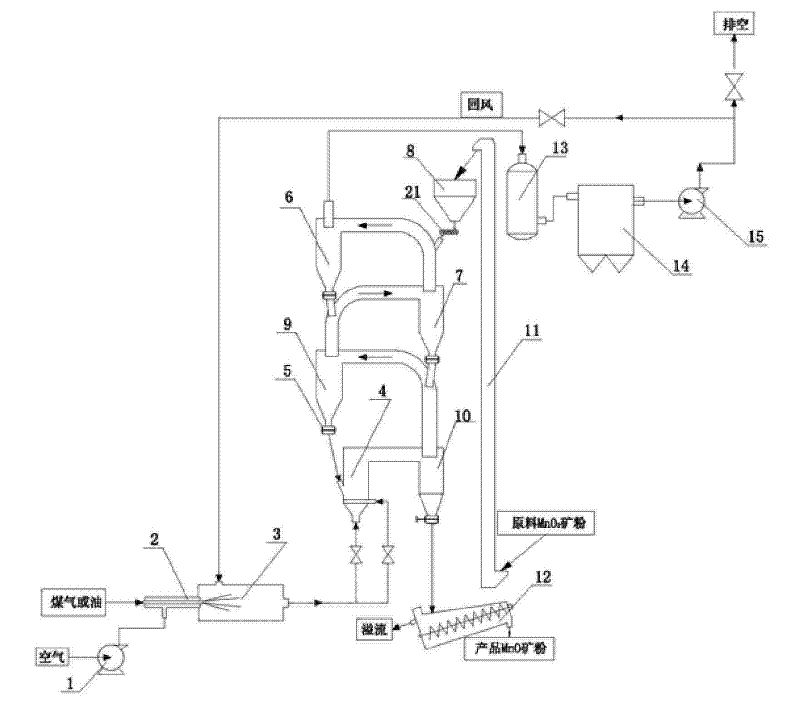

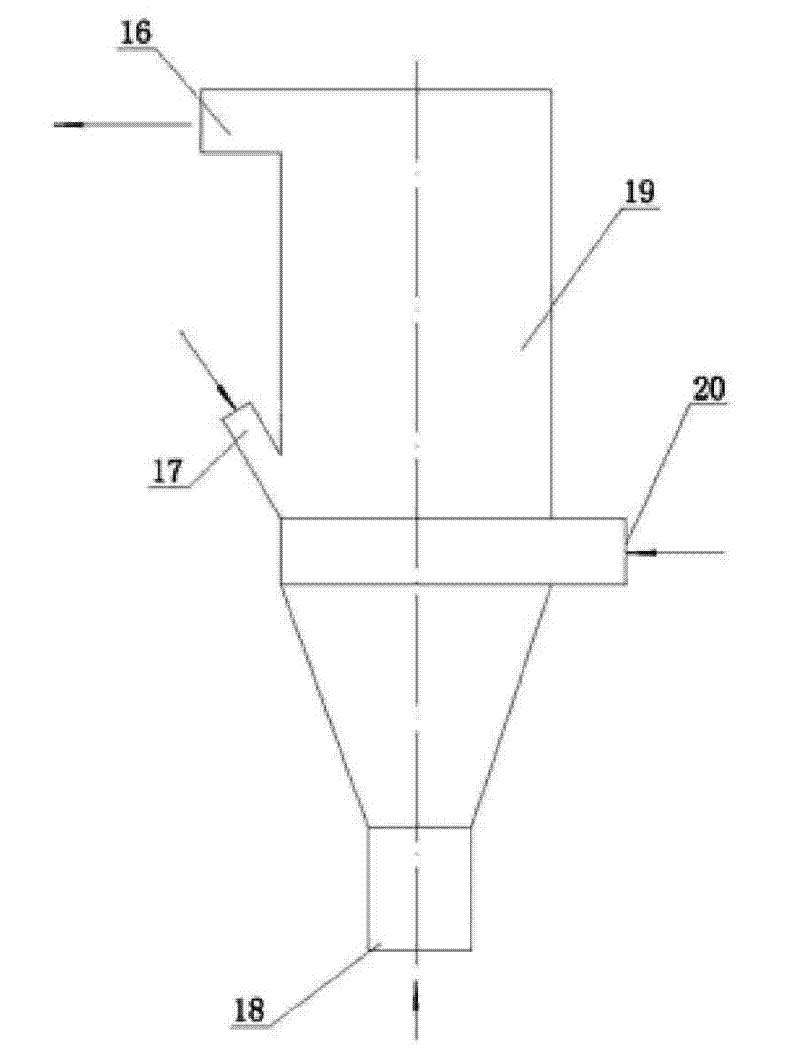

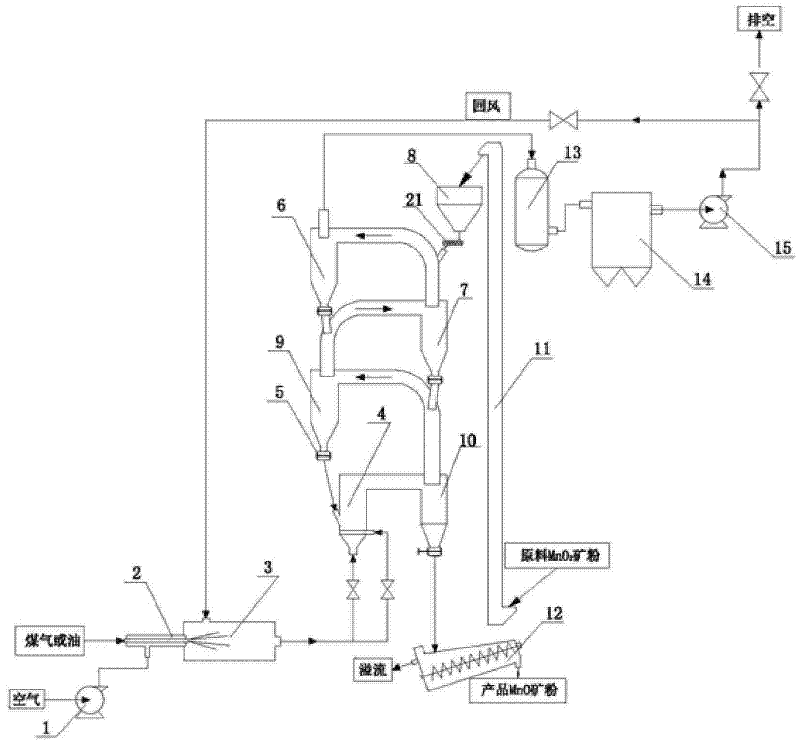

Method and device for reducing and baking for high-valent manganese minerals

The invention provides a method and a device for reducing and baking for high-valent manganese minerals. The method comprises the following steps: (1) combusting combustible gas and air in a hot blast furnace through a nozzle, controlling coefficient of excess air to ensure that the gas of the hot blast furnace is required reduction atmosphere and temperature, and introducing a fluidized roaster;(2) finely grinding manganese minerals, feeding the manganese minerals into a suspension preheat assembly for sufficient heat exchange in several times, separating gas and mineral powder granules, and feeding the granules into the fluidized roaster for a reduction reaction; and (3) controlling the CO content and solid-gas ratio in the fluidized roaster; reducing manganese mineral powder in the fluidized roaster into acidsoluble manganous oxide, and discharging the manganous oxide from a solid material outlet of a cyclone preheater in the last stage. The device comprises a feed assembly, the suspension preheat assembly, the fluidized roaster, a dust-removal exhaust assembly, a gas feed assembly and a combustion assembly. The method and the device have the advantages of simple and compact structure, low cost, simple and convenient operation, good reduction effect, low energy consumption and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com