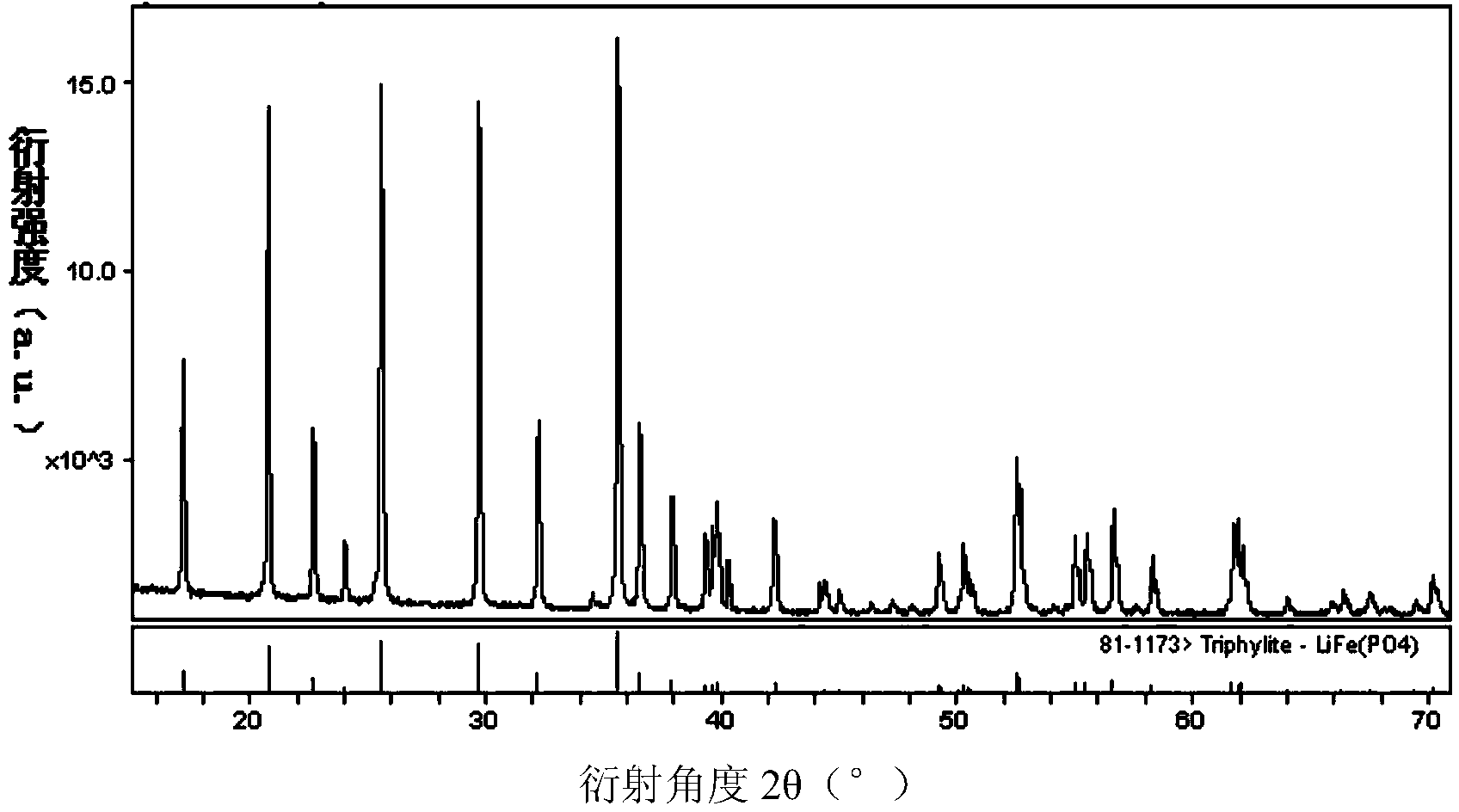

Synthesizing method for lithium ion anode material LiFePO4/C

A technology of positive electrode materials and synthesis methods, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as the adverse effects of LiFePO4 electrical properties, and achieve the effect of improving electrical properties and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 5.0mol Fe 2 o 3 , 0.05mol MnO 2 , 0.05mol TiO 2 and 100g of glucose, mixed with 2.5L of anhydrous salt water, ball milled for 8 hours, spray granulated, and the obtained powder was pretreated at 500°C for 7 hours in an inert atmosphere to obtain a carbon-coated iron source powder. Dissolve 10.0mol of ammonium dihydrogen phosphate in 2.5L of anhydrous brine, add carbon-coated iron source powder, and then slowly add 10.0mol of LiOH·H 2 O, stir evenly, ball mill for 3 hours, and spray granulate to obtain dry powder. The powder was added into the rotary kiln, under N 2 Sinter at 650°C for 8 hours in the atmosphere, then heat up to 800°C and sinter for 20 hours, then cool, sieve, classify and obtain the product.

[0023] The resulting product had a carbon content of 2.1%.

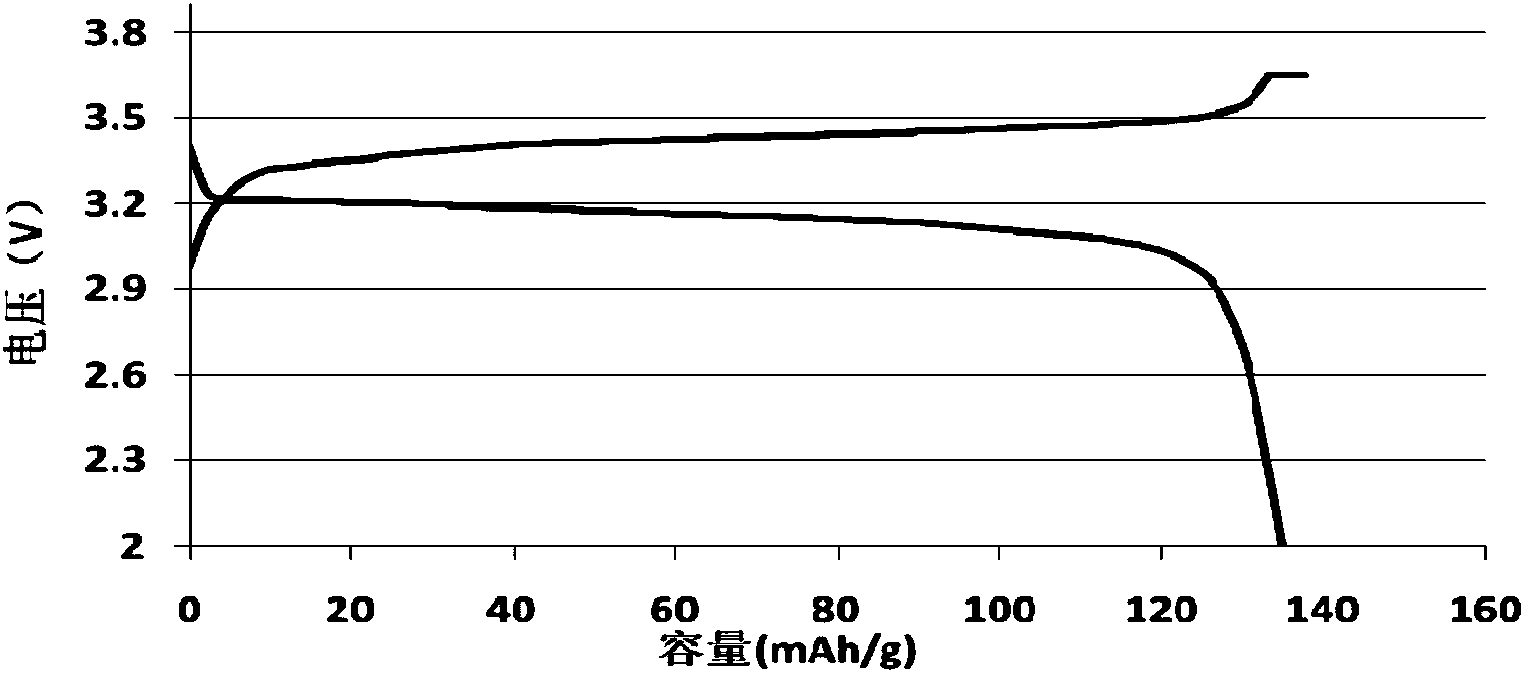

[0024] The material is proportioned LiFePO 4 : SP: KS6: HSV900: NMP = 92.5: 2: 1: 4.5: 100 ratio preparation to make 18650 cylindrical battery. The battery test 1C discharge capacity is 135.5mAh / g...

Embodiment 2

[0027] 5.0mol Fe 2 o 3 , 0.05mol MnO 2 , 0.05mol MgO and 100g sucrose, add 3.0L anhydrous salt water and mix evenly, ball mill for 8 hours, spray granulate, and the obtained powder is pretreated at 500°C for 8 hours in an inert atmosphere to obtain carbon-coated iron source powder. Dissolve 10.0mol of ammonium dihydrogen phosphate in 2.5L of anhydrous brine, add carbon-coated iron source powder, and then slowly add 10.0mol of LiOH·H 2 O, stir evenly, ball mill for 3 hours, and spray granulate to obtain dry powder. The powder was added into the rotary kiln, under N 2 Sinter at 600°C for 8h in the atmosphere, then heat up to 800°C for 20h, cool, sieve, classify by air flow and obtain the product.

[0028] The resulting product had a carbon content of 1.9%.

[0029] The material is proportioned LiFePO 4: SP: KS6: HSV900: NMP = 92.5: 2: 1: 4.5: 100 ratio preparation to make 18650 cylindrical battery. The battery test 1C discharge capacity is 132.3mAh / g.

Embodiment 3

[0031] 5.0mol Fe 2 o 3 , 0.1mol MnO 2 and 100g of polyethylene glycol, mixed with 2.5L of anhydrous salt water, ball milled for 8h, spray granulated, and the obtained powder was pretreated at 500°C for 8h in an inert atmosphere to obtain a carbon-coated iron source powder. Dissolve 10.0mol ammonium dihydrogen phosphate in 2.5L anhydrous salt water, add carbon-coated iron source powder, and then slowly add 10.0mol LiOH·H 2 O, stir evenly, ball mill for 3 hours, and spray granulate to obtain dry powder. The powder was added into the rotary kiln, under N 2 Sinter at 650°C for 8 hours in the atmosphere, then heat up to 820°C for 15 hours, then cool, sieve, classify and obtain the product.

[0032] The resulting product had a carbon content of 1.8%.

[0033] The material is proportioned LiFePO 4 : SP: KS6: HSV900: NMP = 92.5: 2: 1: 4.5: 100 ratio preparation to make 18650 cylindrical battery. The battery test 1C discharge capacity is 130.9mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com