Device promoting reasonable distribution of coal gas flow in shaft furnace

A technology of distribution device and gas flow, applied in shaft furnaces, furnaces, furnace types, etc., can solve the problems of low airflow velocity in the surrounding pipes and loop pipes, clogging of fine dust in the surrounding pipes, and reduced metallization rate, etc., and achieve reasonable distribution of gas flow. , the effect of increasing the residence time and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0033] The specific implementation of a device for promoting the reasonable distribution of gas flow in the shaft furnace in Embodiment 2 will be described in detail below.

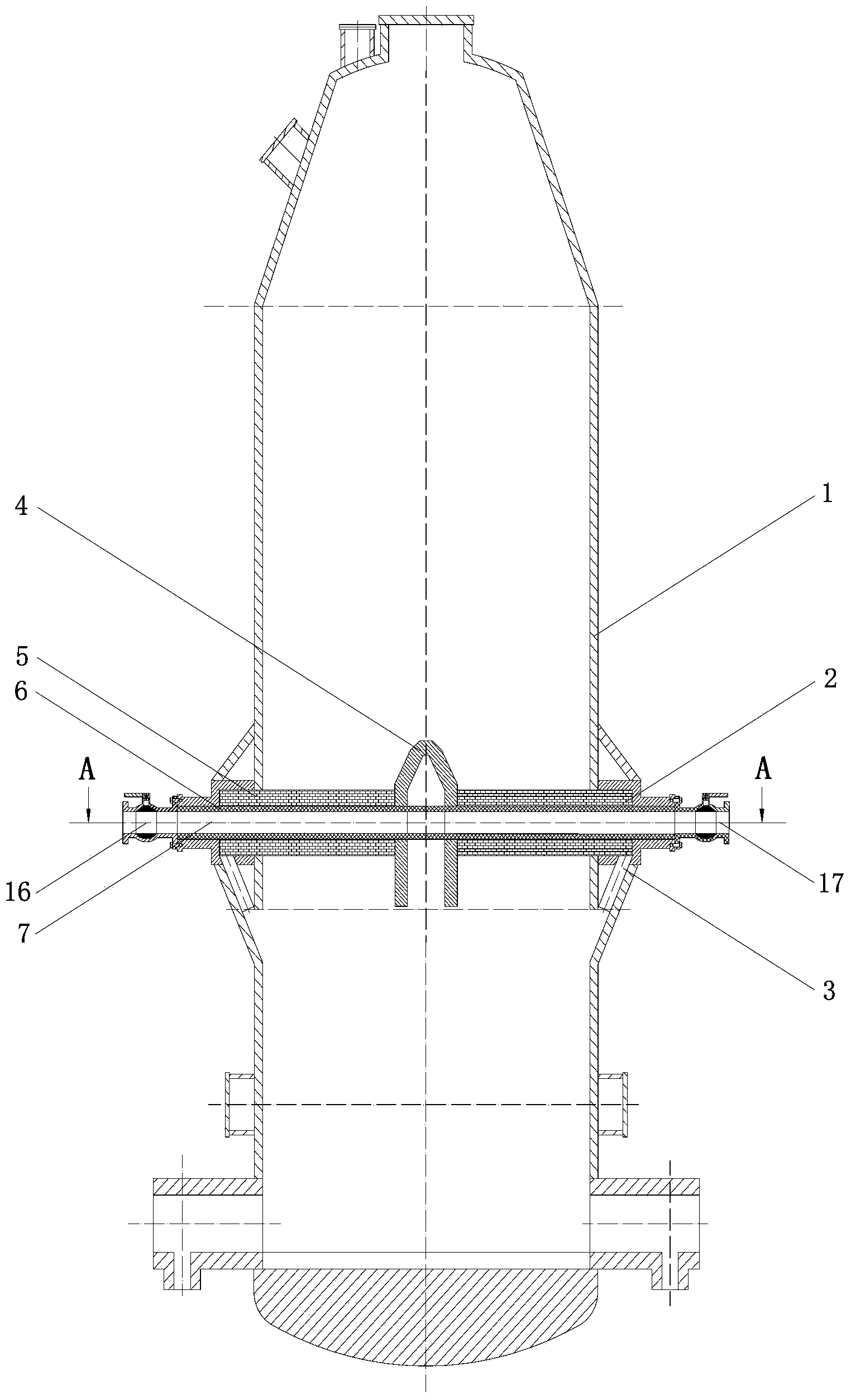

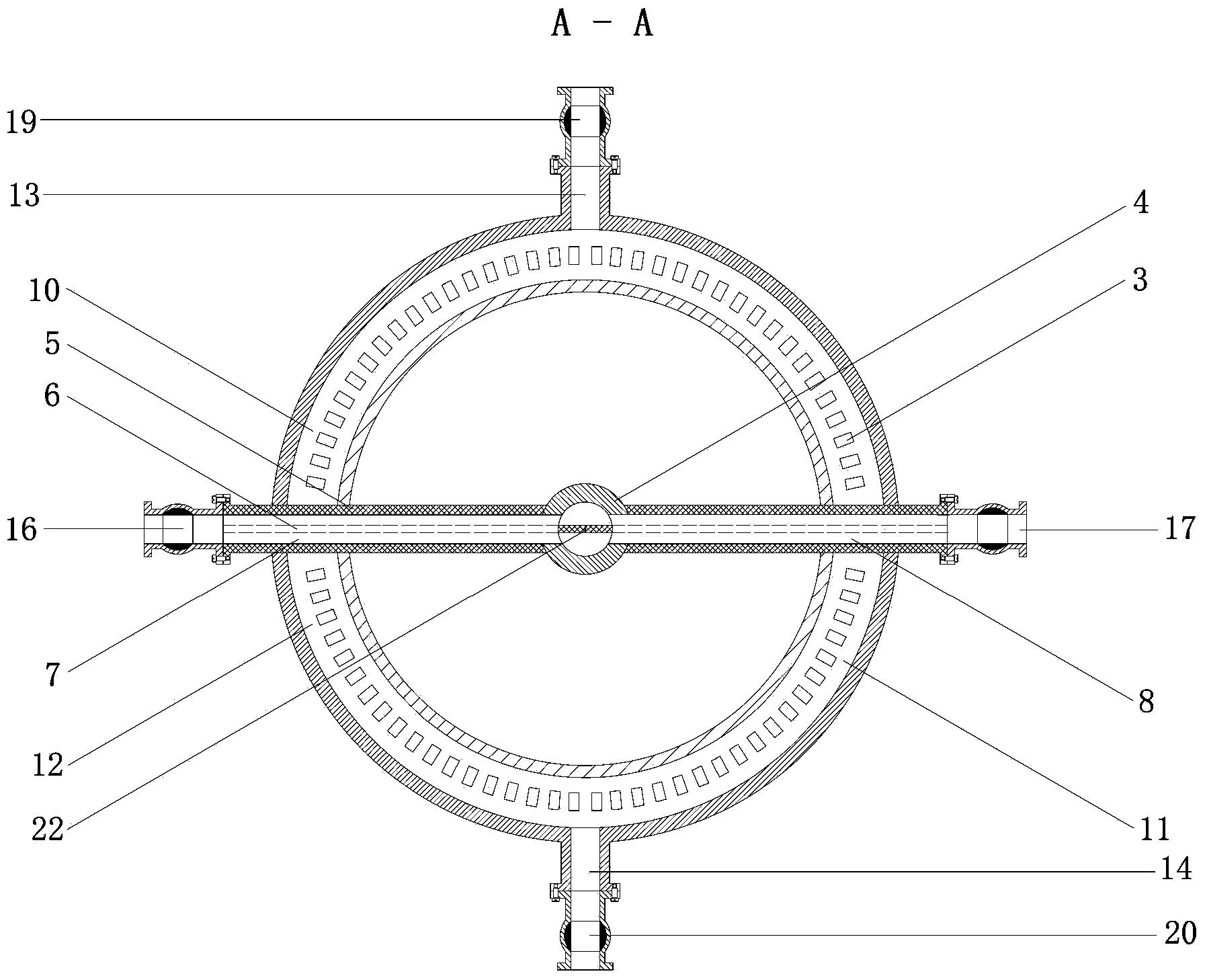

[0034] Figure 4 It is a structural schematic diagram of the embodiment 2 "a device for promoting the reasonable distribution of gas flow in the shaft furnace", Figure 5 for Figure 4 The C-C cross-sectional view mainly includes the shaft furnace body 1, the conical gas distribution device 4 inside the shaft furnace, and three internal gas supply pipes 7, 8, and 9 that are 120° along the circumferential direction, corresponding to the internal gas pipes connected to the internal gas pipes. Air supply flow regulating valves 16, 17, 18, three internal air supply pipes divide the surrounding pipe into three mutually independent surrounding pipe air supply areas 10, 11, 12, and the three independent surrounding pipe air supply areas are respectively connected with The three surrounding pipe gas supply pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com