A system and method for fluidized high-temperature rapid redox of vanadium-titanium magnetite

A vanadium-titanium magnetite, high-temperature and rapid technology, applied in the fields of chemical industry and metallurgy, can solve the problems of high gas velocity, low reduction temperature, and low reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

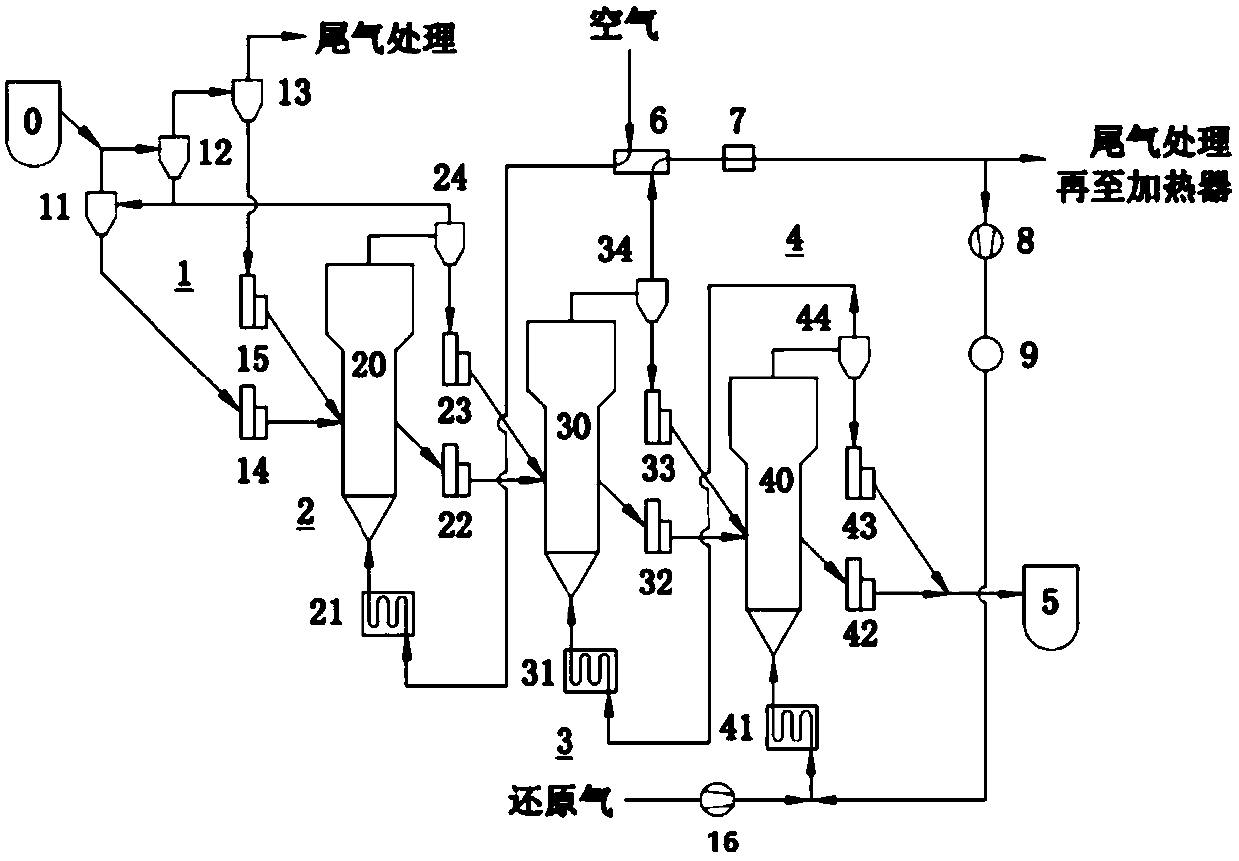

[0064] like figure 1 As shown, a fluidized high-temperature rapid oxidation-reduction system of vanadium-titanium magnetite, the system includes fine ore silo and feeder 0, fine ore preheater 1, oxidation bed 2, the first reduction bed 3 and the second Two reduction bed 4, product silo 5, heat exchanger 6, scrubber 7, reduction tail gas pressurizer 8, carbon dioxide remover 9, reduction gas pressurizer 16.

[0065] The fine ore preheater 1 includes a first-stage cyclone separator 11 , a second-stage cyclone separator 12 , a third-stage cyclone separator 13 , a first feeder 14 for an oxidation bed, and a second feeder 15 for an oxidation bed. The oxidation bed 2 includes an oxidation fluidized bed body 20 , an oxidation bed gas heater 21 , a first discharge device 22 for an oxidation bed, a second discharge device 23 for an oxidation bed, and a cyclone separator 24 for an oxidation bed. The first reduction bed 3 includes a primary reduction fluidized bed body 30, a primary red...

Embodiment 2

[0075] The method for carrying out the fluidized redox of vanadium-titanium-magnetite by the above-mentioned vanadium-titanium-magnetite fluidized high-temperature rapid redox system comprises the following steps: The outlet enters the gas outlet of the first-stage cyclone separator 11 and exchanges heat with the oxidation tail gas from the outlet of the oxidation bed cyclone separator 24, then enters the inlet of the second-stage cyclone separator 12, and is separated by the second-stage cyclone separator 12 , the coarse powder ore discharged from its bottom discharge port enters the inlet of the first stage cyclone separator 11 and enters the feed port of the oxidation bed feeder 14 after exchanging heat with the oxidation tail gas from the outlet of the oxidation bed cyclone separator 24 . The fine powder ore entrained by the gas outlet of the second-stage cyclone separator 12 is separated by the second-stage cyclone separator 13 and then directly enters the feed port of th...

Embodiment 3

[0077] Adopt the present invention to process raw ore chemical composition wt.% to be 55.86% TFe, 15.00% FeO, 63.19% Fe 2 o 3 , 13.71%TiO 2 , 2.21% SiO 2 , 1.16% MgO, 3.18% Al 2 o 3 , 1.57% V 2 o 5, 0.22% CaO vanadium-titanium magnetite powder ore, the powder ore particle size is 0.01-0.3mm. According to the present invention, after the fine ore is preheated and dried, it is first oxidized in an oxidizing fluidized bed, oxidized at 825°C for 15 minutes, the oxidizing gas velocity is 0.22m / s, the operating pressure is 3.1atm, the oxidizing gas is air, vanadium-titanium-magnetite The oxidation degree of ferrous iron reaches 43.17%. Subsequently, the oxidized vanadium-titanium-magnetite powder enters the reduction fluidized bed for reduction, the reduction temperature is 860°C, and the reduction time is 90 minutes in total. The gas velocity of the two reducing beds is 0.76m / s, the operating pressure is 6.8atm, the reducing gas is coal gas, the final metallization rate can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com