Patents

Literature

115results about How to "Uniform oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

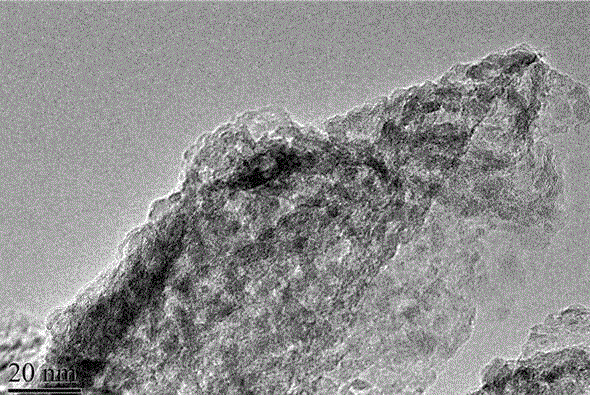

Method for preparing TiC-TiO2 core-shell type nanometer material

InactiveCN102600878ATo achieve fluidization effectUniform oxidationPhysical/chemical process catalystsCell electrodesNanoparticleSolvent

The invention discloses a method for preparing a TiC-TiO2 core-shell type nanometer material. The method comprises the following steps of: taking TiC nanometer grains as a precursor of a core-shell type nanometer material to be prepared; mixing the precursor with a dispersed material which is easily solved in a solvent in which the prepared nanometer grains cannot be solved; and preparing the core-shell type nanometer material compounds with different element proportion contents by controlling a reaction condition. The core-shell type nanometer material prepared according to the method provided by the invention is excellent in reproducibility; the process is simple and is easily controlled; and a noble metal catalyst can be loaded on the core-shell type nanometer material with excellent conductivity and oxidation corrosion resistance, so that the loaded capacity of the noble metal catalyst is reduced and the use ratio of the catalyst is increased.

Owner:SHANGHAI JIAO TONG UNIV

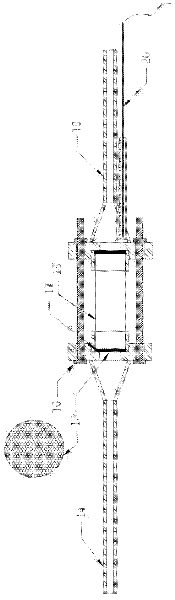

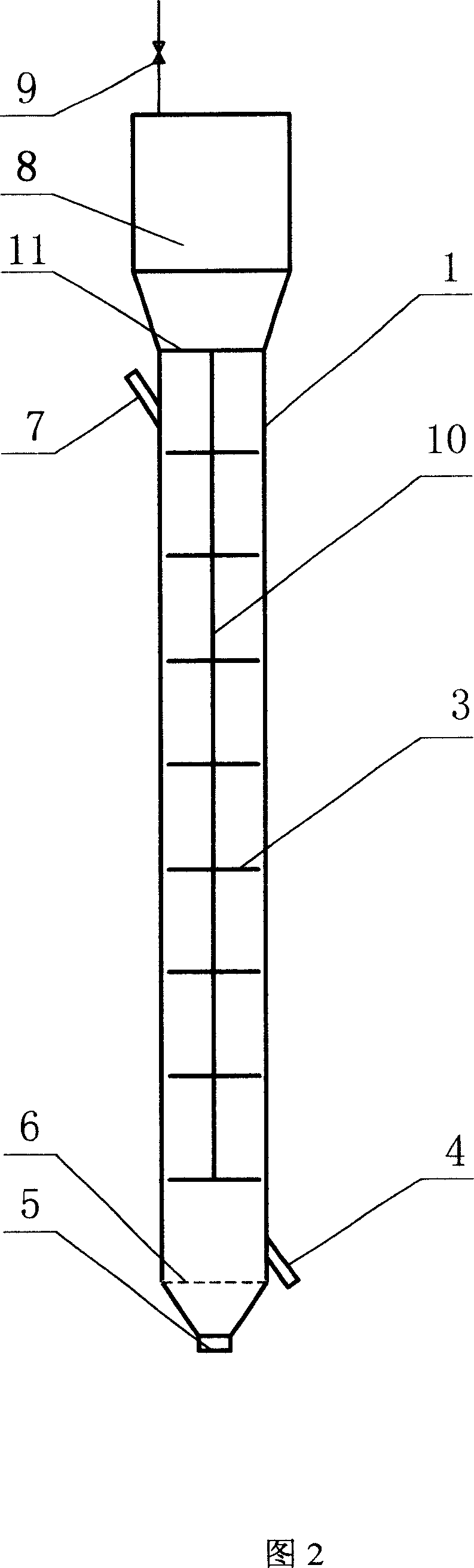

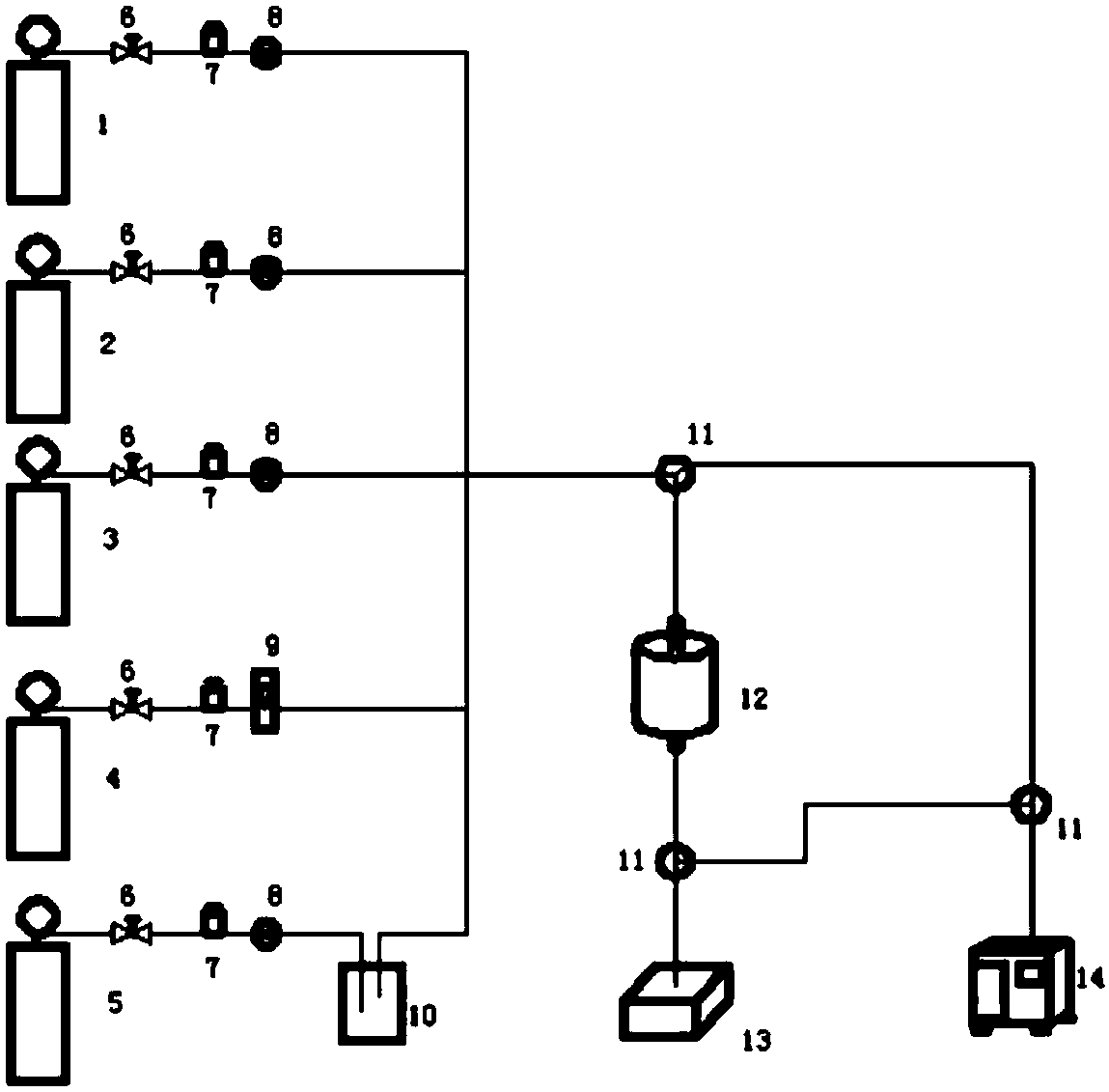

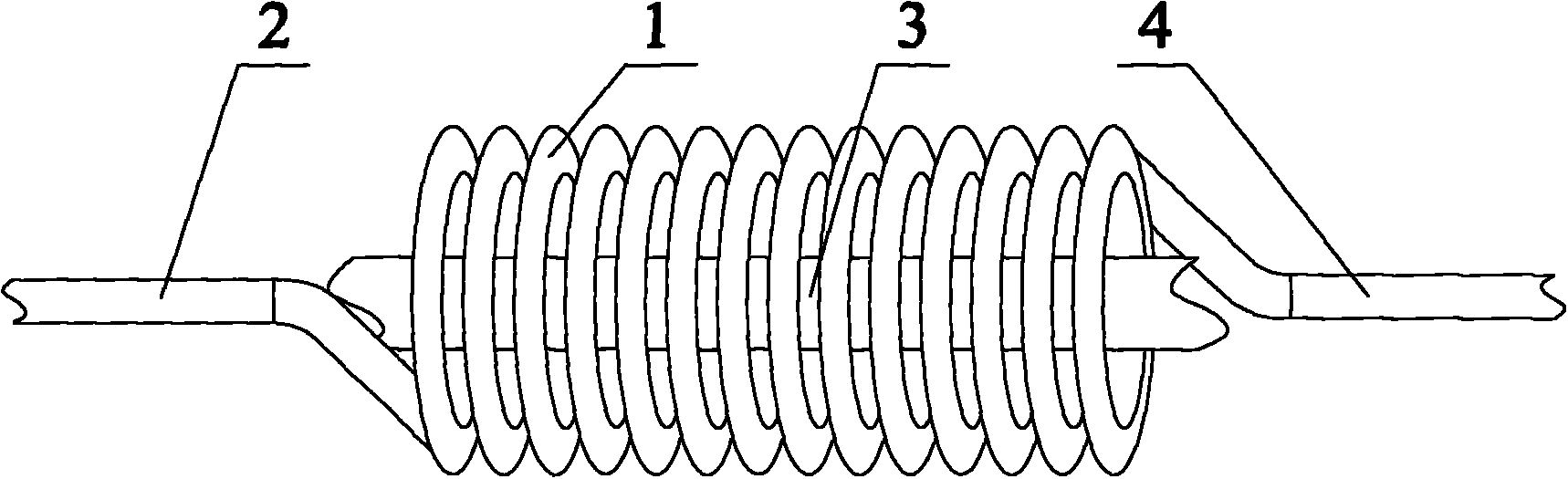

Fluidized-bed reactor for oxidizing carbon black through ozone

InactiveCN1958145AEliminate channelingElimination of Broken AgglomeratesPigmenting treatmentChemical/physical processesFluidized bedProduct gas

A fluidized-bed reactor for oxidizing carbon black by ozone with stable fluidizing and no coagulation of carbon black particles has a main body with lower carbon black discharging outlet, gas inlet on its bottom, upper carbon black inlet, gas outlet on its top, internal barrier plate with slits, and gas distributing plate under the carbon black discharging outlet.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

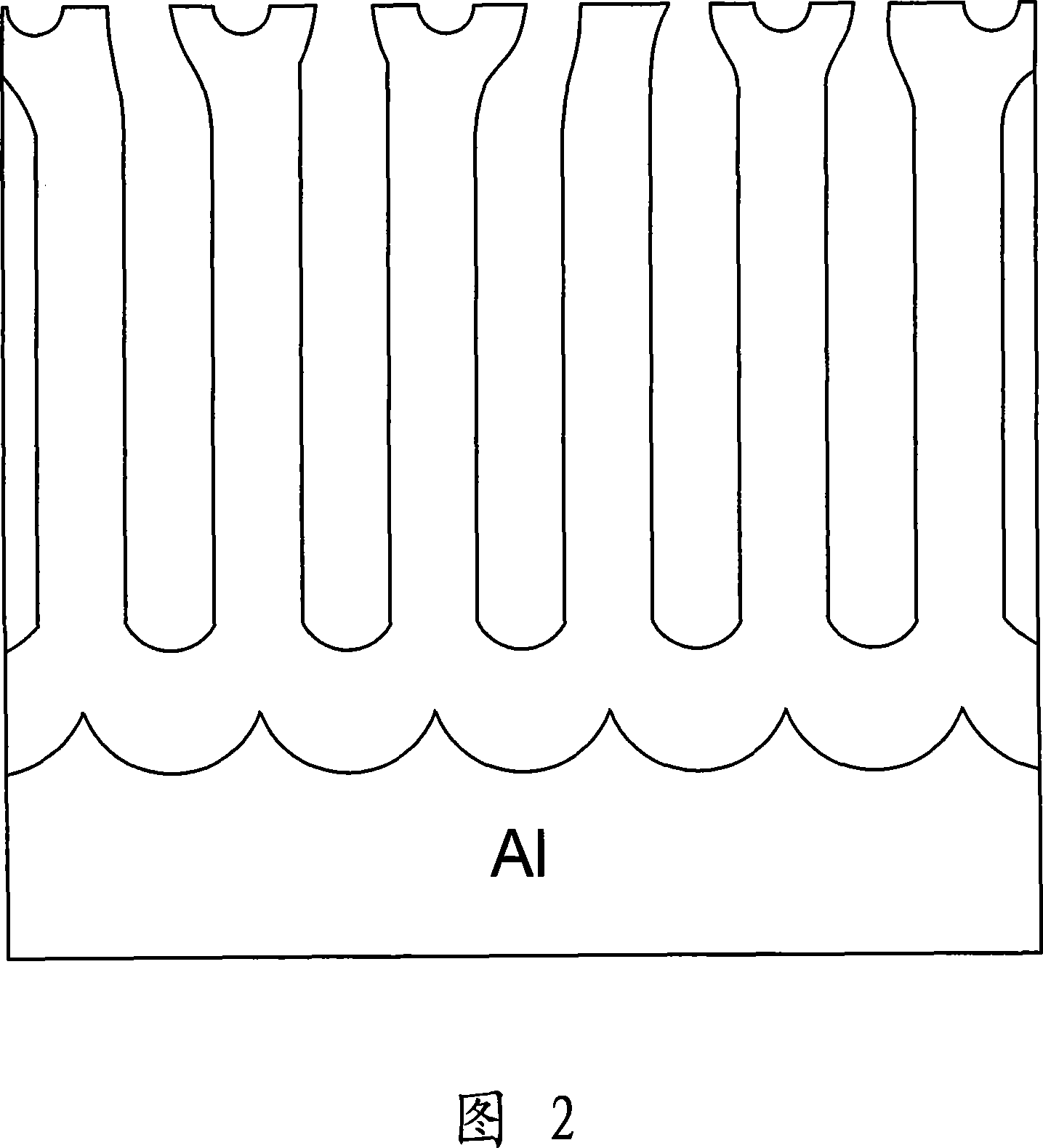

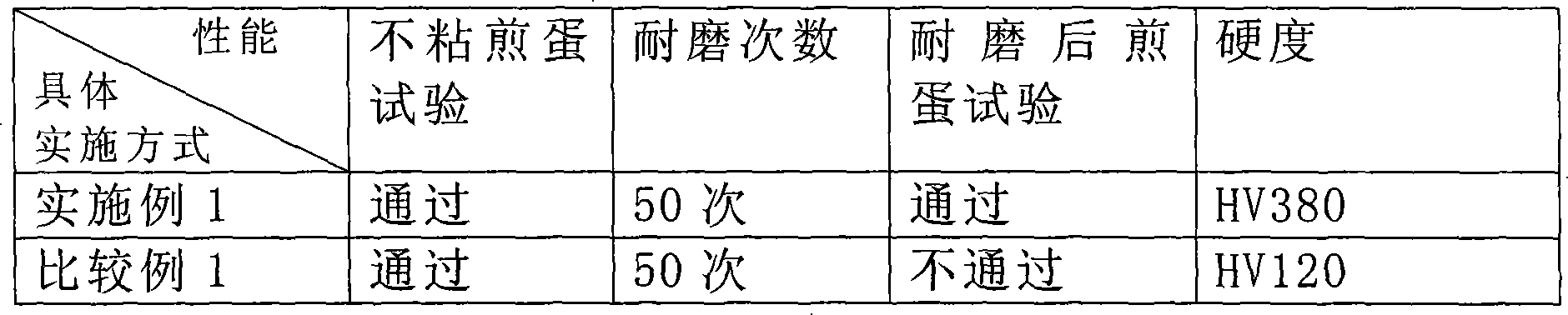

Making process of antiwear nonstick cooker

InactiveCN101019742ANot easy to produce oily smokeImprove thermal conductivityCooking-vessel materialsHardnessHigh wear resistance

The present invention is making process of antiwear nonstick cooker and belongs to the field of daily article making technology. The making process of antiwear nonstick cooker includes the following steps: forming, anode oxidation to form hard oxide layer, permeating, and pore sealing treatment. The antiwear nonstick cooker has the advantages of high nonstick performance, high hardness, high wear resistance and long service life. Besides, the cooker has fewer trend of generating oil smoke and easy cleaning.

Owner:严卫星 +1

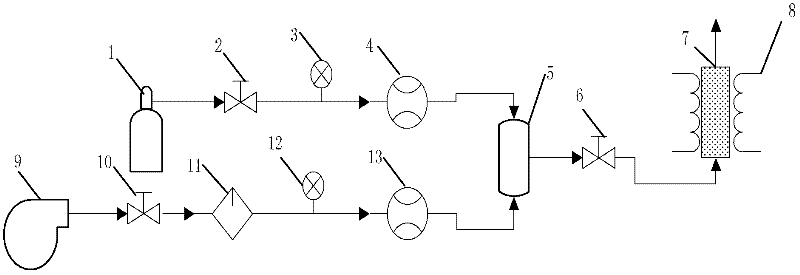

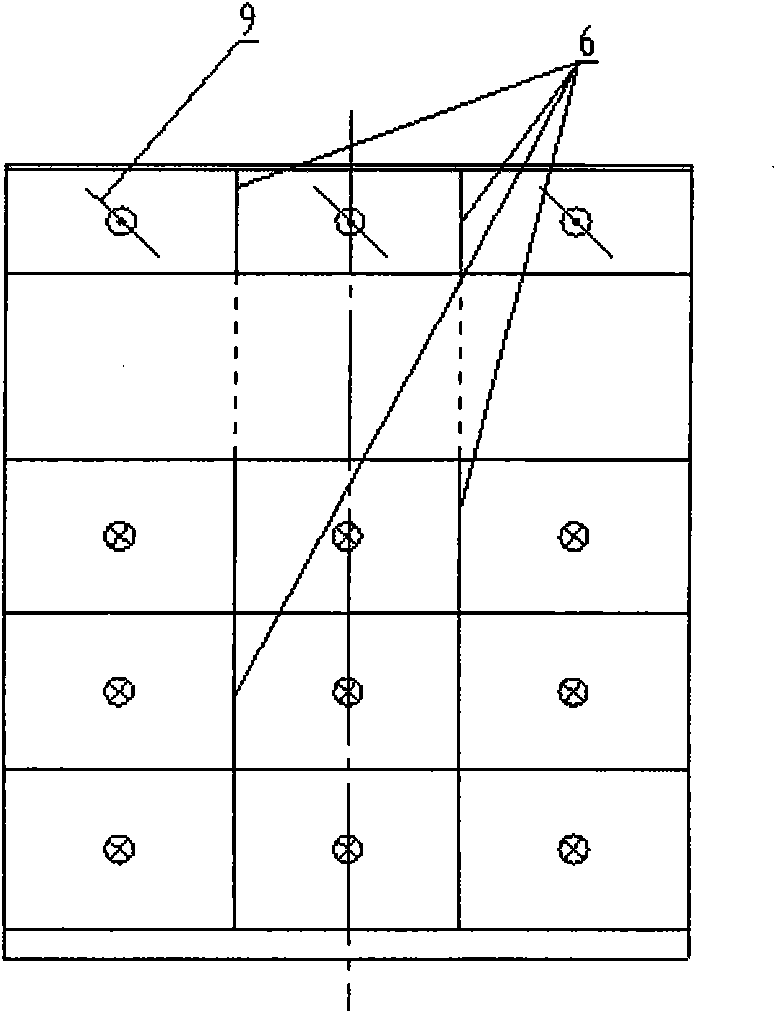

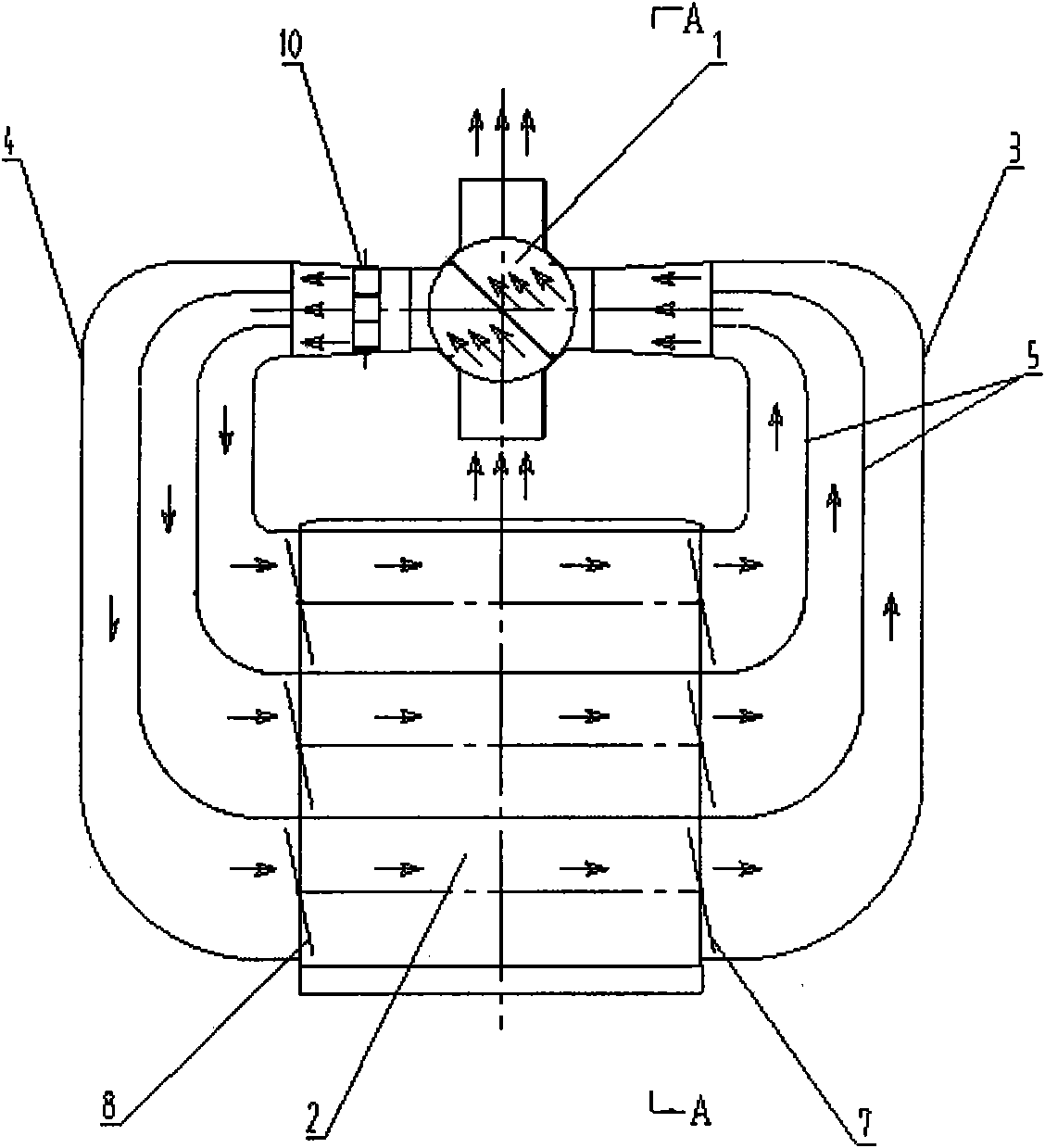

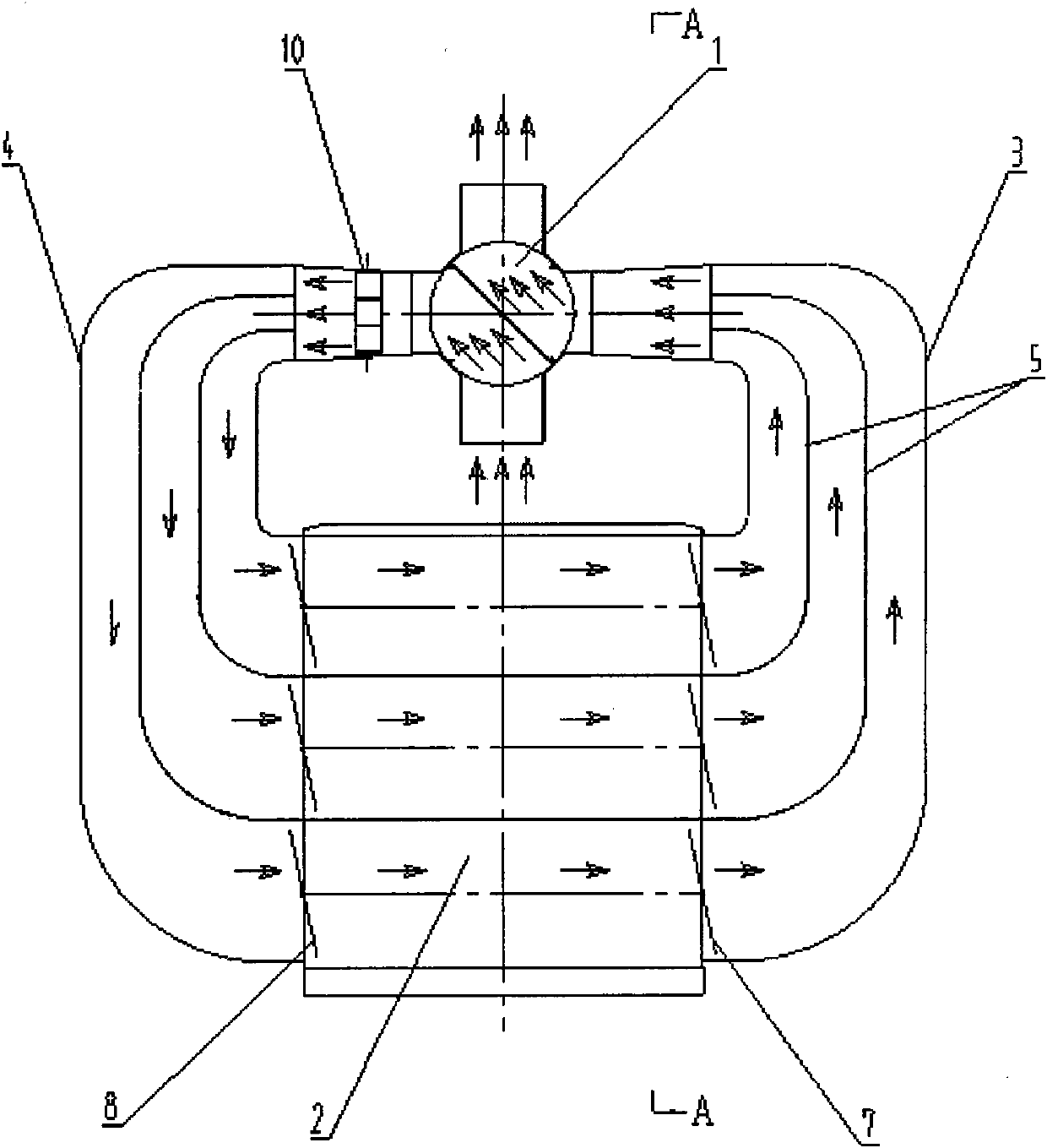

Method for distributing intake airflow and exhaust airflow of coal mine methane device

InactiveCN101906986AUniform oxidationUniform temperature fieldDust removalFire preventionAir volumeCoal mine methane

The invention provides a method for distributing intake airflow and exhaust airflow of a coal mine methane device. The device comprises an intake and exhaust change valve of an oxidation device, an oxidation bed, a right air duct and a left air duct, wherein a divide board and an airflow regulation mechanism are arranged in the right air duct and the left air duct which enter into the oxidation bed, the methane is separated in the horizontal direction and the vertical direction, so that the methane concentration and uniform intake and exhaust of airflow can be maintained in the oxidation bed, methane drifting and temperature field drifting in the oxidation bed can be prevented after the methane is heated in the oxidation device, and constant and stable operation of the oxidation device can be effectively maintained. The invention has the advantages of separating the air ducts with large space dimension of the oxidation device into a plurality of small circulating units in the horizontal direction and the vertical direction along with uniform methane concentration, uniform oxidation and uniform temperature field, automatically maintaining continuous operation of the oxidation device under a condition of lower methane concentration, reducing interactive interference between gases in gas intake and exhaust processes, reducing flow resistance, reducing power consumption of a methane delivery fan and the like, and is mainly applied to coal mine methane oxidation process devices.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

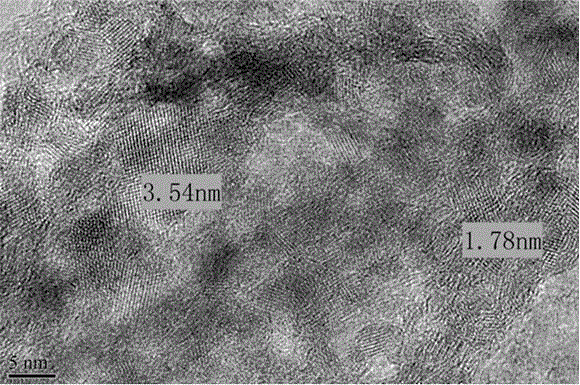

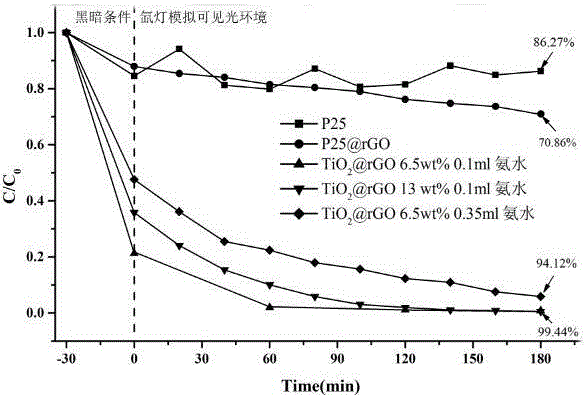

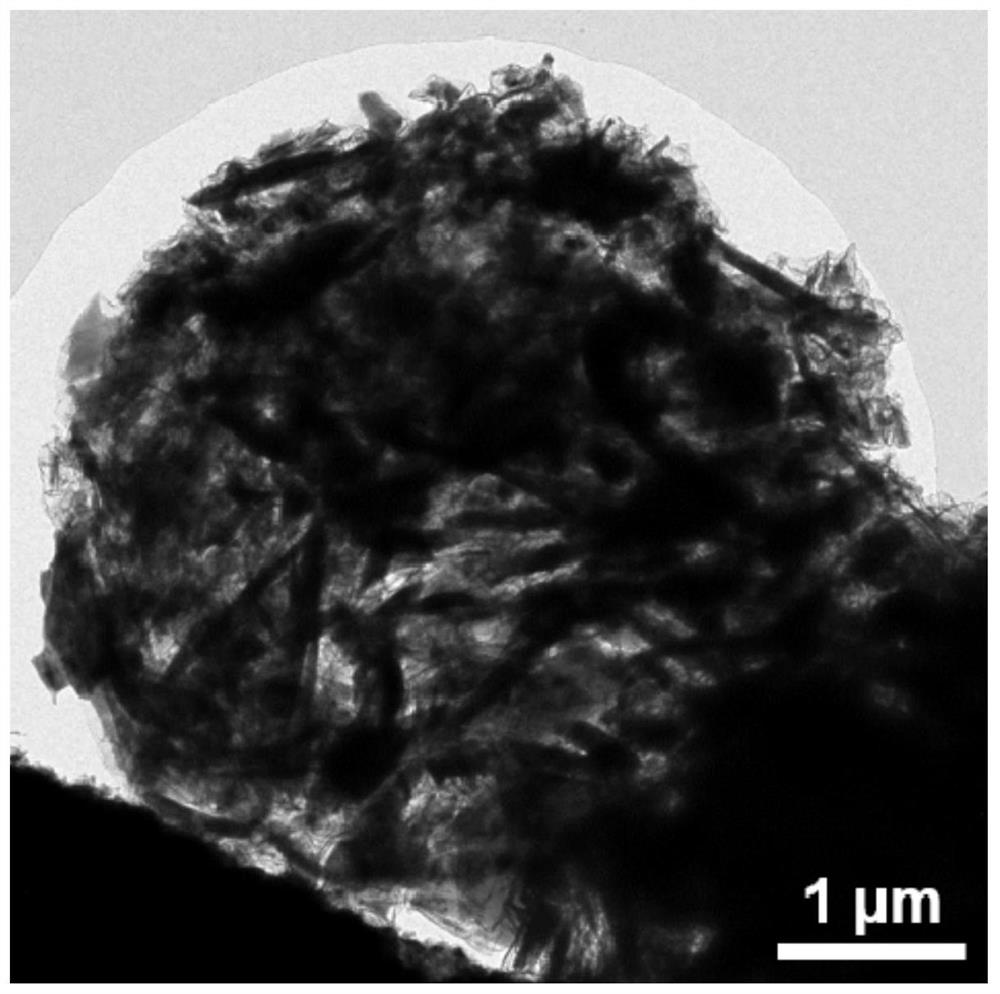

Preparation method and application of graphene and titanium dioxide photo-catalysis nano-crystals

InactiveCN106622201AGood dispersionSimple structureMaterial nanotechnologyPhysical/chemical process catalystsHigh pressureSodium nitrate

The invention discloses a preparation method and application of graphene and titanium dioxide photo-catalysis nano-crystals and belongs to the technical field of inorganic composite materials. The preparation method comprises the following steps: putting graphite powder and sodium nitrate into a flask; adding concentrated sulfuric acid and slowly adding potassium permanganate into the flask; stirring in an ice-bath environment and slowly dropwise adding hydrogen peroxide into the flask; washing with hydrochloric acid under a high-speed centrifuging condition to obtain a graphene oxide ethanol solution; after diluting, slowly adding tetrabutyl titanate, and slowly dropwise adding stronger ammonia water; putting a separated product into an air blowing drying box and drying; putting a dried product into a tubular furnace and inert gas atmosphere, and calcining; cooling to obtain the graphene / titanium dioxide photo-catalysis nano-crystals. The growth of titanium dioxide nano-crystals on graphene can be accurately regulated and controlled and a homogeneous nucleation phenomenon of titanium dioxide in a liquid phase is avoided; a preparation process is moderate and easy to observe, a high-pressure reaction environment is not needed and the safety and reliability of operation are improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method of novel oxycellulose hemostatic product

ActiveCN105561379ASoft textureHigh porositySurgical adhesivesPharmaceutical delivery mechanismIonSolvent

The invention discloses a preparation method of a novel oxycellulose hemostatic product; the preparation method comprises the steps: pre-treating a cellulose product with a sodium hydroxide solution with the concentration of 1%-5%, removing lignin or impurities on a fiber surface, and further carrying out activation treatment on the fiber surface with an alkali solution; after pretreatment and activation, washing with deionized water to be neutral, and air-drying the obtained cellulose product in air to obtain a raw material; taking a sodium hydroxide solution with the concentration of 5%-20% as a solvent, taking the cellulose product with the amount of 3-10% of the sodium hydroxide solution, then adding urea with the amount of 2% of the sodium hydroxide solution and ZnO with the amount of 2% of the sodium hydroxide solution, and implementing other steps. The physical properties of cellulose fibers are directly changed, the porosity of the cellulose product is greatly increased, the specific surface area of the product is increased, the strength of the product is also increased, the crystalline morphology structure of cellulose is improved, and the changes are greatly beneficial for the next step of selective oxidation reaction of the product.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

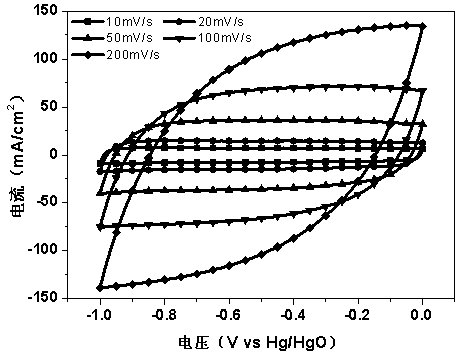

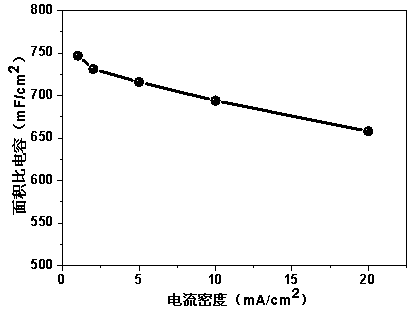

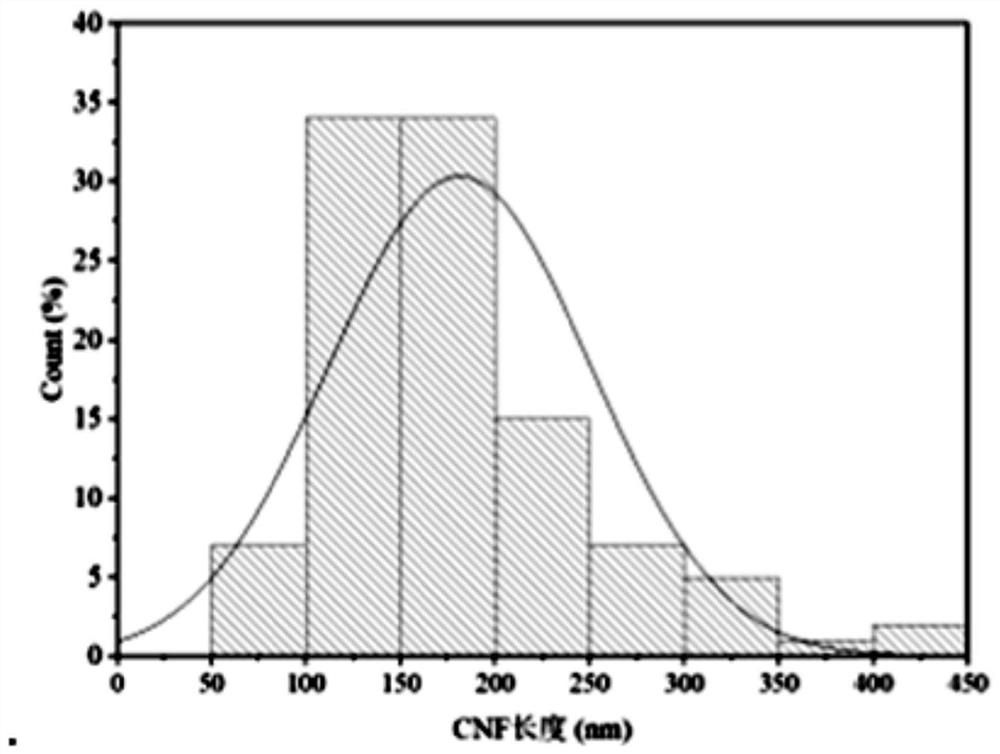

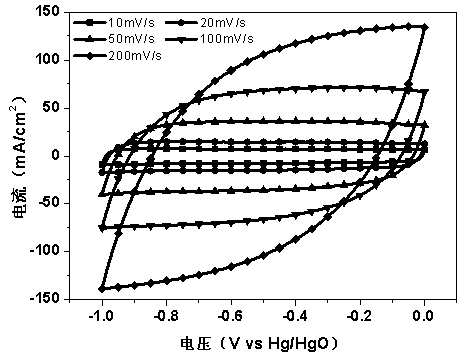

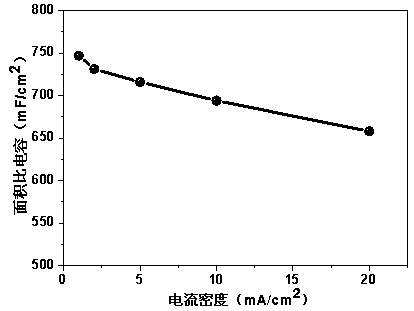

Carbon cloth surface modification method used for flexible supercapacitor electrode

ActiveCN108172417AImprove electrochemical performanceExcellent rate performanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceModified carbon

The invention provides a carbon cloth surface modification method used for a flexible supercapacitor electrode. The carbon cloth surface modification method comprises the following steps that S1: firstly the carbon cloth is arranged in the mixed solution of potassium permanganate and concentrated acid to perform first step of reaction, then the deionized water is added to perform second step of reaction, finally hydrogen peroxide is added and the carbon oxide cloth is prepared, then the carbon oxide cloth is repeatedly washed by the deionized water and ethyl alcohol in turn to the neutral state and dried; and S2: finally the carbon oxide cloth after drying processing of the step S1 is calcinated and reduced by sodium amide under the nitrogen environment and then repeatedly washed by the deionized water and the ethyl alcohol in turn until the washing solution is neutral and dried so as to obtain the surface modified carbon cloth. The modified carbon cloth prepared by the method is uniform in surface and high in specific capacitance, and the capacitance retention rate is more than 85% when the current density is increased to 20mA / cm2 from 1mA / cm2 so as to have excellent rate performance. Besides, the method is simple in technology, low in cost and simple in industrial promotion.

Owner:NANCHANG HANGKONG UNIVERSITY

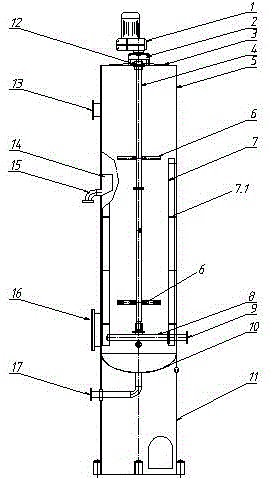

Oxidizing tank

InactiveCN105585103AUniform oxidationPromote oxidationWater/sewage treatment by oxidationCouplingSewage

An oxidizing tank comprises a vertical cylindrical tank body and a stirrer reducer fixed at the top of the tank body through a seat, wherein the bottom of the tank body is mounted on a skirt, the bottom end of the skirt is reliably connected with a ground embedded screw, the top of the tank body is sealed by a sealing cover plate, a stirring shaft in the tank body is connected with the stirrer reducer through a coupler, multiple groups of staggered paddles are arranged on the stirring shaft, an exhaust port and an overflow port are formed in the upper part of the tank body, a manhole, an air inlet and a sewage inlet are formed in the bottom of the tank body, an air distribution pipe is arranged at the bottom inside the tank body, a circle of effluent weir groove is formed at the overflow port in the tank body, and strip-shaped flow blocking plates are arranged on the inner wall of the tank body, distributed around the circle center of the tank body in an arrayed manner, provided with a plurality of connecting pieces from top to bottom and fixedly connected with the inner wall of the tank body. The oxidizing tank is simple in structure, convenient to maintain, uniform in oxidization and high in efficiency.

Owner:JIANGSU SAIOU ENVIRONMENTAL PROTECTION EQUIP

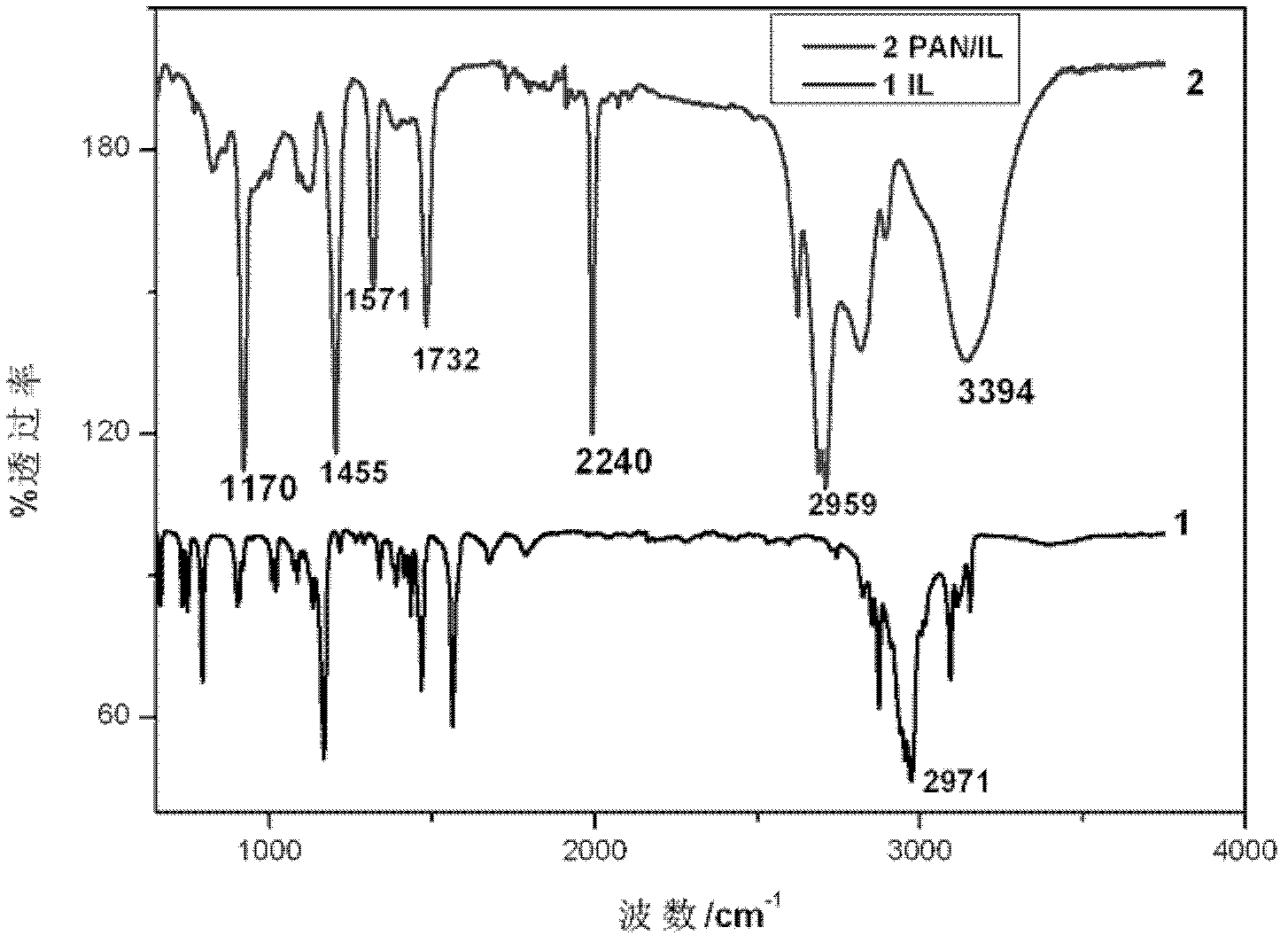

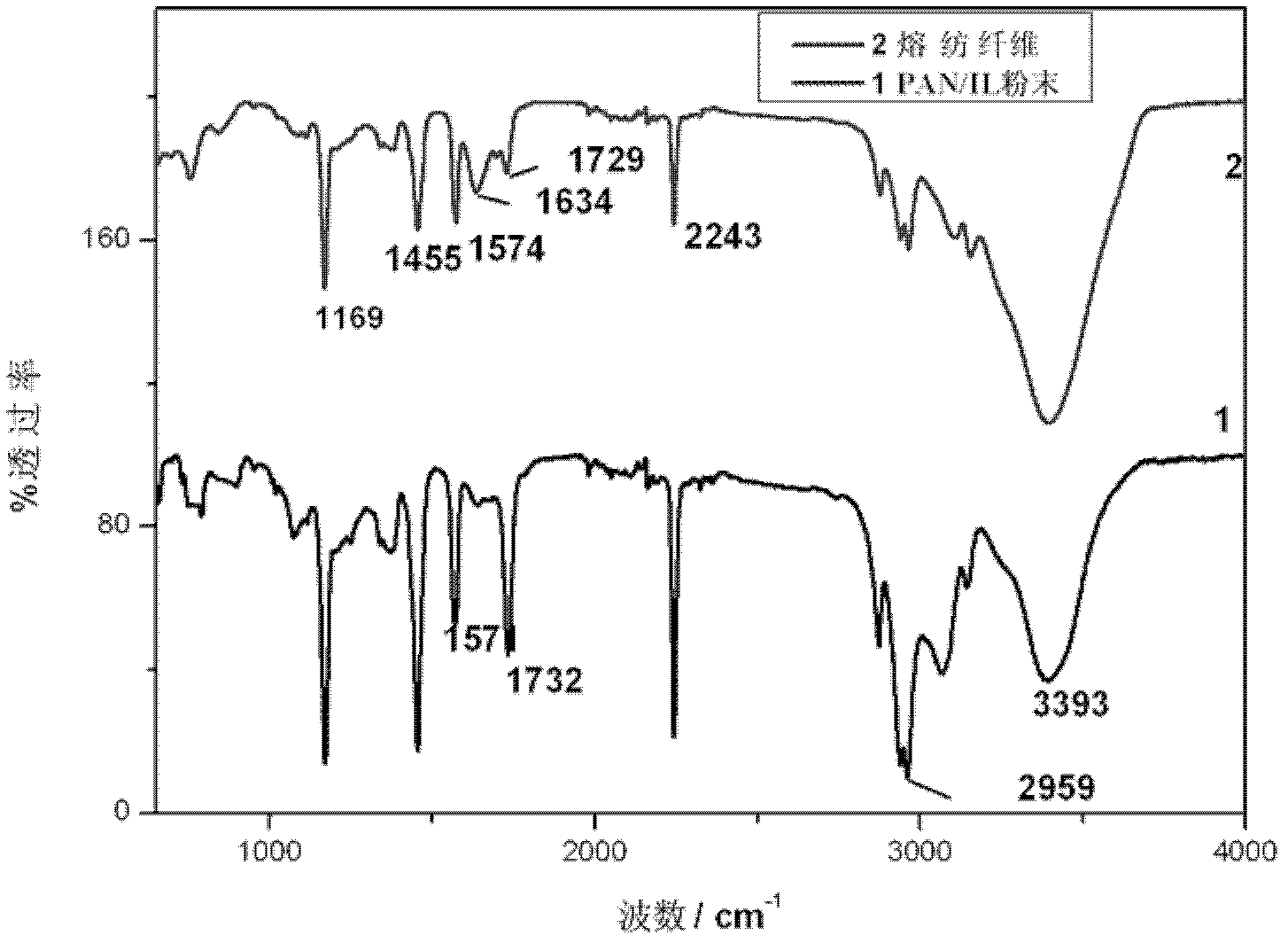

Method for preparing fast-oxidized polyacrylonitrile fiber

InactiveCN102251320AIncrease the speed of preoxidationReduce manufacturing costMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentIonChemistry

The invention relates to a method for preparing a fast-oxidized polyacrylonitrile fiber. The method comprises the following steps of: 1, uniformly mixing polyacrylonitrile powder with ionic liquid according to a weight ratio of 1: 0.25-1:1.8 to prepare a mixture, and introducing oxygen-containing gas at the temperature of 120-200 DEG C to carry out melt spinning to obtain a nascent filament; and 2, carrying out dry heat stretching on the nascent filament, extracting the stretched fiber at the temperature of 50-80 DEG C by using an extracting agent and finally carrying out heat-setting to obtain the polyacrylonitrile fiber, wherein the stretching temperature is 80-120 DEG C and total stretching multiple is 2-10. The method provided by the invention has a simple process and low cost, the prepared fiber can be uniformly oxidized, the skin core structure is reduced, the structure compactness of a carbon fiber is improved, the pre-oxidation rate is increased, the cost of the carbon fiber is reduced and the fast-oxidized polyacrylonitrile fiber has a good application prospect.

Owner:DONGHUA UNIV

Bamboo alpha-pulp for viscose and production method thereof

InactiveCN101736427AUniform oxidationGuaranteed responseArtificial filaments from viscoseMultistage pulping processSulfateHemicellulose

The invention discloses a bamboo alpha-pulp for viscose and a production method thereof. Main quality indexes of a bamboo pulp finished product are that: the degree of polymerization is 500 to 600 DP, alpha cellulose is more than or equal to 92 percent, ash is less than or equal to 0.20 percent, iron is less than or equal to 30 ppm, and the reaction performance is less than or equal to 200s. The production method comprises the following steps: preparing materials, stewing, bleaching, acidating and pulping. The stewing method adopts two-time different processes. The primary stewing adopts a sulfate method and the secondary stewing adopts a pure caustic soda method. The primary stewing can effectively dissolve the lignin in bamboo chips, remove the alkaline lignin and alkali soluble impurities through multistage washing, and reduce the pollution. The secondary stewing further removes hemicellulose and residual lignin, purifies the alpha cellulose, and guarantees that the reaction performance of the bamboo alpha-pulp can totally pass. The production method greatly improves the content of the alpha cellulose and reaction performance passing speed of the bamboo alpha-pulp, reduces the discharge of the stewing waste liquor, and provides a basis for further improving the yield and quality of bamboo fibers in chemical fiber production.

Owner:TANGSHAN SANYOU GRP DONGGUANG PULP CO LTD

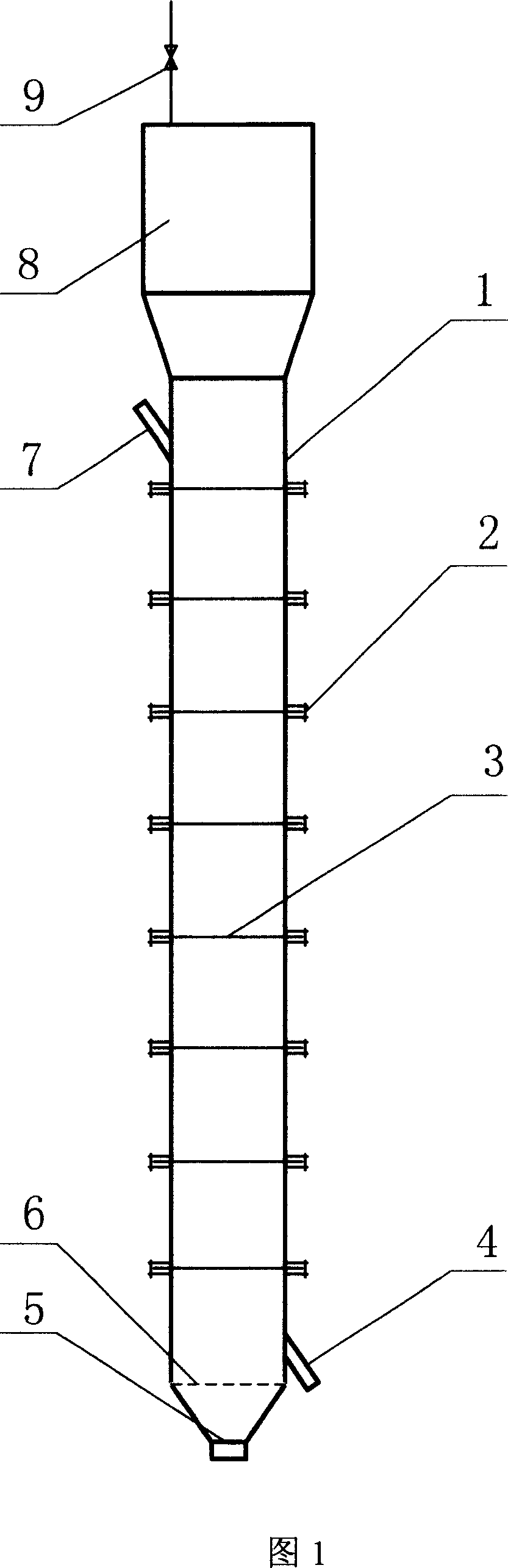

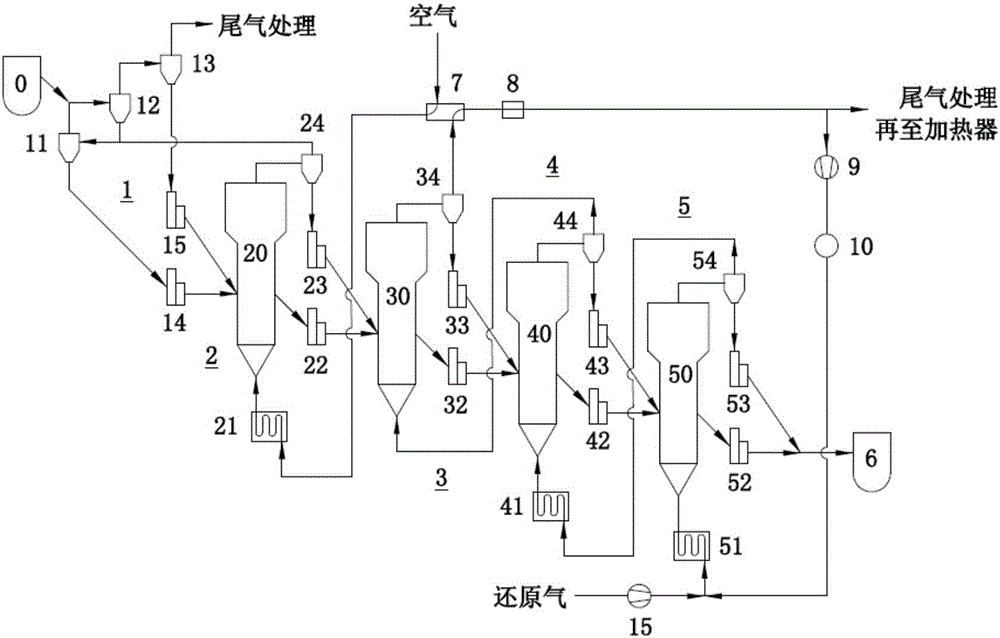

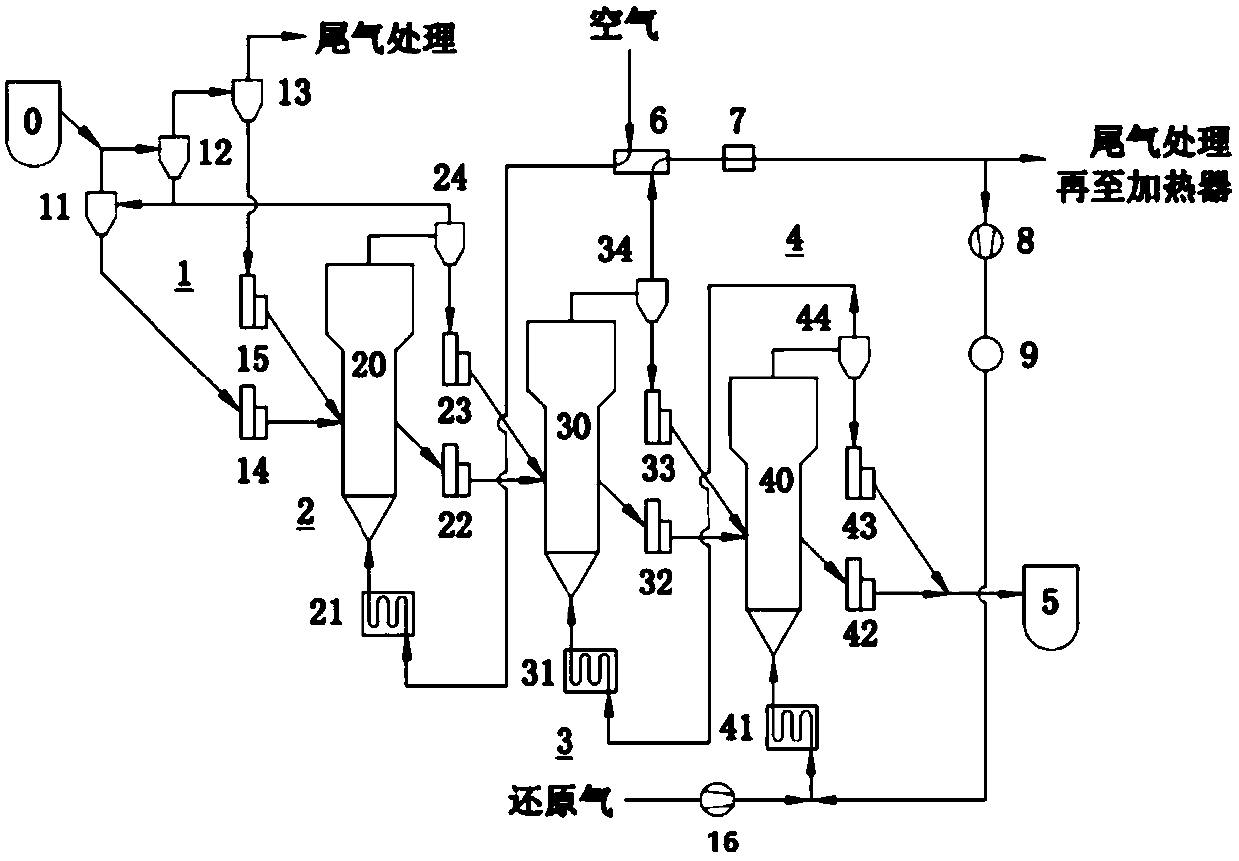

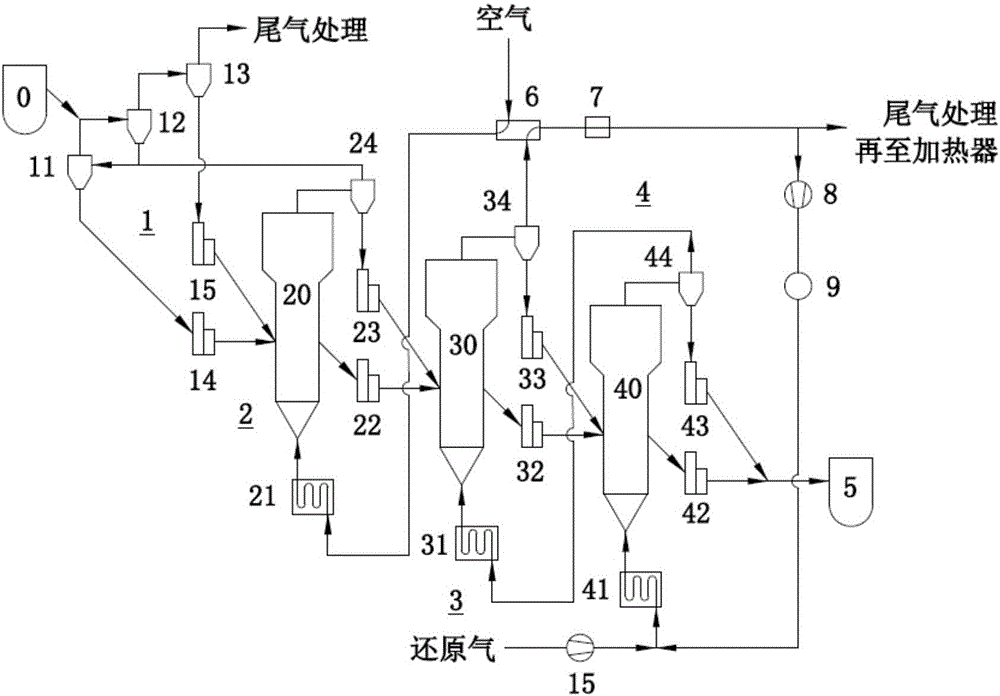

System and method for vanadium titano-magnetite fluidization oxidation and reduction

ActiveCN106319126AImprove reaction efficiencyImprove fluidization stabilityFluidised-bed furnacesHigh energyPhysical chemistry

The invention discloses a system and a method for vanadium titano-magnetite fluidization oxidation and reduction. A four-section fluidized bed is adopted to carry out fluidization oxidation and reduction on vanadium titano-magnetite fine ore; and a fluidized bed reaction body is formed by boiling beds connected in series. Through the technological design of a pre-oxidation treatment and low-gas-velocity reaction fluidized bed, the vanadium titano-magnetite powder fluidization performance can be obviously improved, the reaction efficiency is improved, and the process energy consumption is reduced. The vanadium titano-magnetite fine ore is firstly preheated and dried, enters a low-temperature oxidation bed so as to be subjected to oxidation treatment, then enters a prereduction bed so as to be subjected to prereduction, and finally complete final reduction through a two-stage high-temperature final reduction bed; oxidization tail gas is used for preheating and drying the vanadium titano-magnetite fine ore; after reduction tail gas is heat-exchanged with oxidization air, oxidization components are cleaned and removed, and the reduction tail gas is recycled; and a gas utilization scheme has the advantages of high reaction efficiency and high energy utilization ratio.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A system and method for fluidized redox of vanadium-titanium magnetite

ActiveCN106319126BImprove reaction efficiencyImprove fluidization stabilityFluidised-bed furnacesHigh energyOxidation-Reduction Agent

The invention discloses a system and a method for vanadium titano-magnetite fluidization oxidation and reduction. A four-section fluidized bed is adopted to carry out fluidization oxidation and reduction on vanadium titano-magnetite fine ore; and a fluidized bed reaction body is formed by boiling beds connected in series. Through the technological design of a pre-oxidation treatment and low-gas-velocity reaction fluidized bed, the vanadium titano-magnetite powder fluidization performance can be obviously improved, the reaction efficiency is improved, and the process energy consumption is reduced. The vanadium titano-magnetite fine ore is firstly preheated and dried, enters a low-temperature oxidation bed so as to be subjected to oxidation treatment, then enters a prereduction bed so as to be subjected to prereduction, and finally complete final reduction through a two-stage high-temperature final reduction bed; oxidization tail gas is used for preheating and drying the vanadium titano-magnetite fine ore; after reduction tail gas is heat-exchanged with oxidization air, oxidization components are cleaned and removed, and the reduction tail gas is recycled; and a gas utilization scheme has the advantages of high reaction efficiency and high energy utilization ratio.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

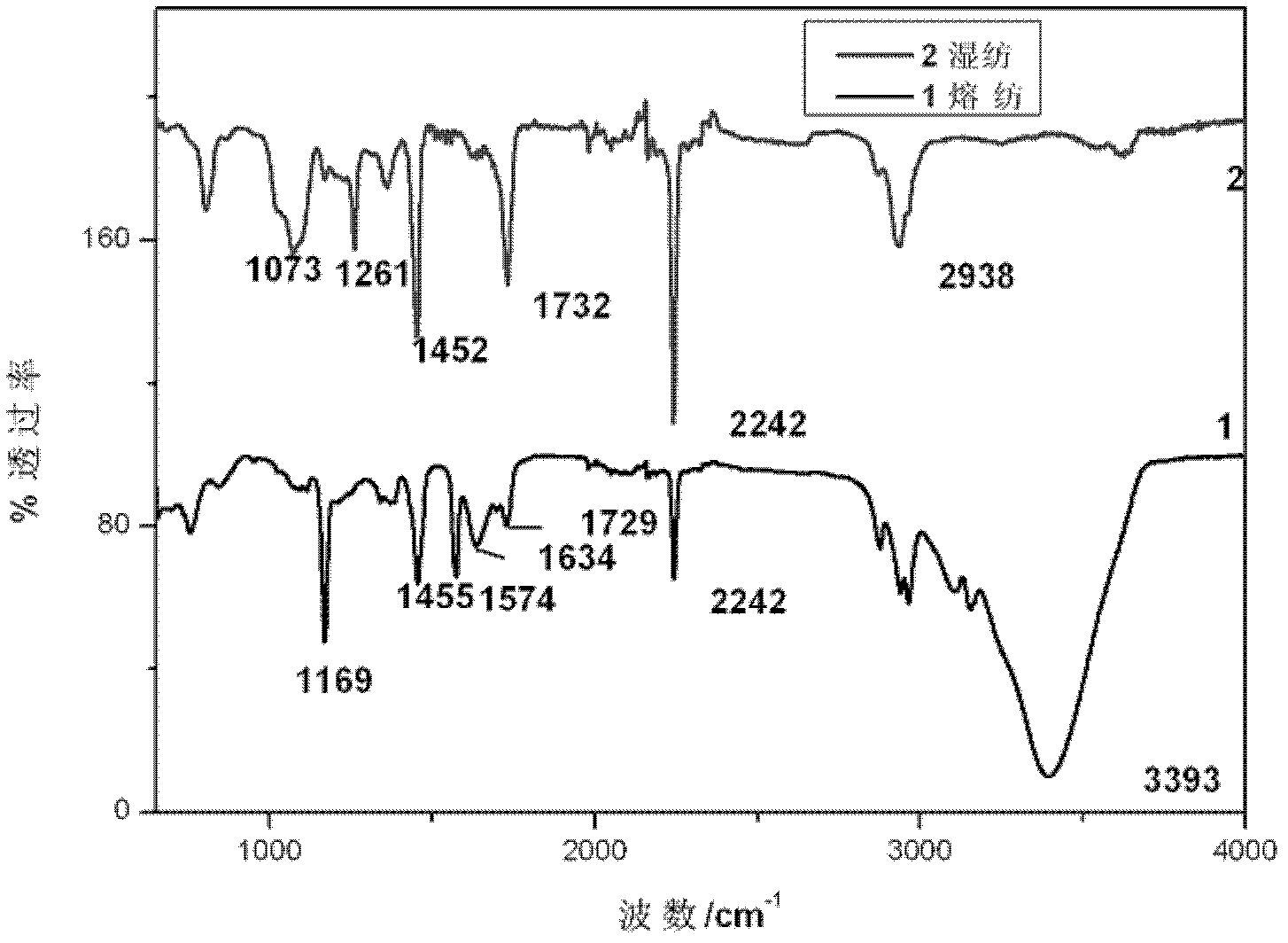

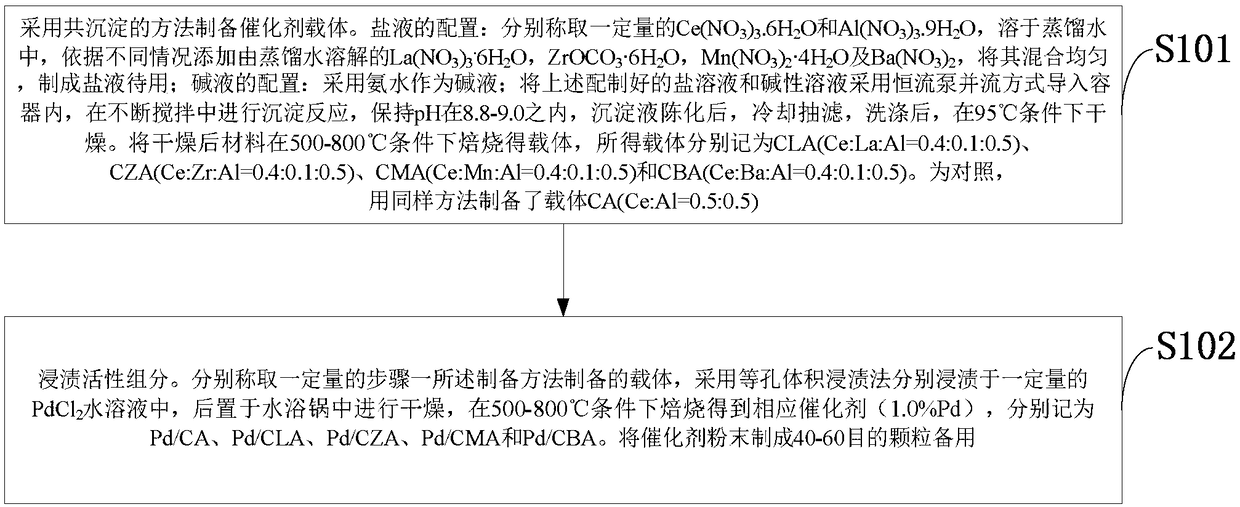

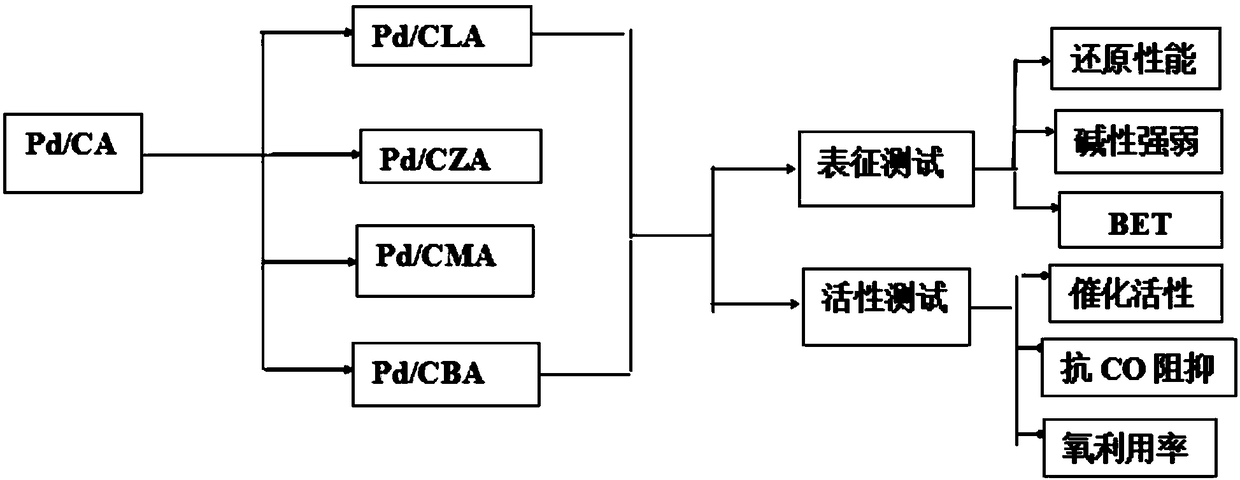

Base metal doped Pd/CeO2-Al2O3 catalyst and preparation method thereof

ActiveCN109201053AEasily reduced oxygen species increaseImprove recovery rateGas treatmentDispersed particle separationAlkalinityCatalytic oxidation

The invention belongs to the technical field of catalyst preparation, and discloses a base metal doped Pd / CeO2-Al2O3 catalyst and a preparation method thereof. The Pd / CeO2-Al2O3 catalyst is doped by La and Ba; La can promote deep oxidation of methanol, and Ba can enhance the catalytic oxidation performance and CO depression resistant performance of methanol. Compared with a conventional three-waycatalyst (Pd / CeO2-ZrO2-Al2O3), based on CO2-TPD, the alkaline property of the catalyst surface is improved through auxiliary agent doping, the alkaline property of the catalyst surface is enhanced; the results of activity tests show that Ba, Mn, and La can improve the catalytic activity and deep oxidation performance of Pd / CeO2-Al2O3, moreover, the oxygen using window of the catalyst is largely enlarged; Ba has the best catalyst assisting performance and best CO depression resistant property; La has the best deep oxidation performance; and the reducing performance and surface alkalinity are the main factors that influence the catalytic conversion of methanol.

Owner:CHENGDU UNIV OF INFORMATION TECH

A system and method for fluidized high-temperature rapid redox of vanadium-titanium magnetite

ActiveCN106467930BImprove reaction efficiencyImprove fluidization stabilityFluidised-bed furnacesReduction treatmentHigh energy

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Making method of black tea cakes

The invention provides a making method of black tea cakes, and belongs to the technical field of black tea making methods. The making method of the black tea cakes adopts fresh tea tree leaves suitable for making black tea as a raw material comprises the following steps: picking fresh leaves, wilting, rolling, fermenting, passing through a red pan, pressing to form cakes, drying, storing, and re-drying to make finished black tea cakes. The making method provided by the invention overcomes the defects of light taste, low and bored smell, dark soup color, insufficient concentration, poor convergence and unfavorable quality stability after long-time storage of traditional technologies, all the steps are technologically improved, and all the steps are accurately grasped and mutually cooperate, so uniform fermentation, bronzed leaf bottom, mellow and fresh taste, strong and lasting fragrance, red and bright soup color and strong convergence of the Tongbai black tea cakes made in the invention are effectively guaranteed, and the quality of the Tongbai black tea cakes is obviously improved.

Owner:桐柏县鑫茗农业有限公司 +2

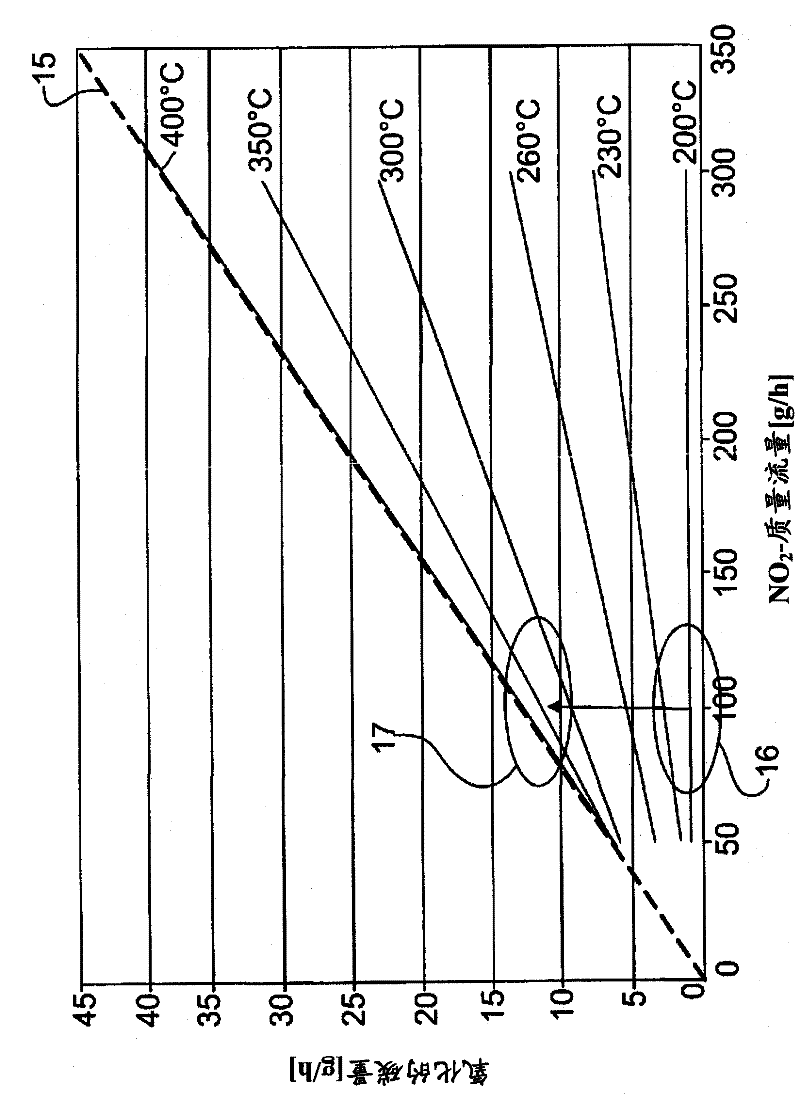

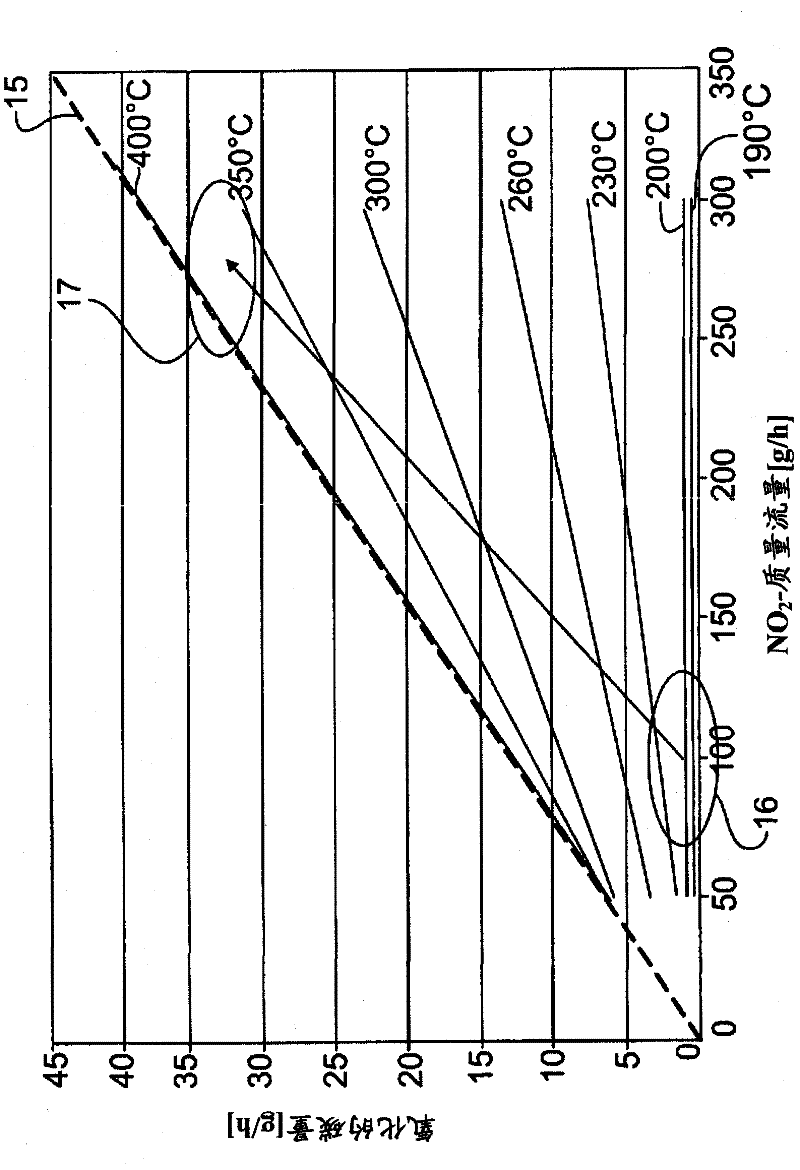

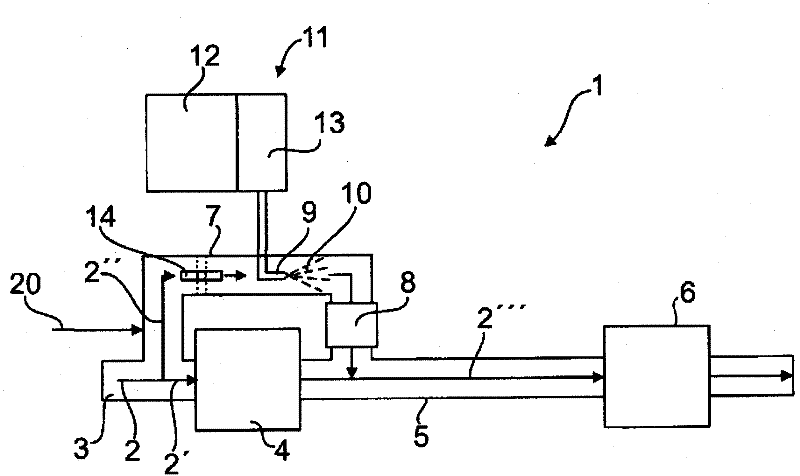

Device and method for regenerating a particle filter arranged in the exhaust tract of an internal combustion engine

ActiveCN102301101AIncrease concentrationIncrease temperatureInternal combustion piston enginesExhaust apparatusDiesel particulate filterExternal combustion engine

The invention relates to a device and a method for regenerating a particulate filter arranged in the exhaust section of an internal combustion engine, having at least one NO oxidation catalytic converter, which is arranged upstream of the particulate filter, for the oxidation of NO in particular to form NO2. According to the invention, at least one heating device (8; 19) is also provided upstream of the particulate filter (6), by means of which heating device (8; 19) an exhaust-gas flow (2'') which is conducted to the particulate filter (6) can be heated to a defined temperature in accordance with defined regeneration parameters, in particular in accordance with a degree of loading of the particulate filter (6) and / or in accordance with an efficiency of an NO2-based regeneration of the particulate filter (6) by means of an NO2 quantity formed in the at least one NO oxidation catalytic converter (4).

Owner:MAN NUTZFAHRZEUGE AG

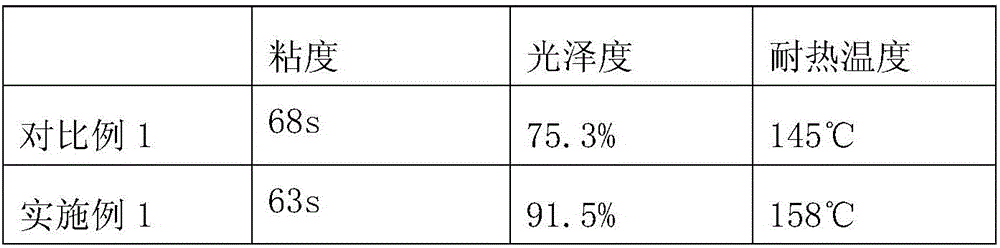

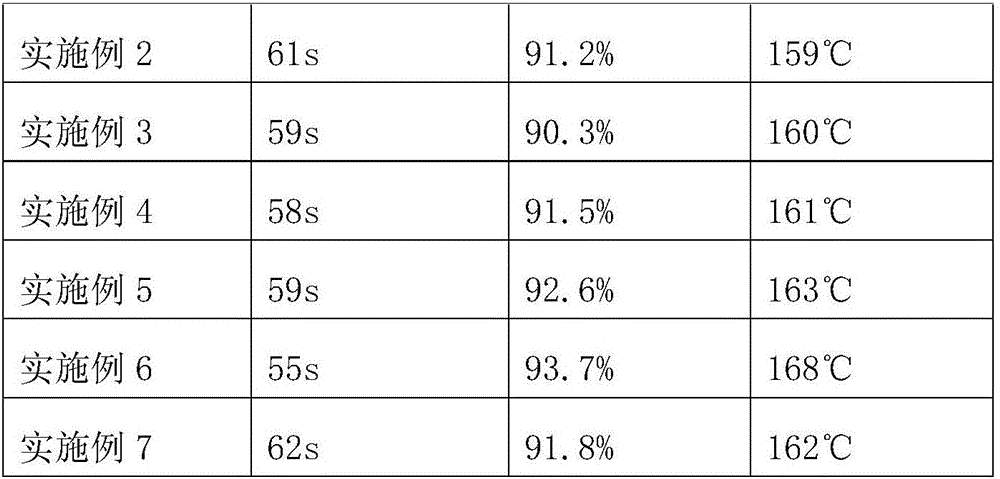

Method for improving ink adhesion in plastic printing product

ActiveCN106480416AFastGood response controllabilityVacuum evaporation coatingSputtering coatingEpoxyDimethylaniline N-oxide

The invention belongs to the field of printing machining and particularly relates to a method for improving ink adhesion in a plastic printing product. The method includes the following steps of (1) pretreatment of the plastic product and (2) printing. An ion sputtering method is adopted to conduct oxidation treatment on the surface of the plastic product, energy can be rapidly transferred to a special functional group on the plastic surface, and purposes of even heating and even oxidization are achieved; printing ink is prepared in the manner that based on ordinary ink, microcrystalline wax, N, N-dimethylaniline, lignin-based epoxy resin and a surface active agent are added, and consistency and permeability of the ink and the plastic product are increased. The plastic printing product prepared through the method has the advantages that adhesion between the plastic product and the ink is high, and friction resistance is achieved.

Owner:义乌市双杰日用品有限公司

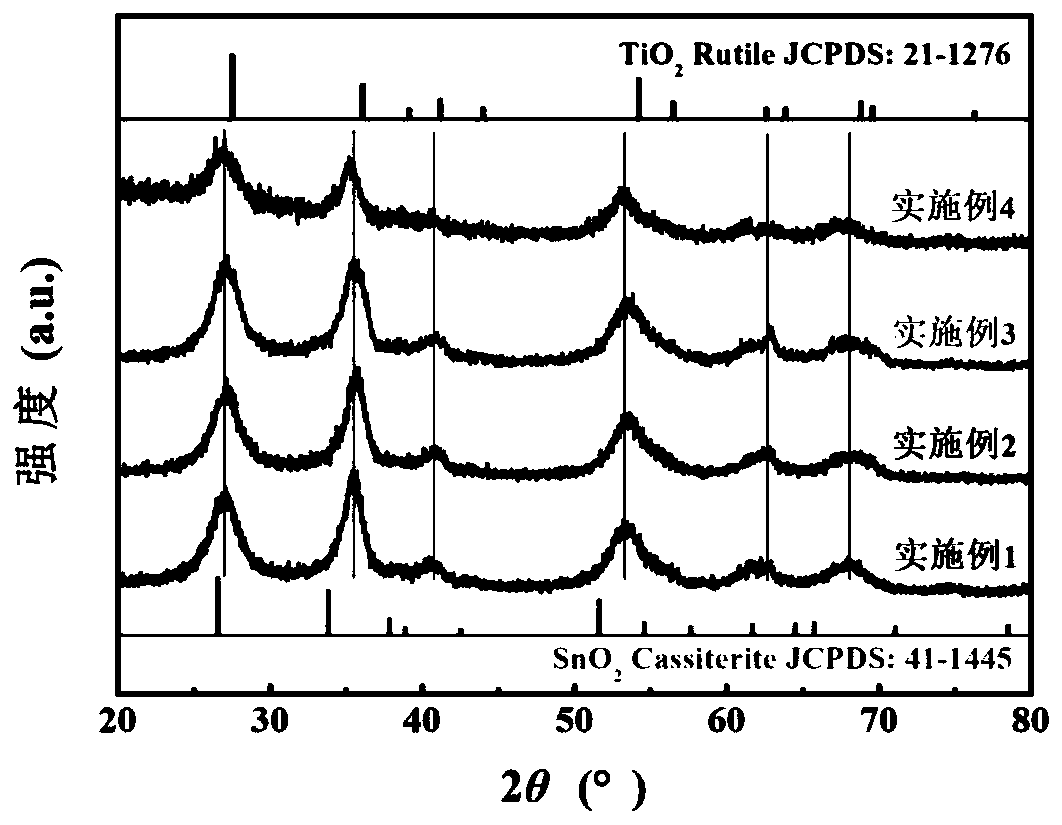

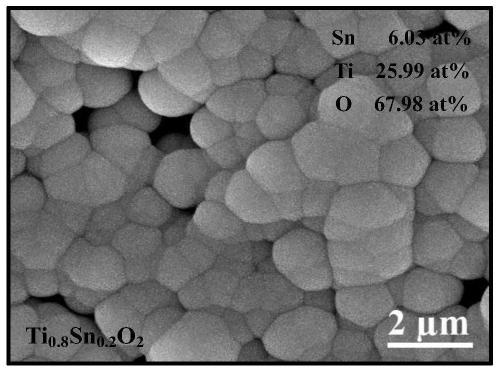

Preparation method of nano TiO2-SnO2 solid solution photocatalytic material

ActiveCN111068647AIncrease corrosion activityAnti-corrosion effectWater/sewage treatment by irradiationWater treatment compoundsPhoto catalysisCopper

The invention relates to a preparation method of a nano TiO2-SnO2 solid solution photocatalytic material. Low-corrosion potential elements or an amorphous alloy with a Ti / Sn atomic ratio of 4:1 to 6:1are adopted as a precursor, nitric acid is adopted as a corrosive and an oxidant, and a nano TiO2-SnO2 solid solution is synthesized through de-alloying oxidation. The method comprises the followingspecific steps: (1) selecting four metal raw materials including Cu, Ti, Sn and low-corrosion potential active elements or three metal raw materials including Cu, Ti and Sn, and smelting the metal rawmaterials through a vacuum arc furnace to prepare an alloy melt ingot; (2) heating the alloy melt ingot by utilizing a magnetic induction coil of vacuum rotary quenching equipment, and spraying alloyliquid to the surface of a copper roller rotating at a high speed when the alloy is completely molten, so as to obtain an amorphous strip; and (3) under the condition of constant temperature, performing de-alloying oxidation treatment on the amorphous strip in a nitric acid solution. The method is simple to operate, use of a large amount of solutions and harsh reaction conditions are not involved, the minimum unit particle size of the prepared material is 3.5-6 nm, and the catalytic degradation efficiency of the prepared material on rhodamine B under 500 W ultraviolet light reaches 99% or above.

Owner:NANJING INST OF TECH

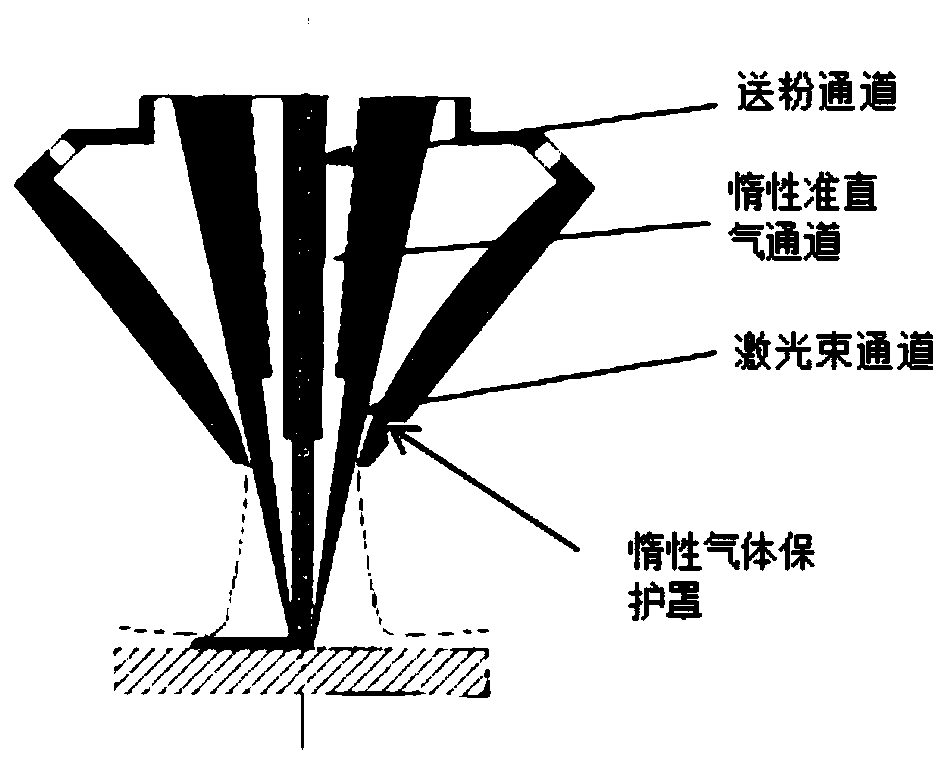

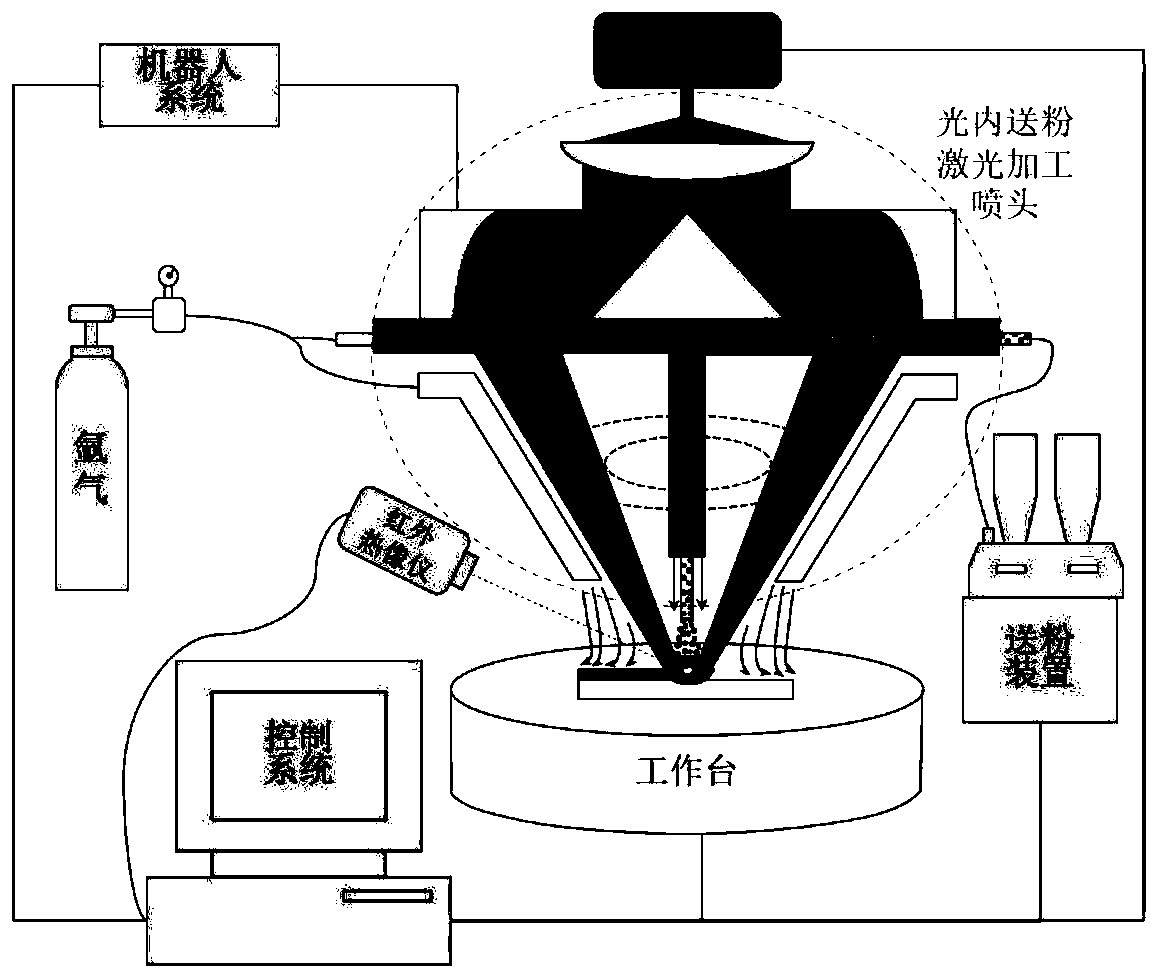

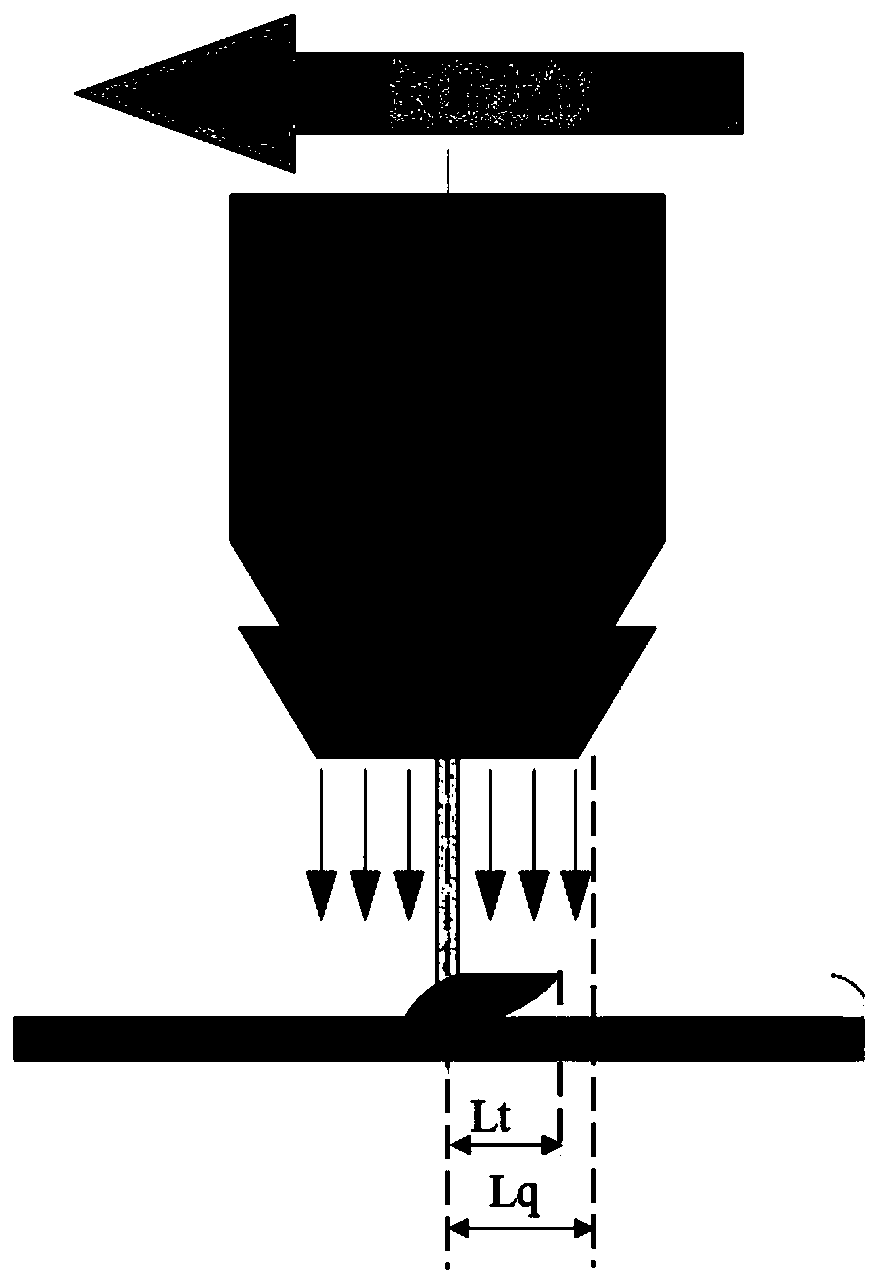

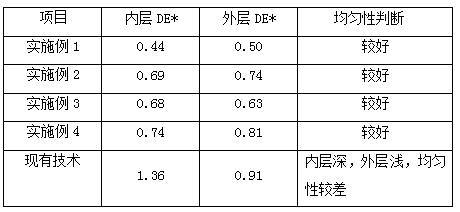

Titanium alloy additive manufacturing method based on inside-laser powder feeding laser processing nozzle

ActiveCN111545914AUniform oxidationTissue distributionAdditive manufacturing apparatusWelding/soldering/cutting articlesLaser processingLoop control

The invention provides a titanium alloy additive manufacturing method based on an inside-laser powder feeding laser processing nozzle, and belongs to the technical field of titanium alloy manufacturing. The method is characterized in that it is guaranteed that L < t > is smaller than or equal to L < q > in the additive manufacturing process, wherein the L < q > is the distance from a powder centerto the outermost side of protective gas, and the L < t > is the maximum distance from the powder center to the position, where the temperature is 400 DEG C, of a formed part in the additive manufacturing process. According to the method, it is guaranteed that the L < t > is smaller than or equal to the L < q >in the additive manufacturing process through a closed-loop control means, which means that it is guaranteed that the protective gas can fully cover the high-temperature area of the formed part in the additive manufacturing process, the situation that the local temperature is too high and uncontrollable due to heat accumulation in the additive manufacturing process is avoided, and it is guaranteed that a final titanium alloy is uniform in components and stable in performance; and according to the data of the embodiment, the surface of the titanium alloy formed part obtained through the embodiment is bright silvery white, and when the stacked height reaches 40 mm, no obvious oxidation discoloration exists; and meanwhile, the content of oxygen elements in all parts of the interior of the formed part is lower than 1,000 ppm.

Owner:苏州天至尊科技有限公司

Dry method for preparing oxidized starch by microwave

The invention relates to a dry method for preparing oxidized starch by microwave. In the preparation method, starch and an oxidant are used as raw materials; and the oxidation reaction of the starch is initiated and catalyzed by using special thermal effect and non-thermal effect of the microwave in a microwave filed to prepare the oxidized starch. The preparation method comprises the following steps of: pouring the starch into a mixer, starting the mixer, spraying 1 to 30 percent oxidant in an amount which is 1 to 20 percent of the mass of the starch and uniformly mixing the starch and the oxidant; and putting the mixture into a microwave reactor, and initiating and catalyzing reaction by microwave radiation to obtain a finished product of the oxidized starch. Compared with the prior art, the dry method for preparing the oxidized starch by the microwave has the characteristics of simple and safe operation, low reaction temperature, short time, high efficiency, low energy consumption, environmental protection, no pollution, uniform starch oxidation, no need of drying, large-scale continuous production and the like, and is a simple, high-efficiency, energy-saving and environmental-friendly method for preparing the oxidized starch.

Owner:罗代洪 +2

Method for dyeing rayon fiber by using reduced dye

The invention discloses a method for dyeing rayon fiber by using reduced dye, and belongs to the technical field of fiber dyeing. The method comprises the following steps: A, pretreating: conveying rayon yarns into a bathtub, adding water, the dye and peregal o, keeping for 9min, then adding caustic soda, then adding bone glue, triethanolamine and water, keeping for 9min, and adding sodium hydrosulfite; B, dyeing: raising the temperature of the bathtub to 60 DEG C, preserving heat for 45 minutes, then adding 5% of the total amount of the sodium hydrosulfite in the step A, and continuing keeping for 15 minutes; C, washing by using water: washing the dyed fiber by using water for 9min each time; D, oxidizing: adding glacial acetic acid and hydrogen peroxide into the bathtub, keeping for 27min, and washing by using water; E, soaping; F, posttreating. By the method, a series of problems which appear in the dyeing process using the vat dye in the prior art are solved; the method is designedfor rayon fiber dyeing, and has the advantages of uniform dyeing and no white core.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

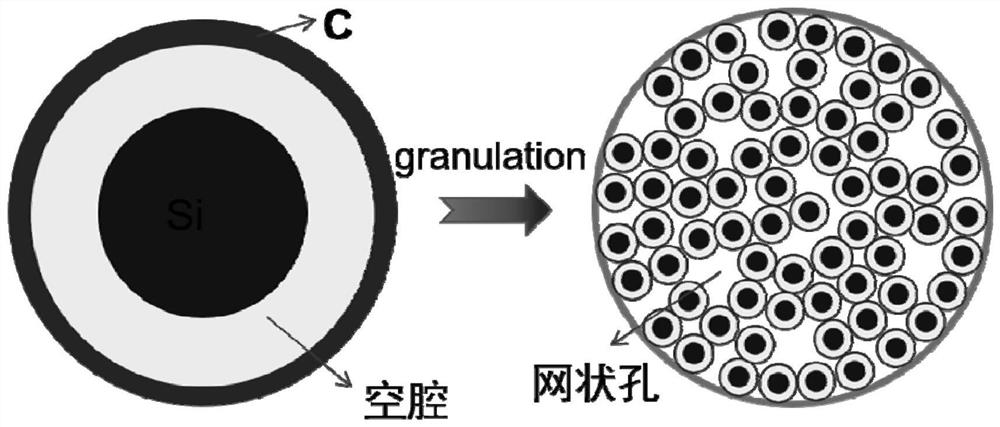

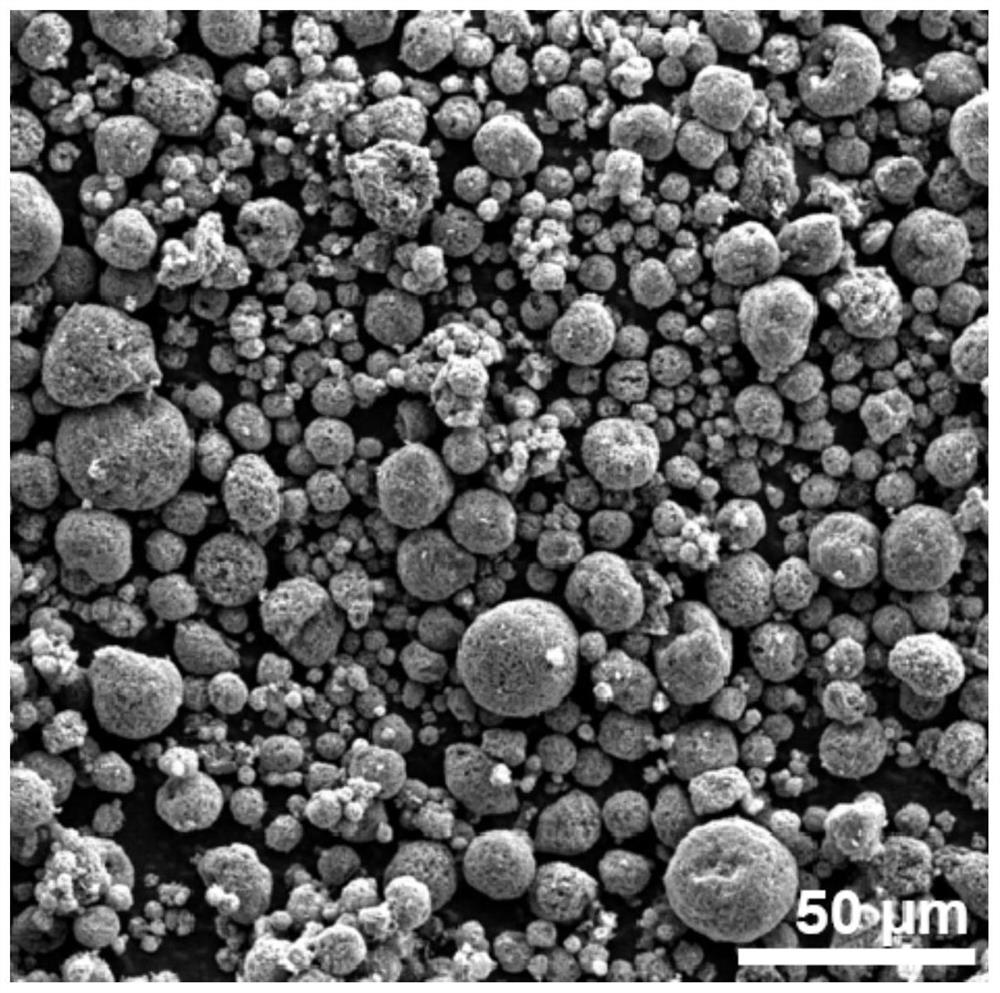

Preparation method of silicon-carbon composite negative electrode material, and prepared negative electrode material

InactiveCN112768671AImprove surface propertiesAppropriate structureMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of a silicon-carbon composite negative electrode material, and the prepared negative electrode material. Micron-scale industrial silicon powder is treated in an oxidizing atmosphere to obtain nano-scale silicon particles, and the electronic conductivity of the material is improved through the first carbon source, so the utilization rate of the silicon particles is increased; the second carbon source constructs a cavity structure, the structural stability of the silicon particles is kept, the third carbon source enhances the connectivity between primary particles, and a complete carbon layer protection shell is constructed, so the structural integrity of the material is improved; and finally, large particles of ten microns are obtained, so that the method is more favorable for industrial production, has the advantages of nanoscale in a laboratory, and also has industrial application conditions.

Owner:HUNAN UNIV

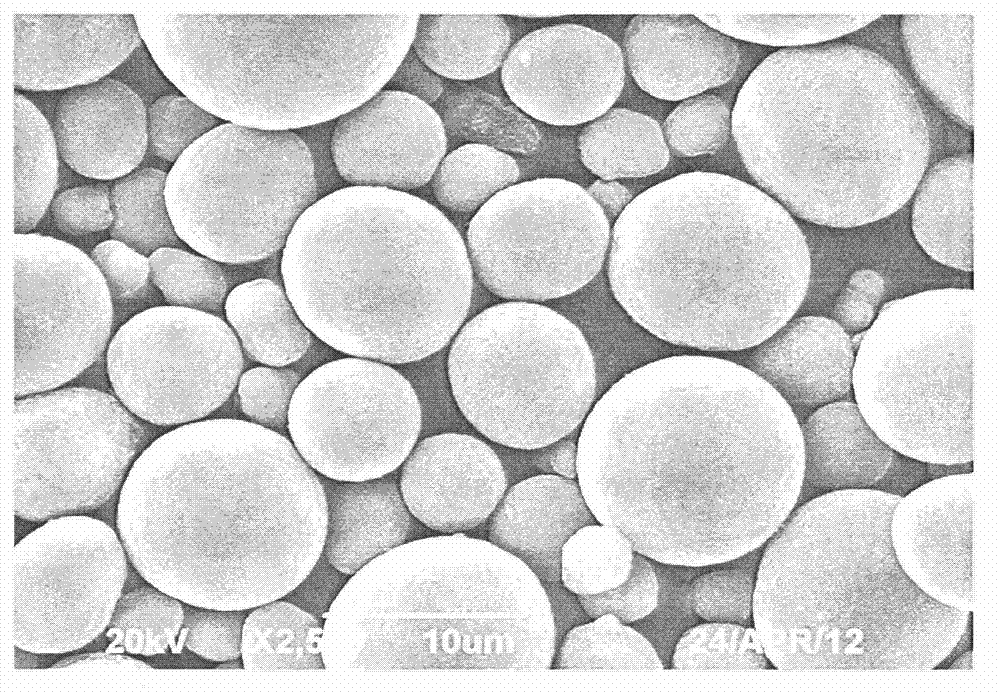

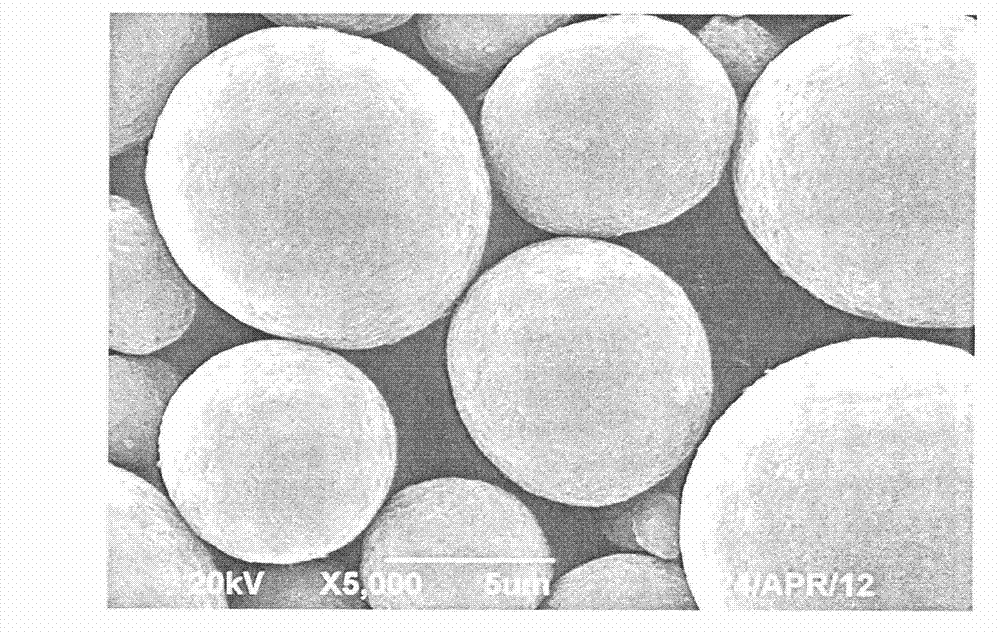

Technology for producing covering cobalt spherical nickelous hydroxide through continuous method

The invention relates to a production technology of covering cobalt spherical nickelous hydroxide, in particular to a technology for producing the covering cobalt spherical nickelous hydroxide through a continuous method. The technology comprises the following steps of: starting a covering cobalt synthesizing kettle, agitating and heating; starting a cobaltous sulfate solution metering pump and an oxidant metering pump, and pouring compressed air so as to continuously react; detecting a pH (Potential Of Hydrogen) and alkalinity of a reaction system in a reaction kettle; starting a sodium hydroxide solution metering pump and an ammonia water solution metering pump; keeping the pH and the alkalinity of the reaction system; detecting solid content of sizing in the reaction kettle; detecting granularity of the covering cobalt spherical nickelous hydroxide through a laser granularity instrument; controlling a flow rate of sodium hydroxide based on detected data and a product standard requirement; so as to control a covering cobalt spherical nickelous hydroxide coating; and flowing the sizing in a covering cobalt synthesizing kettle into a secondary ageing tank through an overflowing port. According to the technology for producing the covering cobalt spherical nickelous hydroxide through the continuous method provided by the invention, a continuous production technology is adopted, production is carried out with low cost and high production efficiency, and high product competitiveness is ensured; the coating in produced covering cobalt spherical nickelous hydroxide coating is uniformly oxidized, and oxidation is completely carried out, and a high degree of sphericity is ensured.

Owner:ANHUI ALAND NEW ENERGY MATERIALS

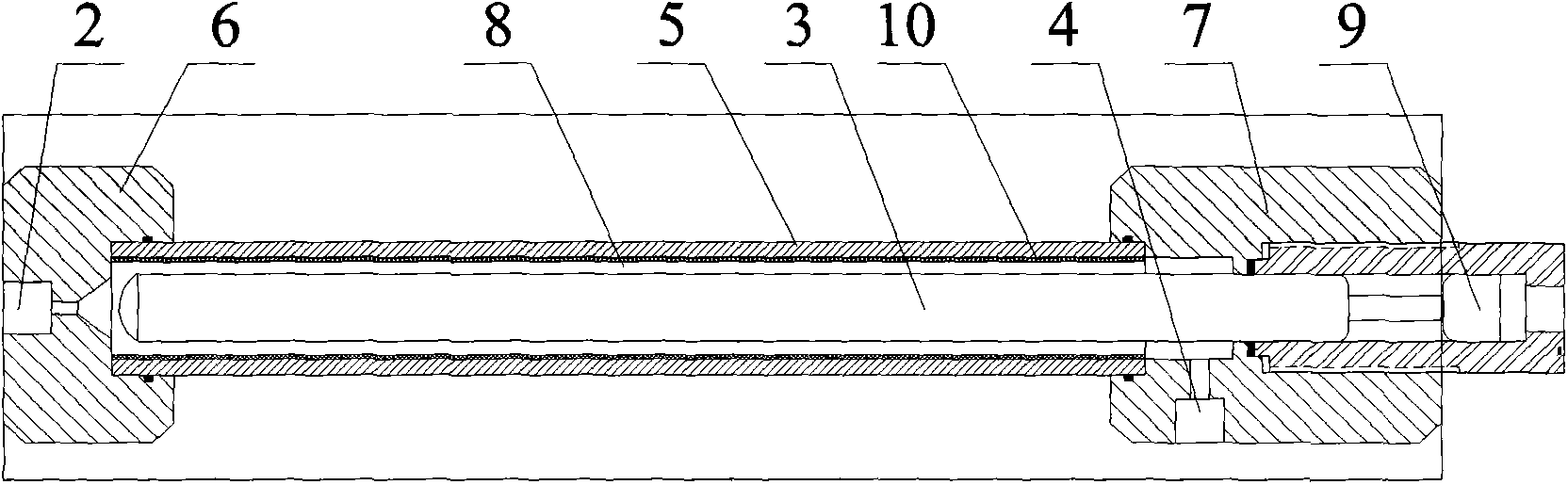

Ultraviolet ray catalyst used for detecting total organic carbon content in water

ActiveCN103395858AFast full oxidative conversionImprove measurement accuracyWater/sewage treatment by irradiationPreparing sample for investigationTitanium metalUltraviolet

The invention discloses an ultraviolet ray catalyst used for detecting total organic carbon content in water. The catalyst comprises an ultraviolet ray lamp with a power line, and a fluid channel with a water inlet and a water outlet. The structure of the fluid channel comprises that: a first fixing device is arranged on a first end of a titanium metal sleeve pipe; the water inlet is arranged at the first fixing device, and is connected in a sealed state with the titanium metal sleeve pipe through a sealing ring; a second fixing device is arranged on a second end of the titanium metal sleeve pipe; the second fixing device is connected in a sealed state with the titanium metal sleeve pipe; the ultraviolet ray lamp is centralized and fixed in the inner cavity of the titanium metal sleeve pipe through the second fixing device; the cavity between the titanium metal sleeve pipe and the ultraviolet ray lamp forms a catalyzing chamber with the fluid channel; and the water outlet is arranged on the lower part of a second end of the titanium metal sleeve pipe. The technical effect is that: with a direct irradiation method, organics in water can be sufficiently oxidized into inorganic carbon; and the content of organic carbon can be deduced through testing the content of inorganic carbon. Therefore, measuring accuracy of organic carbon content in water is improved.

Owner:河北科瑞达仪器科技股份有限公司

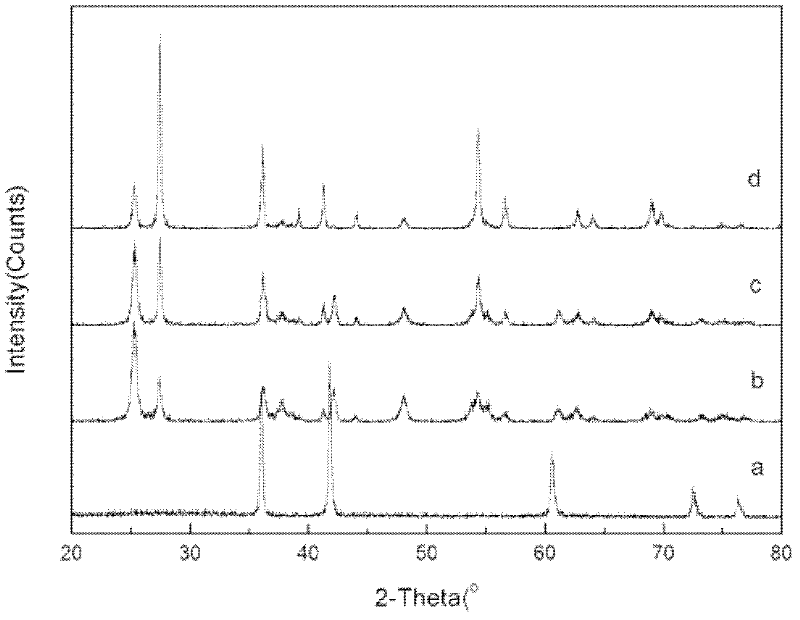

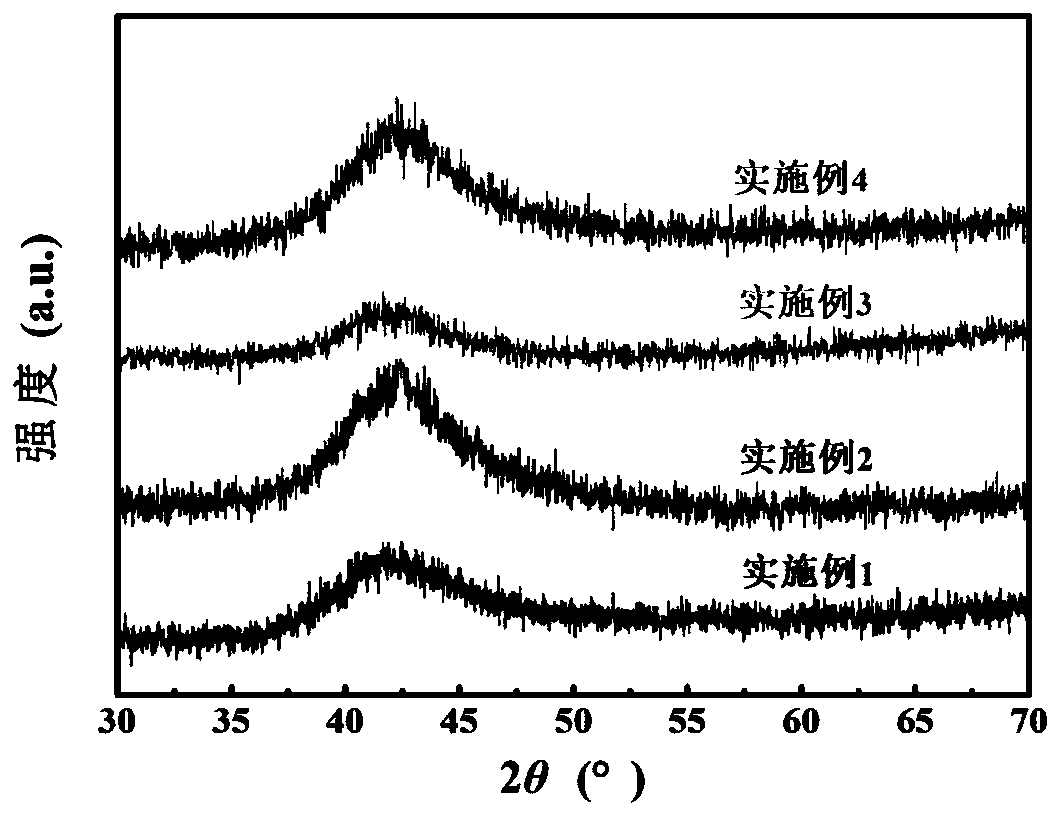

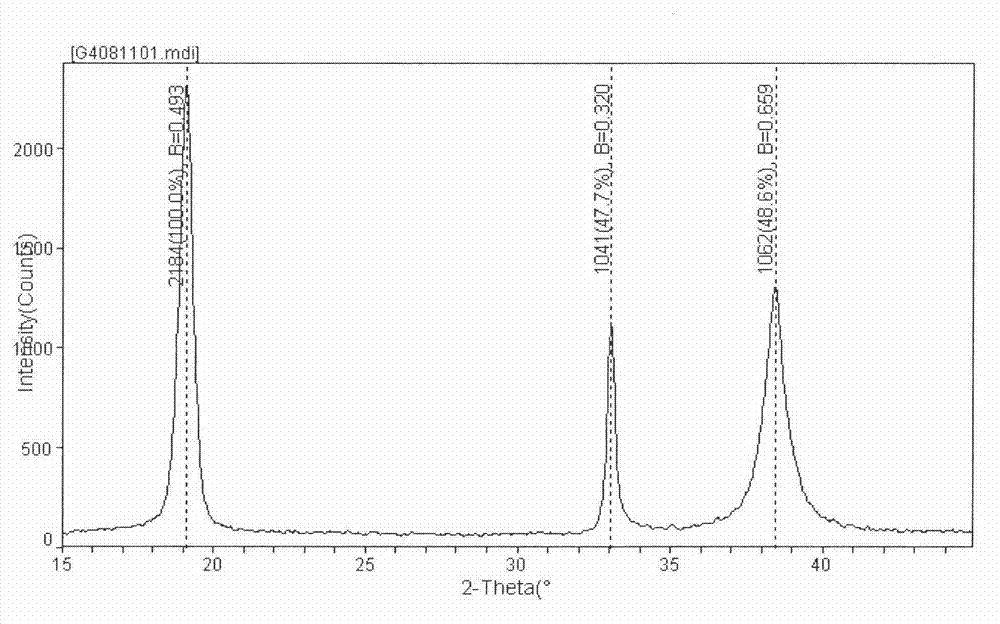

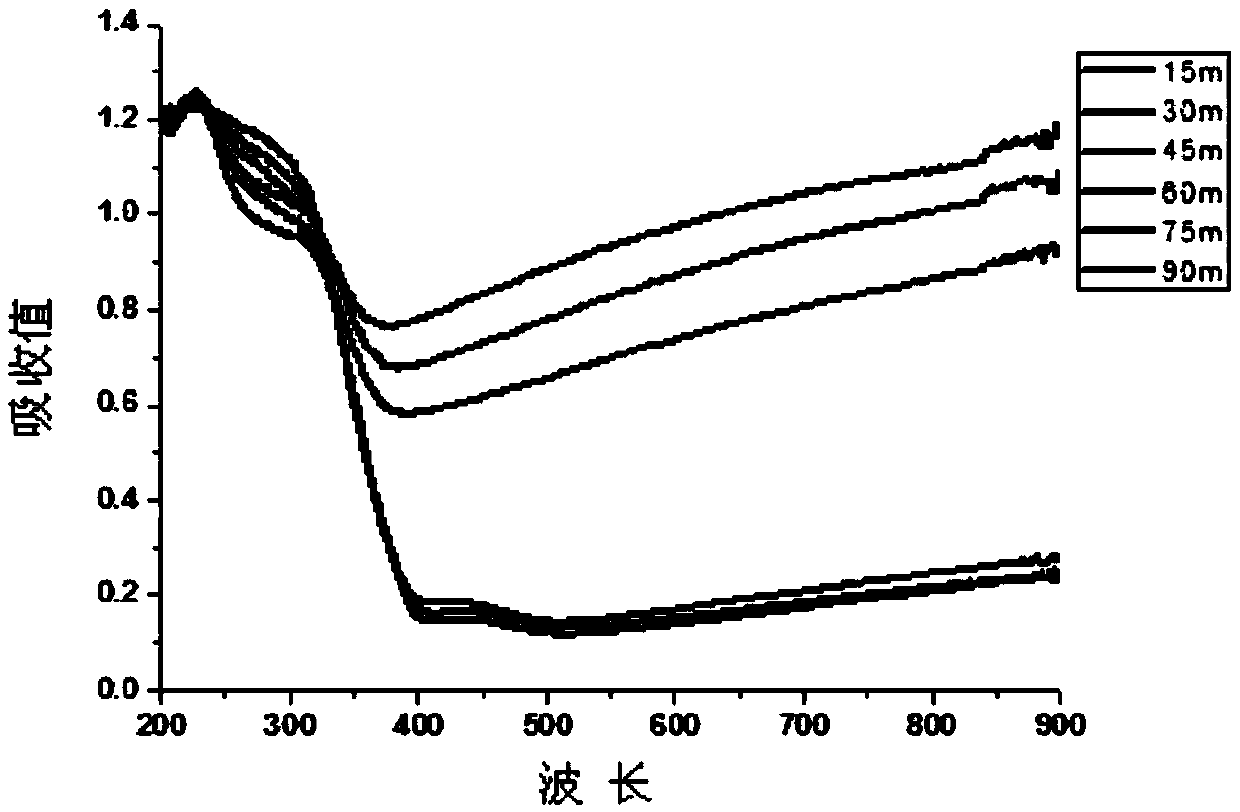

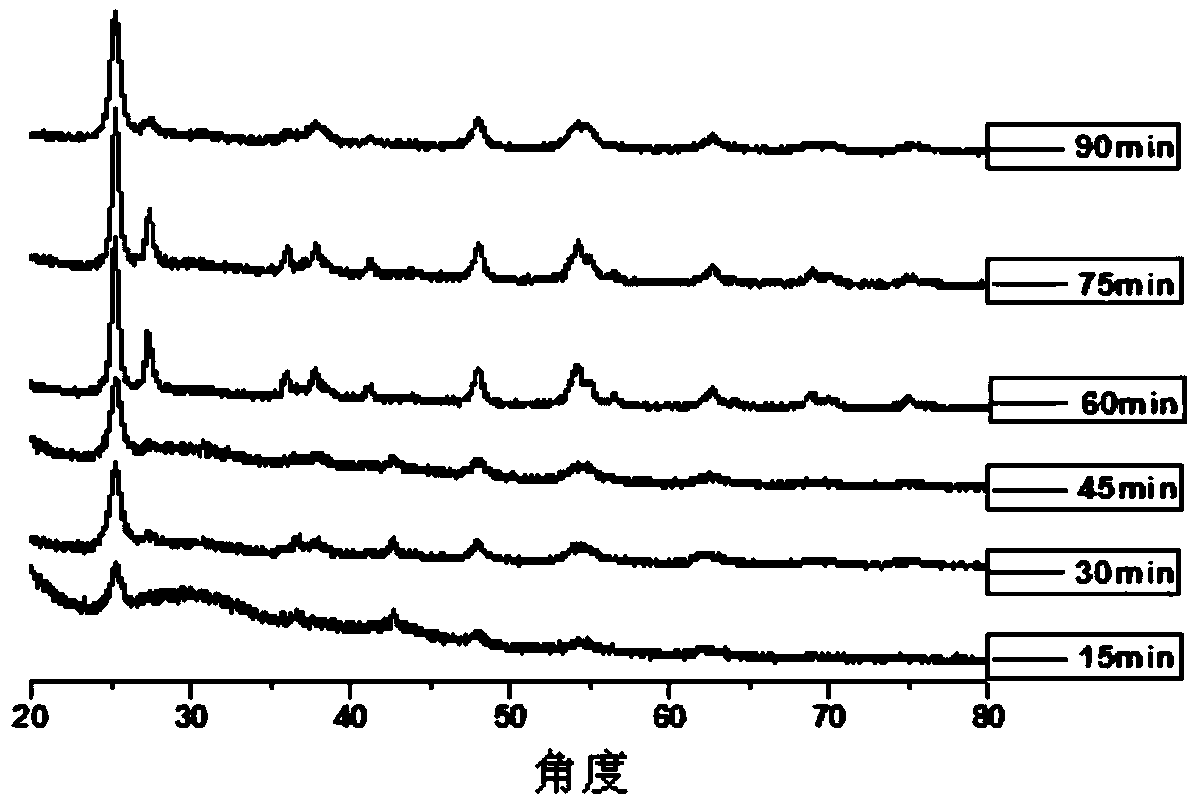

Preparation method for nitrogen-doped anatase titanium dioxide

InactiveCN105498822AIncrease contentStrong visible light absorptionPhysical/chemical process catalystsTitanium nitrideRoom temperature

The invention discloses a preparation method for nitrogen-doped anatase titanium dioxide. The preparation method is characterized by comprising the following steps that 7-10 parts of titanium nitride with the average particle size of 20-50 nm is placed into a muffle furnace, constant-temperature calcination is performed for 15-90 min at the temperature of 395 DEG C-405 DEG C, the temperature is decreased to the room temperature, and a first sample is obtained; the first sample is placed in the muffle furnace, constant-temperature calcinations is performed for 1-8 h at the temperature of 345 DEG C-355 DEG C, then the temperature is decreased to the room temperature, and a second sample, that is, the nitrogen-doped anatase titanium dioxide is obtained, and the second sample forms a 400-500-nm visible light absorption platform through second-time oxidizing calcination. The nitrogen-doped anatase titanium dioxide is applied to the fields of organic pollutant degradation, dye degradation, water photodecomposition and hydrogen production environment restoration.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

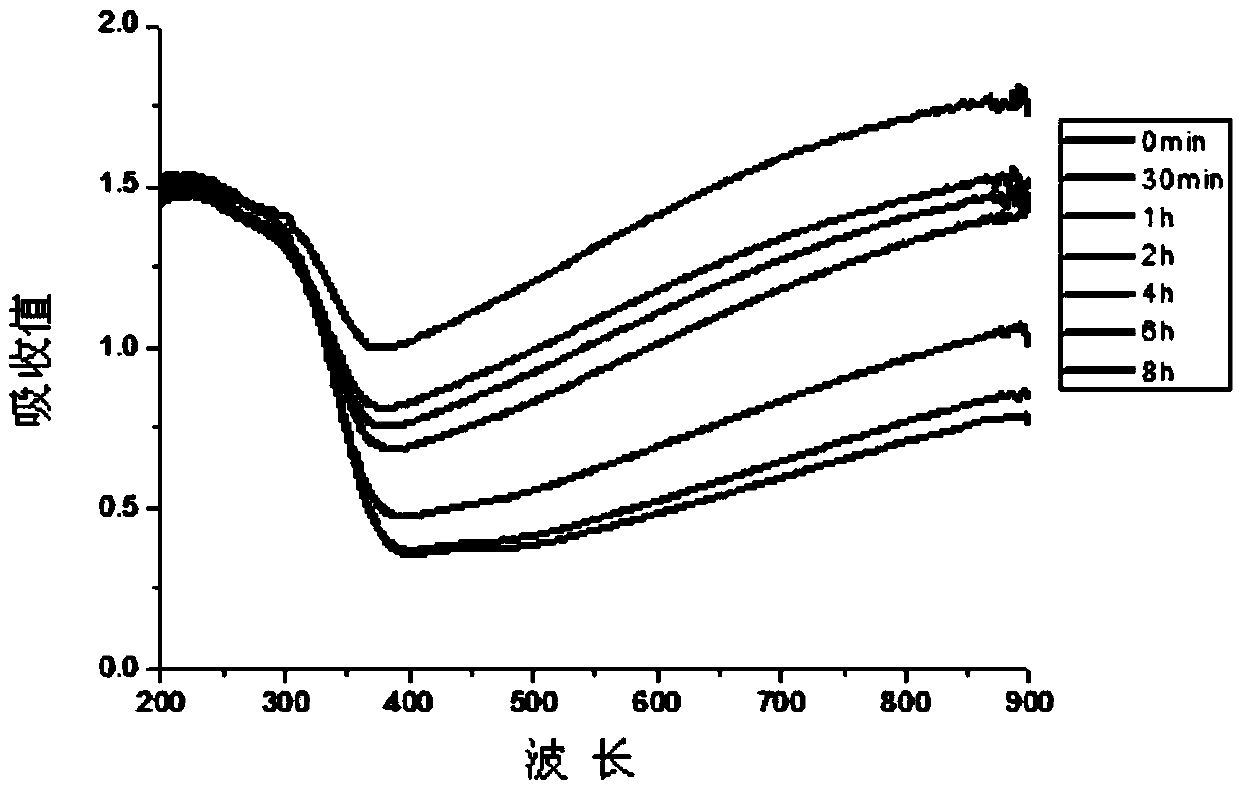

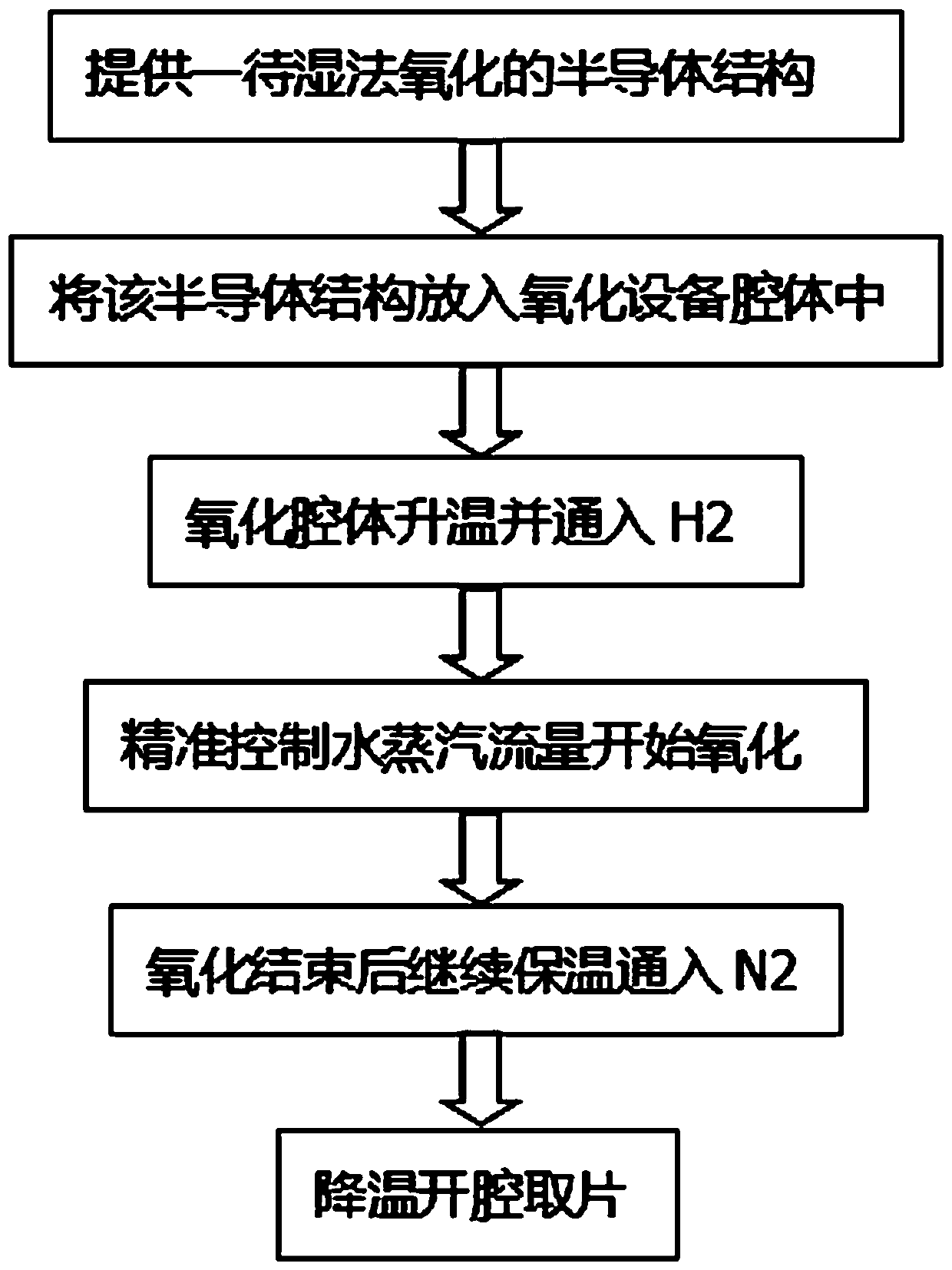

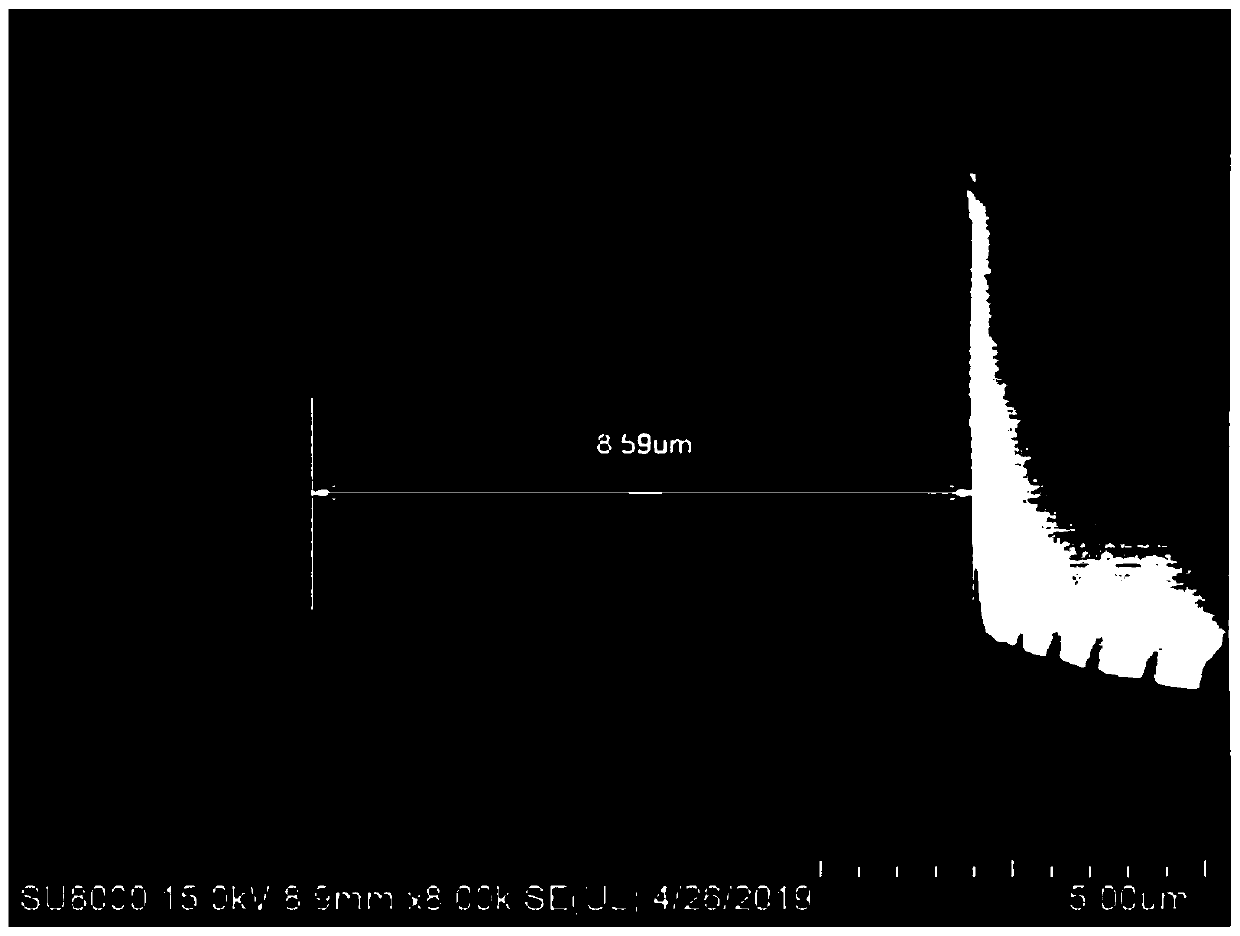

Wet oxidation process for improving oxidation uniformity of vertical cavity surface emitting laser

InactiveCN110994359AUniform oxidationReduce passivationLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserErbium lasers

The invention discloses a wet oxidation process for improving the oxidation uniformity of a vertical cavity surface emitting laser. The oxidation process comprises the following steps: 1, H<2> is introduced before oxidation, pre-treating is performed on the surface of the tablet, and a sheet surface is activated, so the uniformity of subsequent oxidation is facilitated; besides, after the oxidation step is completed, heat preservation continues to be conducted for a period of time, N<2> is continuously introduced till the temperature is reduced to the normal temperature, and oxidation is completed, so that the purpose of continuously introducing N<2> is to remove H<2> in the reaction environment, reduce the passivation effect of H and anneal the wafer; and meanwhile, in the oxidation process, the flow of water vapor is accurately controlled through a liquid flow meter. In addition, the oxidation process can be used for single-sheet oxidation and can also be used for simultaneously carrying out multi-sheet oxidation. The oxidation process provided by the invention can well realize uniform oxidation.

Owner:WUHAN GUANGANLUN OPTOELECTRONICS TECH CO LTD

System and method for vanadium-titanium magnetite ore fluidized oxidation and reduction

ActiveCN106467930AImprove reaction efficiencyImprove fluidization stabilityFluidised-bed furnacesExhaust gasHigh energy

The invention discloses a system and method for vanadium-titanium magnetite ore powder fluidized high temperature rapid oxidation and reduction. The system adopts three boiling fluidized beds connected in series to carry out vanadium-titanium magnetite ore powder fluidized high temperature rapid oxidation and reduction treatment. The vanadium-titanium magnetite ore powder is preheated and dried, then is fed into an oxidized bed and then is subjected to high temperature oxidation treatment, the product is fed into two stages of reduction beds and is subjected to high temperature reduction, oxidation tail gas is used for preheating and drying vanadium-titanium magnetite ore powder, the reduced tail gas undergoes heat exchange with the oxidized air, then the oxidized component is removed through cleaning and the reduction tail gas is recycled. The pre-oxidization treatment unit and the low gas velocity fluidized bed are connected in series so that high temperature fluidization performances of the vanadium-titanium magnetite ore powder are obviously improved, ore reaction efficiency is improved and process energy consumption is reduced. The system and method have the advantages of high reaction efficiency and high energy utilization rate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of oxidized nanocellulose

The invention provides a preparation method of oxidized nanocellulose, which is characterized in that polyhydric alcohol is added, and under the catalytic action of sulfuric acid, the reaction efficiency can be guaranteed, and side reactions occurring in the reaction process can be inhibited. The preparation method disclosed by the invention is environment-friendly and relatively low in cost, and can ensure the output rate of cellulose in unit time, thereby being beneficial to reducing the production cost. Besides, a sodium hypochlorite solution is added, so that the reaction is gentle, the oxidation of the nanocellulose is more uniform, and the oxidized nanocellulose with better uniformity and quality is obtained. Generally, the problems that the prepared nanocellulose is not environmentally friendly enough, equipment is prone to corrosion, and nanocellulose oxidation is uneven in the prior art can be solved.

Owner:水木山海科技(佛山)有限责任公司

Technology for preparing sulfur-free expandable graphite by utilizing high-concentration perchloric acid

The invention discloses a technology for preparing sulfur-free expandable graphite by utilizing high-concentration perchloric acid. The technology comprises the following steps: adding hydrogen peroxide into flake graphite and uniformly stirring; then adding perchloric acid with the concentration of 98 percent and stirring in an ice water bath for 30 to 50 min, wherein the ratio of the hydrogen peroxide to the flake graphite to the perchloric acid is 1 to 5 to 10; after stirring, putting a mixture into a water bath with the temperature of 20 DEG C and oxidizing for 1 h; then washing with a perchloric acid solution with the concentration of 30 percent and performing suction filtration; then dropwise adding an anhydrous acetic acid solution with the concentration of 70 percent; stirring while dropwise adding the solution; after uniformly stirring, reacting for 20 min; then washing with water and perform suction filtration; drying under the temperature condition of 50 DEG C to prepare thesulfur-free expandable graphite. The perchloric acid and the hydrogen peroxide are used as oxidants and both have very strong oxidization performance; the oxidants are used for carrying out layered oxidization on the graphite, the oxidization is uniform and the oxidization depth is proper; the technology is simple in method and low in cost and the product contains no sulfur.

Owner:原东

A method for surface modification of carbon cloth for flexible supercapacitor electrodes

ActiveCN108172417BAchieve the effect of oxidationPromote oxidationHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceModified carbon

The invention provides a method for modifying the surface of carbon cloth used for electrodes of flexible supercapacitors, which includes the following steps: S1: first place carbon in a mixed solution of potassium permanganate and concentrated acid for the first step of reaction, and then add Carry out the second step of reaction with deionized water, and finally add hydrogen peroxide to prepare oxidized carbon cloth, then repeatedly wash the oxidized carbon cloth with deionized water and ethanol until the washing liquid is neutral, and dry it; S2: finally The oxidized carbon cloth after S1 drying treatment was calcined and reduced with sodium amide under a nitrogen atmosphere, and then repeatedly washed with deionized water and ethanol until the washing liquid was neutral, and then dried to obtain a surface-modified carbon cloth. The modified carbon cloth prepared by the method provided by the invention has a uniform surface and a high specific capacitance value. When the current density is from 1mA / cm 2 Increase to 20mA / cm 2 , the capacitance retention rate is above 85%, and has excellent rate performance. Moreover, the method provided by the invention has simple process, low cost and is easy to be popularized in industry.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com