Base metal doped Pd/CeO2-Al2O3 catalyst and preparation method thereof

A ceo2-al2o3, catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of reducing the catalytic activity of the catalyst, so as to improve the catalytic activity And the effect of deep oxidation performance, improvement of reducibility, and widening of oxygen utilization window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

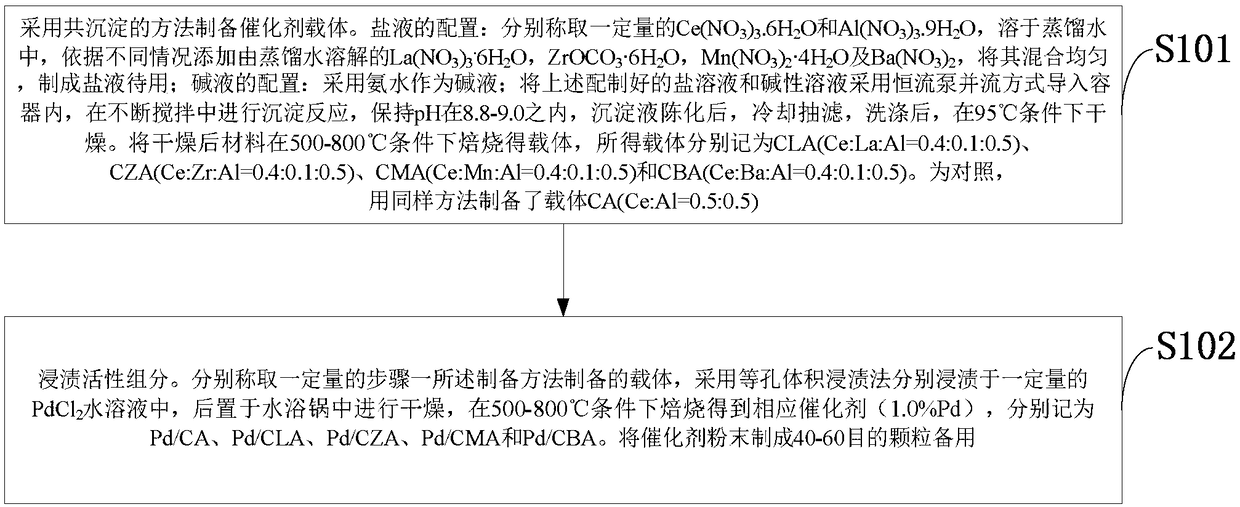

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

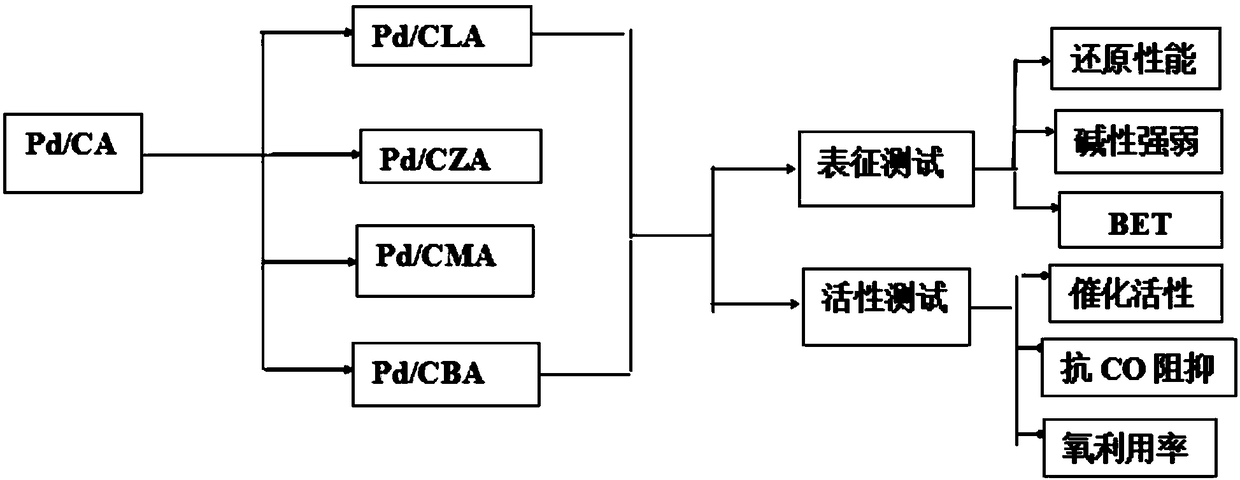

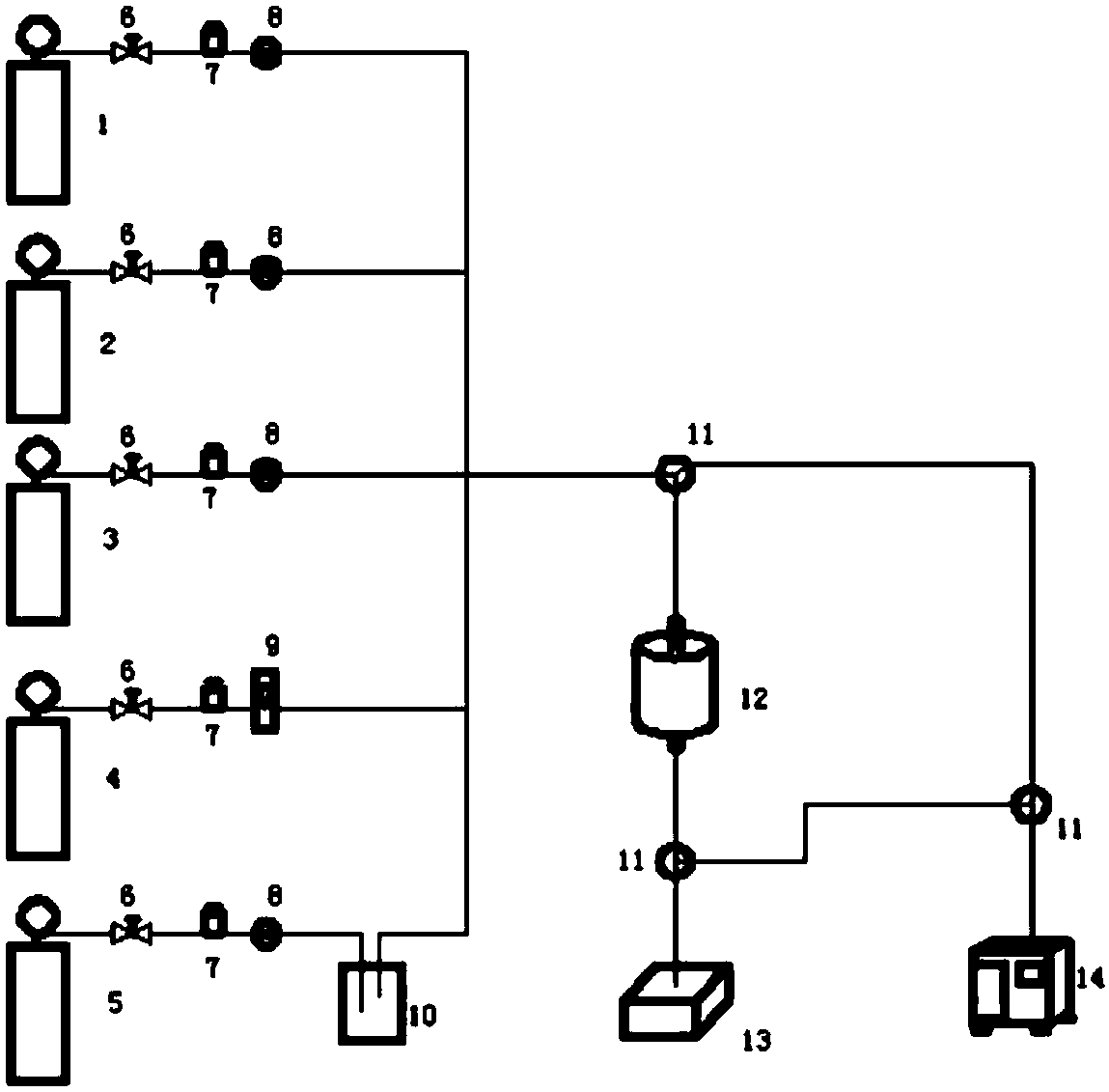

[0045] The present invention adopts equal volume impregnation method to prepare La, Zr, Mn, Ba modified Pd / CeO 2 -Al 2 o 3 catalyst, using CO 2 -TPD,H 2 -TPR, BET and other characterization methods were used to characterize the catalyst, and its properties such as catalytic oxidation of methanol, resistance to CO inhibition and oxygen utilization rate were investigated. h 2 -TPR test results show that the doping of La, Zr, Mn, Ba and other base metals is beneficial to improve the reduction performance of the catalyst; CO 2 -TPD shows that the doping of promoters can significantly increase the basic sites and the stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com