Patents

Literature

66results about How to "Raise the basicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

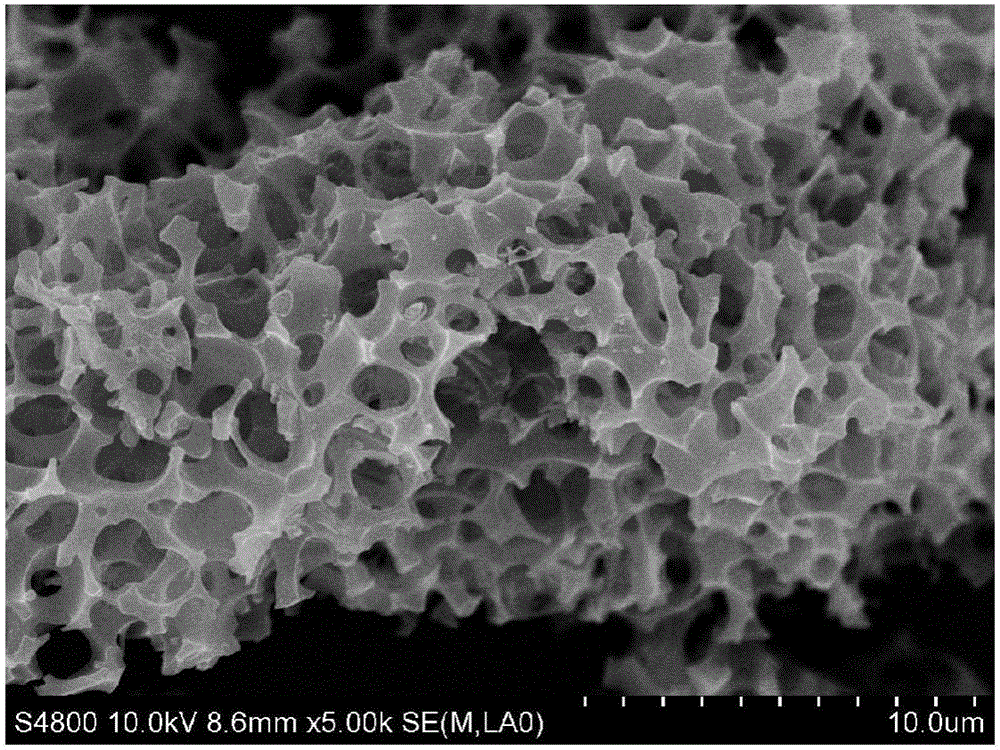

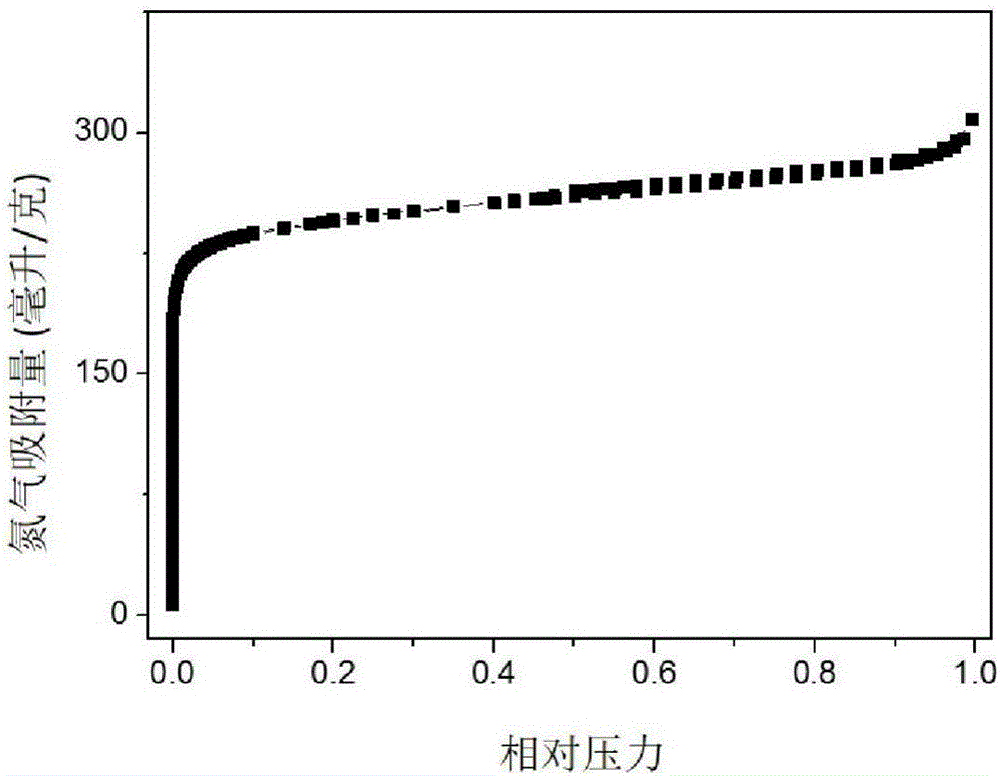

Biomass-based nitrogen-doped porous carbon material, and preparation method and application thereof

InactiveCN106006636ADoping content is controllableEvenly distributedOther chemical processesAlkali metal oxides/hydroxidesBiomassStrong acids

The invention provides a preparation method of biomass-based nitrogen-containing porous carbon with the advantages that simplicity is realized; the implementation is easy; the cost is low. According to the method, the in-situ doping of nitrogen atoms in the carbon material preparation process is realized by a one-step foaming method; cheap and reproducible protein-rich plants are used as carbon precursors; the in-situ doping of nitrogen atoms in the carbon material preparation process is favorably realized, so that the doping content is controllable, and the distribution is uniform. All raw materials are renewable resources; green and environment-friendly effects are achieved; simplicity is realized; the obtaining is easy; the resources are rich; the cost is low. Meanwhile, the method provided by the invention has the advantages that the nitrogen-doped porous carbon material with the large specific surface area can be obtained without complicated multistep operation; the preparation process is simple; the use of high-pollution chemical reagents such as ZnC12, strong base and strong acid is avoided; the environment-friendly effect is achieved; the operation is convenient; equipment cannot be corroded in the production and use processes; the method is suitable for large-scale production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

Method for preparing magnesium oxide modified mesoporous material for adsorbing carbon dioxide

InactiveCN101844068ARaise the basicityHigh carbon dioxide adsorption capacityOther chemical processesCarbon compoundsMesoporous materialCalcination

The invention provides a method for preparing a magnesium oxide modified mesoporous material for adsorbing carbon dioxide. The material is prepared by using a one-step synthetic method, namely the method comprises the following steps of: dissolving P123 serving as a template agent and MgCl2.6H2O into hydrochloric solution fully, adding tetraethyl silicate, and drying and calcining the mixture to prepare the MgO modified mesoporous material directly; or the material is prepared by using a later-period immersing method, namely the method comprises the following steps of: dissolving the P123 serving as the template agent into the hydrochloric solution fully, adding the tetraethyl silicate, immersing a mesoporous material prepared by drying and calcination in MgNO3 solution, and calcining the mesoporous material to prepare the MgO modified mesoporous material. The material provided by the invention has the high capability of adsorbing carbon dioxide, and simultaneously, the preparation method is simple and easy to control and avoids equipment corrosion in the process of production and use.

Owner:WUHAN UNIV OF TECH

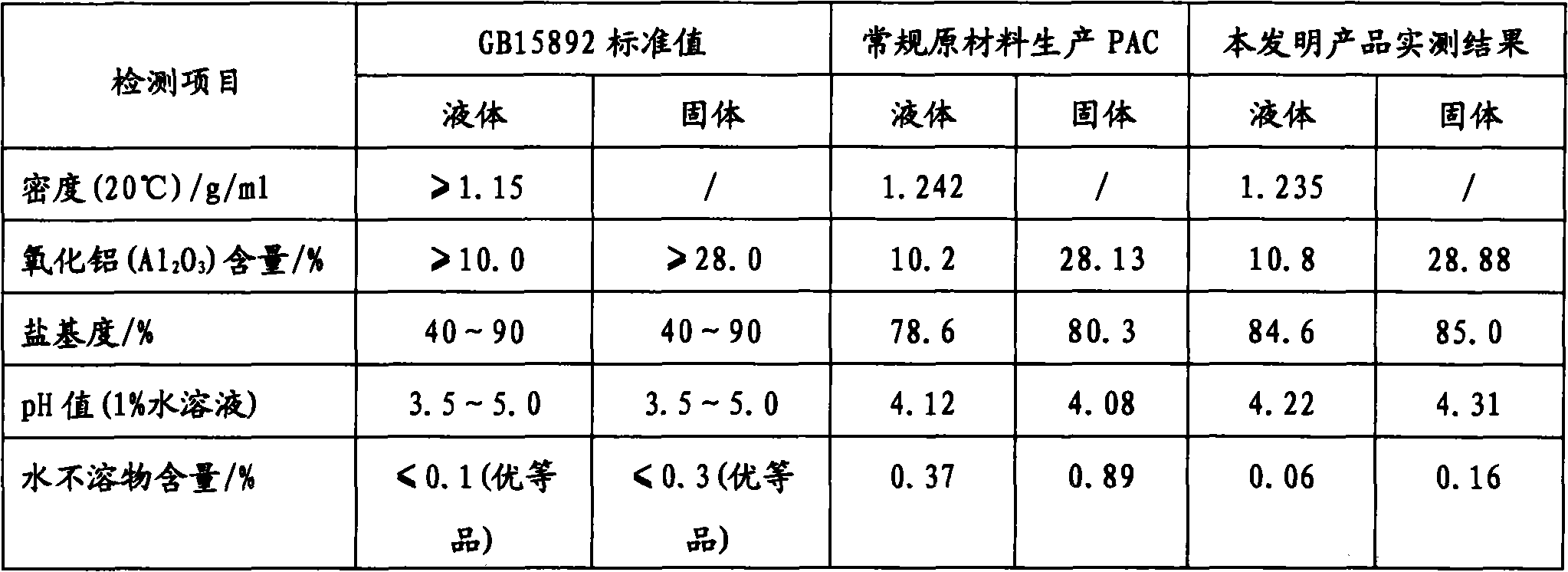

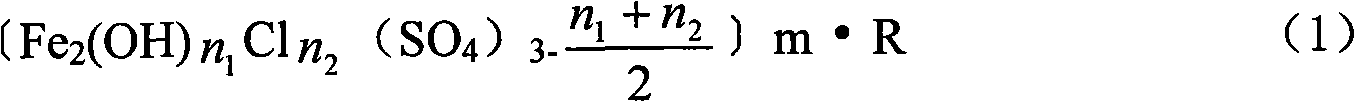

Method for producing polyaluminium chloride

ActiveCN102070170AReduce manufacturing costIn line with the environmental protection concept of energy saving and emission reductionAluminium chloridesWater/sewage treatment by flocculation/precipitationIngotPolyaluminium chloride

The invention relates to a method for producing polyaluminium chloride, which comprises the following steps: adding aluminum-containing waste residue into solution of hydrochloric acid and reacting at 90 to 120 DEG C and under a normal pressure for 3 to 5 hours; filtering, collecting mother solution, filling the mother solution into an acid-resistance and vapor-heated reactor with a stirring device, starting stirring, supplying a proper amount of water, starting to add calcium aluminate powder, and after the addition is finished, regulating the density of feed liquid to more than or equal to 1.20g / ml with water; and adding a synergist, heating and keeping the temperature between 90 and 120 DEG C, reacting at normal temperature for 3 to 5 hours, and obtaining finished liquid polyaluminium chloride. Compared with the prior art, the method, which uses aluminum-containing waste residue obtained after the neutralization of waste liquid from surface pickling of aluminum ingots and bands as raw material, reduces the manufacturing cost of polyaluminium chloride, recycles aluminum-containing waste residue and is in accordance with the environmental-protection concept of energy conservationand emission reduction.

Owner:蓝保(厦门)水处理科技有限公司

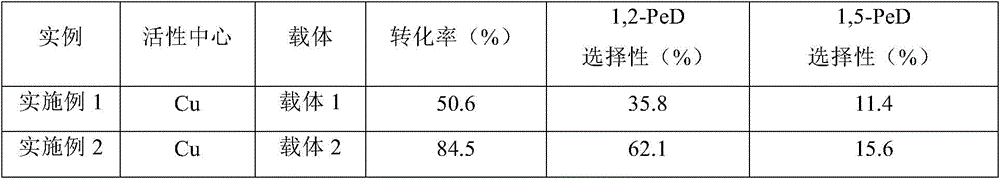

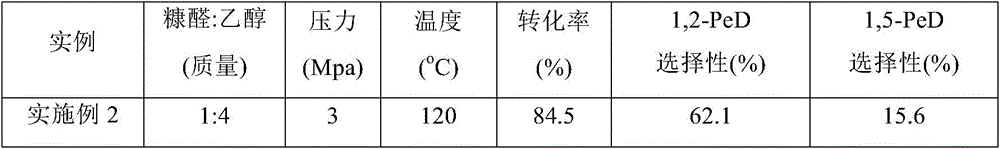

Coal ash catalyst and preparing method and application thereof

ActiveCN105921150AProtect environmentIncreased basicityOrganic compound preparationHydroxy compound preparationScrapChemistry

The invention discloses a coal ash catalyst and a preparing method and application thereof. According to the coal ash catalyst and the preparing method and application thereof, environment-friendly Pt, Cu, Rh, Ni and Ru metal is used as the catalyst activity centers of the catalyst, solid waste coal ash obtained before treatment or after treatment serves as carriers, the catalyst activity centers are fixed to the carriers in a loaded mode, and the weight percent of the catalyst activity centers is 0.5% to 5%. The preparing method includes the steps that 1, the metal activity centers are loaded on the coal ash with a soaking method; 2, the powder prepared in the step 1 is dried and then reduced through hydrogen, and the coal ash catalyst is obtained. The coal ash catalyst is used for preparing pentanediol in the mode that hydrogen is added into furfural. The catalyst is environmentally friendly, waste resources are used, the environment is protected, alkaline sites of the simply-treated coal ash are greatly increased, and the reaction that hydrogen is added into furfural to prepare pentanediol is facilitated.

Owner:NANJING UNIV OF TECH

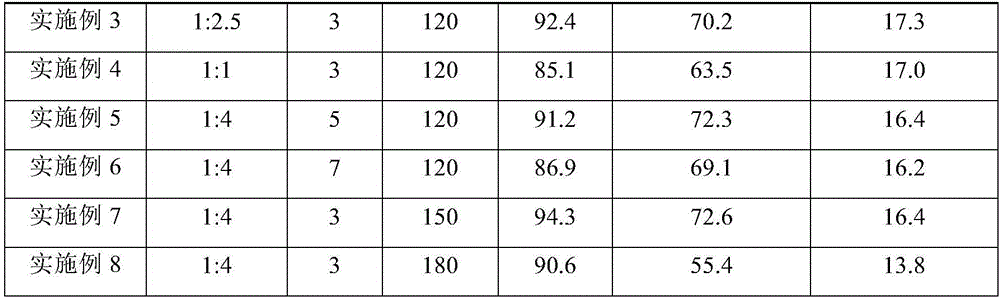

Method for preparing mullite and co-producing polyaluminum chloride by using high-alumina fly ash

ActiveCN107021765AHigh bulk densityLow impurity contentSolid waste disposalAluminium chloridesAbsorption rateChemistry

The invention provides a method for preparing mullite and co-producing polyaluminum chloride by using high-alumina fly ash. The method comprises the steps: activating the high-alumina fly ash in concentrated hydrochloric acid, carrying out liquid-solid separation, and carrying out washing, so as to obtain first washed solid and first washing liquid; subjecting the first washed solid to a desilicification reaction in a concentrated base solution, carrying out liquid-solid separation, and carrying out washing, so as to obtain second washed solid and second washing liquid; washing the second washed solid in dilute hydrochloric acid, carrying out liquid-solid separation so as to obtain third solid and third washing liquid, and washing the third solid by water, so as to obtain fourth solid and fourth washing liquid; carrying out aftertreatment on the fourth solid so as to obtain the mullite, and preparing the polyaluminum chloride from the first washing liquid and / or the third washing liquid. The mullite prepared by the method is low in impurity content, high in bulk density and low in water absorption rate, the polyaluminum chloride flocculant can be coproduced, the source of raw materials is wide, the process is simple, and the acid / base consumption is low, so that the method has good economic, social and environmental benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

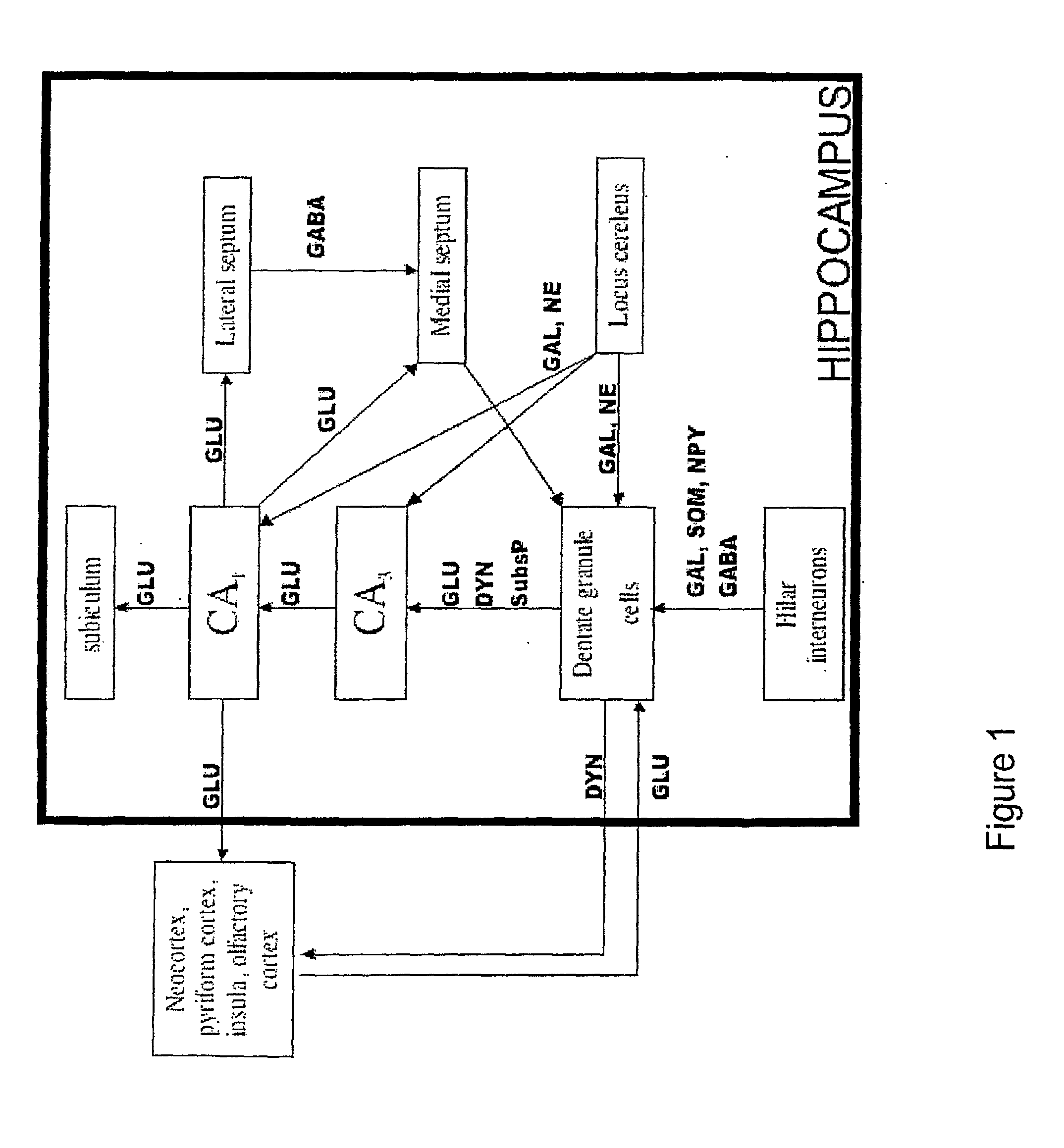

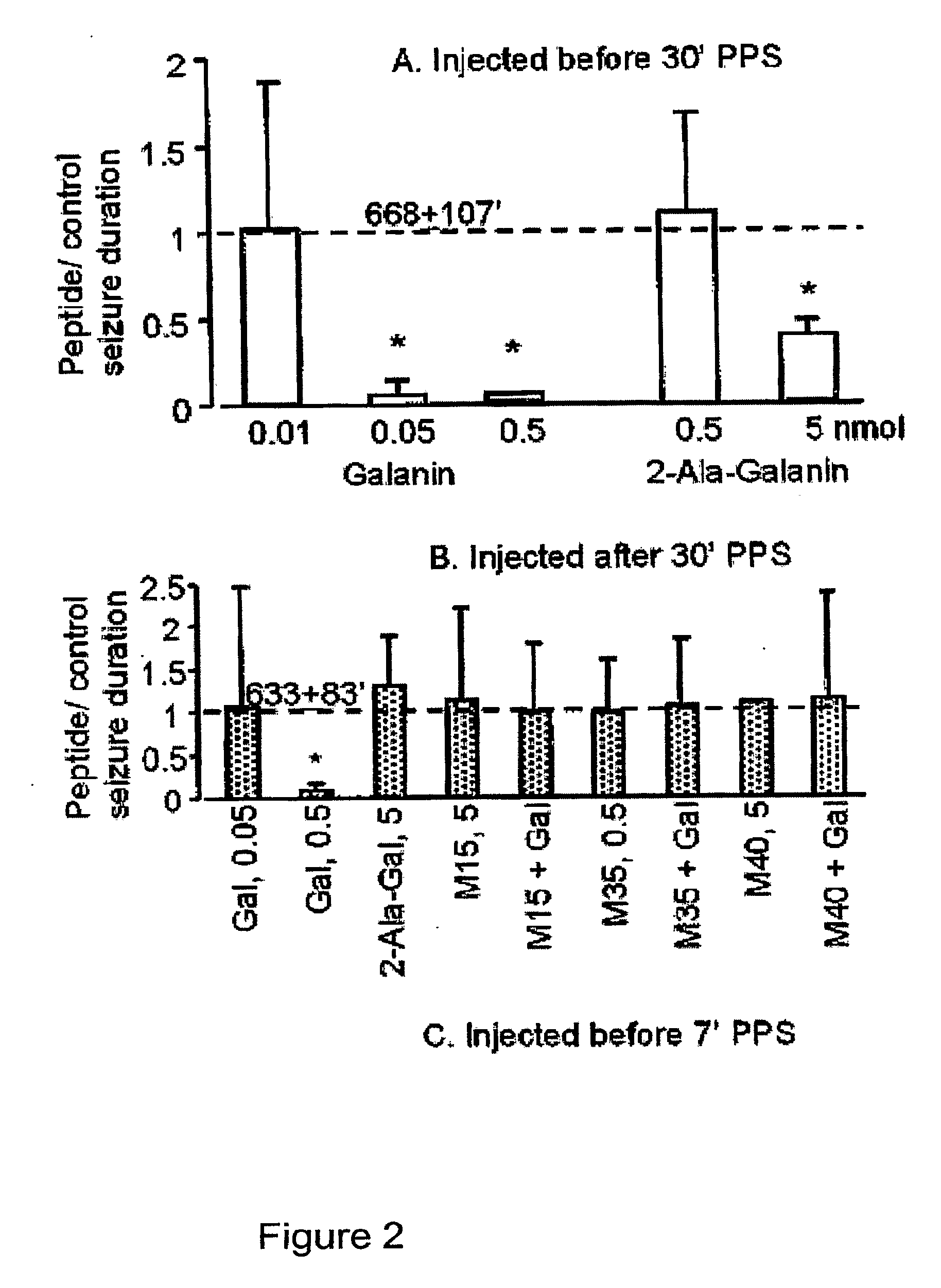

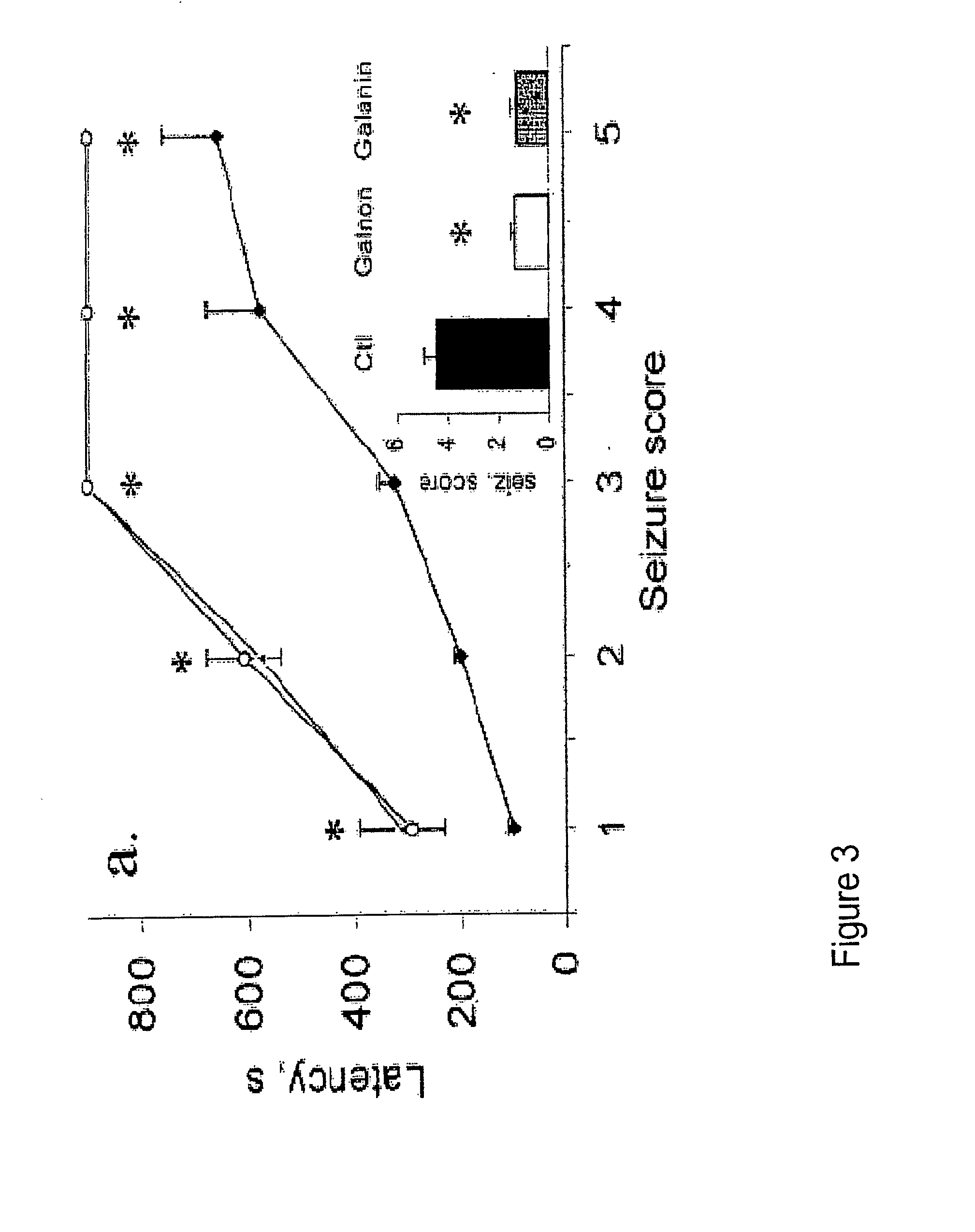

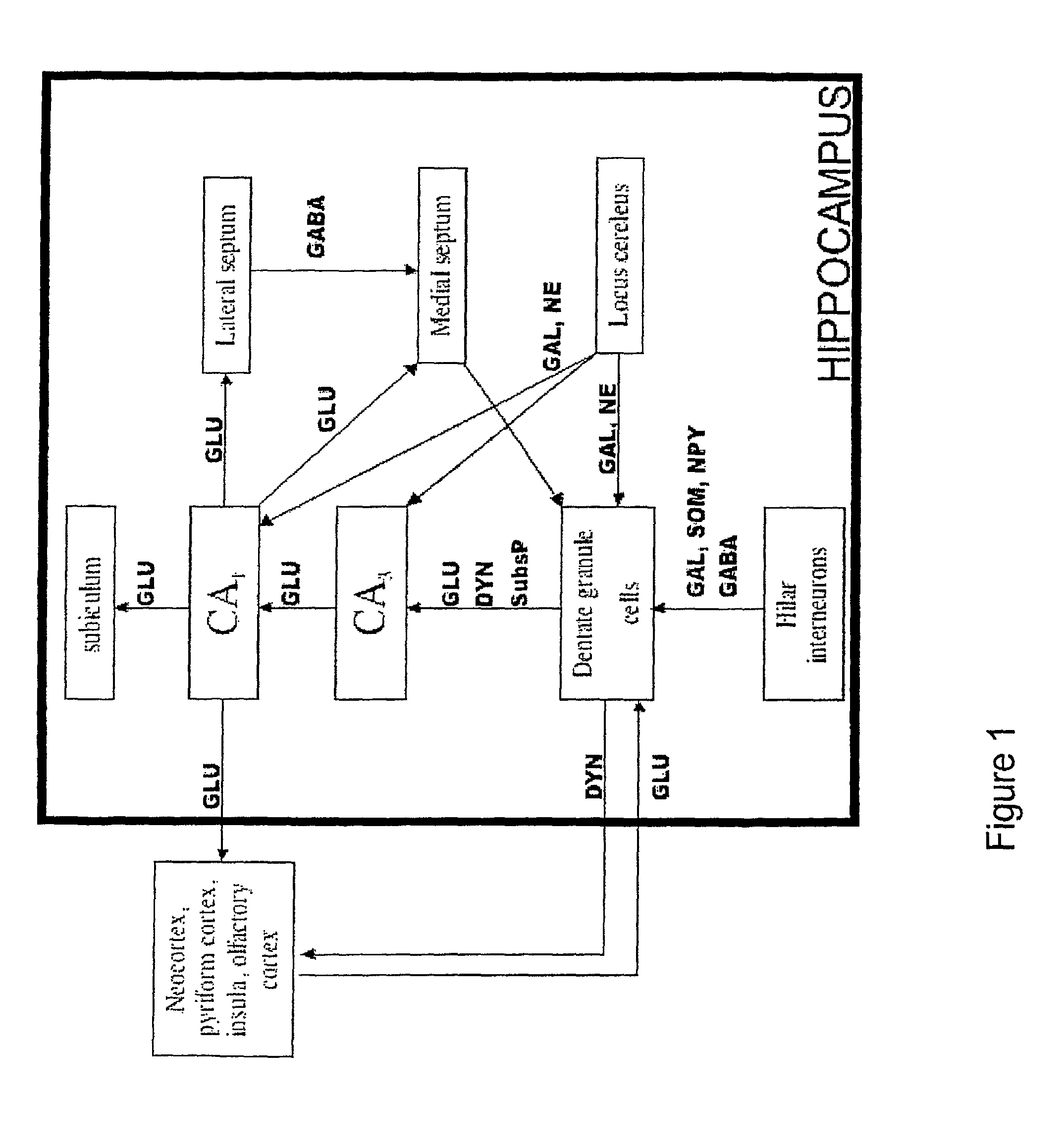

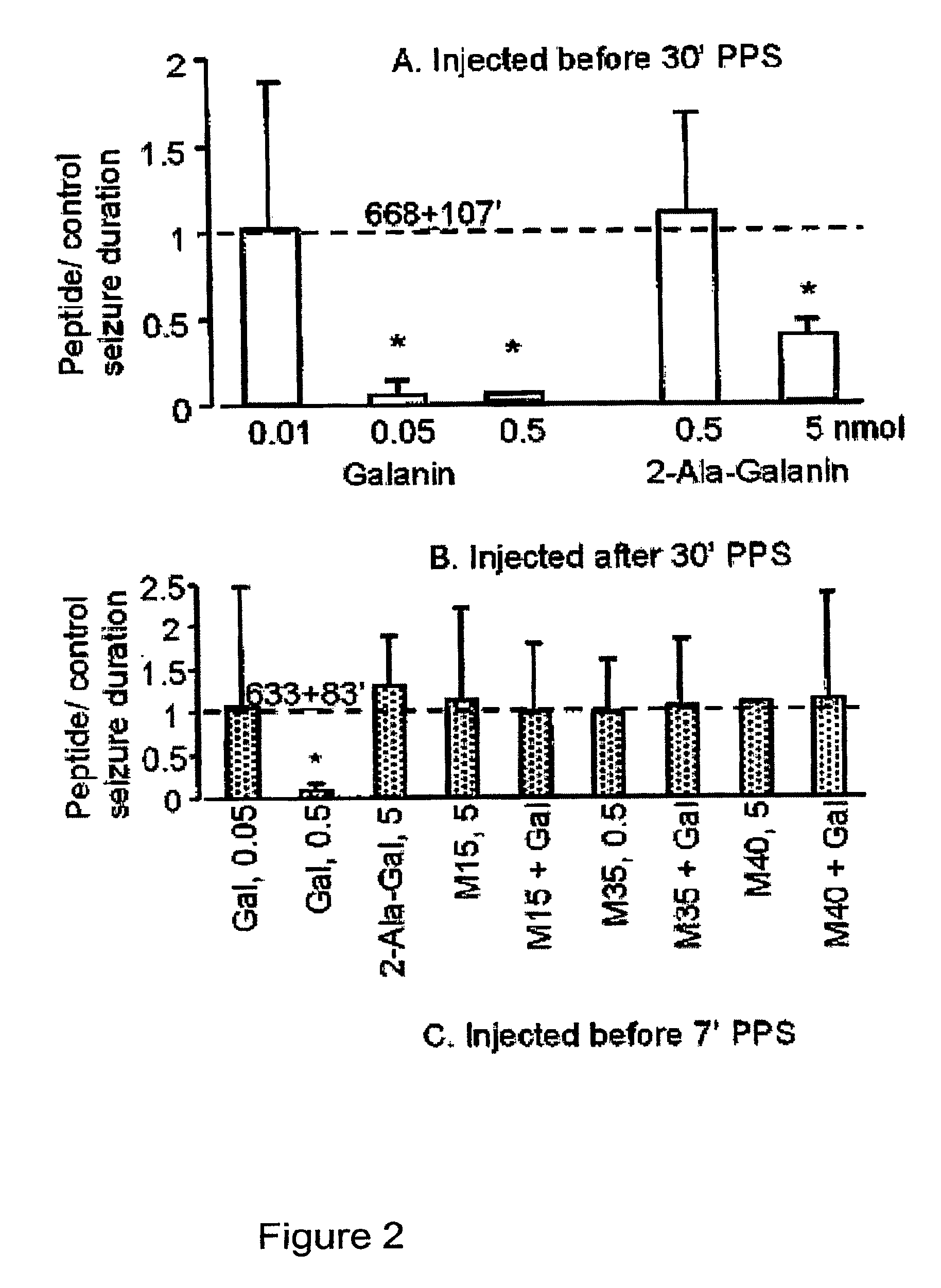

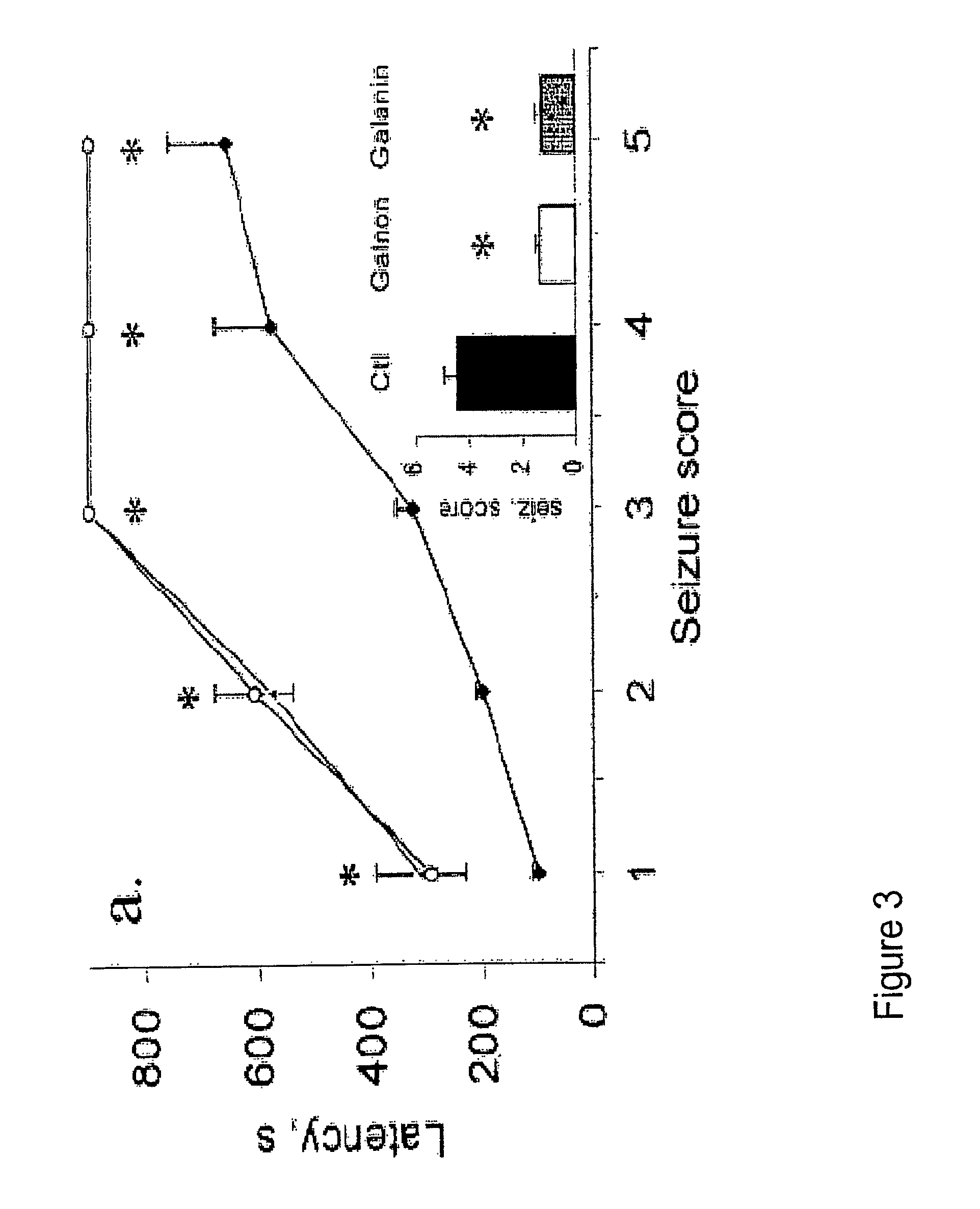

Methods and Compositions Related to Improving Properties of Pharmacological Agents Targeting Nervous System

InactiveUS20090281031A1Improve blood-brain barrier permeabilityIncreased lipophilic characterNervous disorderPeptide/protein ingredientsNervous systemMedicine

Disclosed are compositions and methods related to improving pharmacological properties of bioactive compounds targeting nervous system.

Owner:UNIV OF UTAH RES FOUND

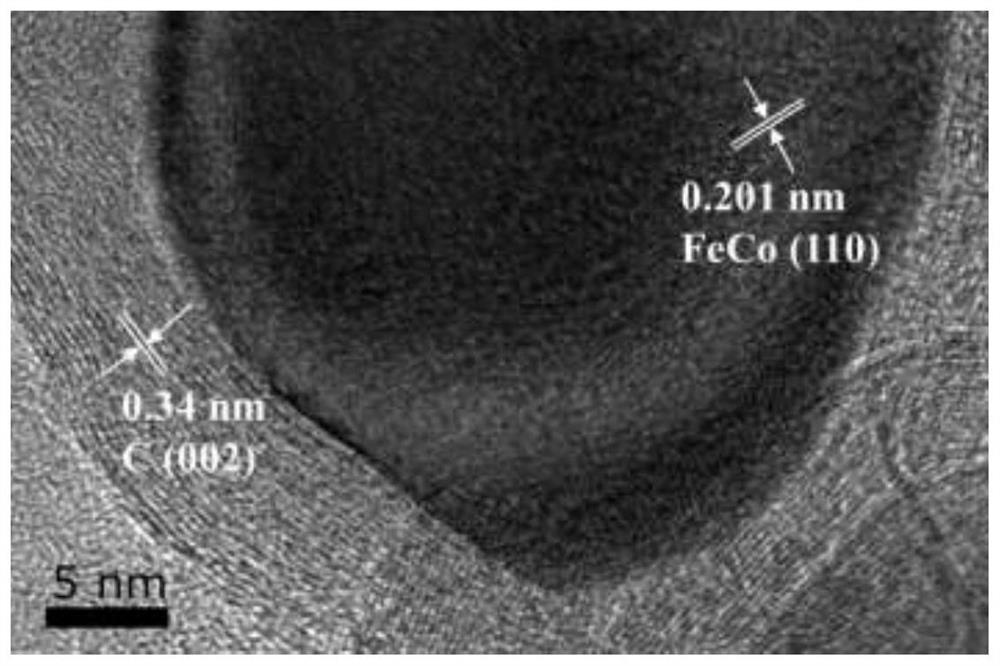

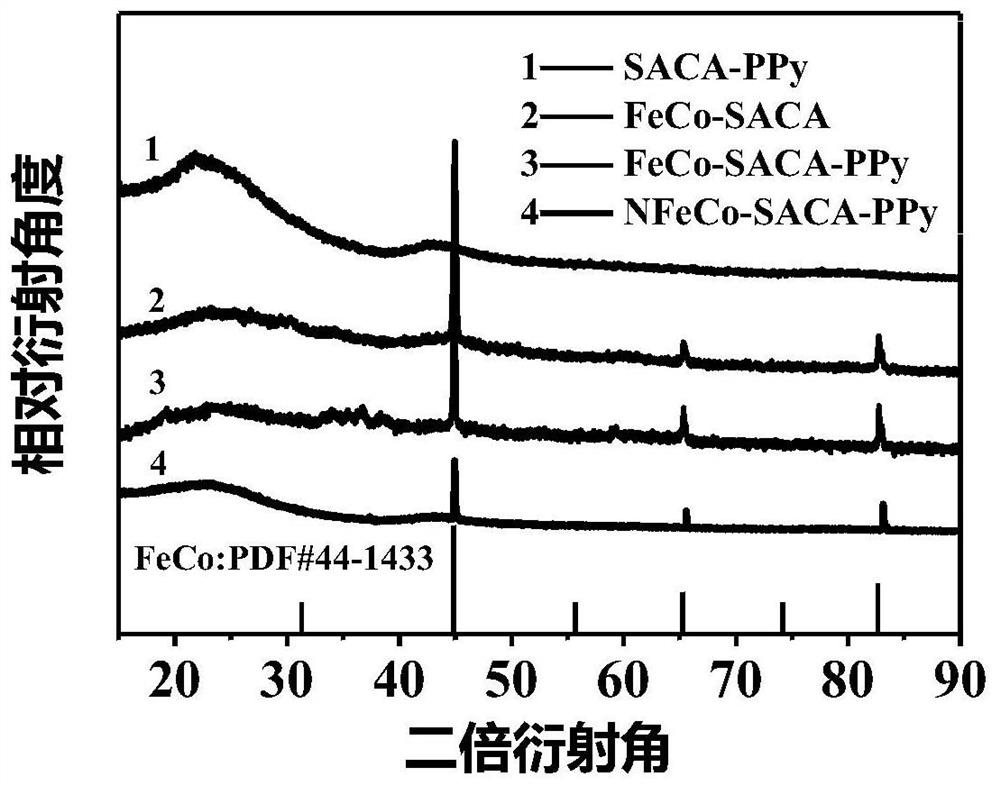

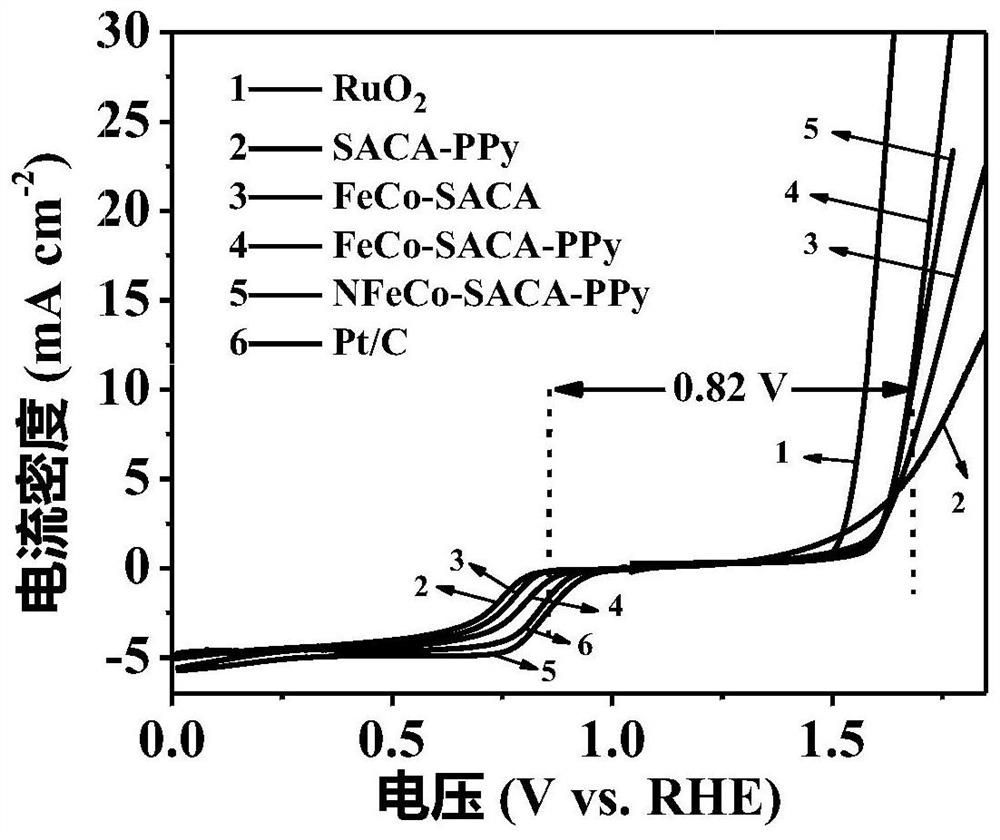

Preparation method of iron-cobalt alloy/nitrogen co-doped carbon aerogel electrode material

ActiveCN111785977AExcellent ORR/OER bifunctional catalytic performanceReduce manufacturing costFuel and secondary cellsCell electrodesPtru catalystPolypyrrole

The invention discloses a preparation method of an iron-cobalt alloy / nitrogen co-doped carbon aerogel electrode material, and relates to the field of catalyst preparation. The preparation method comprises the following steps: dispersing sodium alginate and polypyrrole in water to form a first solution, and dispersing ferric salt and cobalt salt in water to form a second solution; dropwise adding the first solution into the second solution, standing for 1h to obtain hydrogel, freeze-drying, performing calcining in nitrogen at high temperature for 1h, and pickling a sample to obtain carbon aerogel; and dipping and doping the solid powder into melamine, performing drying, and performing roasting in N2 to obtain the sodium alginate-based iron-cobalt alloy / nitrogen co-doped electrode material.The catalyst has oxygen reduction (ORR) and oxygen evolution (OER) bifunctional catalytic performance, and the zinc-air battery assembled by the catalyst has high power density and good charging and discharging performance. According to the method, cheap biomass seaweed is recycled, the preparation process is non-toxic and harmless, the cost is low, and the method has a wide industrial applicationprospect.

Owner:南京绿源智慧科技有限公司

Method for preparing aluminum polychlorid from byproduct generated in methyl diethyl phosphate production

ActiveCN109052444AResolve disposal issuesHigh value-added productsAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideDiethyl phosphate

The invention provides a method for preparing aluminum polychlorid from byproducts generated in methyl diethyl phosphate production. The method comprises the following steps: (1) dispersing byproductsolid dregs into a solvent, analyzing, and collecting a solution; (2) cooling the solution with water, and separating aluminum chloride hydrate crystal; (3) hydrolyzing and polymerizing the aluminum chloride hydrate crystal, and aging, thereby obtaining the aluminum polychlorid. By adopting the method, solid dregs rich in sodium tetrachloroaluminate are adopted as a raw material, an inorganic polymeric flocculant, namely the aluminum polychlorid, is successfully prepared through steps of simple processes, and not only is the problem of waste disposal solved, but also a high additional value product can be successfully made.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

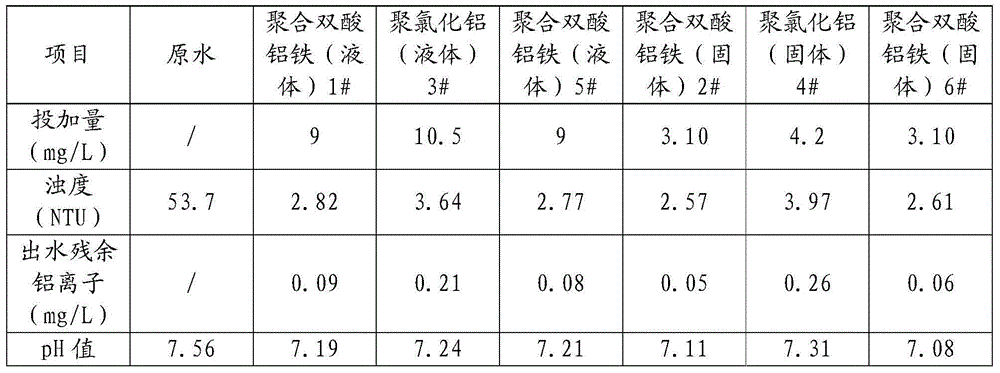

Method for synthesizing composite kieselguhr coagulant from kieselguhr waste liquor

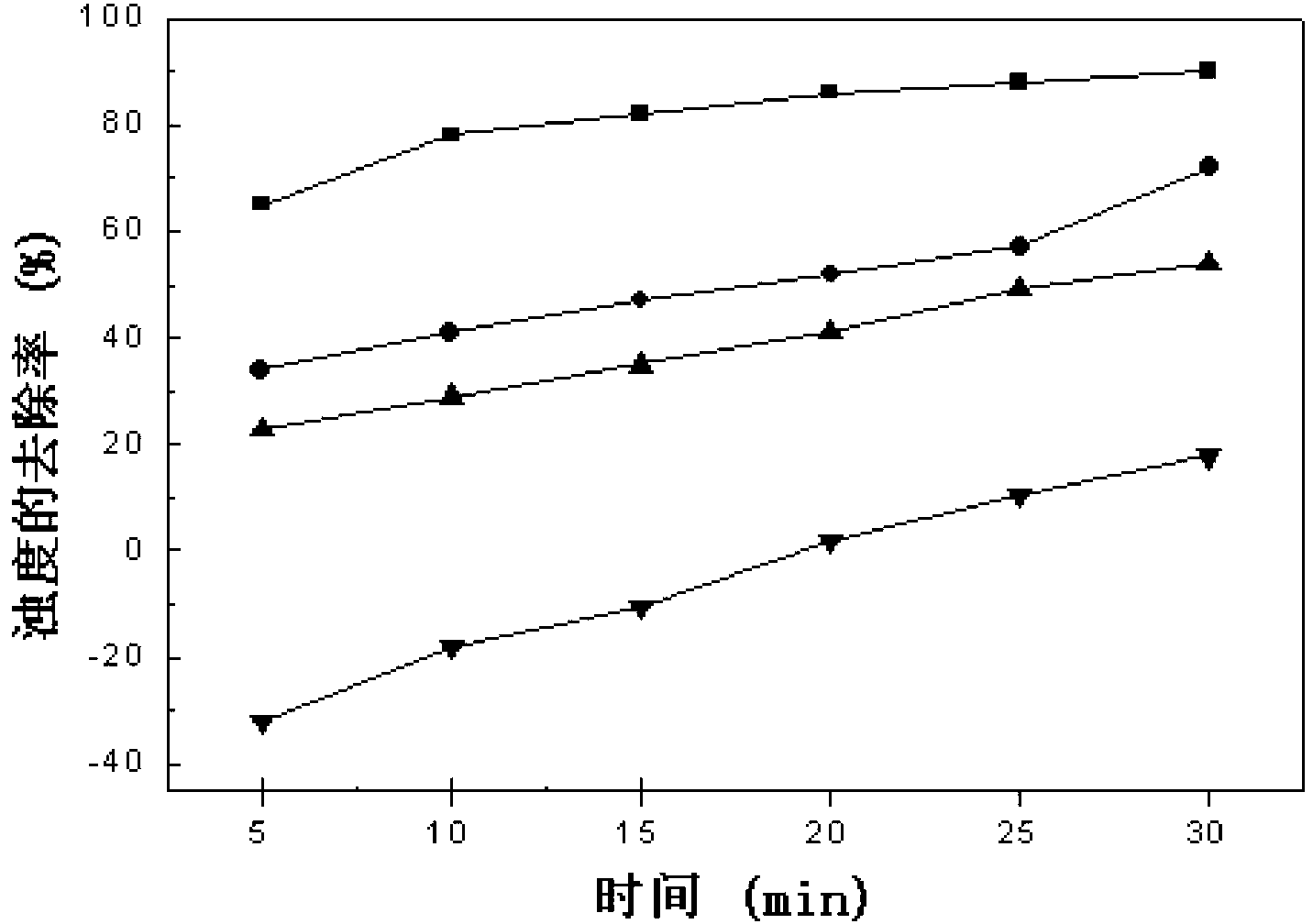

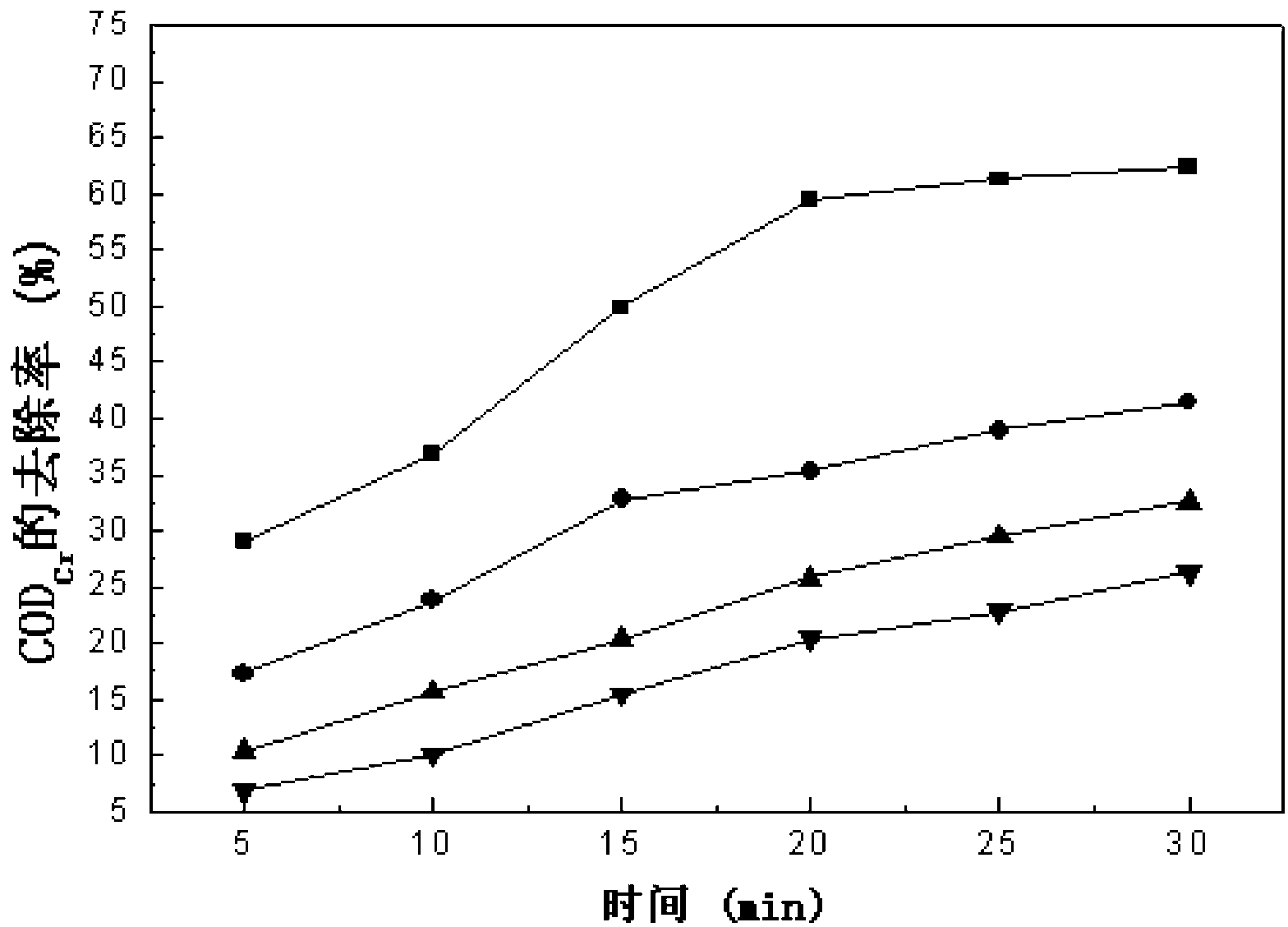

InactiveCN103288192AGood effectHigh removal rateWater/sewage treatment by flocculation/precipitationSulfateTurbidity

The invention relates to a method for synthesizing a composite kieselguhr coagulant, particularly a method for synthesizing a composite kieselguhr coagulant from kieselguhr waste liquor. The invention aims to solve the problems of small basicity of PAFS (polymeric aluminum ferric sulfate) or PAFC (polymeric aluminum ferric chloride) and weak bridge adsorbing function in the kieselguhr coagulant prepared by the existing method. The method comprises the following steps: 1. preparation of fine kieselguhr; 2. modification of the fine kieselguhr; and 3. synthesis of the composite kieselguhr coagulant. The composite kieselguhr coagulant synthesized by the method provided by the invention has the advantages of faovorable removal rate for turbidity and CODCr, small addition amount, wide pH applicability and low price, and enhances the economical efficiency when being used for treating wastewater; and in the composite kieselguhr coagulant preparation process, the previously modified kieselguhr is added to enhance the hydroxy polymerization degree in the PAFS or PAFC preparation process by utilizing the electropositivity on the surface of the modified kieselguhr, thereby greatly increasing the basicity of the PAFS or PAFC and enhancing the bridge adsorbing function of the coagulant.

Owner:JILIN YINDA WATER AFFAIR TECH

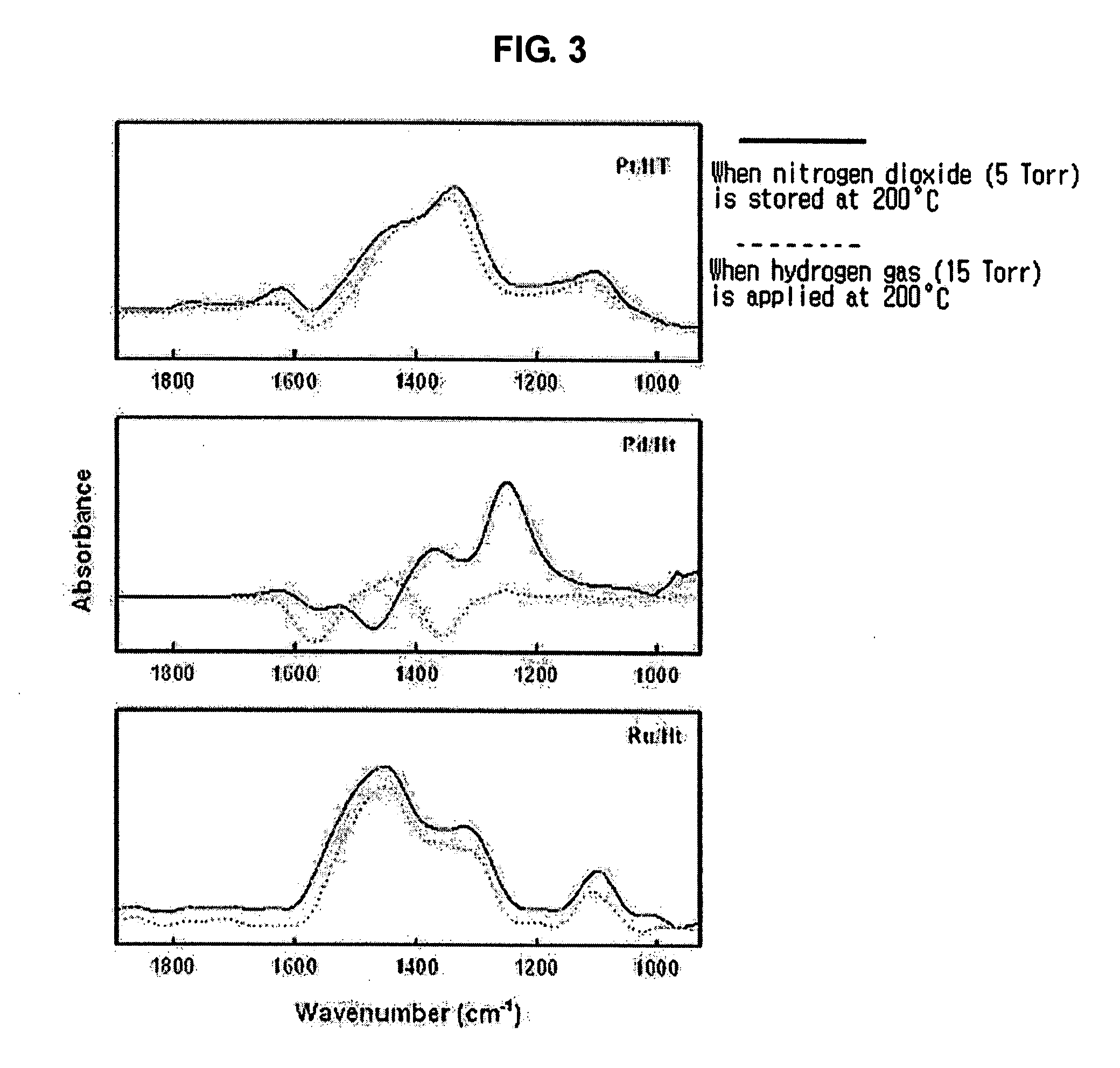

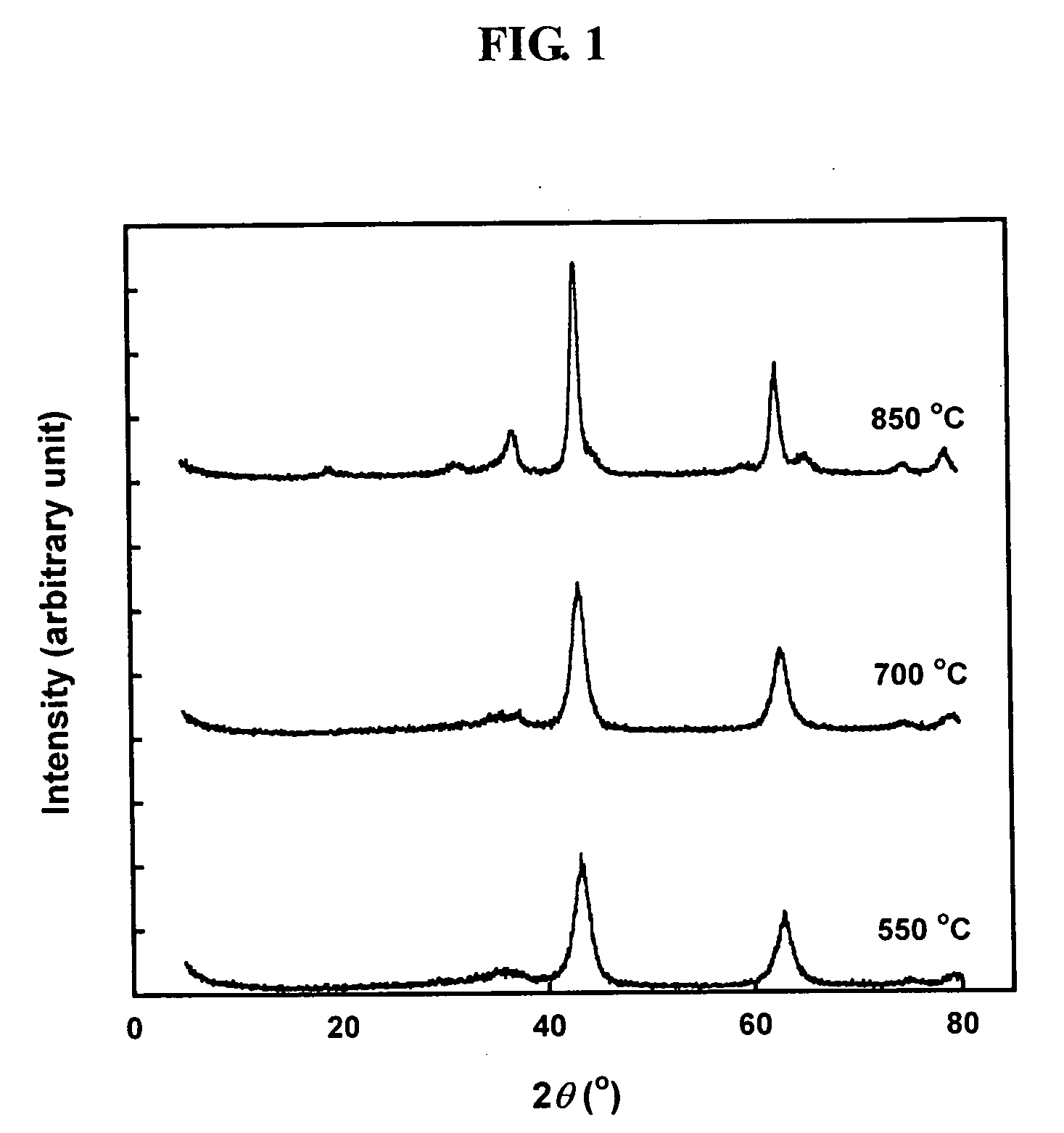

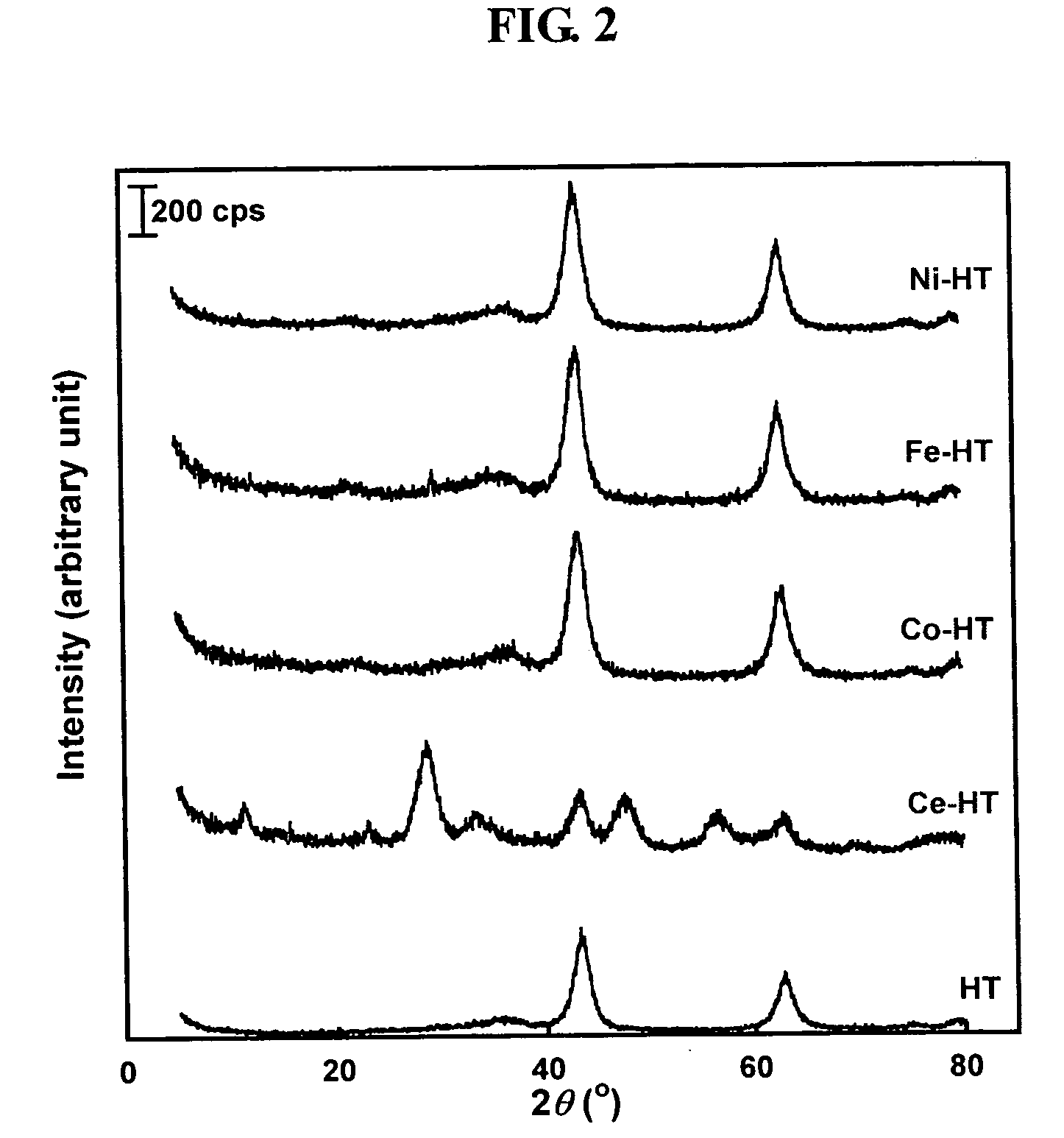

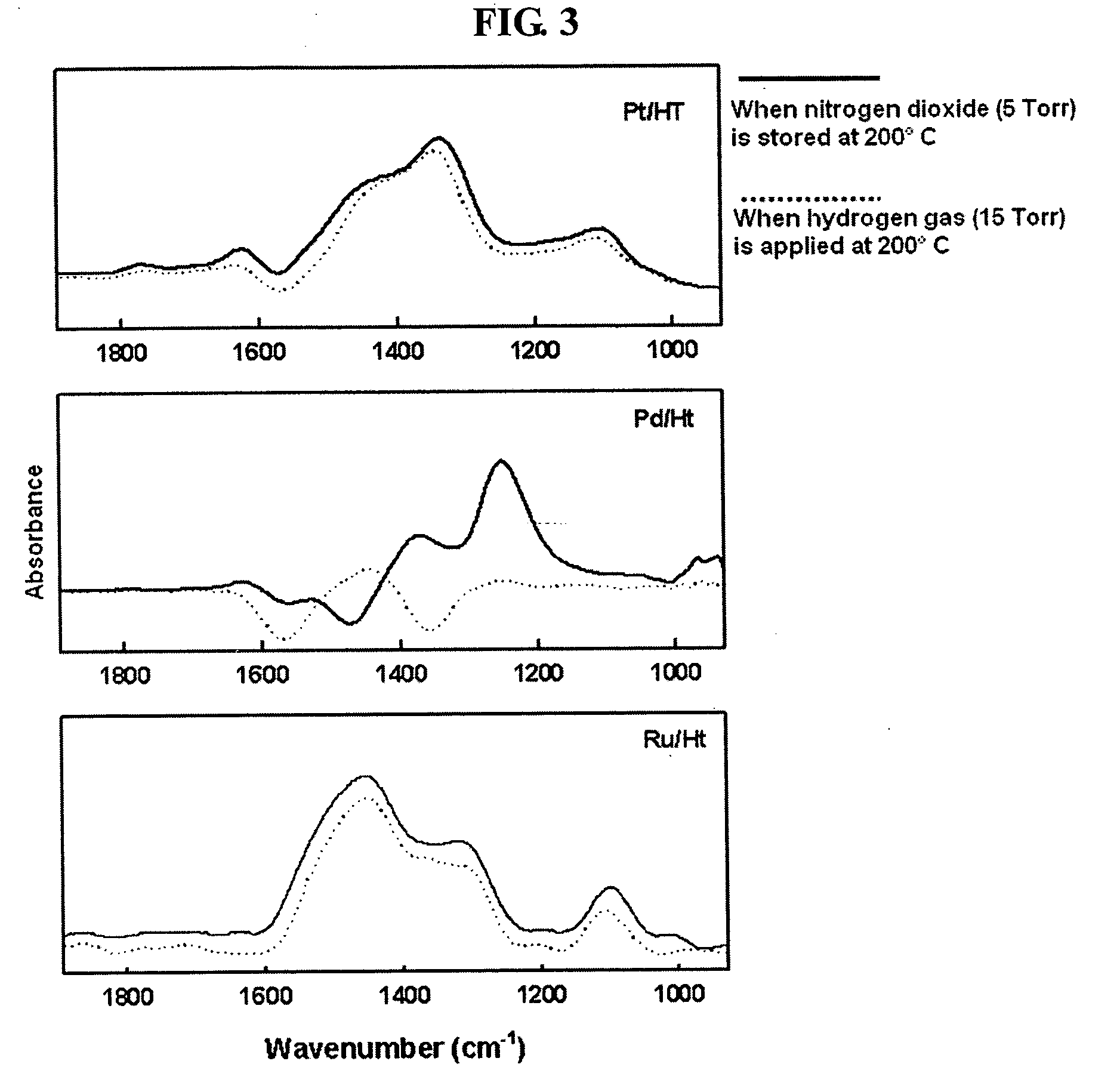

Transition metal-substituted hydrotalcite catalyst for removing nitrogen oxides from the exhaust gas of diesel engine by storage-reduction

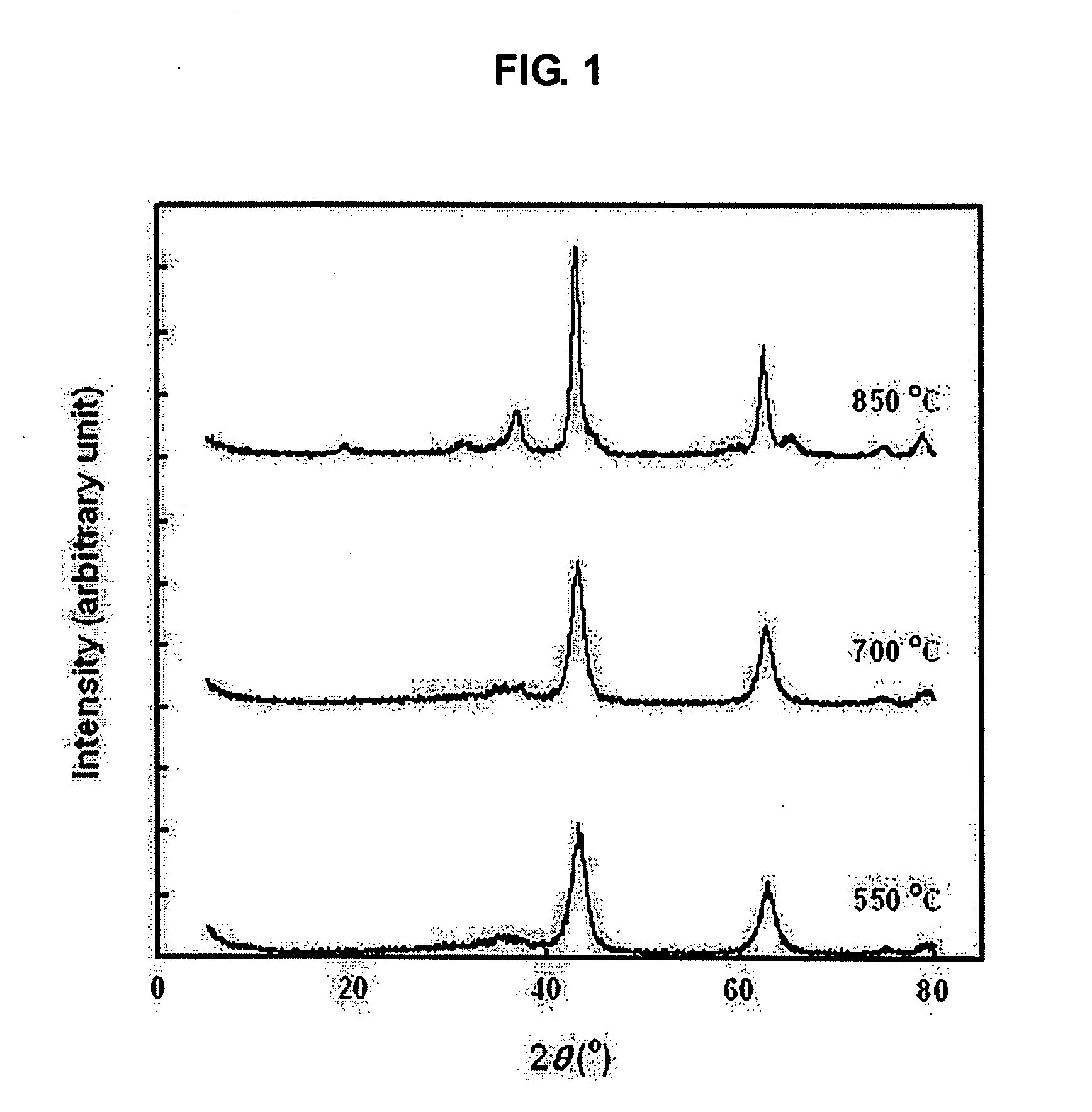

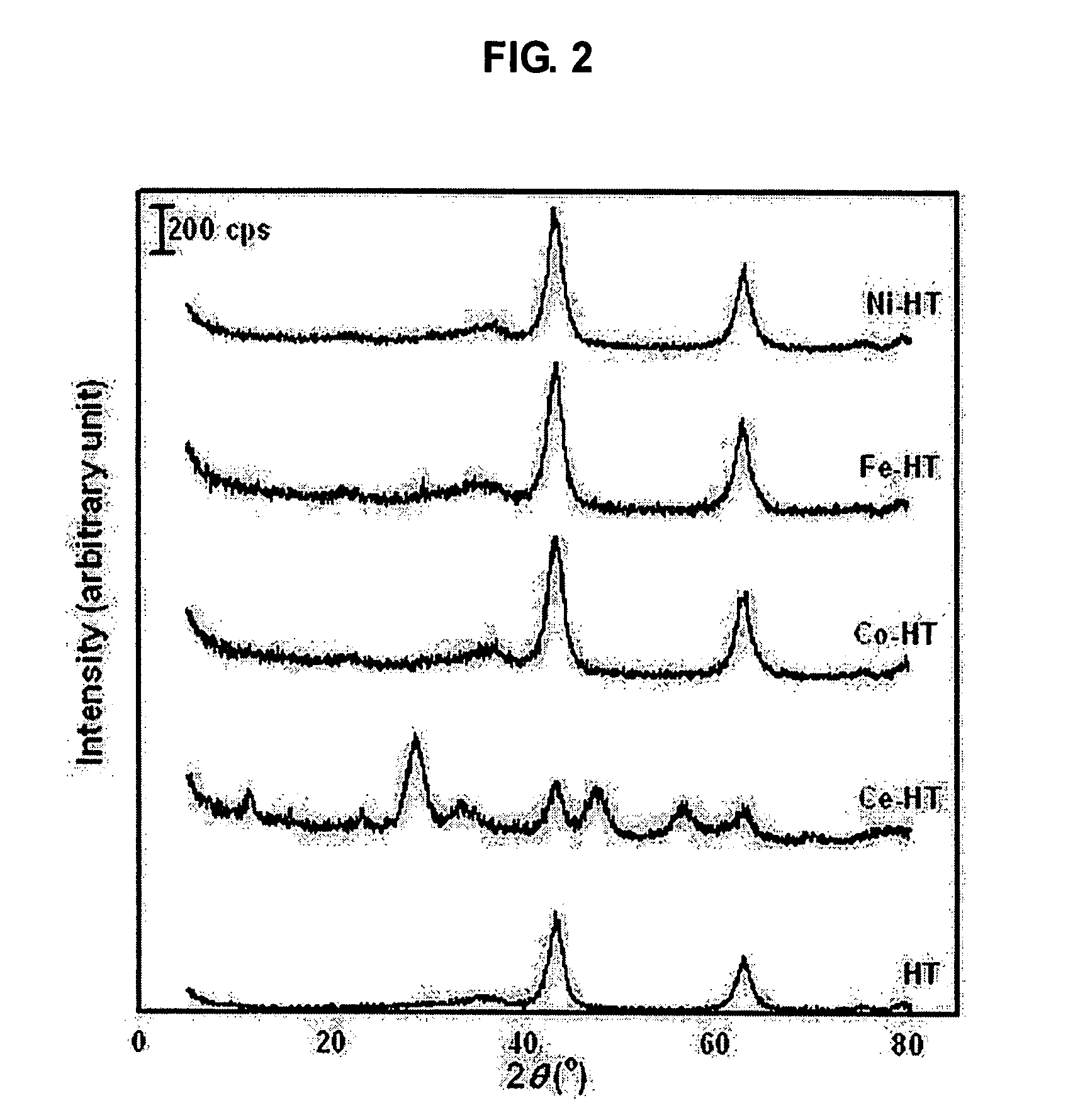

InactiveUS20080026937A1Excellent property of resistance to sulfur dioxide poisoningImprove catalytic performanceGas treatmentDispersed particle separationHydrotalciteNitrogen oxide

Disclosed herein is a transition metal-substituted hydrotalcite catalyst for removing nitrogen oxides using a storage-reduction method, in which a molar ratio of transition metal to magnesium is 0.2 or less, and a method of manufacturing a transition metal-substituted hydrotalcite catalyst for removing nitrogen oxides using a storage-reduction method, including the steps of preparing a hydrotalcite synthesis solution including transition metal precursors such that the molar ratio of transition metal to magnesium is 0.2 or less, and preferably 0.001 to 0.2; aging the synthesis solution; and hydrothermally treating the synthesis solution.

Owner:HEESUNG ENGELHARD CORP

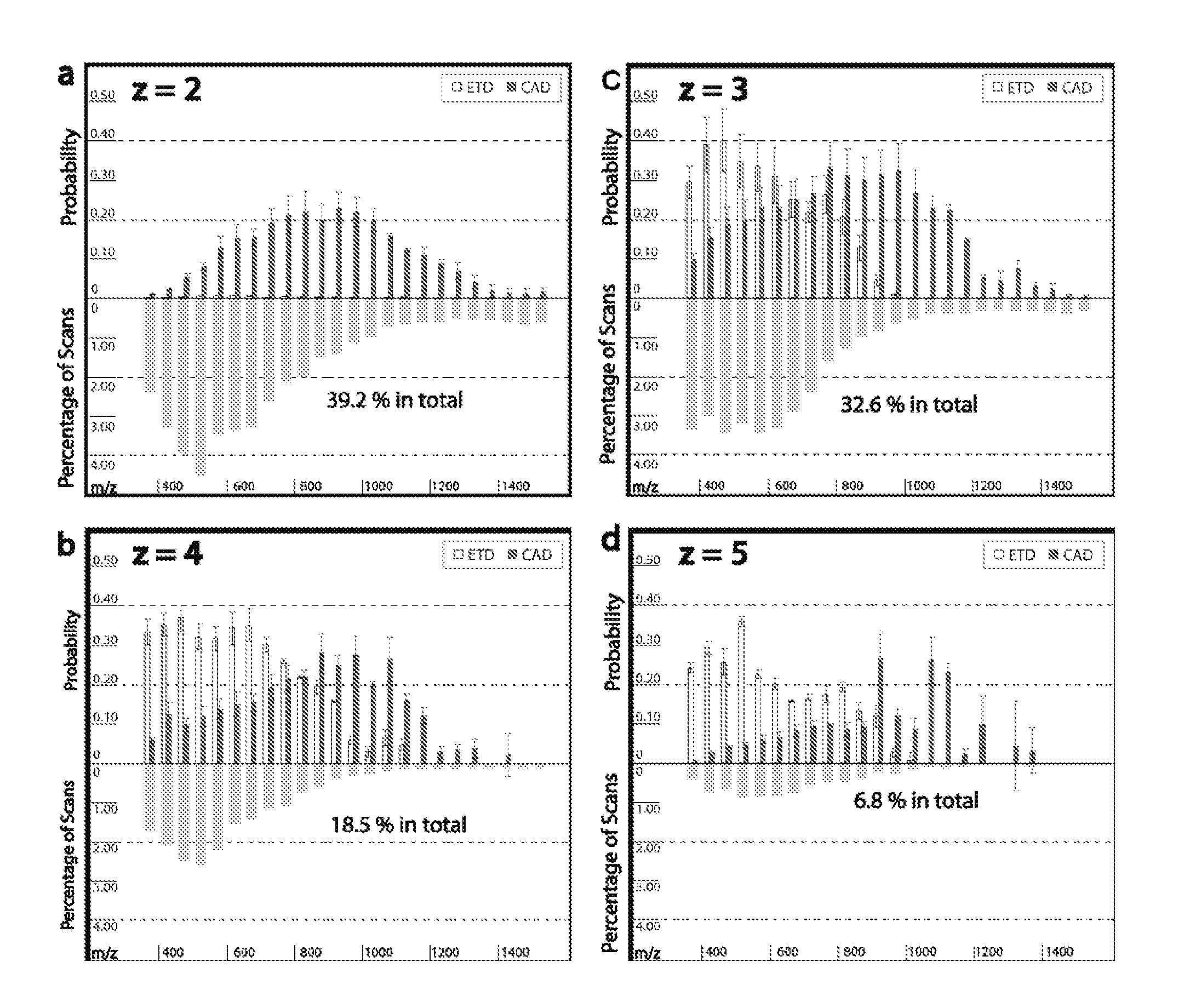

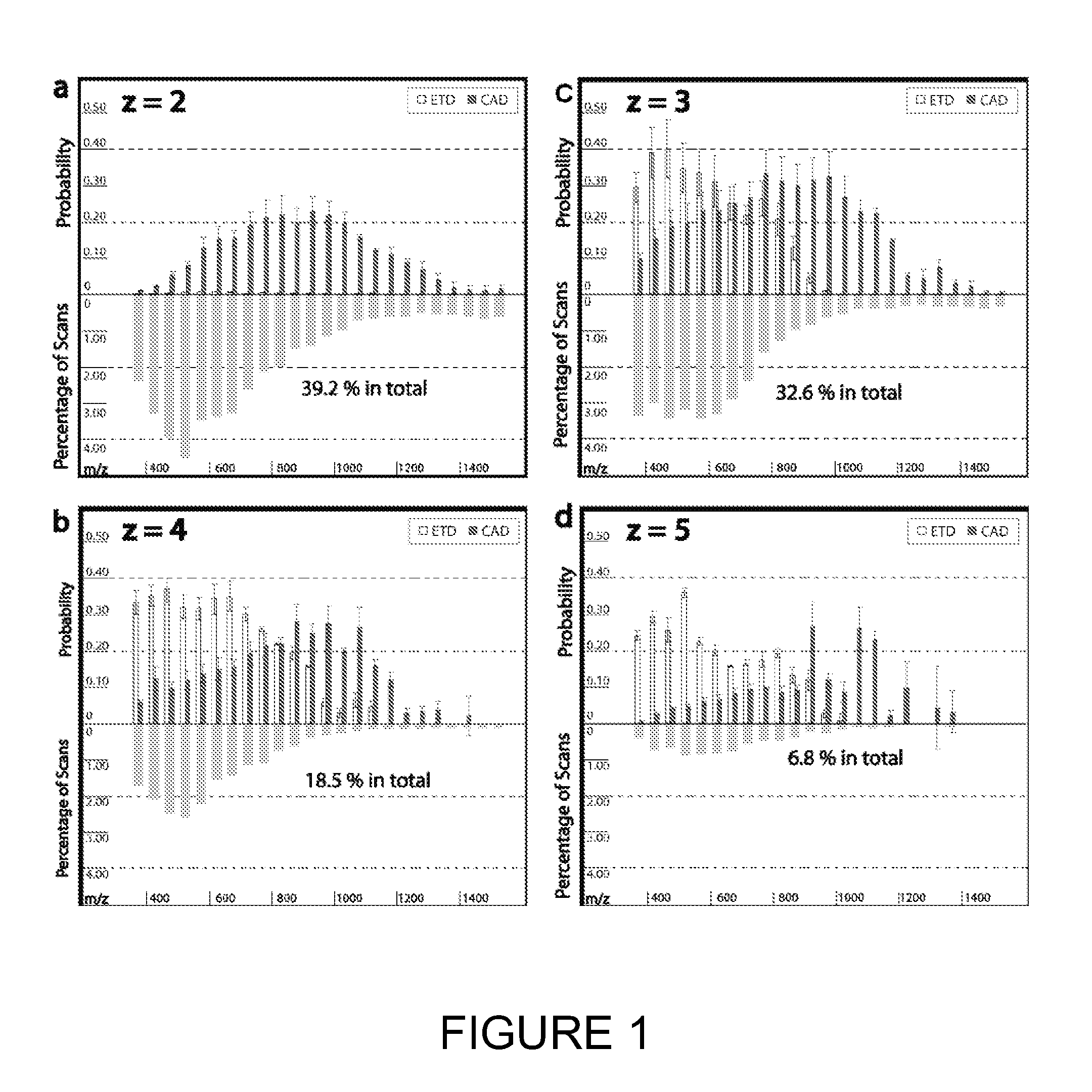

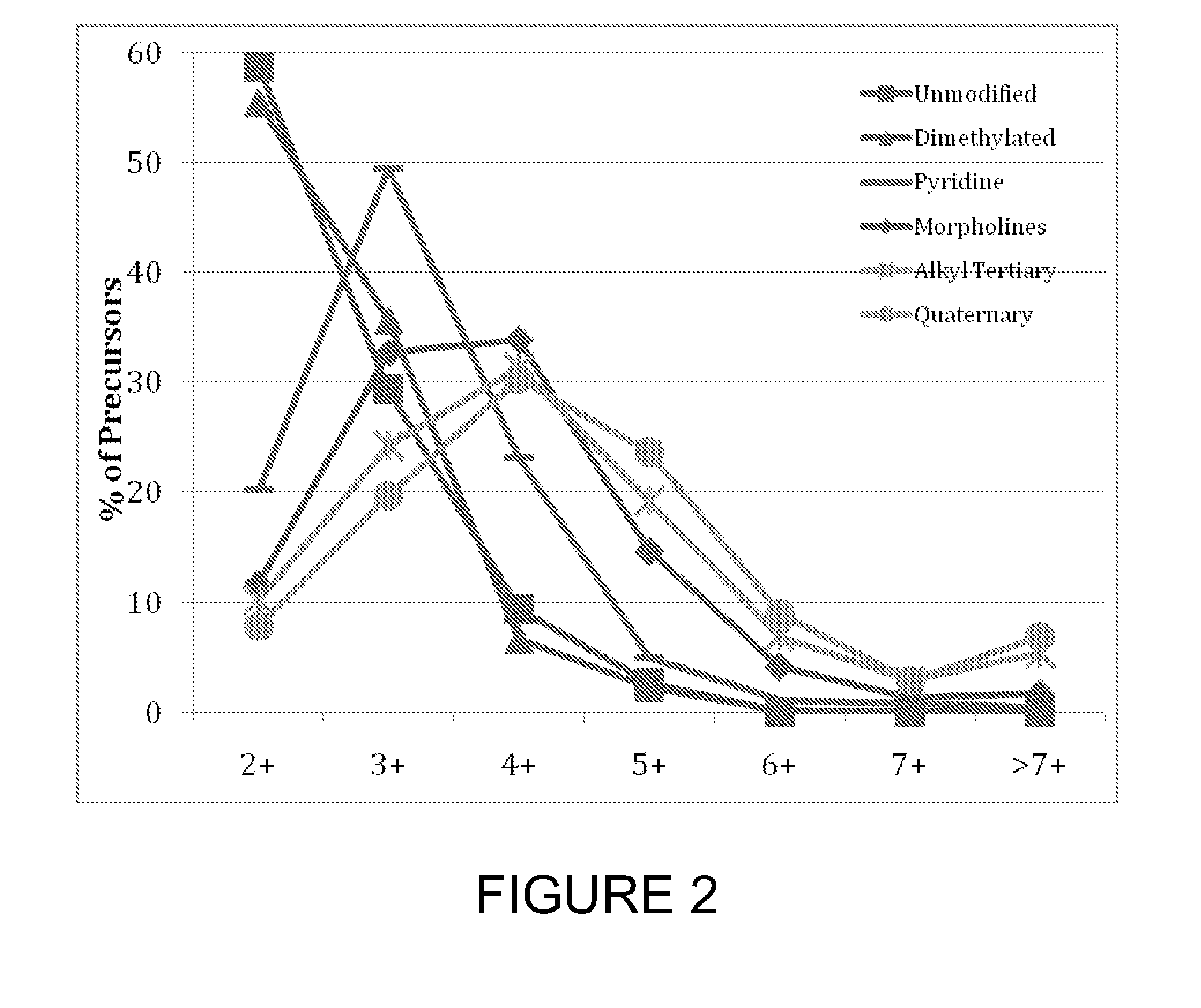

Labeling peptides with tertiary amines and other basic functional groups for improved mass spectrometric analysis

ActiveUS20100330680A1Easy to analyzeImprove fragmenting characteristicPeptide/protein ingredientsPeptide sourcesHighly charged ionGas phase

The present invention provides methods for enhancing the fragmentation of peptides for mass spectrometry by modifying the peptides with a tagging reagent containing a functional group, such as a tertiary amine, having a greater gas-phase basicity than the amide backbone of the peptide. These high gas-phase basicity functional groups are attached to a peptide by reacting the tagging reagent to one or more available carboxylic acid groups of the peptide. Linking these high gas-phase functional groups to the peptides leads to higher charge state ions from electrospray ionization mass spectrometry (ESI-MS), which fragment more extensively during fragmentation techniques, particularly non-ergodic fragmentation techniques such as electron capture dissociation (ECD) and electron transfer dissociation (ETD).

Owner:WISCONSIN ALUMNI RES FOUND

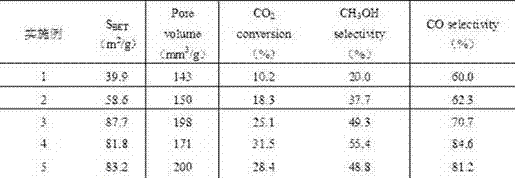

Graphene-doped catalyst for production of methanol by means of carbon dioxide hydrogenation

InactiveCN107042101ARaise the basicityHigh activityOrganic compound preparationHeterogenous catalyst chemical elementsCvd grapheneCarbon dioxide

The invention provides an improved catalyst for production of methanol by means of carbon dioxide hydrogenation, aiming at improving the catalytic activity and stability of the catalyst. The graphene-doped catalyst is prepared by using a parallel flow coprecipitating method; the invention in particular relates to nitrogen-doped graphene doped in the catalyst; the prepared catalyst utilizes the physical and chemical properties of the nitrogen-doped graphene, and the introduced nitrogen-doped graphene has the double functions of an auxiliary agent and a carrier and is high in gas absorption property and high in dispersity of metallic particles, so that the catalyst can easily form a catalytic activity center in a catalytic reaction, CO2 and H2 are easily absorbed, and the CO2 conversion rate, the methanol selectivity and the methanol yield are improved.

Owner:NINGXIA UNIVERSITY

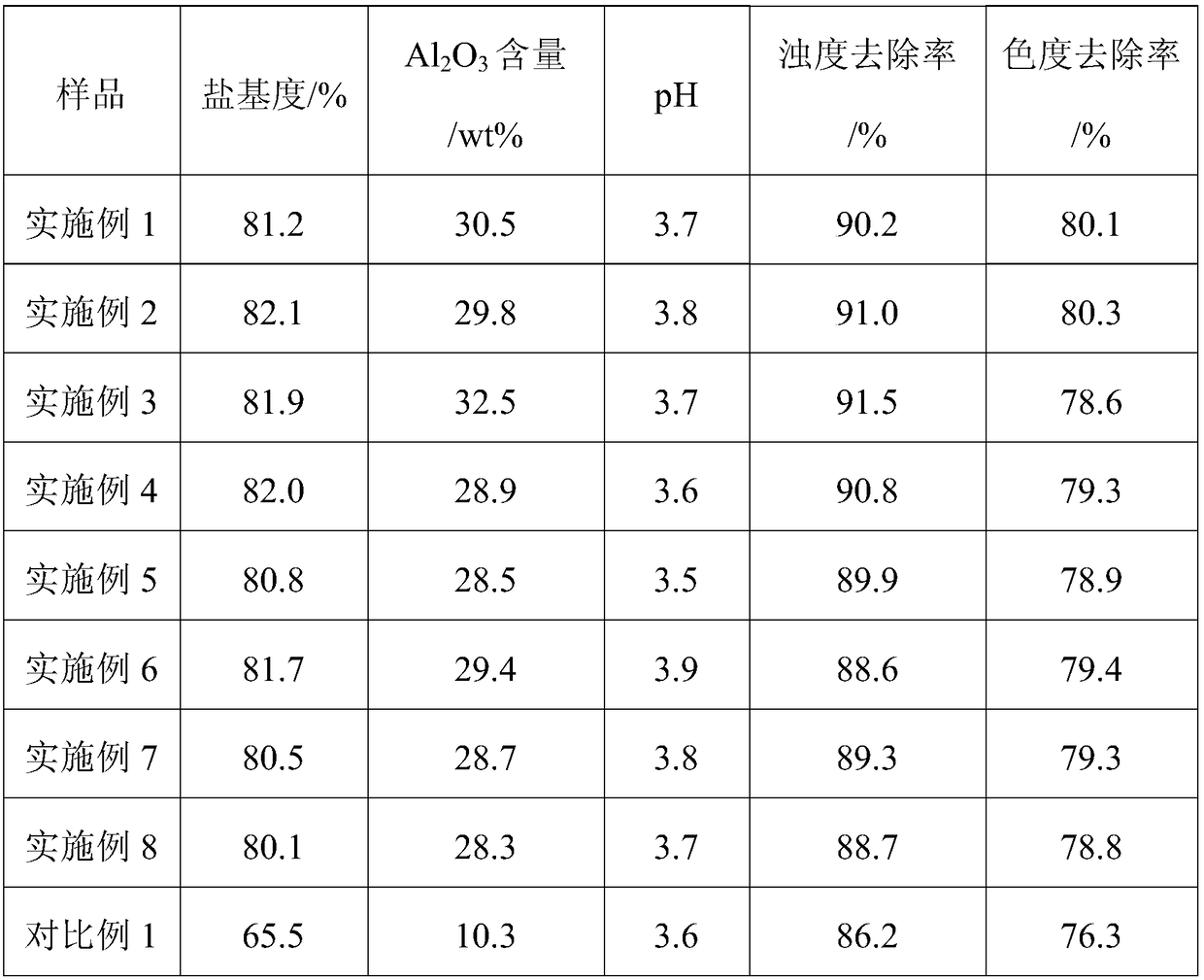

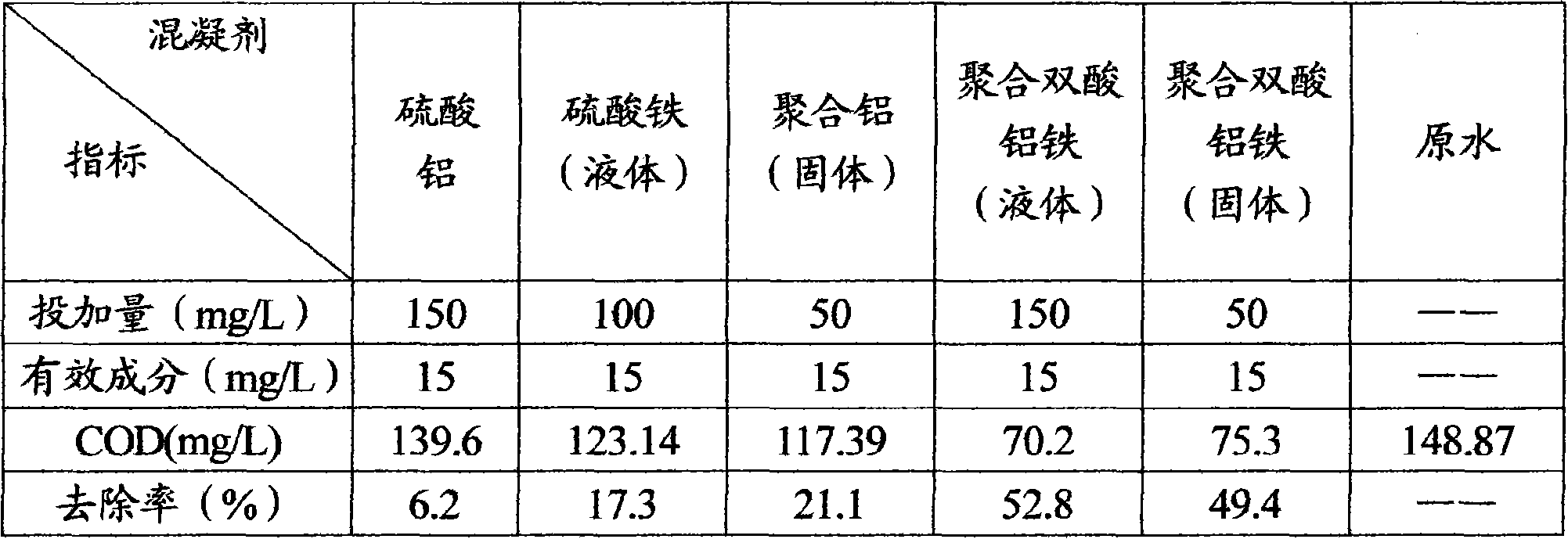

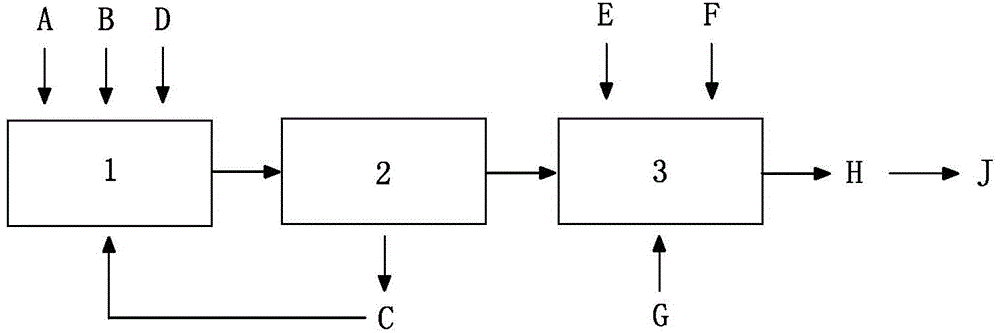

Method for preparing polymerized aluminum-iron diacid water purifying agent and production thereof

InactiveCN101125702AIncrease contentRaise the basicityWater/sewage treatment by flocculation/precipitationAluminium oxides/hydroxidesSodium metasilicateFerrous sulfate iron

The invention discloses a preparation method of a polymeric dual-acid aluminum iron water purifying agent and a product thereof. The preparation method is that: ferrous sulfate, hydrochloride, sulfate, sodium metasilicate, calcium aluminate and bauxite are taken as raw materials. The preparation procedures are that: reserved A liquid is made out of the ferrous sulfate, sodium metasilicate and sulfate which are added into a reactor for synthetic reaction; reserved B liquid is made out of the calcium aluminate, bauxite and sulfate which are added into a reactor for synthesis and reaction; the reserved A liquid and the reserved B liquid are added into the reactor for synthesis and reaction, therefore, the finished polymeric dual-acid aluminum iron water purifying agent is acquired. The product is characterized in that the weight portion of alumina is more than or equal to 10 percent, the weight portion of iron oxide is within 1.0-8 percent and the basicity is 55.0-85.0 percent. The preparation method is characterized by simple technique, low energy consumption and non-three wastes during the whole process. The product has the advantages of high contents of the effective components, high basicity and polymerization, non-toxic, non-corrosive, low dosing mass percentage during water processing and good water purifying effect, etc.

Owner:张国平

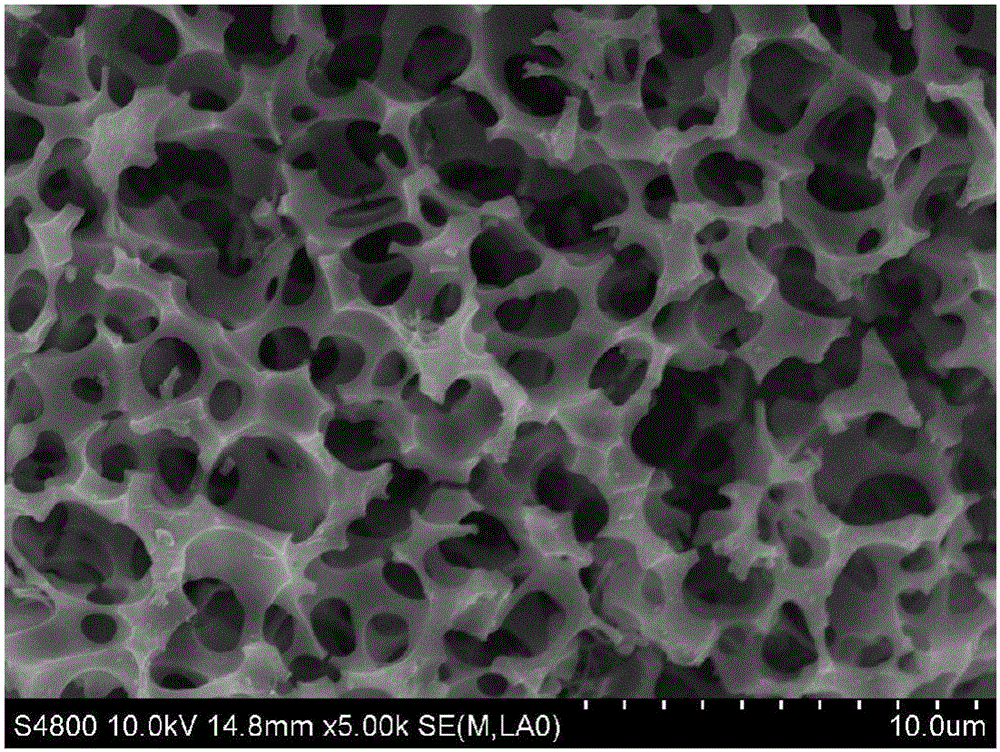

Amidine modified mesoporous foam material used for carbon dioxide adsorption and preparation method of amidine modified mesoporous foam material

InactiveCN104475062ALarge specific surface areaUniform pore sizeGas treatmentOther chemical processesFiltrationMesoporous silica

The invention discloses an amidine modified mesoporous foam material used for carbon dioxide adsorption and a preparation method of the amidine modified mesoporous foam material and belongs to the technical field of carbon dioxide adsorption. The amidine modified mesoporous foam material is a PEI modified mesoporous silica foam material, a PEI and heptane modified mesoporous silica foam material or a mixed amine modified mesoporous silica foam material, wherein mixed amine is prepared from PEI and one of DETA and APTMS. The preparation method comprises the following steps: dissolving P123, NH4F, heptane and TEOS in a hydrochloric acid solution, carrying out heating reaction by virtue of a reaction kettle, carrying out air pump filtration, washing, drying and calcining to prepare a mesoporous foam material; and then putting the mesoporous foam material into the PEI and a solution of the PEI and the heptane or the mixed amine, and soaking to obtain the amidine modified mesoporous foam material. The amidine modified mesoporous foam material is high in carbon dioxide adsorption capability and simple in preparation method and provides a good carbon adsorption material for realizing a carbon capturing technology.

Owner:WUHAN UNIV

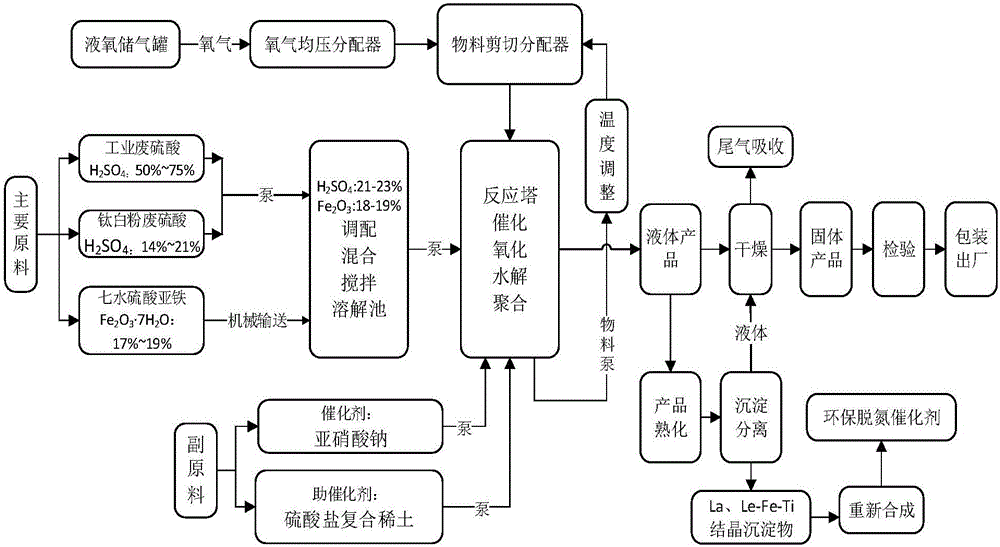

Polyferric sulfate and preparation method of polyferric sulfate

ActiveCN105692717AAdjust the reaction temperatureIncrease acidityIron sulfatesWater/sewage treatment by flocculation/precipitationRare earthIron(III) sulfate

The invention discloses polyferric sulfate as well as a preparation method and a preparation device of the polyferric sulfate. The preparation method comprises the following steps: conveying the following components into a mixing tank in percentage by weight: 40 percent to 50 percent of iron sulfate heptahydrate and 60 percent to 50 percent of titanium dioxide waste sulfuric acid, and blending the materials; adjusting the concentration range of the titanium dioxide waste sulfuric acid H2SO4 to be 21 percent to 23 percent to obtain mixed reaction materials; conveying the reaction materials into a reaction tower, and adding a sulfate composite rare-earth solution as a reaction cocatalyst when conveying the reaction materials into the reaction tower; controlling the temperature in the reaction tower to be 40 DEG C to 60 DEG C; after all the blended materials enter the reaction tower, adding a sodium nitrite solution as a reaction catalyst; continually introducing oxygen gas into the reaction tower so that the oxygen gas and the reaction materials make oxidization, hydrolysis and polymerization reactions under the action of the cocatalyst and the catalyst; after effectively converting Fe<2+> ions in the materials into Fe<3+> ions, obtaining liquid polyferric sulfate. With the adoption of the polyferric sulfate as well as the preparation method and the preparation device of the polyferric sulfate, the production efficiency can be greatly improved, environmental hazards are reduced, and a more prominent water purification and coagulation effect is realized.

Owner:广西继禹环保科技有限公司

Transition metal - substituted hydrotalcite catalyst for removing nitrogen oxides from the exhaust gas of diesel engine by storage - reduction

ActiveUS20090257934A1Excellent property of resistance to sulfur dioxide poisoningImprove catalytic performanceNitrogen compoundsIron compoundsNitrogen oxidesHydrotalcite

Disclosed herein is a transition metal-substituted hydrotalcite catalyst for removing nitrogen oxides using a storage-reduction method, in which a molar ratio of transition metal to magnesium is 0.2 or less, and a method of manufacturing a transition metal-substituted hydrotalcite catalyst for removing nitrogen oxides using a storage-reduction method, including the steps of preparing a hydrotalcite synthesis solution including transition metal precursors such that the molar ratio of transition metal to magnesium is 0.2 or less, and preferably 0.001 to 0.2; aging the synthesis solution; and hydrothermally treating the synthesis solution.

Owner:HEESUNG ENGELHARD CORP

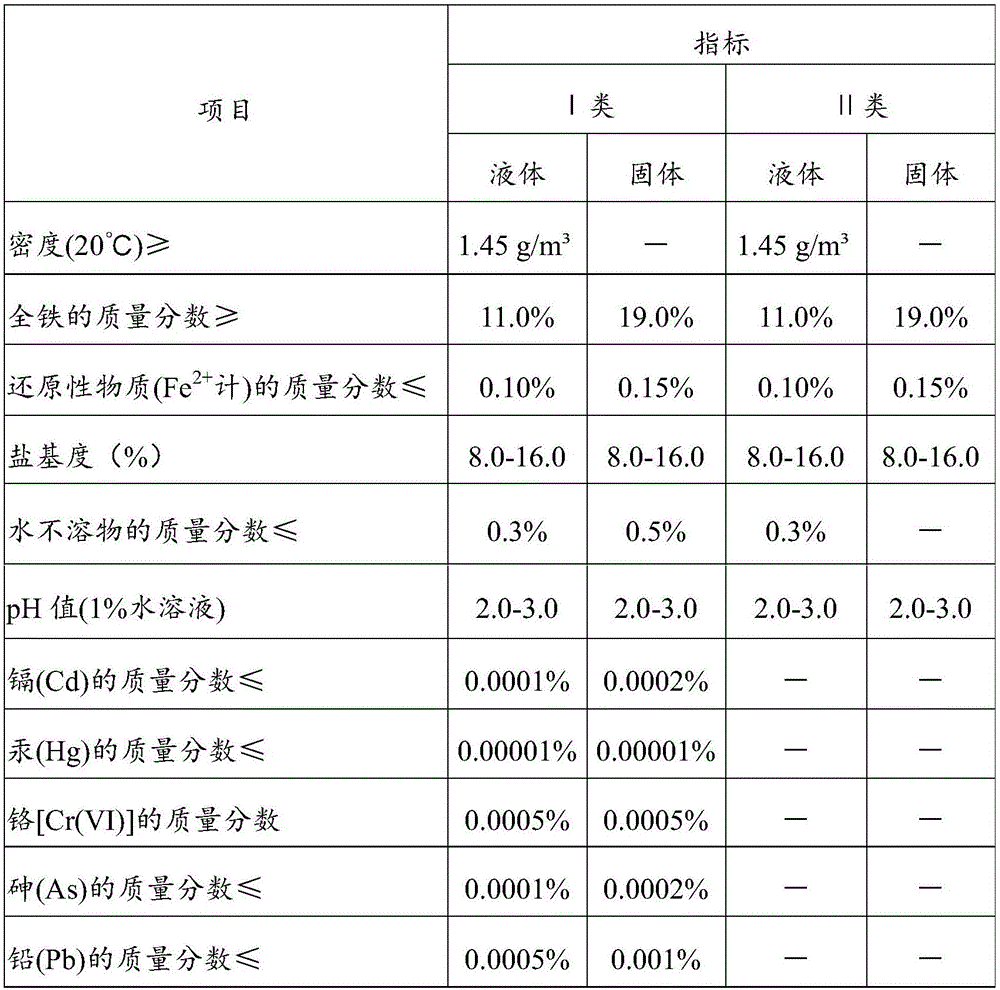

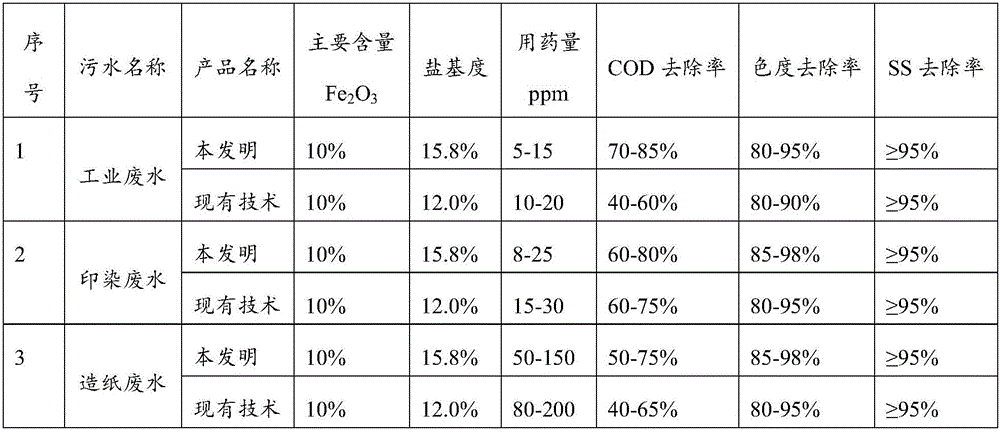

Iron-based compound water treatment agent FPFS-1 and preparation method thereof

InactiveCN101786703AStrong hydrolysis-polymerization-precipitation tendencyImprove securityWater/sewage treatment by flocculation/precipitationIron sulphateWater quality

The invention discloses an iron-based compound water treatment agent FPFS-1 and a preparation method thereof. The preparation method comprises the following steps: dissolving green copperas with water, adds sulphuric acid and a catalyst into the mixture for reaction to make Fe2+ completely oxidized and polymerized to form inorganic polymer compound liquid polymeric ferric sulfate, wherein the reaction temperature is room temperature, the reaction time is between 0.5 and 4.0 hours, and the material weight ratio of ferrous sulfate heptahydrate to the sulphuric acid to the catalyst is 100:4-20:3-10; and then adding an organic polymer compound into the obtained liquid polymeric ferric sulfate for compounding to form a colloidal FPFS-1 product of the invention. Tests show that the total iron accounts for 11 to 13 mass percent of the product, the basicity of the product is between 12 and 16 percent and the reducing substance (taking Fe2+ as a reference) accounts for less than 0.005 mass percent of the product. The iron-based compound water treatment agent FPFS-1 obviously improves the flocculation performance, has rapid sedimentation and clear water in the water treatment process, has good sediment filter performance, has no iron ion migration and has the unique characteristics of removing COD, BOD and chroma and deodorizing.

Owner:HUNAN CHEM RES INST

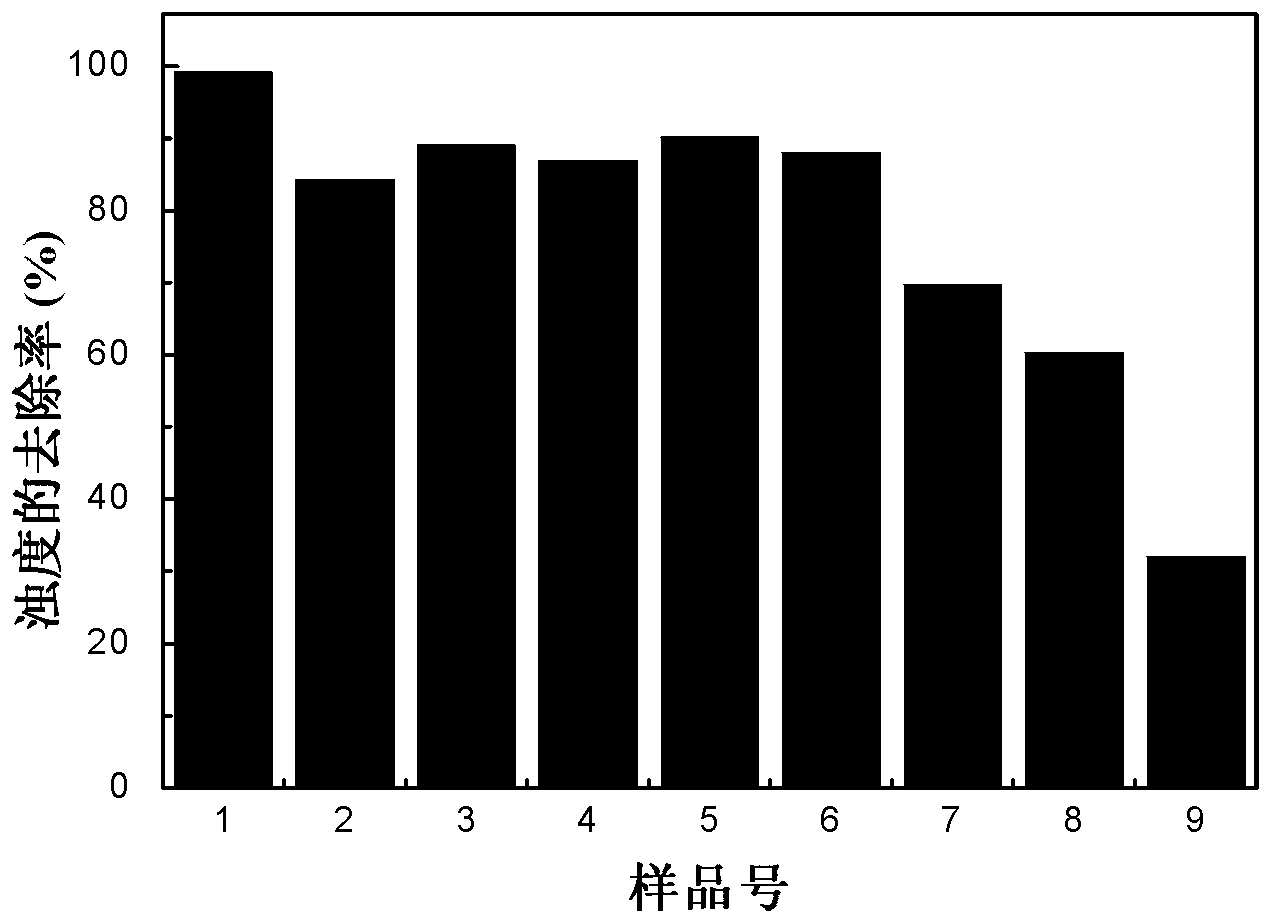

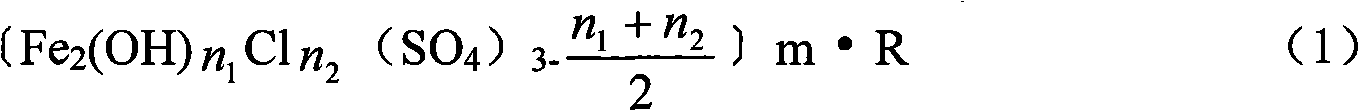

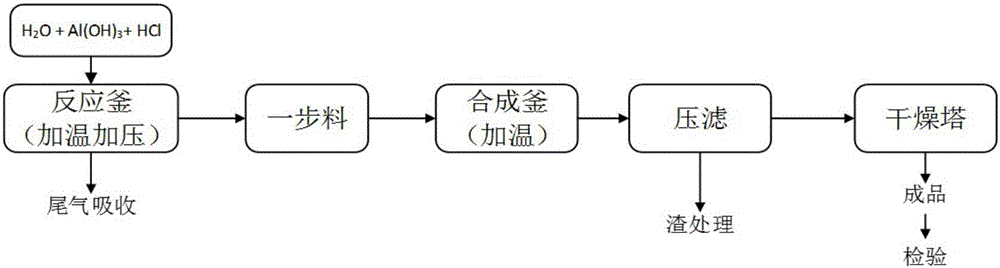

High-purity high-basicity nanoscale PACS flocculating agent and preparation method thereof

ActiveCN106517463ARaise the basicitySolve the degree of polymerization of hydroxyl groupsAluminium chloridesWater/sewage treatment by flocculation/precipitationPolymerizationHydroxy compound

The invention relates to a preparation method of a high-purity high-basicity nanoscale PACS flocculating agent. The method comprises the following steps: (1) generating a first-stage PAC material; (2) generating a second-stage high-purity PAC material; (3) performing primary separation on the materials; (4) performing secondary separation on the materials. The PACS flocculating agent prepared by the preparation method has a nanoscale crystal structural form, and the hydroxyl polymerization degree and basicity are increased remarkably, so that the organic high molecular weight is increased, and a very good water purifying effect is achieved.

Owner:广西继禹环保科技有限公司

Multi-piece golf ball

ActiveUS20130172114A1Strong alkalineEfficiently neutralizedGolf ballsSolid ballsThermoplastic elastomerCarboxylic acid

A multi-piece golf ball includes a core composed of a center, an envelope layer and at least one cover. The center is formed from a composition containing at least one resin component and a basic metal salt of a fatty acid. The resin component is selected from a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid, an ionomer resin consisting of a metal ion-neutralized product of a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid, a ternary copolymer composed of an olefin, an α,β-unsaturated carboxylic acid and an α,β-unsaturated carboxylic acid ester, and an ionomer resin consisting of a metal ion-neutralized product of a ternary copolymer composed of an olefin, an α,β-unsaturated carboxylic acid and an α,β-unsaturated carboxylic acid ester. The envelope layer is formed from a composition containing a thermoplastic resin and / or a thermoplastic elastomer as a resin component.

Owner:SUMITOMO RUBBER IND LTD

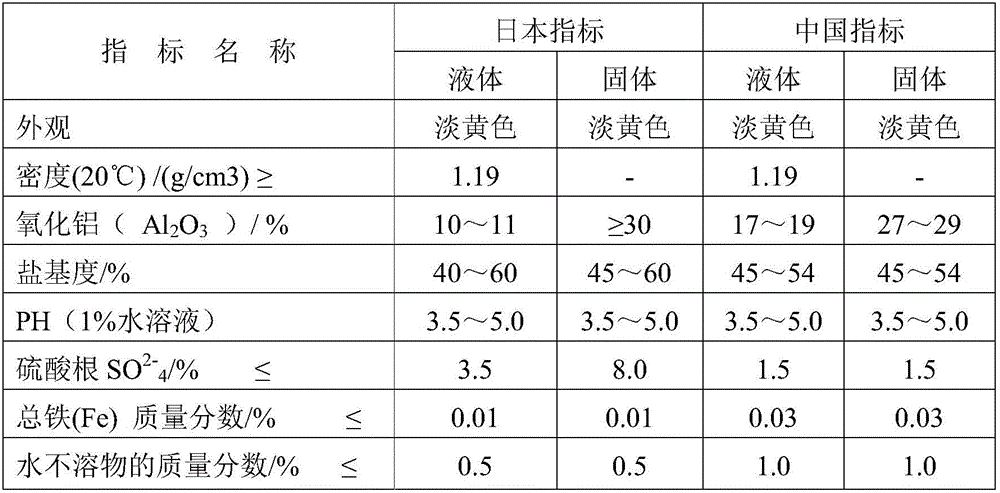

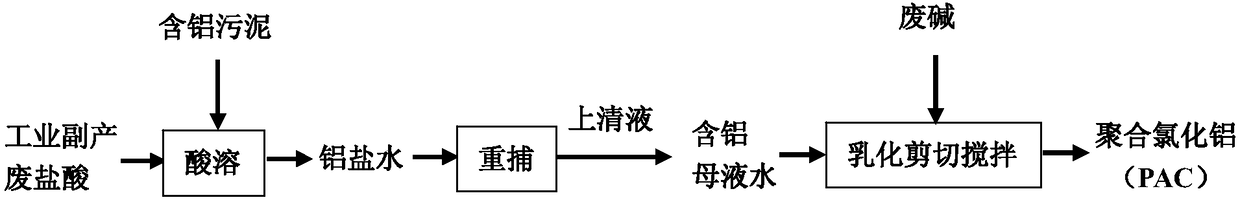

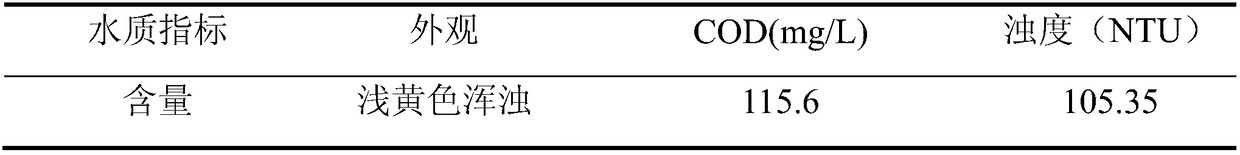

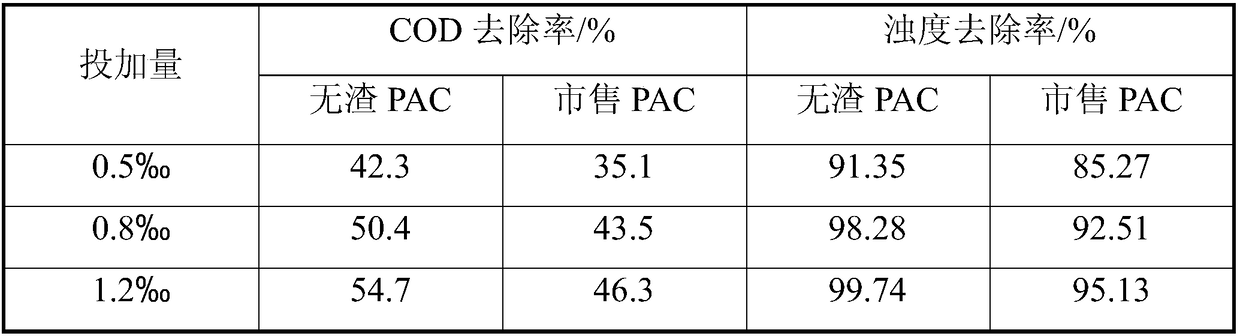

Method for preparing slag-free PAC by means of high-efficiency emulsification shear stirring technology

ActiveCN108455642AEasy to operateReasonable designAluminium chloridesWater/sewage treatment by flocculation/precipitationSlagSludge

The invention provides a method for preparing slag-free PAC by means of a high-efficiency emulsification shear stirring technology. The method comprises the steps of acid dissolution, recapturing andemulsification shear stirring. The method has the advantages that waste alkali is used for replacing traditional bauxite resources, dust pollution is avoided, no secondary hazardous waste is generated, and the quality of products is ensured; the PAC is quickly prepared by means of the novel high-efficiency emulsification shear mixing technology, the operation is simple, the processing capacity islarge, the production cycle is short, the yield is high, the energy consumption is low, the equipment investment cost is low, and the cost is low. Regeneration and comprehensive utilization of resources including aluminum-containing sludge, waste hydrochloric acid and waste alkali are achieved, waste is turned into treasure, sustainable development of upstream enterprises is ensured, the production cost of the enterprises is saved, and double benefits of economy and environmental protection are achieved. The prepared slag-free PAC is pure, clear, stable in quality, good in fluidity and dispersibility and capable of achieving higher basicity, and the decolorization and turbidity removal capabilities of the PAC are 5-10% times higher than those of general PACs sold on the market.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

Preparation method of high-stability and polymeric-form polyaluminum chloride

ActiveCN110745852AReduce flocculationImprove stabilityNature of treatment waterAluminium chloridesGel preparationAluminium chloride

The invention discloses a preparation method of high-stability and polymeric-form polyaluminum chloride. The gel preparation process of polyaluminum chloride is combined with the polymerization reaction of an organic monomer to make aluminum ions react with the organic monomer in order to wrap the aluminum ions and stabilize the point position, so PAC has a good stability, and the aluminum form isnot substantially changed within 2 years, thereby the validity period of the product is prolonged, the product can be stored for 2 years, the treatment effect is stable, and the problem of poor stability of an existing liquid PAC product is solved. The method has the advantages of simple preparation process, easiness in operation, wide sources of raw materials, and mild preparation conditions, and the product has the characteristics of high purity, high Alb content, short reaction time and good treatment effect, and has the advantages of low dosage, high COD and turbidity removal rate, high stability and low residual aluminum content when applied to the treatment process of coal chemical industry wastewater.

Owner:NANJING UNIV OF TECH

PAFC (polyamuminum ferric chloride) liquid product and preparation method thereof

ActiveCN106395917AShorten the timePrevent precipitationCobalt halidesWater/sewage treatment by flocculation/precipitationAluminium chlorideHigh concentration

The invention provides a PAFC (polyamuminum ferric chloride) liquid product and a preparation method thereof. According to the preparation method of the PAFC liquid product, during stirring, a sodium hydroxide solution is added to an aluminum chloride and ferric chloride mixed solution in a spray form, precipitate caused by excessive high local pH can be effectively avoided, the time required for preparation of the PAFC liquid product is greatly shortened, meanwhile, the PAFC liquid product with high concentration can be prepared from reaction raw materials with higher concentration, and a large amount of energy can be saved for the following drying procedure. The PAFC liquid product has higher concentration and higher basicity than those of conventional PAFC liquid products in the prior art and can meet higher use requirements as a liquid product, and a large amount of energy can be saved for the following drying procedure in production of solid products.

Owner:新疆澄润环保科技有限公司

Method for recycling copper by-product polyaluminum chloride from acidic CuC12 waste etching solution

InactiveCN106086460ARaise the basicityReduce pressure on environmental protectionCopper chloridesEtchingElectrolysis

The invention discloses a method for recycling copper by-product polyaluminum chloride from an acidic CuC12 waste etching solution. The method is characterized in that a material containing metal aluminum is directly added into the acidic CuC12 waste etching solution to be substituted for copper in the solution; or, free hydrochloric acid in the acidic CuC12 waste etching solution is heated and evaporated at first, then, a material containing metal aluminum is added to be substituted for copper in the solution, filtration is carried out, and copper powder or copper sponge and a cementation leaching solution are obtained. The obtained copper powder is washed, dried and sold. The obtained copper sponge is washed and electrolytically refined, and cathode copper is obtained; alkaline matter is added into the obtained cementation leaching solution; and evaporation and concentration are carried out after the pH value is adjusted, a polyaluminum chloride product is obtained, the copper and chlorine in the acidic CuC12 waste etching solution are sufficiently utilized, and zero emission in the copper separation and recovery technological process is achieved. The method has the advantages of being simple in technology, low in comprehensive recovery cost, good in economic benefit and the like.

Owner:CENT SOUTH UNIV

Purification decolouring method of poly aluminium chloride solution used for paper making sizing precipitant and its technology

InactiveCN1624240AGood removal effectFast decolorizationPulp bleachingAluminium chlorideAluminium chlorohydrate

This invention relates to a purification decoloration technique and process by ordinary aggregated alumina, the characters are: adding such as-reduced aluminum materials as aluminum crumbs to ordinary aggregated alumina solution, and heat it to a certain temperature. Through acid dissolution of alumina and the surface arrosion of metal aluminum, metal ion and organic impurities in oxidation reduction solution, the aim of purification and decoloration can be achieved, and its products can be used as precipitant in paper-making. The technique is simple, the decoloration speed is high, the efficiency is high, and it is easy to manipulate, the cost is low and can improve the qualities of aggregated alumina.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Methods and compositions related to improving properties of pharmacological agents targeting nervous system

InactiveUS8435940B2Improve blood-brain barrier permeabilityIncreased lipophilic characterBiocideNervous disorderNervous systemMedicine

Disclosed are compositions and methods related to improving pharmacological properties of bioactive compounds targeting nervous system.

Owner:UNIV OF UTAH RES FOUND

Recycling process of polymeric aluminum ferric chlorine sulfate filter residue

The invention discloses a recycling process of polymeric aluminum ferric chlorine sulfate filter residue; the process is as follows: adding water, hydrochloric acid and sulfuric acid into a first reaction kettle, adding the filter residue, stirring until the filter residue is completely dissolved; adding iron-containing trihydrate bauxite powder for reacting at 93 to 115 DEG C for 2-5h; controlling the basicity of the material liquid after the reaction to be 19% + / -7% by adjustment of weight parts of hydrochloric acid, sulfuric acid and the filter residue; separating the residue from the material liquid after the reaction, taking mother liquor, adding a proper amount of water, adding calcium aluminate powder; adjusting the material liquid density to be greater than or equal to 1.20g / ml, adding a synergist solution, reacting at 85-125 DEG C under normal pressure for 3-5h to obtain liquid polymeric aluminum ferric chlorine sulfate; collecting and recycling the produced filter residue for reusing in production system to continue participating into the reaction. The recycling process achieves reuse of the filter residue in the polymeric aluminum ferric chlorine sulfate production without addition of process equipment and other materials, greatly reduces the polymeric aluminum ferric chlorine sulfate production cost, reduces filter residue emissions, and is circular and economic.

Owner:蓝保(厦门)水处理科技有限公司

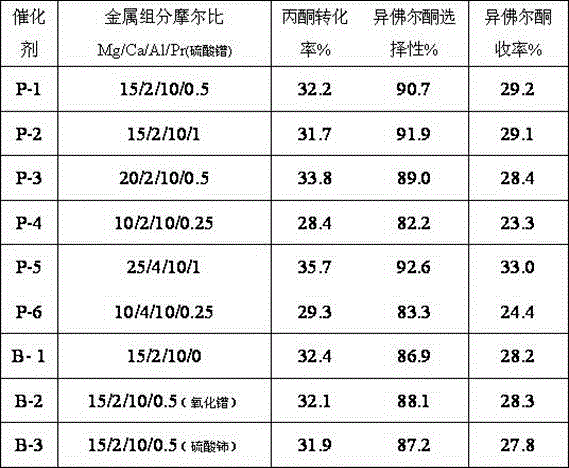

Catalyst of preparing isophorone by condensation of acetone and preparation method of catalyst

ActiveCN104549371ARaise the basicityAcid-base blendingPhysical/chemical process catalystsOrganic compound preparationIsophoroneAluminum composites

The invention discloses a catalyst of preparing isophorone by condensation of acetone and a preparation method of the catalyst. The catalyst comprises a magnesium-calcium-aluminum composite oxide and praseodymium sulfate, wherein mol ratios of all components in the terms of metallic elements are as follows: the mol ratio of Mg to Al is (1-3):1, the mol ratio of Mg to Ca is (5-20):1, and the mol ratio of Mg to Pr is (10-40):1. The preparation method comprises the following steps: preparing the magnesium-calcium-aluminum composite oxide according to a coprecipitation method, performing spray-soaking treatment on the magnesium-calcium-aluminum composite oxide by using a praseodymium sulfate solution, and drying and roasting to prepare a finished catalyst. According to the catalyst, when the selectivity of a target product isophorone is improved, the yield of the product isophorone is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

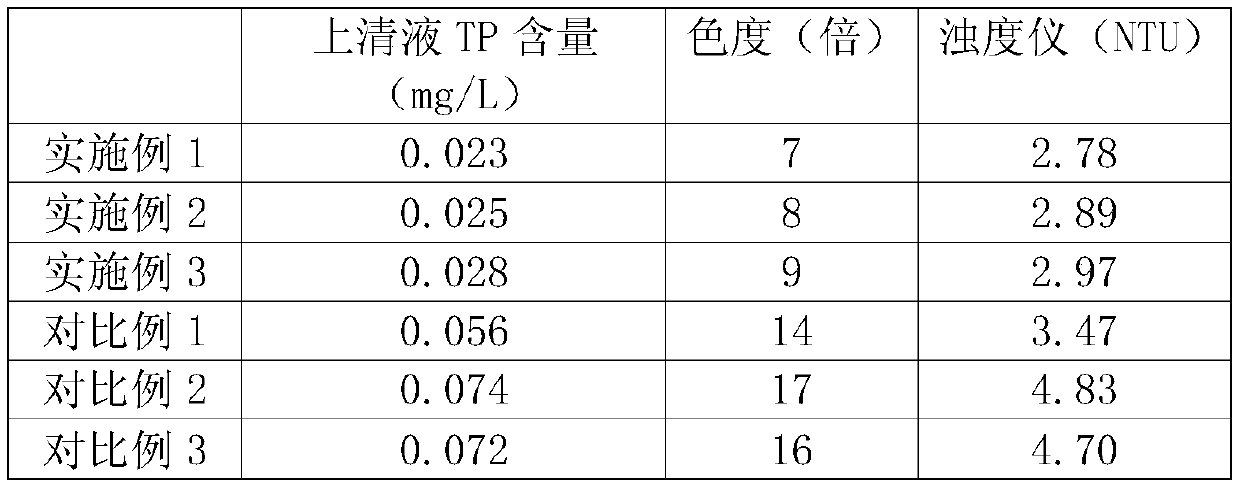

High-efficiency composite dephosphorization agent and preparation method thereof

The invention discloses a high-efficiency composite dephosphorization agent and a preparation method thereof and belongs to the technical field of water disposal. The method comprises the steps of adding poly-aluminum chloride and an additive into a ferric trichloride solution, uniformly stirring the mixture, and adopting liquid alkali for adjusting the pH value of the solution to be 1-2.5 to obtain the high-efficiency composite dephosphorization agent, wherein the content of iron element in the high-efficiency composite dephosphorization agent is 11 wt.%, the molar ratio of the iron element to aluminum element is (2-7):(8-3), and the molar ratio of the additive to the sum of the iron element and the aluminum element is 0.02-0.15. The provided method has the advantages of simple operationand low cost; the high-efficiency composite dephosphorization agent prepared by means of the method is high in stability and has a good dephosphorization effect when applied to sewage disposal, and the chromaticity of water is low.

Owner:宁波华昕环保科技有限公司

Catalyst for preparing isophorone by condensation of acetone and preparation method thereof

ActiveCN104549371BRaise the basicityAcid-base blendingPhysical/chemical process catalystsOrganic compound preparationIsophoroneSulfate

The invention discloses a catalyst of preparing isophorone by condensation of acetone and a preparation method of the catalyst. The catalyst comprises a magnesium-calcium-aluminum composite oxide and praseodymium sulfate, wherein mol ratios of all components in the terms of metallic elements are as follows: the mol ratio of Mg to Al is (1-3):1, the mol ratio of Mg to Ca is (5-20):1, and the mol ratio of Mg to Pr is (10-40):1. The preparation method comprises the following steps: preparing the magnesium-calcium-aluminum composite oxide according to a coprecipitation method, performing spray-soaking treatment on the magnesium-calcium-aluminum composite oxide by using a praseodymium sulfate solution, and drying and roasting to prepare a finished catalyst. According to the catalyst, when the selectivity of a target product isophorone is improved, the yield of the product isophorone is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

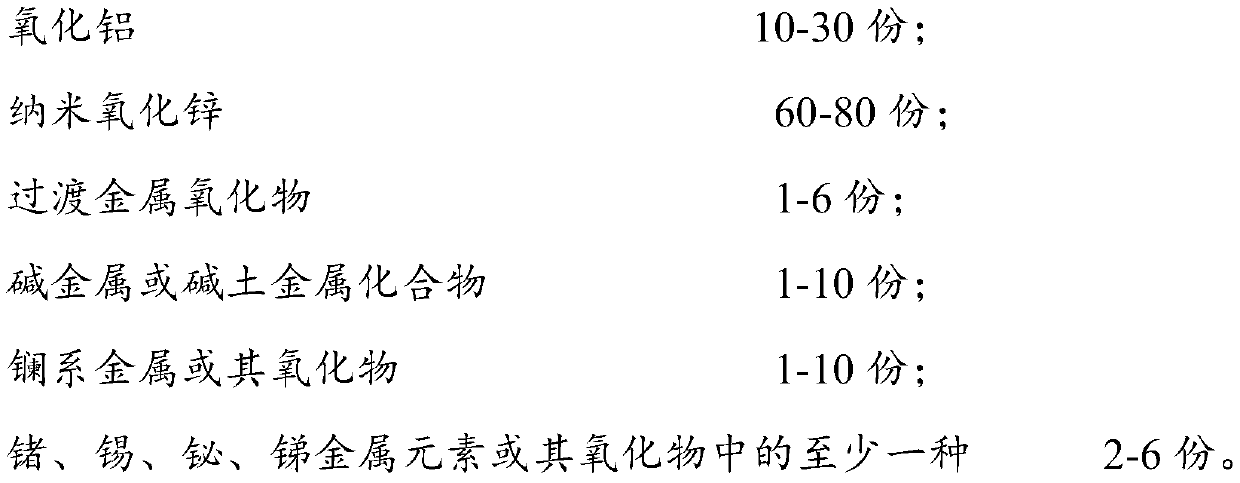

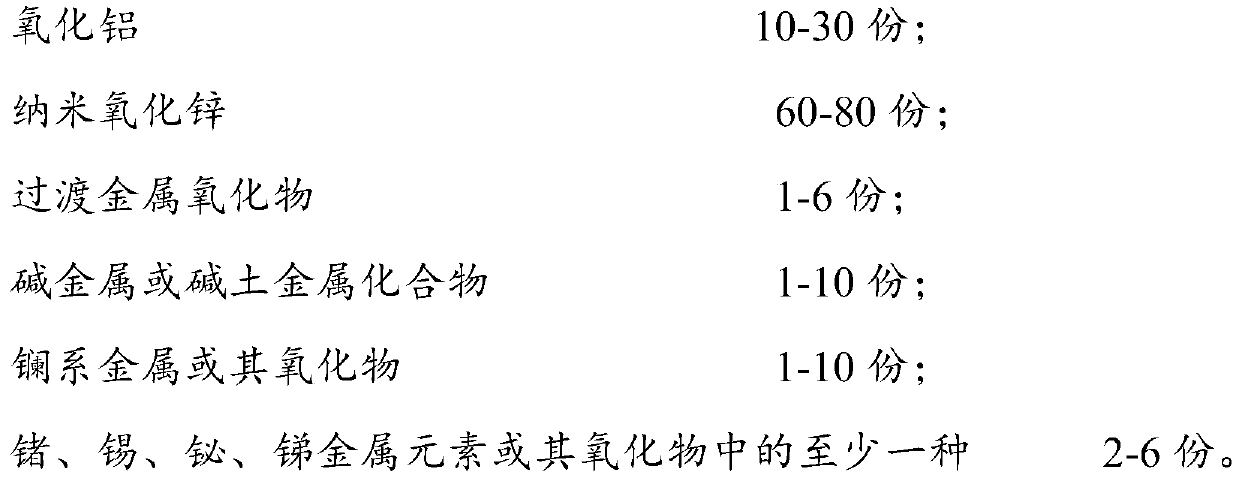

Deep purification fine desulfurizing agent and preparation method thereof

InactiveCN110564457AReduce the amount requiredImprove desulfurization effectGas treatmentDispersed particle separationAlkaline earth metalLanthanum

The invention belongs to the technical field of desulfurizing agent preparation, and particularly relates to a deep purification fine desulfurizing agent and a preparation method thereof, wherein thedesulfurizing agent comprises at least one selected from germanium, tin, bismuth and antimony or oxides thereof, aluminum oxide, nanometer zinc oxide, a transition metal oxide, an alkali metal or alkaline earth metal compound, and a lanthanum-based metal or an oxide thereof, and can remove organic sulfur and inorganic sulfur from synthesis gas at a temperature of 40 DEG C under a space velocity of16000 h<-1> to reduce the total amount of the organic sulfur and the inorganic sulfur in the synthesis gas to 3 ppb from 20 ppm, such that the desulfurizing agent has characteristics of good desulfurizing effect and high activity. According to the present invention, the method has characteristics of simple process, short preparation period, low energy consumption, and easy operation and implementin actual production; and the desulfurizing agent prepared by the method can remove organic sulfur and inorganic sulfur at the same time.

Owner:SHENYANG SANJUKAITE CATALYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com