Deep purification fine desulfurizing agent and preparation method thereof

A technology of deep purification and fine desulfurization agent, which is applied in chemical instruments and methods, separation methods, and combustible gas purification, etc., can solve the problems of high desulfurization temperature and difficulty in reducing sulfur content, and achieve high activity, high reaction rate, and sufficient reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

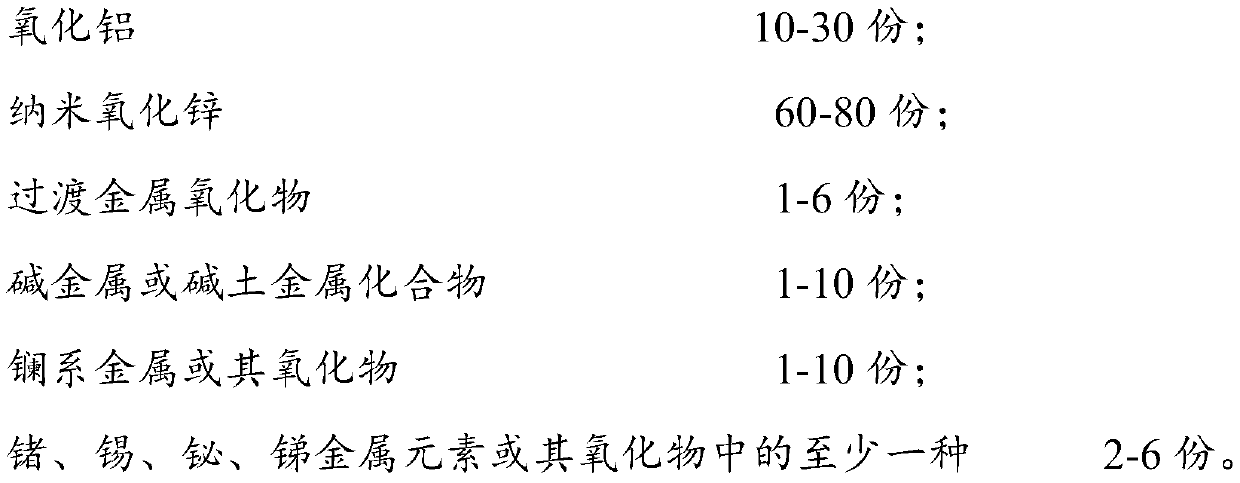

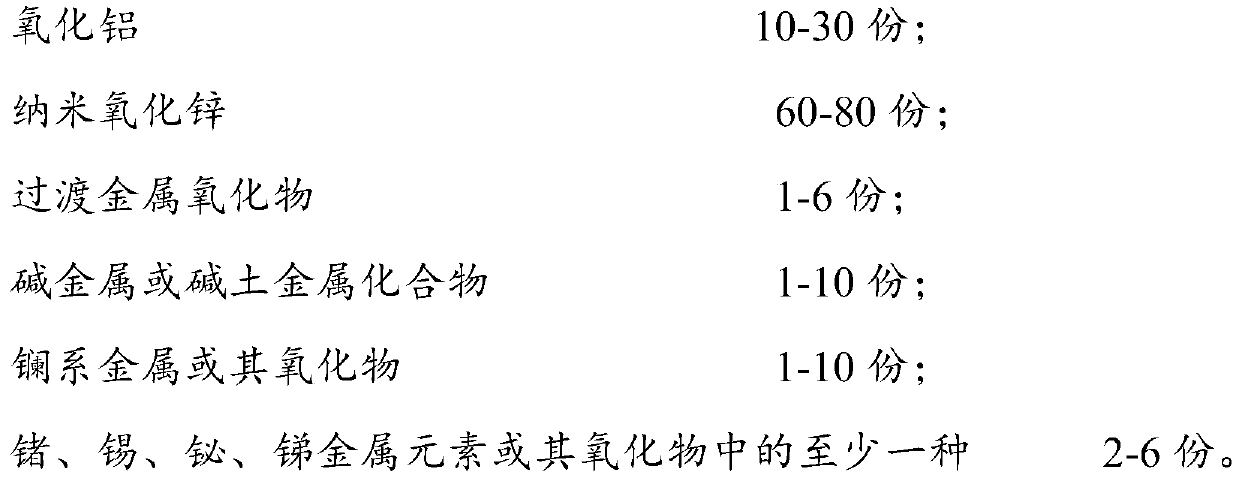

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a desulfurizer and a preparation method thereof, specifically comprising:

[0038] Weigh 500g zinc nitrate to prepare 1000ml solution, add 180g sodium carbonate as precipitant, adjust pH to 5, then add 165g cetyltrimethylammonium bromide at a rate of 3ml / min to fully react, and take out the product , washed with deionized water, then suction filtered, put the product after suction filtration in an oven at 110° C. for 2 hours, and grind after cooling to prepare 7nm nanometer zinc oxide for future use;

[0039] Weigh 60g of nanometer zinc oxide, 20g of aluminum oxide powder, 10g of sodium bicarbonate, 5g of manganese oxide, 5g of lanthanum and 6g of bismuth oxide, add 35g of silica sol after kneading for 45 minutes, and mix and grind the above materials for 30 minutes until a paste is formed, then Extrude into Ф4 strips, dry at 110°C for 2 hours, and then bake at 300°C for 2 hours to obtain the desulfurizer.

[0040] The physical properties of th...

Embodiment 2

[0043] This embodiment provides a desulfurizer and a preparation method thereof, specifically comprising:

[0044] Take by weighing 500g zinc acetate and be mixed with 1000ml solution, add 230g sodium bicarbonate, as precipitating agent, adjust pH to 3, then add 238g linear alkylbenzene sulfonate full reaction with the drop rate rate of 5ml / min, take out product, Wash with deionized water, then suction filter, put the filtered product in an oven at 110°C for 2 hours, and grind it after cooling to prepare 8nm nanometer zinc oxide for use;

[0045] Weigh 60g of nano-zinc oxide, 20g of alumina powder, 4g of sodium bicarbonate, 6g of manganese oxide, 10g of lanthanum and 2g of tin, knead for 45 minutes, add 35g of silica sol, and mix and grind the above materials for 30 minutes until a paste is formed, then Extrude into Ф4 strips, dry at 110°C for 2 hours, and then bake at 300°C for 2 hours to obtain the desulfurizer.

[0046] The physical properties of the above-mentioned fine d...

Embodiment 3

[0048] This embodiment provides a desulfurizer and a preparation method thereof, specifically comprising:

[0049] Weigh 500g of zinc sulfate to prepare 1000ml solution, add 330g of sodium carbonate as a precipitant, adjust the pH to 7, then add 236g of sodium lauryl sulfate at a rate of 4ml / min for a full reaction, take out the product, and use a deionized Washing with water, and then suction filtration, put the product after suction filtration in an oven at 110° C. to dry for 2 hours, and grind after cooling to prepare 7nm nanometer zinc oxide, which is ready for use.

[0050] Weigh 60g of nanometer zinc oxide, 20g of aluminum oxide powder, 10g of sodium bicarbonate, 6g of nickel oxide, 4g of lanthanum and 2g of bismuth oxide, add 35g of silica sol after kneading for 45 minutes, and mix and grind the above materials for 30 minutes until a paste is formed, then Extrude into Ф4 strips, dry at 110°C for 2 hours, and then bake at 300°C for 2 hours to obtain the desulfurizer.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com