Method for preparing mullite and co-producing polyaluminum chloride by using high-alumina fly ash

A technology of polyaluminum chloride and high-aluminum fly ash, which is applied in the directions of aluminum chloride, chemical instruments and methods, and aluminum halide, can solve the problems of low quality of mullite products and high impurity content of sodium, potassium, calcium, and iron. Achieve zero emissions, increase bulk density, and good environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

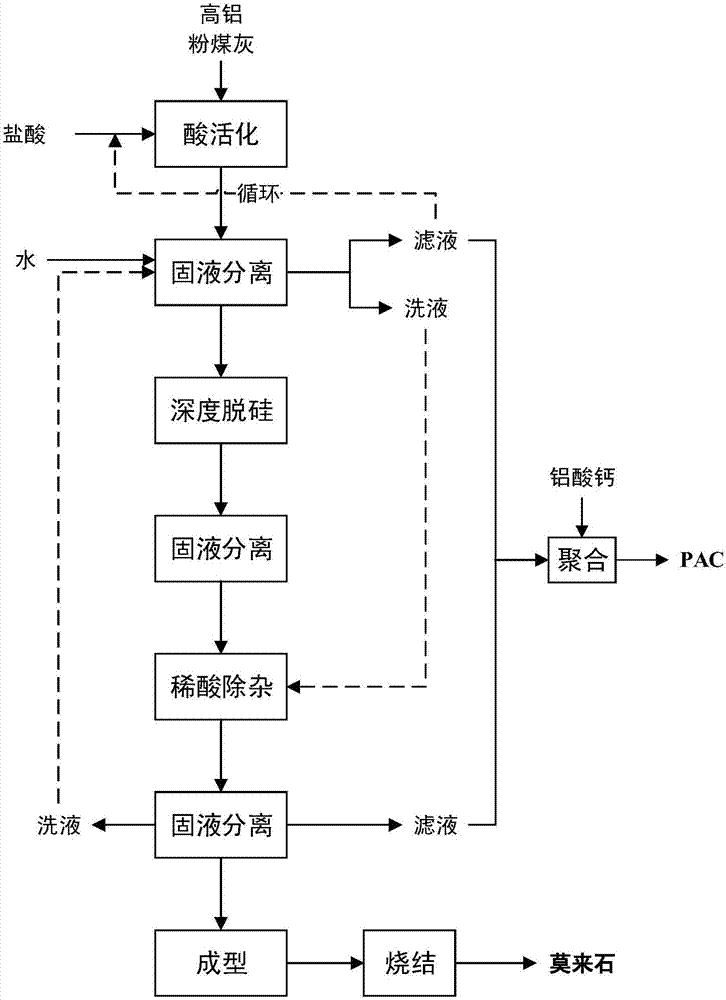

Image

Examples

Embodiment 1

[0079] A method for preparing mullite co-production polyaluminium chloride by utilizing high-alumina fly ash, comprising the steps of:

[0080] The high-aluminum fly ash is treated according to the process of acid activation-desilication-dilute acid solution washing, the concentration of hydrochloric acid in the acid activation section is 250g / L, the liquid-solid ratio is 5mL / g, the reaction temperature is 85°C, and the reaction time is 2h; The concentration of sodium hydroxide in the silicon section is 200g / L, the liquid-solid ratio is 6mL / g, the reaction time is 70min, and the reaction temperature is 90°C; the dilute acid solution washing section uses the first washing liquid as the reaction solution, the reaction temperature is 60°C, and the reaction time is 1h; The first liquid and the third washing liquid are used to prepare polyaluminum chloride, the liquid-solid ratio of the polymerization reaction is 12mL / g, the temperature of the polymerization reaction is 80°C, the ti...

Embodiment 2

[0083] A method for preparing mullite co-production polyaluminium chloride by utilizing high-alumina fly ash, comprising the steps of:

[0084] The high-aluminum fly ash is treated according to the process of acid activation-desilication-dilute acid solution washing, the concentration of hydrochloric acid in the acid activation section is 255g / L, the liquid-solid ratio is 4mL / g, the reaction temperature is 90°C, and the reaction time is 1h; The concentration of sodium hydroxide in the silicon section is 220g / L, the liquid-solid ratio is 5mL / g, the reaction time is 70min, and the reaction temperature is 95°C; the dilute acid solution washing section uses the first washing liquid as the reaction solution, the reaction temperature is 60°C, and the reaction time is 1h; The first liquid and the third washing liquid are used to prepare polyaluminium chloride, the liquid-solid ratio of the polymerization reaction is 11mL / g, the temperature of the polymerization reaction is 80°C, the t...

Embodiment 3

[0087] A method for preparing mullite co-production polyaluminium chloride by utilizing high-alumina fly ash, comprising the steps of:

[0088] The high-alumina fly ash is treated according to the process of acid activation-desilication-dilute acid solution washing, the concentration of hydrochloric acid in the acid activation section is 265g / L, the liquid-solid ratio is 6mL / g, the reaction temperature is 80°C, and the reaction time is 1h; The concentration of sodium hydroxide in the silicon section is 230g / L, the liquid-solid ratio is 7mL / g, the reaction time is 60min, and the reaction temperature is 92°C; the dilute acid solution washing section uses the first washing liquid as the reaction solution, the reaction temperature is 70°C, and the reaction time is 40min; The first liquid and the third washing liquid are used to prepare polyaluminum chloride, the liquid-solid ratio of the polymerization reaction is 10mL / g, the temperature of the polymerization reaction is 90°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com