Preparation method of iron-cobalt alloy/nitrogen co-doped carbon aerogel electrode material

A technology of iron-cobalt alloy and carbon aerogel, which is applied in battery electrodes, fuel cell half-cells, secondary battery-type half-cells, circuits, etc., can solve the problem of not effectively reusing, increasing marine pollution, and having no Utilize and other issues to achieve excellent catalytic performance, improve catalytic performance, and increase the effect of basic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

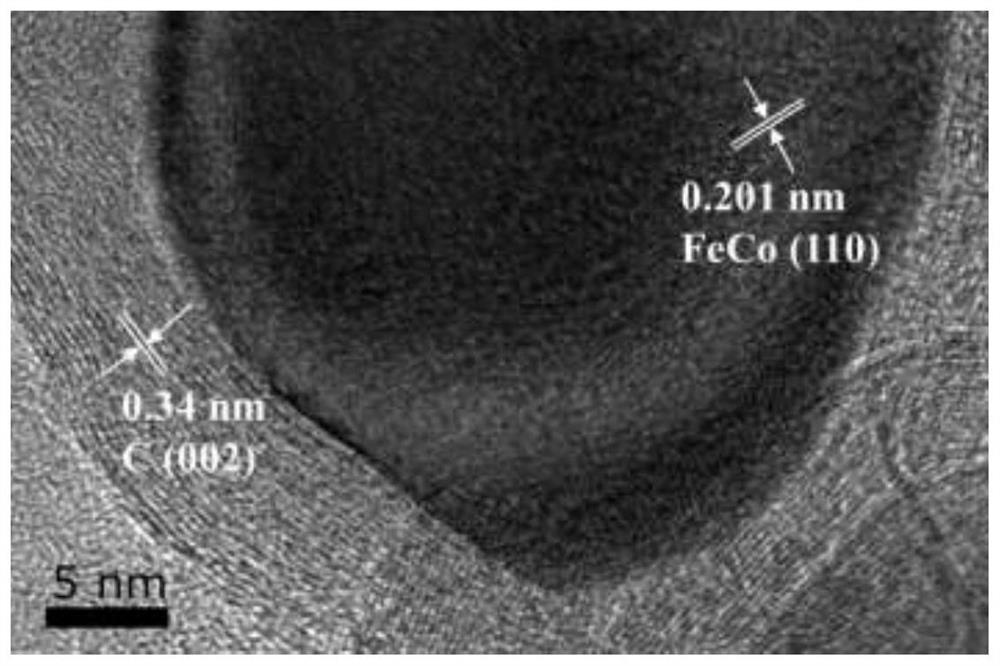

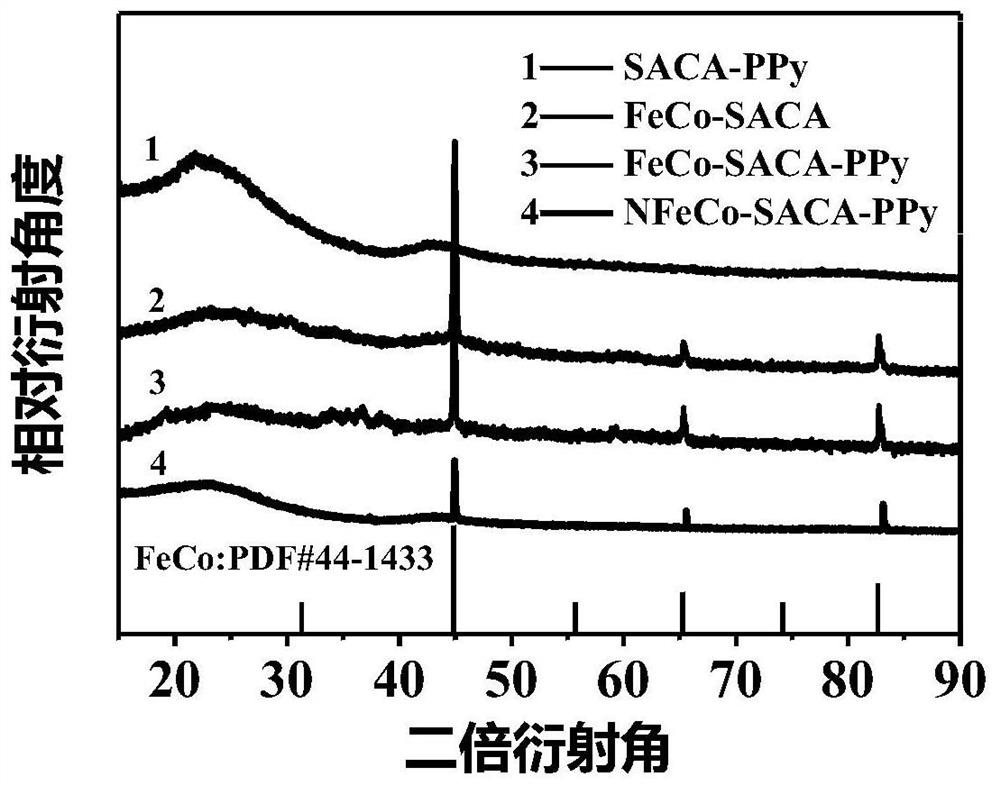

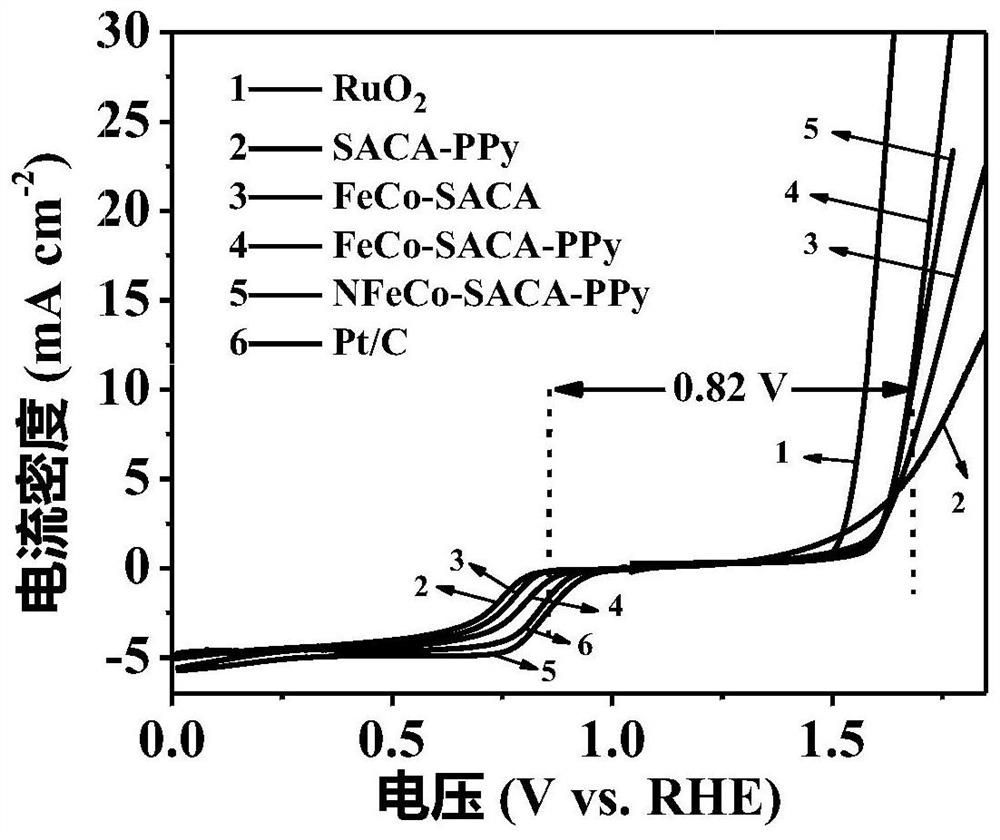

[0035] Sodium alginate was selected as the precursor, polypyrrole and melamine were used as the nitrogen source, cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) is cobalt salt, ferric chloride hexahydrate (FeCl 3 ·6H 2 O) is iron salt, prepares the iron-cobalt alloy / nitrogen co-doped carbon airgel electrode material based on sodium alginate:

[0036] Firstly, 1 g of sodium alginate (SA) and 0.1 g of polypyrrole (PPy) were weighed and placed in beaker A, and 50 mL of deionized water was added to dissolve to form a first solution. Weigh 1.25g CoCl 2 ·6H 2 O, 1.25g FeCl 3 ·6H 2 O was placed in beaker B and 50mL of water was added to ultrasonically dissolve to form a second solution, in which Fe 3+ and Co 2+ The molar ratio is about 1:1. Then the mixed solution in beaker A was dripped into B with a syringe, and after standing at room temperature (20° C.) for 1 h, it was washed with deionized water and freeze-dried to obtain a yellow-green airgel. The freeze-dried product wa...

Embodiment 2

[0042] Embodiment 2 (comparative example)

[0043] The difference from Example 1 is that the material is not re-impregnated with nitrogen-doped carbonization after freeze-drying, high-temperature calcination and pickling, and the generated material is carbon aerogel doped with iron-cobalt alloy based on sodium alginate. Labeled as FeCo-SACA-PPy.

Embodiment 3

[0044] Embodiment 3 (comparative example)

[0045] The difference from Example 1 is that no polypyrrole was added to the material when the first solution was prepared, and there was no impregnation and nitrogen doping and re-carbonization process afterwards, and the prepared material was marked as FeCo-SACA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com