A kind of preparation method of iron-cobalt alloy/nitrogen co-doped carbon aerogel electrocatalytic material

An electrocatalytic material, iron-cobalt alloy technology, applied in the direction of fuel cell-type half-cell and secondary battery-type half-cell, circuits, electrical components, etc. Utilize and other problems to achieve excellent catalytic performance, improve catalytic performance, and increase the effect of basic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

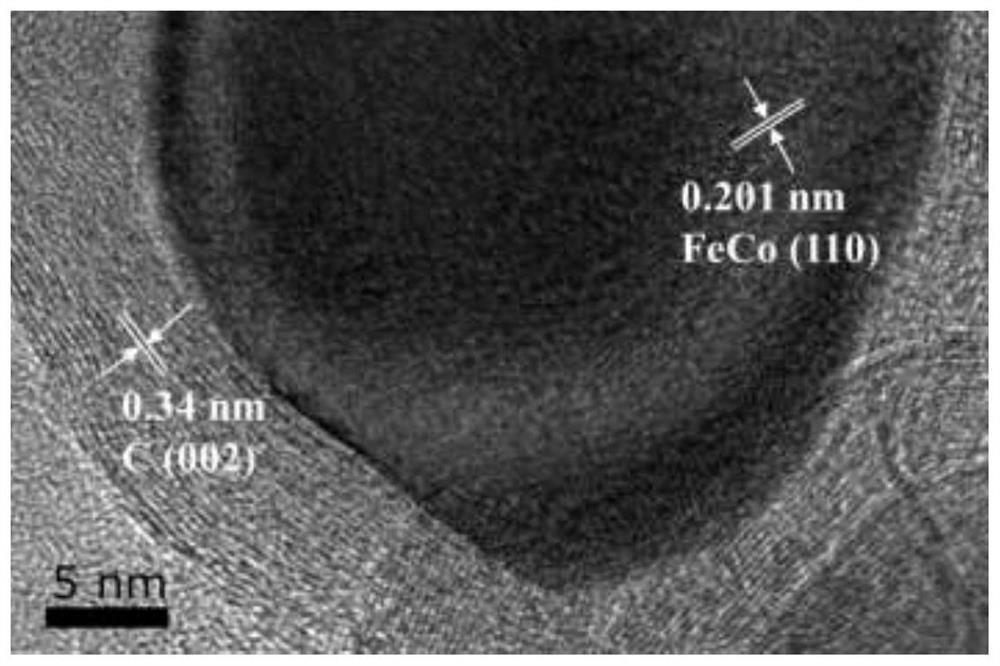

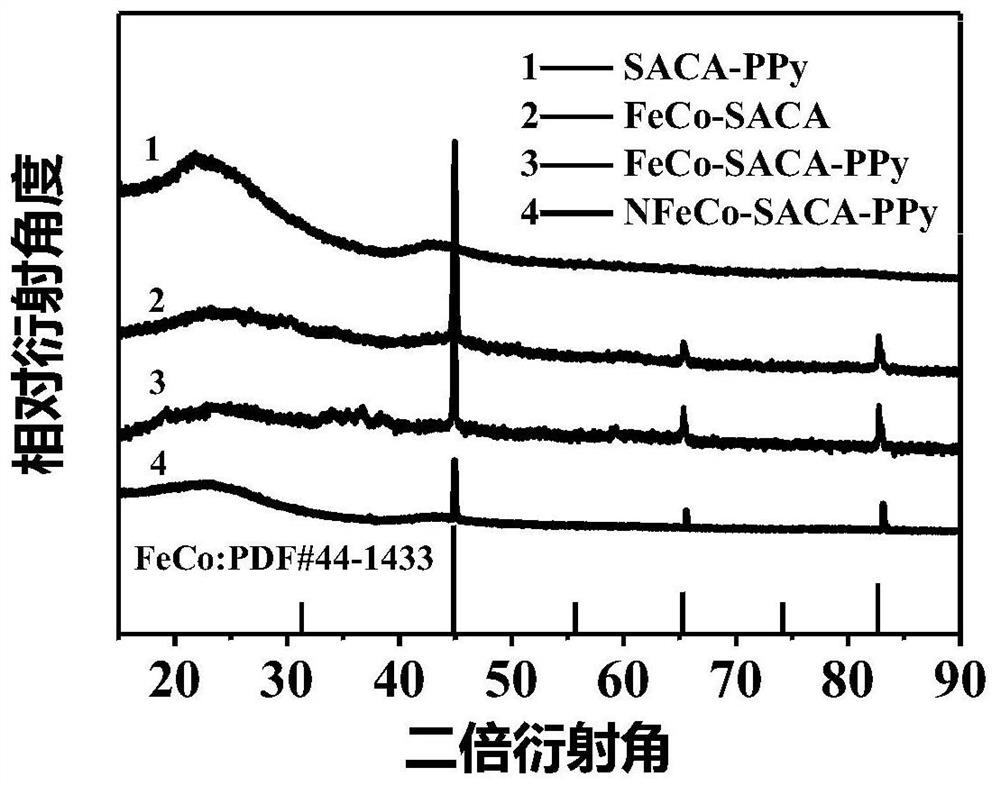

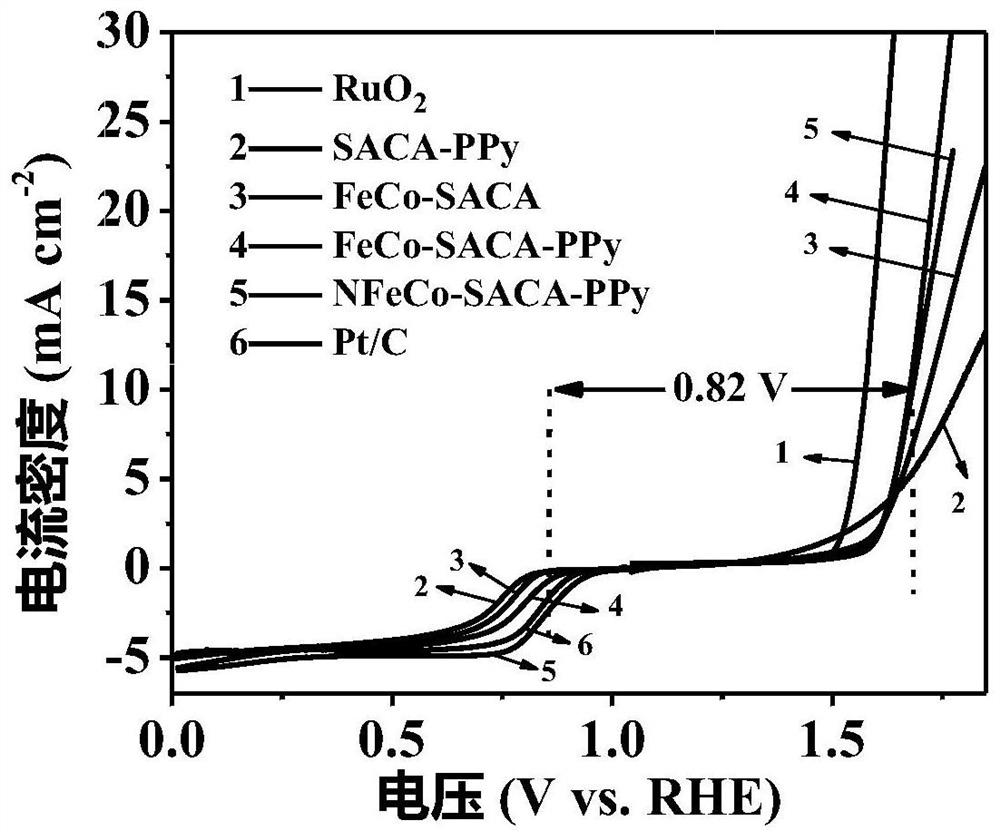

Image

Examples

Embodiment 1

[0035] Select sodium alginate as the precursor, polypyrrole and melamine as nitrogen sources, cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) is cobalt salt, ferric chloride hexahydrate (FeCl 3 ·6H 2 O) is an iron salt to prepare an iron-cobalt alloy / nitrogen co-doped carbon aerogel electrode material based on sodium alginate:

[0036] First, weigh 1 g of sodium alginate (SA) and 0.1 g of polypyrrole (PPy) into beaker A and add 50 mL of deionized water to dissolve to form the first solution. Weigh 1.25 g CoCl 2 ·6H 2 O, 1.25 g FeCl 3 ·6H 2 O is placed in beaker B and 50 mL of water is added to dissolve it ultrasonically to form a second solution, in which Fe 3+ and Co 2+The molar ratio is about 1:1. Then, the mixed solution in beaker A was dropped into B with a syringe, placed at room temperature (20°C) for 1 h, washed with deionized water, and freeze-dried to obtain a yellow-green aerogel. The freeze-dried product was calcined at 256 °C for 1 h at a heating rate of 2 °...

Embodiment 2

[0042] Example 2 (comparative example)

[0043] The difference from Example 1 is that the material is not impregnated with nitrogen and carbonized again after freeze-drying, high-temperature calcination and pickling, and the resulting material is an iron-cobalt alloy-doped carbon aerogel based on sodium alginate. Labeled as FeCo-SACA-PPy.

Embodiment 3

[0044] Example 3 (comparative example)

[0045] The difference from Example 1 is that no polypyrrole was added when the material was prepared in the first solution, and there was no process of impregnation and nitrogen-doping and recarbonization afterward. The prepared material was marked as FeCo-SACA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com