Patents

Literature

90results about How to "High value-added products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

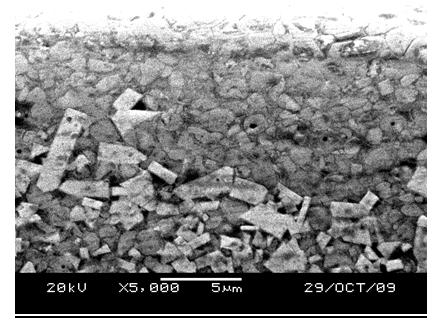

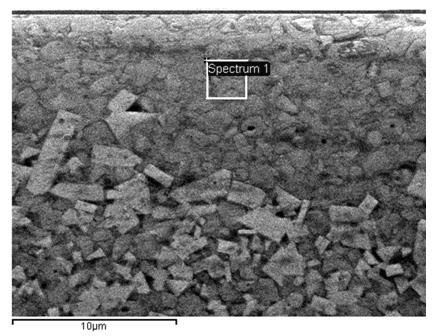

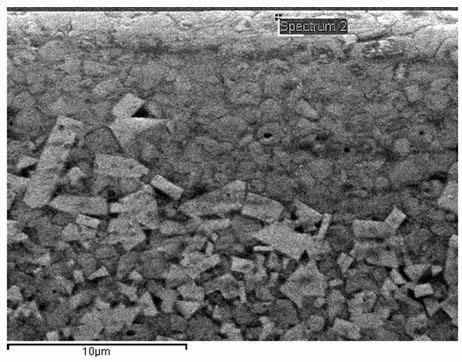

Functionally gradient hard alloy with cubic phase-rich surface and preparation method thereof

InactiveCN102134660AHigh value-added productsEasy to realize technology transformationSolid state diffusion coatingGradient materialAlloy

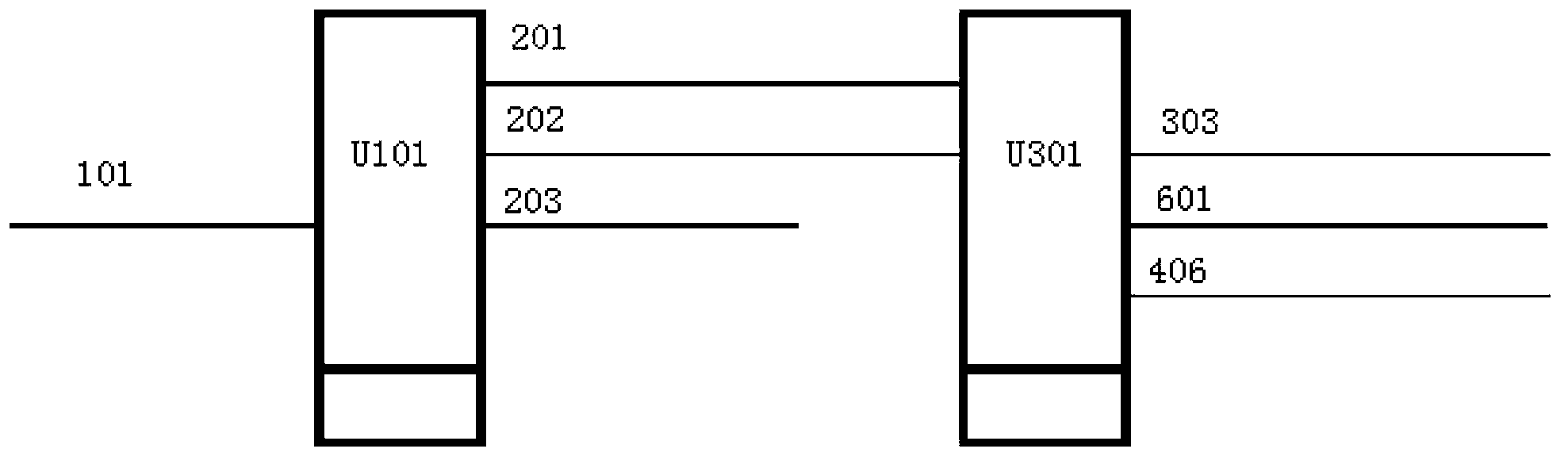

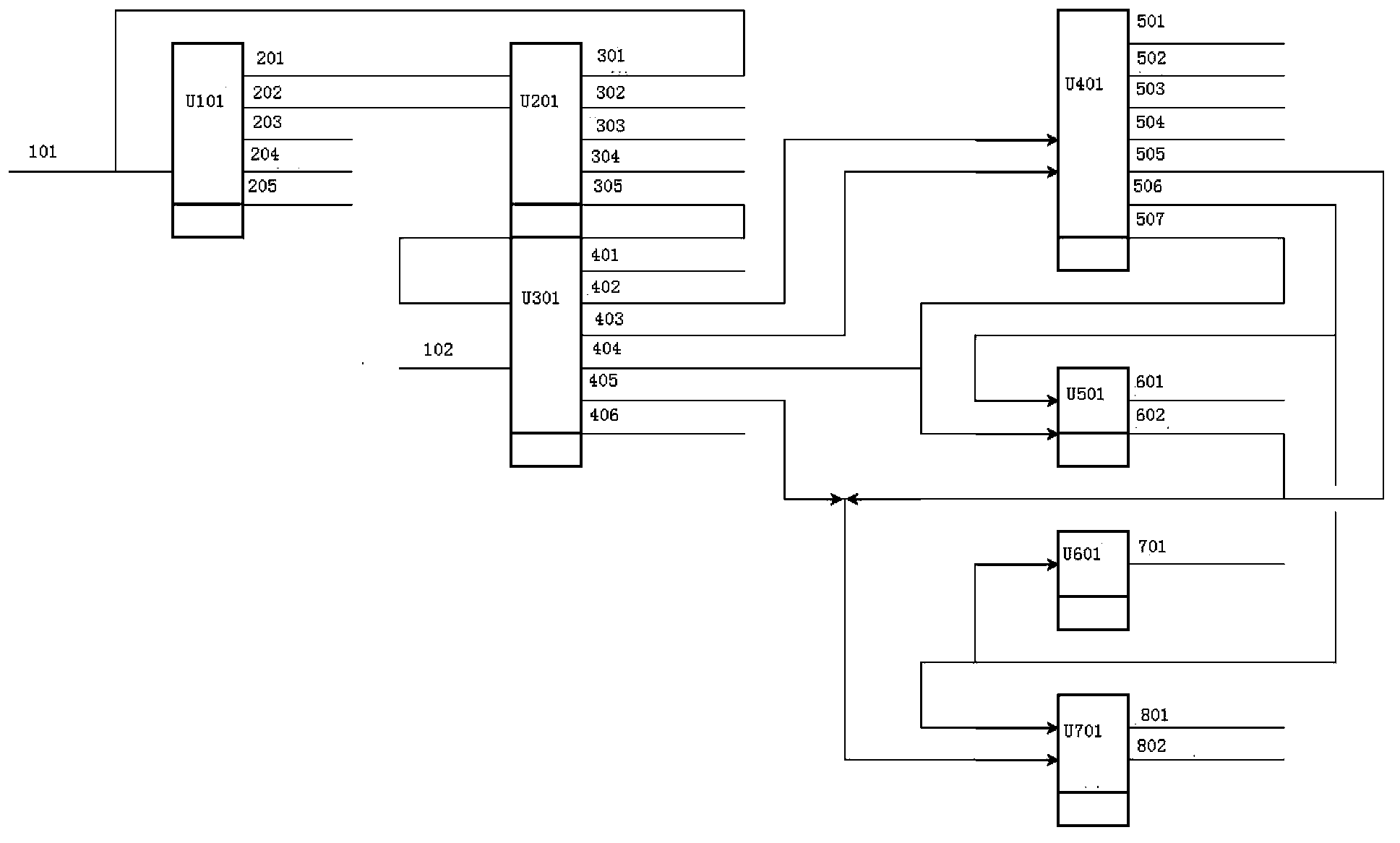

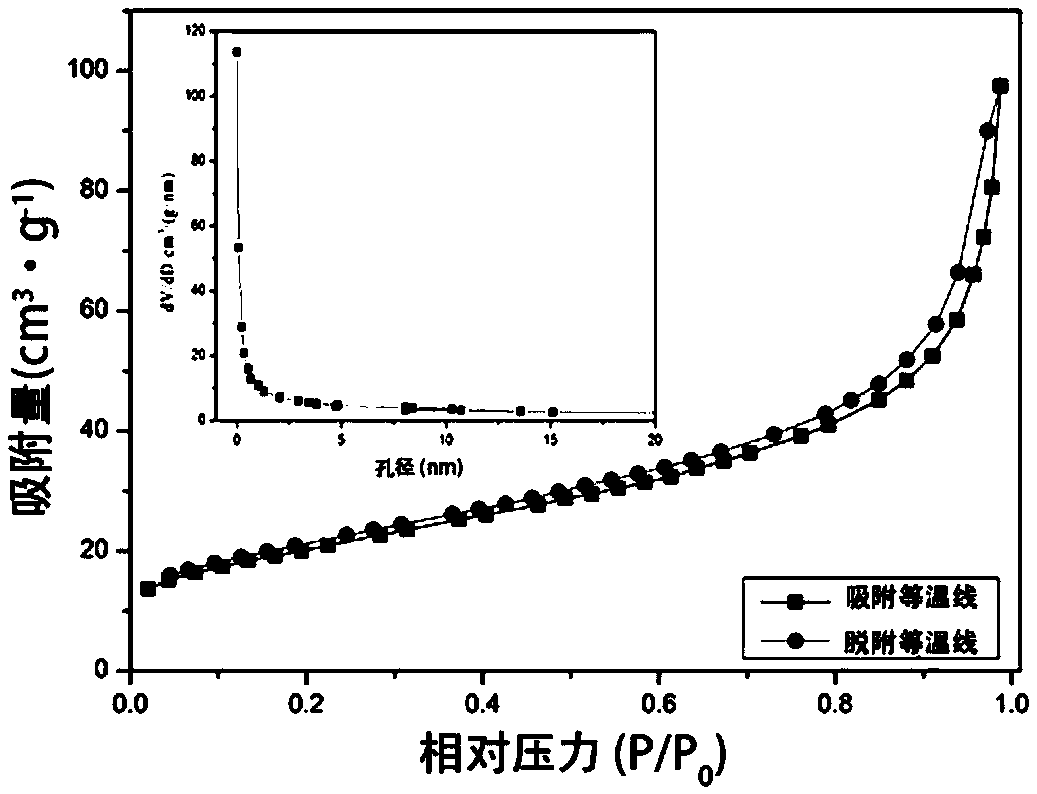

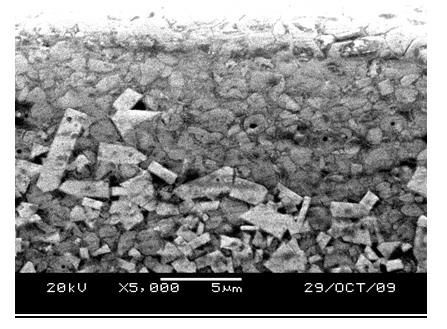

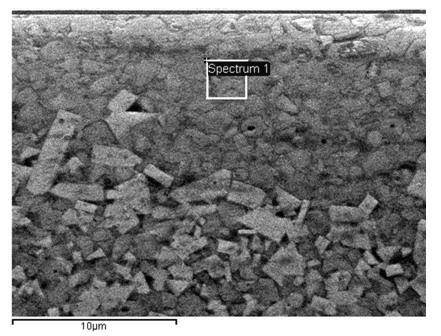

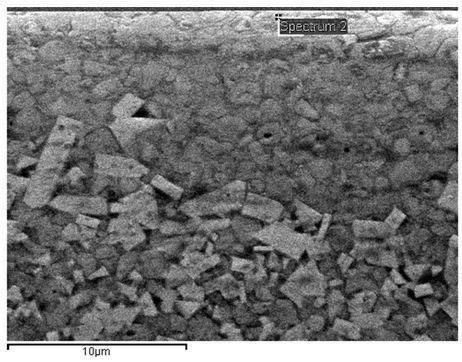

The invention discloses a functionally gradient hard alloy with a cubic phase-rich surface and a preparation method thereof, and belongs to the technical field of preparation of gradient materials through surface nitriding treatment. A gradient layer of the hard alloy comprises a surface layer rich in cubic phases, and a transition layer rich in binding phases under the surface layer; and the wear resistance and toughness of the alloy can be improved simultaneously, and the alloy can be used for machining metals. In the preparation method, the functionally gradient hard alloy is prepared by a nitriding and sintering process; and by controlling the sintering temperature, sintering time and a nitrogen pressure parameter, the components and thickness of the gradient layer of the alloy are controlled. The invention has the advantages that: the conventional equipment and process are not changed greatly, and the functionally gradient hard alloy can be produced; and the invention is suitable for industrial production.

Owner:CHONGQING UNIV OF ARTS & SCI +1

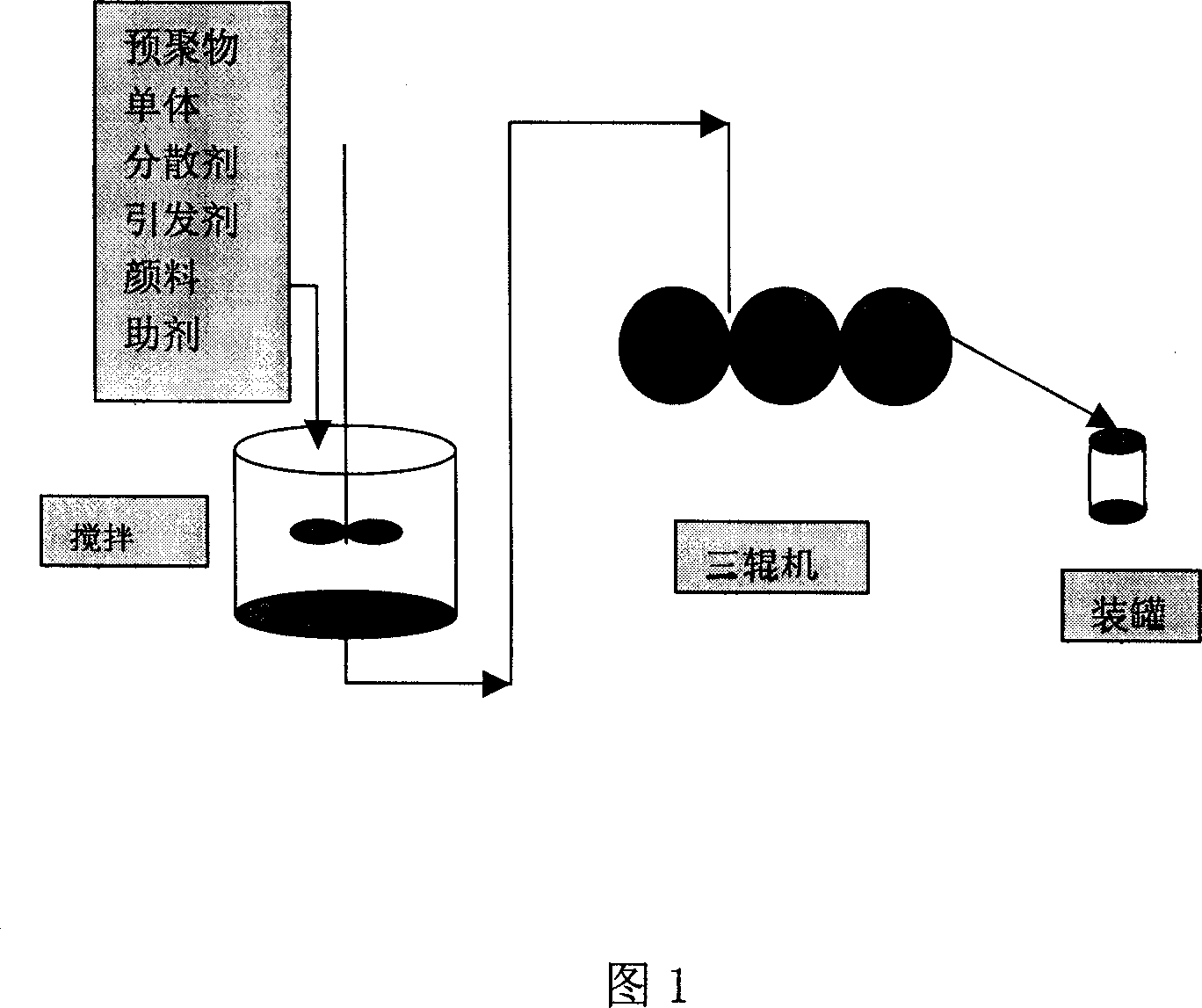

Environmental protection type tin printing ink solidified by ultraviolet light

This invention discloses environmentally friendly UV-curing tin plate ink, which comprises: acrylic acid prepolymer 50-70 wt.%, acrylic acid monomer 10-15 wt.%, initiator 5-10 wt.%, pigment 10-25 wt.%, dispersant and other additives 5-10 wt.%. The UV-curing tin plate ink is a color printing ink used on metal and cured by UV. The UV-curing tin plate ink has such advantages as low energy consumption, rapid curing, no VOC discharge, high efficiency, high safety and no pollution.

Owner:FOSHAN ROCKLINK CHEM

Method of recovering light hydrocarbon from byproduct gas of Fischer-Tropsch synthesis

ActiveCN103626898ASimple compositionHigh yieldLiquid hydrocarbon mixture productionPolyolefinPolymer science

The invention discloses a method of recovering light hydrocarbon from byproduct gas of Fischer-Tropsch synthesis. The method includes exhaust gas treatment, light hydrocarbon recovery, olefin conversion and polyolefin synthesis. The exhaust gas treatment includes decarburization and crude separation of a C1 stream and a C2 stream. The light hydrocarbon recovery includes separating the C2 stream, cracking gas and a portion of mixed C4 to obtain a stream comprising ethane, ethylene, propane, propylene, the mixed C4 and light naphtha. The olefin conversion includes reacting C4 olefins with the ethylene to produce the propylene. The polyolefin synthesis includes subjecting the obtained ethylene and the obtained propylene to polymerization to obtain polyethylene and polypropylene. The method is capable of increasing the yield of effective products of Fischer-Tropsch synthetic products, increasing the product kinds, improving the added valve of the products and increasing benefit.

Owner:CHINA PETROCHEMICAL CORP +1

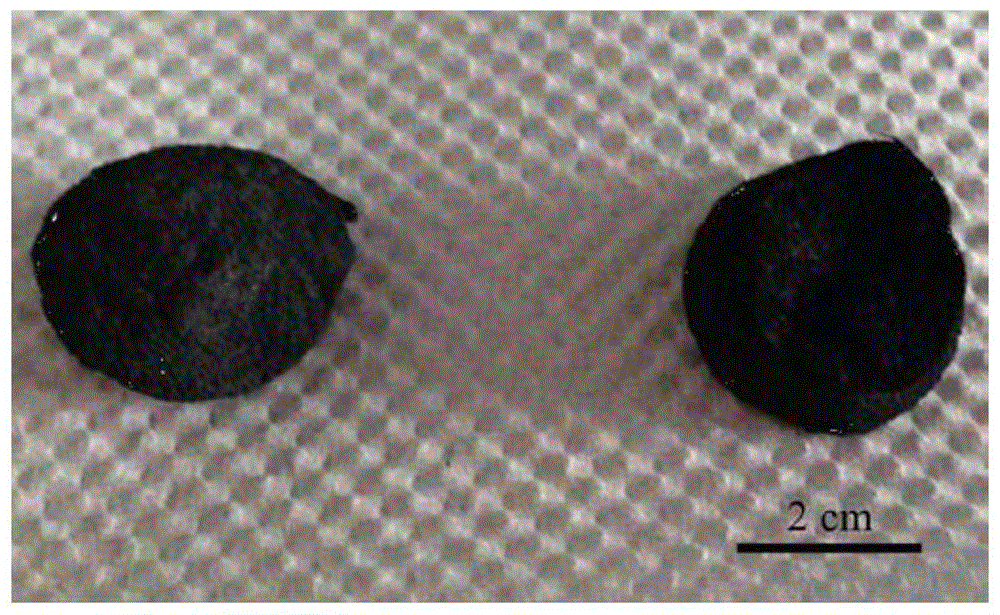

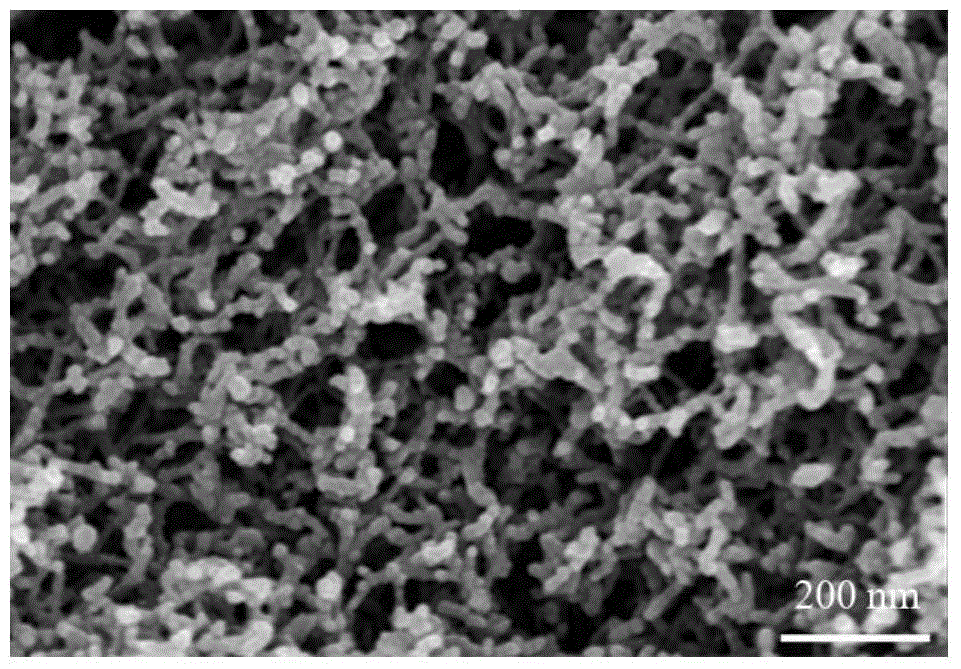

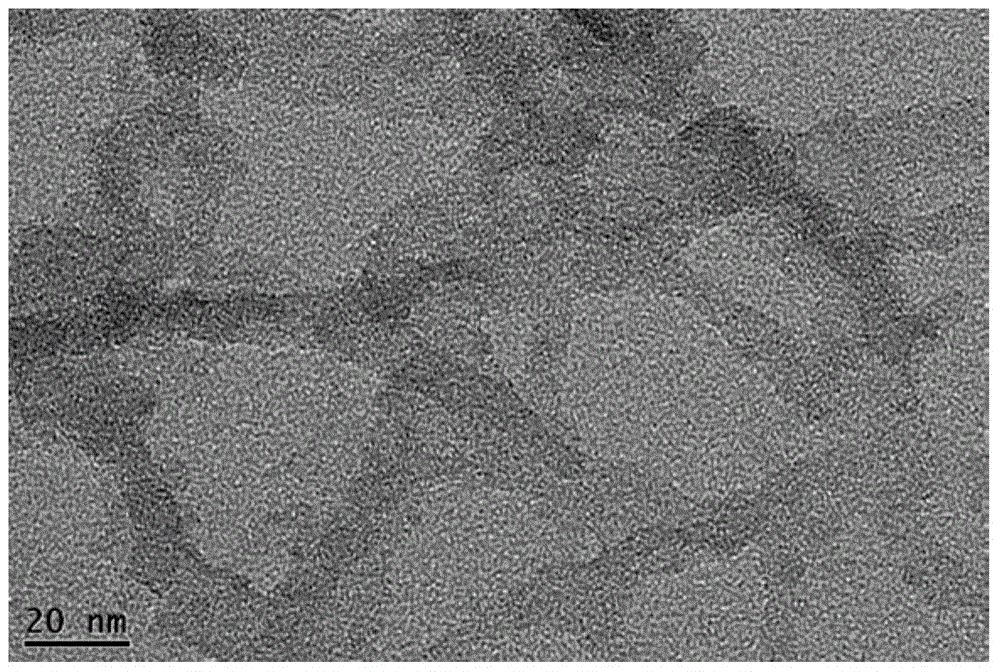

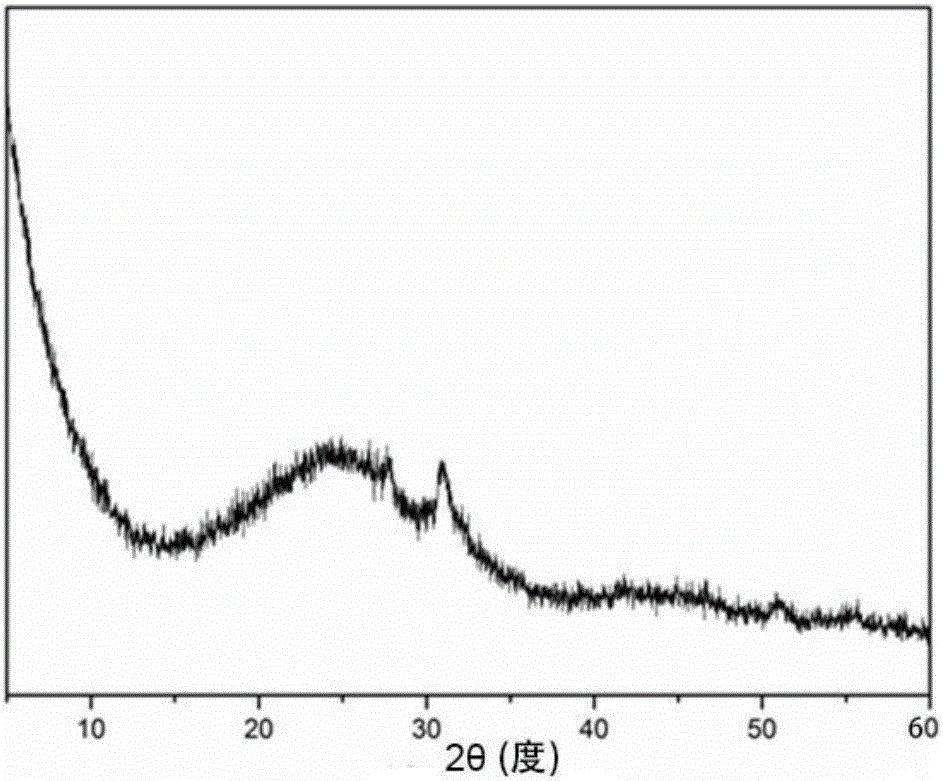

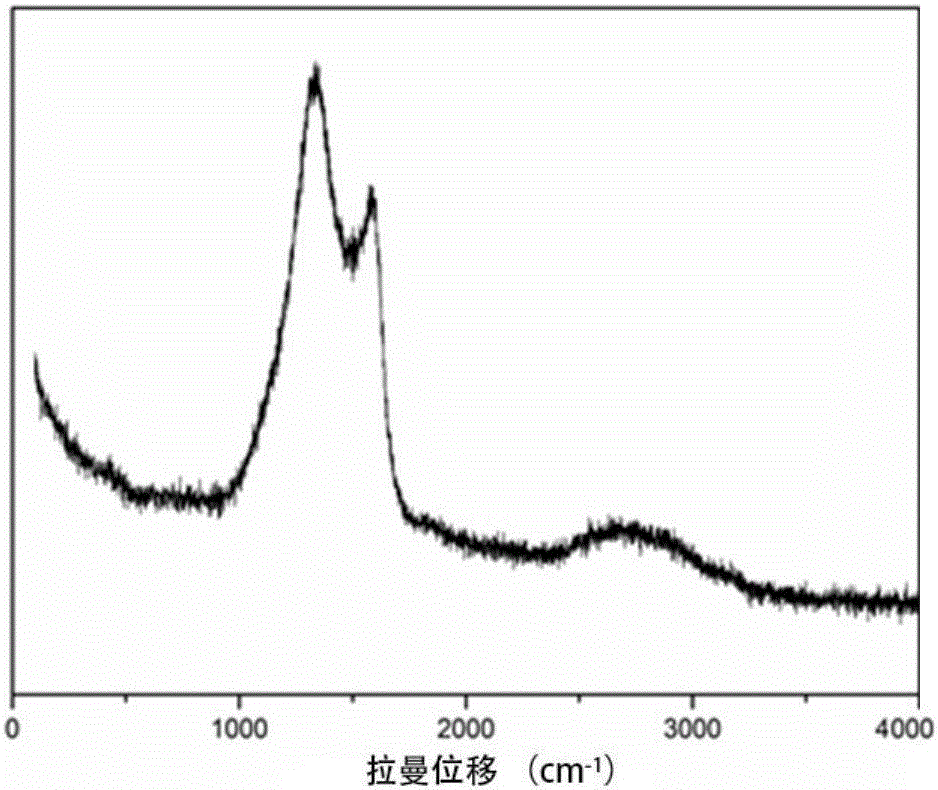

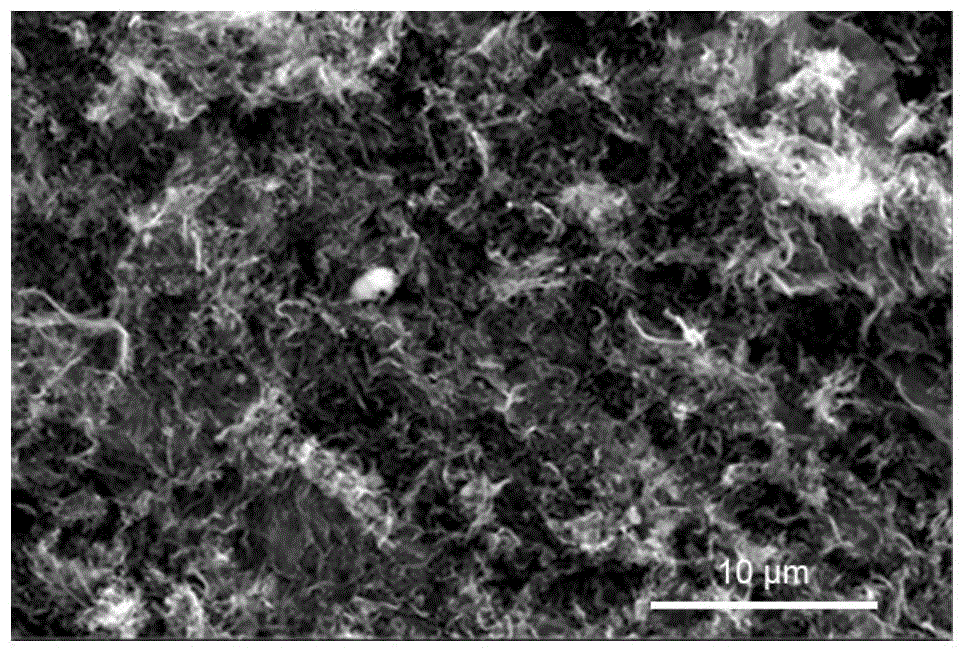

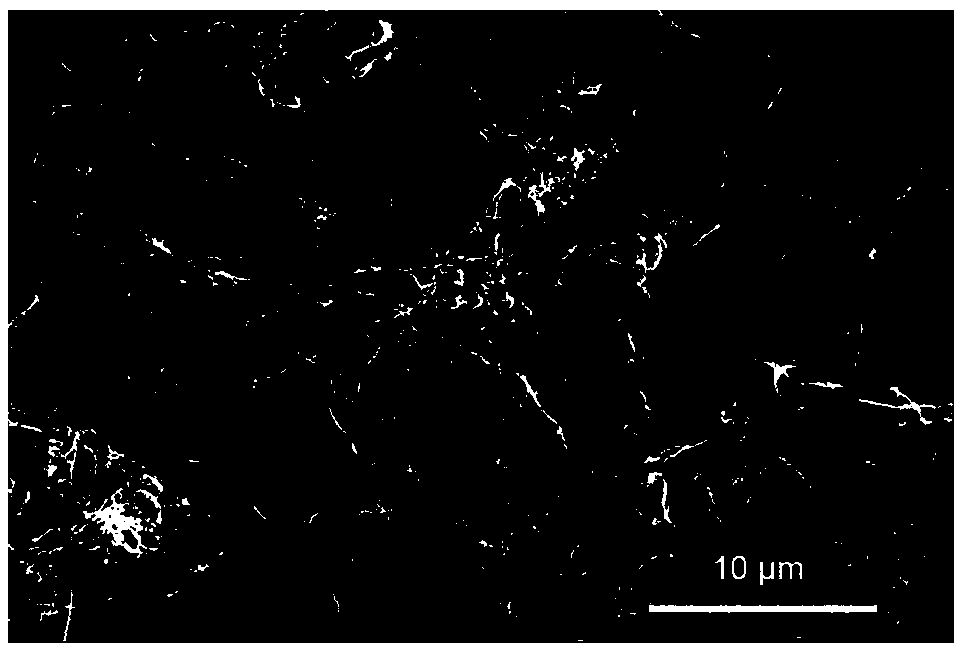

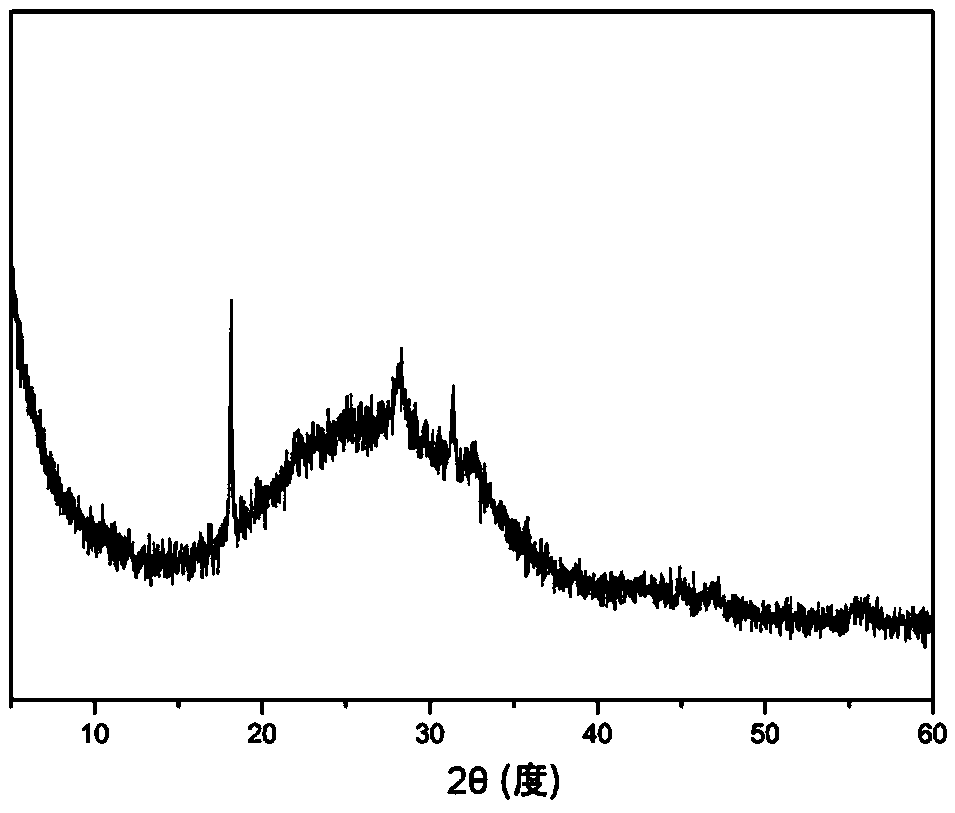

Carbon aerogel prepared from superfine nano aerogel obtained through TEMPO (2,2,6,6-tetramethylpiperidinooxy) oxidation and preparation method of carbon aerogel

The invention discloses carbon aerogel prepared from superfine nano aerogel obtained through TEMPO (2,2,6,6-tetramethylpiperidinooxy) oxidation. The superfine nano aerogel is prepared with a TEMPO oxidation method, then, preoxidation at the high temperature is performed, and the carbon aerogel is prepared with a carbonization method under the inert gas shielding condition. Used TEMPO is an environment-friendly solvent and has high safety, and therefore, the prepared carbon aerogel cannot have toxicity and cannot corrode instrument equipment or pollute the environment. TEMPO as an oxidizing agent can be recycled, and the condition of environment pollution caused by metal ions serving as a catalyst can be avoided.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Nitrogen-doped carbon aerogel prepared by utilizing natural-structure macromolecular nano-fiber aerogel and preparation method of nitrogen-doped carbon aerogel

The invention discloses nitrogen-doped carbon aerogel prepared by utilizing natural-structure macromolecular nano-fiber aerogel. A biomass polysaccharide structural macromolecular material is prepared into cellulose aerogel through a mechanical method, a chemical oxidization pre-treatment method and an enzyme pre-treatment method, and is then treated in a nitrogen-rich atmosphere by a high-temperature pyrolysis method. With the adoption of the nitrogen-doped carbon aerogel, the utilization value of the biomass polysaccharide structural macromolecular material is improved, and novel concept and method are provided for efficiently utilizing carbon material resources.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

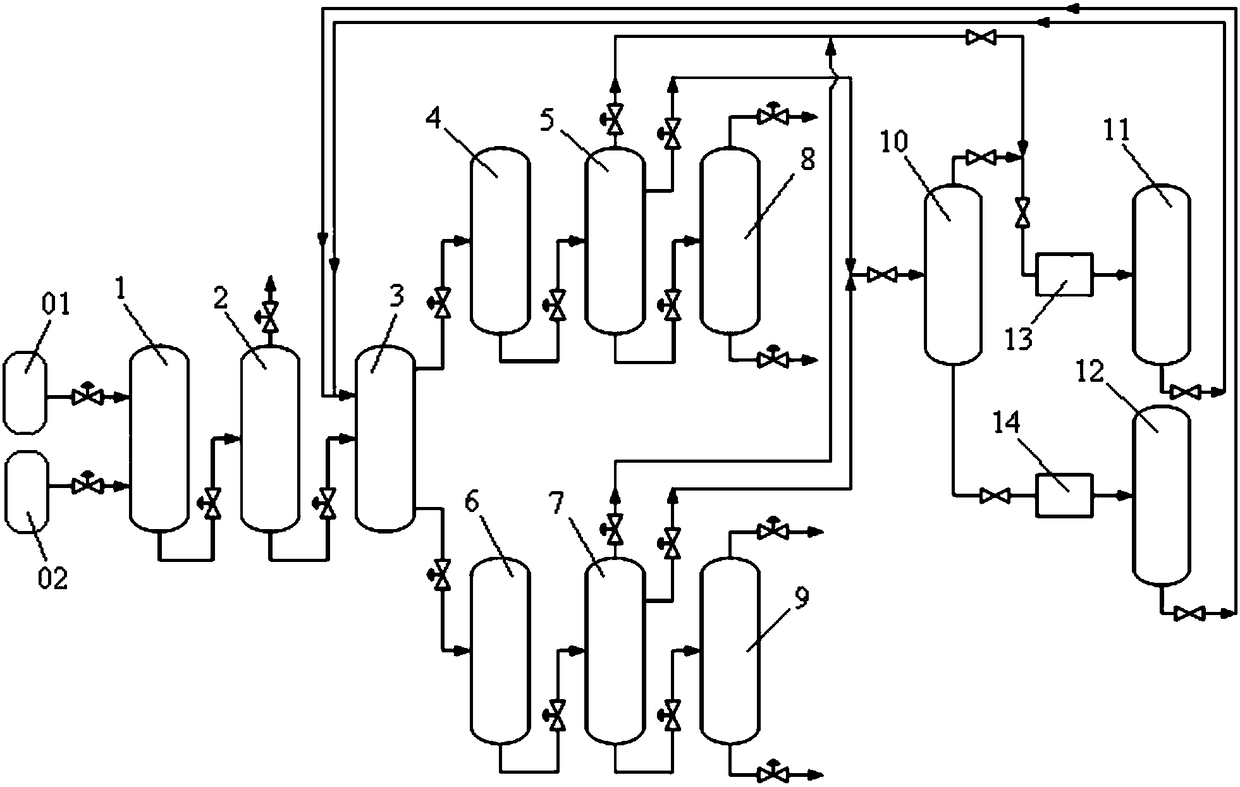

Reprocessing system and method of Fischer-Tropsch synthetic diesel fraction

PendingCN108102694AIncrease economic benefitsHigh value-added productsTreatment with plural serial refining stagesAlkaneMolecular sieve

The invention provides a reprocessing system and method of Fischer-Tropsch synthetic diesel fraction. The reprocessing system comprises a raw material buffering tank, a raw material pre-rectifying tower, a molecular sieve adsorption tower, an extract liquid feeding buffering tank, an extract liquid tower, a residual extract liquid feeding buffering tank and a residual liquid pumping tower, whereinthe raw material buffering tank receives C10 to C14 alkane fractions in a Fischer-Tropsch diesel synthesis process; the raw material pre-rectifying tower is used for pre-rectifying materials from theraw material buffering tank; the molecular sieve absorption tower absorbs and separates the material on the bottom of the raw material pre-rectifying tower; the extract liquid feeding buffering tankis used for refractionating the material of the extract liquid feeding buffering tank; the residual extract liquid feeding buffering tank receives the bottom residual extract liquid of the molecular sieve absorption tower; and the residual extract liquid tower is used for fractionating the material of the residual extract liquid feeding buffering tank. By adopting the reprocessing system and method, the C10 to C14 alkane fractions of the Fischer-Tropsch diesel synthesis process can be reprocessed, so that a product with high additional value can be obtained, the economic benefit of the Fischer-Tropsch diesel synthesis process can be increased, and the diversified development of the product can be realized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

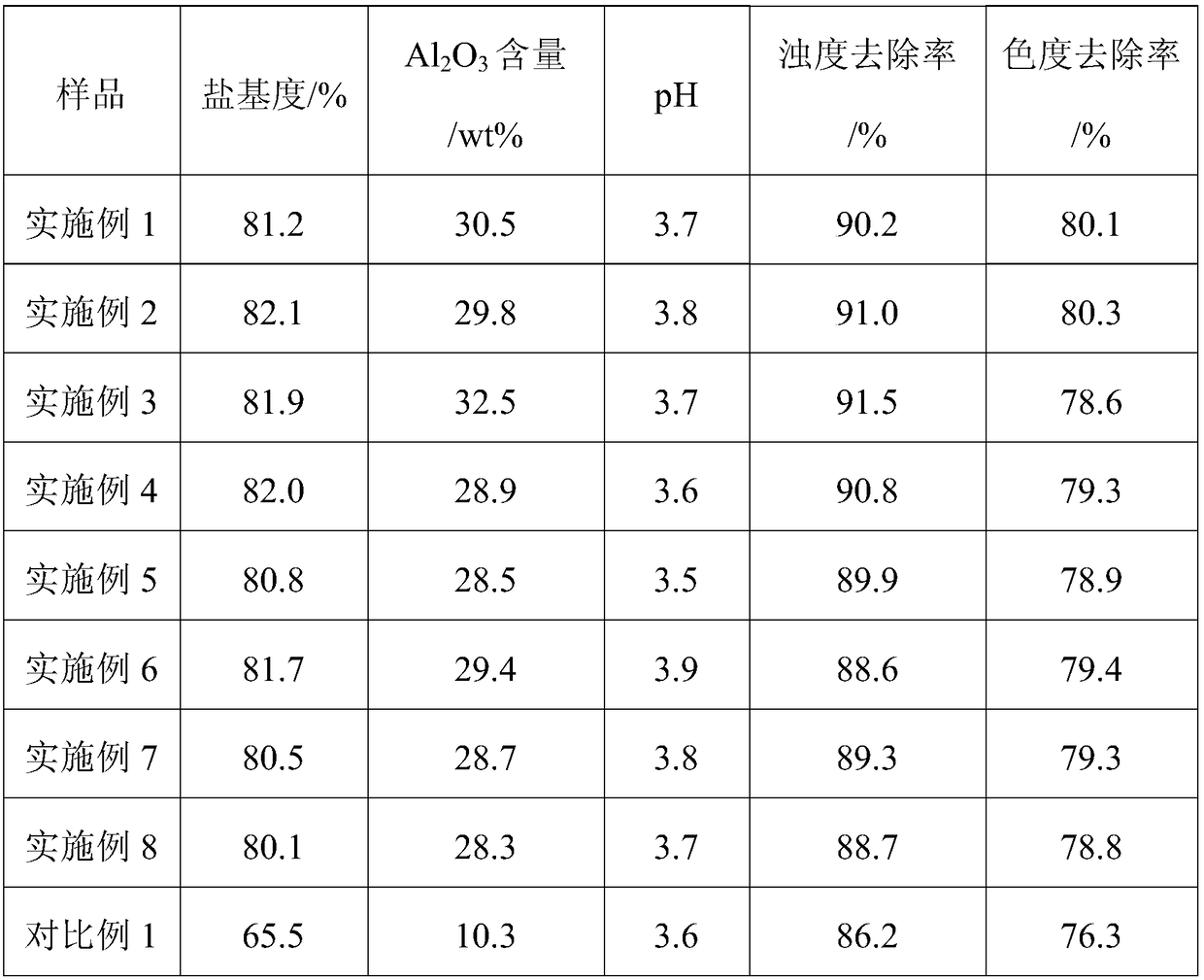

Method for preparing aluminum polychlorid from byproduct generated in methyl diethyl phosphate production

ActiveCN109052444AResolve disposal issuesHigh value-added productsAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideDiethyl phosphate

The invention provides a method for preparing aluminum polychlorid from byproducts generated in methyl diethyl phosphate production. The method comprises the following steps: (1) dispersing byproductsolid dregs into a solvent, analyzing, and collecting a solution; (2) cooling the solution with water, and separating aluminum chloride hydrate crystal; (3) hydrolyzing and polymerizing the aluminum chloride hydrate crystal, and aging, thereby obtaining the aluminum polychlorid. By adopting the method, solid dregs rich in sodium tetrachloroaluminate are adopted as a raw material, an inorganic polymeric flocculant, namely the aluminum polychlorid, is successfully prepared through steps of simple processes, and not only is the problem of waste disposal solved, but also a high additional value product can be successfully made.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

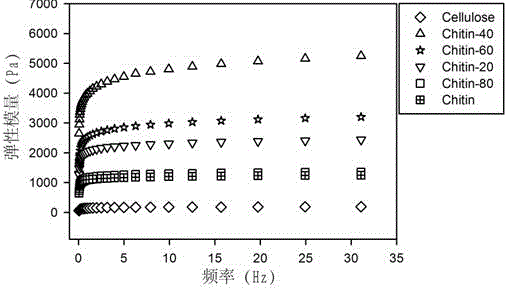

Carbon aerogel prepared from chitin aerogel and preparation method thereof

The invention discloses carbon aerogel prepared from chitin aerogel. Chitin nano-fiber aerogel is prepared by means of a mechanical method or a chemical oxidation method, and then the carbon aerogel is obtained through a method for carbonization under the inert gas shielding. The preparation method is simple, the technology is easy to control, the adopted oxidizing agent is the environment-friendly green solvent and is safe and free of toxicity, the green preparation technology is achieved, the cost is lowered, the obtained carbon aerogel is free of toxicity, the 3D network structure is obtained, the surface area is large, the porosity is high, and the certain mechanical strength is achieved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Signal peptide and application thereof in synthesis of l-arginine from conjac powder and value enhancement of conjac powder

ActiveUS20180258385A1Promote cell growthEfficient productionBacteriaPeptidesΒ mannanaseL-ornithine L-aspartate

The present invention relates to application of a novel signal peptide in L-arginine and its derivatives production from konjac powder, which belongs to the field of gene engineering, enzyme engineering and metabolism engineering. The present invention fused the signal peptide set forth in SEQ ID NO.1 with the β-mannanase of Bacillus subtilis CCTCC M 209200, and expressed the fused gene in the strain with high L-arginine yield. The recombinant strain Corynebacterium crenatum CGMCC 0890 / p MSPman had advantages on utilizing cheaper konjac powder as substrate, and after fermenting for 96 hours in a 5 L bioreactor, the L-arginine yield reached 45 g / L. Another two recombinant strains were constructed based on Corynebacterium crenatum CGMCC 0890 / pMSPman, and after fermenting for 96 hours in a 5 L bioreactor, the L-ornithine yield and L-citrulline reached 23.5 g / L and 26.3 g / L respectively.

Owner:JIANGNAN UNIV

Previous metal modified catalyst for fischer-tropsch synthesis and preparation method thereof

InactiveCN105833883AHigh strengthHigh selectivityHeterogenous catalyst chemical elementsLiquid hydrocarbon mixture productionRheniumSilicon oxide

The invention provides a previous metal modified catalyst for fischer-tropsch synthesis and a preparation method thereof .Silicon oxide serves as a catalyst carrier, cobalt serves as an active ingredient, zirconium and lanthanum serve as carrier modified auxiliaries, rhenium, ruthenium, rhodium and platinum serve as precious metal auxiliaries, and the mass percentage of the components is 100%; the active ingredient accounts for 10-40%; the carrier modified auxiliaries account for 0.2-3.2%; the precious metal auxiliaries account for 0.05-2.0%; the balance is the catalyst carrier .The preparation method of the precious metal modified catalyst includes the following steps of 1 preparation of raw materials; 2, processing of the catalyst carrier; 3, modification of the catalyst carrier; 4, drying; 5, calcination; 6, preparation of the catalyst, and the previous metal modified catalyst is obtained .The previous metal modified catalyst has important use significance and is high in selectivity, high in stability, high in additional value, high in mechanical strength, small in catalyst damage rate and long in service life, the preparation method which is reasonable in step and convenient to operate is provided, and industrialized production prospect is achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

Functionally gradient hard alloy with cubic phase-rich surface and preparation method thereof

InactiveCN102134660BHigh value-added productsEasy to realize technology transformationSolid state diffusion coatingSurface layerGradient material

The invention discloses a functionally gradient hard alloy with a cubic phase-rich surface and a preparation method thereof, and belongs to the technical field of preparation of gradient materials through surface nitriding treatment. A gradient layer of the hard alloy comprises a surface layer rich in cubic phases, and a transition layer rich in binding phases under the surface layer; and the wear resistance and toughness of the alloy can be improved simultaneously, and the alloy can be used for machining metals. In the preparation method, the functionally gradient hard alloy is prepared by anitriding and sintering process; and by controlling the sintering temperature, sintering time and a nitrogen pressure parameter, the components and thickness of the gradient layer of the alloy are controlled. The invention has the advantages that: the conventional equipment and process are not changed greatly, and the functionally gradient hard alloy can be produced; and the invention is suitablefor industrial production.

Owner:CHONGQING UNIV OF ARTS & SCI +1

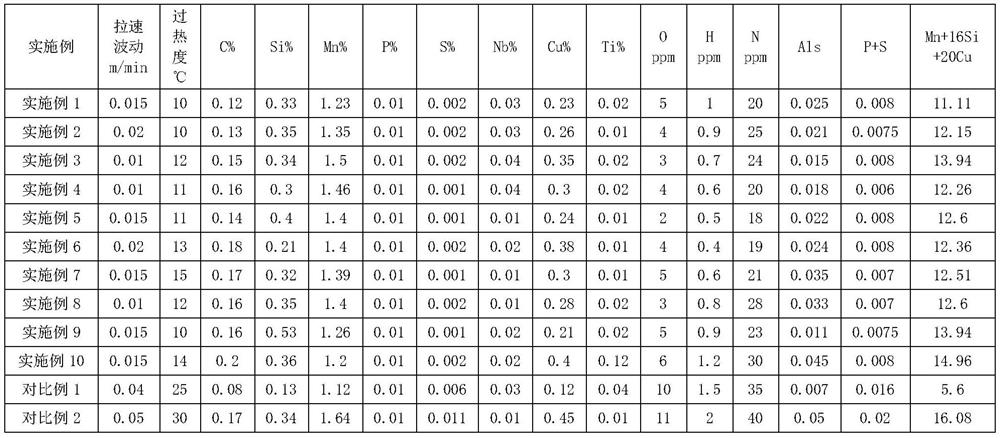

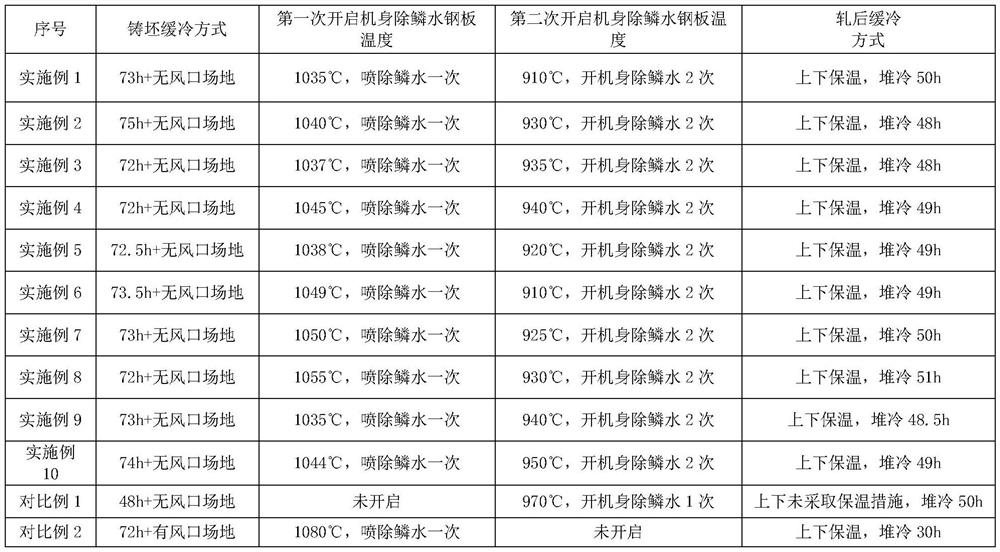

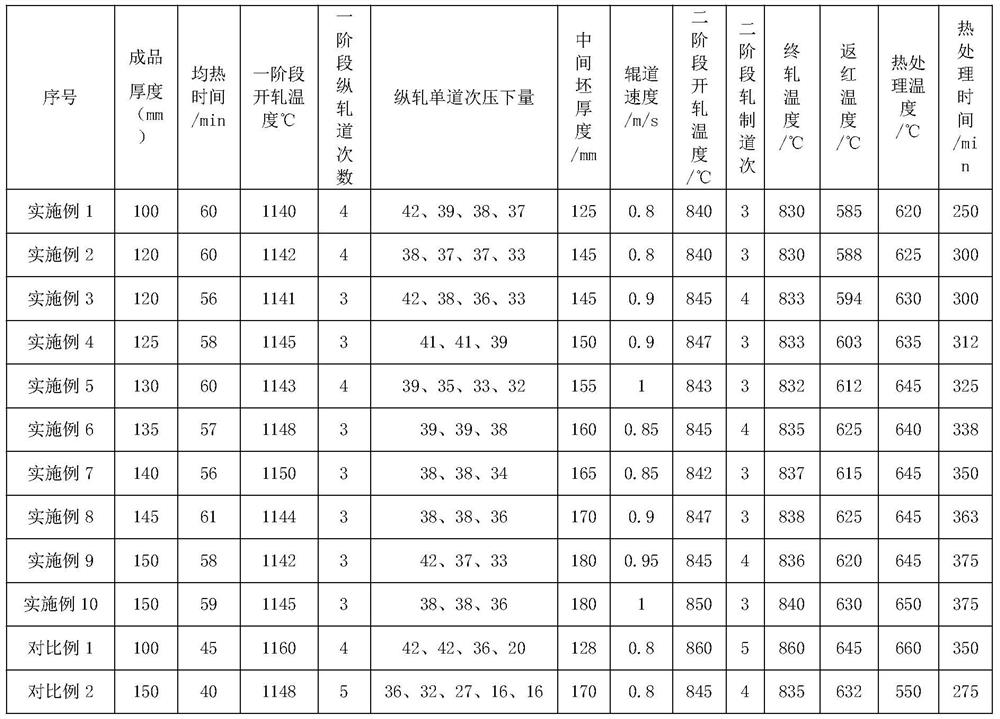

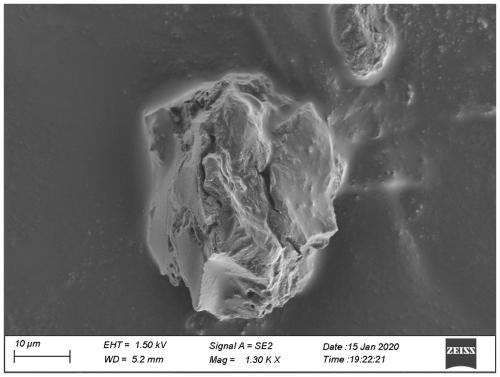

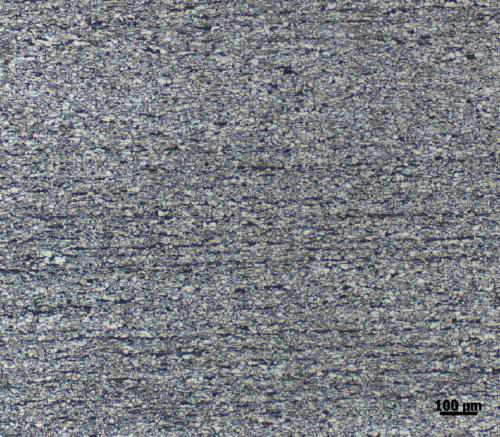

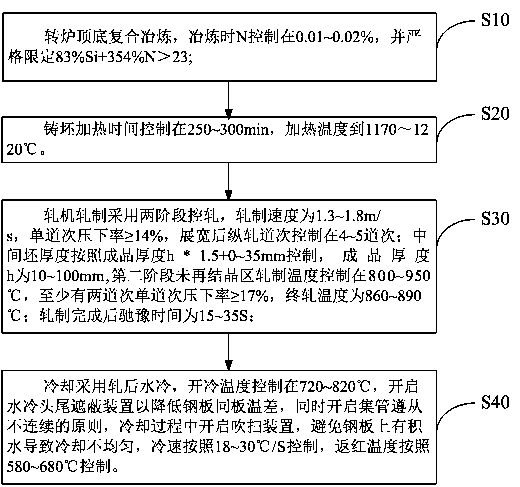

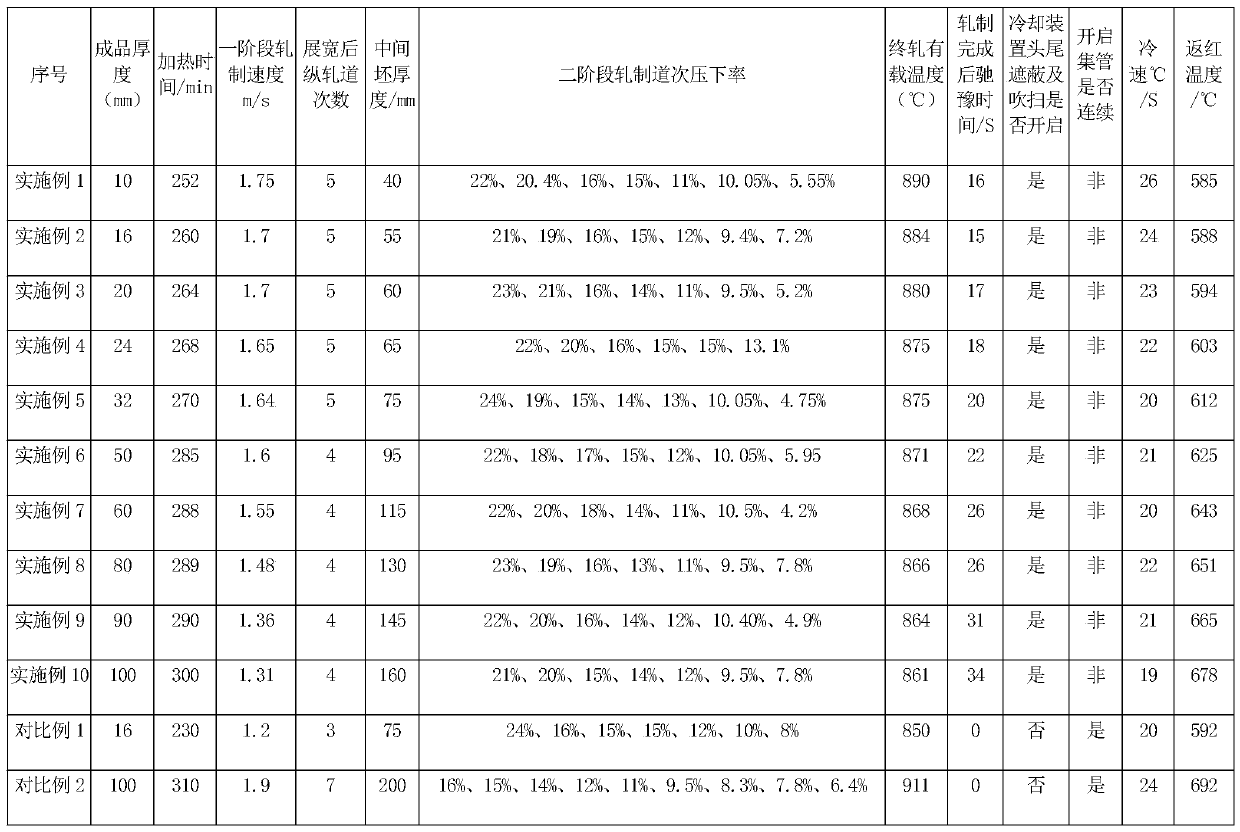

Production method for producing ultra-thick high-strength building steel plate with excellent thickness direction performance on basis of single continuous casting billet rack

ActiveCN111926234AReduce defectsGrain refinementFurnace typesHeat treatment furnacesSmelting processEconomic benefits

The invention discloses a production method for producing an ultra-thick high-strength building steel plate with excellent thickness direction performance on the basis of a single continuous casting rack. The steel plate is simple in component design and mainly uses cheap Ti, Cu and a proper amount of Nb alloy as main strengthening alloy elements. In the production method, the addition ratio of Si, Mn to Cu in the steel plate and the content of harmful elements P, S and P+S are mainly controlled in a smelting process, so that the generation of the gas content, inclusions, shrinkage cavities and other defects in a casting blank is reduced; by controlling rolling, the coarse columnar crystal structure of the casting blank is crushed, crystal grains are refined, the fine and uniform structurein the thickness direction is ensured, and the strength is improved at the same time. Through controlling heat treatment, the structure defects are further eliminated, the structure is improved, thecomponents are homogenized, the crystal grains are refined to obtain good thickness direction performance, and meanwhile, it is ensured that the strength meets the requirements. The method has the advantages of low production cost, high product performance and high added value, improves the production efficiency and economic benefits, and has great popularization significance.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

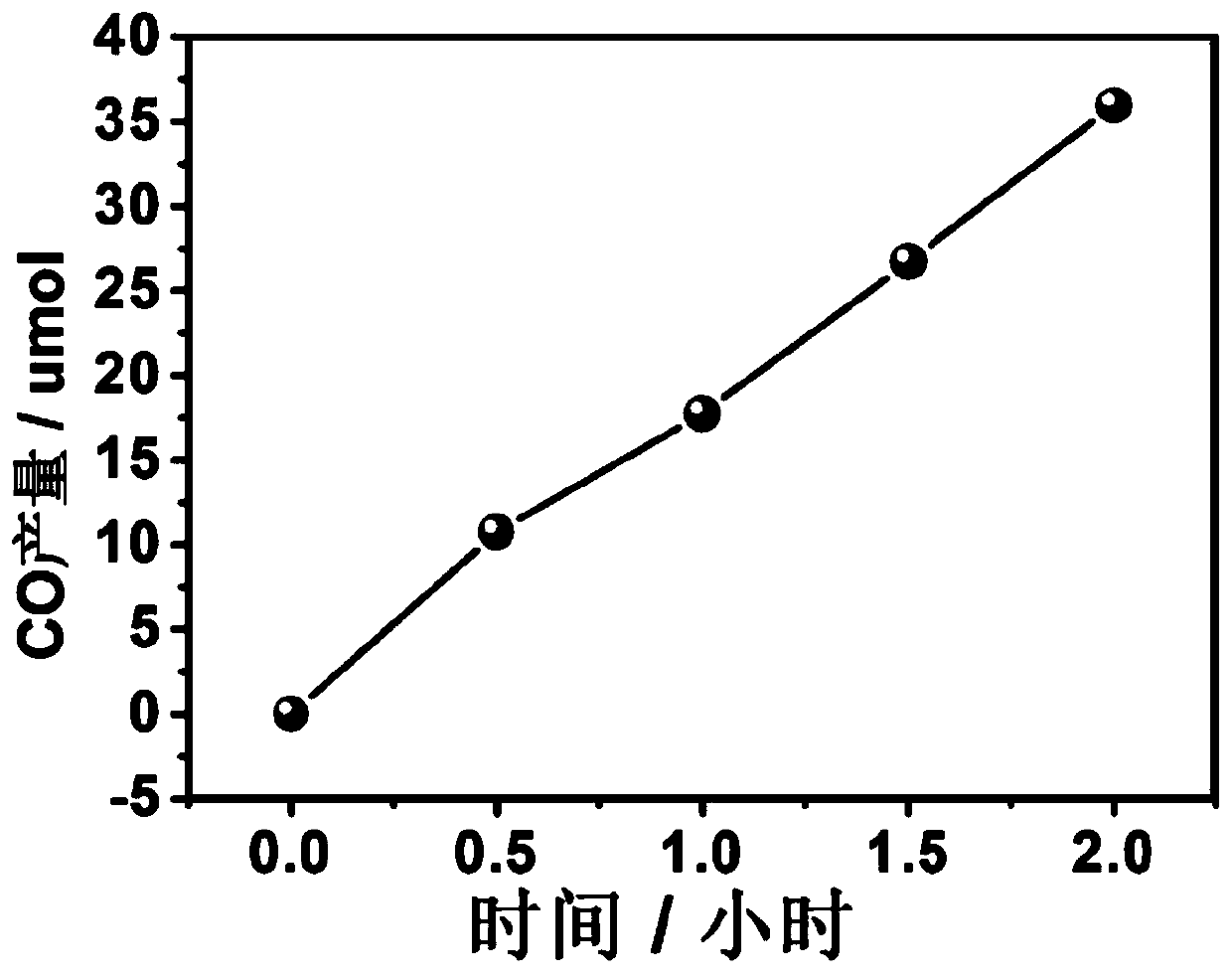

Method for preparing carbon dioxide reduction photocatalyst by utilizing hyperaccumulators

ActiveCN111111660AWide variety of sourcesSimple preparation processCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsPhoto catalyticHyperaccumulator

The invention provides a method for preparing a carbon dioxide reduction photocatalyst by utilizing hyperaccumulators. The method comprises the steps: firstly, carrying out crushing and sand removal treatment on the hyperaccumulators; adding distilled water into the hyperaccumulators, uniformly mixing, and carrying out hydrothermal reaction at the temperature of 120-250 DEG C for 2-50 h to obtaina reaction product; and finally, centrifuging, washing and drying the obtained reaction product to obtain the carbon dioxide reduction photocatalyst. The preparation method is simple; the prepared carbon dioxide reduction photocatalyst can realize the reduction of carbon dioxide, and high added value products such as carbon monoxide are obtained; in addition, the invention provides a new method for resource utilization of the hyperaccumulators, and the method has wide application prospects in the fields of treatment of the hyperaccumulators containing heavy metals, reduction of carbon dioxideand other energy and chemical engineering.

Owner:SUN YAT SEN UNIV

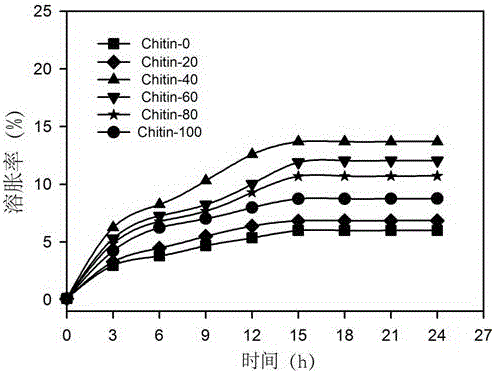

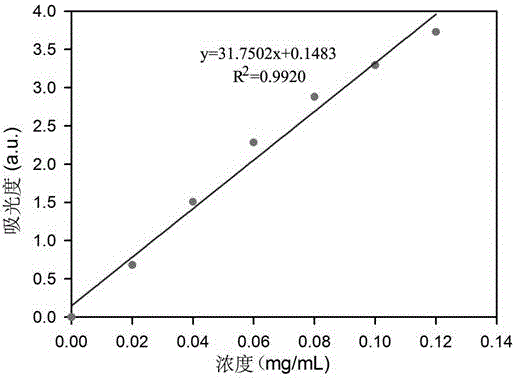

Nano-biomass-based anticancer and sustained-release gel and preparation method of nano-biomass-based anticancer and sustained-release gel

ActiveCN106727280ALow costHigh value-added productsOrganic active ingredientsAerosol deliveryDrugBiomass

The invention discloses nano-biomass-based anticancer and sustained-release gel and a preparation method of the nano-biomass-based anticancer and sustained-release gel and belongs to the field of biomass medical materials. The invention aims at providing pure biomass-based anticancer and sustained-release gel which has the advantages of simple and convenient apply, biodegradability and low preparation cost, and a preparation method of the pure biomass-based anticancer and sustained-release gel. The preparation method comprises the following steps: defibering a bleached pulp board; oxidizing to prepare nano cellulose with negative charges; carrying out impurity removal, deacetylation and protonation treatment on a chitosan raw material to prepare nano chitosan with positive charges; slowly adding the nano chitosan into the nano cellulose and stirring to crossly link to form hydrogel; after swelling the hydrogel, which is dried in vacuum, into an anticancer medicine, drying in vacuum again to prepare the nano-biomass-based anticancer and sustained-release gel. The method is simple in preparation process; the prepared anticancer and sustained-release gel is biodegradable pure biomass gel; a chemical cross-linking agent is not added, so that the nano-biomass-based anticancer and sustained-release gel is easily utilized in the field of the medical materials.

Owner:SOUTH CHINA UNIV OF TECH

Steel plate uniform in longitudinal performance and obtained by normalizing rolling and manufacturing method therefor

The invention discloses a steel plate uniform in longitudinal performance and obtained by normalizing rolling and a manufacturing method therefor. The steel plate comprises the following components: C, Mn, Ti, Si, N, Als, P, S and the balance Fe and impurities, and the components are necessary to limit in element content simultaneously: 83%Si + 354%N > 23; and according to the manufacturing method, medium and low carbon is employed on the composition of a steel grade, and N and Ti low in cost serve as main strengthened alloy elements to limit the addition ratio of Si to N; and then, under thesupplement of a right amount of Mn, the content of P and S of harmful elements is strictly controlled. The yield strength of the steel plate provided by the invention is 370-432 MPa at normal temperature, the tensile strength is 533-566 MPa, the ductility is 25-30.5 %, and the impact energy is 185-231 J at -20 DEG C; moreover, the intra-plate longitudinal strength difference is 5-24 MPa, and the intra-plate tensile strength difference is 2-17 MPa; the steel plate produced by employing the method has mechanical property equivalent to the mechanical property of a steel plate hot treated by normalizing, and has uniform longitudinal performance; the production cost is greatly reduced; process flows are reduced; the production efficiency and the economic benefit are increased; and the method has great popularizing significance.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

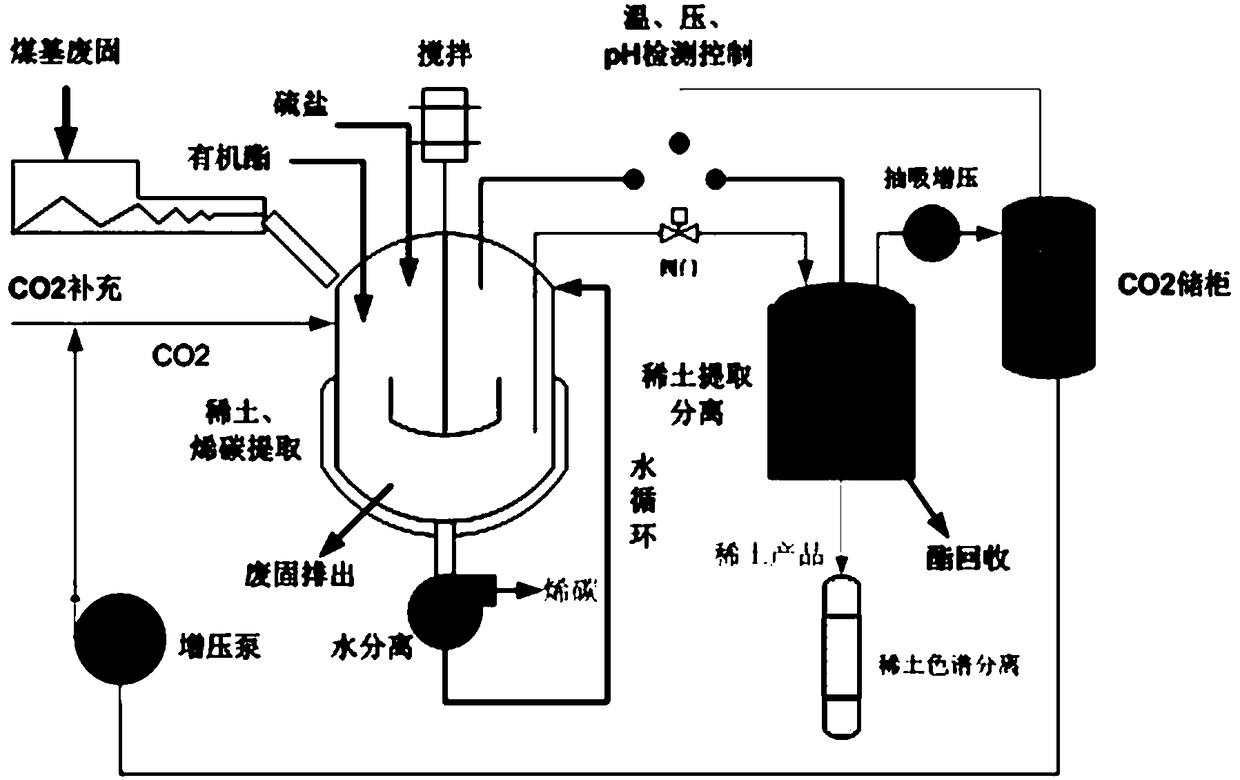

Method for extracting olefin carbon, enriching rare earth and separating inorganic materials by solid waste liquid waste three-phase method

ActiveCN108546825AAbundant supplyPlay a protective effectCarbon preparation/purificationProcess efficiency improvementRare-earth elementLiquid waste

The invention particularly discloses a method for extracting olefin carbon, enriching rare earth and separating inorganic materials by a solid waste liquid waste three-phase method. The method is mainly based on supercritical ScCO2 / H2O / organic fat three-phase extraction system, and the means, such as stirring, microwave, ultrasonic or heating or moderately adding acid and enhanced extraction and enhanced mass transfer, are used in an supplementary mode. When necessary, high-speed ball milling and other mechanical forces are used for stripping and enhancing the breakage and re-bonding of chemical bonds. ScCO2 phase is cooperated with H2O phase to form supercritical and acidic environment to dissolve and separate rare earth and carbon in solid waste. Complexation is carried out on safe and environmental-friendly organic lipid additives and the rare earth to extract the rare earth soluble in the H2O phase, the porous carbon or graphene carbon is basically retained in H2O, and the rare earth is transferred to CO2 phase when an organic ester is the same to form a stable CO2 extended solution phase, so that the distribution coefficient of solute in the two phases is changed, and the separation and extraction of rare earth elements and olefin carbon are completed.

Owner:山西中谱能源科技有限公司

Signal peptide, l-glutamic acid thereof synthesized using konjac flour and high-value application thereof

ActiveUS20180245114A1Promote cell growthEfficient productionPolypeptide with localisation/targeting motifMicroorganismsΒ mannanaseL glutamate

The present invention relates to application of a novel signal peptide in L-glutamate and its derivatives production from konjac powder, which belongs to the field of gene engineering, enzyme engineering and metabolism engineering. The signal peptide which mediated secretion of β-mannanase was invented, and the recombinant strain with this signal peptide had advantages on utilizing konjac powder to produce related products, and its utilization efficiency of konjac powder, production efficiency, and yield were higher than other signal peptides. The recombinant strain possessing this new signal peptide had advantages on utilizing cheaper konjac powder as substrate to lower the process costs on L-glutamic acid and its high-value-added products.

Owner:JIANGNAN UNIV

Camellia oleifera fruit phase separation process

PendingCN107502446AThe process steps are simpleImprove food palatability and food safetyBiofuelsFatty-oils/fats refiningSolid phasesNutrient

A camellia oleifera fruit phase separation process comprises: (1) selection, which includes selecting newly-picked fresh plump camellia oleifera fruits; (2) hulling, which includes hulling the camellia oleifera fruits to obtain fresh plump camellia oleifera seeds; (3) washing, which includes washing the camellia oleifera seeds obtained from the step (2) with water; (4) pulverization, which includes putting the camellia oleifera seeds obtained from the step (3) to a pulverizer to obtain camellia oleifera seed granules; (5) phase separation 1, which includes putting the camellia oleifera seed granules obtained from the step (4) to a juice extractor, and performing extruding to obtain solid fiber powder and liquid whey; (6) medium separation, which includes sending the whey obtained from the step (5) to a reaction pot, performing heating, adding a medium, and performing continuous stirring and heating for layering; (7) phase separation 2, which includes centrifuging the emulsion obtained from step (6) to obtain light-phase camellia oil, a heavy-phase tea saponin solution, solid-phase protein, and a starch mixture; and (8) cold extraction. The process is simple in steps and high in oil yield, allows a lot of nutrients to be kept, and fully utilizes the camellia oleifera fruits.

Owner:湖南大三湘油茶生态产业有限公司

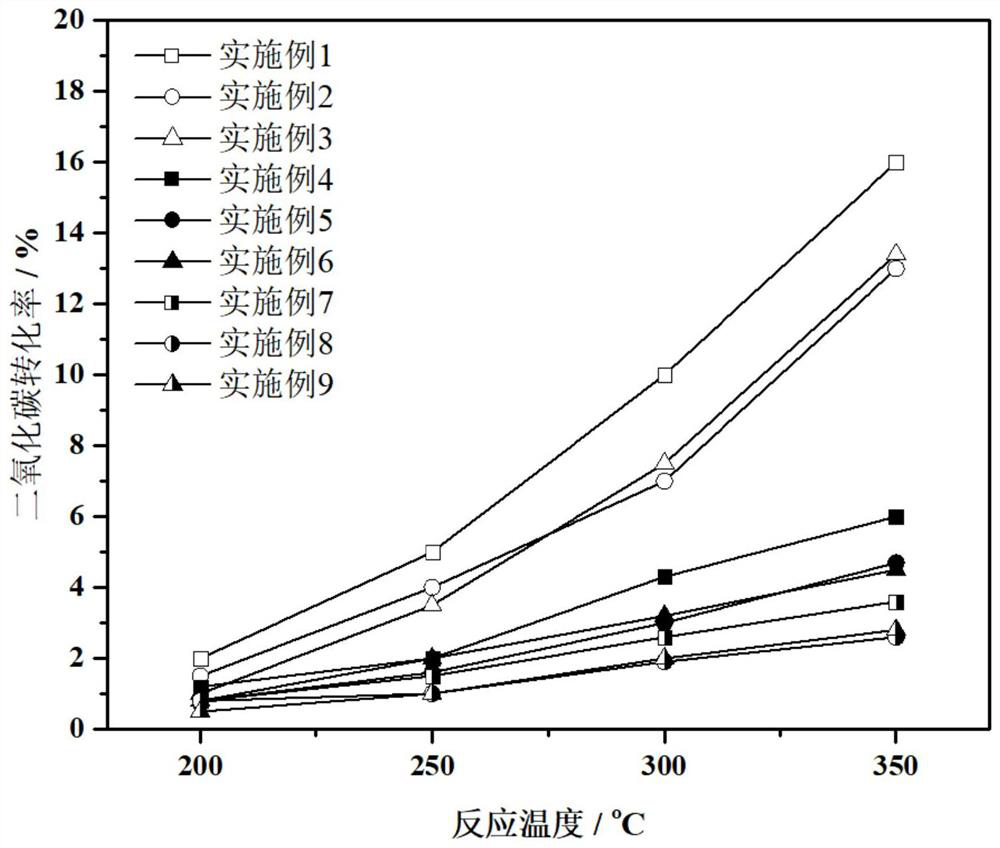

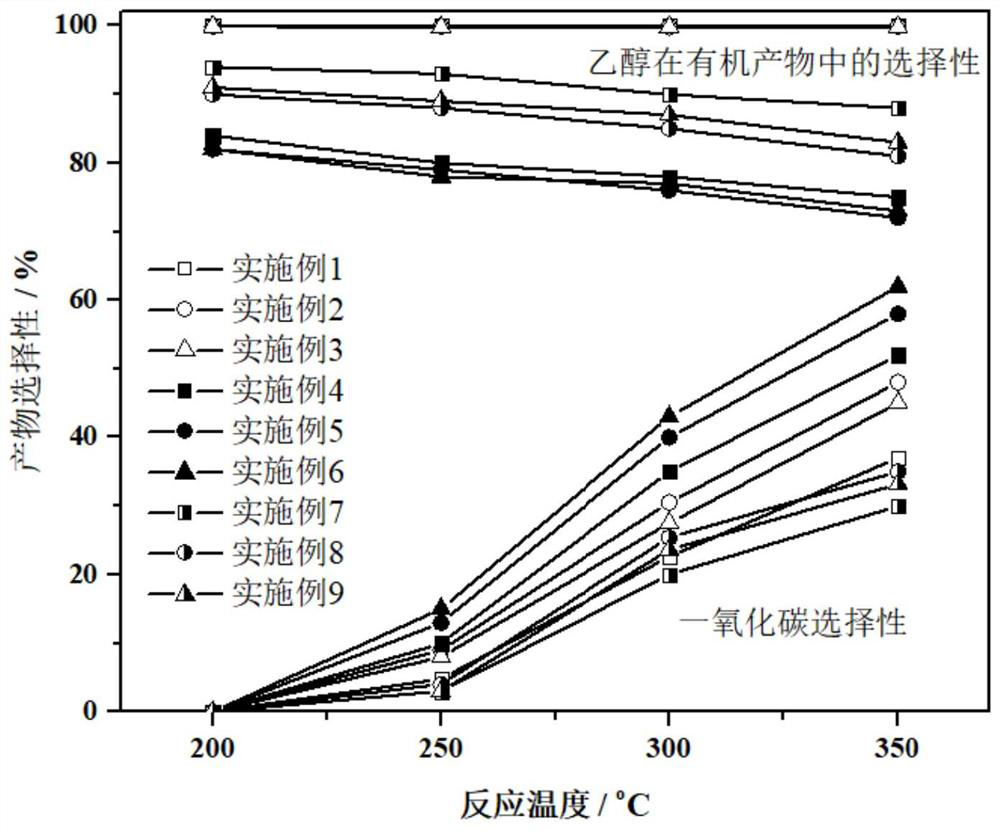

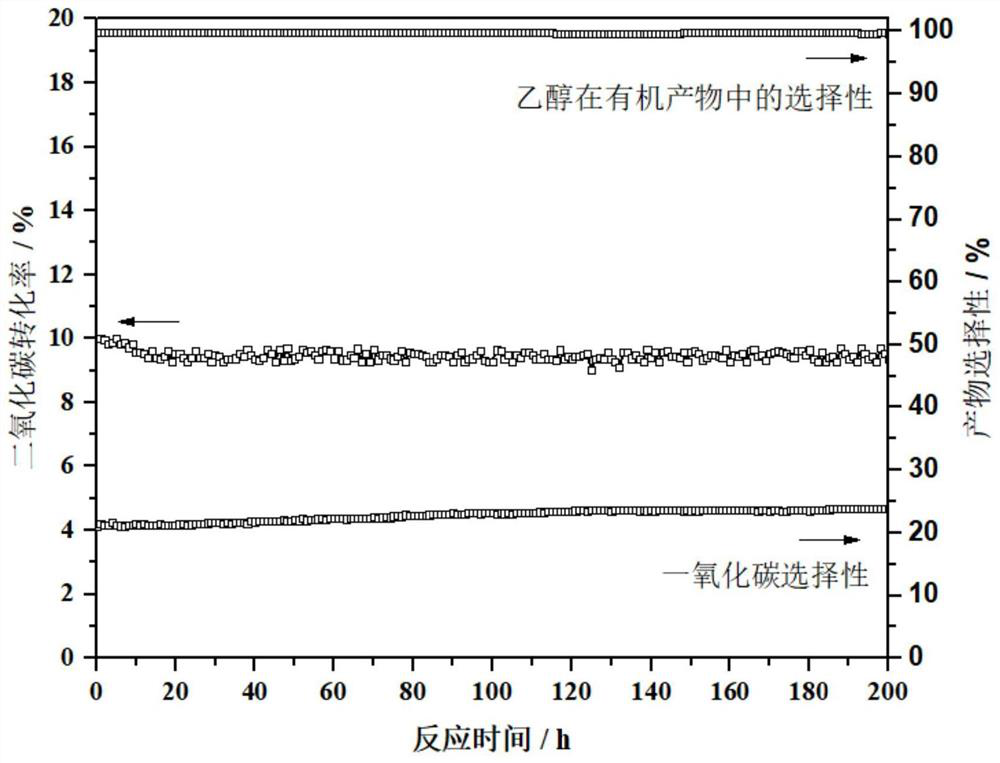

Porous copper-based catalyst for preparing ethanol through carbon dioxide hydrogenation and preparation method thereof

PendingCN113751062ALarge specific surface areaLow costMolecular sieve catalystsOrganic compound preparationMolecular sieveHigh activity

The invention discloses a porous copper-based catalyst for preparing ethanol through carbon dioxide hydrogenation and a preparation method thereof, and belongs to the technical field of carbon dioxide resource utilization. The method comprises the following steps: dissolving a template agent and soluble salt of copper in a solvent, depositing on a molecular sieve by an equivalent-volume impregnation method, drying and roasting to obtain a loaded molecular sieve; reacting the loaded molecular sieve with a strong alkali solution, removing the template agent after the reaction, and drying to obtain a sample; mixing an aluminum source, a silicon source, strong alkali, a template agent and a sample to obtain a gel embedding body, and then performing aging and drying to obtain dry gel; and crystallizing the dry gel, and then performing washing, drying and roasting to obtain the copper-based catalyst. The catalyst disclosed by the invention is applied to preparation of ethanol by hydrogenation of carbon dioxide, has the characteristics of high specific surface area, low cost, high activity, high ethanol selectivity and high stability, and has a good application prospect.

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司 +1

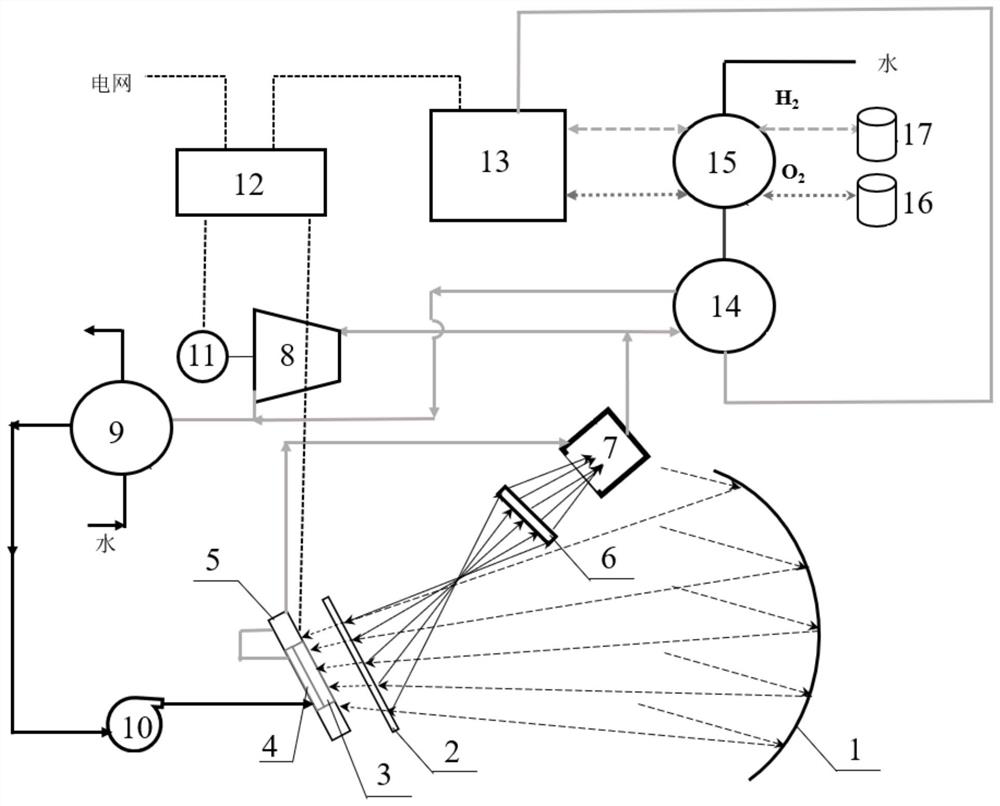

Comprehensive energy supply system based on solar frequency division utilization

ActiveCN113411036ALess heat productionRaise the inlet temperatureCellsSolar heating energyOrganic Rankine cycleAlternating current

The invention relates to a comprehensive energy supply system based on solar frequency division utilization. The system comprises a solar frequency division utilization-concentrating photovoltaic photo-thermal module which is configured to receive solar energy and generate electric energy and heat energy through the frequency division utilization of the solar energy; an organic Rankine cycle module which is configured to receive the heat energy generated by the solar frequency division utilization-concentrating photovoltaic photo-thermal module and convert the heat energy into electric energy; a fuel cell-electrolytic tank integrated module which is configured to convert redundant electric energy into chemical energy for storage through an electrolytic tank under the condition of strong solar radiation, and convert the chemical energy into electric energy through a fuel cell under the condition of weak solar radiation; and a current modulation module which is configured to modulate the generated electric energy, complete conversion between alternating current and direct current, and realize electric energy distribution to a power grid. The solar energy comprehensive utilization rate is increased, the energy storage function is achieved, solar energy fluctuation is stabilized, peak clipping and valley filling are achieved, meanwhile, high-added-value products can be obtained, and an electricity and hydrogen double-supply comprehensive energy supply system is formed.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

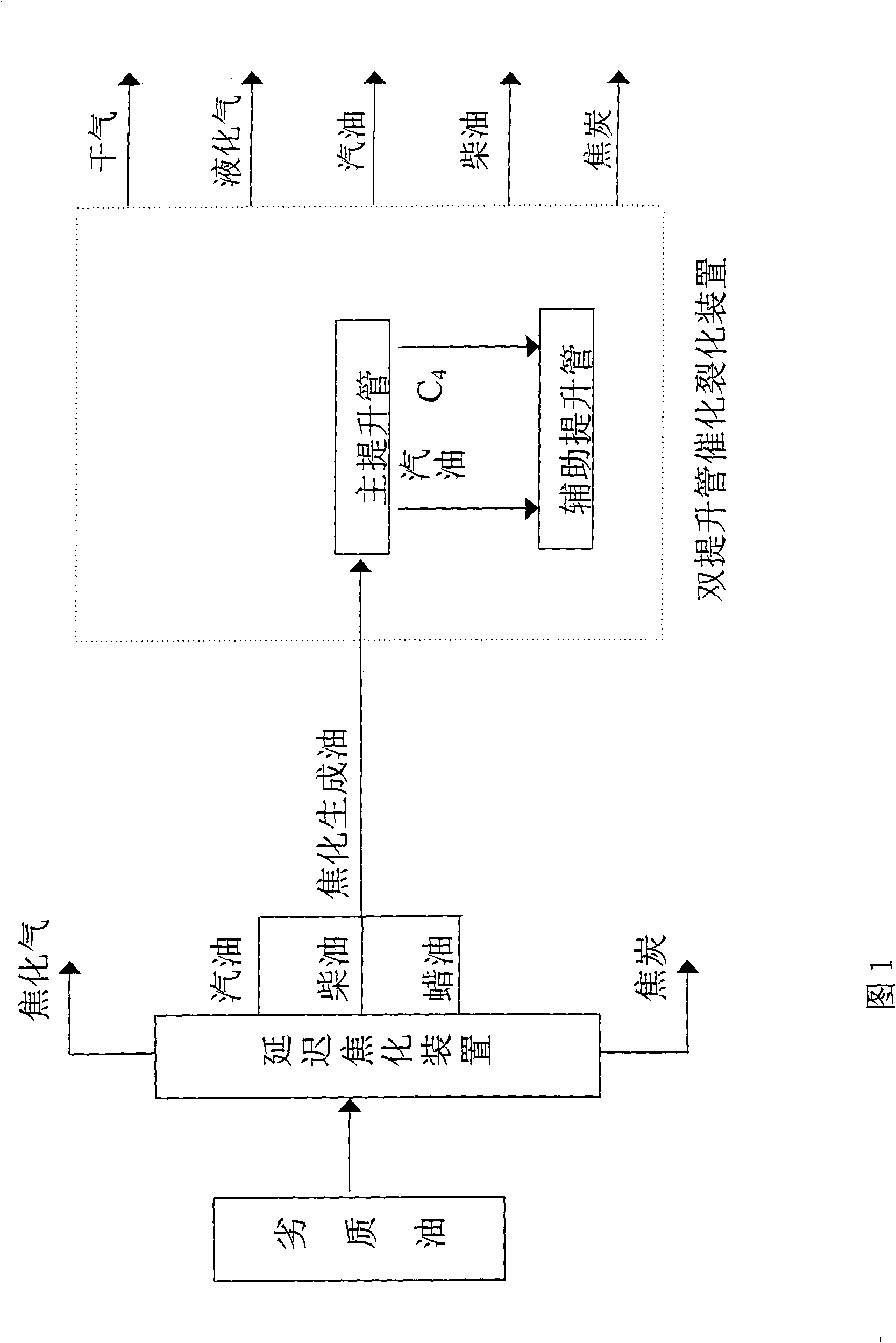

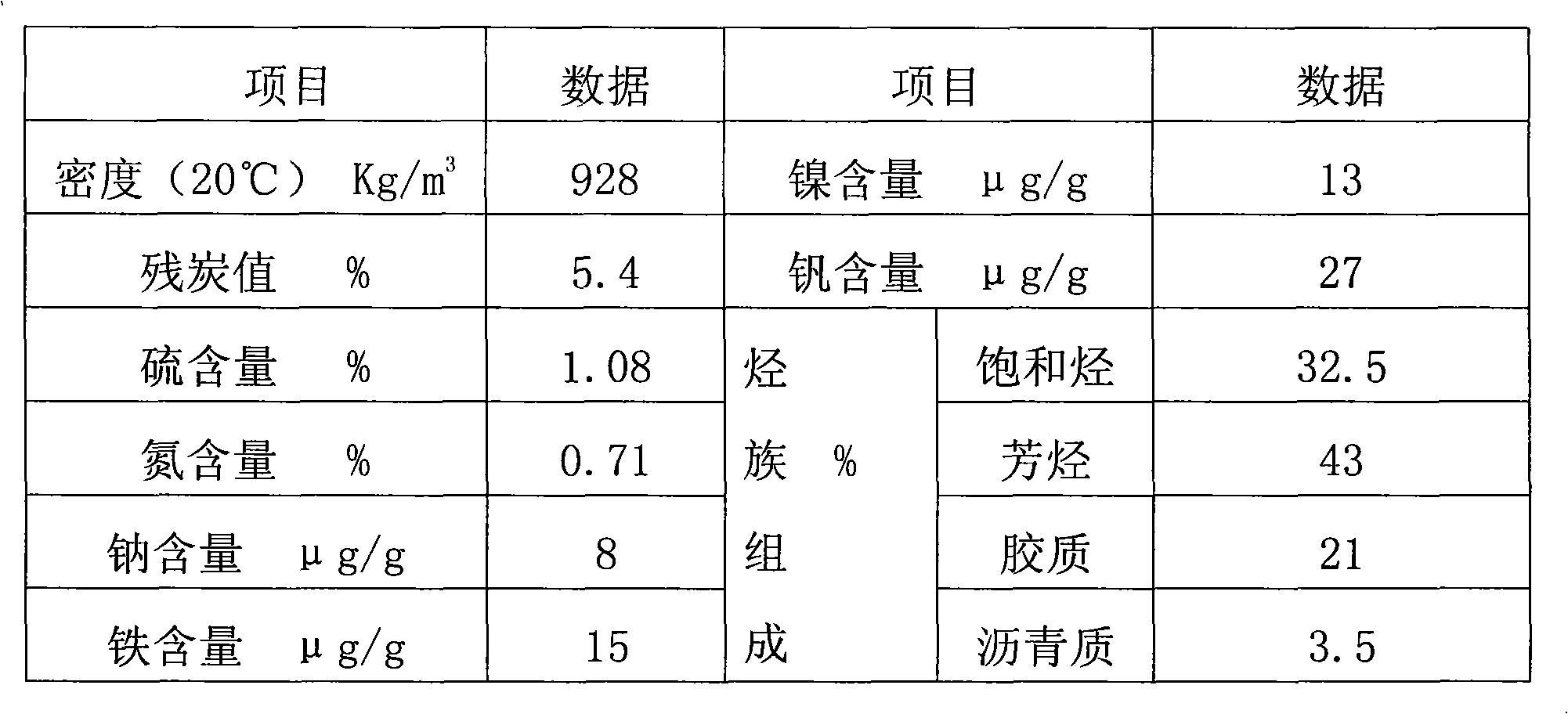

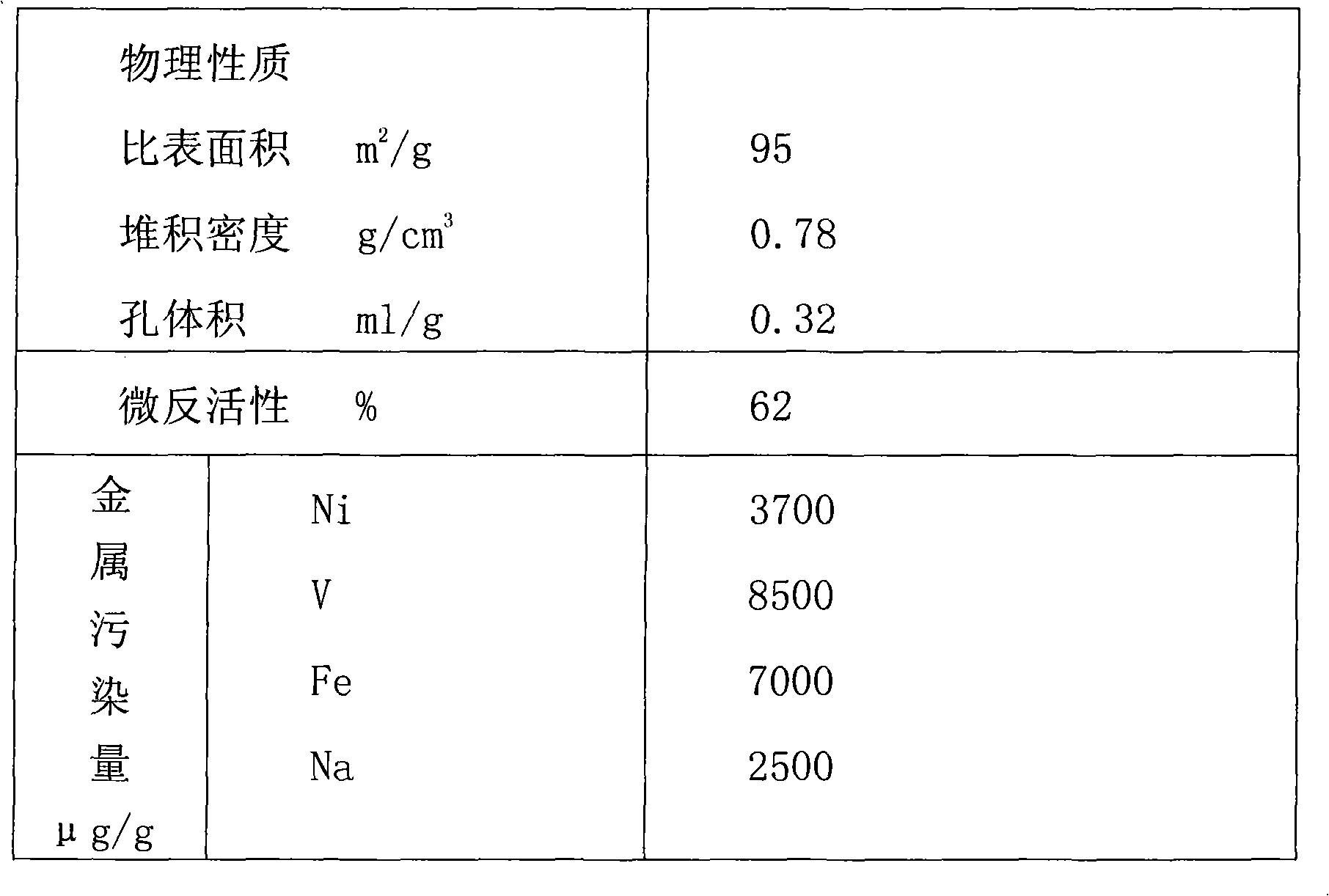

Process for preparing olefin hydrocarbon and light aromatic hydrocarbon with poor oil in high limit

InactiveCN101314722AReduce yieldQuality improvementCatalytic crackingHydrocarbon oils refiningChemistryPoor quality

The invention provides a process for maximizing the production of alkenes and light arenes from poor-quality oil, wherein the poor-quality oil is fed into a delayed coking device, and the mixture of the produced coker gasoline, coker diesel and coker gatch is used as the feeding material form the main riser of a double-riser catalytic cracking device; and the catalytic gasoline containing C4 component or even partial diesel is used as the feeding material for the auxiliary riser.

Owner:袁培林 +2

Direct fresh oil camellia fruit squeezing method

ActiveCN107586602APreserve the original ecological rich fragrance flavorAchieve full utilizationFatty-oils/fats refiningFatty-oils/fats productionFiberPhase splitting

The invention discloses a direct fresh oil camellia fruit squeezing method which comprises the following steps: (1) selecting, namely selecting fresh and full oil camellia fruits; (2) removing shells,namely removing shells of the oil camellia fruits obtained in the step (1) so as to obtain oil camellia seeds; (3) performing cleaning and selection, and washing the oil camellia seeds with water; (4) performing crushing, namely crushing the oil camellia seeds obtained in the step (3) so as to obtain oil camellia seed granules; (5) performing phase splitting 1, namely squeezing the oil camellia seed granules obtained in the step (4) in a squeezing machine so as to obtain solid fiber powder and liquid slurry; (6) performing gelatinization, namely conveying the slurry obtained in the step (5) into a reaction tank, and performing heating gelatinization; (7) performing medium separation, namely cooling, putting a medium into the reaction tank of the step (6), and performing stirring layering;(8) performing phase splitting 2, namely centrifuging an emulsion obtained in the step (7) so as to obtain light-phase camellia oil; (9) performing separation extraction, namely purifying light phasecamellia oil obtained in the step (8), thereby obtaining high-quality camellia oil. By adopting the method, high oil yield is achieved, a great amount of nutrient substances are maintained, and comprehensive utilization of oil camellia fruits is achieved.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

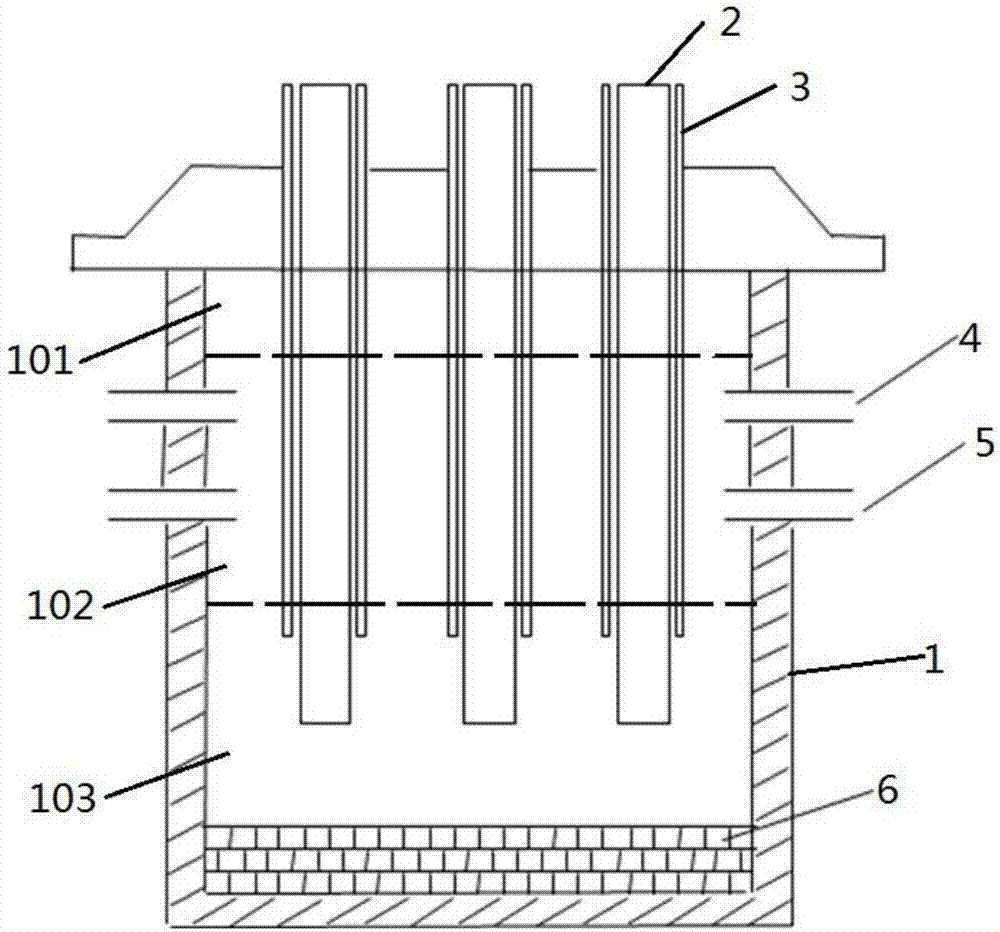

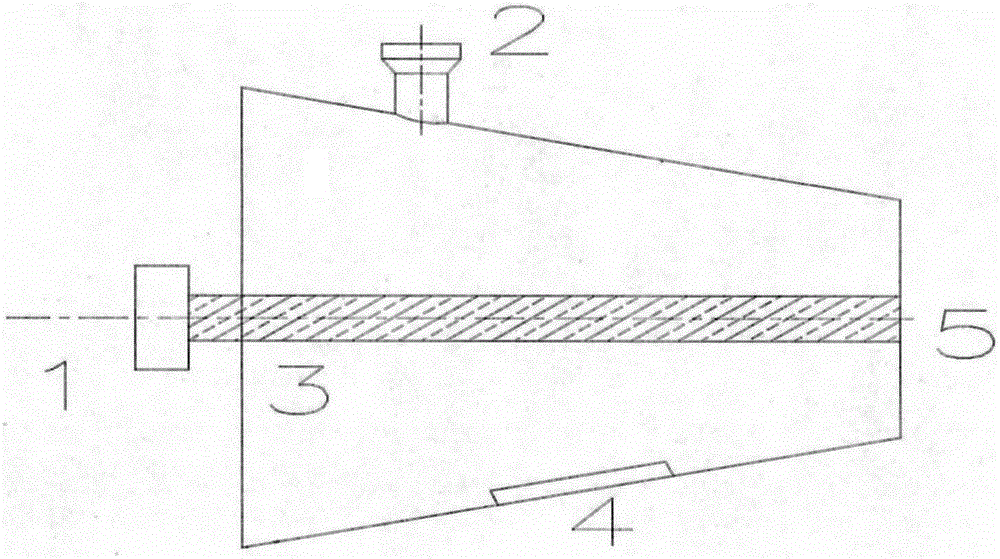

Calcium carbide furnace

PendingCN106966394AIncrease raw material temperatureReduce power consumption in calcium carbide productionCalcium carbideMagnesiaExhaust gasMagnesium

The invention discloses a calcium carbide furnace which comprises a furnace body, an electrode, a feeding pipe, a tail gas outlet and an oxygen-containing gas inlet. The electrode and the feeding pipe are embedded at the top of the furnace body and extend into a cavity of the furnace body, the cavity of the furnace body is divided into a material layer area, a heat layer area and a reaction area sequentially from top to bottom, and temperature of the heat layer area is 1400-1600 DEG C when the calcium carbide furnace works; the tail gas outlet is arranged on the side wall of the heat layer area of the furnace body, and the oxygen-containing gas inlet is arranged on the side wall of the furnace body and positioned below the tail gas outlet. By arranging the tail gas outlet in the heat layer area, magnesium steam in tail gas is ensured not to be in oxidizing reaction with CO; by arranging the oxygen-containing gas inlet below the tail gas outlet, part of carbon in raw materials is combusted, so that energy consumption during calcium carbide production is lowered.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

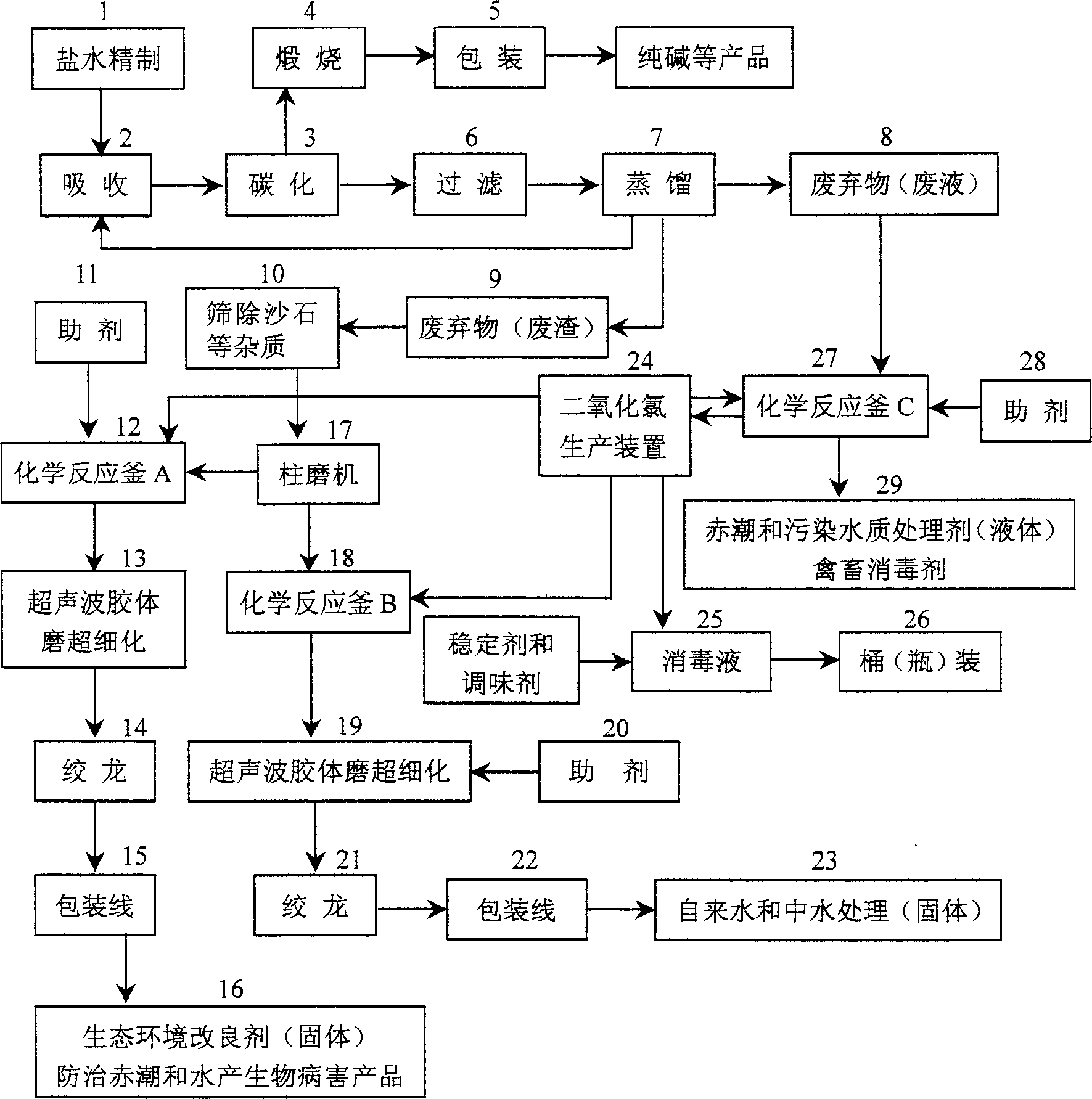

Chemical alkali manufacture waste harness and high value utilization process

InactiveCN1762850AStrong chemical oxidation propertiesStrong physical adsorption propertiesSolid waste disposalWater/sewage treatment by neutralisationLiquid wasteLiquid product

The present invention is comprehensive process of treating and high-value utilizing alkali producing wastes, including base slag and waste alkali liquid, and aims at realizing optimized no-pollution and zero-exhaust technological process. The wastes are modified physically and chemically to produce new product with the unique property of nanometer material and strong oxidizing property. The base slag is treated through filtering, depositing, sieving, coarse grinding, reaction with ClO2 and other chemicals and grinding to form product of grain size from 0.1 nm to 15 microns. The waste alkali liquid is made to react with ClO2 and other chemicals in reactor to obtain liquid product, with the ClO2 material having concentration of 1-3 %. The products of the present invention may be used in preventing and treating organism diseases and treating water.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

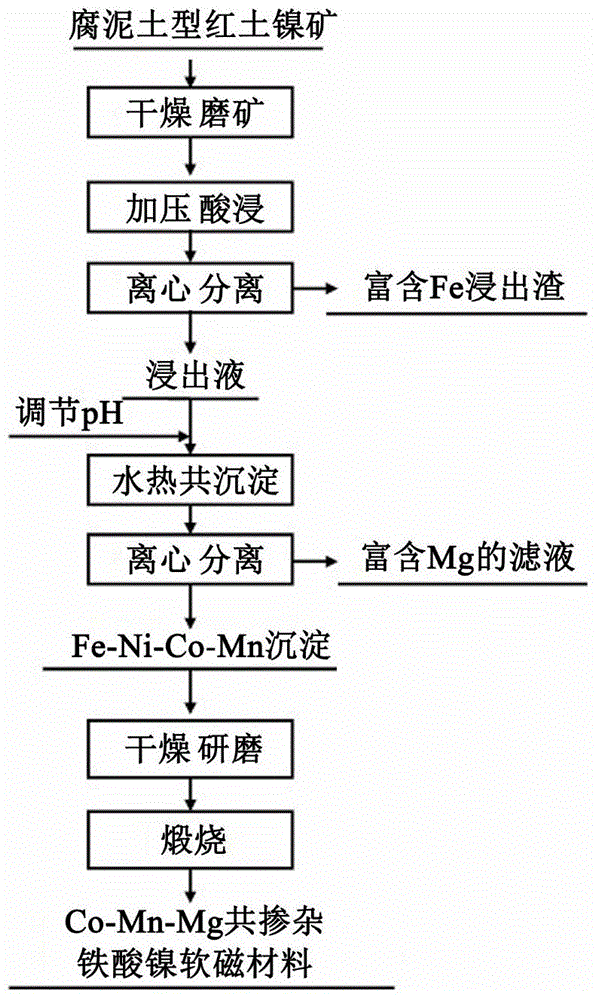

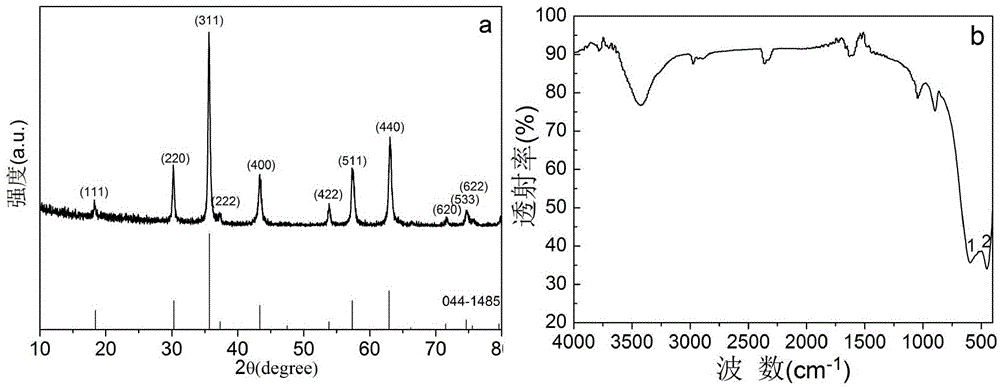

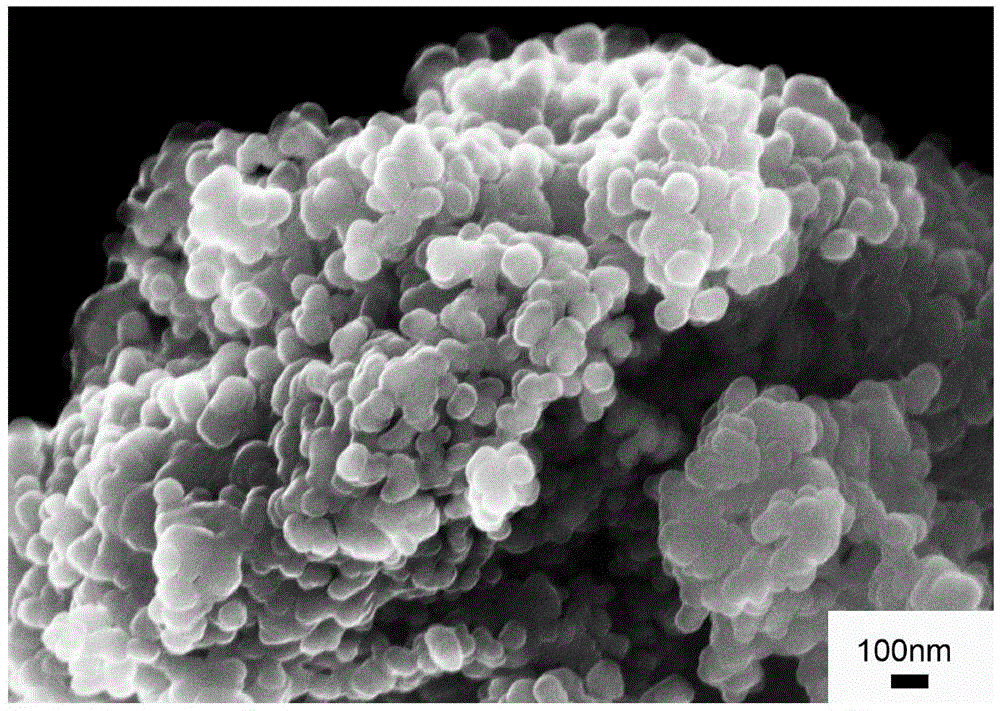

Method for synthesizing co-doping nickel ferrite soft magnetic material by using nickel laterite ore

The invention discloses a method for preparing a co-doping nickel ferrite soft magnetic material by using a saprolite type nickel laterite ore as a raw material, and belongs to the field of a magnetic material. The raw material for synthesizing the co-doping nickel ferrite soft magnetic material is the nickel laterite ore. The preparation method comprises the following steps: drying and grinding the nickel laterite ore, then mixing nickel laterite ore powder with acid, thus obtaining leachate meeting conditions by pressing and acid leaching; adjusting the pH value of the leachate put in a reaction kettle, then heating to an appointed temperature, and carrying out heat preservation for a certain time; centrifuging, and washing so as to obtain precipitates; and drying and grinding the precipitates, and calcining precipitate powder so as to obtain the co-doping nickel ferrite soft magnetic material. The preparation method has the beneficial effects that valuable metallic elements Ni, Co, Mn, Fe and Mg in the nickel laterite ore are fully utilized, the comprehensive utilization of resources is realized, the raw materials are low in cost, and the technology is simple and easy to operate. The composite ferrite soft magnetic material prepared by adopting the method has excellent magnetic property.

Owner:UNIV OF SCI & TECH BEIJING

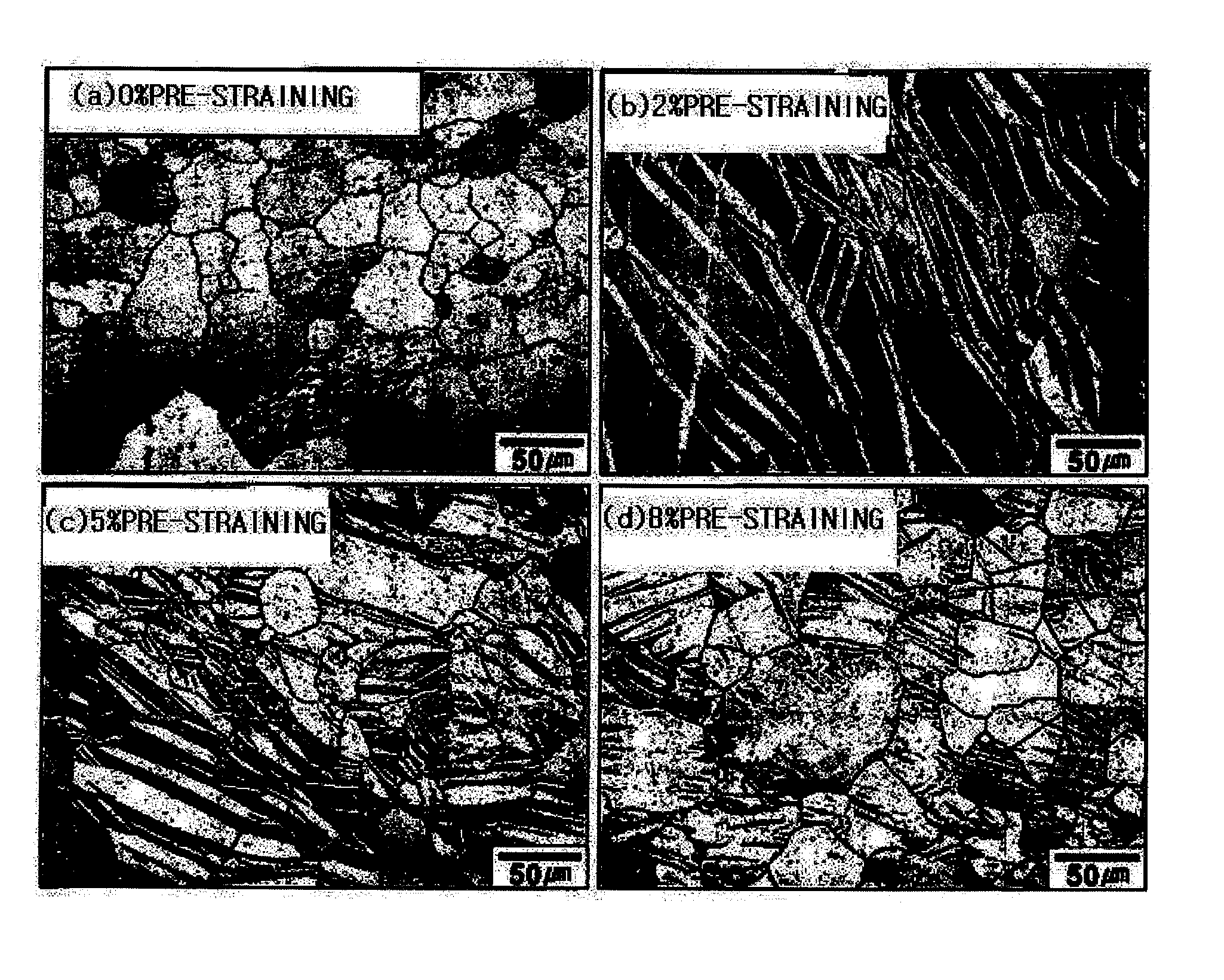

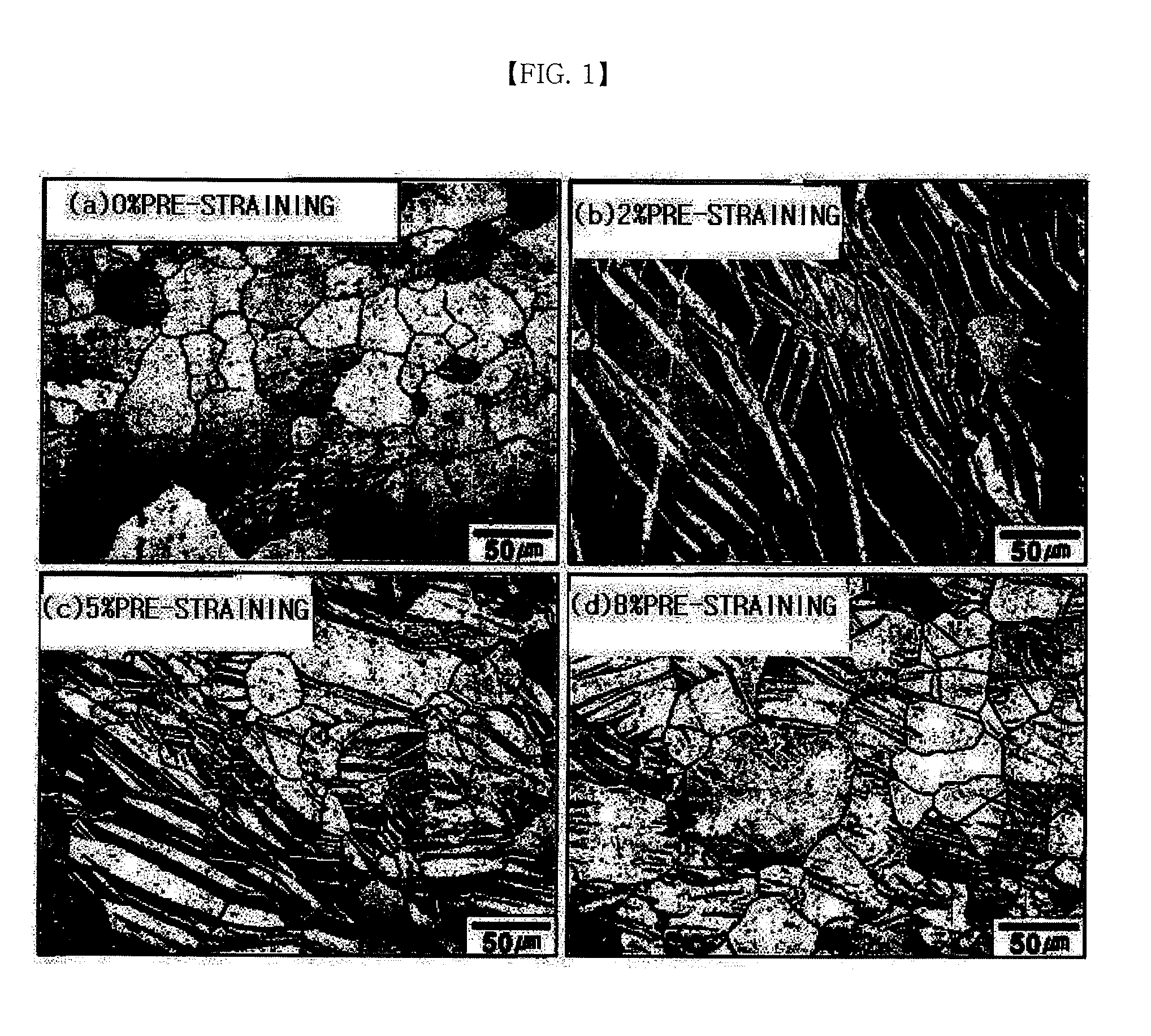

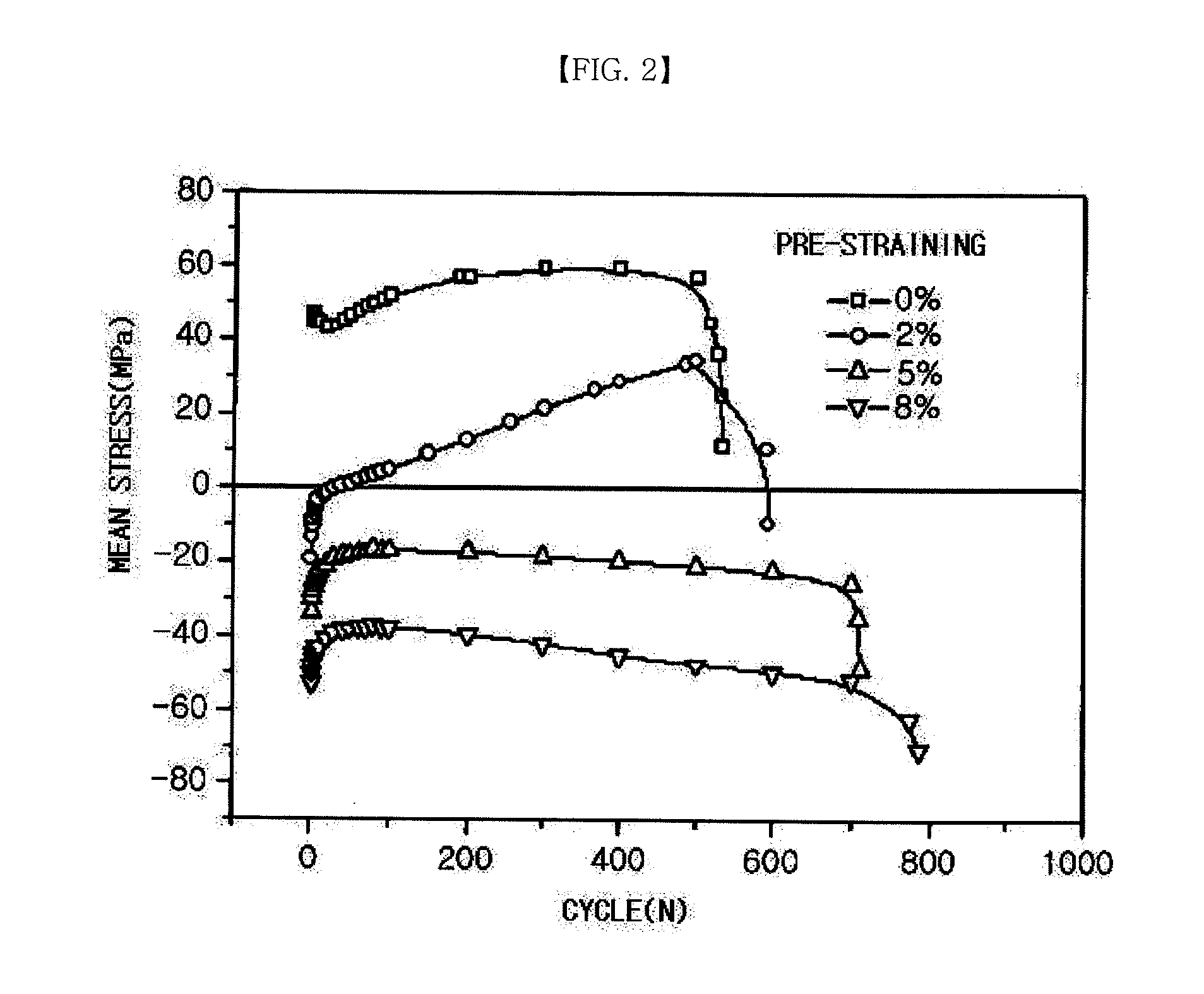

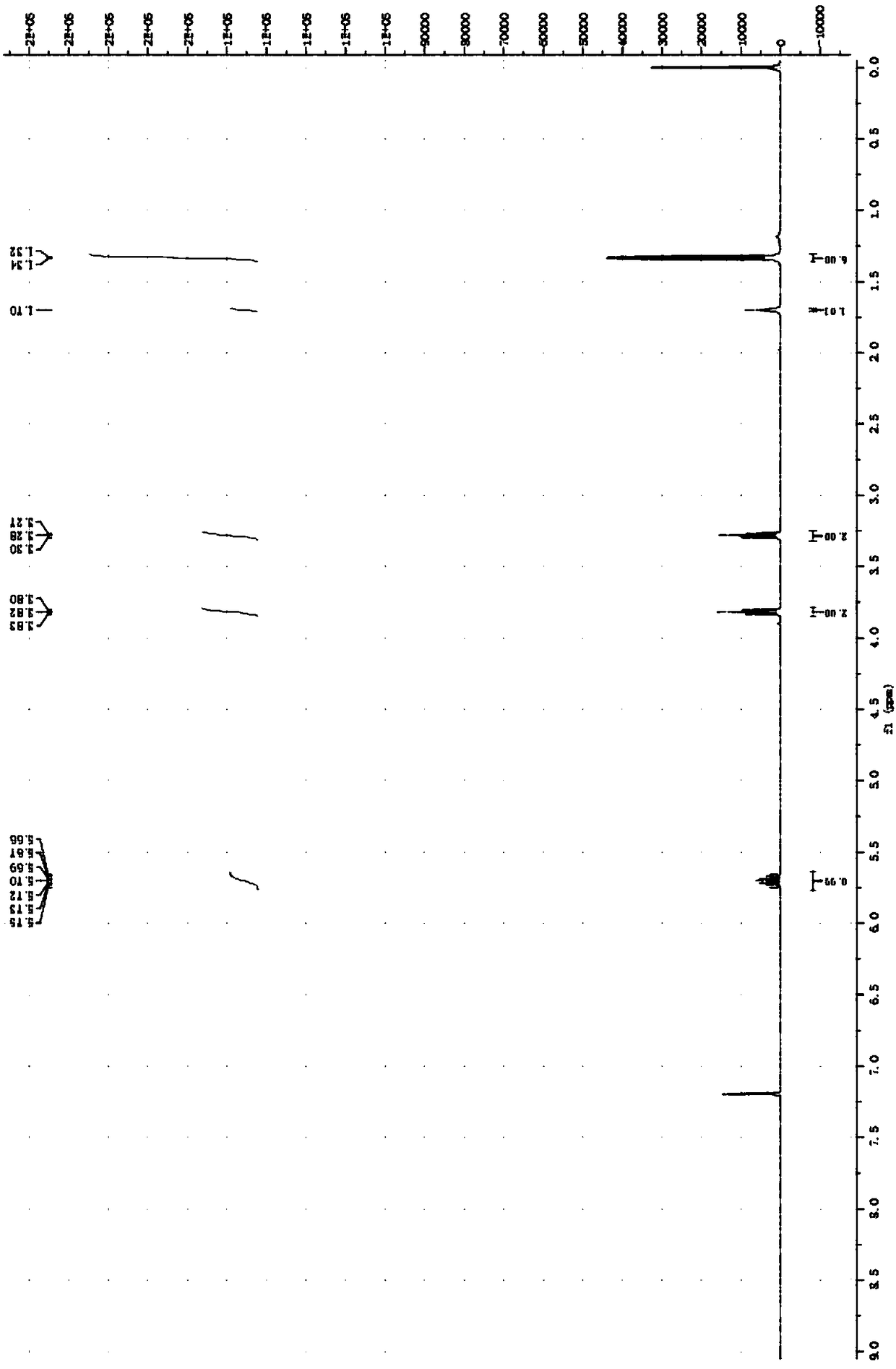

Method of manufacturing magnesium alloy processing materials with low cycle fatigue life improved by pre-straining

ActiveUS20120111081A1Process safety and stabilityLow cycle fatigueMetal rolling arrangementsPre strainingLow-cycle fatigue

The present invention relates to a method of manufacturing magnesium alloy processing materials capable of improving low cycle fatigue life. The manufacturing method for magnesium alloy processing materials with improved low cycle fatigue life comprises pre-straining a magnesium alloy processing material which is processed.

Owner:POSTECH ACAD IND FOUND

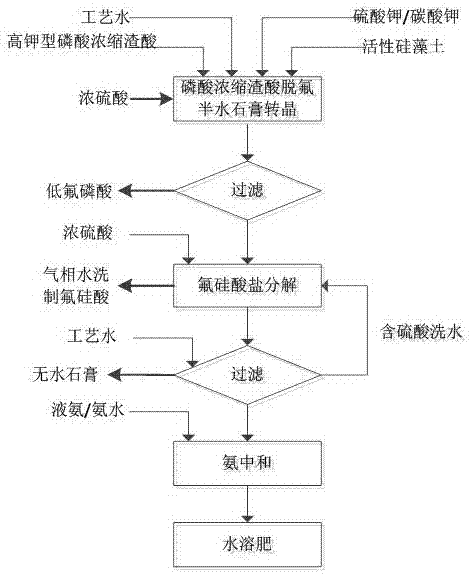

Method for recycling phosphorus and fluorine in phosphoric acid concentrated sludge acid and producing low-fluorine water-soluble fertilizer through cogeneration

ActiveCN107473775AHigh yieldEfficient removalAlkali orthophosphate fertiliserCalcium/strontium/barium sulfatesGas phaseSludge

The invention discloses a method for recycling phosphorus and fluorine in phosphoric acid concentrated sludge acid and producing a low-fluorine water-soluble fertilizer through cogeneration. The method comprises the following steps: putting process water, potassium sulfate / potassium carbonate, active kieselguhr and concentrated sulfuric acid into phosphoric acid concentrated sludge acid, removing free fluorine in the sludge acid, converting semi-hydrated gypsum in the sludge acid into dihydrate gypsum to release inter-crystal phosphorus, and performing filtering separation so as to obtain a water phase, namely low-fluorine phosphoric acid; and enabling solid phase filter cakes to react with the concentrated sulfuric acid to decompose fluosilicate, performing water washing on a gas phase so as to obtain fluosilicic acid, pulping a reaction material with water, performing filtering separation, and neutralizing the liquid phase with liquid ammonia / ammonium hydroxide, thereby obtaining a mixed water-soluble fertilizer of oligomerization APP (Ammonium Polyphosphate), ammonium sulfate and potassium sulfate, and a solid phase, namely anhydrite. By adopting the method, recycling and reuse of phosphoric acid and fluosilicic acid in phosphoric acid concentrated sludge acid are achieved, the low-fluorine water-soluble fertilizer is produced through cogeneration, efficient utilization of phosphorus and potassium is achieved, and the difficulties that phosphoric acid is hard to recycle and fluorine impurities are hard to separate from phosphoric acid concentrated sludge acid, a sludge acid byproduct fertilizer is high in fluorine content, and the potassium element cannot be efficiently utilized, are solved.

Owner:SINOCHEM YUNLONG

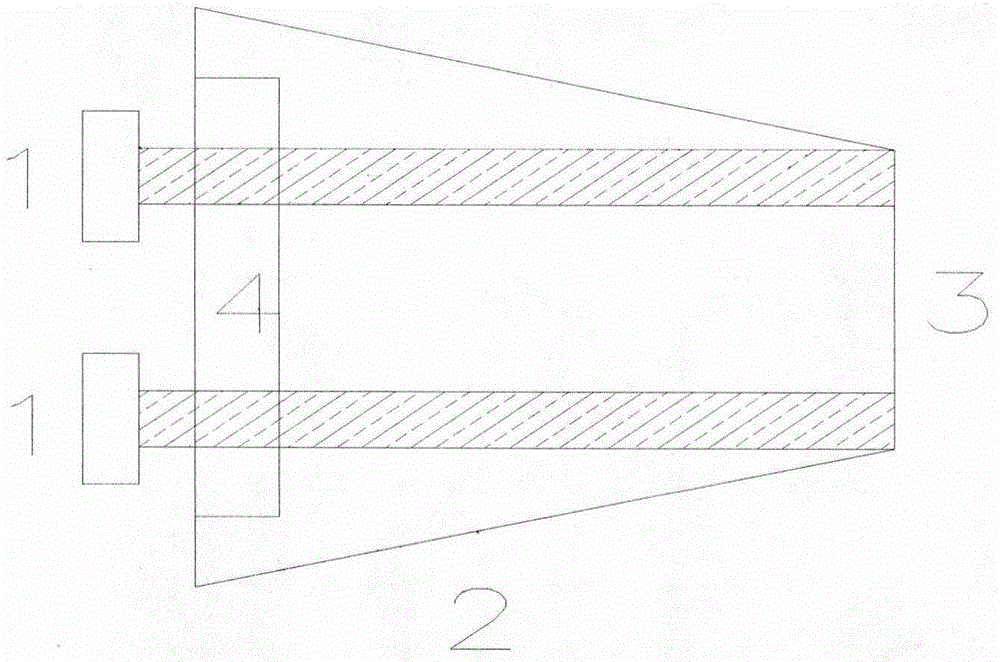

Machinery pretreatment method for dissolving lignocellulose raw material

InactiveCN105463893AIncreased dissolution yieldIncrease dissolution ratePulp properties modificationFibrous raw materialsFiberCellulose

The invention discloses a machinery pretreatment method for dissolving a lignocellulose raw material, and belongs to the field of lignocellulose processing and application, and aims at providing a machinery pretreatment process for dissolving lignocelluloses, and the machinery pretreatment process is simple and fast, and is high in efficiency. The machinery pretreatment method comprises that a, the lignocellulose raw material and an impregnating solution are mixed, and fully stirred, and are heated and swollen; b, a certain quality of the mixture of the lignocellulose raw material and the impregnating solution is conveyed to a machinery pretreatment device; c, the machinery pretreatment device continuously rubs, impregnates and extrudes the lignocellulose raw material and the impregnating solution; and d, lignocellulose is collected after being extruded and serves as a dissolving raw material. With respect to the machinery pretreatment method for dissolving the lignocellulose raw material, an existing extruding device is refitted, investment of extra complex equipment is not needed, efficient pretreatment to lignocellulose can be completed, and the comprehensive production cost of lignocellulose dissolving and processing is saved.

Owner:NANJING FORESTRY UNIV

Method for preparing thionocarbamates and co-producing 2-mercaptoethanol or O-alkylthioethyl xanthogenate

ActiveCN108569989AReduce generationTake advantage ofThiol preparationFlotationAcid washingMineral flotation

The invention belongs to field of mineral flotation collecting agent materials and in particular discloses a method for preparing thionocarbamates. The method comprises the following steps: carrying out esterification reaction on xanthogenate and 2-halogenated ethanol to obtain O-alkyl-S-hydroxyethyl xanthogenate; carrying out ammonolysis reaction on the O-alkyl-S-hydroxyethyl xanthogenate and fatty amine to obtain a mixture of the thionocarbamates and 2-mercaptoethanol; after carrying out alkali washing on the mixture of the thionocarbamates and the 2-mercaptoethanol, carrying out oil-water separation, wherein an oil phase is the thionocarbamates and a water phase is 2-hydroxyethanethiol salt; carrying out acid washing on the 2-hydroxyethanethiol salt to obtain 2-mercaptoethanol. The invention further provides O-alkylthioethyl xanthogenate which is prepared by enabling the 2-hydroxyethanethiol salt and alkyl halide to react to obtain 2-alkylthioethyl ethanol and enabling the 2-alkylthioethyl ethanol to react with carbon disulfide and alkali. According to the method provided by the invention, the yield of the prepared thionocarbamates, 2-mercaptoethanol and O-alkylthioethyl xanthogenate is high and the purity is high; a product is easy to separate and purity and co-production is realized; the cost is saved and the reaction efficiency is also improved; the method is green and environmentally friendly.

Owner:CENT SOUTH UNIV

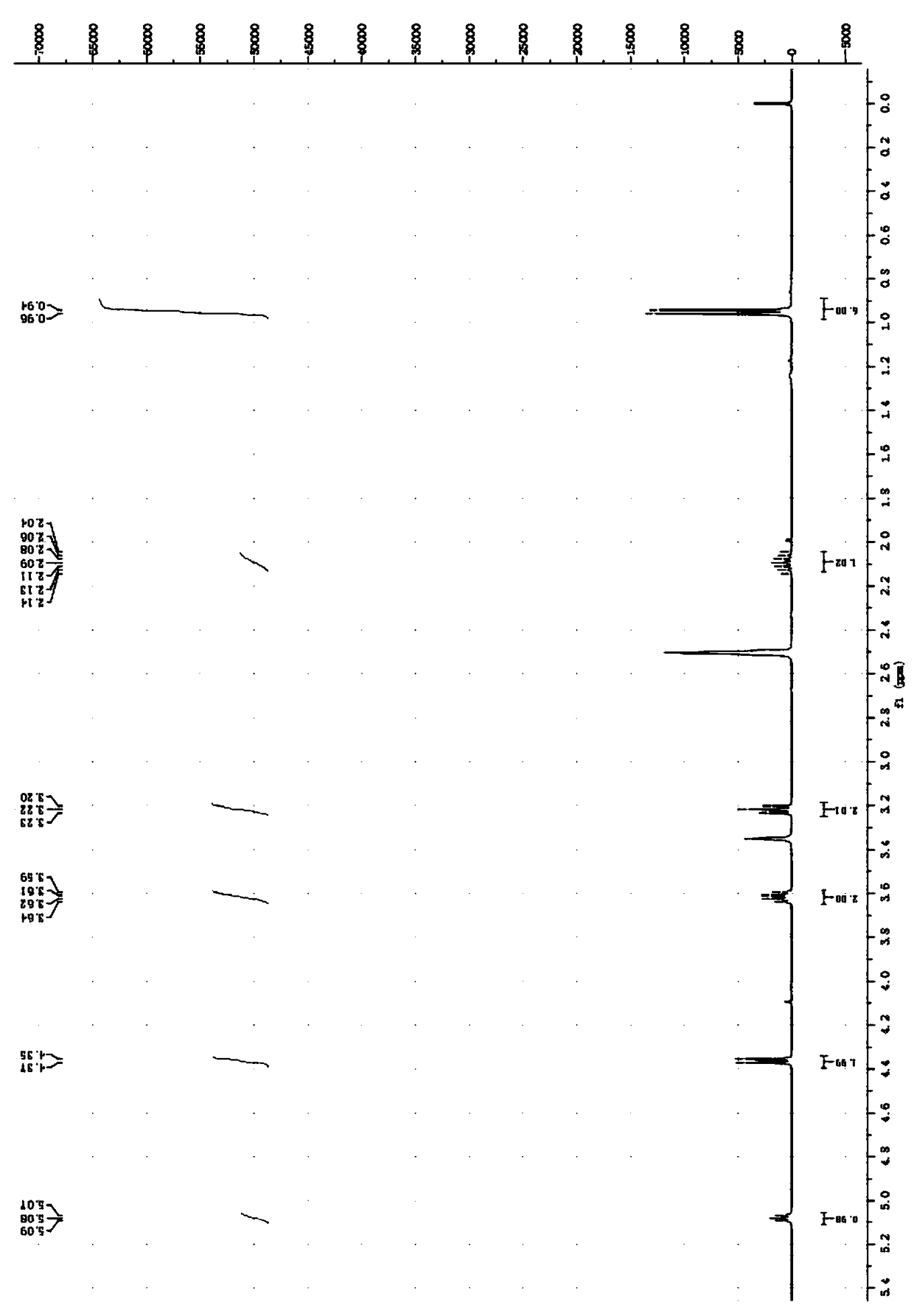

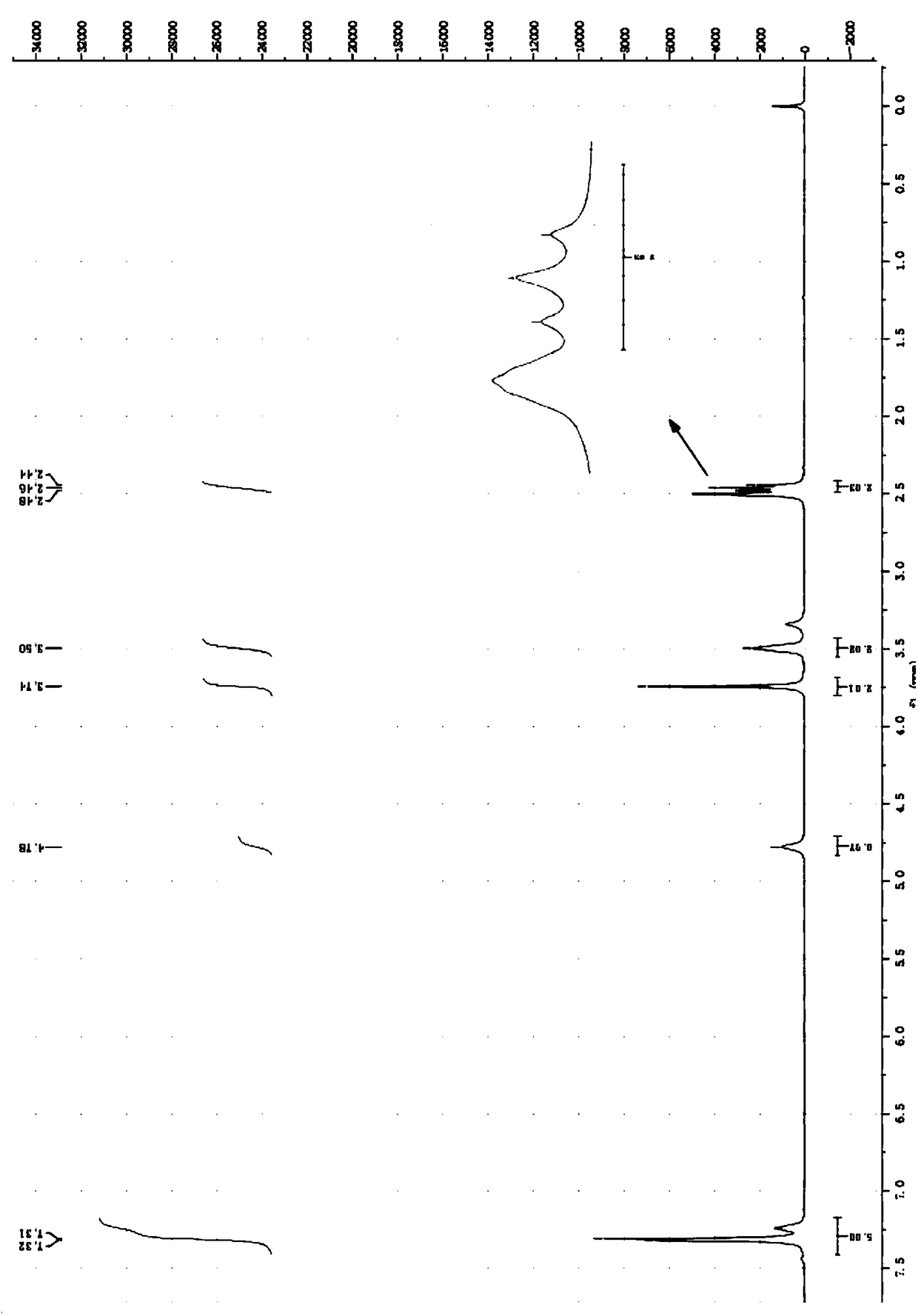

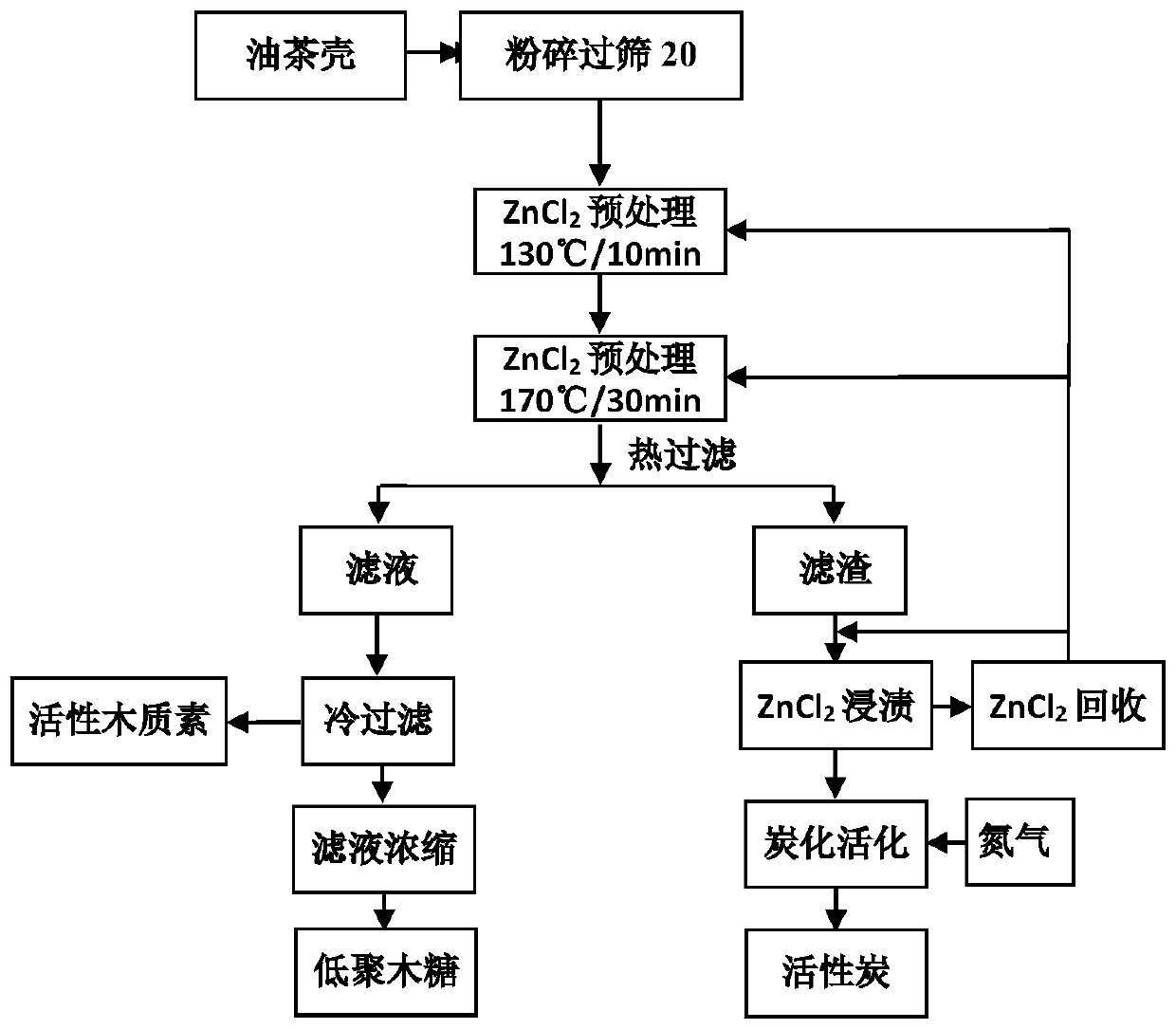

Co-production method of camellia oleifera xylooligosaccharide, lignin and active carbon

ActiveCN111470505AExcellent performance indexHigh yieldCarbon compoundsXylose productionActivated carbonCamellia oleifera

The invention belongs to the technical field of biomass chemistry and chemical engineering, and particularly relates to a co-production method of camellia oleifera xylooligosaccharide, lignin and active carbon. The method comprises the following steps: taking camellia oleifera shells as a raw material, carrying out a zinc chloride variable-temperature pretreatment and filtering; treating the filter residue I with zinc chloride, filtering, carbonizing and activating to obtain active carbon; cooling and filtering the filtrate I, drying the obtained filter residue II to obtain lignin, and concentrating and drying the obtained filtrate II to obtain xylooligosaccharide. A single catalyst zinc chloride is adopted for the first time, serves as a catalyst for the pretreatment of the camellia oleifera shells and also serves as an activating agent for preparing active carbon from camellia oleifera shell solid residues; meanwhile, through combination of specific variable-temperature pretreatmentand an activation process, lignin is obtained, the yield of xylooligosaccharide and active carbon is greatly increased, and the performance index of the active carbon is more excellent, so that the utilization rate of camellia oleifera shell components and the additional value of the product are higher.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com