Co-production method of camellia oleifera xylooligosaccharide, lignin and active carbon

A technology of xylo-oligosaccharides and lignin, which is applied in the production of sugar, xylose, sugar production, etc., can solve the problems of low added value and low utilization rate of products, and achieve high added value and high utilization rate of products. , The effect of activated carbon with excellent performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

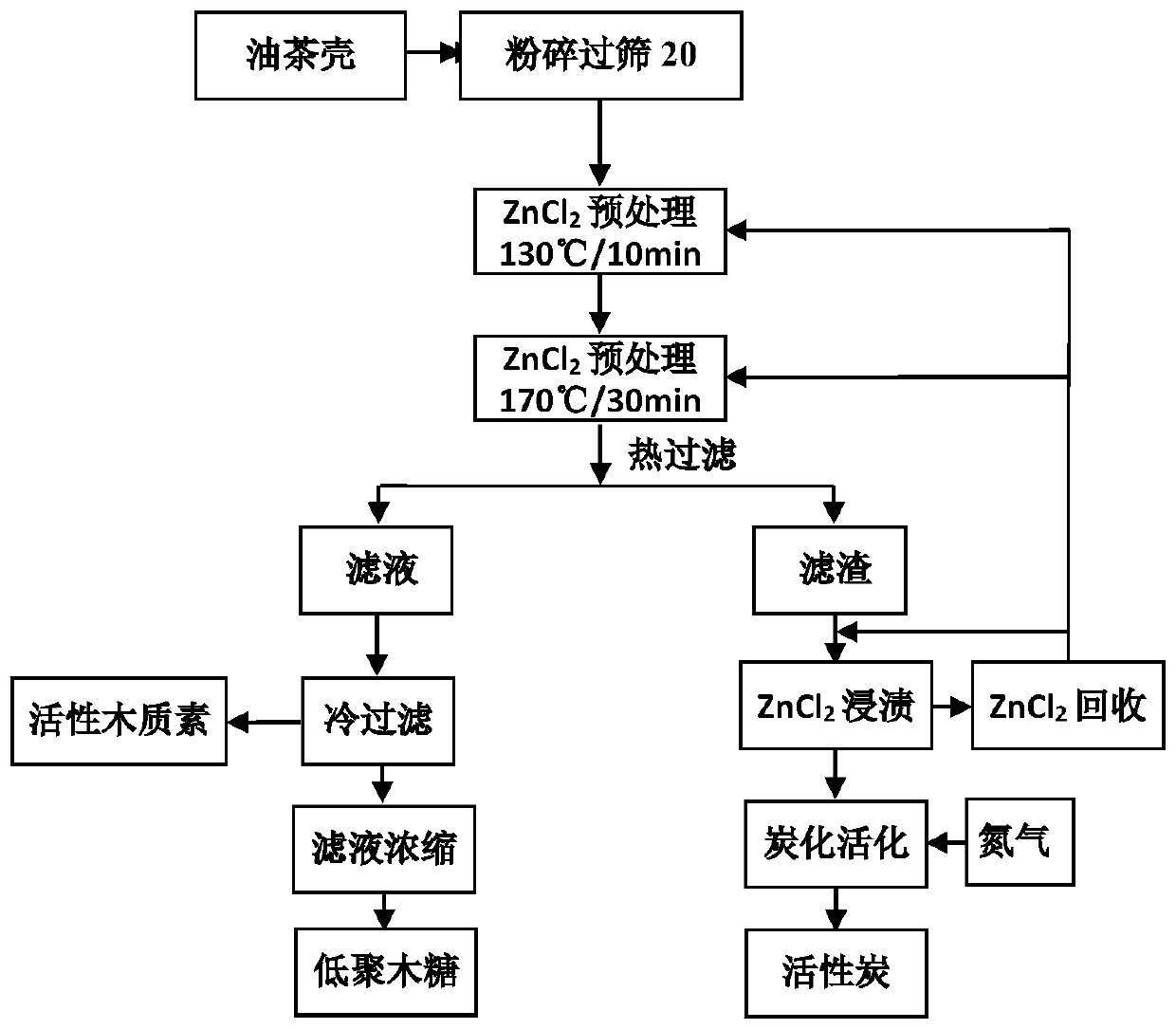

[0031] The present embodiment provides a kind of method utilizing Camellia oleifera to co-produce lignin, xylo-oligosaccharides and activated carbon, such as figure 1 shown, including:

[0032] Air-dry the harvested Camellia oleifera husks, pulverize them with a pulverizer, and sieve them through a 20-mesh sieve with a moisture content of ≤8%.

[0033] Use a 0.5% zinc chloride aqueous solution with a mass concentration of 130°C to pretreat the camellia oleifera shell for 10 minutes, and the solid-to-liquid ratio is 1:10; continue to heat up to 170°C, pretreat for 30 minutes, and the reaction is over, moderately cool down to 85°C, and keep warm filter.

[0034] After drying the filter residue, impregnate it with 16% zinc chloride aqueous solution for 12 hours, the solid-to-liquid ratio is 1:2, and after filtering, place it in a nitrogen-filled tube furnace and heat it to 500°C, synchronously carbonize and activate it for 1 hour, cool down to room temperature, and wash with 10%...

Embodiment 2

[0037] The present embodiment provides a method for co-producing lignin, xylooligosaccharides and activated carbon by using Camellia oleifera, including:

[0038] Air-dry the harvested Camellia oleifera husks, pulverize them with a pulverizer, and sieve them through a 20-mesh sieve with a moisture content of ≤8%.

[0039] Use 0.5% zinc chloride aqueous solution to pretreat the camellia oleifera shell at 130°C for 10 minutes, with a solid-to-liquid ratio of 1:10; continue to heat up to 170°C, pretreat for 10 minutes, and after the reaction is complete, moderately cool down to 85°C and filter while hot. After drying the filter residue, impregnate it with 16% zinc chloride aqueous solution for 12 hours, the solid-to-liquid ratio is 1:2, and after filtering, place it in a nitrogen-filled tube furnace and heat it to 500°C, synchronously carbonize and activate it for 1 hour, cool down to room temperature, and wash with 10% HCl Three times, wash with distilled water to neutrality, an...

Embodiment 3

[0042] The present embodiment provides a method for co-producing lignin, xylooligosaccharides and activated carbon by using Camellia oleifera, including:

[0043] Air-dry the harvested Camellia oleifera husks, pulverize them with a pulverizer, and sieve them through a 20-mesh sieve with a moisture content of ≤8%.

[0044]Use 0.5% zinc chloride aqueous solution to pretreat the camellia oleifera shell at 130°C for 10 minutes, and the solid-to-liquid ratio is 1:10; continue to heat up to 170°C, pretreat for 50 minutes, and after the reaction is completed, moderately cool down to 85°C and filter while hot. After drying the filter residue, impregnate it with 16% zinc chloride aqueous solution for 12 hours, the solid-to-liquid ratio is 1:2, and after filtering, place it in a nitrogen-filled tube furnace and heat it to 500°C, synchronously carbonize and activate it for 1 hour, cool down to room temperature, and wash with 10% HCl Three times, washed with distilled water until neutral,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com