Nano-biomass-based anticancer and sustained-release gel and preparation method of nano-biomass-based anticancer and sustained-release gel

A slow-release gel and biomass technology, which can be used in anti-tumor drugs, drug combinations, drug delivery, etc., can solve the problems of cellulose gel application and cleaning difficulties, and achieve improved use value, low preparation cost, and material source. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Add distilled water to the 10g bleached eucalyptus pulp board, make it overflow the pulp board, then loosen in the cellulose dissociation machine, every gram of slurry adopts 0.016gTEMPO, 20mmol sodium hypochlorite, 0.16g sodium bromide, and the described oxidation temperature is At 30°C, oxidize the decomposed cellulose at pH=10.5 until the pH value remains stable. Measure the solid content of oxidized cellulose, add deionized water to prepare a cellulose dispersion with a mass concentration of 1.6%, put it in a supercell pulverizer and ultrasonically for 30 minutes to obtain a nanocellulose dispersion with a negative charge on the surface, and place it at 4 °C Stored under a sealed seal, the charge on the surface of the nanocellulose is -42.56mv, and the carboxyl content of the nanocellulose is 1.2mmol / g.

[0043] Soak 10g of discarded shrimp shells in 0.1mol / L sodium hydroxide solution for 1h to remove residual protein, then wash with deionized water to neutral, then ...

Embodiment 2

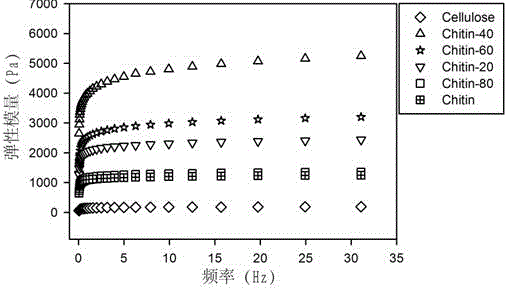

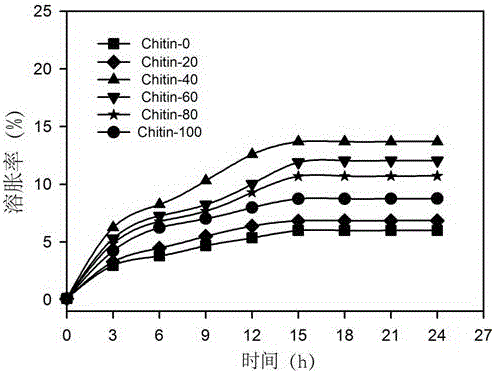

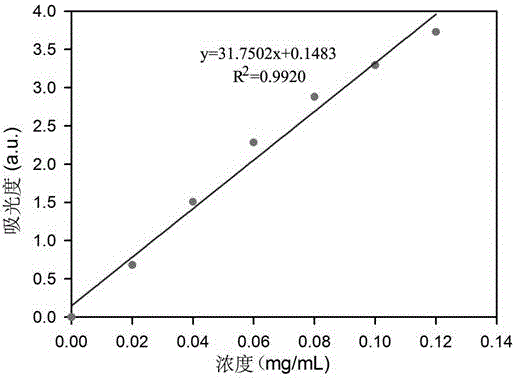

[0045] The nano-chitin dispersion prepared in Example 1 was vacuum-dried at 55° C. for 5 h, weighed 0.1 g of dried nano-chitin, and then placed in 20 ml of 0.5 mg / ml 5-fluorouracil in PBS solution, soaked for 24 h to make it Completely swell, and then vacuum-dry the swollen nano-chitin at 55°C for 5 hours again to obtain drug-loaded nano-chitin with a charge of +43.25mv and a drug loading of 341 micrograms, Figure 1a It is the electron micrograph of nano-chitin after freeze-drying, and the elastic modulus of nano-chitin dispersion is shown in figure 2 , figure 2 Among them, cellulose means nano-cellulose, Chitin means nano-chitin, Chitin-20 means nano-chitin 20% mixed gel, Chitin-40 means nano-chitin 40% mixed gel, Chitin-60 means nano-chitin 60 % mixed gel, Chitin-80 means nano-chitin 80% mixed gel.

Embodiment 3

[0047] The nanocellulose dispersion prepared in Example 1 was vacuum-dried at 55°C for 5 hours, weighed 0.1 g of dried nanocellulose, and then placed in 20 ml of 0.5 mg / ml 5-fluorouracil in PBS solution, soaked for 24 hours to make it completely Swell, and then vacuum-dry the swelled nanocellulose again at 55°C for 5h to obtain drug-loaded nanocellulose, which has a charge of -42.56mv and a drug load of 233.6 micrograms, Figure 1b It is the electron micrograph of nanocellulose after freeze-drying, and the elastic modulus of nanocellulose dispersion is shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com