Porous copper-based catalyst for preparing ethanol through carbon dioxide hydrogenation and preparation method thereof

A technology of carbon dioxide and porous copper, which is applied in the preparation of organic compounds, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of no industrialization prospects, low activity and ethanol selectivity, expensive precious metals, etc., and achieve mild conditions , simple application method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

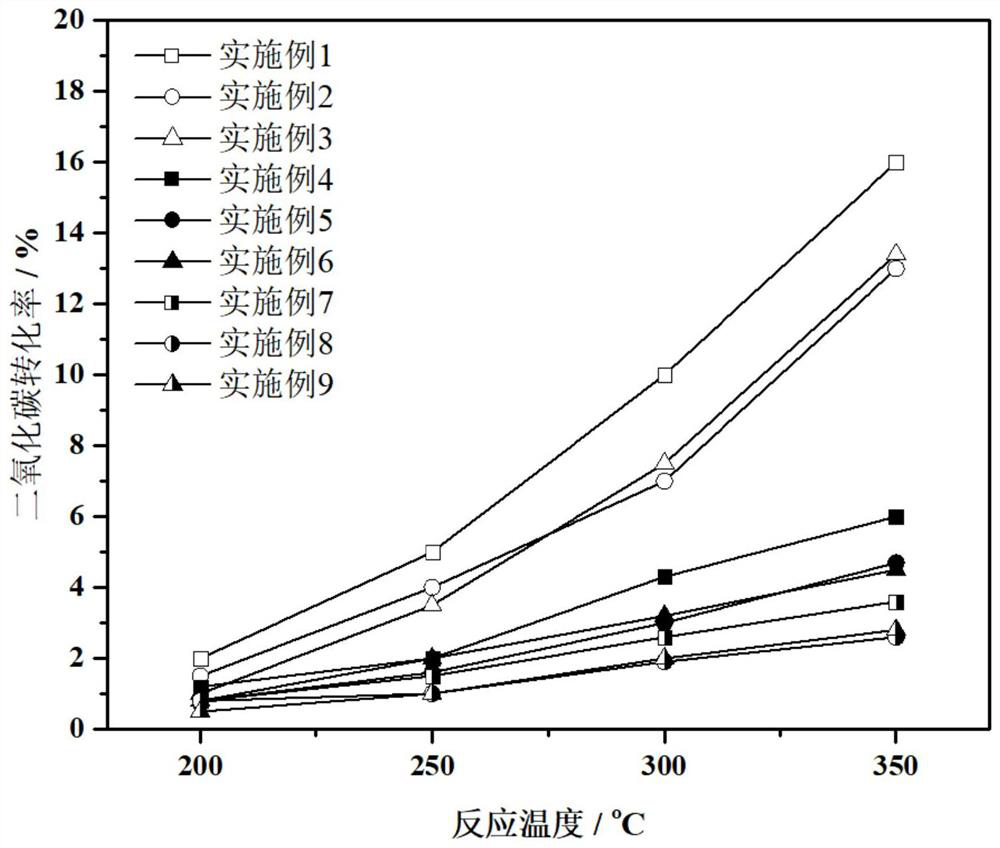

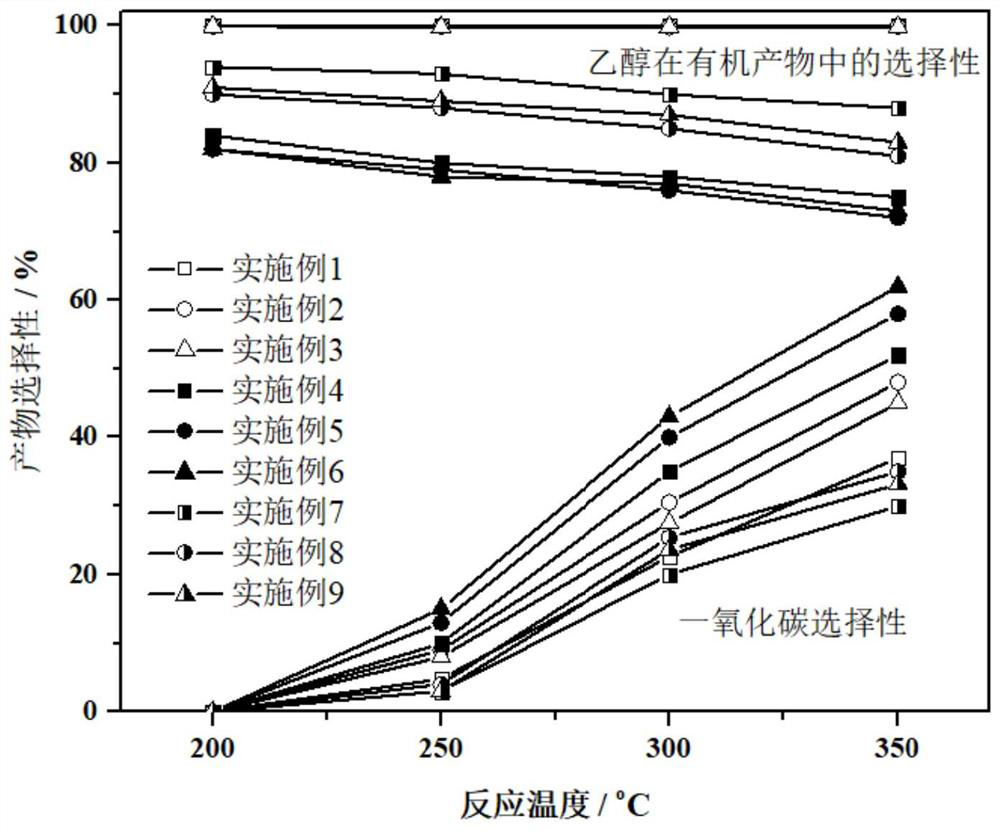

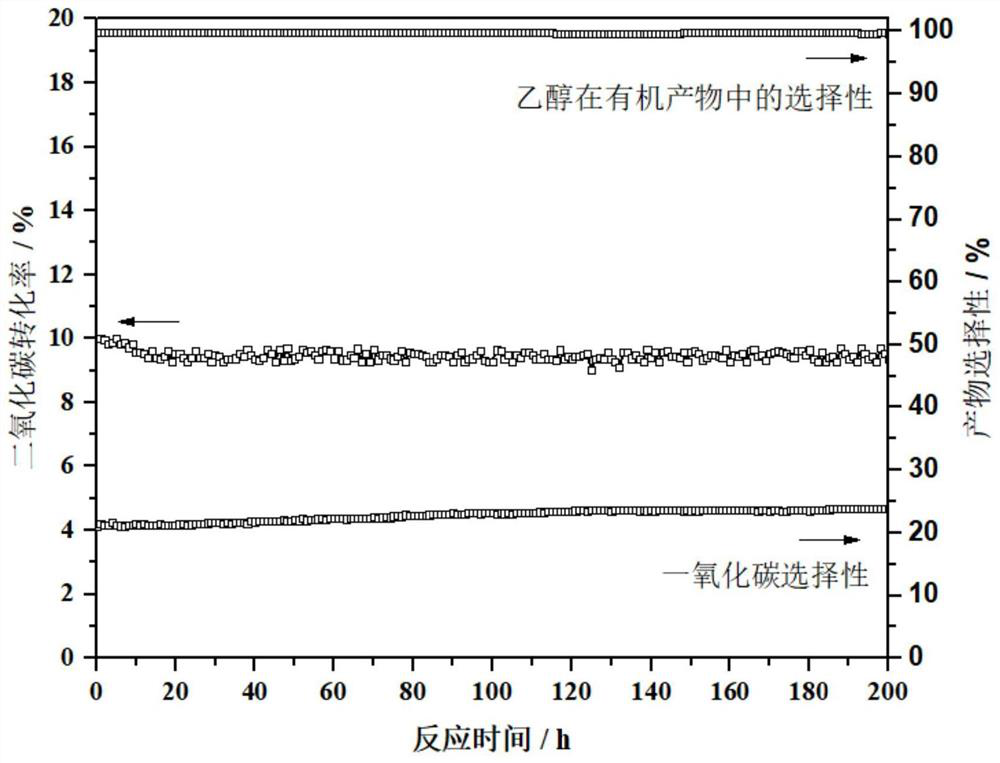

Examples

Embodiment 1

[0052] The preparation concentration is 0.15mol L -1 Cesium hydroxide solution; Weigh 6g Beta molecular sieve, disperse in 180mL prepared cesium hydroxide solution under the condition of 80℃ oil bath, stir for 30min; filter the suspension, wash the Beta molecular sieve after alkali treatment with deionized water , and then place it in a blast oven at 110°C for 12 hours;

[0053] Take by weighing 2.28g copper nitrate trihydrate, be dissolved in the deionized water of a certain amount (the water absorption of Beta type molecular sieve after 6g alkali treatment minus 0.51g), carry out equal volume impregnation to Beta type molecular sieve after alkali treatment; Beta-type molecular sieves were dried in a blast oven at 110°C for 12 hours, and then calcined in a muffle furnace at 450°C in an air atmosphere for 3 hours. The obtained samples were designated as Cu / Cs-Beta;

[0054] Under stirring conditions, 0.12g of aluminum sulfate octadecahydrate, 0.54g of silicon dioxide, 0.10g o...

Embodiment 2

[0057] According to the method of Example 1, only the alkali solution for processing Beta molecular sieves was changed to sodium hydroxide solution, and the 0.10 g of cesium hydroxide used for preparing the gel was changed to 0.03 g of sodium hydroxide, and other conditions remained unchanged.

Embodiment 3

[0059] According to the method of Example 1, only the alkali solution for processing Beta molecular sieves was changed to potassium hydroxide solution, and the 0.10 g of cesium hydroxide used for preparing the gel was changed to 0.04 g of potassium hydroxide, and the remaining conditions were unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com