Reprocessing system and method of Fischer-Tropsch synthetic diesel fraction

A Fischer-Tropsch synthesis and reprocessing technology, applied in the field of coal chemical industry, can solve the problem of no Fischer-Tropsch synthesis products, and achieve the effect of improving economic benefits and realizing diversified development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

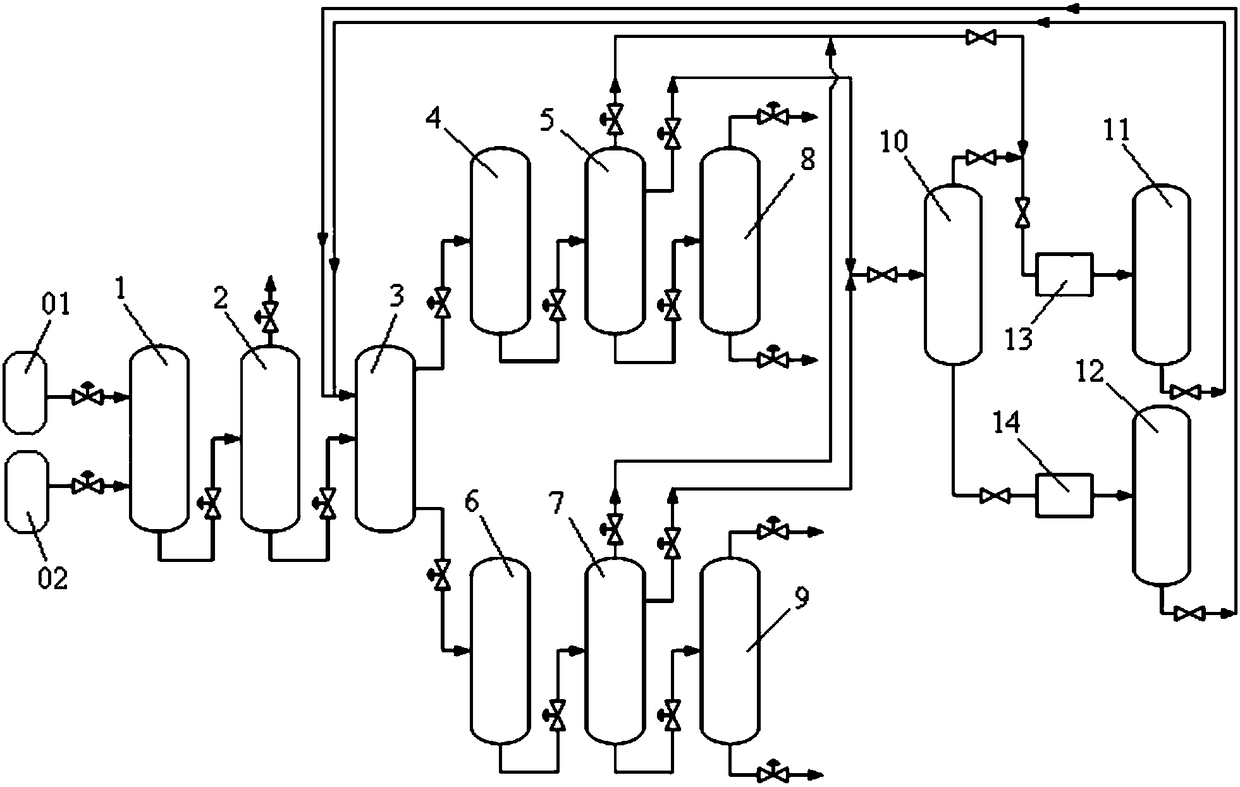

[0109] Using the reprocessing system of the present invention according to the method of the present invention, the C10-C14 alkane fractions from Fischer-Tropsch synthesis hydrotreating unit 01 and Fischer-Tropsch synthesis hydrocracking unit 02 are reprocessed to obtain the first product and the second product respectively , the third product, the fourth product, and the fifth product. in,

[0110] Molecular sieve adsorption tower 3 is a simulated moving bed adsorption separation tower, and the adsorbent used is 5A molecular sieve; the desorbent is a mixture of n-pentane and isooctane, and the mass ratio of n-pentane and isooctane is 2.5: 1; The flushing liquid is isooctane; the operating conditions are: temperature 175°C, pressure 2.73MPa;

[0111] The operating conditions of the raw material pre-rectification tower 2 are: tower top temperature 120°C, tower top pressure 0.12MPa, tower bottom temperature 260°C, tower bottom pressure 0.2MPa;

[0112] The operating conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com