Functionally gradient hard alloy with cubic phase-rich surface and preparation method thereof

A cemented carbide and functionally graded technology, which is applied in the field of functionally graded cemented carbide and functionally graded cemented carbide combined with wear resistance and toughness, can solve the problems of inconvenient industrial production and complicated process, and achieve easy technology transformation, The effect of simple equipment and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

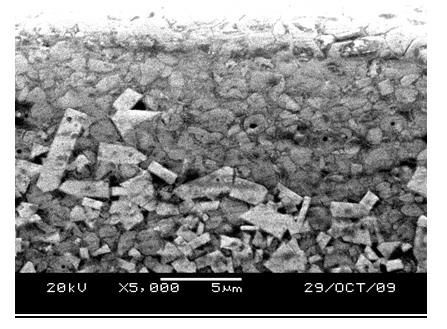

[0031] Example 1: Preparation of a functionally graded cemented carbide with a gradient layer thickness of about 5 μm

[0032] 1. Prepare tungsten carbide (WC), compound carbide ((Ti, W)C) and cobalt (Co) into powder according to the mass percentage of 79WC-15TiC-6Co, and add grinding balls according to the ball-to-material ratio of 4:1. Ball milled in absolute ethanol for 48 hours, then sieved and dried.

[0033] 2. Add SBS rubber molding agent (styrene-butadiene-styrene triblock copolymer thermoplastic elastomer) in the proportion of 110 mL / Kg to the mixed powder, sieve and granulate after drying.

[0034] 3. Press the powder into a Type B sample (20×6.5×5.25 mm) on a 20 t manual press.

[0035] 4. Put the sample into a sintering furnace with controllable atmosphere, carry out degumming treatment below 600 ℃, then raise the temperature (5 ℃ / min) to the solid-phase sintering temperature (1250 ℃), keep it warm for 1 hour, and keep it below 10 Pa The vacuum degree; then slowl...

Embodiment 2

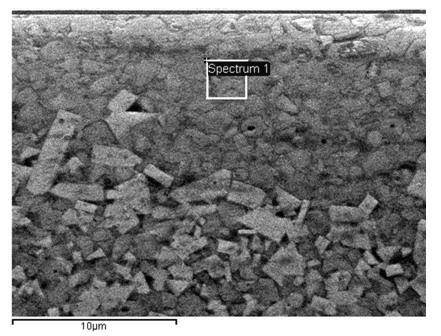

[0043] Example 2: Preparation of a functionally graded cemented carbide with a gradient layer thickness of about 7 μm

[0044] 1. The tungsten carbide (WC), compound carbide ((Ti, W)C), titanium carbonitride (Ti(C, N)), cobalt (Co) according to 73WC-14TiC-5Ti(C, N)- The mass percentage of 8Co is formulated into powder, and balls are added according to the ball-to-material ratio of 4:1, ball milled in absolute ethanol for 48 hours, then sieved and dried.

[0045] 2. Add SBS rubber molding agent (styrene-butadiene-styrene triblock copolymer thermoplastic elastomer) to the mixed powder at a ratio of 90 mL / Kg, sieve and granulate after drying.

[0046] 3. Press the powder into a Type B sample (20×6.5×5.25 mm) on a 20 t manual press.

[0047] 4. Put the sample into a sintering furnace with controllable atmosphere, carry out degumming treatment below 600 ℃, then raise the temperature (8 ℃ / min) to the solid-phase sintering temperature (1200 ℃), keep it warm for 1 hour, and keep it b...

Embodiment 3

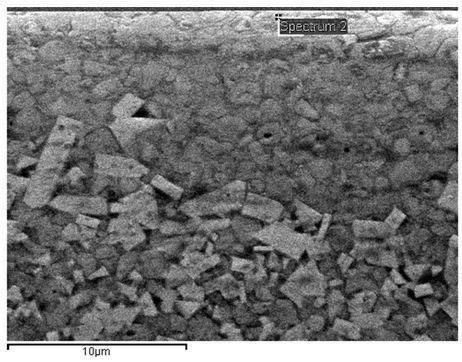

[0048] Example 3: Preparation of a functionally graded cemented carbide with a gradient layer thickness of about 12 μm

[0049] 1. The tungsten carbide (WC), compound carbide ((Ti, W)C), titanium carbonitride (Ti(C, N)), cobalt (Co) according to 67WC-16TiC-7Ti(C, N)- The mass percentage of 10Co is formulated into powder, and balls are added according to the ball-to-material ratio of 4:1, ball milled in absolute ethanol for 48 hours, then sieved and dried.

[0050] 2. Add SBS rubber molding agent (styrene-butadiene-styrene tri-block copolymer thermoplastic elastomer) to the mixed powder at a ratio of 95 mL / Kg, sieve and granulate after drying.

[0051] 3. Press the powder into a Type B sample (20×6.5×5.25 mm) on a 20 t manual press.

[0052] 4. Put the sample into a sintering furnace with controllable atmosphere, carry out degumming treatment below 600 ℃, then raise the temperature (7 ℃ / min) to the solid-phase sintering temperature (1230 ℃), keep it warm for 1 hour, and keep i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com