Method for recycling phosphorus and fluorine in phosphoric acid concentrated sludge acid and producing low-fluorine water-soluble fertilizer through cogeneration

A phosphoric acid concentration and water-soluble fertilizer technology, which is applied in the field of phosphorus chemical industry, can solve the problems of inefficient utilization of potassium, difficulty in separating fluorine impurities, and high fluorine content in products, so as to achieve improved reaction conversion efficiency, good fluidity, and low viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

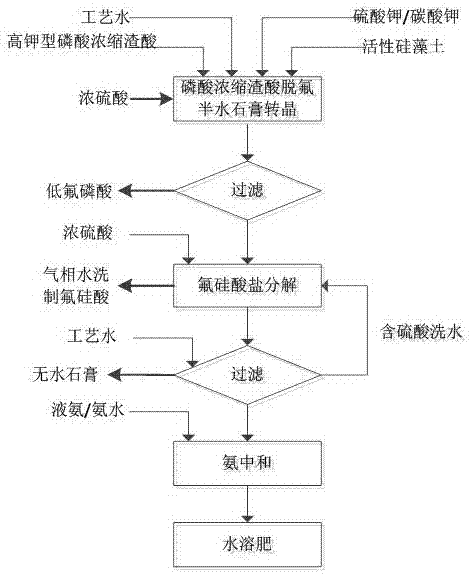

Image

Examples

Embodiment 1

[0040] Phosphoric acid concentrated slag acid detection index:

[0041] Analysis Project

Phosphorus pentoxide / %

Solid content / %

Free fluorine / %

20

60

10

3

0.1

[0042] Use a small amount of process water to adjust the acid-liquid-solid ratio of phosphoric acid concentrated slag to 1.5:1, the mass fraction of water-soluble phosphorus pentoxide is 15%, add an excess of 10% active diatomite and potassium sulfate to remove free fluorine, and add sulfuric acid to adjust The mass fraction of sulfur trioxide is 3% to promote the conversion of hemihydrate gypsum in slag acid to dihydrate gypsum to release intercrystalline phosphorus. The reaction temperature is 40°C and the reaction time is 3 hours. The liquid phase low-fluorine phosphoric acid and solid phase filter cake are obtained by filtration and separation. The mass fraction of phosphorus pentoxide in low-fluorine phosphoric a...

Embodiment 2

[0049] Phosphoric acid concentrated slag acid detection index:

[0050] Analysis Project

Phosphorus pentoxide / %

Solid content / %

Sodium oxide / %

Free fluorine / %

25

52

9

2.5

0.2

[0051] Use a small amount of process water to adjust the acid-liquid-solid ratio of phosphoric acid concentrated slag to 1.6:1, the mass fraction of water-soluble phosphorus pentoxide is 20%, add an excess of 20% active diatomite and potassium carbonate to remove free fluorine, and add sulfuric acid to adjust The mass fraction of sulfur trioxide is 3.5% to promote the conversion of hemihydrate gypsum in slag acid to dihydrate gypsum to release intercrystalline phosphorus. The reaction temperature is 50°C, the reaction time is 2h, and the liquid phase low-fluorine phosphoric acid and solid phase filter cake are obtained by filtration and separation. The mass fraction of phosphorus pentoxide in low-fluorine phosphoric ...

Embodiment 3

[0058] Phosphoric acid concentrated slag acid detection index:

[0059] Analysis Project

Solid content / %

Potassium oxide / %

Sodium oxide / %

Free fluorine / %

30

45

8

2

0.5

[0060] Use a small amount of process water to adjust the acid-liquid-solid ratio of phosphoric acid concentrated slag to 1.8:1, the mass fraction of water-soluble phosphorus pentoxide is 25%, add an excess of 40% active diatomite and potassium sulfate to remove free fluorine, and add sulfuric acid to adjust The mass fraction of sulfur trioxide is 4% to promote the conversion of hemihydrate gypsum in slag acid to dihydrate gypsum to release intercrystalline phosphorus. The reaction temperature is 50°C, the reaction time is 1h, and the liquid phase low-fluorine phosphoric acid and solid phase filter cake are obtained by filtration and separation. The mass fraction of phosphorus pentoxide in low-fluorine phosphoric acid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com