Patents

Literature

180results about "Fluosilicic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

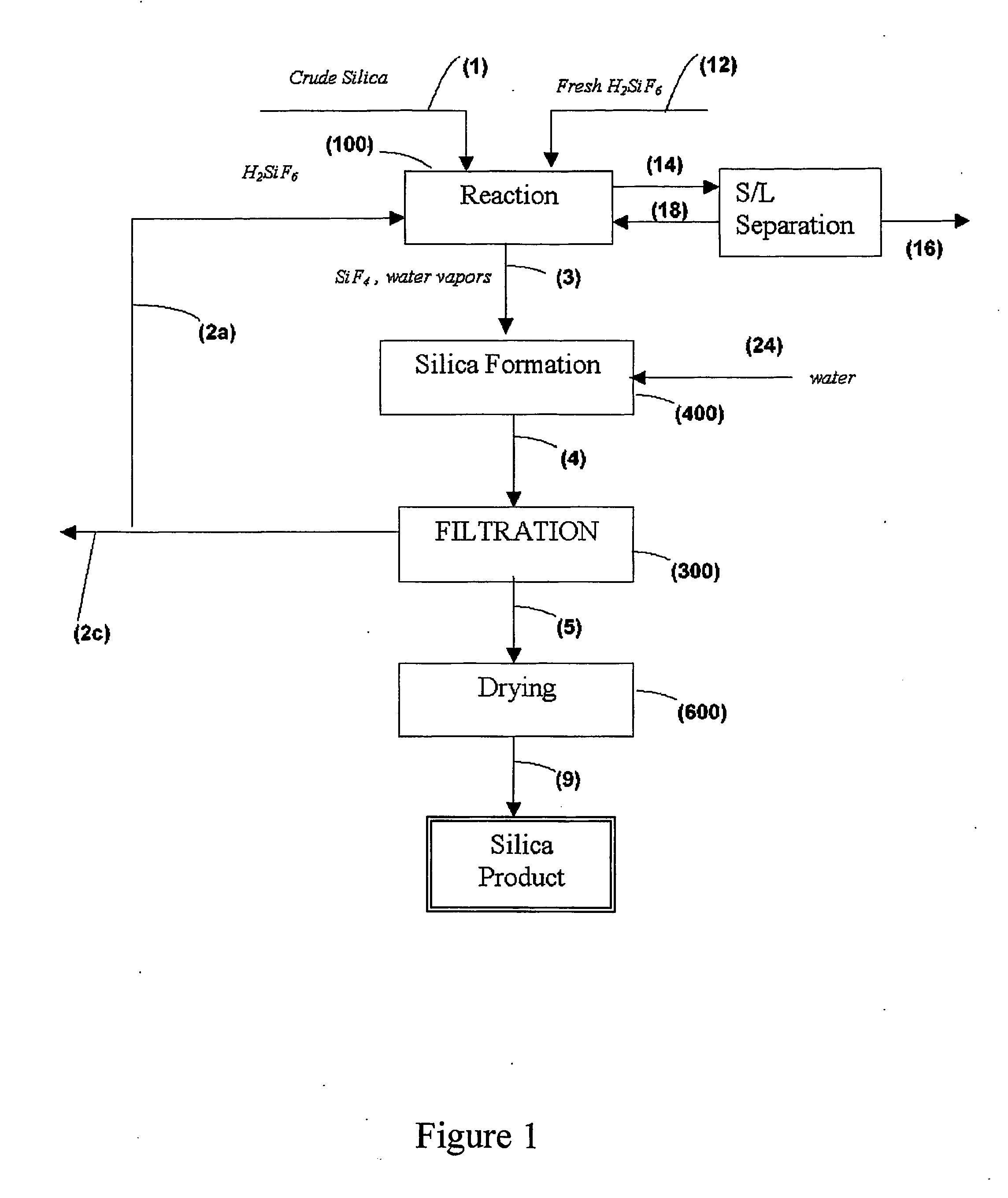

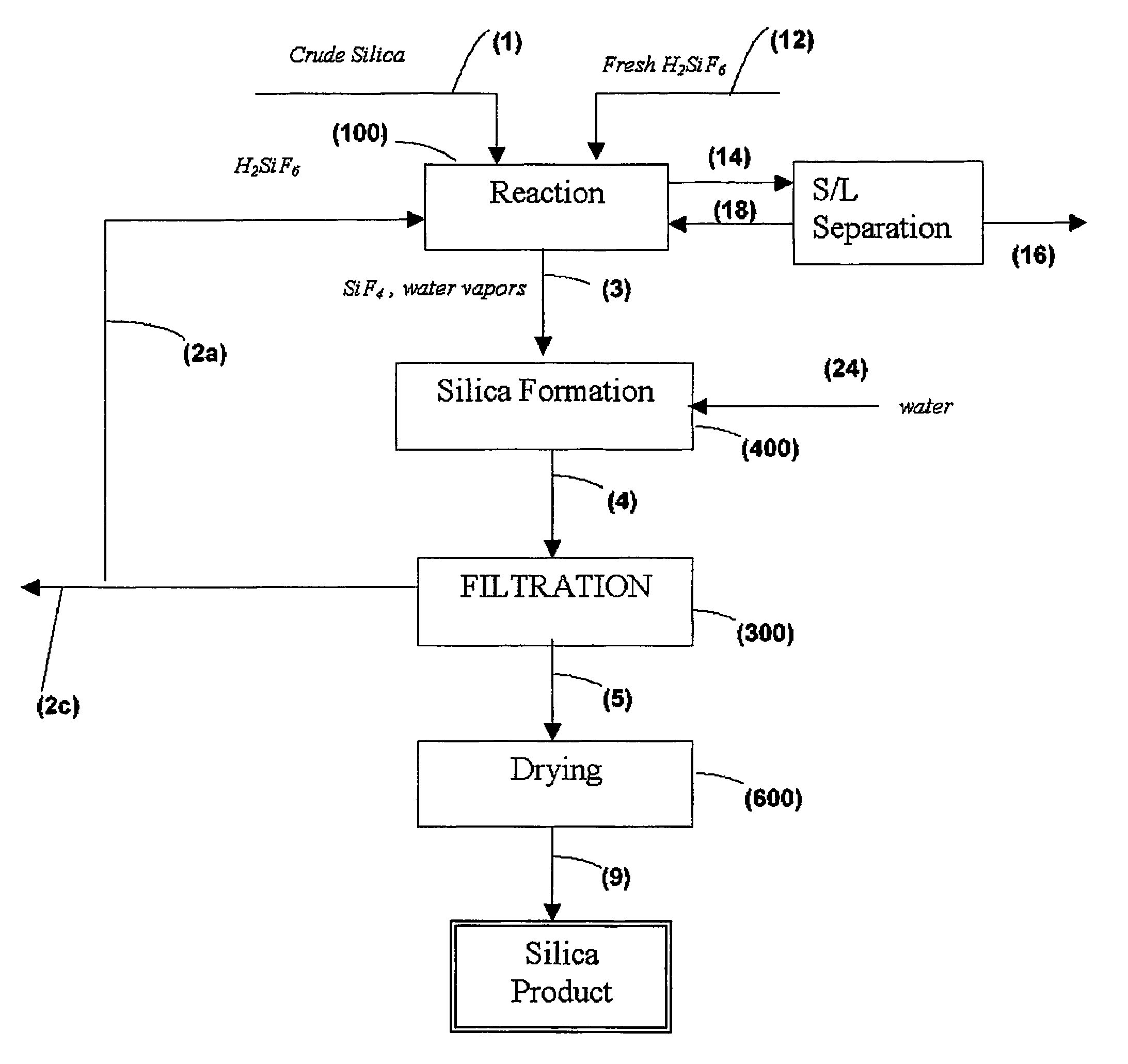

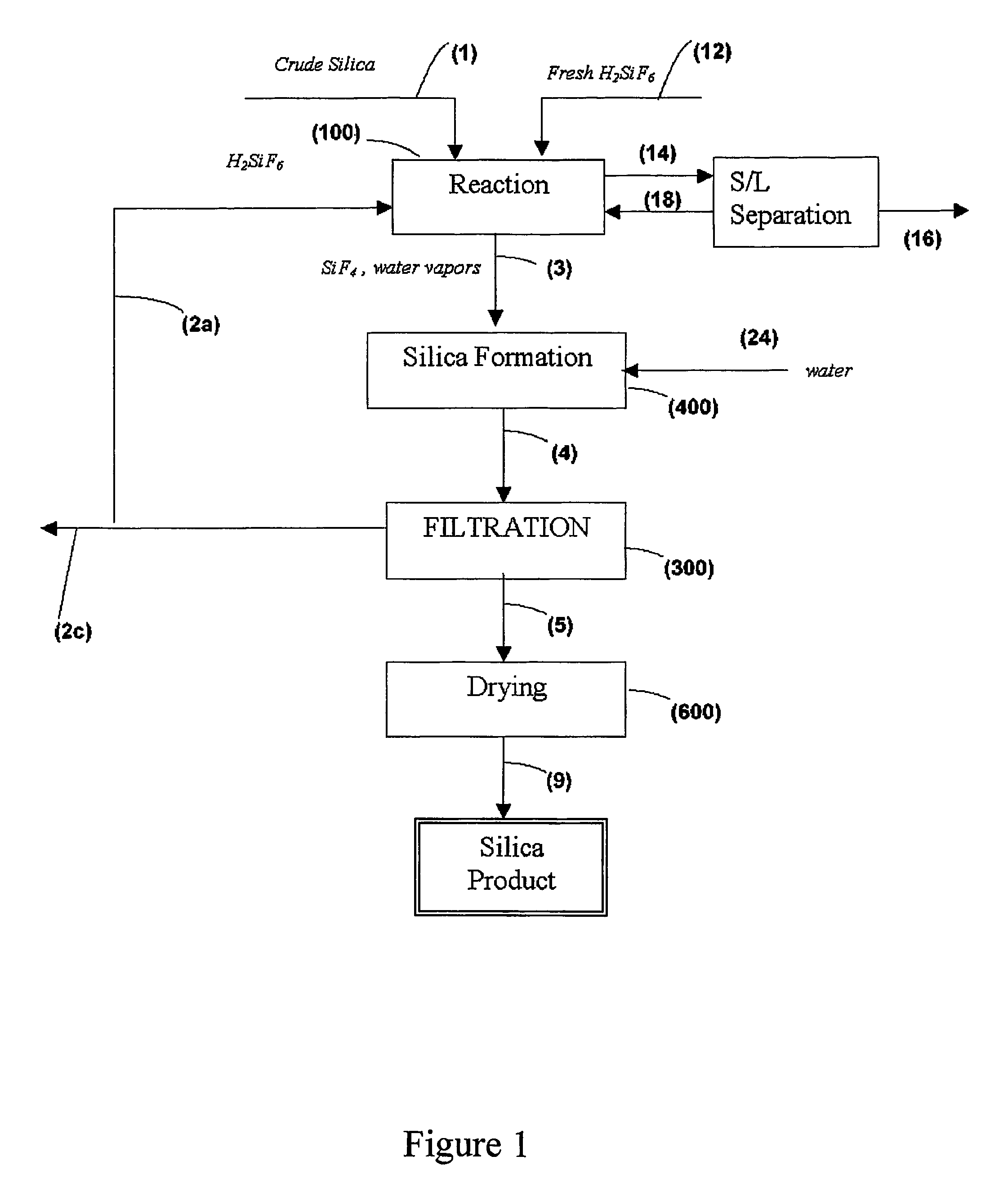

Process for the preparation of pure silica

InactiveUS20050106091A1Simple and efficient and cost-effectiveSilicaFluosilicic acidSilicon tetrafluorideSilicon dioxide

A production process for producing high-purity silica from a crude silica source by means of fluosilic acid, including the steps of: (a) subjecting the crude silica souce and the fluosilicic acid to a reaction in a reaction stage, so as to produce silicon tetrafluoride and water; (b) selectively evaporating the silicon tetrafluoride with respect to at least a portion of at least one impurity derived from the crude silica source, and (c) reacting the silicon tetrafluoride with water to produce the high-purity silica, wherein the reaction stage (a) is performed at a temperature above 75° C.

Owner:ATI ALUMINUM TECH ISRAEL

Silicon Production Process

An improved process for producing high purity silicon results from the reaction of sodium with pure silicon tetrafluoride gas, which produces sodium fluoride as a by-product. The silicon tetrafluoride gas is formed by decomposing sodium fluorosilicate. The sodium fluorosilicate is produced by precipitation when fluorosilicic acid (FSA) is reacted with the by-product sodium fluoride in closed loop process. Likewise, the fluorosilicic acid is preferably formed at high purity using a source material that consists essentially of silica by reacting the by-product sodium fluoride with an acid to create reactive fluoride ions.

Owner:CIRCULON HUNGARY

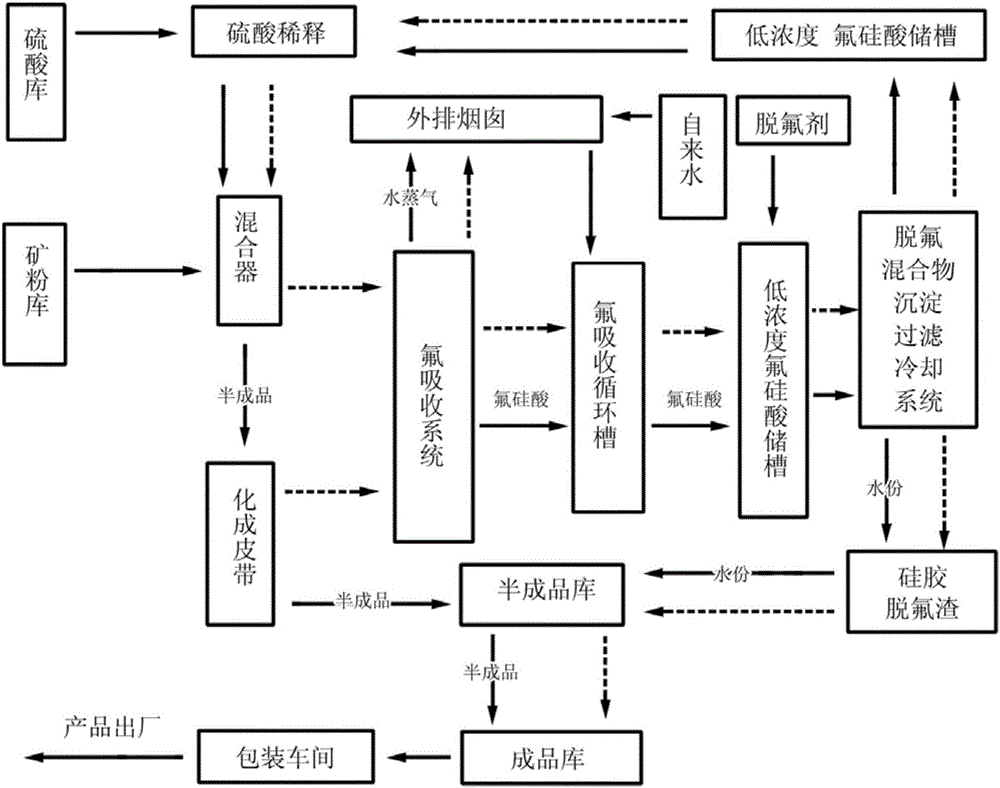

Fluosilicic acid comprehensive recycling technology

InactiveCN106587073ASatisfy the phenomenon of non-blocking wallEffective temperature controlFluosilicic acidPhosphoric acidHexafluorosilicic acid

The invention relates to a fluosilicic acid comprehensive recycling technology. The technology is characterized in that calcium superphosphate and a by-product, namely fluosilicic acid, generated by a fluorine absorption system in the wet-process phosphoric acid production technology are used as main materials. The technology includes the material reaction step, wherein clean water is added into a fluorine absorption circulating tank, after overflowing fluorine-containing gas is cyclically absorbed, circulating liquid enters a low-concentration fluosilicic acid storage tank and then enters a defluorination system after being cooled and precipitated, silica gel defluorination residues are removed after defluorination and filtering, filter residues serve as product filler, most of filter liquor serves as diluting sulfuric acid, very little part of the filter liquor overflows to the circulating tank through a high-place pond and absorbed and circulated again with newly added clean water, and sulfuric acid consumption is reduced; clean water circulating liquid injected into the fluorine absorption circulating tank for the first time is absorbed and then conveyed to the high-place low-concentration fluosilicic acid (1.5-1.8 baume degrees) storage tank to serve as diluted concentrated sulfuric acid, and remaining circulating liquid enters the fluorine absorption circulating tank to be absorbed. The technology has the advantage of effectively achieving the aims of energy conservation, emission reduction and efficient comprehensive recycling.

Owner:杨海

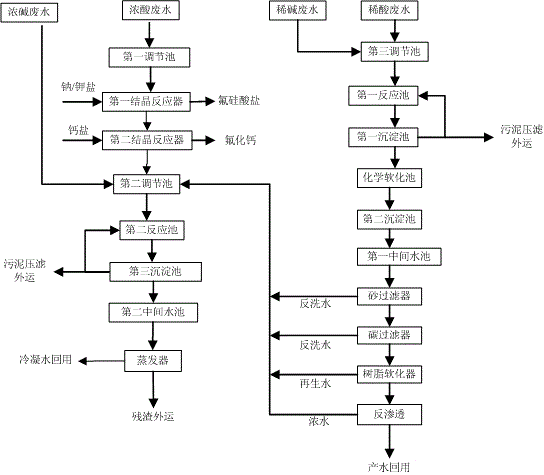

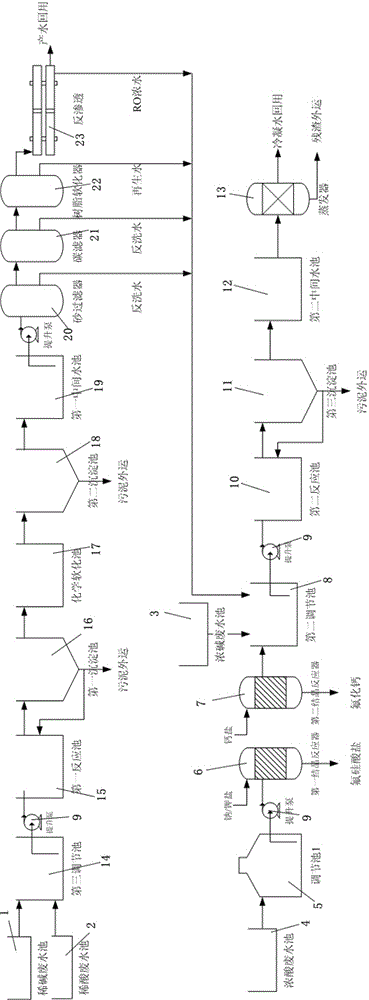

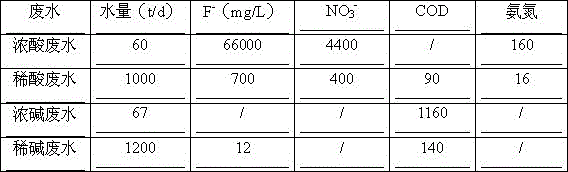

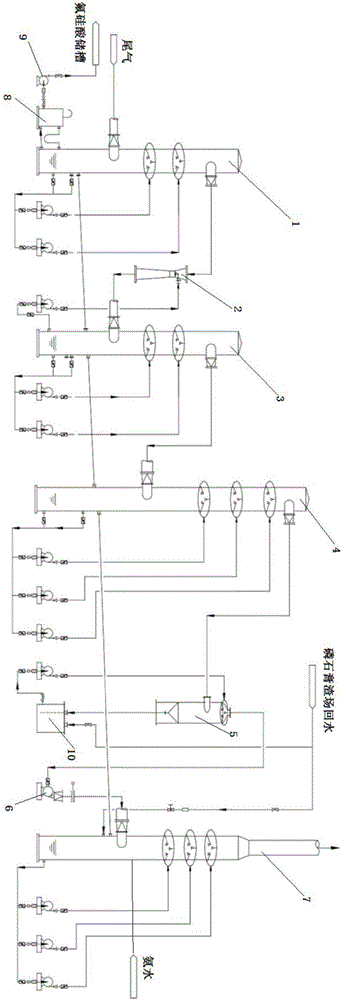

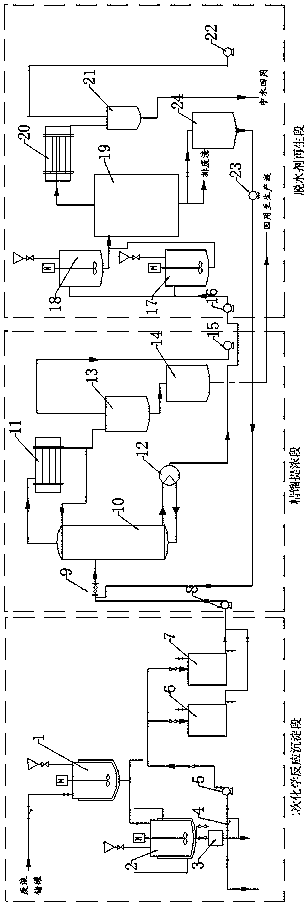

Process and system for resourcing and recycling fluorine-containing wastewater in photovoltaic industry

ActiveCN106746113AThe process is highly targetedReduce processing difficultyCalcium/strontium/barium fluoridesScale removal and water softeningPhotovoltaic industryActivated carbon filtration

The invention provides a process for resourcing and recycling fluorine-containing wastewater in the photovoltaic industry. The process comprises the following steps: sorting and collecting concentrated acid wastewater, concentrated alkali wastewater, diluted acid wastewater and diluted alkali wastewater; adding sodium salt or potassium salt into the concentrated acid wastewater according to the concentration of fluorosilicate ions of the concentrated acid wastewater to perform crystallizing reaction to obtain fluosilicate, and adding calcium salt into the concentrated acid wastewater according to the fluorinion concentration of the concentrated acid wastewater to perform crystallizing reaction to obtain calcium fluoride; removing fluorine from the diluted alkali wastewater and diluted acid wastewater, feeding into a precipitation tank for precipitating treatment, performing chemical softening treatment, sequentially passing through a sand filter, an activated carbon filter, a resin softener and a reverse osmosis device to obtain produced water; crystallizing the concentrated acid wastewater, feeding system effluent and concentrated alkali wastewater into a reaction tank for fluorine removal treatment, feeding into the precipitation tank for precipitating treatment, and producing condensed water through an evaporator. Furthermore, the invention provides a system for resourcing and recycling the fluorine-containing wastewater in the photovoltaic industry.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +1

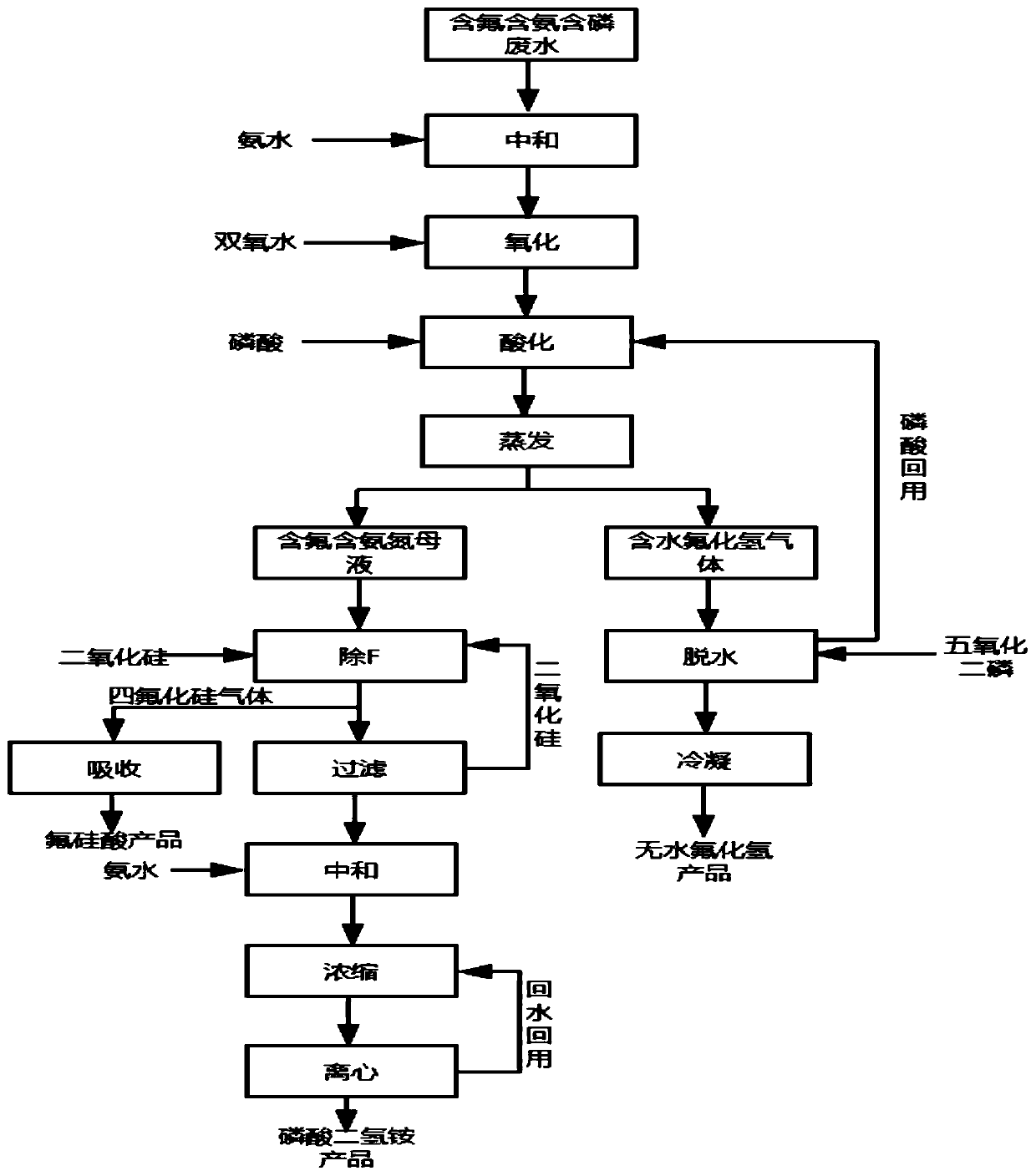

Treatment method for wastewater containing fluorine, ammonia nitrogen and phosphorus

ActiveCN110092523ACombined enoughEnsure the efficiency of phosphorous and hypophosphorousWater/sewage treatment by centrifugal separationWater treatment parameter controlDistillationPhosphoric acid

The invention discloses a treatment method for wastewater containing fluorine, ammonia nitrogen and phosphorus. The treatment method comprises the following steps: (1) adding ammonia water to the wastewater to adjust the obtained solution to be alkaline, adding hydrogen peroxide to the wastewater, and performing heating and stirring; (2) adding concentrated phosphoric acid to the wastewater obtained in step (1), performing uniform stirring to adjust the obtained solution to be strong acidic, and heating and distilling the solution; (3) adding an excess amount of silica to a mother liquor obtained after the distillation in step (2), and performing stirring; (4) filtering a solution obtained in step (3) to remove silica, adding ammonia water to neutralize the obtained filtrate to be weakly acidic, and heating the filtrate to concentrate the filtrate; and (5) placing and centrifuging a mother liquor obtained in step (4) in a centrifuge to obtain ammonium dihydrogen phosphate crystals, andreusing the centrifuged clear liquid in the concentrating process in the step (4).

Owner:盛隆资源再生(无锡)有限公司

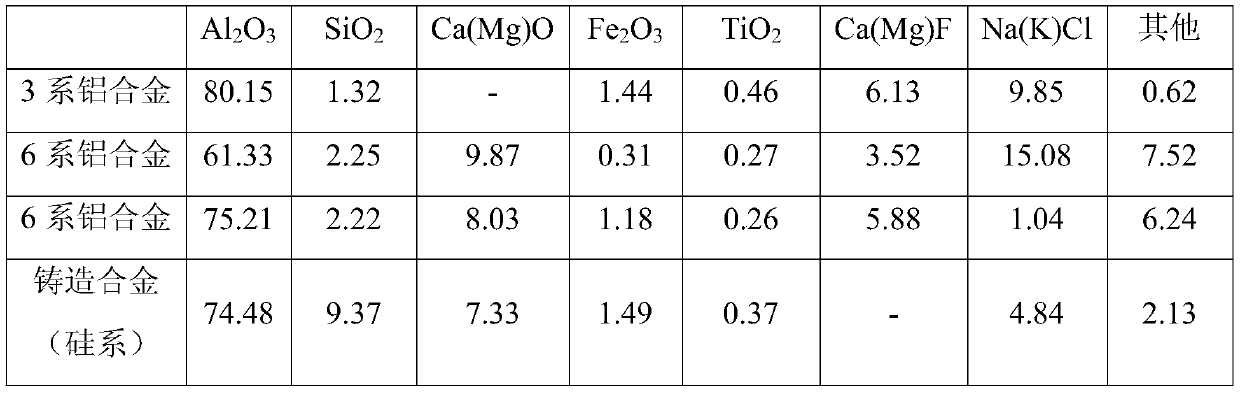

Resource separation and recycling method of aluminum ash

The invention relates to a resource separation and recycling method of aluminum ash. The method comprises the following steps: (1) preparing washed aluminum ash; preparing a sodium hydroxide solution;(2) putting the sodium hydroxide solution into a reactor, stirring, gradually adding the washed aluminum ash, and discharging generated hydrogen and ammonia gas; (3) adding water to dilute and stirring when hydrogen and ammonia gas are stopped being discharged, and filtering to obtain a primary filtrate; (4) under a stirring condition, adding hydrofluoric acid into the primary filtrate until thepH value is 3-5 to obtain a solid-liquid mixture; (5) filtering to obtain secondary filtrate and secondary filter residues; drying the secondary filter residues to obtain cryolite; and concentrating the secondary filtrate to prepare a Na2SiF6 product. According to the method disclosed by the invention, the aluminum ash is separated, recycled and utilized in a resource manner.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

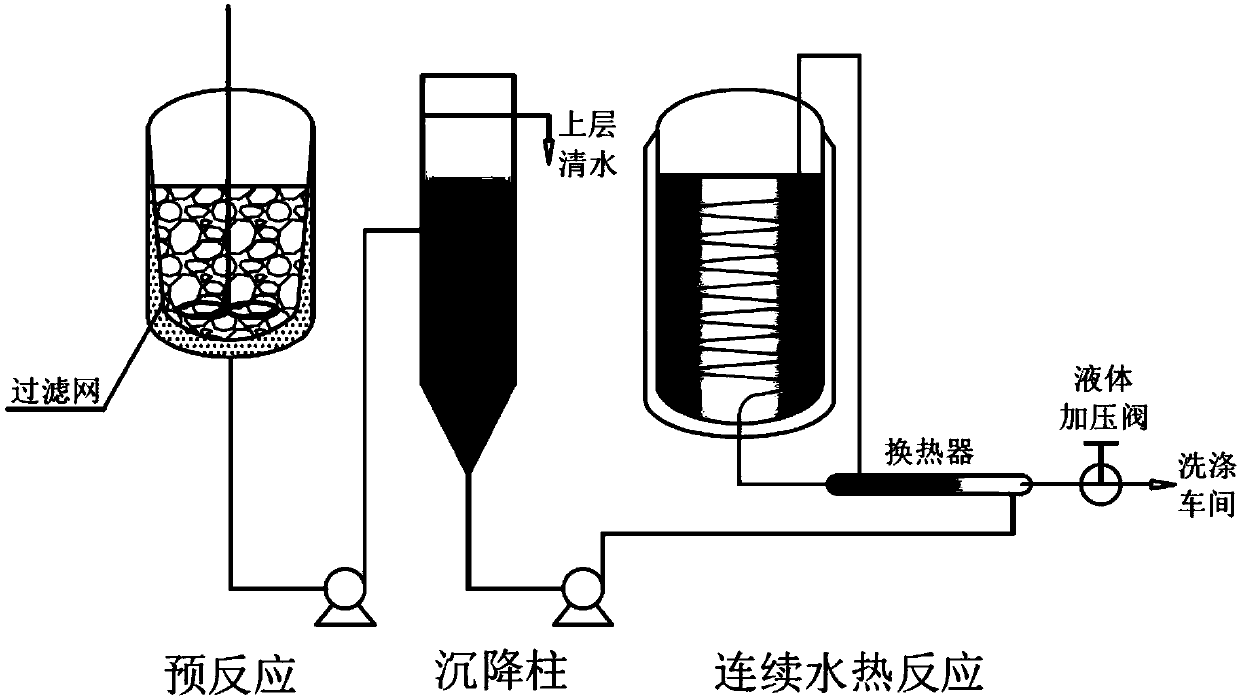

Preparation method of high transparent magnesium silicate and derivative thereof

ActiveCN108394912ARealize Gradient HeatingRealize instant response processMagnesium silicatesAluminium silicatesSettling columnSolid content

The invention relates to a preparation method of high transparent magnesium silicate and a derivative thereof, comprising the following steps: step S1: evenly mixing a silicone-containing compound solution, a magnesium-containing compound solution, a modified compound solution and a pH regulator, thus forming a reaction precursor; step S2: putting the reaction precursor into a constant temperaturekettle at 0-95 DEG C, and performing pre-reaction for 0-36h; step S3: putting the reaction precursor into a settling column, after the solid content of the reaction precursor is 5-10 percent, drivingthe reaction precursor into a heat exchanger by a pump, enabling the reaction precursor to flow into a constant temperature heating area at 150-350 DEG C and then flow out through the heat exchanger,and washing and drying a reactant which flows out to prepare a product. By regulating temperature and pressure, hydrothermal reaction can be performed instantaneously; meanwhile high hydrothermal cost is reduced, the product is stable in property, and industrialized production is easy.

Owner:云南格莱尼科技有限公司

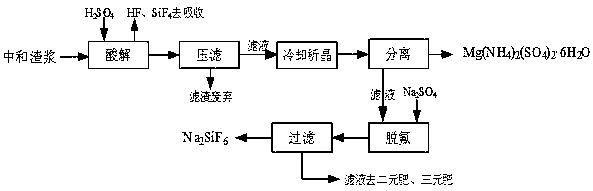

Method for recycling fluorine in neutralized slurry of industrial monoammonium phosphate

ActiveCN107827113AQuality improvementEasy to operateMagnesium sulfatesFluosilicic acidPhosphateSlurry

The invention relates to a method for recycling fluorine in neutralized slurry of industrial monoammonium phosphate. The method comprises the following steps: a, preparing the neutralized slurry and water into turbid liquid; b, slowly adding sulfuric acid in the turbid liquid and reacting, and then filtering to obtain acid-hydrolyzed filtrate; c, cooling, crystalizing and filtering the acid-hydrolyzed filtrate to obtain impurity-removed acid-hydrolyzed filtrate; and d, adding anhydrous sodium sulfate solid in the impurity-removed acid-hydrolyzed filtrate, reacting and filtering, and washing and drying filter cakes to obtain sodium fluosilicate products, wherein the filtrate is used for production of complex fertilizers. The method is simple to operate and low in treatment cost; and a way for comprehensive utilization of the neutralized slurry is provided for industrial monoammonium phosphate production enterprises.

Owner:HUBEI XIANGYUN GROUP CHEM

Method for recovering fluorine resource from fluorination residues of feed phosphate

ActiveCN105819452AReduce wasteReduce miningCalcium/strontium/barium sulfatesFluosilicic acidCyclic processPhosphate

The invention discloses a method for recovering fluorine resource from fluorination residues of feed phosphate. According to the method, enriched fluorine compounds in the fluorination residues produced during feed phosphate production is subjected to acid dissolution to remove the calcium compounds in the fluorination residues, and after the fluorine resources enter liquid phase from solid phase, a precipitator is added to recover the fluorine resources, so that the fluorine resources discarded in the prior art are completely utilized, the economic benefit of the production is increased, the resource waste is decreased, the exploitation of fluorite resources is saved, the economic benefit and social benefit of the feed phosphate production are improved, and the chemical production requirements of sustainable development are met; meanwhile, a continuous cyclic process is adopted, so that the processing efficiency is greatly improved and the processing cost is reduced.

Owner:龚家竹

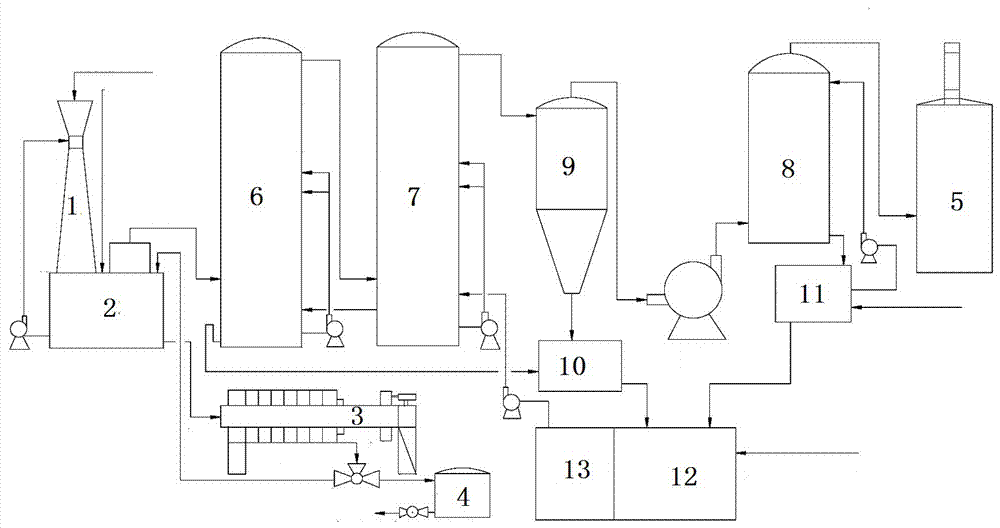

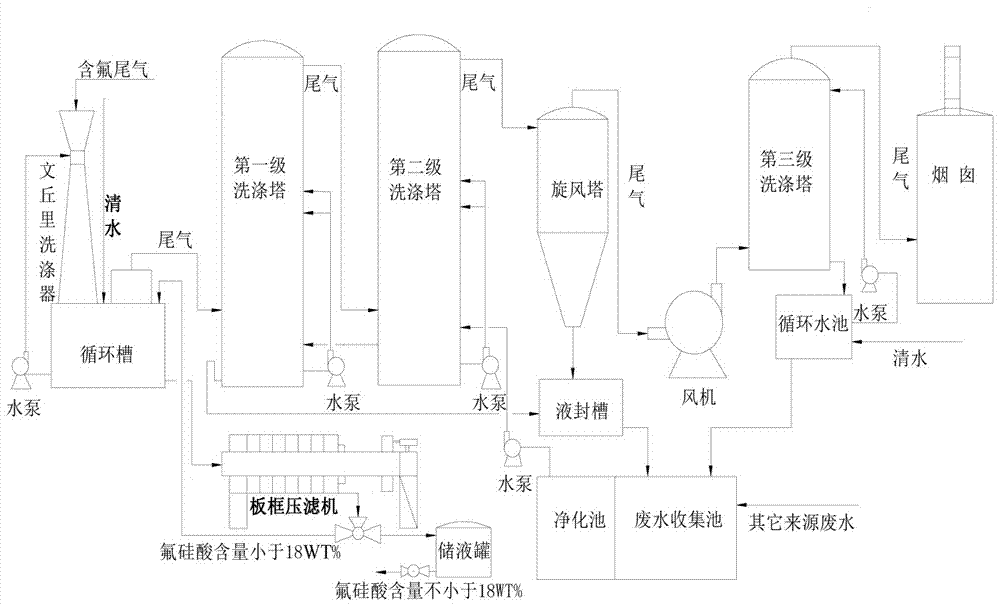

Washing and absorbing device and method for wet process phosphoric acid production tail gas

ActiveCN106268180AThe washing absorption effect is obviousImprove recycling ratesSilicaDispersed particle separationPhosphoric acidIodine

The invention discloses a washing and absorbing device and method for wet process phosphoric acid production tail gas. Five-stage countercurrent washing absorbing modes of a mono-fluoro washing and absorbing tower, a venturi washing absorber, a difluoro washing and absorbing tower, a trifluoro washing and absorbing tower and a tail gas washing and absorbing tower are adopted, after washing and absorbing are performed, high-altitude emission is performed at 80 m high part, when the concentration of a washing and absorbing solution (mainly H2SiF6) of the mono-fluoro washing and absorbing tower is larger than or equal to 10%, the solution is drained to a tail gas washing and absorbing system defluorinated silica acid storage tank to be sedimented, a supernate is adopted as a raw material of a Na2SiF6 workshop and an anhydrous HF workshop after dissolved iodine in the supernate is recycled, and lower sedimentation silica gel is adopted as a raw material of a white carbon black workshop. The device has the advantages that the obvious wet process phosphoric acid production tail gas washing and absorbing effects are obvious, the recycling rate of fluorosilicone iodine resources in tail gas is high, the device automatic degree is high, and the operation and maintenance cost is low.

Owner:GUIZHOU KAILIN GRP CO LTD

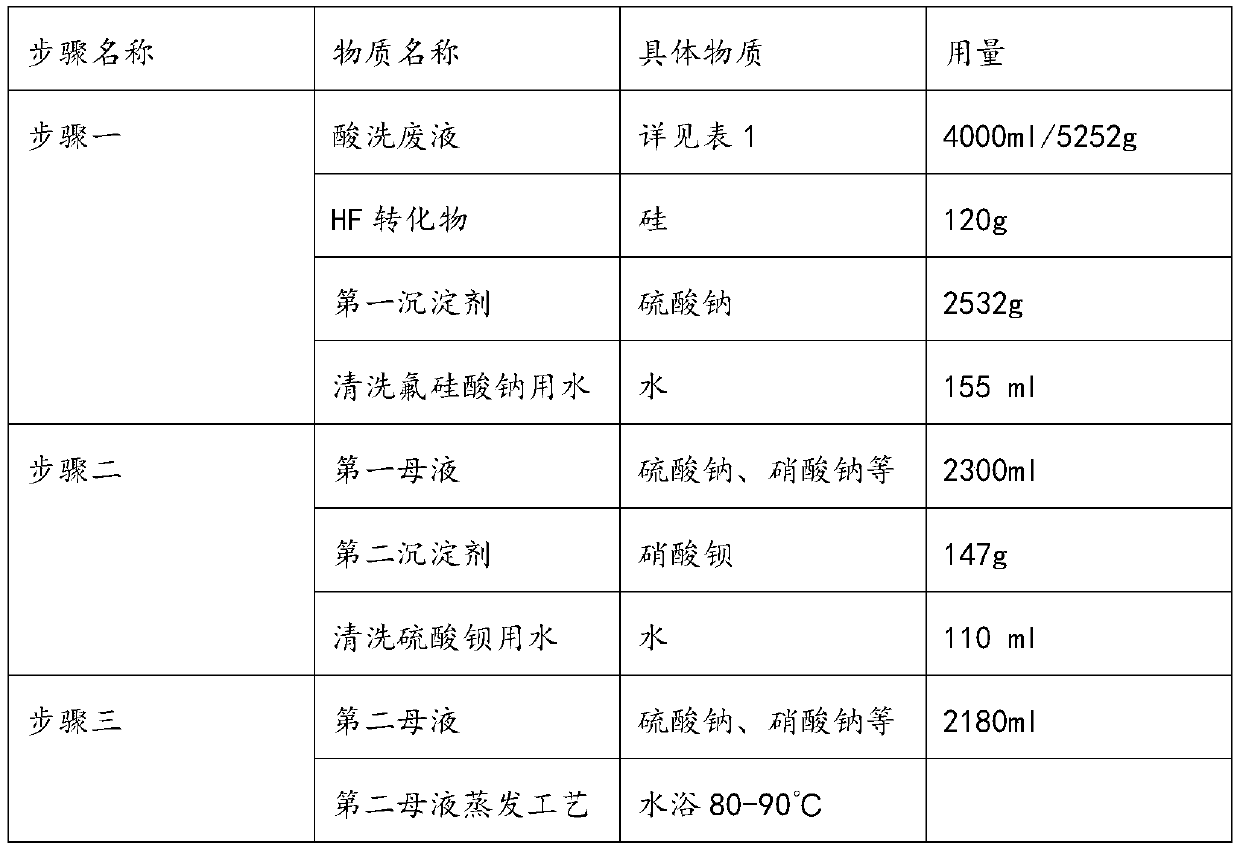

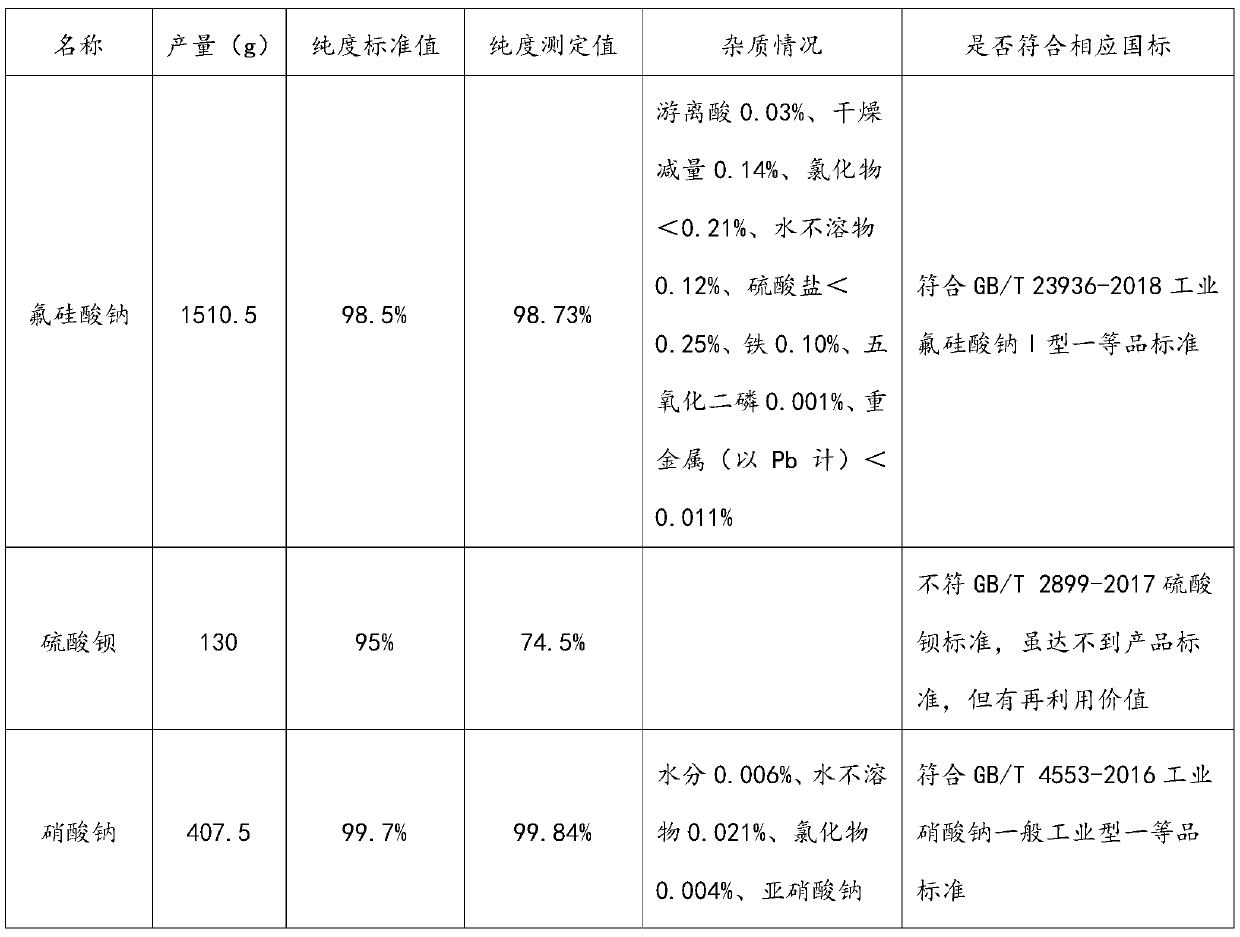

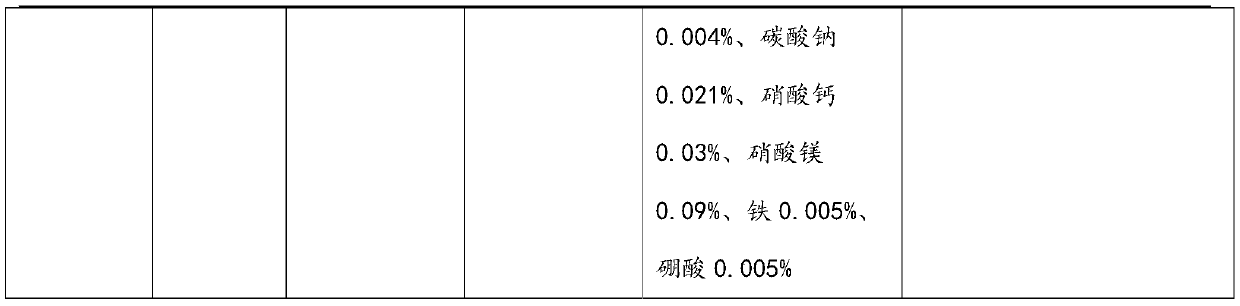

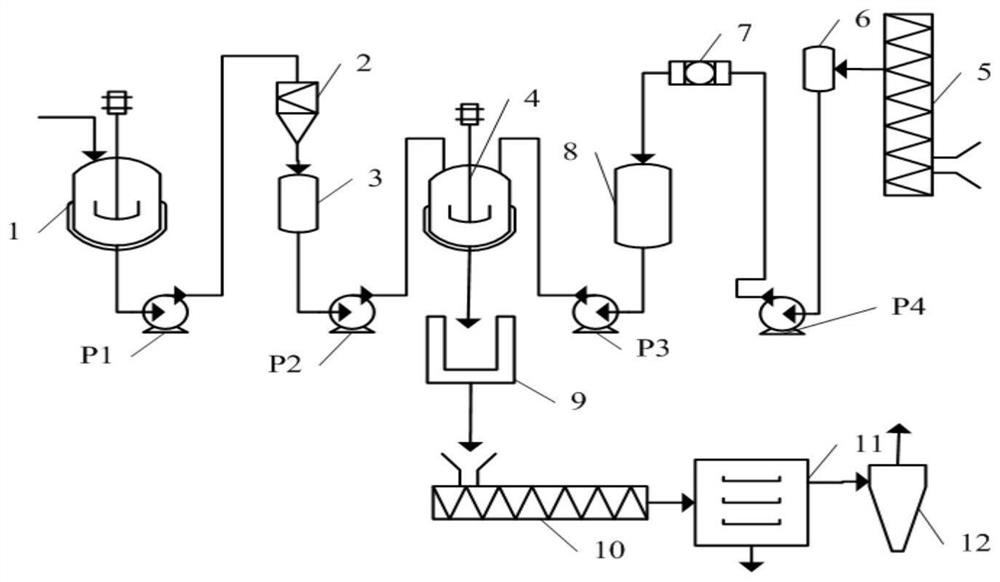

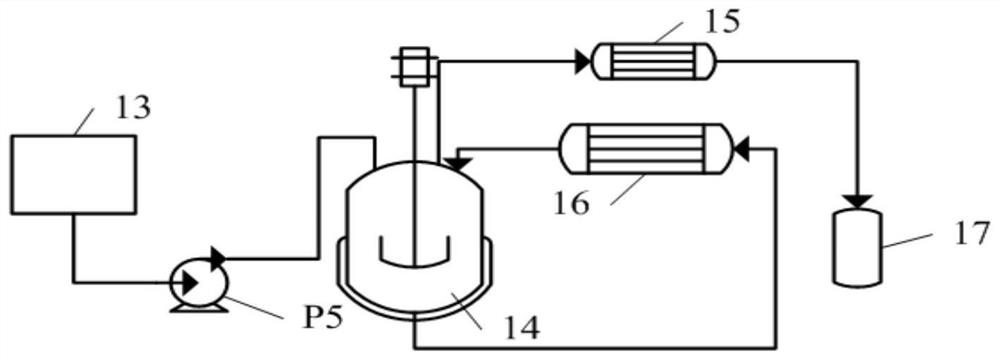

Method for recovering high-purity products from acid washing waste liquid step by step

PendingCN110980739AHigh purityNo hazardous waste generatedNitrogen compoundsAlkali metal nitratesNitrate saltsProcess engineering

The invention discloses a method for recovering high-purity products from an acid washing waste liquid step by step. The method comprises the following steps: 1, recovering fluosilicate, wherein silicon or silicon dioxide is added into an acid washing waste liquid to convert the HF in the waste liquid into H2SiF6, a first precipitant is added into the converted H2SiF6, a neutralization salifying reaction is performed to generate fluosilicate precipitate and generate a first mother liquor, and the obtained fluosilicate precipitate is cleaned, dried and powdered to obtain a first target productfluosilicate; 2, adding a second precipitant into the first mother liquor, carrying out a replacement reaction to generate sulfate precipitate and a second mother liquor, cleaning the obtained sulfateprecipitate, drying, and powdering to obtain second target sulfate; and 3, evaporating and concentrating the second mother liquor, carrying out cooling crystallizing to generate crystallized nitrate,drying, and powdering to obtain a third target product nitrate, wherein a third mother liquor is generated, 80% of the third mother liquor is refluxed and reused to be mixed with the second mother liquid, and 20% of the third mother liquor is treated according to dangerous solid waste. According to the method, high-purity fluosilicate and nitrate are sequentially recovered step by step, the recovered products can reach related standards such as GB / T36936-2018, GB / T4553-2016 and the like, the cost is low, the recovery effect of the acid washing waste liquid is good, and environmental pollutionis small.

Owner:ZHEJIANG HAIHE ENVIRONMENTAL TECH

Device and method for preparing potassium fluosilicate and nitric acid by using fluorine-containing nitric acid etching solution

PendingCN112357926AReduce usageSimple structureNitric acidFluosilicic acidPotassium nitratePotassium silicate

The invention relates to a device and a method for preparing potassium fluosilicate and nitric acid by using fluorine-containing nitric acid etching liquid. The device comprises an etching liquid pretreatment system, a potassium fluosilicate recovery system and a nitric acid evaporation recovery system, wherein the potassium fluosilicate recovery system comprises a potassium fluosilicate preparation unit and a potassium fluosilicate drying unit which are connected in sequence; wherein the nitric acid evaporation recovery system is connected with the potassium fluosilicate preparation unit, andthe etching liquid pretreatment system comprises a first reaction kettle, a silicon slag thickener and a precipitation tank which are connected in sequence; the precipitation tank is connected with the potassium fluosilicate preparation unit; the potassium fluosilicate preparation unit comprises a second reaction kettle, a potassium nitrate dissolving tank and a centrifugal machine; the second reaction kettle is respectively connected with the settling tank, the potassium nitrate dissolving tank and the centrifugal machine; and the centrifuge is connected with the potassium fluosilicate drying unit and the nitric acid evaporation recovery system respectively. The device and the method have the advantages of simple structure, less auxiliary materials, good continuity, high treatment efficiency and low production and operation cost, realizes the recycling of waste acid, and maximally saves resources.

Owner:陕西水发环境有限公司

Method for recycling fluorine resources in phosphate fertilizer production

InactiveCN105776221AImprove product qualityReduce wastePhosphorus compoundsFluosilicic acidSodium phosphatesPhosphoric acid

The invention discloses a method for recycling fluorine resources in phosphate fertilizer production. The method comprises the following steps: adding active silicon into the fluorine left in phosphoric acid in phosphate fertilizer production for reacting so that all fluorine is left in the solution in a form of fluosilicic acid; and in the presence of a sodium fluosilicate seed crystal, precipitating a fluosilicate precipitate compound by using sodium phosphate. In the method, the fluorine recovery rate in wet-process phosphoric acid exceeds 98%, so that the resource economic benefit of the raw material phosphorus ore in phosphate fertilizer production is increased, and the waste of the fluorine resources is reduced. The mining of the fluorite resources is saved, the market needs for the fluorine resources are met, and the economic benefits and social benefits of the phosphate fertilizer production and processing are increased; and moreover, since the fluorine content in the fertilizer is reduced, the product quality of phosphate fertilizer is improved, and the requirement for chemical production for sustainable development is met.

Owner:龚家竹

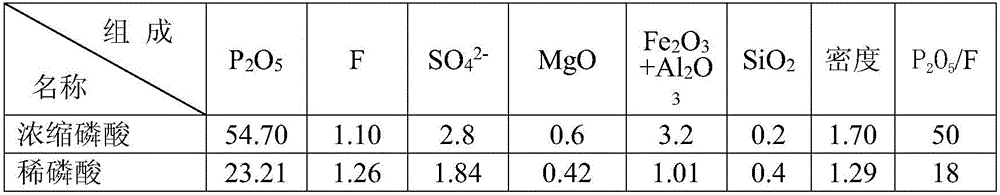

Method of recycling phosphorus in concentrated acid residue from wet process phosphoric acid and co-producing dihydrate gypsum and sodium fluosilicate

ActiveCN107827114AHigh recovery rateImprove filtering effectCalcium/strontium/barium sulfatesFluosilicic acidEconomic benefitsPhosphoric acid

The invention relates to the field of development and application of phosphorus chemical techniques and particularly discloses a method of recycling phosphorus in concentrated acid residue from wet process phosphoric acid and co-producing dihydrate gypsum and sodium fluosilicate. The method comprises: proportionally mixing concentrated acid residue from wet process phosphoric acid and process water, and adding the mixture into a crystal transformer trough; adding a crystal transformation control agent and a crystal transformation aid proportionally into the crystal transformer trough to perform semi-hydrated gypsum crystal transformation; after crystal transformation, feeding slurry into a suspension separator to perform precipitating separation; discharging the slurry from the bottom of the suspension separator, filtering the slurry, purifying with gypsum, filtering, and washing to obtain finished dihydrate gypsum; discharging slurry from the top of the suspension separator, filteringthe slurry, purifying for sodium fluosilicate, filtering, and washing to obtain finished sodium fluosilicate. Filtrates obtained may be returned directly to a phosphorite extraction trough or a dilute phosphoric storage trough. The method of the invention has the advantages that recycling of phosphorus in concentrated acid residue from wet process phosphoric acid and comprehensive use of waste residue are achieved, utilization value of the concentrated acid residue is improved, the process is simple, phosphorus recycling rate is high, no waste residue is produced, and the economic benefit issignificant.

Owner:SINOCHEM YUNLONG

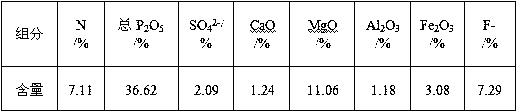

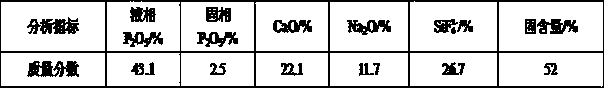

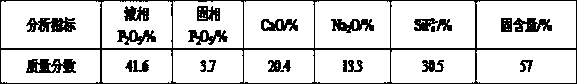

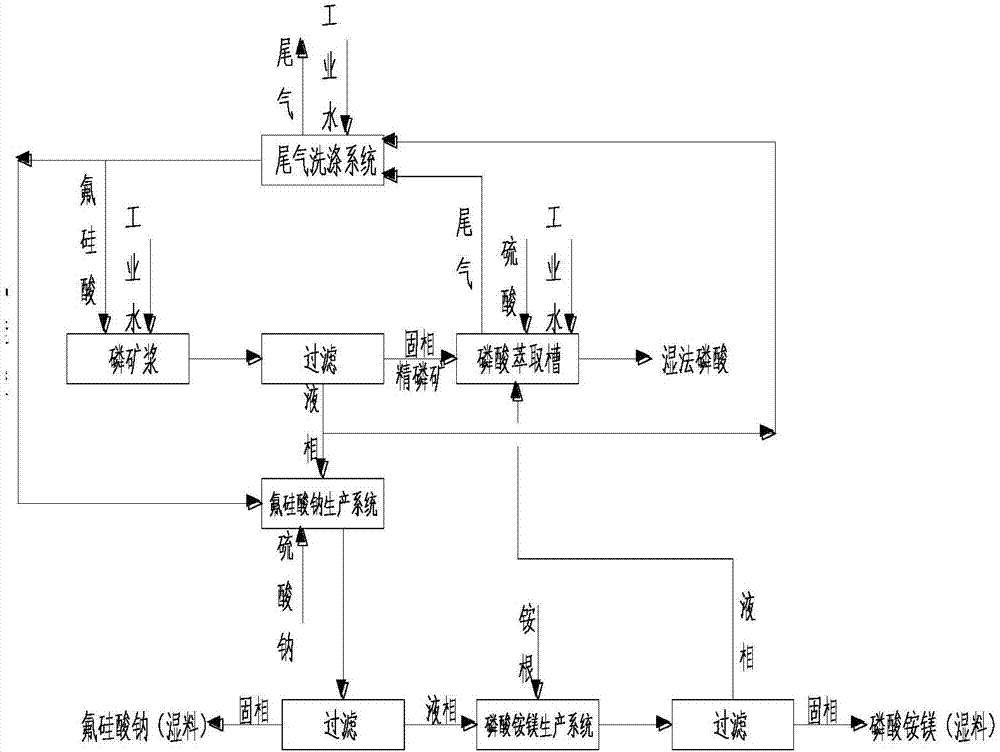

Method for removal of magnesium from phosphate rock and co-production of sodium fluorosilicate and magnesium sulfate

ActiveCN107879321AReduce the ratio of magnesium to phosphorusReduce serious adverse effectsMagnesium sulfatesRaw phosphate material treatmentPhosphoric acidPhosphorite

The invention belongs to the technical field of quality improvement of phosphate rocks, and particularly relates to a method for removal of magnesium from phosphate rocks and co-production of sodium fluorosilicate and magnesium sulfate. The method comprises the following steps of: (1) removal of magnesium; (2) synthesis of sodium fluorosilicate; and (3) synthesis of magnesium ammonium phosphate. According to the method for removal of magnesium from the phosphate rocks and co-production of sodium fluorosilicate and magnesium sulfate, general coupling of magnesium removal of the phosphate rocks,production of sodium fluorosilicate, production of magnesium ammonium phosphate and wet extraction production of phosphoric acid is achieved, sewage closed loop circulation during the production of sodium fluorosilicate and secondary use of a fluorosilicic acid intermediate product are achieved, and the consumption of sulfuric acid during the wet extraction production of phosphoric acid is reduced; a two-step chemical precipitation method is utilized to synthesize sodium fluorosilicate and magnesium ammonium phosphate sequentially by using magnesium removing liquid of the phosphate rocks, multiple shortcomings of a traditional treatment process of the magnesium removing liquid of the phosphate rocks are overcome, and co-production of sodium fluorosilicate and magnesium ammonium phosphateis achieved.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

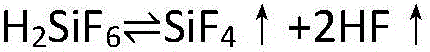

Preparation method of anhydrous hydrofluoric acid

InactiveCN108439340ASimple processReduce energy consumptionSilicaCalcium/strontium/barium sulfatesHydrogen fluorideHydrofluoric acid

The invention discloses a preparation method of anhydrous hydrofluoric acid. The preparation method comprises the following steps of: adopting a sulfuric-acid method to mix sodium fluorosilicate and concentrated sulfuric acid uniformly, after reaction, obtaining sodium sulfate for reaction with fluosilicic acid to prepare sodium fluorosilicate; freezing to obtain liquid hydrofluoric acid, and after distillation, obtaining an anhydrous hydrogen fluoride product; absorbing the remaining gas by water to obtain fluosilicic acid solution and silicon dioxide, adding solid sodium sulfate into the fluosilicic acid solution, and separating to obtain anhydrous hydrofluoric acid. The preparation method disclosed by the invention has the beneficial effects that the fluorine utilization rate in sodiumfluorosilicate is high, so that not only can the technical process be simplified, but also the production cost can be reduced; the new method is simple in operation and high in safety, and is especially suitable for large-scale industrial production.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

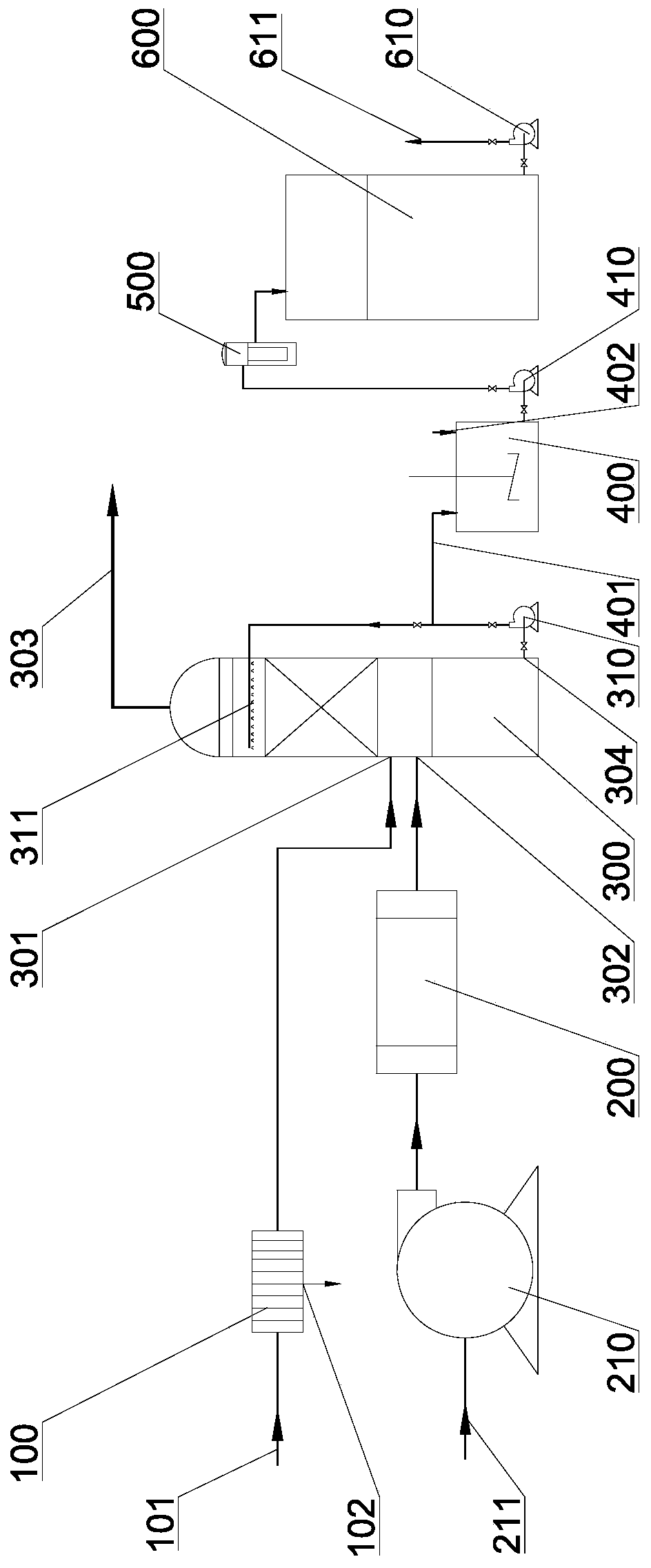

Fluosilicic acid concentration method and device

PendingCN110240164AAvoid temperature conditionsAchieve evaporationFluosilicic acidAcid concentrationHexafluorosilicic acid

The invention relates to a fluosilicic acid concentration method and device and solves the technical problems of slightly low concentration and high impurity content of existing fluosilicic acid. The fluosilicic acid concentration device is provided with separation equipment used for separating silica gel in fluosilicic acid, heating equipment used for heating air, concentration equipment used for concentrating the fluosilicic acid and purification equipment used for removing arsenic and mechanical impurities; the front end of the concentration equipment respectively communicates with the separation equipment and the heating equipment; and the rear end of the concentration equipment communicates with the purification equipment. The fluosilicic acid concentration device can be widely applied to concentration and recovery of low-concentration fluosilicic acid.

Owner:威海恒邦化工有限公司

Device and method for high-quality recovery of fluorine from wet-process phosphoric acid tail gas

PendingCN107954428ALow impurity contentImprove qualityDispersed particle separationFluosilicic acidFiltrationPhosphoric acid

The invention discloses a device and a method for high-quality recovery of fluorine from wet-process phosphoric acid tail gas. The device comprises a venturi scrubber, wherein a circulating tank is arranged at the bottom of the venturi scrubber, the circulating tank and the venturi scrubber are connected to constitute a scouring water internal circulating pipeline, a discharge port of the circulating tank is connected with a filter device, and a filtrate outlet of the filter device is connected to a fluorosilicic acid storage tank and the circulating tank; a tail gas outlet of the circulatingtank is connected with multi-stage scrubbing towers, and a tail gas outlet of the last-stage scrubbing tower is connected to a chimney. The tail gas scrubbing process further comprises multi-stage countercurrent scrubbing besides scrubbing by the venturi scrubber; furthermore, clear water or recycled water subjected to defluorination treatment is adopted in the countercurrent scrubbing process, fluorine content of water is low, so that fluorine in the tail gas is sufficiently scrubbed, and the requirement of up-to-standard discharge of the tail gas is met; according to the method, the high-quality fluorosilicic acid solution is recovered, fluorine resources are sufficiently utilized, environmental pollution caused by fluorine emission is avoided, economic benefit and social benefit are remarkable, and the method can be popularized and applied.

Owner:YICHANG EZHONG CHEM +1

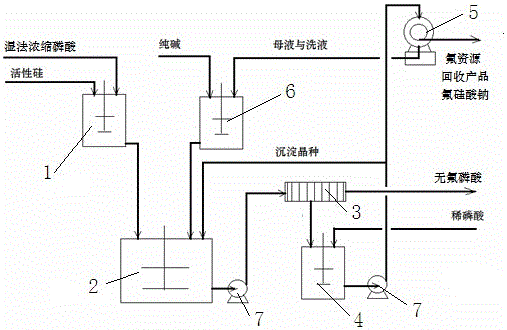

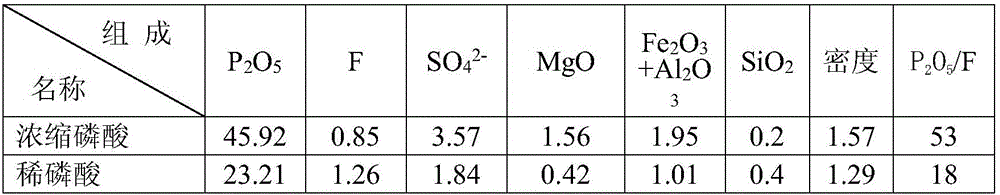

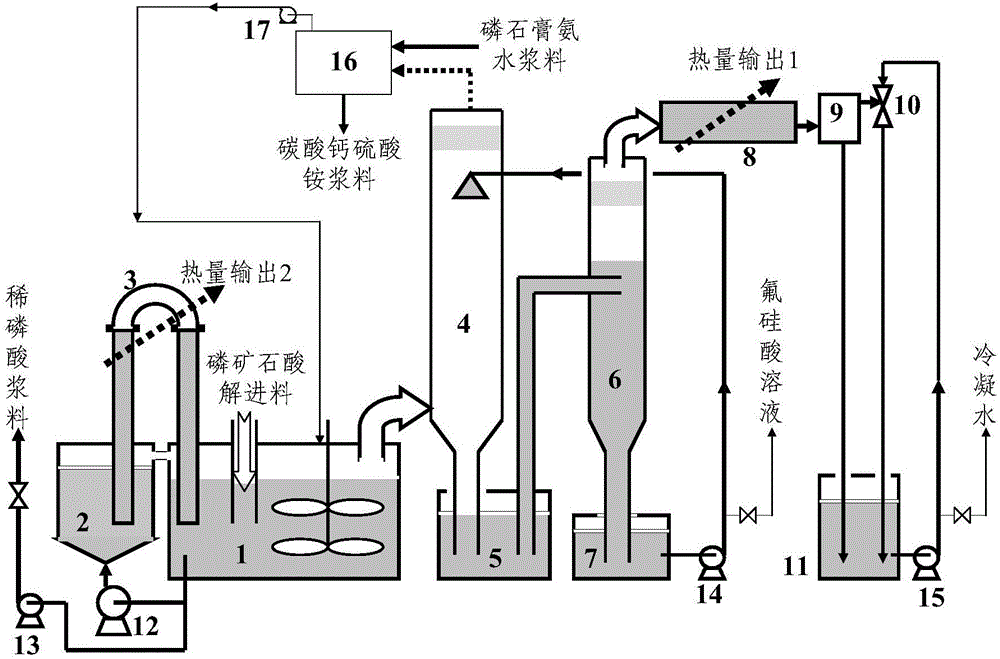

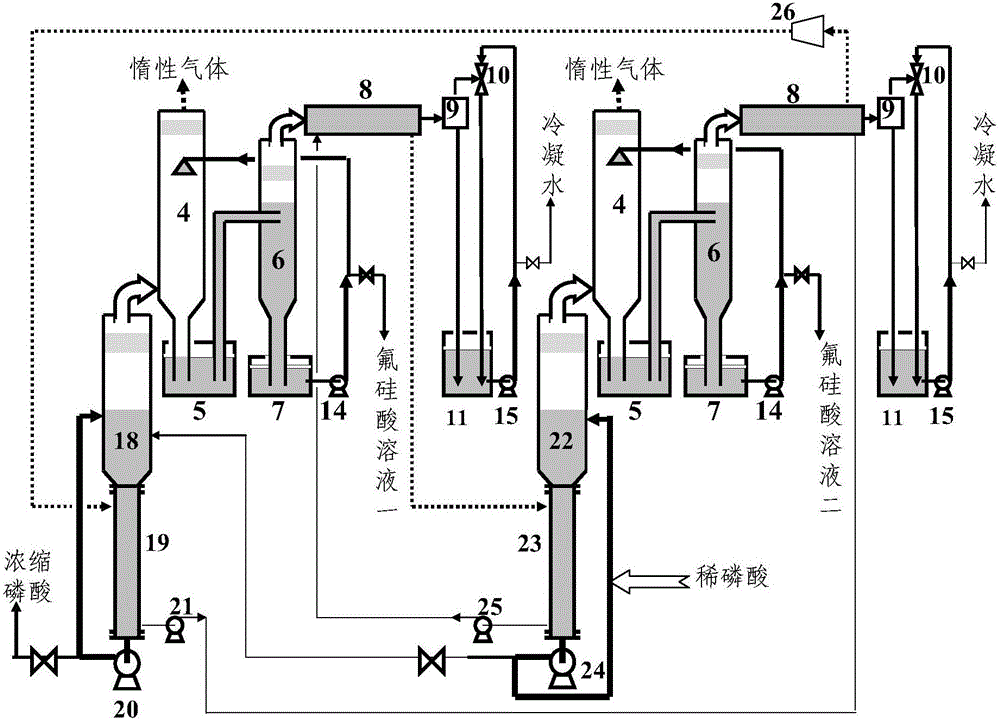

Wet-process phosphoric acid technology and fluosilicic acid processing method free of fluorine-containing exhaust gas emission

The invention discloses a wet-process phosphoric acid and fluosilicic acid production method free of fluorine-containing exhaust gas and waste heat emission. The method is suitable for a technology for decomposing phosphate ore to prepare a wet-process phosphoric acid of which the P2O5 content is 18-43% through phosphoric acid and a technology for preparing a concentrated phosphoric acid of which the P2O5 content does not exceed 54% through wet-process phosphoric acid evaporation and concentration. According to the method, a wet-process phosphoric acid technology system is isolated from a water environment, a heat source is provided for phosphoric acid concentration by using a clean heat-carrying working medium gasification-condensation cycle or heat pump recovery reaction heat or condensation heat, a fluosilicic acid of which the concentration is greater than 15% is produced by the method of coupling fluorine-containing steam condensation and fluosilicic acid concentration, so that closed wet-process phosphoric acid production is achieved, no fluorine-containing exhaust gas or waste heat is generated, and the concentrated phosphoric acid of which the P2O5 content does not exceed 54% and the fluosilicic acid of which the concentration is not lower than 15% can be produced without an external heat supply source.

Owner:SICHUAN UNIV

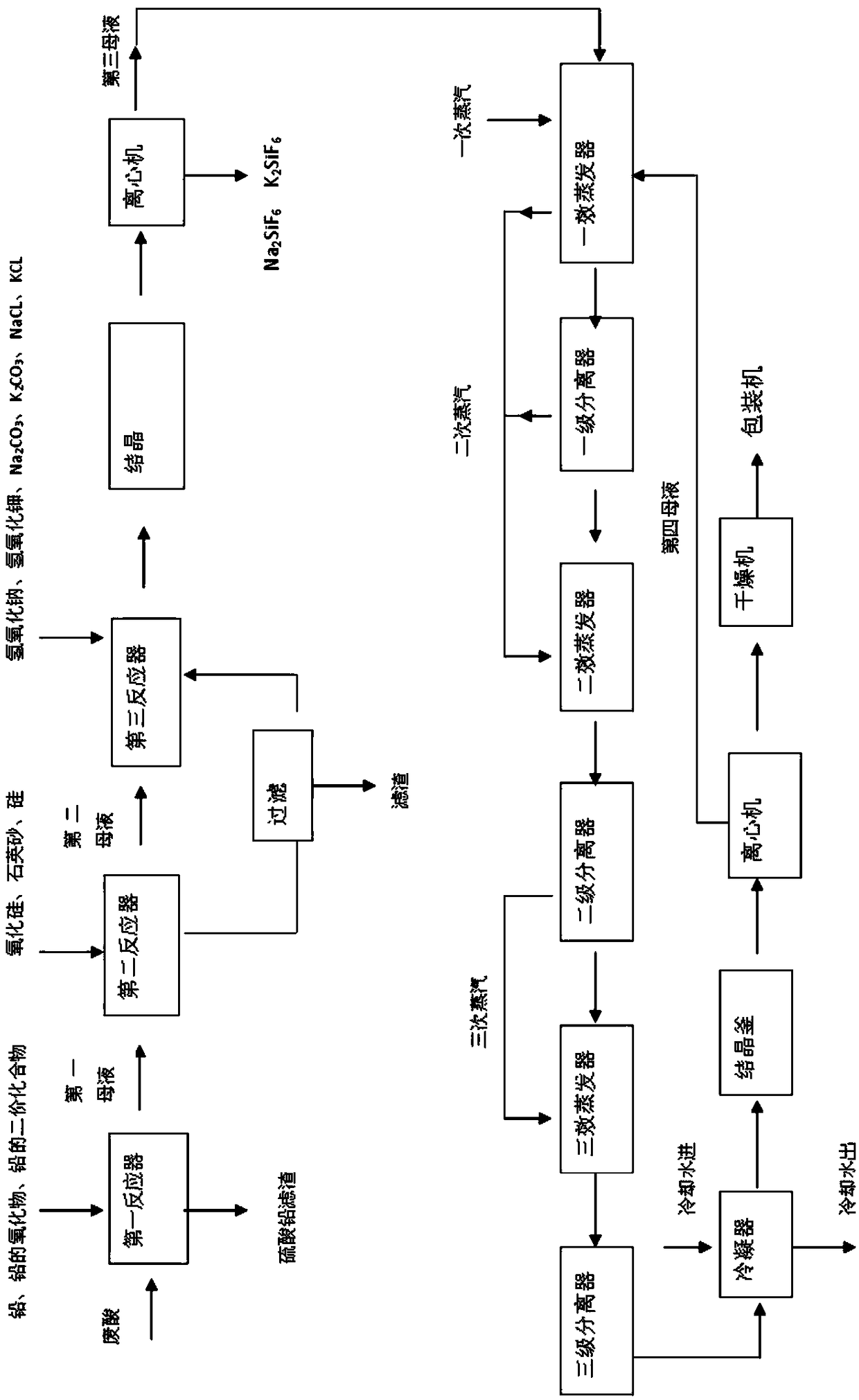

Waste acid resource utilization process

ActiveCN108190945ASolve processing problemsRealize resourcesAlkali metal nitrate preparationLead sulfatesResource utilizationSlag

The invention relates to the field of waste acid treatment, and discloses a waste acid resource utilization process. The waste acid resource utilization process comprises the following steps of addingwaste liquid into a first reactor; then, adding precipitating agents for separating lead sulfate filtering slag through reaction; feeding first mother liquid into a second reactor; adding one or several kinds of materials of carbon dioxide, quartz sand and silicon; converting fluorine ions into hydrofluosilicic acid; feeding second mother liquid into a third reactor; adding alkali or salts into the third reactor; performing reaction crystallization to obtain crystals and third mother liquid; adding the third mother liquid into a triple effect evaporator; performing evaporation concentration to obtain nitrates so as to realize the resource utilization of the waste acid. Through medicament addition and special process utilization, fluorine and nitric acid in the waste acid are used for generating useful fluorine salts and nitrate; the treatment cost of the waste acid generated in the electronic industry production process such as solar batteries can be greatly reduced; the goals of changing dangerous waste into resources and reducing the quantity of the dangerous waste can be achieved, so that the goals of protecting the environment and improving the economic benefits are achieved.

Owner:应韵进

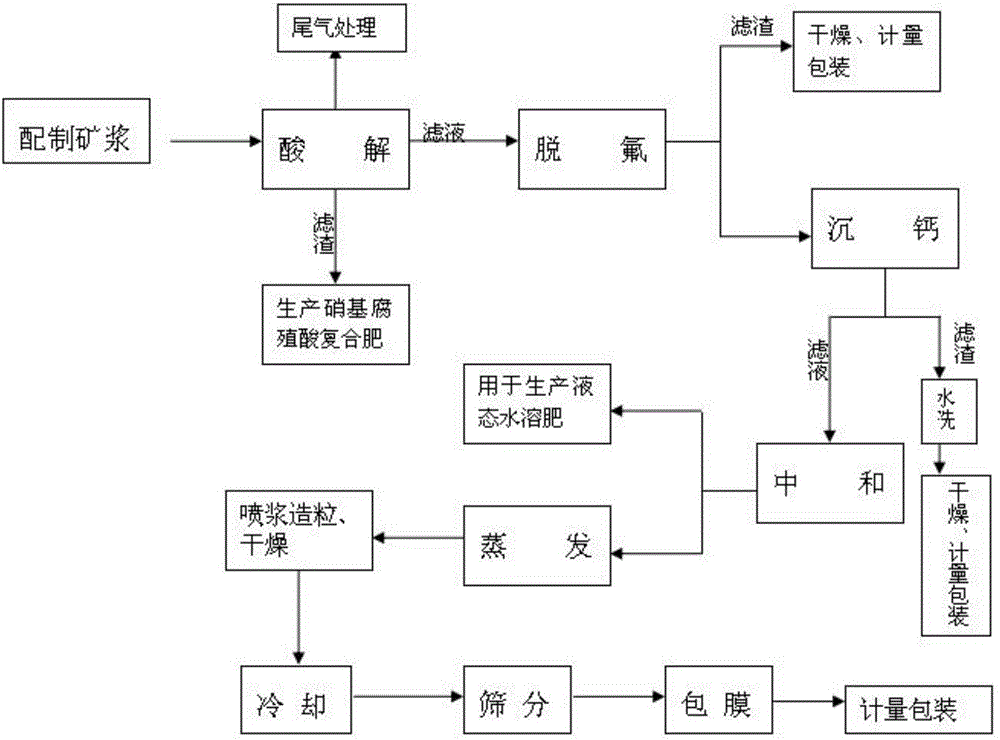

Method for co-production of chemical synthetic fertilizer by industrial calcium products

ActiveCN106517293ASimple product structureSimple structureCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesChemical synthesisNitrohumic acid

The invention relates to a method for co-production of a chemical synthetic fertilizer by industrial calcium products, and belongs to the field of production of agricultural fertilizers. The method comprises the following steps: preparing phosphorite powder into ore pulp by using a raw material slurry method, reacting the ore pulp with nitric acid, and filtering; feeding filter residues to a compound fertilizer workshop to produce a nitrohumic acid compound fertilizer; adding sodium nitrate in the filtrate to remove fluoride; centrifugally dehydrating; drying the filter residues to prepare sodium fluosilicate; adding ammonium sulfate, potassium sulphate or potassium carbonate in the filtrate to deposit calcium; then filtering; preparing the industrial calcium products from the filter residues; and neutralizing, concentrating, guniting, drying, cooling, enveloping, metering and packing the filtrate to obtain the chemical synthetic fertilizer.

Owner:CHONGQING HUAQIANG ECOLOGICAL FERTILIZER IND CO LTD

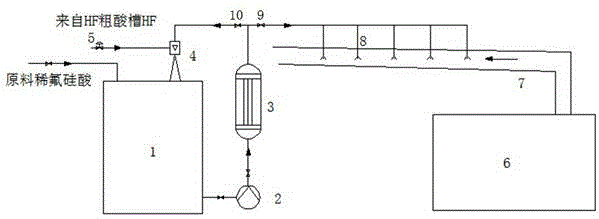

Online cleaning method for off-gas pipe in fluosilicic acid concentration system

ActiveCN104624586AAvoid influenceAvoid blind spotsHollow article cleaningFluosilicic acidPhysical chemistryAcid concentration

The invention discloses an online cleaning method for an off-gas pipe in a fluosilicic acid concentration system. The online cleaning method comprises the steps that firstly, diluted fluosilicic acid is led into an acid blending tank (1) and serves as an acid blending mother solution; afterwards, a circulating pump (2) is started to enable the diluted fluosilicic acid mother solution to pass through a cooler (3) and then to enter a Venturi (4) for spraying, so that total reflux operation is performed; after stabilization, an HF flow control valve (5) can be opened to lead in crude acid HF, flow is controlled to be 1-2 m<3> / h, and the acid blending temperature is not higher than 40 DEG C; leading in of the crude acid HF is stopped after the blended solution reaches 80%-90% the liquid level of the acid blending tank (1), and then acid blending is completed; when the off-gas pipe in the concentration system needs to be cleaned, a valve (9) between an outlet of the circulating pump (2) and the off-gas pipe is opened, a reflux valve (10) is closed, fluorhydric acid is fed into a gas-phase pipe (7) through an off-gas pipe nozzle (8), makes full contact with silicon dioxide and then flows into a concentration system (6) along a pipeline, and the cleaning effect can be completely achieved after spraying of 5 min-10 min. The online cleaning method guarantees continuous and stable operation of a device and fully utilizes raw material acid resources.

Owner:贵州瓮福蓝天氟化工股份有限公司

Silicon solar cell texturization waste liquid recycling method

InactiveCN107117753AEmission reductionSupplement fresh dosageWater/sewage treatment by centrifugal separationHydrogen fluorideSilicon solar cellStock solution

The invention discloses a silicon solar cell texturization waste liquid recycling method. The method includes: fluosilicic acid removing, HF / HNO3 separation, purification and other processes, can acquire a chemical stock solution level single chemical or mixed chemical used for a texturization process, and basically reduces discharge of waste chemicals.

Owner:ZHEJIANG DONGFU PLASTIC SCI & TECH

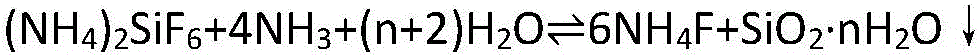

Method of separating and recycling SiO2 and ammonium fluorosilicate from fluorine-containing dust

ActiveCN108928825AGuaranteed qualityFull circulationSilicaFluosilicic acidPregnant leach solutionSlurry

The invention provides a method of separating and recycling SiO2 and ammonium fluorosilicate from fluorine-containing dust, which includes: 1) independently adding two types of fluorine-containing dust, which are sorted according to whiteness of 80%, respectively to different leaching troughs, adding water, circulating washing liquid or crystallization mother liquid for dissolution, wherein the solution is heated during the process with complete stirring, thus leaching the substance; 2) filtering or press-filtering the leached slurry while hot, and separating a leachate and filter residue; 3)adding the leachate into a crystallization kettle for cooling crystallization, and after the substance is completely crystallized, separating the crystal and the crystallization mother liquid; 4) carrying out heat-leaching to the filter residue with the crystallization mother liquid again and performing secondary cooling crystallization; 5) performing multistage countercurrent washing to the filter residue, produced from the material with whiteness being higher than 80%, and drying and crushing the product to obtain SiO2; 6) mixing the crystallization mother liquid and primary concentrated washing liquid of the filter residue, and performing evaporative concentration-cooling crystallization to a part of the solution to obtain the ammonium fluorosilicate.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

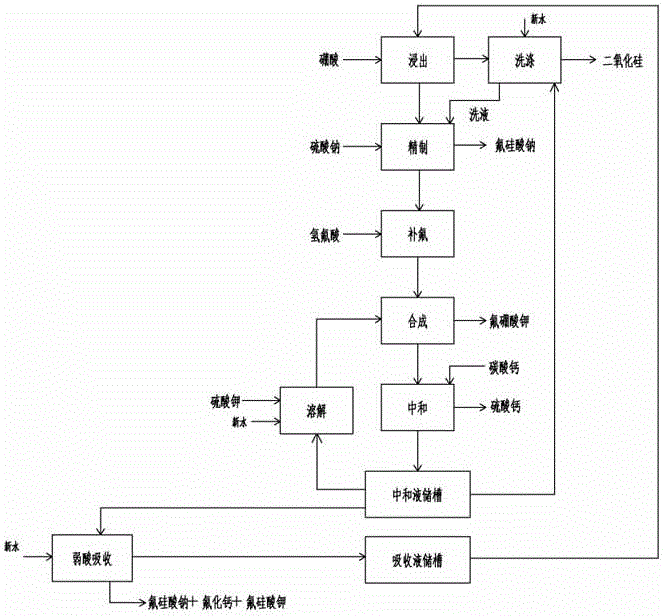

Method for preparing potassium fluoborate by recycling mother liquor

ActiveCN106587089AAchieve recyclingSolve accumulated problemsSilicaCalcium/strontium/barium sulfatesHexafluorosilicic acidFluoboric acid

The invention discloses a method for preparing potassium fluoborate by recycling a mother liquor. The method comprises the steps of injecting new water into a weak acid absorption apparatus of a hydrofluoric acid production system; adjusting the content of fluosilicic acid and hydrofluoric acid in the system; adding solid boric acid into a solution to obtain a silicon dioxide byproduct and a coarse fluoboric acid solution; adding solid sodium sulfate into the coarse fluoboric acid solution to obtain sodium fluosilicate and a refined fluoboric acid solution; adding hydrofluoric acid and potassium sulfate solutions to obtain potassium fluoborate crystals and the mother liquor; and adding calcium carbonate solid into the mother liquor to obtain a calcium sulfate byproduct, wherein one part of the mother liquor is used for absorbing tail gas in the hydrofluoric acid system, one part of the mother liquor is used for dissolving potassium sulfate, and one part of the mother liquor is used for washing silicon dioxide, so that the recycling of the mother liquor of the potassium fluoborate production system is realized. The method realizes recycling of wastewater, solves the problems of difficulty in treating potassium fluoborate wastewater and high cost, is environment-friendly, and has very high economic benefits.

Owner:南通金星氟化学有限公司

Comprehensive utilizing method for fluorine-containing silicon dioxide

InactiveCN105540594AAchieve fixationImprove adsorption capacityOther chemical processesAlkaline-earth metal silicatesPhosphateSilicon dioxide

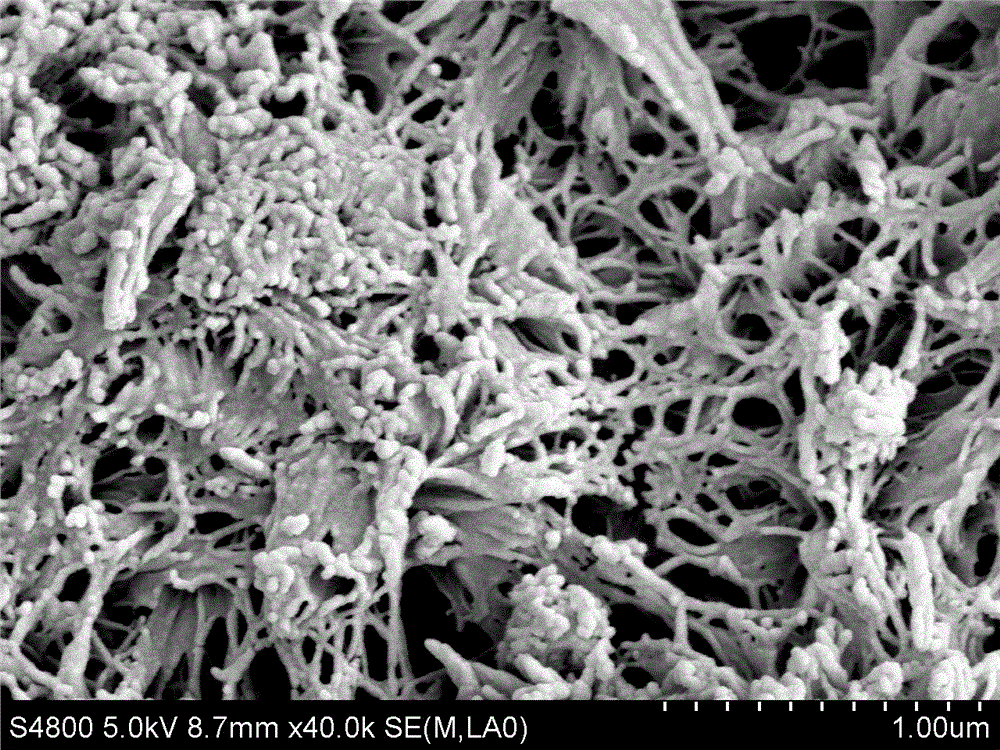

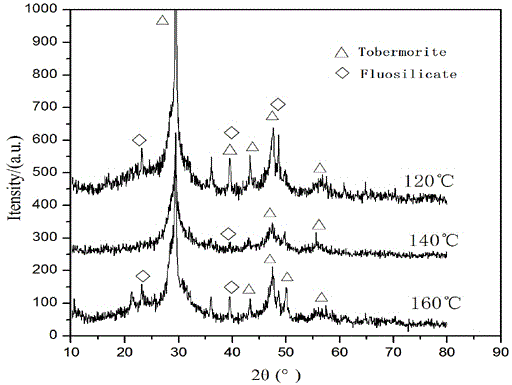

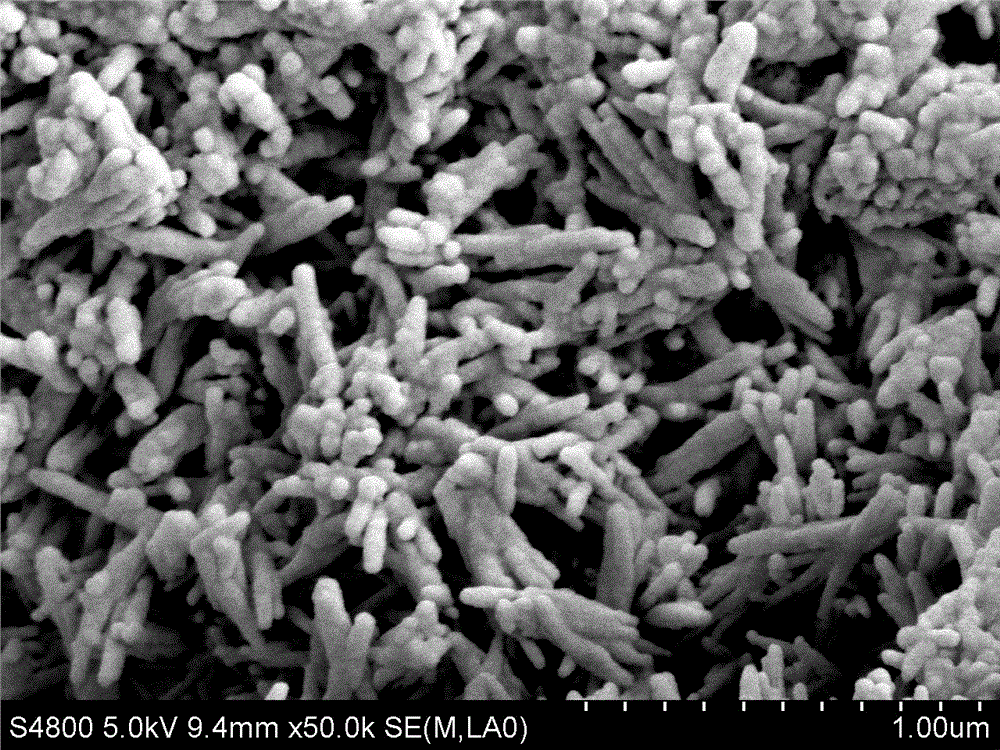

The invention discloses a comprehensive utilizing method for fluorine-containing silicon dioxide. The comprehensive utilizing method comprises the steps that the industrial byproduct fluorine-containing silicon dioxide and industrial-grade calcium hydroxide serve as raw materials, the two raw materials at a certain calcium to silicon mole ratio are mixed with water, and the formed mixture is put into a reaction kettle for a hydrothermal reaction; the conditions of the hydrothermal reaction are controlled within the range that the calcium to silicon mole ratio is 0.4-0.9, and the temperature is 120-160 DEG C, the static constant-temperature hydrothermal reaction is carried out for 8-12 h, fluorine-containing hazardous materials are immobilized in the hydrothermal reaction process, a phosphate adsorbing agent with the specific area ranging from 120 m<2> / g to 500 m<2> / g is obtained at the same time, and thus waste is turned into wealth; the phosphate adsorbing agent obtained through the hydrothermal reaction has good phosphate adsorbing capability on wastewater including phosphate radicals, and a mixture obtained after phosphate adsorbing saturation can be further used for adsorbing heavy metal ions. According to the comprehensive utilizing method, waste is controlled by waste through waste conversion, and thus the purpose of high added-value utilization of by products is achieved while the phosphate adsorbing agent obtained through the hydrothermal reaction is used for eliminating environment pollution.

Owner:SICHUAN UNIV

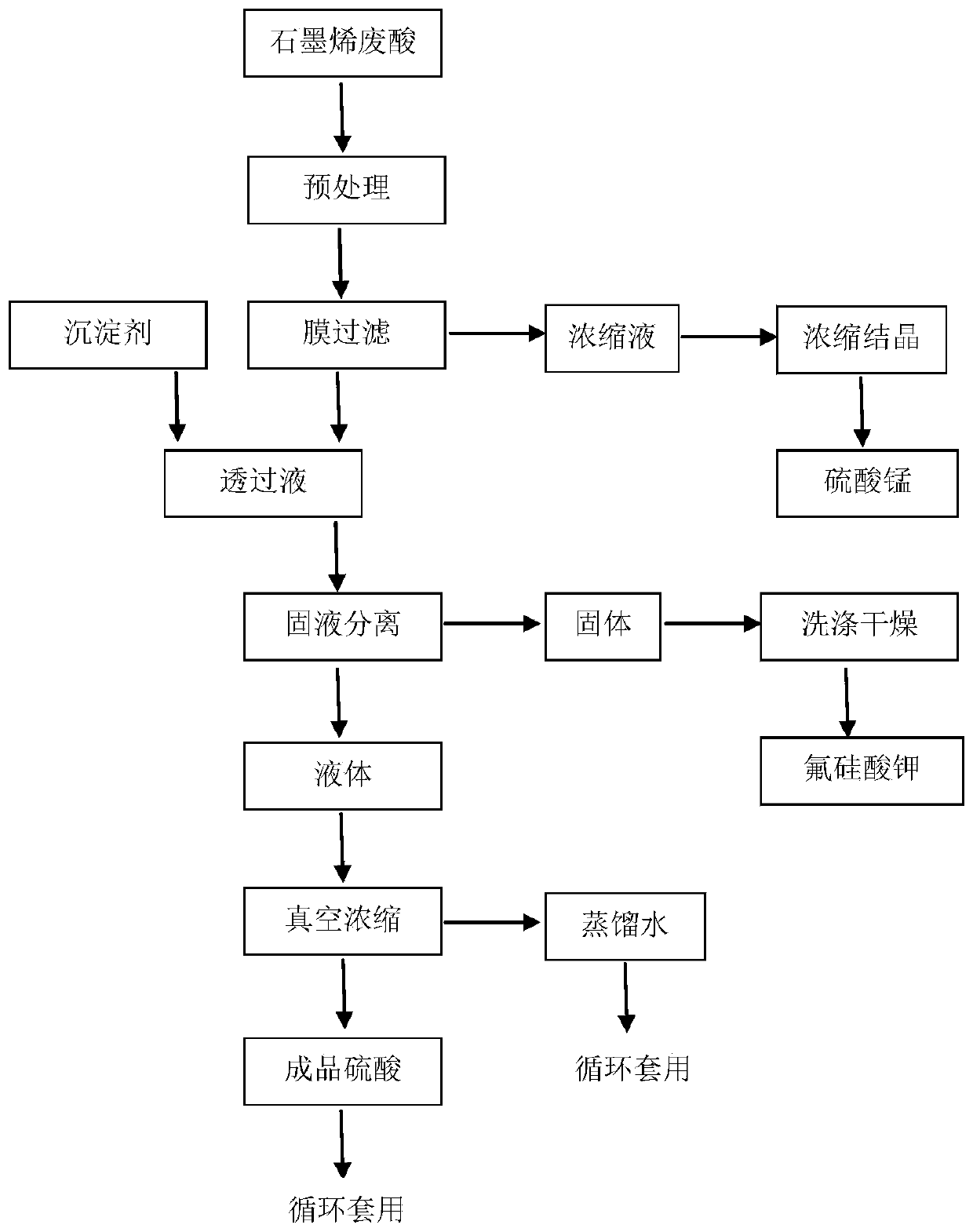

Method for resource utilization of graphene waste acid

ActiveCN110002649APromote enrichmentReduce energy consumptionWater/sewage treatmentMultistage water/sewage treatmentSuspended particlesResource utilization

The invention belongs to the technical field of graphene waste acid treatment, and particularly relates to a method for resource utilization of graphene waste acid. The method comprises the followingsteps: a) pre-treatment: adjusting the content of sulfuric acid in waste acid and removing suspended particles and macromolecular impurities in the waste acid; b) membrane filtration: treating the pre-treated waste acid by an aromatic polyamine nanofiltration membrane to obtain a concentrated liquor and a permeable liquid; c) precipitating treatment: adding silicofluoric acid into the permeable liquid and filtering the mixture to obtain a filter cake and a filtrate; and d) vacuum concentration: concentrating the filtrate in a vacuum condition to obtain sulfuric acid, of which the mass fraction is greater than 95%. Sulfuric acid is recycled and metal ions are recovered in a graphene production process, so that the industrial value is improved, and the industrial production cost of grapheneis lowered. The method has an obvious economical benefit. In addition, the environmental pollution is also eliminated, the environmental quality is improved favorably and the method has a good socialbenefit.

Owner:NANJING GUANSHAN CHEM TECH +1

Method for preparing fluosilicic acid from calcium fluoride containing waste

ActiveCN107265463AIncrease productivitySimple processCalcium/strontium/barium sulfatesFluosilicic acidScrapSulfuric acid

Owner:衢州市鼎盛化工科技有限公司

Process for the preparation of pure silica

InactiveUS7534411B2Simple and efficient and cost-effectiveSilicaFluosilicic acidSilicon tetrafluorideSilicon dioxide

Owner:ATI ALUMINUM TECH ISRAEL

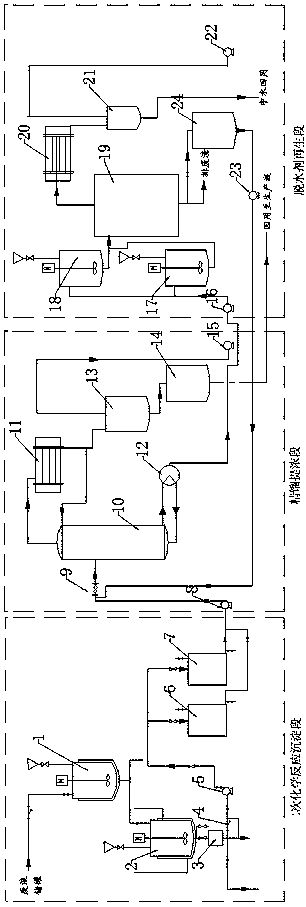

Device and method for recycling waste acid liquid produced in polycrystalline silicon texturing

ActiveCN111170320ALow costReduce manufacturing costAfter-treatment detailsWater contaminantsFluorosilicate saltFluorhydric Acid

The invention relates to a device and a method for recycling waste acid liquid produced in polycrystalline silicon texturing. According to the method, in a secondary chemical reaction precipitation section, hydrofluoric acid is neutralized through a primary reaction, a fluorosilicate precipitate is generated through a secondary reaction, and the precipitate can be sold; in a rectification and purification section, rectification and purification can be performed on dilute nitric acid to generate concentrated nitric acid; the nitric acid is evaporated and concentrated to obtain about 65% of dilute nitric acid through a dehydrating agent reduced-pressure rectification process, and the dilute nitric acid can be directly reused in a texturing liquid system, so the cyclic utilization of nitric acid is achieved, and reagent cost is reduced; and in a dehydrating agent regeneration section, a certain amount of magnesium oxide is added into a solution containing a small amount of dilute magnesium nitrate for neutralization, and then evaporation is carried out so as to obtain high-concentration concentrated magnesium nitrate which can be directly used as a dehydrating agent and applied to therectification and purification section. According to the invention, resource utilization and recycling of waste water and solid waste are realized, the operation cost and production cost of enterprises are further reduced, and the requirements of energy conservation, high efficiency and environmental protection are met.

Owner:SUZHOU KZONE EQUIP TECH

Popular searches

Alkali metal silicates Treatment involving filtration Water/sewage treatment by ion-exchange Energy based wastewater treatment Water/sewage treatment by heating Treatment involving sedimentation Water/sewage treatment by flocculation/precipitation Phosphates Water/sewage treatment by neutralisation Water treatment multistage treatments

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com