Device and method for recycling waste acid liquid produced in polycrystalline silicon texturing

A waste acid solution and polysilicon technology, applied in chemical instruments and methods, fluosilicic acid, nitric acid, etc., can solve the problems of increased investment, serious equipment corrosion, and the production of equal volumes of dilute waste acid, etc., to reduce purification costs, The effect of reducing drug costs and stabilizing product indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

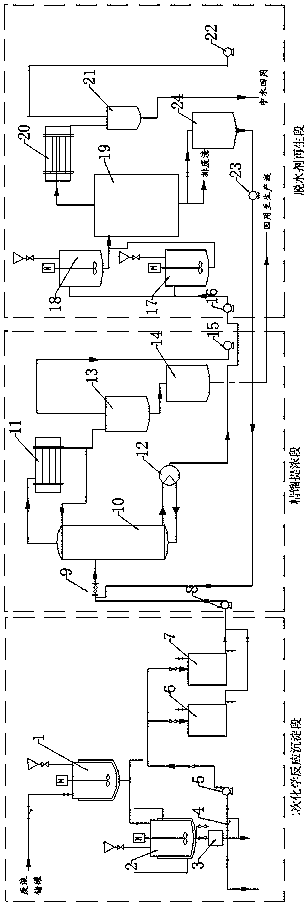

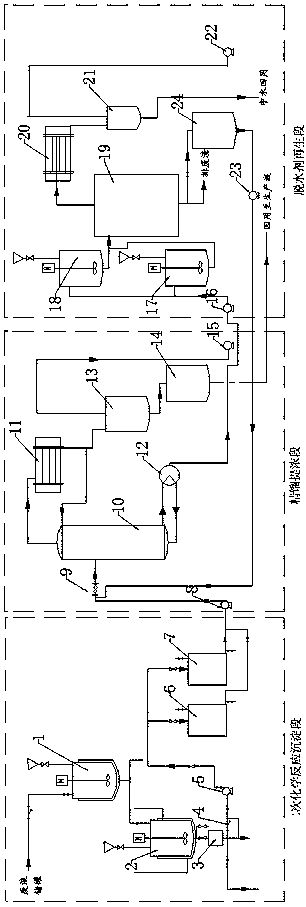

[0038] This embodiment describes a device for recycling waste acid liquid from polysilicon texturing, such as figure 1As shown, it mainly includes a silica reactor 1, a nitrate reactor 2, a bag filter 3, a rectification tower 10, a first condenser 11, a vacuum buffer tank 13, a concentrated nitric acid storage tank 14, and dilute magnesium nitrate Storage tanks 17, 18, evaporator 19, second condenser 20, reclaimed water buffer tank 21 and concentrated magnesium nitrate storage tank 24 are also provided with some pump valves for pumping and transporting liquid or gas. Wherein, the silica reaction kettle 1, the nitrate reaction kettle 2, the bag filter 3, the rectifying tower 10, the first condenser 11, the vacuum buffer tank 13, and the concentrated nitric acid storage tank 14 are connected successively by pipelines , the dilute magnesium nitrate storage tanks 17, 18 are connected to the rectification tower 10 for collecting the dilute magnesium nitrate remaining at the bottom ...

Embodiment 2

[0046] In particular, this embodiment describes a method for recycling polysilicon texturing waste acid solution, which includes:

[0047] Step 1: Determining the content of nitric acid, hydrofluoric acid and fluorosilicic acid in the waste acid solution of texturing;

[0048] Step 2: After measuring the content of each acid solution, mix and add silicon dioxide into the waste acid solution for texturing, and the ratio of the molar amount of silicon dioxide added to the molar amount of hydrofluoric acid is 1:1, and the reaction is stirred for 30 minutes. React the hydrofluoric acid in it to generate fluosilicic acid and silicon tetrafluoride, and silicon tetrafluoride can be used as a gas to pass through the exhaust channel to the exhaust gas treatment equipment;

[0049] Step 3: Potassium nitrate is added to the mixed acid solution after adding silicon dioxide to react. The molar ratio of potassium nitrate to fluosilicic acid is 2:1. After stirring for 30 minutes, the tempera...

Embodiment 3

[0054] In this example, the waste acid from the polysilicon texturing production line is used, and the content is about 30% of nitric acid, about 3% of hydrofluoric acid, about 5% of fluosilicic acid, and metal ions such as silver ions, aluminum ions, calcium ions, The content of potassium ions, sodium ions, zinc ions, etc. ranges from hundreds of ppb to tens of thousands of ppb, and the processing capacity is 1 ton / day. Waste acid liquid is collected in batches and sent to silica reactor 1 (1 cubic meter), add 24.8 kilograms of silicon dioxide, stir and react for 30 minutes, then send to potassium nitrate reactor (1 cubic meter), add 116.4 kilograms of potassium nitrate , after stirring for 30 minutes, the potassium nitrate reaction kettle is a jacketed stirring reaction kettle. After the reaction is completed, the jacket is fed with cooling water at 5 to 7 degrees Celsius for half an hour, and then passed through a bag filter. Filter through filter 4, the filter residue is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com