Patents

Literature

44 results about "Fluorosilicate salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curing agent for sealing and hardening surface of concrete, as well as preparation and construction methods thereof

The invention relates to the technical field of curing agents and particularly relates to a curing agent for sealing and hardening surface of concrete, as well as preparation and construction methods thereof. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, comprises the following components in percentage by weight: 0.1-2% of fluorosilicate, 0.001-0.02% of surfactant, 5.0-30.0% of at least one of silica sol or silicate and the balance of water. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, has the advantages of short curing time, thick surface hardened layer and high surface hardness, and can be widely used for surface hardening and curing treatment of concrete buildings or structures of highways, squares, garages, supermarkets, factory buildings and the like.

Owner:DONGGUAN MERROCK IND

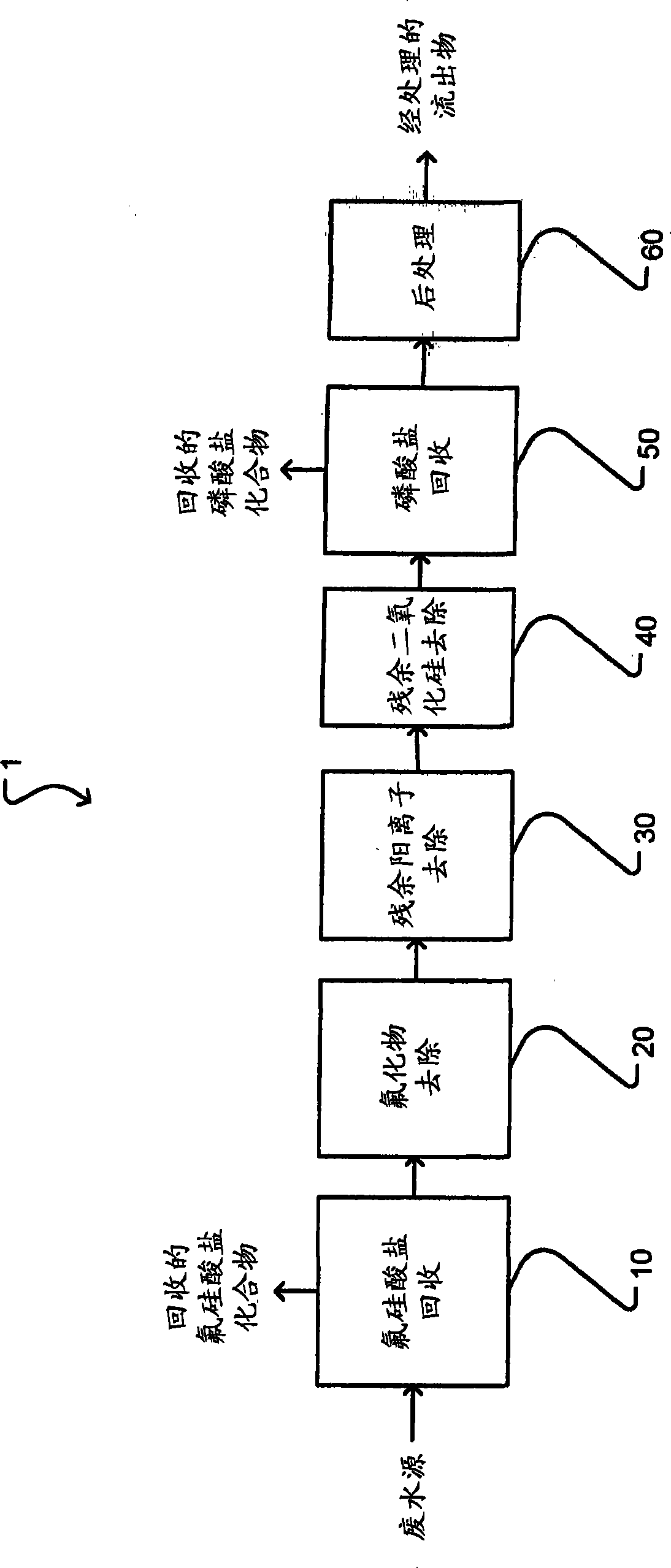

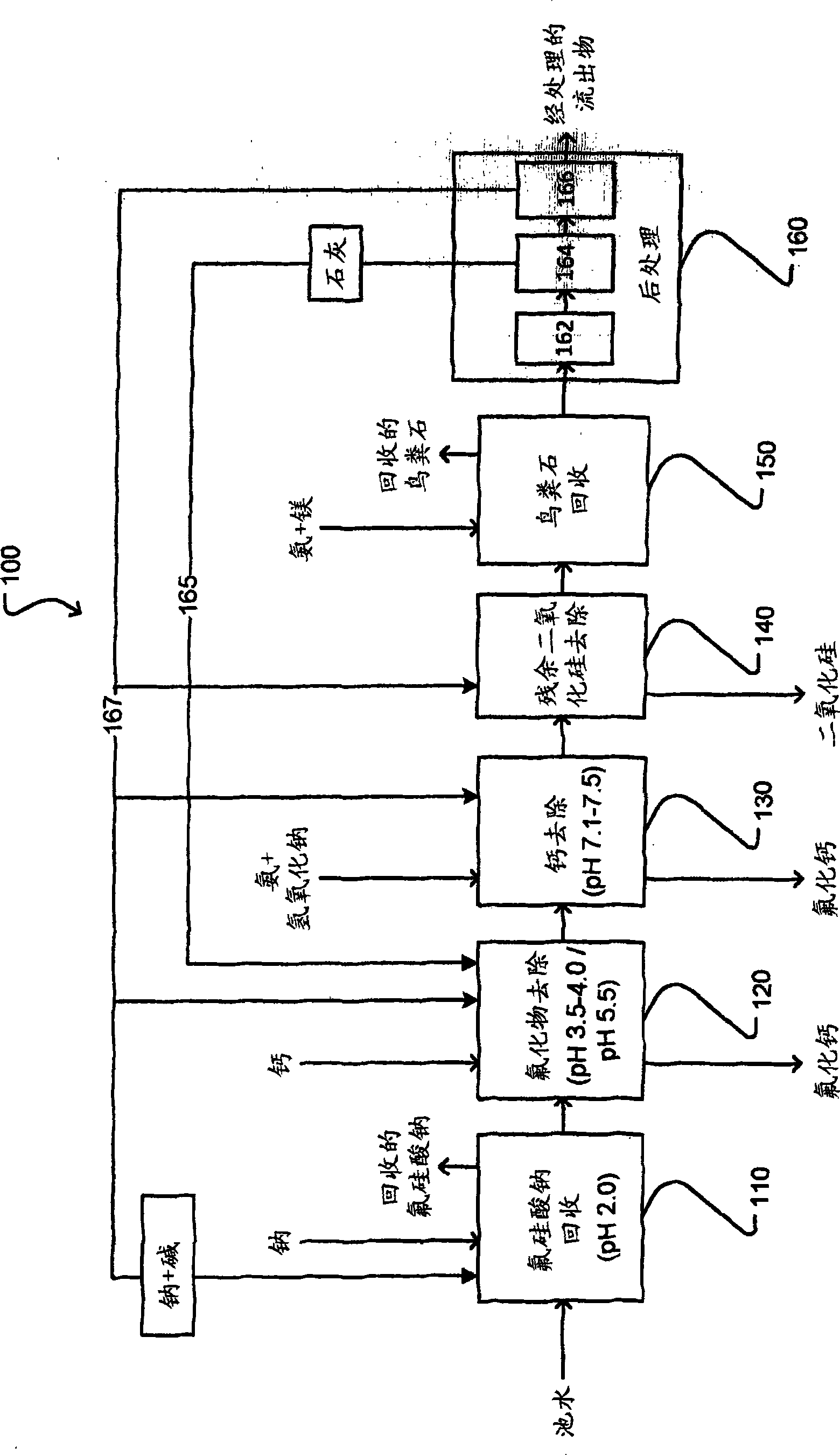

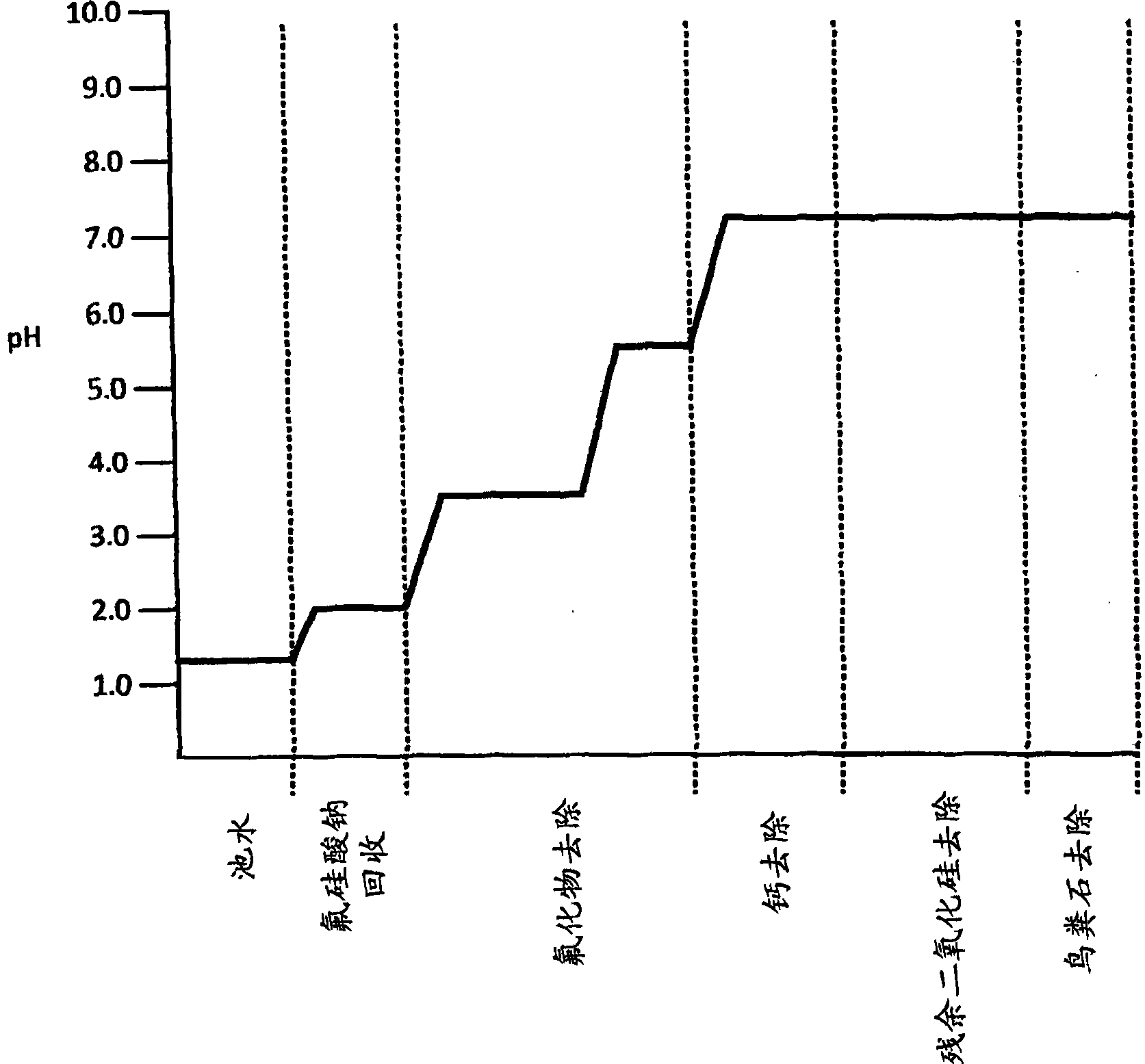

Treatment of phosphate-containing wastewater with fluorosilicate and phosphate recovery

ActiveCN103813987ARaise the pHWater contaminantsWater/sewage treatment bu osmosis/dialysisPhosphateWastewater

A method for treating phosphate-containing wastewater, such as phosphogypsum pond water. The method includes the steps of: (a) adding a first cation to the wastewater to precipitate fluorosilicate from the wastewater; (b) adding a second cation to the wastewater to precipitate fluoride from the wastewater; (c) raising the pH of the wastewater to precipitate the second cation from the wastewater; (d) removing residual silica from the wastewater; and (e) precipitating phosphate from the wastewater. The precipitated fluorosilicate may be sodium fluorosilicate. The precipitated phosphate may be struvite.

Owner:OSTARA NUTRIENT RECOVERY TECH INC

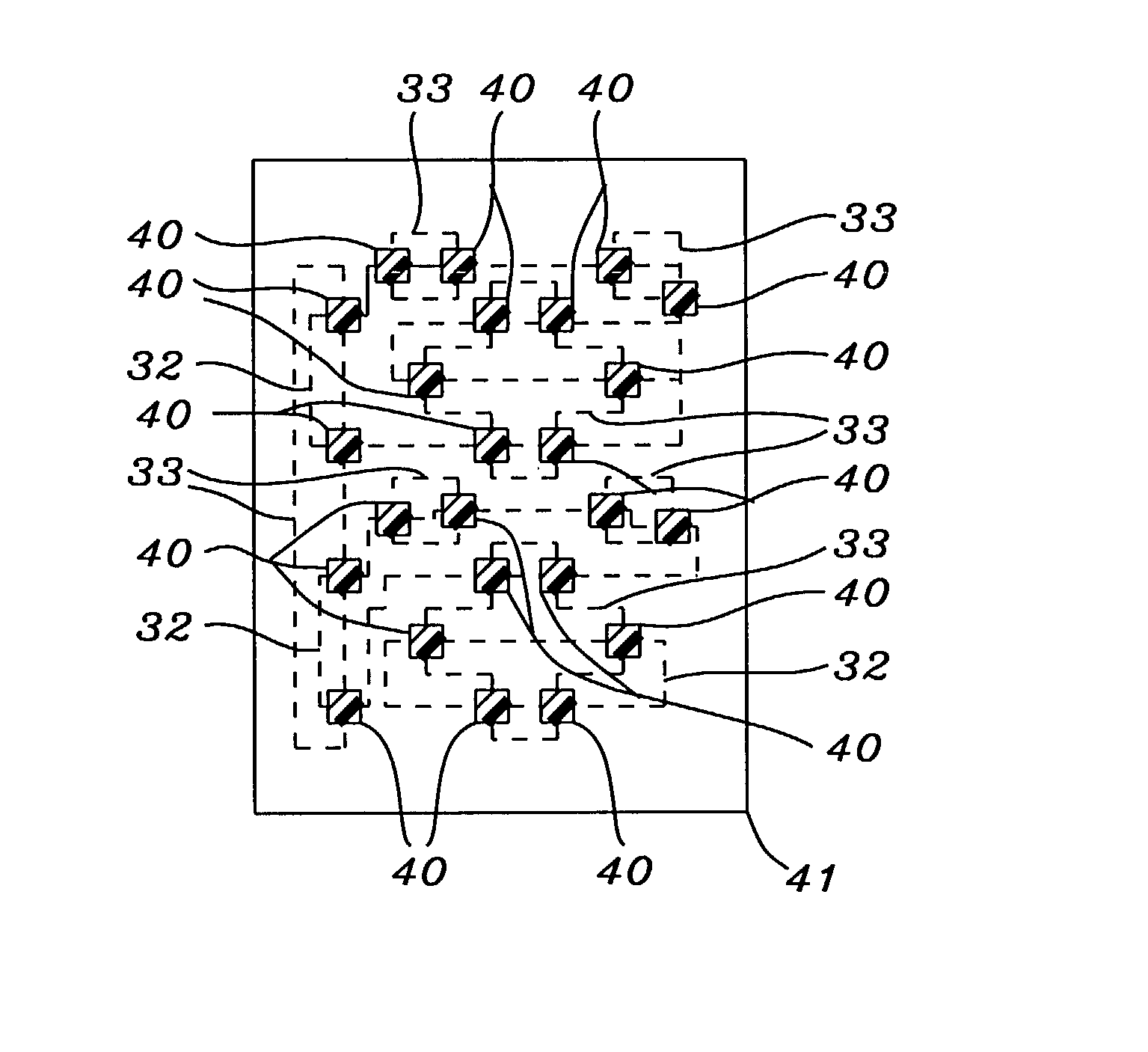

Complementary replacement of material

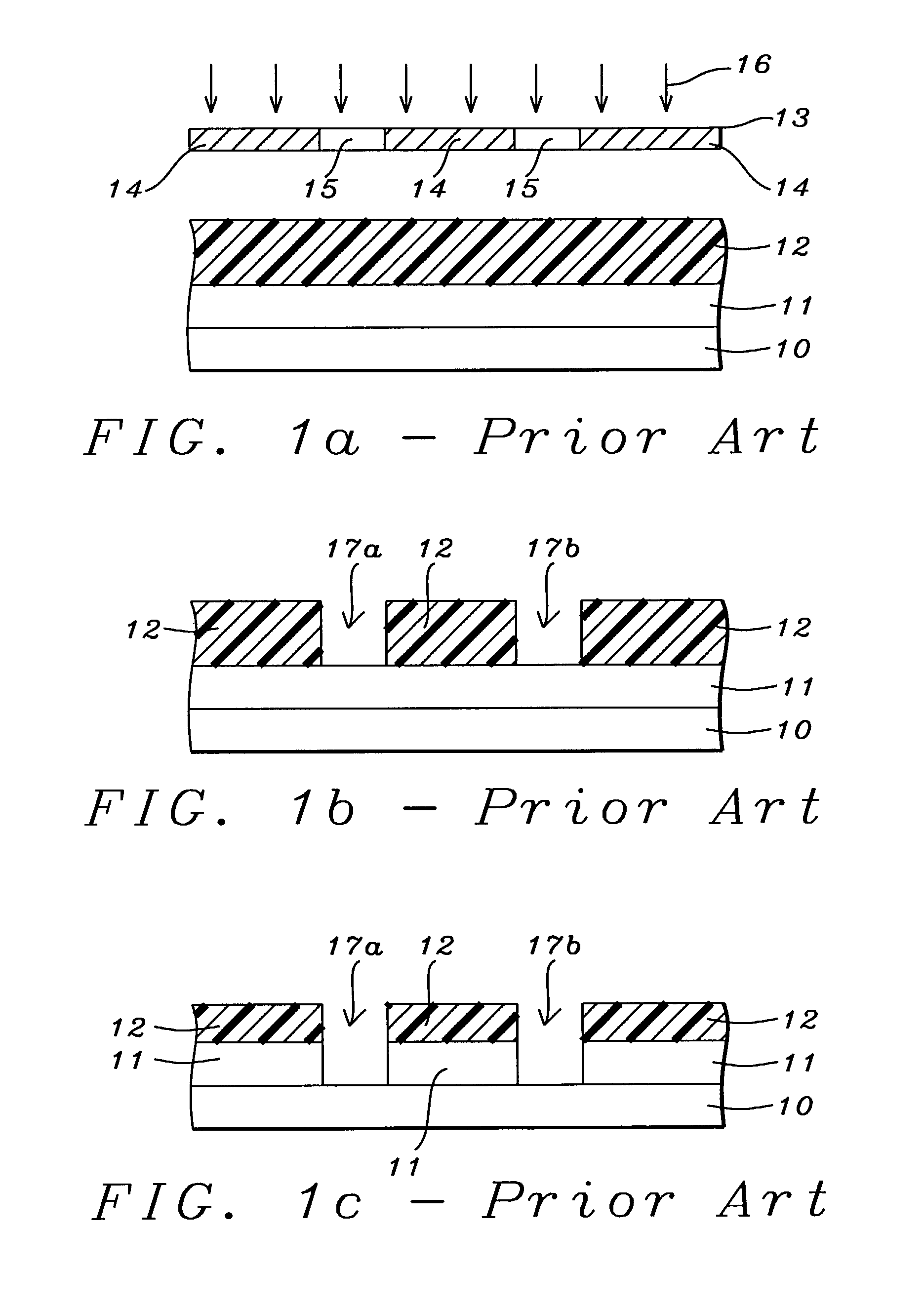

InactiveUS7399709B1Increase contrastMinimized roughnessDecorative surface effectsSolid-state devicesResistResolution enhancement technologies

An image reversal method is described that removes the etch resistance requirement from a resist. A high resolution resist pattern comprised of islands, lines, or trenches is formed with a large process window by exposing through one or more masks including phase edge masks and optionally with resolution enhancement techniques. A complementary material replacement (CMR) layer comprised of an organic polymer or material such as fluorosilicate glass which has a lower etch rate than the resist is coated over the resist pattern. CMR and resist layers are etched simultaneously to provide an image reversed pattern in the CMR layer which is etch transferred into a substrate. The method avoids edge roughness like bird's beak defects in the etched pattern and is useful for applications including forming contact holes in dielectric layers, forming polysilicon gates, and forming trenches in a damascene process. It is also valuable for direct write methods where an image reversal scheme is desired.

Owner:TAIWAN SEMICON MFG CO LTD

Method for detecting mixed acid solution in manufacturing process of polycrystalline silicon solar cell

ActiveCN102621273ASimple processReal-time monitoring of the texture processAnalysis using chemical indicatorsChemical analysis using titrationFluorosilicate saltPhysical chemistry

The invention discloses a method for detecting a mixed acid solution in the manufacturing process of a polycrystalline silicon solar cell. The method is used for detecting a mixed acid system which consists of hydrofluoric acid, nitric acid and fluorosilicic acid. The method comprises the following steps of: detecting the total acid concentration of the solution by using an acid-base neutralization method; heating and boiling the solution which is subjected to acid-base neutralization, decomposing fluorosilicate to generate hydrogen ions, determining the content of the hydrogen ions by alkali liquor titration, and thus obtaining the concentration of the fluorosilicic acid by calculation; detecting the concentration of the nitric acid in the mixed acid solution by using an oxidation-reduction titration method; and subtracting the concentration of the fluorosilicic acid and the concentration of the nitric acid from the total acid concentration, and thus obtaining the concentration of the hydrofluoric acid. The method is simple in flow, easy to operate and low in economic investment and can be applied to long-term monitoring of a texturing process and an etching process in the production process of the polycrystalline silicon solar cell and stability of equipment, manpower resources are saved, high-end equipment is eliminated, detection accuracy can be over 95 percent.

Owner:济宁高新科达科技项目服务有限公司

Light metal anodization

Using aqueous electrolytes containing complex fluorides or oxyfluorides such as fluorozirconates, fluorotitanates, and fluorosilicates, articles containing light metals such as magnesium and aluminium may be rapidly anodized to form protective surface coatings. White coatings may be formed on aluminium articles using pulsed direct current or alternating current. When the article to be anodized is comprised of magnesium, pulsed direct current having a relatively low average voltage is preferably used.

Owner:HENKEL KGAA

Zinc layer surface conversion film forming liquid, and application method thereof

InactiveCN102234799AReduce pollutionImprove performanceMetallic material coating processesFluorosilicate saltPhosphate

The invention discloses a zinc layer surface conversion film forming liquid, and an application method of the film forming liquid. The prepared zinc layer surface conversion film forming liquid is an aqueous solution with a pH value of 0.5 to 2, where in the pH value is regulated by nitric acid or sulfuric acid. The film forming liquid is prepared from cerium salt, halide, phosphate, meta-vanadate, fluorosilicate and water. The method comprises the steps that: a surface oxide layer of a galvanized material is removed through alkali washing and desmutting treatments; the treated galvanized material is immersed in the zinc layer surface conversion film forming liquid for 30 seconds to 30 minutes under a temperature of 10 DEG C to 70 DEG C; such that a conversion film is formed on the surface of the galvanized material. The formed conversion film has a uniform color and an excellent anti-corrosion performance. The film forming liquid and the method provided by the invention have values to be widely applied in industrial productions.

Owner:北京小铱新材料科技有限公司

Cleansing agent for ceramic filter plate

InactiveCN104593172AEfficient removalUse decay period extensionOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsFluorosilicate saltNitrate

The invention discloses a cleansing agent for ceramic filter plate. The cleansing agent for the ceramic filter plate comprises the following raw materials in parts by weight: 0.1-1 part of a principal agent, 0.11-0.6 part of an adjuvant, 0.01-0.1 part of an oxidant and 1.7-6.5 parts of an acidity adjuster. According to the invention, the principal agent is one or two of hydroxy ethyl fork bisphosphonic acid and hydroxy ethyl fork bisphosphonat, the adjuvant is one or more of soluble nitrate, chloride, fluoride and fluoride silicate. The cleansing agent prepared according to the formula can effectively clean and remove blockages on the surface or the inside of micro-pores in the ceramic filter plate, especially a ceramic filter plate in a ceramic filter used for filtrating high-sulphur ore pulp. The cleansing agent can dissolve substances enriched in micropores with a good cleansing effect. Specifically, tests prove that solid-liquid separation rate of a ceramic filter plate washed by the cleansing agent can restore to 70%-82% that of the initial state.

Owner:ANHUI TONGGUAN MACHINERY

Medical carbon rod and its prepn. method

InactiveCN1911184AIncrease healing energyEasy to useElectrotherapyInorganic active ingredientsFluorosilicate saltPhysical chemistry

A medical carbon rod for treating disease by discharge combustion to generate 2500-3800 deg.C and various spectra is prepared from carbon black and asphalt through high-temp calcining, pulverizing, moulding, high-temp calcining again to obtain a hollow carbon rod, filling metal oxide, fluorosilicate, Fe salt, K salt and RE metal, and high-temp baking.

Owner:程永起

Cleaning composition for removing etching residues

PendingCN111793531AOrganic detergent compounding agentsDetergent mixture composition preparationFluorosilicate saltPhosphate

The present invention provides a cleaning solution for removing etching residues, which includes a fluorine-containing compound, wherein the fluorine-containing compound is selected from the group consisting of fluoride salt, fluoroalkane, hexafluorosilicic acid, hexafluorosilicate, fluorophosphoric acid, hexafluorophosphate, fluoroboric acid, fluoroborate, trifluoromethanesulfonic acid, trifluoromethanesulfonate, fluorosulfonic acid, fluorosulfonate, and any combination of the above. The cleaning solution can improve the effect of removing silicon-containing by-products produced by etching silicon-containing materials such as silicon nitride.

Owner:JOYFULNESS ADVANCED CHEM CO LTD

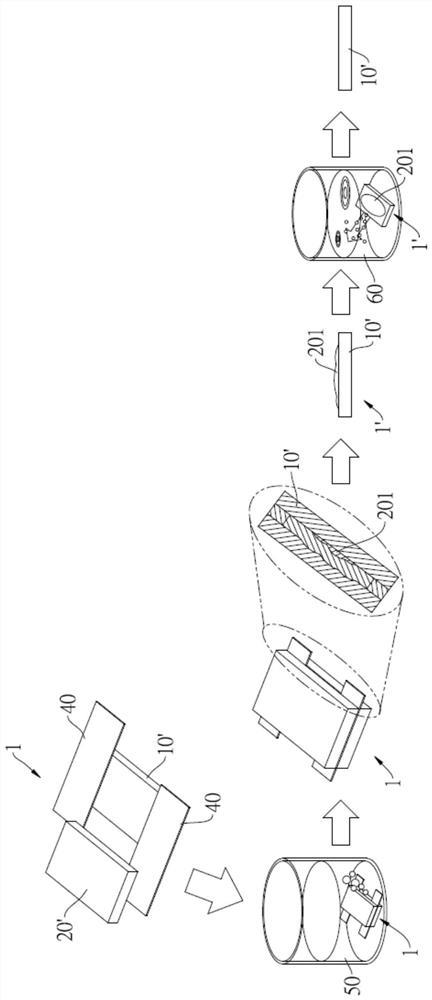

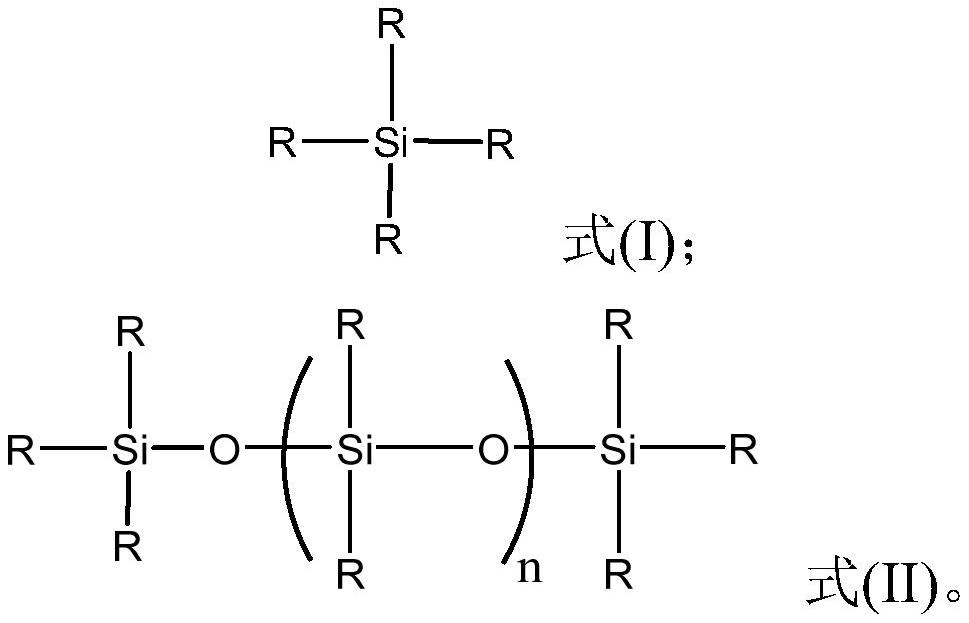

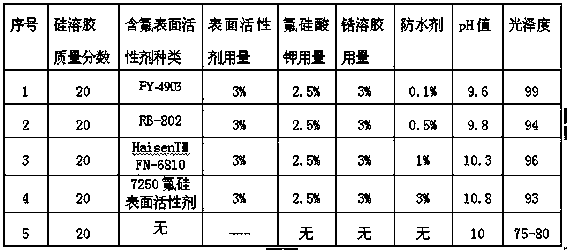

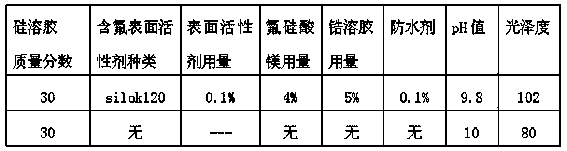

Preparation method of modified zirconium silica sol ceramic polishing liquid

ActiveCN104046244AGood dispersionImprove polishing effectPolishing compositions with abrasivesSilica gelSilicon dioxide

The invention discloses a preparation method of a modified zirconium silica sol ceramic polishing liquid, and the preparation method includes the following steps: 1), a fluorine-containing surfactant is added into silica sol to form a system A, wherein the particle size of the silica sol is 5-20nm, the PH = 9.5-10.5, the mass fraction of silica is 10-30%, and the mass fraction of the silica sol in the system A is 95-99.9%; 2), the system A is stirred and heated up to 50-100 DEG C, then zirconium sol and fluorosilicate are added into the system A to form a system B, wherein the particle size of the zirconium sol is 10-20nm, the mass fraction of zirconia is 10-20%, and PH = 2-9, and the weight ratio of system A to zirconium sol to fluorosilicate is 98-99.45: 0.5-1:0.05-1; and 3), the system B is stirred, a waterproof agent accounting for 0.1-3% by weight of the system B is added, and the pH is regulated to 9.5-11. The modified zirconium silica sol ceramic polishing liquid prepared by the preparation method has the advantages of low production cost, long stable storage time, strong hardness and good polishing effect.

Owner:GUANGDONG WELL SILICASOL

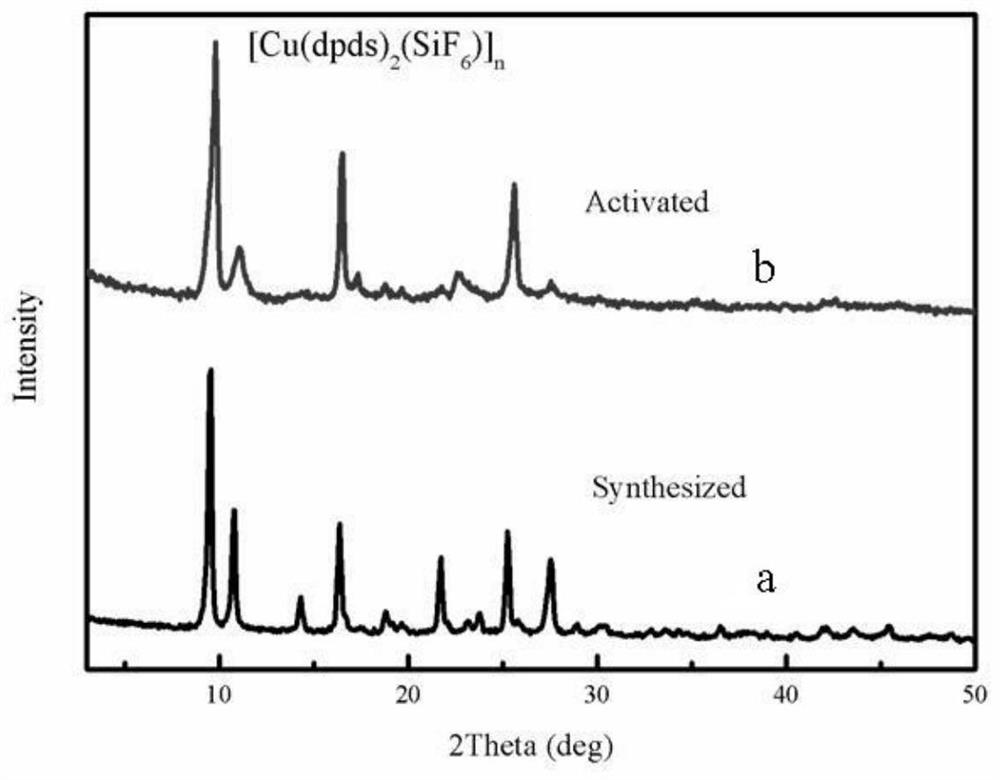

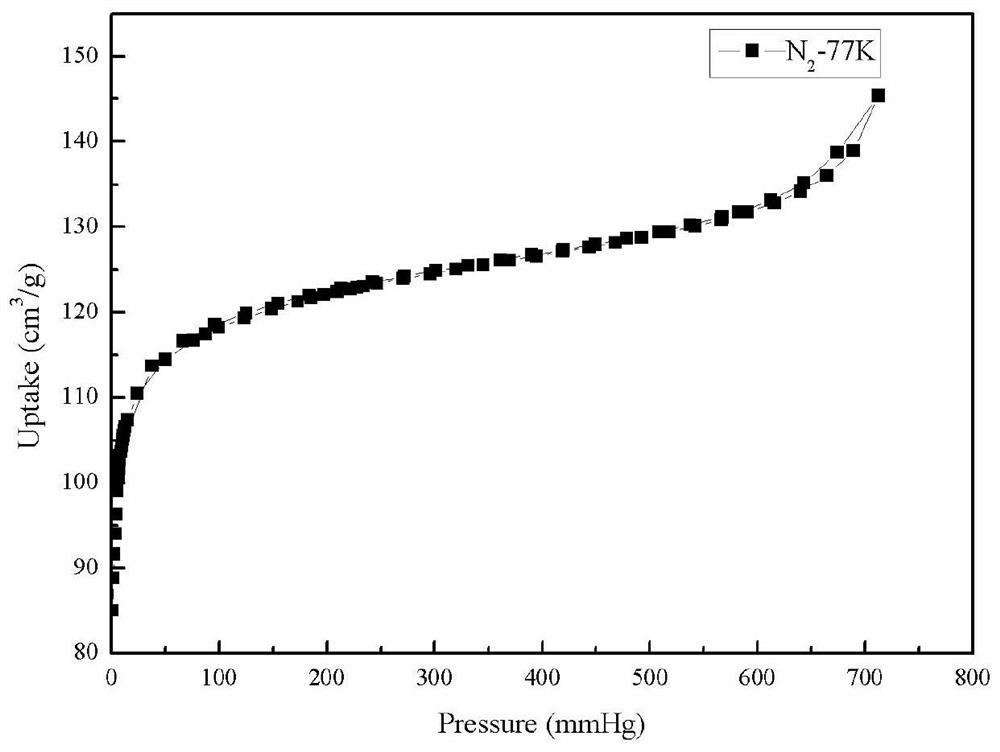

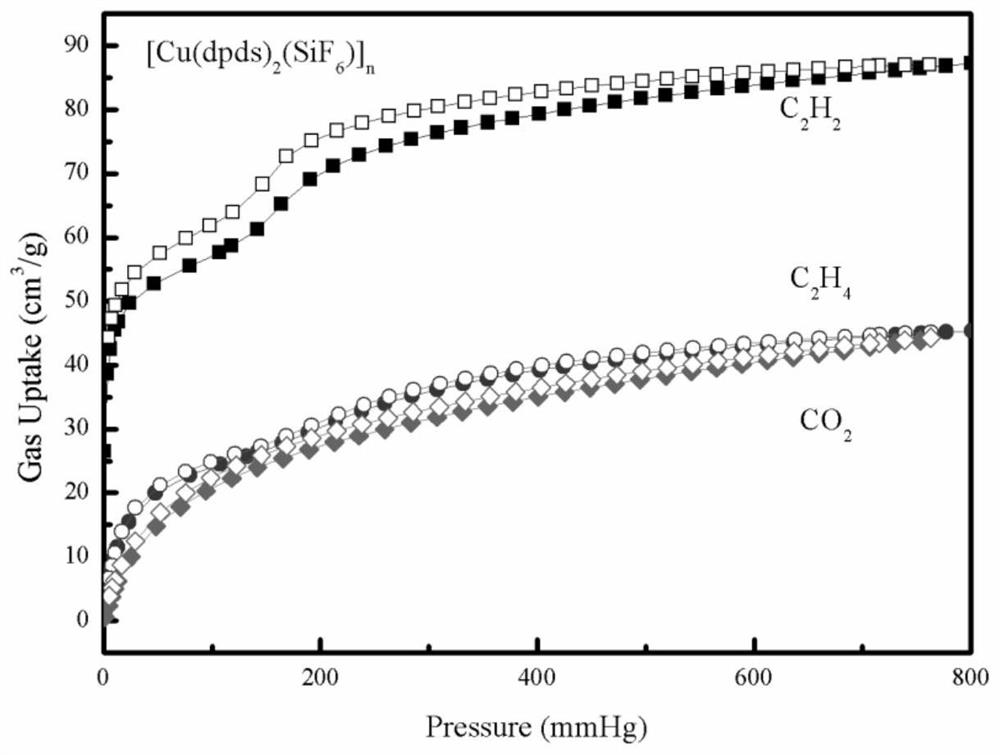

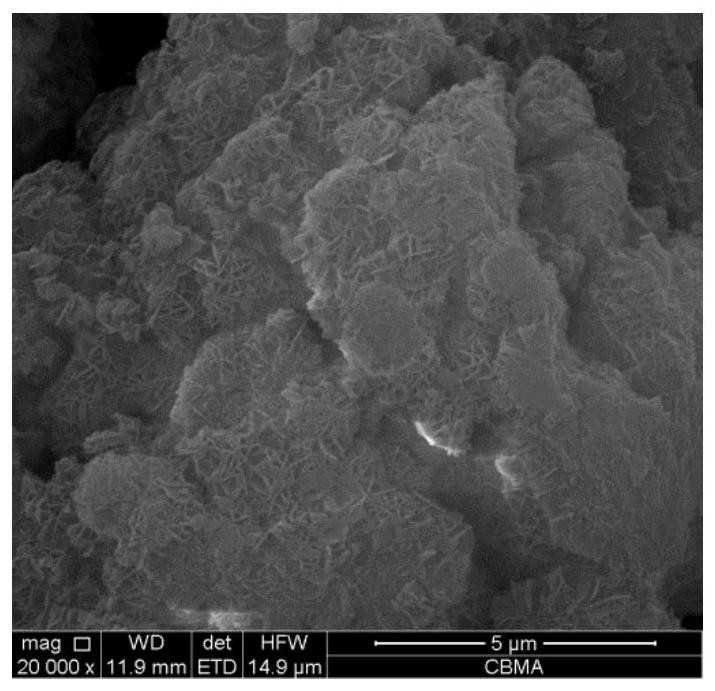

Fluorosilicate porous hybrid material as well as preparation method and application thereof

PendingCN112295550ALow priceLow costGas treatmentOther chemical processesFluorosilicate saltMetal-organic framework

The invention relates to the technical field of industrial gas separation, in particular to a fluosilicate porous hybrid material and a preparation method and application thereof. The structural general formula of the fluosilicate porous hybrid material is [Cu(dpds)2(SiF6)]n, and dpds is 4,4'-dipyridyl disulfide. A metal salt used by the fluosilicate porous hybrid material is copper hexafluorosilicate, the organic ligand is 4,4'-dipyridyl disulfide, and the fluosilicate porous hybrid material is an anionic pillared metal organic framework material with a proper pore diameter and a proper fluorination functional site; the preparation method is low in raw material price, cost-saving, simple to operate, easy to control conditions and easy to industrialize; and the fluosilicate porous hybrid material provided by the invention has appropriate pore diameter and fluorinated functional sites, can enhance the recognition of acetylene through the action of hydrogen bonds, can separate C2H2 / C2H4mixed gas and / or C2H2 / CO2 mixed gas at the same time, and has higher separation selectivity, larger adsorption capacity and higher separation performance than most existing solid adsorption materials.

Owner:ZHEJIANG UNIV OF TECH

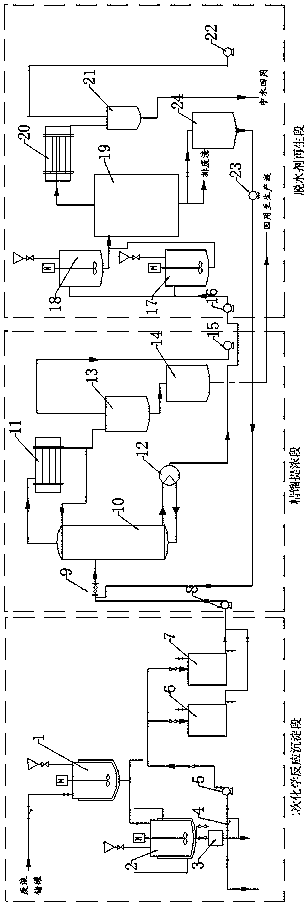

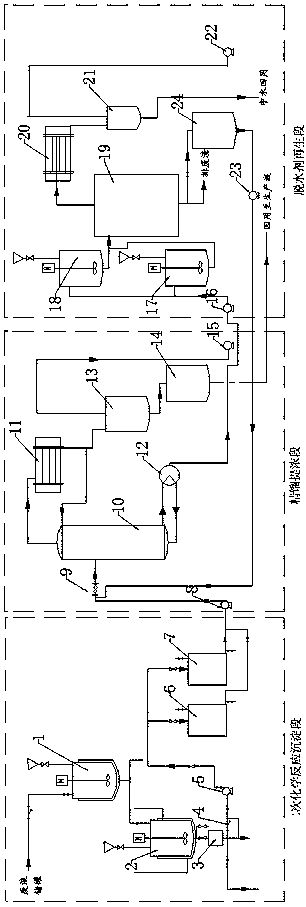

Device and method for recycling waste acid liquid produced in polycrystalline silicon texturing

ActiveCN111170320ALow costReduce manufacturing costAfter-treatment detailsWater contaminantsFluorosilicate saltFluorhydric Acid

The invention relates to a device and a method for recycling waste acid liquid produced in polycrystalline silicon texturing. According to the method, in a secondary chemical reaction precipitation section, hydrofluoric acid is neutralized through a primary reaction, a fluorosilicate precipitate is generated through a secondary reaction, and the precipitate can be sold; in a rectification and purification section, rectification and purification can be performed on dilute nitric acid to generate concentrated nitric acid; the nitric acid is evaporated and concentrated to obtain about 65% of dilute nitric acid through a dehydrating agent reduced-pressure rectification process, and the dilute nitric acid can be directly reused in a texturing liquid system, so the cyclic utilization of nitric acid is achieved, and reagent cost is reduced; and in a dehydrating agent regeneration section, a certain amount of magnesium oxide is added into a solution containing a small amount of dilute magnesium nitrate for neutralization, and then evaporation is carried out so as to obtain high-concentration concentrated magnesium nitrate which can be directly used as a dehydrating agent and applied to therectification and purification section. According to the invention, resource utilization and recycling of waste water and solid waste are realized, the operation cost and production cost of enterprises are further reduced, and the requirements of energy conservation, high efficiency and environmental protection are met.

Owner:SUZHOU KZONE EQUIP TECH

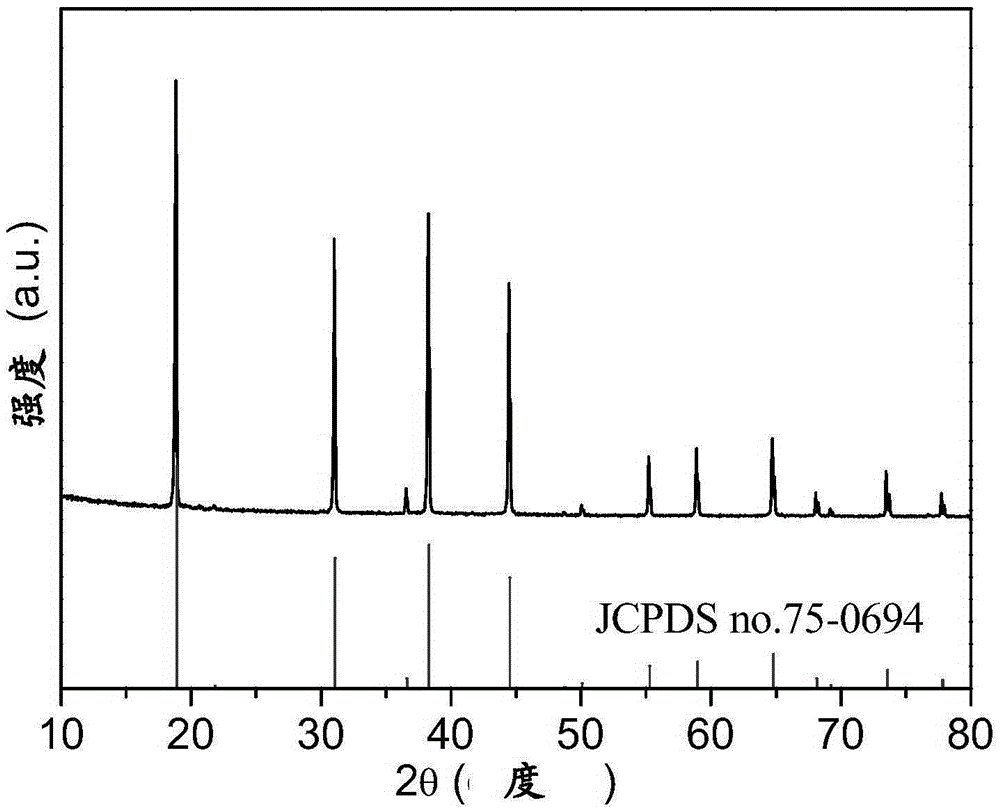

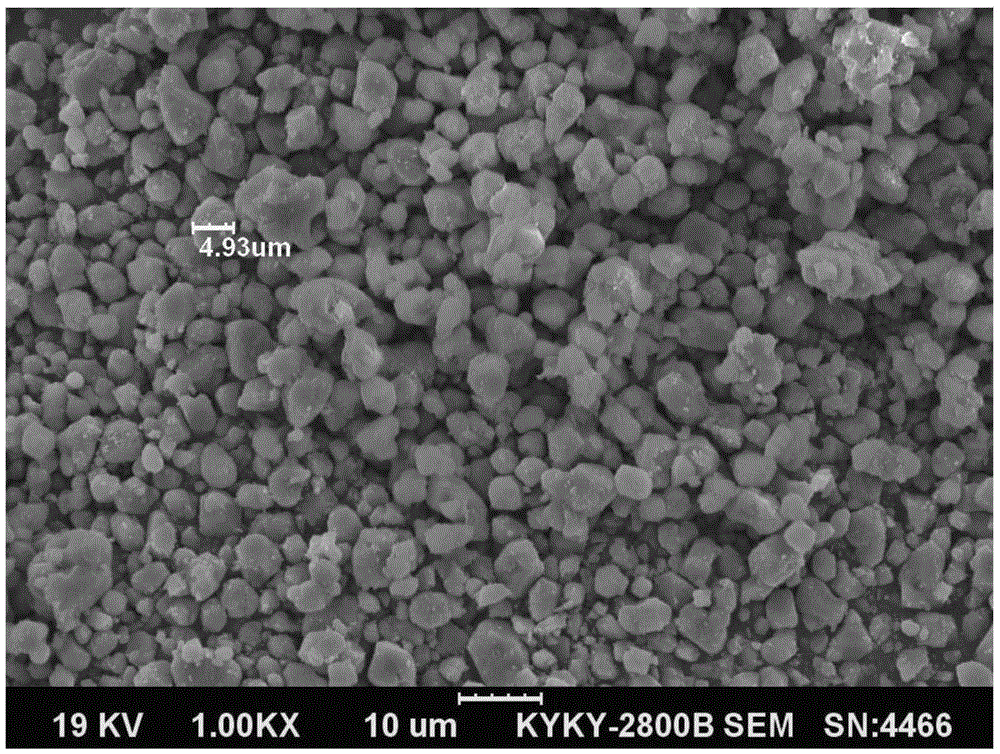

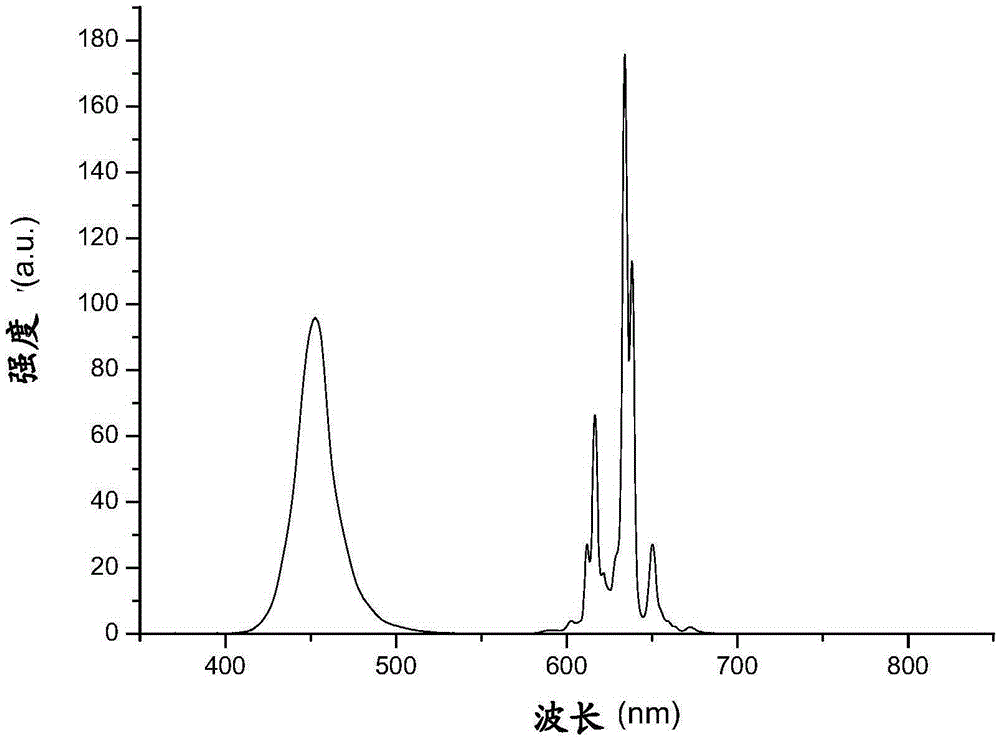

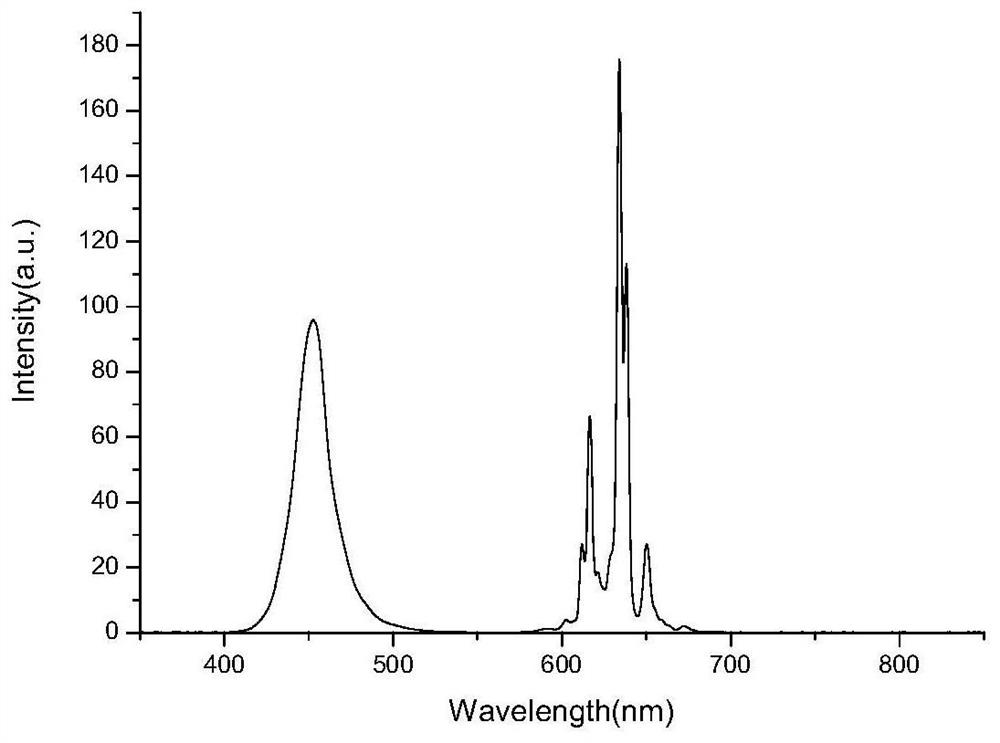

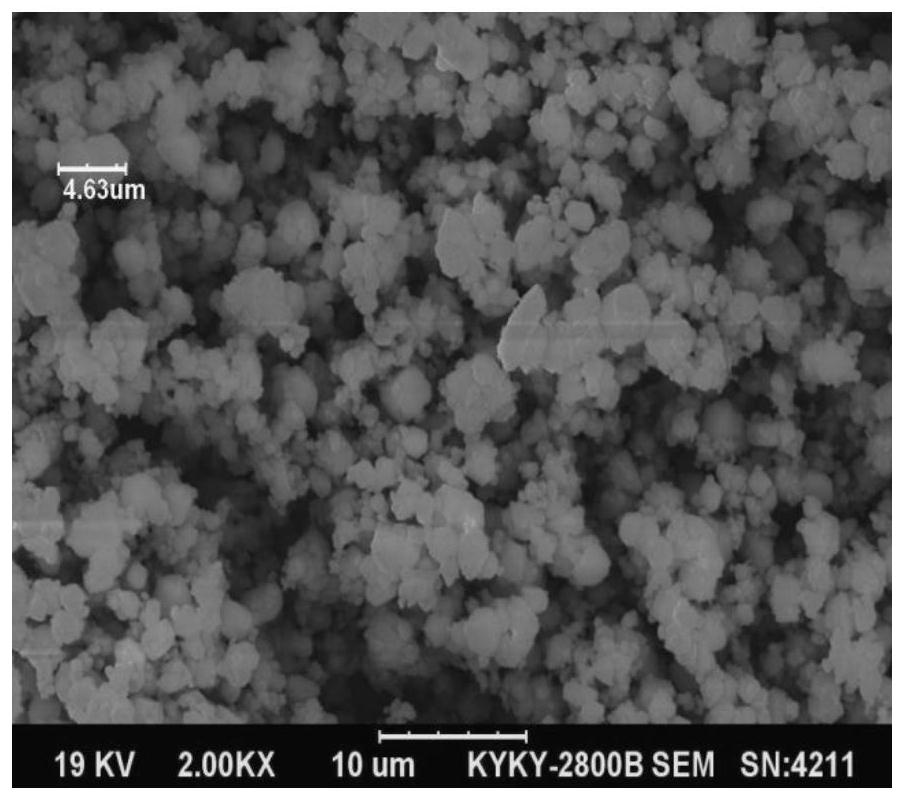

Preparation methods of fluorosilicate red fluorescent powder and composition containing fluorescent powder, products and applications

ActiveCN105419789AGood dispersionUniform particle size distributionLuminescent compositionsSemiconductor devicesHydrofluoric acidOrganic solvent

The invention provides a preparation method of fluorosilicate red fluorescent powder. The red fluorescent powder is shown by a general formula I: M2SiF6: Mn<4+> (I), wherein M is selected from one or two of K and Na. The preparation method of the fluorosilicate red fluorescent powder comprises the following steps: (1) adding MMnO4 and MF into hydrofluoric acid, carrying out stirring until the aforementioned three materials are uniformly mixed, and dropwise adding H2O2 into the mixture until the color of the solution is changed to obtain mixed liquor; (2) adding a powdery substance containing silicon oxide into the mixed liquor, heating the liquor with the substance at first for full reaction, then carrying out cooling to separate out a crystal, and carrying out filtration to obtain a yellow solid; and (3) washing the yellow solid obtained in the step (2) by separately using a small amount of pure water and an organic solvent, and carrying out drying treatment to obtain the red fluorescent powder. The invention also provides a preparation method of a composition containing the fluorescent powder, the red fluorescent powder or the composition containing the fluorescent powder prepared by using the method, and applications of the fluorescent powder or the composition containing the fluorescent powder in LED (Light-Emitting Diode) illumination or backlight elements or equipment.

Owner:烟台布莱特光电材料有限公司

Low-permittivity material and processing method via CVD

InactiveCN1255573CHigh porosityLow dielectric constantSemiconductor/solid-state device detailsCeramicsFluorosilicate saltGas phase

The present invention discloses an organofluorosilicate glass film comprising organic and inorganic matter and not including appreciable amounts of fluorocarbons. A preferred thin film is represented by the formula: Si v o w C x h y f z , where v+w+x+y+z=100%, v from 10-35 atomic%, w from 10-65 atomic%, y from 10-50 atomic%, x from 1-30 atomic%, z from 0.1-15 at%, x / z optionally greater than 0.25, wherein substantially no fluorine is attached to carbon. In addition, the present invention also provides a CVD method, comprising: (a) providing a substrate in a vacuum chamber; (b) introducing a gas-phase reactant into the vacuum chamber, the reactant comprising fluorine-supplying gas, oxygen-supplying gas, and at least a precursor gas selected from organosilanes and organosiloxanes; and (c) applying energy to gas phase reactants in the chamber to cause the gas phase reactants to react and form a film on the substrate.

Owner:AIR PROD & CHEM INC

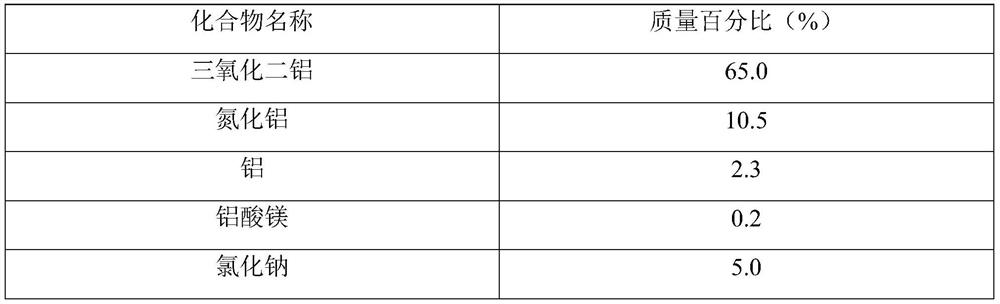

Refining agent for aluminum alloy containing high proportion of returned materials and its application method

ActiveCN106834876BExcellent degassing, impurity and slag removalDiffuse fullyTransportation and packagingMetal-working apparatusAluminateFluorosilicate salt

The invention discloses a refining agent for aluminum alloys containing a high proportion of returned charge and a method for using the same. The refining agent includes general components and functional components, and the general components include chloride metal salts, fluorine metal salts, and fluoroaluminate Or one or two of fluorosilicates; functional components include the following components: niobium alloy, copper alloy, metal zinc, rare earth. After the refining agent of the present invention is added to the aluminum alloy melt containing a high proportion of recycled materials, it can fully diffuse from bottom to top without adsorption and agglomeration, quickly exerts the refining effect, and obtains a high-purity aluminum alloy melt. When it is used to refine aluminum alloy melt containing a high proportion of returned materials, the hydrogen content of the aluminum melt can be reduced to a level not exceeding 0.10ml / 100g Al, and the total oxygen content of the aluminum melt can be reduced to 80ppm. In addition to its excellent degassing and impurity removal effects, the refining agent can also significantly reduce the number and size of β‑Al5FeSi phase in the casting structure, eliminate the harmful effect of impurity iron in aluminum alloys, and thus improve the mechanical properties of cast aluminum alloy castings performance and yield.

Owner:BEIHANG UNIV

Self hardening glass carbomer composition

InactiveCN1809329AHigh hardnessReduce sensitivityImpression capsSurgical adhesivesFluorosilicate saltAcid water

The present invention relates to a self hardening glass carbomer composition obtainable by treating a fluorosilicate glass powder with: (a) a poly(dialkylsiloxane) having terminal hydroxyl groups, wherein the alkyl groups contain 1 to 4 carbon atoms, (b) an aqueous acid solution, and (c) separating the treated fluorosilicate glass powder from the aqueous acid solution. The glass carbomer compositions according to the invention have for example good toughness and strength and excellent fluoride release, In addition, the glass carbomer compositions according to the invention do not show shrinkage or expansion, an essential property for providing fillings for cavities having high strength and long durability. Moreover, the glass carbomer composition according to the present invention has a lower sensitivity towards abrasion and wear, a greater stiffness, a smoother surface, a better colourfastness, a better adherence to e.g. bone tissue and a lower water sensitivity.

Owner:健康玻璃基金会

Method for detecting mixed acid solution in manufacturing process of polycrystalline silicon solar cell

ActiveCN102621273BSimple processReal-time monitoring of the texture processAnalysis using chemical indicatorsChemical analysis using titrationFluorosilicate saltPhysical chemistry

The invention discloses a method for detecting a mixed acid solution in the manufacturing process of a polycrystalline silicon solar cell. The method is used for detecting a mixed acid system which consists of hydrofluoric acid, nitric acid and fluorosilicic acid. The method comprises the following steps of: detecting the total acid concentration of the solution by using an acid-base neutralization method; heating and boiling the solution which is subjected to acid-base neutralization, decomposing fluorosilicate to generate hydrogen ions, determining the content of the hydrogen ions by alkali liquor titration, and thus obtaining the concentration of the fluorosilicic acid by calculation; detecting the concentration of the nitric acid in the mixed acid solution by using an oxidation-reduction titration method; and subtracting the concentration of the fluorosilicic acid and the concentration of the nitric acid from the total acid concentration, and thus obtaining the concentration of the hydrofluoric acid. The method is simple in flow, easy to operate and low in economic investment and can be applied to long-term monitoring of a texturing process and an etching process in the production process of the polycrystalline silicon solar cell and stability of equipment, manpower resources are saved, high-end equipment is eliminated, detection accuracy can be over 95 percent.

Owner:济宁高新科达科技项目服务有限公司

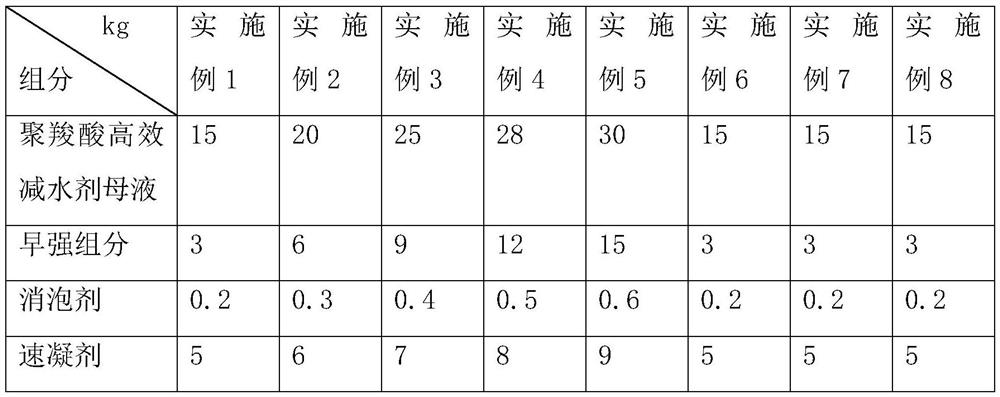

A kind of alkali-free liquid quick-setting agent and its preparation method and application

ActiveCN110255955BImprove the coagulation effectImprove long-term stabilityShotcreteFluorosilicate salt

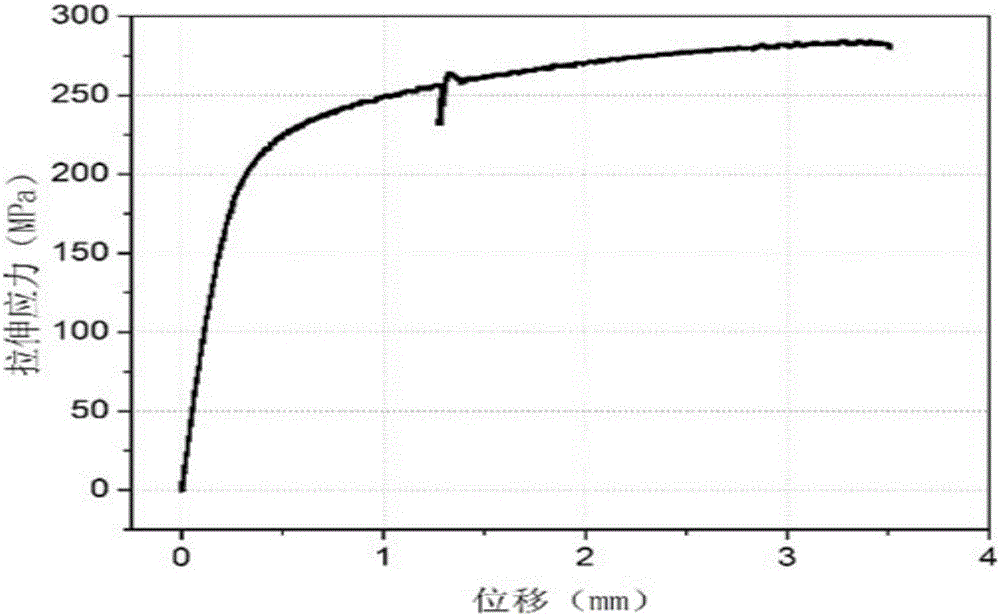

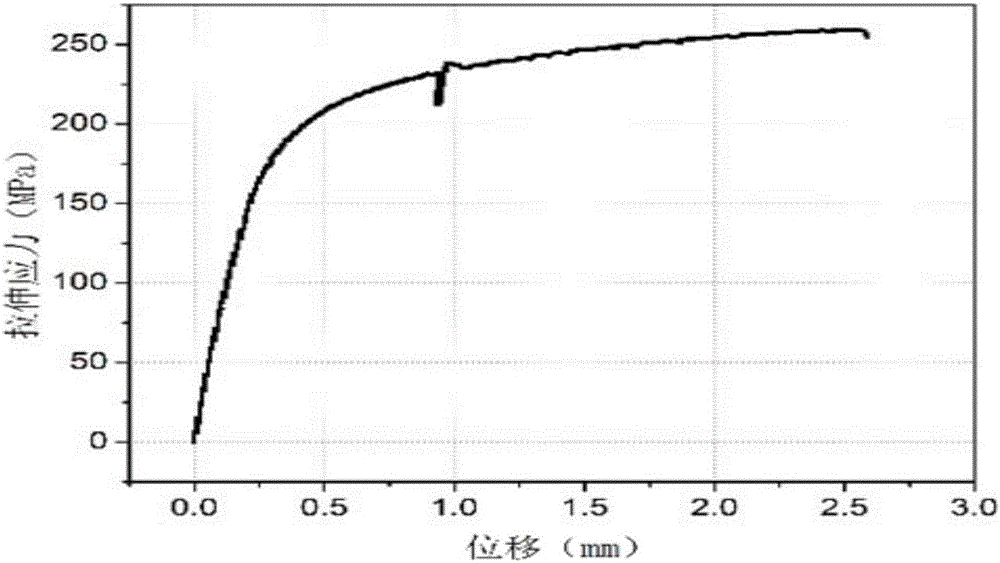

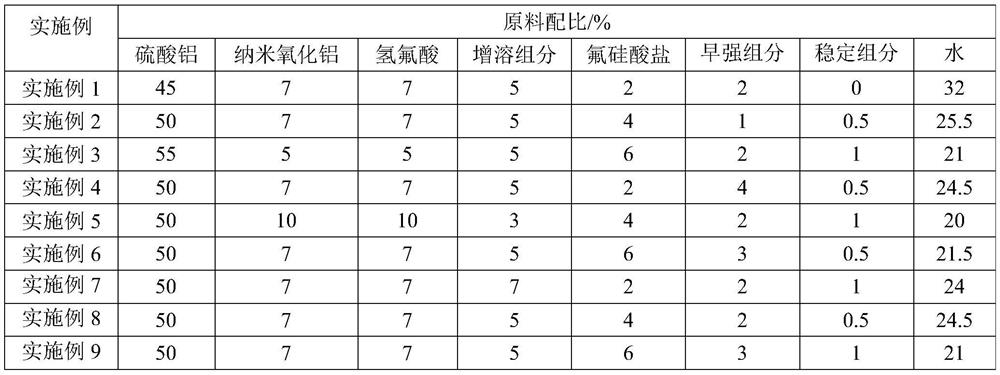

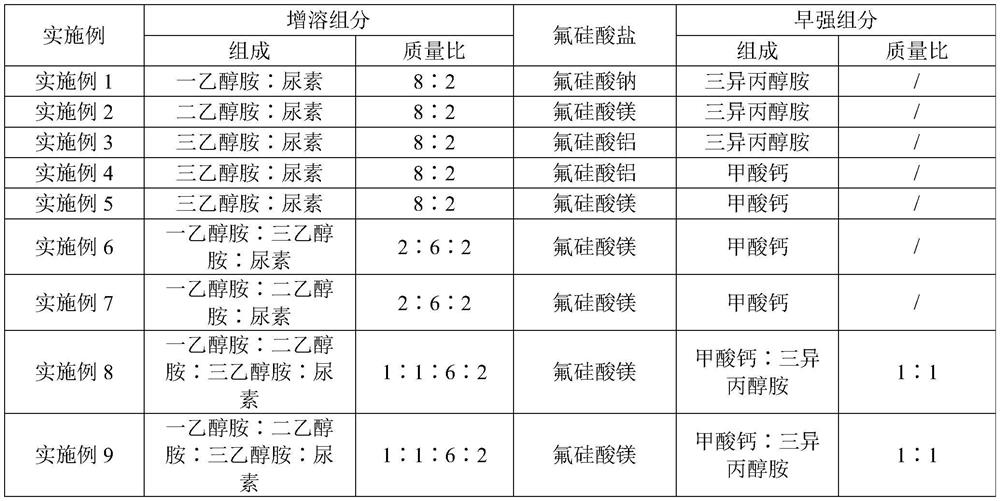

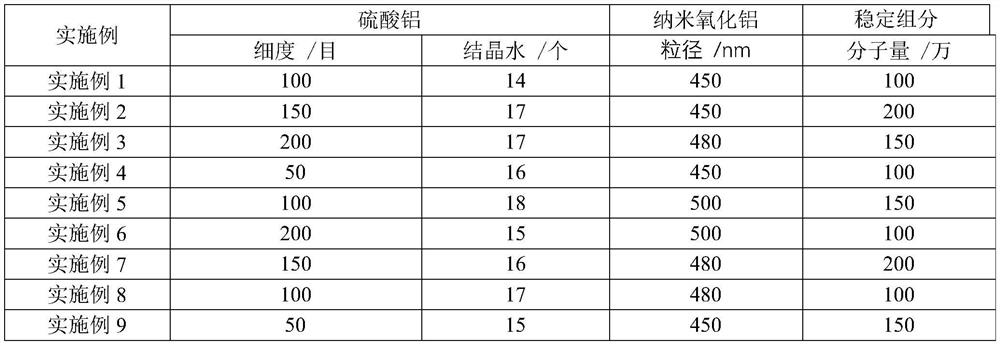

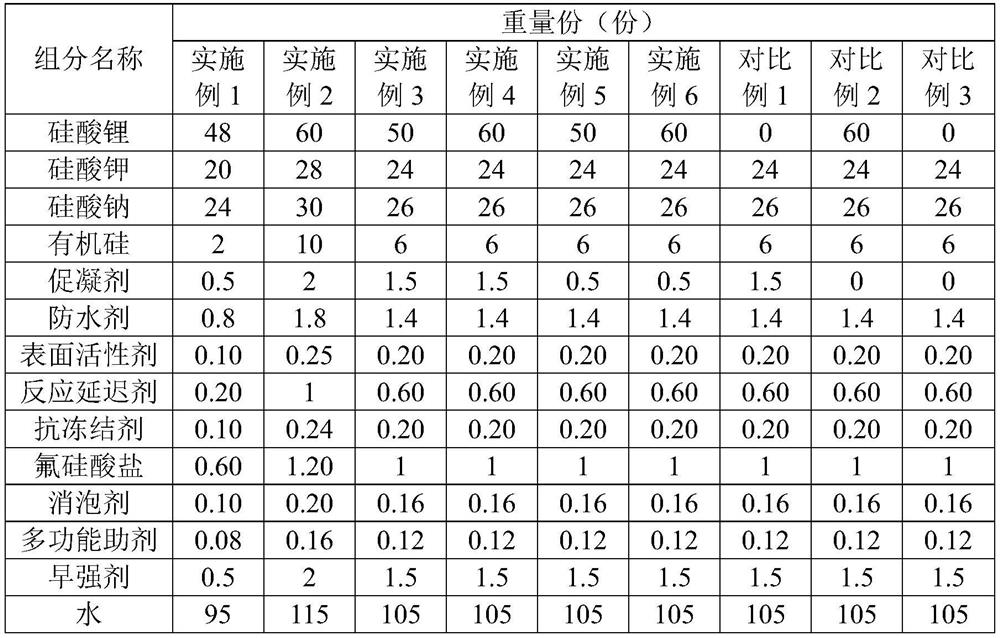

The invention provides a non-alkali liquid quick-setting agent and its preparation method and application. In terms of mass percentage, the raw materials of the non-alkali liquid quick-setting agent include the following components: aluminum sulfate: 45% to 55%, nano-alumina: 5%~10%, hydrofluoric acid: 5%~10%, solubilizing component: 3%~7%, fluorosilicate: 2%~6%, early strength component: 1%~4%, stable Components: 0.5-1%, water: 20-32%. The alkali-free liquid quick-setting agent of the present invention uses aluminum sulfate as the main raw material, and is equipped with nano-alumina, hydrofluoric acid, solubilizing components, fluorosilicates, early-strength components, and stabilizing components, so that it has good Accelerating effect, long-term stability and low rebound rate. At 7% dosage, all performances have reached the standard JC477-2005 "Accelerators for Shotcrete" for first-class accelerators Requirements, and the non-alkali liquid quick-setting agent of the present invention can greatly improve the early strength of concrete, and can make the later strength have a higher strength retention rate.

Owner:WUHAN UNIV OF TECH

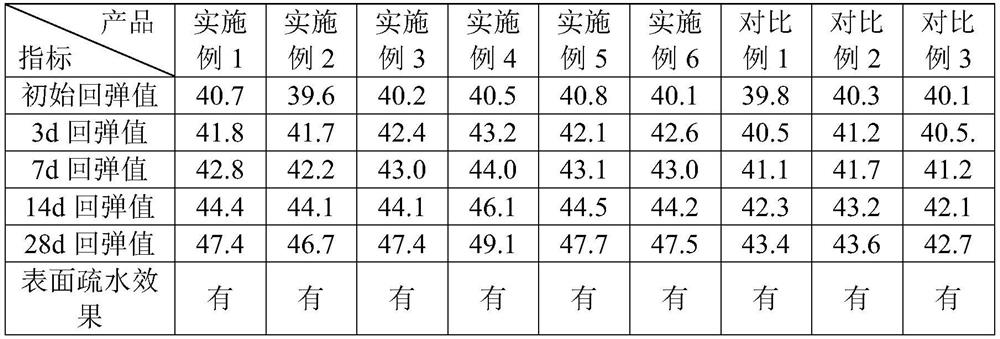

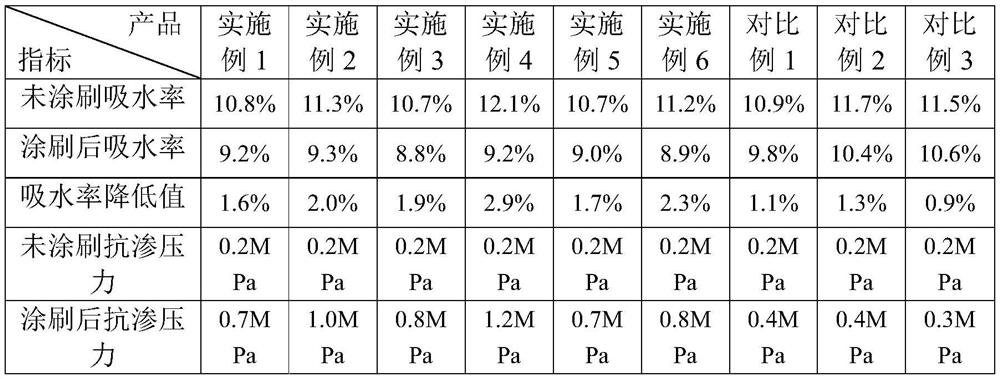

A water-based permeable crystalline concrete surface repair reinforcement material and its preparation method and application

The invention discloses a water-based permeable crystalline concrete surface repair reinforcing material and a preparation method and application thereof. The material comprises 48-60 parts of lithium silicate, 20-28 parts of potassium silicate, 24-30 parts of sodium silicate, organic 2-10 parts of silicon, 0.5-2 parts of coagulant, 0.8-1.8 parts of waterproofing agent, 0.1-0.25 parts of surfactant, 0.2-1 part of reaction retarder, 0.1-0.24 part of anti-freezing agent, 0.6 part of fluorosilicate ~1.2 parts, defoamer 0.1~0.2 parts, multifunctional auxiliary 0.08~0.16 parts, early strength agent 0.5~2 parts, water 95~115 parts. The water-based permeable crystalline concrete surface repair reinforcing material of the invention has the characteristics of rapid increase in strength, obvious repair effect on concrete and mortar, can repair and heal cracks and small cracks, thus can improve the water permeability resistance of concrete, and has good durability, Long life, simple preparation and convenient construction.

Owner:SUZHOU GUARDEX NEW MATERIAL TECH CO LTD

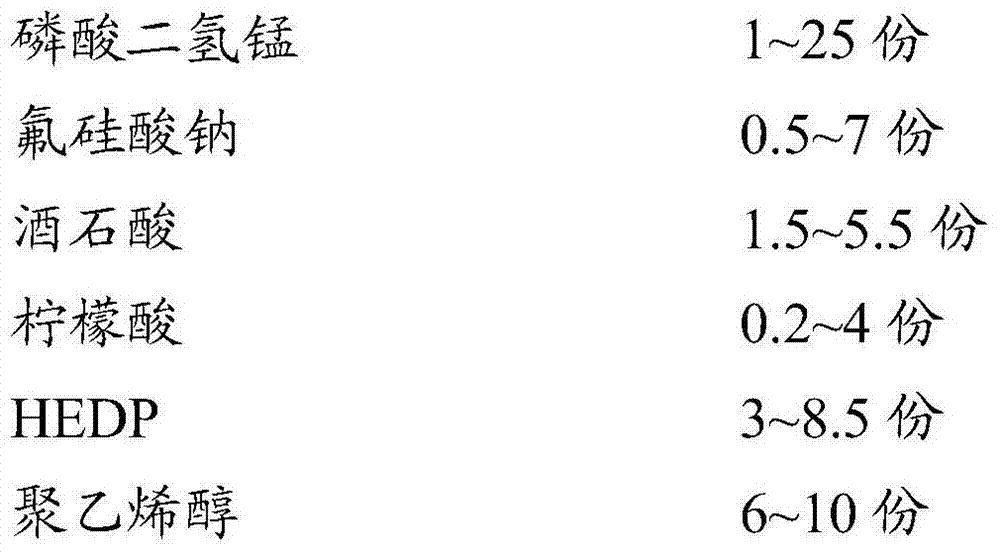

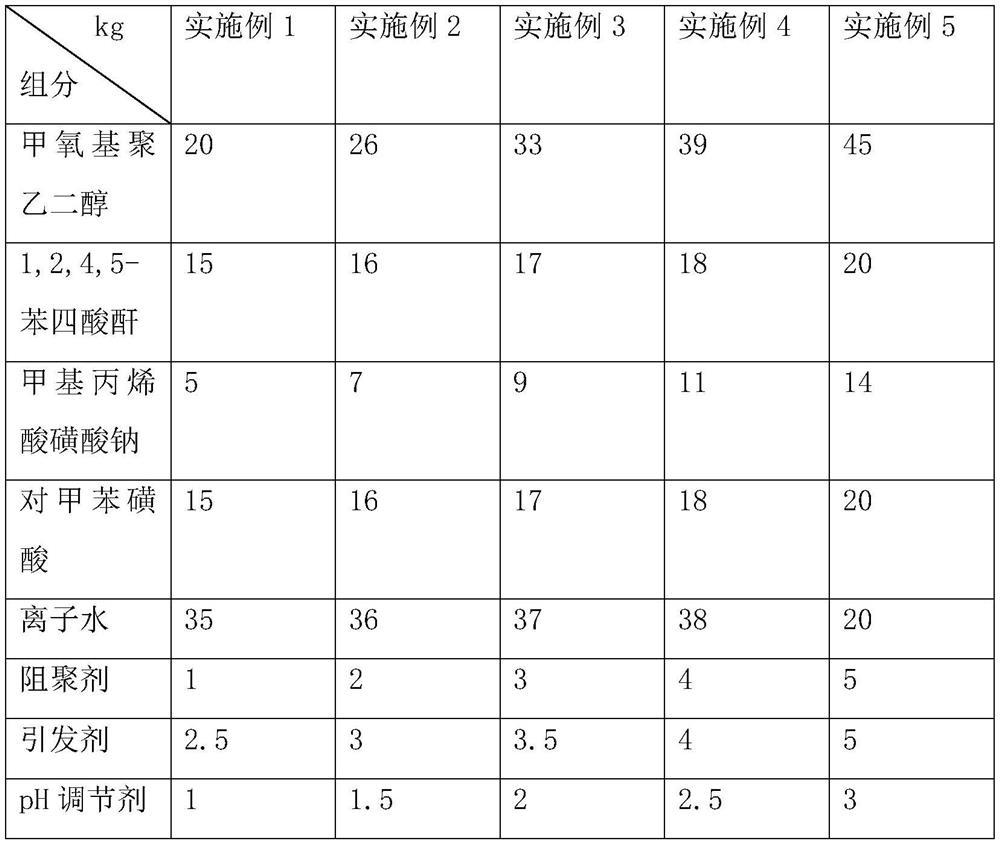

A kind of manganese series phosphating solution additive and using method thereof

ActiveCN104962898BStable pHGrain refinementMetallic material coating processesFluorosilicate saltPhosphate

The invention provides a manganese-based phosphating solution additive and a using method thereof, belonging to the field of industrial phosphating solutions. The additives include manganese dihydrogen phosphate, sodium fluorosilicate, tartaric acid, citric acid, HEDP, polyvinyl alcohol, starch phosphate monoester and gluconic acid; the degree of substitution of the starch phosphate monoester is 0.12. Compared with the prior art, the manganese-based phosphating solution additive of the present invention has the advantages of using tartaric acid instead of nitrite and cooperating with fluorosilicate to accelerate the film-forming speed; organic carboxylate is complexed with metal cations to make The crystal grains are refined, and the phosphating solution sediment is reduced at the same time to ensure the quality of the phosphating film. Coating adhesion; the additive has a wide application range, low cost, convenient use, energy saving and environmental protection, and is beneficial to industrial production.

Owner:DALIAN BETRUST ENVIRONMENTAL PROTECTION TECH CO LTD

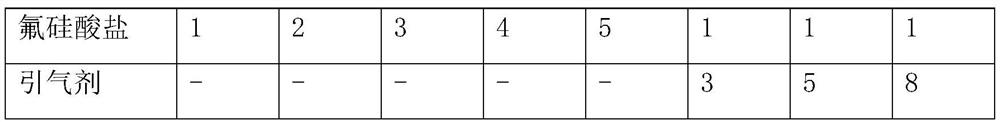

A kind of early-strength polycarboxylate water reducer and its preparation method and application

ActiveCN110451839BGood water reduction effectGood slump performanceFluorosilicate saltCarboxylic acid

Owner:重庆腾治科技有限公司

Treatment method for dangerous solid waste containing fluorosilicate

PendingCN113369289AIncrease contact areaEnsure complete responseSolid waste disposalFluorosilicate saltEngineering

The invention relates to a method for treating dangerous waste residues, in particular to a treatment method for dangerous solid waste containing fluorosilicate. The method comprises the following steps that a raw material cushion layer containing calcium carbonate is formed at the bottom, then a waste residue layer containing fluorosilicate, a raw material middle layer containing calcium carbonate and a soil layer are sequentially laid from bottom to top, and water flows through the soil layer, the middle layer containing the calcium carbonate, the waste residue layer containing the fluorosilicate and the cushion layer containing the calcium carbonate from top to bottom. According to the treatment method, harmless treatment can be carried out on the dangerous solid waste containing the fluorosilicate, a waste residue field with fluorine pollution can be repaired, the calcium carbonate reacts with the dangerous solid waste containing the fluorosilicate to generate non-toxic and water-insoluble calcium fluoride precipitates, fluorine elements in the solid waste and waste residues are effectively removed, fluorine pollution is eliminated, the concentration of fluorine ions in discharged reaction liquid is less than 10 mg / L, and the concentration meets the national sewage comprehensive discharge standard.

Owner:JIAYING UNIV

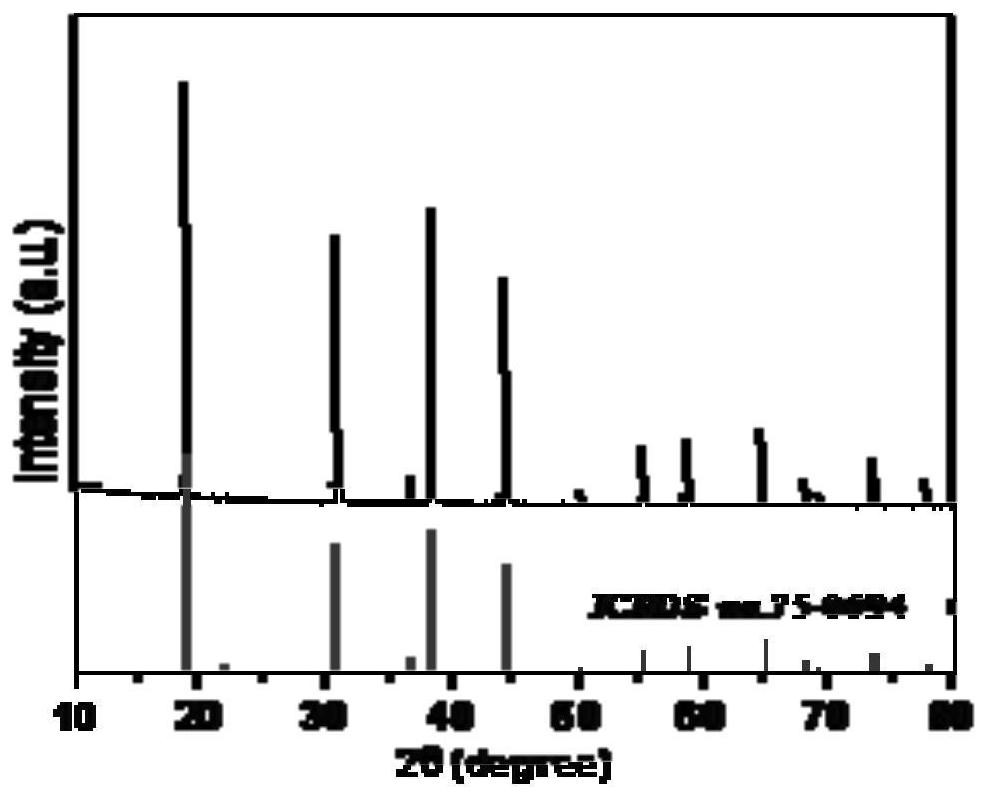

Fluorosilicate red fluorescent powder and preparation method thereof

PendingCN113773832AMeet application requirementsGood dispersionLuminescent compositionsSemiconductor devicesOXALIC ACID DIHYDRATEFluorosilicate salt

The invention discloses fluorosilicate red fluorescent powder. The chemical formula of the fluorosilicate red fluorescent powder is Ca<1-x>SiO2F2:xMn2+, wherein the value range of x is 0.17 to 0.56. The invention also discloses a preparation method of the fluorescent powder. The preparation method comprises the following steps: (1) weighing raw materials according to the stoichiometric ratio of the chemical formula; (2) mixing the raw materials, adding a fluxing agent, performing grinding, uniformly performing grinding, and performing sieving to obtain a mixture; (3) putting the mixture obtained in the step (2) into a crucible, performing sintering for 4-6 hours in a high-temperature furnace in a reducing atmosphere at the sintering temperature of 800-1,000 DEG C, and performing cooling to obtain the fluorosilicate red fluorescent powder, wherein the raw material is a mixture of calcium fluoride, potassium fluoride, silicon dioxide, oxalic acid and manganese dioxide; the addition amount of the fluxing agent is 0.2-0.4% of the total weight of the raw materials, the fluxing agent is a mixture of ammonium fluoride and ammonium chloride, and the weight ratio of ammonium fluoride to ammonium chloride is (3.5-8.4): 1. According to the invention, the fluorosilicate red fluorescent powder with good dispersibility, uniform particle size distribution and high luminescence performance can be prepared, and the application requirements of fluorescent powder in LED packaging can be met.

Owner:烟台布莱特光电材料有限公司

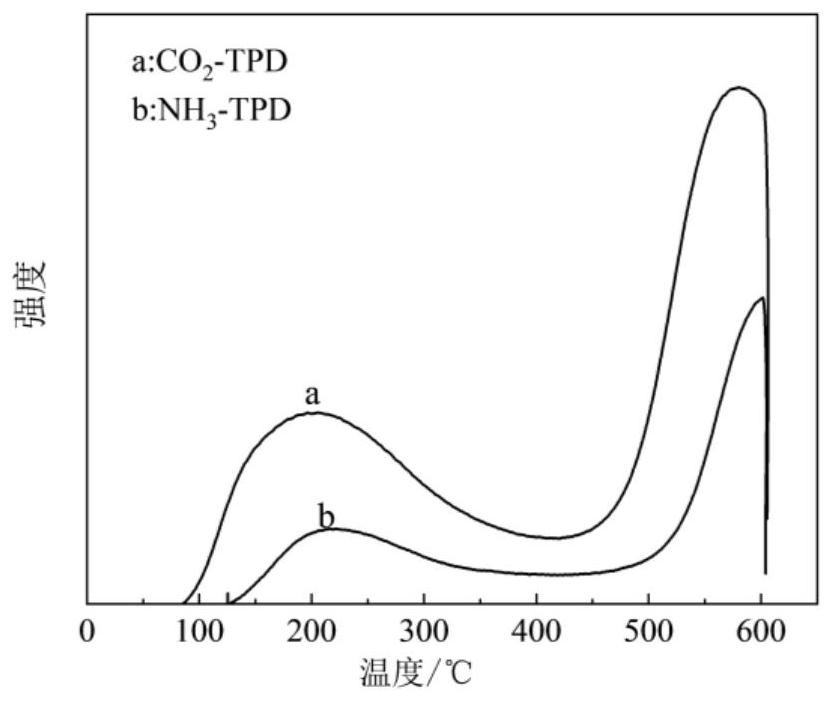

Catalyst for preparing anisole from phenol and dimethyl carbonate

ActiveCN112808318BAdjust acidity and alkalinityGood effectCatalyst activation/preparationChemical recyclingFluorosilicate saltAlkaline earth metal

The invention provides a catalyst for preparing anisole from phenol and dimethyl carbonate, which utilizes IIA group alkaline earth metal salt and aluminum nitrate to form hydrotalcite through co-precipitation of sodium hydroxide and sodium carbonate, and then adds fluorosilicate and / or obtained by intercalation modification of fluoroaluminate.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Sponge brick produced from aluminum ash and preparation process thereof

PendingCN114105612AEffective consumptionEfficient use ofCeramic materials productionCeramicwareSocial benefitsFluorosilicate salt

Owner:淄博天之润生态科技有限公司

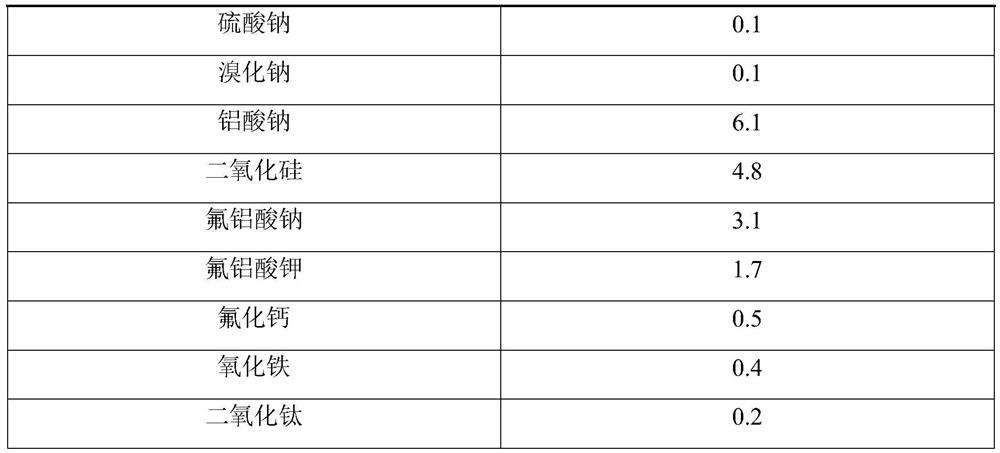

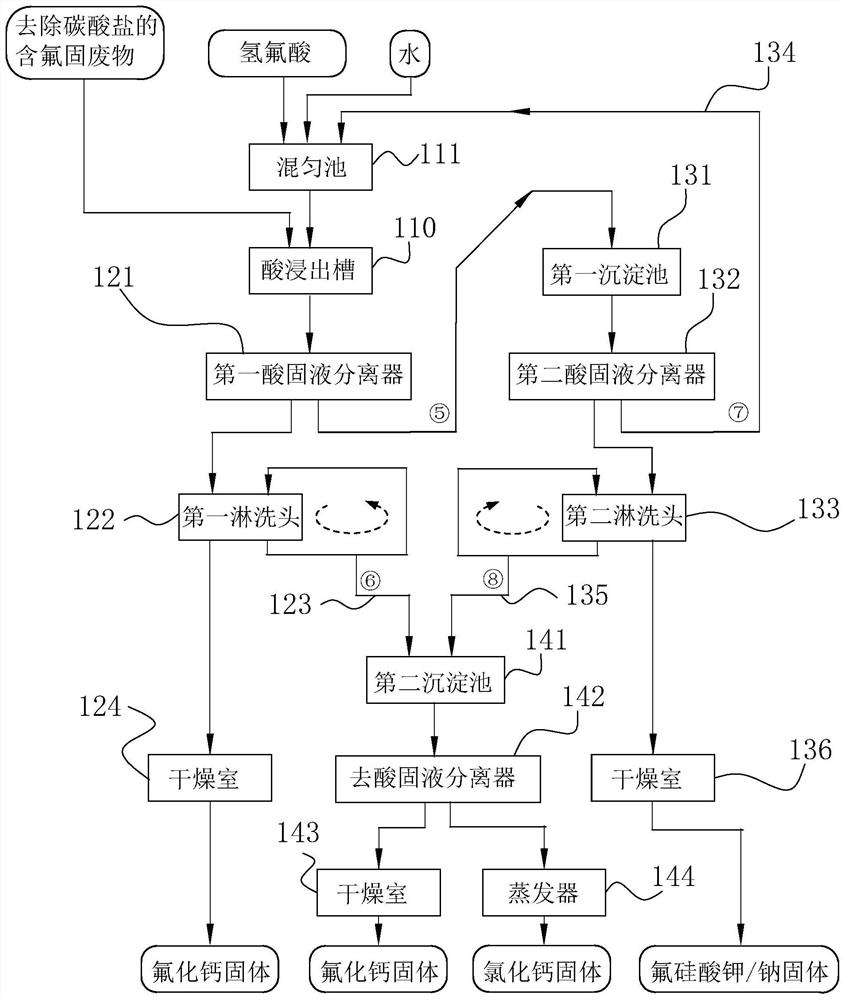

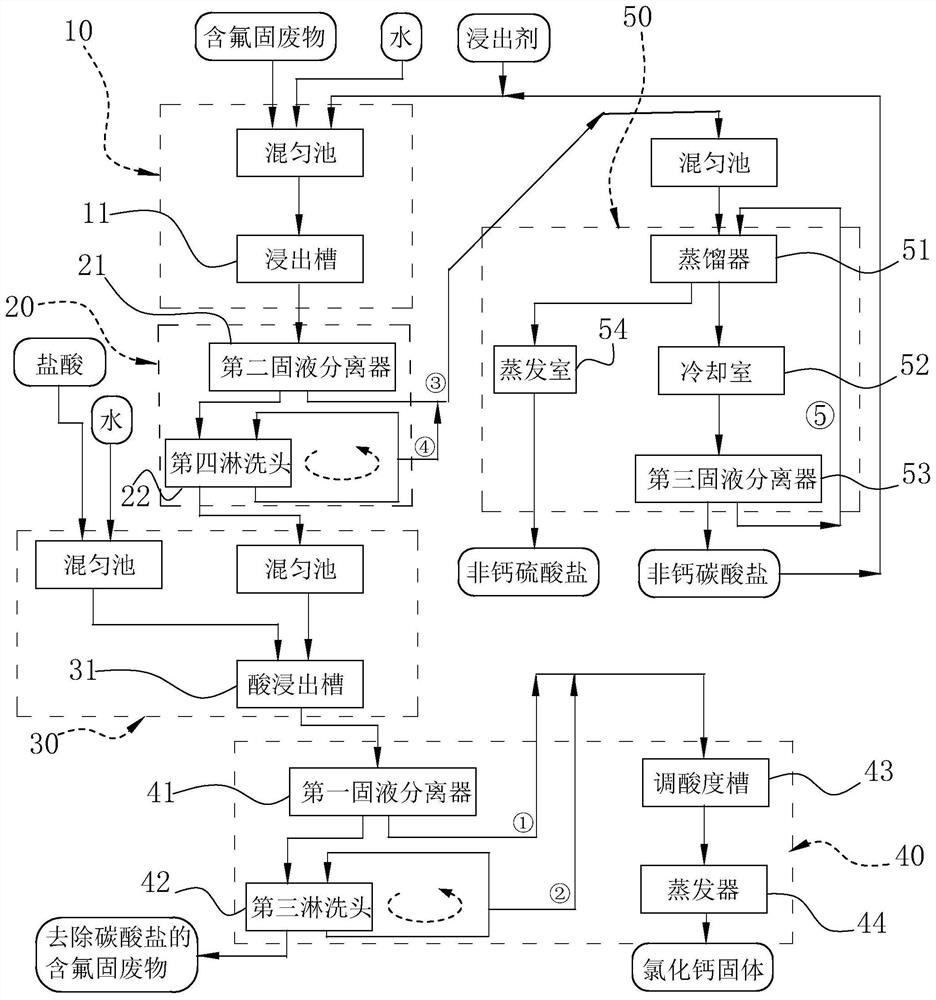

Method and equipment for purifying calcium fluoride from decarbonated fluorine-containing solid waste

ActiveCN111377474BHigh yieldHigh purityCalcium/strontium/barium fluoridesFluorosilicate saltSilicon dioxide

Owner:深圳市考拉生态科技有限公司

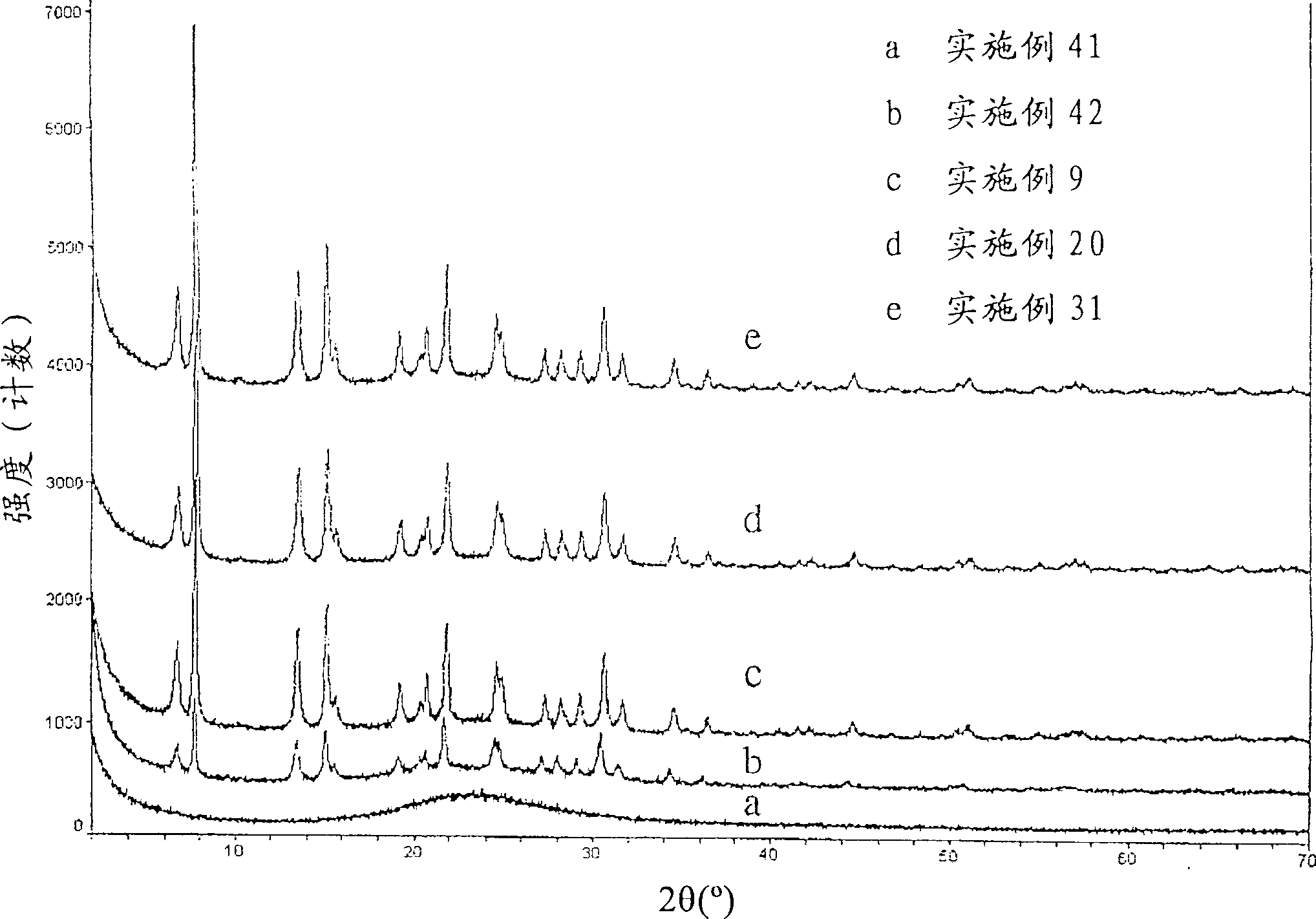

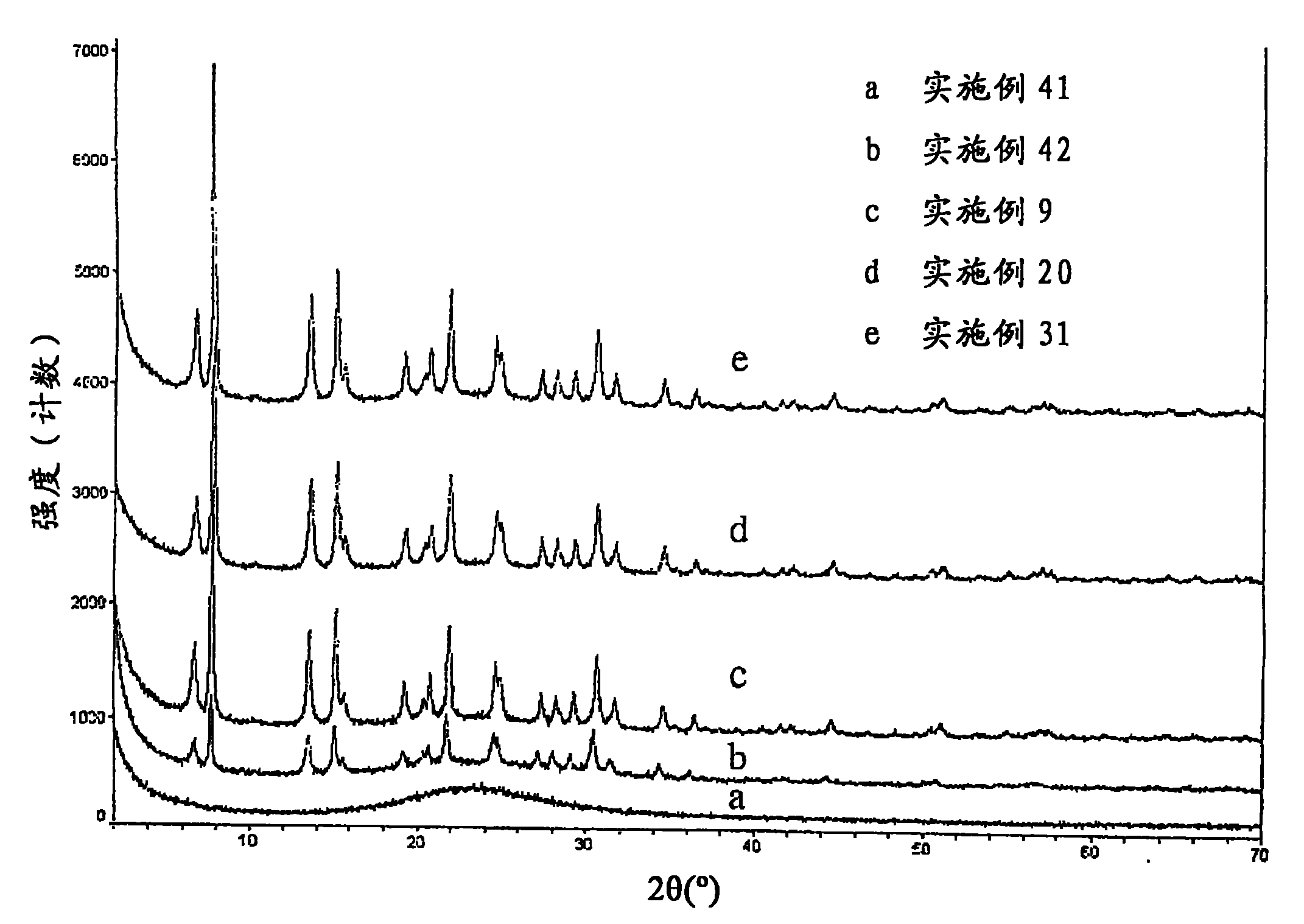

Crystalline aluminosilicate zeolitic composition: UZM-4M, preparing method thereof and use in hydrocarbon conversion process and molecule substance mixture isolation

InactiveCN1313372CHydrocarbon by isomerisationMolecular sieve catalystsFluorosilicate saltAlkaline earth metal

Applicants have synthesized a new crystalline aluminosilicate zeolite identified as UZM-4M. This new zeolite is obtained by treating a UZM-4 zeolite with a fluorosilicate salt to obtain a zeolite having the empirical formula:where M1 is an alkali metal, alkaline earth metal, rare earth metal, hydronium ion or ammonium ion, E can be gallium, iron, boron, indium and mixtures thereof and has a Si / Al ratio of 1.5 to about 10.

Owner:UOP LLC

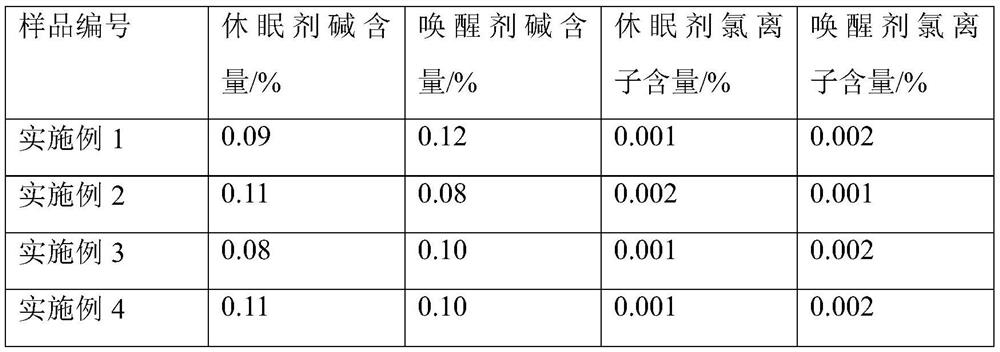

A kind of non-alkali and non-chlorine dormant wake-up agent composition for wet shotcrete and its application method

ActiveCN110981268BRealize ultra-long-distance transportationLong working performance retention timeFluorosilicate saltPhysical chemistry

The invention discloses an alkali-free and chlorine-free dormant wake-up agent composition for wet shotcrete and a method for using the same. The dormancy agent in the composition consists of fluorosilicate, hydroxycarboxylic acid, chelating agent, polyacrylic acid and water. ; The wake-up agent in the composition is composed of water-soluble calcium salt, alkanolamine, silica sol and water. The beneficial effects of the invention are: the product does not contain alkali metal ions such as potassium and sodium, and does not contain chloride ions. It can effectively improve the working performance retention time of wet shotcrete and at the same time effectively improve the spraying effect of shotcrete. It has good adaptability to alkaline and non-alkali accelerator, and the application method is simple.

Owner:云南凯威特新材料股份有限公司

A curing agent for sealing and hardening of concrete surface and its preparation and construction method

The invention relates to the technical field of curing agents and particularly relates to a curing agent for sealing and hardening surface of concrete, as well as preparation and construction methods thereof. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, comprises the following components in percentage by weight: 0.1-2% of fluorosilicate, 0.001-0.02% of surfactant, 5.0-30.0% of at least one of silica sol or silicate and the balance of water. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, has the advantages of short curing time, thick surface hardened layer and high surface hardness, and can be widely used for surface hardening and curing treatment of concrete buildings or structures of highways, squares, garages, supermarkets, factory buildings and the like.

Owner:DONGGUAN MERROCK IND

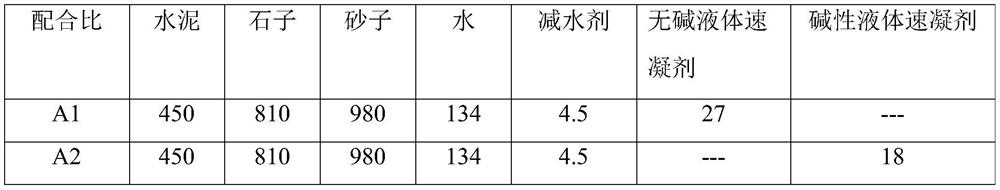

Treatment method of grinding waste liquid and hydrofluoric acid-containing waste liquid

PendingCN113912014ALow toxicityReduce processing costsFluoride preparationAluminium fluoridesFluorosilicate saltPhysical chemistry

A method for treating a grinding waste liquid and a hydrofluoric acid-containing waste liquid comprises the following steps: providing the grinding waste liquid which comprises an oxide capable of reacting with hydrofluoric acid to generate a non-water-soluble product; providing another waste liquid containing fluosilicic acid and hydrofluoric acid; mixing the two waste liquids to form a first mixed liquid in which the oxide reacts with the hydrofluoric acid to form a non-water-soluble fluoride; filtering the first mixed solution; taking out a first recovery product comprising fluoride; providing a metal salt capable of reacting with fluosilicic acid to generate fluosilicate; mixing a metal salt with the first mixed liquor from which the first recovery product is taken out to form a second mixed liquor, in which the metal salt reacts with the fluosilicic acid to generate a water-insoluble fluosilicate; filtering the second mixed solution; and withdrawing a second recovery product comprising the fluorosilicate.

Owner:ENVIRO-INNOVATE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com